Page 1

STEP 1

T

Install Batteries

Remove the battery cover on the

back of the

four AA alkaline batteries as

shown in Figure 1.

, and install the

T150

STEP 2

Power Up T150

T150 / R150 User Guide

Figure 1

Activation of any switch will cause the

safety feature, the

already pressed, released within 10 seconds for unit to remain powered

up.

[EStop]

switch must be pressed and released, or if

to power up. However as a

T150

STEP 3

Using The T150

The

ACTIVE

is transmitting to the

LED will flash brightly upon activation of the switch and return to flashing at

a rate of two times per second when there is no switch activity.

During normal operation the

battery condition.

The

[EStop]

safe way of powering down the

Each switch has a device specific label to identify its function.

LED will flash two times per second indicating that the

. When a function switch is used, the

R150

LOW BATT.

button is used for both an emergency shutdown as well as a

T150

LED will flash to indicate a low

after operation.

T150

ACTIVE

T150

R150

The Trigger is a Proportional Control switch used in conjunction with a

function switch (i.e.

dependent on the option of the receiver but will generally be either a

Voltage, PWM or Current Control.

his device complies with the requirements of the Federal Communication Commissio n (FCC) as specified in document CFR47 Part 15.247 and Industry and

Science Canada (ISC), as specified in document RSS 210. The device is permitted only on a no-interference, no-protection basis, that is, it must cease operation

when it is determined that it causes harmful interference to the services authorized by the FCC or the ISC.

Changes or modifications to the equipment not expressly approved by OMNEX will void the warranty.

DMAN-2293-01

[ROT CW]

Bldg. 74 – 1833 Coast Meridian Road, Port Coquitlam, BC, Canada V3C 6G5

). The type of Proportional Control output is

Rev. 1.03

Page 2

Setting ID Codes

Required when replacing either the Transmitter or Receiver

The Transmitter has its

programmed into it. To do this, the Receiver needs to have its cover removed – refer to Figure 2. Follow the

procedure below to program the Receiver

1. Release the

2. Turn the

3. While holding the

“Download Password” mode.

4. Release the

5. Toggle the switches in sequence:

password code (3142), followed by toggling the

LED’s will flash twice per second. This confirms the unit is in the “Ready to Download” state.

BATT.

6. Press and hold the

per second while depressed and then begin flashing rapidly indicating that the

“Configuration Data” from the

flashing rapidly.

7. Momentarily toggle the

the

R150.

8. Press the

ID Code

[EStop]

on by toggling the

T150

[SW5]

Release

[EStop]

factory programmed. Its matching receiver needs to have this same code

ID Code

switch on the

switch in the UP position, press and release the

[SW5]

switch. The

[SETUP]

[SW5]

and release the

[SW5]

switch to power down the

T150

[SW5]

ACTIVE

[SW3], [SW1], [SW4]

button on the

T150.

switch to the UP position; this enables the

to match its corresponding Transmitter.

.

switch to the UP position.

LED will flash once per second.

and then

switch to the UP position. Both the

[SW5]

for 5 seconds. The

R150

Continue holding the

[SETUP]

T150

button.

, and restart the

[SETUP]

[SW2]

STATUS

button after the

T150

[EStop]

to the UP position to enter the

T150

– refer to

switch. This enables the

LED on the

is ready to receive

R150

STATUS

to send “Configuration Data” to

STEP 2.

ACTIVE

will flash once

R150

LED begins

and

LOW

Current Control Module Calibration

Permits the user to adjust minimum and maximum currents

1. Release the

2. Turn the

3. While holding the

“Download Password” mode.

4. Release the

5. Toggle the switches in sequence:

password code (3144), followed by toggling the

LED’s will flash alternately once per second. This confirms the

6. Select and hold one of the “Proportional Functions” (i.e.

7. With the trigger

[SW5]

8. With the trigger ON (fully engaged), the “MAX” level is set. The “MAX” level may be increased by toggling the

[SW5]

[EStop]

T150 ON

[SW5]

switch up or decreased by toggling the

switch up or decreased by toggling the

on the

by toggling the

switch in the UP position, press and release the

[SW5]

switch. The

(fully released), the “MIN” level is set. The “MIN” level may be increased by toggling the

OFF

.

T150

switch to the UP position.

[SW5]

ACTIVE

LED will flash once per second.

[SW3], [SW1], [SW4]

[SW5]

[SW5]

[SW5]

[EStop]

and then

switch to the UP position. The

[SW4] or [ROT CW]

switch down.

switch down.

[SW4]

T150

to the

is sending “Calibration Data” to the

switch. This enables the

DOWN

).

position to enter the

ACTIVE

and

LOW BATT.

R150

.

9. To reset the “MIN” and “MAX” settings to the factory default, hold the

position for 5 seconds.

10. To exit, press the

[EStop]

switch.

switch in either the UP or

[SW5]

DOWN

Page 3

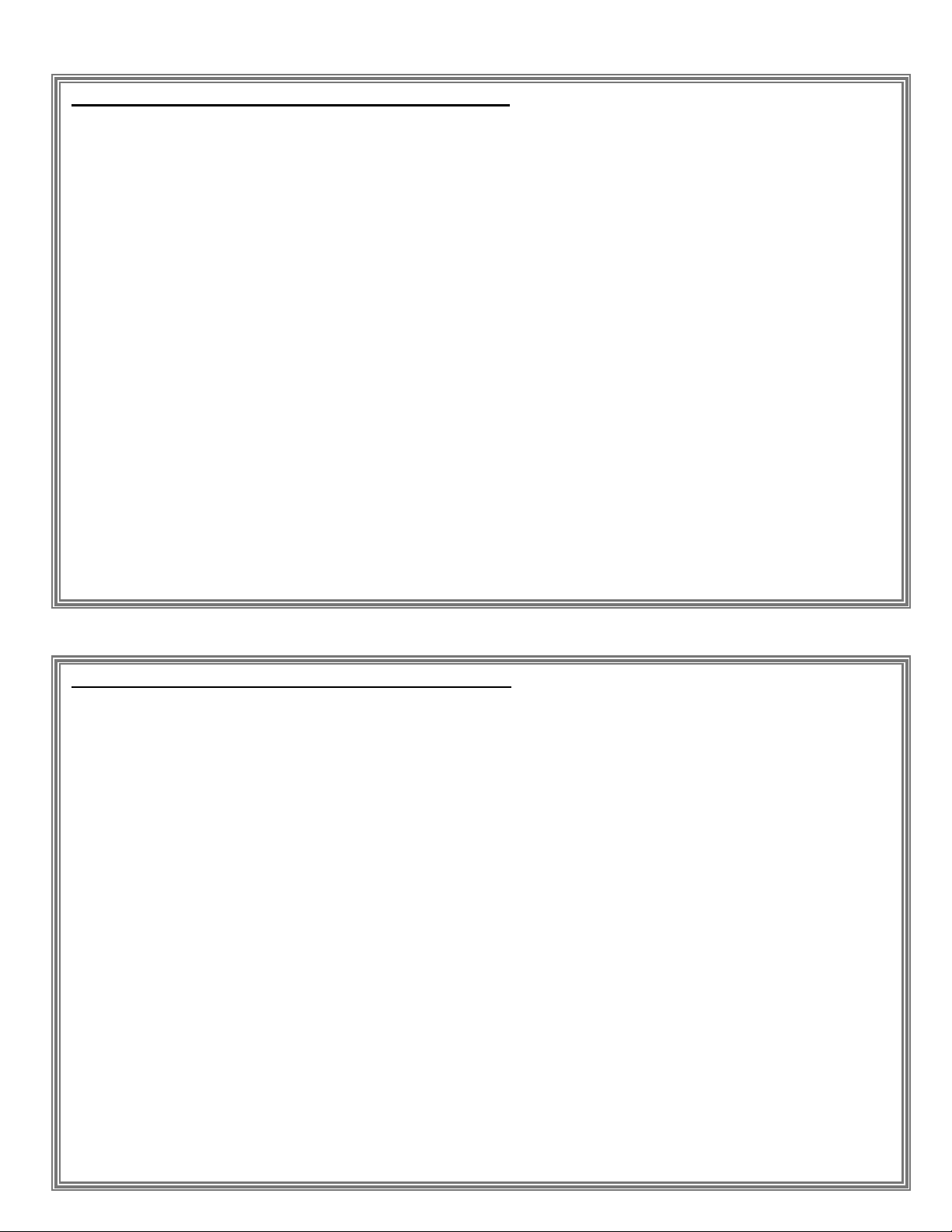

Transmitter / Receiver Replacement and Service

Fuse

Stat us LED’s

In order to program the

remove the circuit board from the housing of the

or replace the fuse, you will first need to

R150

. This is done by

R150

releasing the two side tabs on the housing, and sliding the connector block

and circuit board out of the housing until the four

visible and the

Also refer to

Codes

Setting ID Codes

to match on both the Transmitter and the Receiver.

[SETUP]

SW1 button is accessible. See Figure 2.

for a step by step procedure of setting

SW 5

STATUS

LED’s are

ID

EStop

[SETUP] SW1

Figure 2

SW 6

SW 1 SW 2 SW 3 SW 4

T150 / R150 Swi tch Func ti on Ta ble

Sw itch Number Position Output Control Pin Assignment Color Code Function

SW1

SW2

SW3

SW4

SW5

SW6

Trigger

Power

Ground

UP Output 9 B3 Green

DOWN Output 10 B4 Green (Blac k / Whi t e)

UP Output 7 B1 White (Red/Black)

DOWN Output 8 B2 Red (Black/White)

UP Output 5 A10 Orange (Blac k )

DOWN Output 6 A12 Orange (Red)

UP Output 3 A9 White (Red)

DOWN Output 4 A11 Blue (Red)

UP Output 11 B5 White

DOWN Output 12 B6 Orange

UP Output 1 A7 Orange (Green)

DOW N Out put 2 A 8 Red (Green)

Released

Engaged

A4 Green (Blac k )Output 13

A6

A3

Red

Black

Proportional Control

9 to 30VDC

Ground

EStop

Driver Power

EStop Output A5

Driver Power Input A2

Jumpered Ex t ernall y

]--

Page 4

Troubleshooting

Inputs and Outputs

The

has 4 LED’s that are used to indicate device status:

R150

ESTOP LED

GREEN – indicates RUN

RED – indicates ESTOP

Flashing RED – indicates fuse blown or relay fault

FUNCTION/FAULT LED

GREEN – indicates function ON, no fault

RED – indicates no voltage to relay, short to ground or blown

fuse

Flashing RED – indicates short to supply or shorted output relay

Not lit – indicates no function

LINK LED

GREEN – indicates Link

RED – indicates No Link

STATUS LED

GREEN – indicates STATUS OK

RED – indicates unrecoverable fault; requires factory authorized

service

Flashing RED – indicates low battery

The

has 2 LED’s that display the mode and status of the device

T150

ACTIVE LED

Momentarily ON or Flashing indicates Power Up procedure or

Programming status. LED will flash with each function during

normal operation indicating Transmit Status to the R150 is good

LOW BATT. LED

Momentarily ON or Flashing indicates Power Up procedure or

Programming status

During normal operation, this LED will only flash to indicate

battery low

ACTIVE and LOW BATT. LED’s

Both LED’s flashing in sync indicates one of the switches is stuck

!!!!!!!

!!!!!!!

!!!!!!!

!!!!!!!

""""

!!!!

!!!!

!!!!

""""

""""

!!!!

!!!!

!!!!

Inputs

4 x 0-5VDC analog inputs (factory

configurable only)

Outputs

Option 1

13 x Form A relay, monitored, 3A max.

each, total combined current 10A

Option 2

12 x Form A relay, monitored, 3A max.

each, total combined current 10A max.

NOTE:

1 x

The Current Control Module may be

Proportional Control

installed as an option giving the user Proportional

Control on output 13 of the

Control Module Calibration

- refer to

R150

for Proportional

Current

Calibration procedures.

The Proportional Control option is available from

the factory in either Voltage Control, PWM or

Current Control.

Replaceable Parts

MINI® Fuse Type,10A LittelFuse

Fuse

Mating Plugs

Pins

Sealing Plug

Wedge

Switches

EStop Switch

EStop Contact Block

Batteries

OMNEX (p/n F0047) or equiv.

OMNEX (p/n’s J0418 / J0419)

OMNEX (p/n J0417)

OMNEX (p/n J0421)

OMNEX (p/n J0420)

OMNEX (p/n S0042)

OMNEX (p/n S0072)

OMNEX (p/n S0071)

OMNEX (p/n B0010) 4 x AA

I/O Diagram Deutsch Connector Pin Assignments

4.92”

R150 Internal

EStop

Internal Power

13

1

Dimensions

7.87”

A4

B6

B5

B4

B3

B2

B1

A12

A10

A11

A9

A8

A7

Internally Fused

A2

A5

A6

A3

4.13”

R150 Relay Outputs

R150

The

shown using a 10A MINI® fuse.

Follow the steps in Transmitter /

Receiver replacement to open

the

Driver Power Input

Jumpered on wiring harness

EStop Out

Power

Ground

is internally fused as

R150

for fuse replacement.

R150

5.13”

Connector A (Grey)

Output 6

Output 4

Output 5

Output 3

Output 2

Output 1

12

11

10

9

8

7

OMNEX Control Systems Inc. Warrants to the original purchaser that the OMNEX

products are free from defects in materials and workmanship under normal use and

service for a period of ONE YEAR, parts (EXCLUDING: SWITCHES, CRYSTALS, OR

PARTS SUBJECT TO UNAUTHORIZED REPAIR OR MODIFICATION) and labor

from the date of delivery as evidenced by a copy of the receipt. OMNEX’s entire

liability and your exclusive remedy shall be, at OMNEX’s option, either the (a) repair

or (b) replacement of the OMNEX product which is returned within the warranty period

to OMNEX freight

purchase receipt and with the return authorization of OMNEX. If failure has resulted

from accident, abuse or misapplication, OMNEX shall have no responsibility to repair

or replace the product under warranty. In no event shall OMNEX be responsible for

incidental or consequential damage caused by defects in its products, whether such

damage occurs or is discovered before or after replacement or repair and whether or

not such damage is caused by the negligence of OMNEX Control Systems Inc.

Neither OMNEX nor its Distributors shall be liable for any delay or failure of the

performance of any of its obligations under this agreement caused by acts of God,

labor disputes, embargoes, boycotts, shortage of parts or any cause beyond its

reasonable control.

Neither OMNEX nor its Distributors shall be responsible for incurred costs associated

with border clearance or with the delay of the OMNEX products in transit to OMNEX.

Any charges associated with the return of the OMNEX products may be subject

to billing to the original purchaser in the event that the OMNEX products are

NOT covered by the warranty as noted above.

1

Input 1

2

Driver Power

GND

3

4

Output 13

EStop Output

5

Power

6

WARRANTY

by the OMNEX APPROVED carrier with a copy of the

collect

Output 12

Output 11

Output 10

Output 9

Output 8

Connector B (Black)

6

5

4

3

2

1Output 7

7

8

9

10

11

12

Factory Configurable Only

RS485 B

RS485 A

RS485 EN

Input 4

Input 3

Input 2

AB

4.00”

Bldg. 74 – 1833 Coast Meridian Road, Port Coquitlam, BC, Canada V3C 6G5

Loading...

Loading...