Page 1

GENERIC

Installation / Configuration Manual

T2300 Transmitter

R2160 Receiver

D180 Expansion Module

Revised September 9, 2005

Version 6

DMAN - xxxx - xx

DMAN-xxxx-xx

#74-1833 Coast Meridian Road, Port Coquitlam, BC, Canada • V3C 6G5

Ph# (604) 944-9247 • Fax# (604) 944-9267

Toll Free 1-800-663-8806

www.omnexcontrols.com

1

call toll free: 1-800-663-8806

Page 2

Table of Contents

System Overview .........................................................................................................................................................3

Features........................................................................................................................................................................3

T2300 Dimensions and Controls ..................................................................................................................................3

Installing the Receiver ..................................................................................................................................................4

Receiver Dimensions....................................................................................................................................................4

Installing the Expansion Module...................................................................................................................................5

Installation Considerations............................................................................................................................................6

Power the Transmitter ..................................................................................................................................................6

Test the Transmitter / Receiver Link.............................................................................................................................7

Download ID Code........................................................................................................................................................7

Calibrating Proportional Controls..................................................................................................................................9

Diagnostics—T2300 Transmitter..................................................................................................................................10

Diagnostics—D180 Expansion Module........................................................................................................................10

Diagnostics—R2160 Receiver......................................................................................................................................11

Trouble Shooting Guide................................................................................................................................................12

Parts & Accessories......................................................................................................................................................16

Specifications................................................................................................................................................................16

Warranty Information....................................................................................................................................................16

NOTE: These instructions are intended only for installing and operating the remot e control equipment described here. This is not a

complete Operator’s Manual. For complete operating instructions, please read the Operator’s Manual appropriate for your particular

machine.

Safety Precautions

READ ALL INSTRUCTIONS

CAUTION: Changes or modifications not expressly approved by the party responsible for complian ce could void the

user's authority to operate the equipment.

Failure to follow the SAFETY PRECAUTIONS may result in radio equipment failure and serious personal injury

Installation

PROVIDE A SAFETY CUTOFF SWITCH. If maintenance is required, the radio must be disconnected from power

USE PROPER WIRING. Loose or frayed wires can cause system failure, intermittent operation, machine damage, etc.

DO NOT INSTALL IN HOT AREAS. This apparatus can be damaged by heat in excess of 158° F (70° C)

Personal Safety

MAKE SURE MACHINERY AND SURROUNDING AREA IS CLEAR BEFORE OPERATING. Do not activate the remote

system unless it is safe to do so.

TURN OFF THE RECEIVER POWER BEFORE WORKING ON MACHINERY. Always disconnect the remote system

before doing any maintenance to prevent accidental operation of the machine

Care

KEEP DRY. Do not clean the transmitter / receiver under high pressure. If water of other liquids get inside the transmitter battery or receiver compartment, immediately dry the unit. Remove the case and let the unit air dry

CLEAN THE UNIT AFTER OPERATION. Remove any mud, dirt, concrete, etc. from the unit to prevent clogging of buttons, switches, etc. by using a damp cloth.

Maintenance / Welding

DISCONNECT THE RADIO RECEIVER BEFORE WELDING on this machine. Failure to disconnect will result in the destruction of the radio receiver.

DMAN-xxxx-xx

www.omnexcontrols.com

2

call toll free: 1-800-663-8806

Page 3

System Overview

The ORIGA T2300 / R2160 / D180 is a portable, long range, programmable radio remote control syst em. Designed

as a compact and easy-to-use product, this member of the ORIGA family puts complete control of your crane where

it’s needed most, with the operator. It’s robust, easy to install and has complete self-diagnostics. This system can be

a simple cable replacement or add intelligence to make it a total control package. It’s a radio, a PLC and a valve

driver all in one.

The ORIGA T2300 R2160 / D180 system uses Frequency Hopping Spread Spectrum (FHSS) technology. FHSS devices concentrate their full power into a very narrow signal that randomly hops from frequency to frequency within a

designated band. This transmission pattern, along with CRC-16 error-checking techniques, enables signals to overcome interference that commonly affects licensed radios.

The R2160 receiver is designed to be powered from a 12VDC or 24VDC system. It features 19 solid state, high-side

driver input / output controls and a reliable E-Stop control.

The D180 Expansion Unit has up to fourteen current-control, PWM, or voltage outputs, or a combination of these

types.

The T2300 transmitter comes with up to sixteen proportional and sixteen digital controls. The T2300 can accommodate up to eight single axis paddles, eight three-position switches and a re-settable E-Stop. A unique ID code is used

by each T2300 to ensure that no two systems will conflict on a job site.

T2300 Transmitter

Features

• FCC, ISC, CE approve d

• License free

• 1200 foot range @ 900 MHz (900 ft @ 2.4 GHz)

• Compact / weatherproof / ergonomic

• Simple “wire-and-use” installation

• Resilient to impact and shock

• Available in both 900 MHz and 2.4 GHz

• Available with paddles and/or joysticks for propor-

tional control

• Available with an optional pendant cable

• Factory configurable for all custom applications.

R2160 Re-

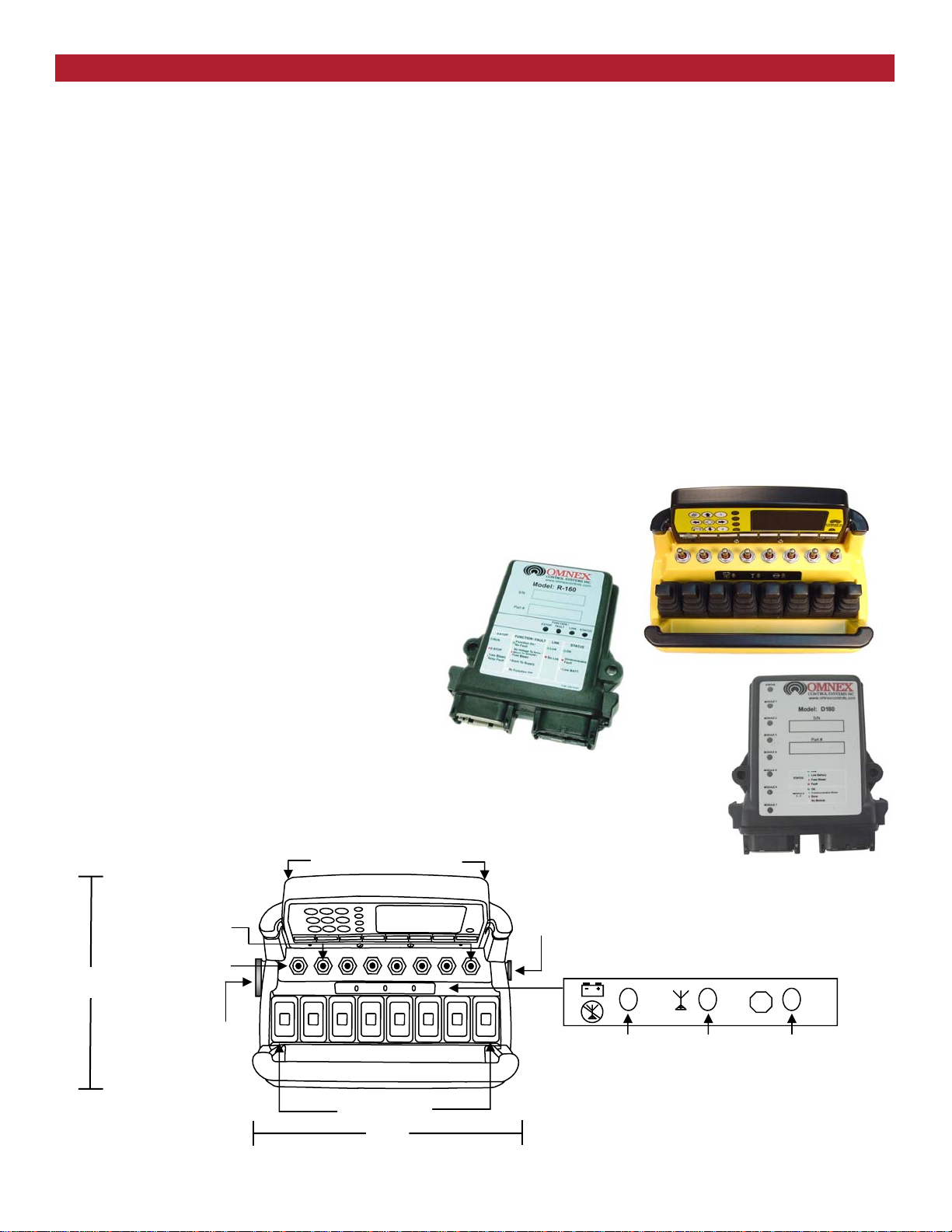

T2300 Dimensions and Controls

LCD Screen and Controls

Switches 2 - 8

Power/Calibration

6.0”

switch

DMAN-xxxx-xx

E-Stop

Pendant connector

Paddles 1 - 8

9.5”

www.omnexcontrols.com

3

Battery/

Pendant LED

D180 Module

STOP

Active LED

E-Stop LED

call toll free: 1-800-663-8806

Page 4

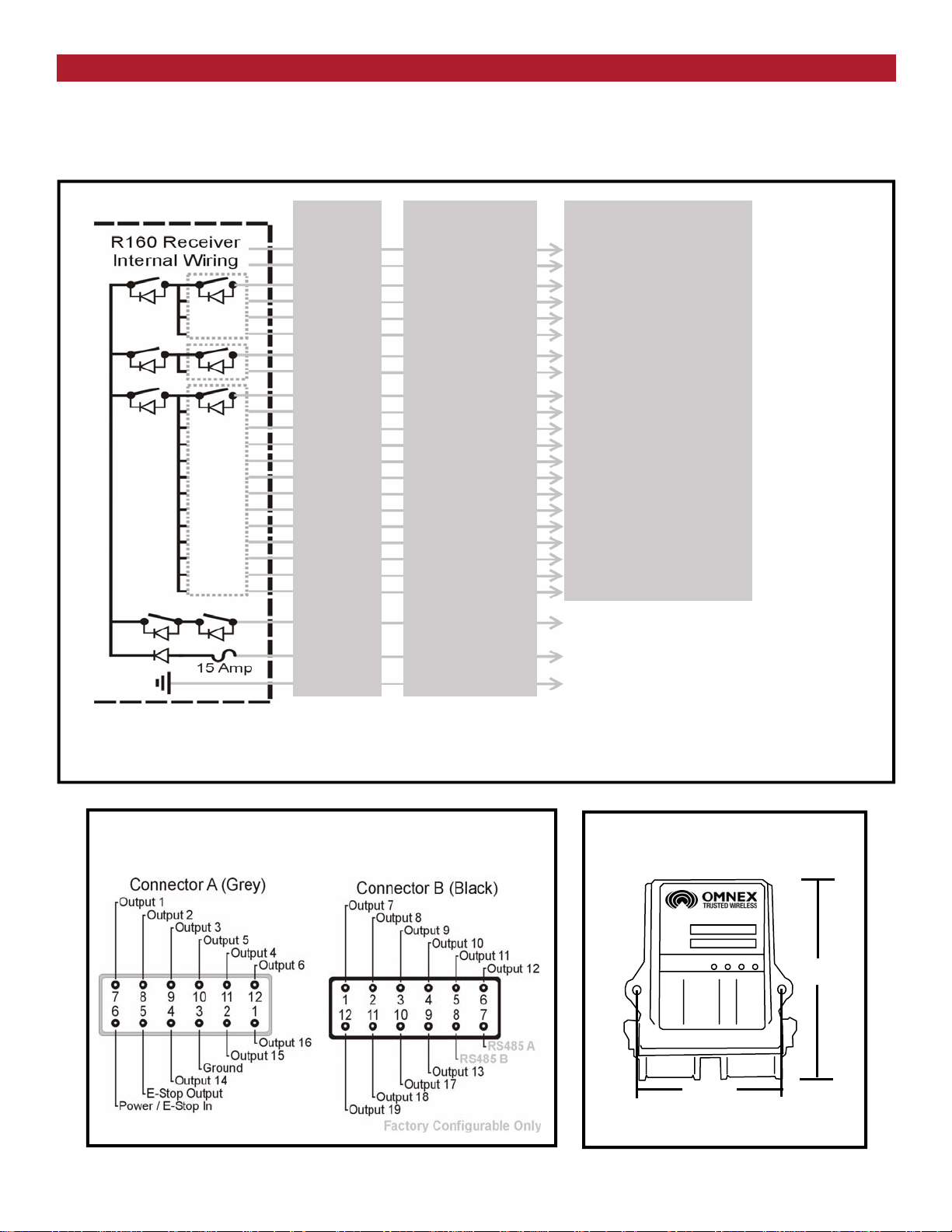

Installing the Receiver

Use the Wiring Diagram and the Connector Diagram below to connect the receiver pins directly to the appropriate

contacts of the machine electronics. R2160 Output Cables can be provided with every system to simplify the wiring

process. The Wire Color column below only applies to the OMNEX Output Cable configuration. Tips on mounting,

power connections and filtering are also provided under Installation Considerations.

Wiring Diagram

Pin-Output

B7

B8

B12 - 19

B11 - 18

B10 - 17

A1 - 16

A2 - 15

A4 - 14

B9 - 13

B6 - 12

B5 - 11

B4 - 10

B3 - 9

B2 - 8

B1 - 7

A12 - 6

A10 - 5

A11 - 4

A9 - 3

A8 - 2

A7 - 1

A5

A6

A3

Wire Colors

Black/Red

White/Black

Blue/White

Blue/Black

Black/White

Green/Black

Red/White

Orange

White

Green/Black/White

Green

Red/Black/White

White/Red/Black

Orange/Red

Orange/Black

Blue/Red

White/Red

Red/Green

Orange/Green

Black/White/Red

Red

Black

Functions

Factory Configurable Only

Factory Configurable Only

Input / Output

Input / Output

Input / Output

Input / Output

Input / Output

Input / Output

Input / Output

Input / Output

Input / Output

Input / Output

Input / Output

Input / Output

Input / Output

Input / Output

Input / Output

Input / Output*

Input / Output*

Input / Output**

Input / Output**

Switches to Power with

Link

Power Input

(+9V to 30VDC)

Ground

________________

________________

________________

________________

________________

________________

________________

________________

________________

________________

________________

________________

________________

________________

________________

________________

________________

________________

________________

________________

________________

Note: Enable output:

On when the T2300

"Enable" switch is on.

Notes

Outputs: 19 solid state, high-side driver outputs, 5A max. each, total combined current 15A

Inputs: All output pins can be factory configured as inputs.

Connector Pin Assignments

Connectors as seen from under the receiver

R2160 / D180 Dimensions

ES FA L STA

A B

4.00”

call toll free: 1-800-663-8806

DMAN-xxxx-xx

www.omnexcontrols.com

4

5.13”

Page 5

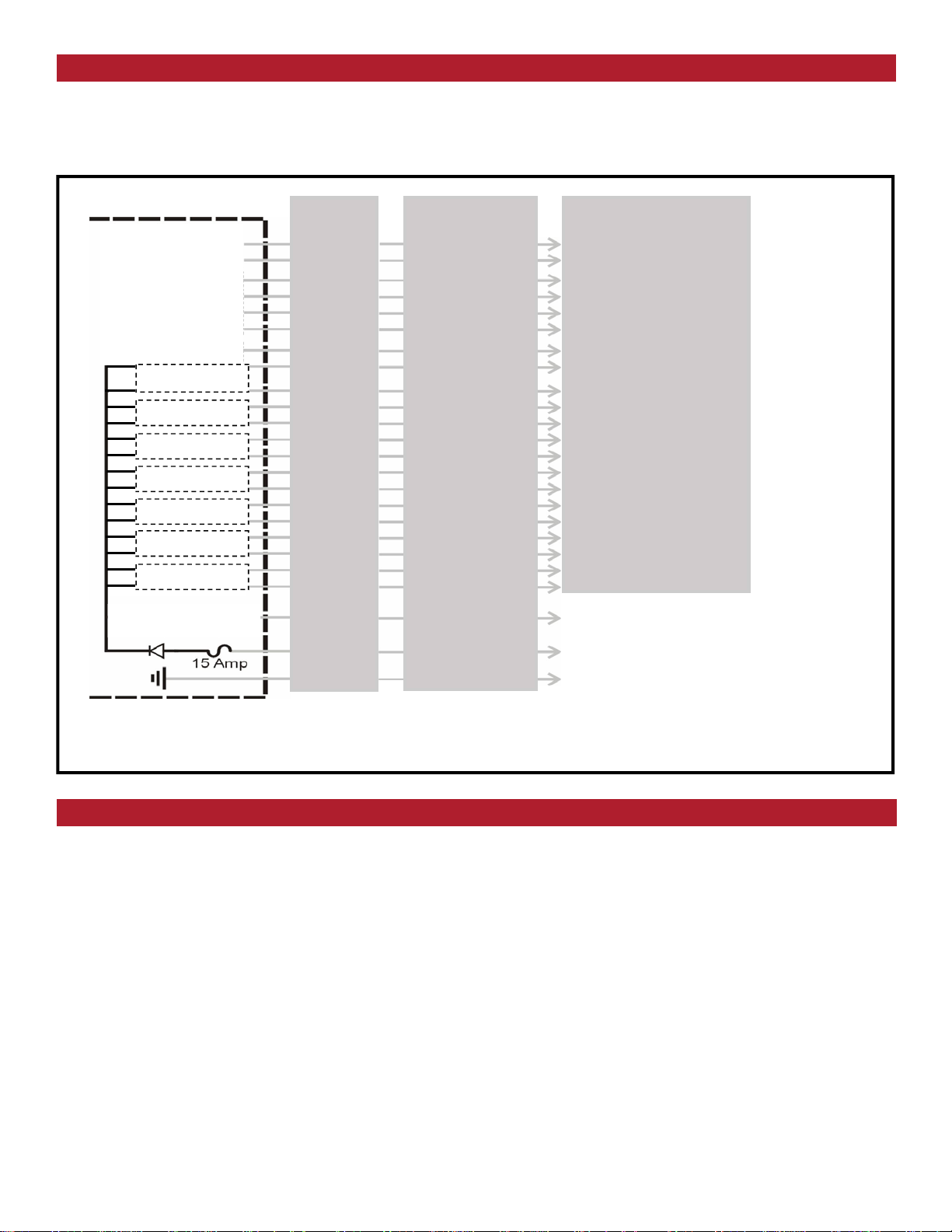

Installing the Expansion Module

Use the Wiring Diagram and the Connector Diagram below to connect the Expansion module pins directly to the appropriate contacts of the machine electronics. D180 Output Cables are provided with every system to simplify the wiring process. The Wire Color column below only applies to the OMNEX Output Cable configuration. Tips on mounting,

power connections and filtering are also provided under Installation Considerations.

Wiring Diagram

D180 Module

Internal Wiring

Module 7

Module 6

Module 5

Module 4

Module 3

Module 2

Module 1

Pin-Output

B7

B8

B12 - 19

B11 - 18

B10 - 17

A1 - 16

A2 - 15

A4 - 14

B9 - 13

B6 - 12

B5 - 11

B4 - 10

B3 - 9

B2 - 8

B1 - 7

A12 - 6

A10 - 5

A11 - 4

A9 - 3

A8 - 2

A7 - 1

A5

A6

A3

Wire Colors

Black/Red

White/Black

Blue/White

Blue/Black

Black/White

Green/Black

Red/White

Orange

White

Green/Black/White

Green

Red/Black/White

White/Red/Black

Orange/Red

Orange/Black

Blue/Red

White/Red

Red/Green

Orange/Green

Black/White/Red

Red

Black

Functions

Factory Configurable Only

Factory Configurable Only

Unused Output

Unused Output

Unused Output

Unused Output

Unused Output

Unused Output

Unused Output

Digger Dig

Digger Rev

Lift Up

Lift Down

3rd Ext Out

3rd Ext In

2nd Ext Out

2nd Ext In

Rotate CW

Rotate CCW

Winch Up

Winch Down

Power Input

(+9V to 30VDC)

Ground

________________

________________

________________

________________

________________

________________

________________

________________

________________

________________

________________

________________

________________

________________

________________

________________

________________

________________

________________

________________

________________

Notes

Outputs: 14 solid state, high-side driver Current Control outputs 5A max. each, total combined current 15A

Inputs: All output pins can be factory configured as inputs.

Special Functions

DMAN-xxxx-xx

www.omnexcontrols.com

5

call toll free: 1-800-663-8806

Page 6

Installation Considerations

Mounting and Installation

The receiver can be mounted by fastening two ¼” bolts through the two mounting holes in the unit’s enclosure. When

mounting, ensure that the receiver is oriented so that the text is reading right.

When selecting a mounting point for the receiver, it is recommended that the location require only a minimal length of wiring to connect it to the control panel, that it will be in a visible area where it has good exposure to the operator and that it

is mounted on a surface that sustains minimal vibration. It is also recommended that the receiver have the best possible

line of sight with the transmitter

Power Connections and Wiring

Whenever a power connection is made to an electronic device, it is a good practice to make both the Power (+) and

Ground (-) connections directly to the Battery and avoid connecting the power from the charging side of existing wiring or

making use of existing "ACC" or other peripheral connection points.

Make sure that wire of sufficient gauge and insulator type is used when connecting the outputs of the receiver to the control panel. Observe any component manufacturer's instructions and recommendations for proper integration of their product. This includes the power ratings and requirements of such compone nts as relays, valves, solenoids, etc.

Be sure to test each of the outputs with a multi-meter prior to connecting the outputs to your end devices. This will ensure

that each output has been programmed to operate in the manner required by each end device.

Filtering and Noise Suppression

Whenever a solenoid or electromagnetic switch is controlled by the receiver, it is a good practice to install a Diode across

its terminals to ensure that surges and spikes do not continue back into the circuit. Appropriate 36V Bi-directional Diode s

kits can be ordered under the OMNEX part number “AKIT-2492-01”.

Power the Transmitter

1. Install the batteries in the transmitter

Batteries are installed in the transmitter by removing the battery cover using a slotted

screwdriver and inserting 4 “C” alkaline batteries. Orientation of the batteries is embossed inside the battery housing. No batteries are required when the transmitter is connected to the receiver by a Pendant cable.

NOTE: For operation at temperatures below –10° C to –40° C, lithium batteries are recommended. Low tem-

peratures reduce battery performance for both alkaline and lithium types. Refer to the battery manufacturer’s

specifications for detailed information on low temperature performance.

2. Turn on the transmitter

Ensure all transmitter switches and paddles are in the neutral position. Turn on the transmitter by, pressing and

releasing the [Power] switch. The RED (E Stop) light will flash quickly. Release the [E Stop], the yellow (Active) light

on the transmitter will flash.

WARNING: do not install batteries backwards, charge, put in fire, or mix with other battery types. May explode or leak causing injury.

Replace all batteries at the same time as a fresh set and do not mix and match battery types.

A. Press the [E Stop]

B. Press and release [Power] switch

C. Turn CW & Release [E-Stop]

Transmitter Battery

Housing

Light Legend

DMAN-xxxx-xx

Solid

Slow

Flash

Fast

Flash

Red

Light

Green

Light

www.omnexcontrols.com

6

Yellow

Light

Alternating Red

& Green Light

call toll free: 1-800-663-8806

Page 7

Test the Transmitter / Receiver Link

Follow these steps to ensure that there is a Radio Link between the transmitter and receiver

Refer to the Light Legend below for diagram details

1. Press [E-Stop]

2. Power the R2160

FAULT LINK

ESTOP

STATUS

The (E Stop) light and the (Link)

light will come on RED (provided the

transmitter is off), and the (Status)

3. Power the T2300

light will come on GREEN.

FAULT LINK

ESTOP

STATUS

If the (Active) light on the transmitter is flashing and the (Link) light

on the receiver is flashing GREEN,

a link between the two exists.

NOTE: The transmitter will shut itself off (and the receiver will then shut off all outputs) after 4 hours of inactivity as a battery saving feature. To restart

the timer before the transmitter shuts off automatically, momentarily operate any toggle switch or paddle.

The ORIGA System is now ready for use.

If the receiver's (Link) light does not become GREEN follow the steps under Download ID Code.

Download ID Code (Use in case of Link Test failure)

Follow these steps to download the transmitter’s unique ID Code into the receiver. This will allow the receiver to establish

a Radio link with a specific transmitter. Refer to Trouble Shooting Chart #4 for Tips and Considerations

NOTE: It is necessary to download the ID code when replacing either the transmitter or the receiver.

NOTE: If the transmitter is connected to the receiver with a Tether Cable, completing only steps 4 and 6 is necessary (it is not

necessary to open the R2160 case and press the Setup button).

1. Opening the R2160

The cap is held on by two plastic tabs at

opposing sides, which can be unlatched as

shown using a screwdriver. Once the cap

is free, the R2160 can slide open.

Use a small slotted screwdriver to press the

Side Tabs inward.

2. Prepare T2300

A.

A. Press [E-Stop]

B. Twist CW & release [E-Stop]

B.

ESTOP

FAULT LINK

STATUS

Light Legend

DMAN-xxxx-xx

Solid

Slow

Flash

Fast

Flash

Red

Light

Green

Light

www.omnexcontrols.com

7

Yellow

Light

Alternating Red

& Green Light

call toll free: 1-800-663-8806

Page 8

3. Power R2160

A. Supply power to the re-

ceiver. The (E-Stop) light

and the (Link) light will

come on RED and the

(Status) light will come on

GREEN

NOTE: For this document, orientation

of the paddle and switch operation will

be defined as follows:

Paddle UP—is towards the switches

Paddle DOWN—is away from switches

Switch UP—is away from paddles

Switch DOWN—is towards the paddles.

4. Power T2300 into Configuration

A.

FAULT LINK

ESTOP

STATUS

UP DOWN

A. Hold [Power] switch UP

B. Press [E-Stop]

C. Twist CW & release [E-Stop]

D. Release [Power] Switch

5. Put R2160 into Setup

A. Press & hold [Setup] button

until (Status) light goes from

slow flash to fast flash

B. Release [Setup] button.

(Status) light goes to solid

GREEN, (Link) light turns off

A.

C.

A.

Setup

Button

B.

D.

0

B.

ESTOP

FAULT LINK

STATUS

Setup

Button

ESTOP

FAULT LINK

STATUS

NOTE: If left idle in Setup Mode for over 30 seconds, the receiver will time out. The (Link) light and (Status) light will flash RED rapidly. To return to Setup Mode, repeat step 5.

6. Download ID Code

A.

B.

A. Press [Power] switch UP

and release

B. (Link) light goes to GREEN.

Once complete, (Link) light

ESTOP

FAULT LINK

goes to RED as the transmitter turns off

Light Legend

DMAN-xxxx-xx

Solid

Slow

Flash

Fast

Flash

Red

Light

Green

Light

www.omnexcontrols.com

8

Yellow

Light

Alternating Red

& Green Light

call toll free: 1-800-663-8806

STATUS

Page 9

LCD Display Operations

DMAN-xxxx-xx

www.omnexcontrols.com

9

call toll free: 1-800-663-8806

Page 10

Calibrating Proportional Controls

The transmitter’s Paddles control the receiver’s proportional output. The Paddles/Joysticks are used in conjunction with

any of the transmitter’s switches. The proportional output can be activated when a switch is held UP or DOWN; it will become active at an increasingly high level as the Paddle/Joystick is pushed/pulled. The minimum and maximum levels of

the proportional output can be calibrated by following these steps.

Refer to the Light Legend below for diagram details.

NOTE: Calibration settings can be reset to factory default in steps 3 & 4 by holding the [Power] switch UP or DOWN for 5 seconds.

1. Power T2300, Power R2160

A. Refer to steps in “Power the

Transmitter”

B. Supply power to the R2160

2. Setup T2300 into Configuration

A. Hold [Power] switch DOWN

for 5 seconds until the

(Battery) LED goes to alternating RED and YELLOW.

B. Release [Power] switch

3. Set Minimum Level

A. Push the paddle (function) in the

direction you wish to calibrate

until the (Active) LED comes on

B. Hold paddle and Press [Power]

switch UP to increase minimum

level or DOWN to decrease it

A.

A.

A.

B.

B.

B.

ESTOP

FAULT LINK

STATUS

4. Set Maximum Level

A.

A. Fully push the paddle (function) in

the direction you wish to calibrate

until the (E-Stop) LED comes on.

B. Hold paddle and Press [Power]

switch UP to increase maximum

level or DOWN to decrease it

Note: Repeat steps 3 and 4 for each paddle (function) that needs to be calibrated.

5. Power Off

A.

A. Press [E-Stop]

Light Legend

DMAN-xxxx-xx

Solid

Slow

Flash

Fast

Flash

Red

Light

www.omnexcontrols.com

10

Green

Light

B.

Yellow

Light

Alternating Red

& Yellow Light

call toll free: 1-800-663-8806

Page 11

Diagnostics—T2300 Transmitter

STOP

Tether connection detected

STOP

STOP

STOP

STOP

STOP

STOP

Low battery. Unit will run approximately 20 hours after Battery light starts flashing.

The transmitter is in Calibration mode

Power switch is stuck in the “UP” position.

The Active light remain on momentarily when a function is activated (i.e. a switch or

paddle is triggered). This is normal operation.

Normal Operation

The transmitter is in Download Mode.

Normal Operation

The Active light will flash 2 times per second, indicating that the transmitter is sending

signals to the receiver.

STOP

STOP

Stuck switch detected. Ensure that all switches are in a centered position. The transmitter will not power up when a function is ON.

On Power Up

Release the E-Stop button within 10 seconds to power up the transmitter, or the unit will

power down.

STOP

On Power Up

Press and release the E-Stop button within 10 seconds to power up the transmitter, or

the unit will power down.

Diagnostics - D180 Expansion Module

Indicator lights for the D180 Expansion Module

Status Indicator

STATUS

STATUS

STATUS

Module 1-7 Indicators

MODULE

MODULE

Module is operating properly

There is a fault with the module Fuse blown

Communication to the module is active

Module is installed and operating properly

There is a short to ground / over current No Module installed

STATUS

STATUS

MODULE

MODULE

Status

Module 1

Module 2

Module 3

Module 4

Module 5

Module 6

Module 7

Low battery condition detected

There is a short to supply

Light Legend

DMAN-xxxx-xx

Solid

Slow

Flash

Fast

Flash

Red

Light

Green

Light

www.omnexcontrols.com

11

Yellow

Light

Alternating Red

& Yellow Light

call toll free: 1-800-663-8806

Page 12

Diagnostics - R2160 Receiver

Normal Operation

FAULT LINK

ESTOP

FAULT LINK

ESTOP

FAULT LINK

ESTOP

FAULT LINK

ESTOP

Trouble Indicators

Note: In some cases, the indicator lights will be different depending on whether the transmitter is on or off. Please note the transmitter status in the

“Description” column for each case.

Indicator Lights Description Solution

FAULT LINK

ESTOP

FAULT LINK

ESTOP

FAULT LINK

ESTOP

FAULT LINK

ESTOP

FAULT LINK

ESTOP

FAULT LINK

ESTOP

FAULT LINK

ESTOP

FAULT LINK

ESTOP

FAULT LINK

ESTOP

STATUS

STATUS

Transmitter is OFF

If the transmitter is off, the receiver is operating properly.

Transmitter is ON

When the transmitter is turned on, the Link light (fast flashing) and E-Stop (GREEN) indicates the receiver is

operating properly

STATUS

Transmitter is in Operation

When a function is activated on the transmitter, the Fault light will turn on GREEN. This indicates the

receiver is operating properly

STATUS

Transmitter is OFF

When a latched function is activated then the transmitter is turned off, the Fault light will stay on GREEN. If the

system was intentionally designed this way, the receiver is operating properly, if not call for service.

STATUS

STATUS

STATUS

STATUS

STATUS

STATUS

STATUS

STATUS

STATUS

Transmitter is ON

The reason is the transmitter is not

communicating with the receiver.

Transmitter is ON

A low battery condition has been detected.

Transmitter is ON

An internal fault with the E-Stop has

been

detected.

Transmitter is ON

A short to ground or excessive current

draw on an output. It is most likely

caused by a wiring fault.

Transmitter is ON

The E-Stop output has been connected

with one of the other outputs

Transmitter is OFF

A wiring short to the battery has been

detected.

Transmitter is OFF

The receiver has detected an internal

fault.

Transmitter is OFF

Blown fuse detected.

Transmitter is ON

A setup failure has occurred.

Refer to Trouble Shooting Chart #3 for solutions

To detect intermittent conditions caused by poor or corroded

ground or power circuits, the GREEN light will continue to flash for

30 seconds after the condition has been removed.

Inspect E-Stop wiring for short circuit. Disconnect E-Stop wire as

close to the receiver output as possible. If the Status light changes to:

• GREEN, a short occurs after disconnection point.

• Stays flashing RED, send it in for service .

Ensure transmitter is functioning properly, check status of each output

connection: Press each function button and observe Fault Light.

• If GREEN, everything is OK.

• If RED, there is a short in that connection.

Follow the wire and check for connections with other wires, disconnect to see if condition clears. If not, call for service.

Refer to Trouble Shooting Chart #1 for solutions

Refer to Trouble Shooting Chart #1 for solutions

Refer to Page 6 for instructions on how to open the receiver case to

access fuse. Check wiring for shorts or bare spots. If fuses continue to blow, call for service.

Either hold the Setup button for 5 seconds to return to Setup mode or

cycle power to return to the normal operating mode.

FAULT LINK

ESTOP

Light Legend

STATUS

Transmitter is OFF

The receiver is powered incorrectly.

DMAN-xxxx-xx

Solid

Slow

Flash

Most likely cause of this condition is that an output wire or the E-Stop

wire has been connected to the power supply while the power wire is

disconnected from the power supply.

Fast

Flash

Red

Light

Green

Light

www.omnexcontrols.com

12

Yellow

Light

Alternating Red

& Green Light

call toll free: 1-800-663-8806

Page 13

Trouble Shooting Guide Chart #1

Test the Receiver—R2160

Start

Initial Condition:

Turn transmitter off (all lights are off—press the

E-Stop button)

Cycle power to receiver (turn off and back on)

Problem state:

Status—RED

Problem state:

Status—flashing

GREEN & RED

Is the Status

light flashing

RED?

NO

What is the

state of the E-

Stop light ?

YES

Problem state:

E-Stop— Flashing

RED

Fuse is blown, change fuse

1. Inspect wiring looking for short circuits (e.g. bare wires)

2. If problem re-occurs, call for service.

What is the state

of the lights on

the receiver?

The system is wired incorrectly.

Most likely cause is one of the input/output wires has been

connected to the power source.

Inspect E-Stop wiring looking for short circuits (e.g. bare

wires)

Disconnect the E-Stop output as close to the

receiver output as possible.

If the Status light changes to:

• GREEN, there is a short is the wiring after the disco n-

nection point.

• Stays flashing RED, call for service .

OK state:

Status—GREEN

Link—RED

E-Stop—RED

Fault—OFF

Note: If there is a short to ground on

an output, it is not indicated at this

stage. To test for short to ground,

refer to the “*Fault Light is RED*”

procedure at the bottom of this page

and follow the instructions.

Go to Chart 2

OK state:

E-Stop—RED

What is the

state of the

Fault light ?

DMAN-xxxx-xx

Fault Light is

OFF

Fault Light is

Flashing RED

*Fault Light is

RED*

www.omnexcontrols.com

Call for service.

There is a short to supply.

1. Disconnect A & B connectors from receiver and check all

outputs for power (e.g. bare wires, improper connections)

make the correct adjustments

2. Call for service.

There is a short to ground.

Note: This should only occur when the transmitter is on and a

function button is pressed. In this case the Status light will be

GREEN and will turn RED at the same time as the Fault light.

Go to Chart 2 to test the transmitter. If the transmitter is functioning properly, proceed to check the status of each of the output connections:

Press each of the function buttons and observe the Fault Light.

If the light turn GREEN, everything is OK.

If the Light turns RED, there is a short in that connection.

call toll free: 1-800-663-8806

13

Page 14

Trouble Shooting Guide (con’t) Chart #2

Test the Transmitter—T2300

Turn off the receiver

Ensure there are good batteries in the transmitter

Turn on the transmitter

OK state:

What is the state of

the lights?

Active light—steady for

about 3 seconds then

goes to fast flash.

Battery light—OFF

E-Stop light—OFF

Toggle a switch

or paddle

No light comes on

at any time

Both the Active light

and the E-Stop light

flash at the same time

Both the Active light

and the Battery light

flash at the same time

Go to Chart 3

Complete the following steps in order:

1. Check battery orientation

2. Clean battery contacts

3. Check or Replace batteries

4. Call for service

Stuck switch/paddle:

1. Return all paddles/switches to neutral

(OFF) position

2. Toggle the switch/paddle a few times

3. Call for service

Power switch is stuck in UP position:

1. Return switch to neutral position

2. Toggle the switch a few times

3. Call for service

YES

Does the Active

light go to solid

YELLOW?

NO

Either the switch/paddle is

defective or the switch/paddle

connection to the circuit board

is broken.

Call for service

Active light and

Battery light flashing

alternately

Battery light alternates between RED

and GREEN.

Battery light flashes

for 10 seconds then

all lights are OFF

DMAN-xxxx-xx

Low Battery—Change Batteries

Note: Low batteries will last approximately 20 hours once the Low Battery

light begins to flash.

Replace batteries by next shift.

The transmitter is in Calibration mode

1. Turn unit OFF, then turn back ON

2. If condition persists, call for service.

Press and release E-Stop if the condition

persists, then either there is a faulty EStop or transmitter failure—call for service

www.omnexcontrols.com

14

call toll free: 1-800-663-8806

Page 15

Trouble Shooting Guide (con’t) Chart #3

Testing the Transmitter / Receiver Communication

Transmitter:

Active light is flashing

Receiver:

Status—GREEN

Link—RED

Fault—OFF

E-Stop—RED

There is no link between the

transmitter and receiver

Do you have a

matched set? (i.e. the

transmitter and re-

ceiver should have

identical ID codes

YES

What is the status of

the lights of both the

transmitter and

receiver?

Call for service.

Transmitter:

Active light is flashing

Receiver:

Status—GREEN

Link—Flashing GREEN

Fault—OFF

E-Stop—GREEN

Transmitter and receiver

should be working properly.

The problem may rest with

the machine instead of the

radio system

Call for service

NO

Was the transmitter

accidentally swapped

with another one on

the job site?

NO

The transmitter

code may need to

be re-downloaded

to the receiver

DMAN-xxxx-xx

POSSIBLY

NO

Search the job site for

the correct transmitter.

Was it found?

!!Caution!!

YES

Turn on the transmitter

to check if the units

function correctly. If

not, proceed to Chart 1

Note: Before you proceed with the Download ID procedure located on Page 7 & 8, great

care and caution must be adhered to. Also, refer to Chart #4 for Tips and Considerations.

If by accident, the transmitters have been switched with another unit, by downloading the

ID code to a new receiver, it is possible for the transmitter to operate 2 units at the same

time (if the original receiver unit is still on the job site). Therefore it must be

certain that the transmitter / receiver pair are the correct set.

Secondly, once the download procedure is completed, ensure all other units on the job site

are stopped. Test the operation of the newly configured set to ensure no other

machines on the site work with the same transmitter.

Once you are certain that the transmitter / receiver pair are a unique set, continue

normal operations.

www.omnexcontrols.com

15

call toll free: 1-800-663-8806

Page 16

Trouble Shooting Guide (con’t) Chart #4

Considerations when Downloading the ID

Potential downloading issues

If testing of the receiver and transmitter both show the system as working (Chart 1 & 2), then the transmitter and receiver

will both go into Download/Configuration mode.

Possible issues could arise during Step 4, the download phase of reprogramming. In this case there are 2 symptoms to

look for:

1. The Link light on the receiver will not turn GREEN when the power switch is toggled on the transmitter to download

2. The receiver will “time out” indicating that it didn’t receive a signal from the transmitter within the 30 seconds from

the time the receiver was put into Setup Mode.

If all indications appear normal during the download phase, test the link by turning on the transmitter (note: the transmitter shuts off after transmitting the ID code in Step 4)

1. If the Link light on the receiver doesn’t turn GREEN, the receiver didn’t receive all of the information that was sent

from the transmitter.

Possible Solutions

1. Try the Downloading steps again

2. If this doesn’t correct the problem, send both the transmitter and receiver in for service.

Note: you could try to determine whether the fault lies with the transmitter or receiver by completing the downloading

procedure with a different transmitter. If this step works, then the fault lies with the original transmitter. If not, the

fault may lie with the receiver.

!!Caution!!

Note: Before attempting downloading with another transmitter, understand that repro -

gramming the receiver with another transmitter, could result in two receivers on the job

site responding to the one transmitter. If the original transmitter was sent in for repair,

Disconnect the receiver (disconnect connector A) to continue using the machine without remote capability and without fear of inadvertently operating the machine with the

other transmitter.

Connector A

Reprogramming Tips:

1. Use a pointy instrument to depress the Setup button on the receiver (i.e. a pen) as the button is relatively small

2. Follow each step as laid out in the procedure

3. Never lay the receiver circuit board down on anything metallic (there are contact points on the back which could contact the metal and damage the receiver)

DMAN-xxxx-xx

www.omnexcontrols.com

16

call toll free: 1-800-663-8806

Page 17

The antenna(s) used for this transmitter must not be co-located or

operating in conjunction with any other antenna or transmitter.

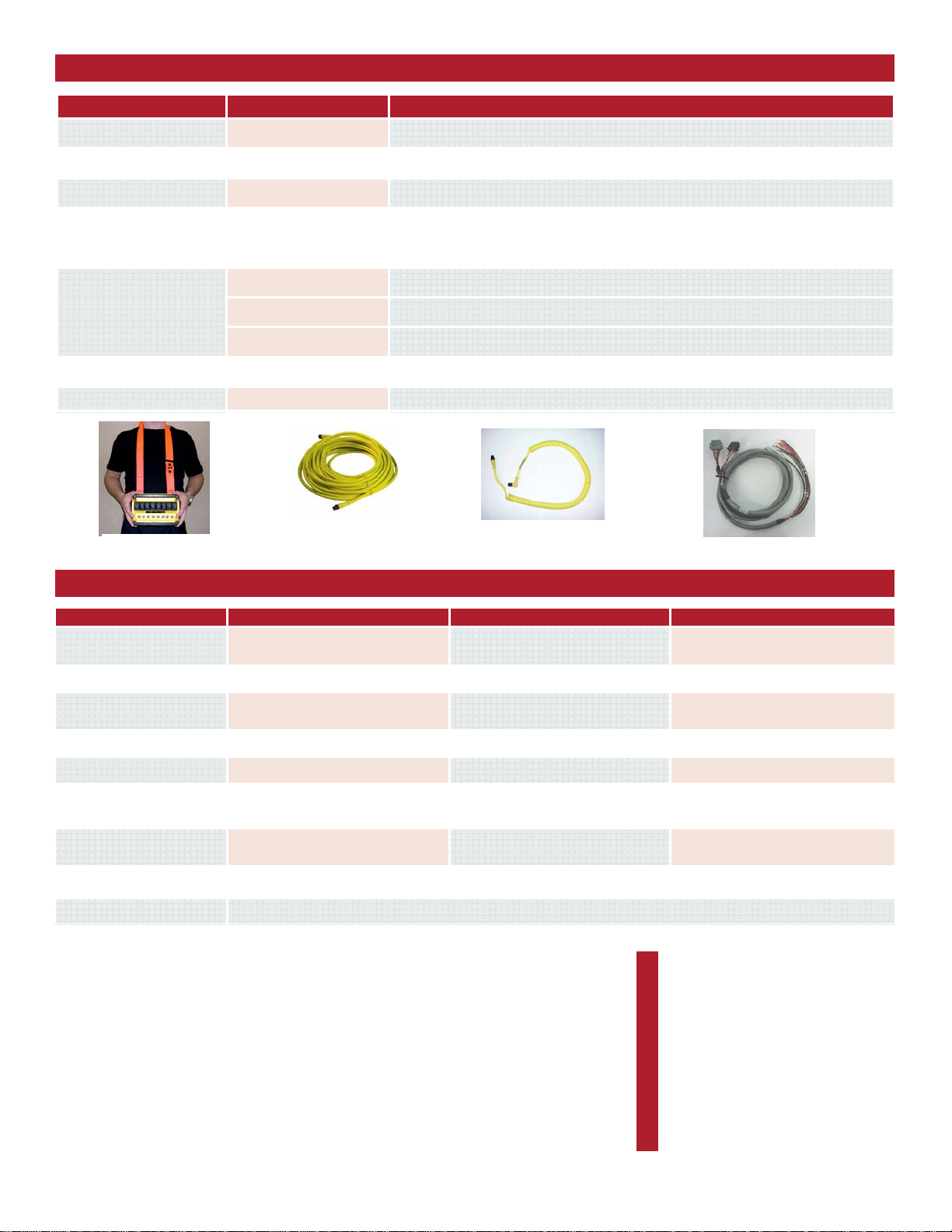

Parts & Accessories

Part OMNEX Part Number Description

Batteries

Fuse

Shoulder Strap

Output Cable

Pendant Cable

Connector Kit

Bipolar Diode Kit

Shoulder Strap

B0012 4 x “C” al kaline

F0039 36V Bi-directional, Bussman ATC-15

FMEC-2709-01 T2300 Tear-away shoulder strap

ACAB-2493-01 R2160 Output Cable, Generic

ACAB-2493-03 R2160 Output Cable, Generic, Tethered

ACAB-2455-01 Tether Cable, 10m

ACAB-2455-02 Tether Cable, 8m

ACAB-2710-01 Tether Cable, 4-12ft

AKIT-2337-01 Includes Deutsch socket connectors, wedges, pins and sealing plugs

AKIT-2492-01 Motorola P6KE36CA

Pendant Cable

Pendant Coil

R2160 Output Cable

Specifications

D180 Module R2160 Receiver T2300 Transmitter

Size

Weight

Construction

Input Power

Battery Life

Operating

Temperature Range

Outputs

Antenna

Approvals

FCC Rules and Compliance

This device complies with Part 15

of the FCC Rules. Operation is

subject to the following two conditions: (1) This device may not

cause harmful interference, and

(2) this device must accept any

interference received, including

interference that may cause undesired operation.

FCC Part 15.247

ISC RSS 210

DMAN-xxxx-xx

5.1” x 4.7” x 1.4”

(130mm x 119mm x 36mm)

0.65lbs (0.295kg) 0.65lbs (0.295kg) 3.5 lbs (incl. batteries) (1.2kg)

High impact plastic, weather-

proof

+9V to 30VDC +9V to 30VDC 4C alkaline batteries

N/A N/A 500 hours (continuous use)

-40F to 158F (-40C to 70C) -40F to 158F (-40C to 70C) -40F to 140F (-40C to 60C)

3A (max) each (sourcing),

15A (max) each (combined)

N/A Internal Internal

USA - FCC part 15.247 Canada - ISC RSS 2210 Europe - EN 440 Australia- C-Tick

Warranty

OMNEX Control Systems Inc. warrants to the original purchaser that the OMNEX products are free from defects in materials and workmanship under normal

use and service for a period of ONE YEAR, parts (EXCLUDING: SWITCHES,

CRYSTALS, OR PARTS SUBJECT TO UNAUTHORIZED REPAIR OR MODIFICATION) and labor from the date of delivery as evidenced by a copy of the

receipt. OMNEX's entire liability and your exclusive remedy shall be, at OMNEX's option, either the (a) repair or (b) replacement of the OMNEX product

which is returned within the warranty period to OMNEX freight collect by the

OMNEX APPROVED carrier with a copy of the purchase receipt and with the

return authorization of OMNEX. If failure has resulted from accident, abuse or

misapplication, OMNEX shall have no responsibility to repair or replace the

product under warranty. In no event shall OMNEX be responsible for incidental

or consequential damage caused by defects in its products, whether such dam-

www.omnexcontrols.com

5.1” x 4.7” x 1.4”

(130mm x 119mm x 36mm)

High impact plastic, weatherproof

3A (max) each (sourcing),

10A (max) each (combined)

17

9.5" x 6.0" x 5.0"

(240mm x 152mm x 127mm)

High impact, low temperature

plastic, weatherproof

N/A

OMNEX Control Systems Inc.

74-1833 Coast Meridian Road

Port Coquitlam, BC, Canada

V3C 6G5

Tel: 604-944-9247

Fax: 604-944-9267

Toll Free: 1-800-663-8806

www.omnexcontrols.com

call toll free: 1-800-663-8806

Loading...

Loading...