Page 1

T245 Control System

Installation and Operations Manual

DMAN-2053-01

Issue 5

November 27, 2001

2001 OMNEX Control Systems Inc.

All rights reserved.

Page 2

T245 Control System Manual

OMNEX Control Systems, Inc.

#74 – 1833 Coast Meridian Road,

Port Coquitlam, B.C.

Canada V3C 6G5

Telephone: (604) 944-9247

Fax: (604) 944-9267

http://www.omnexcontrols.com

ii

Page 3

T245 Control System Manual

Revision History

Issue Description Pages

04 Revision history added, T247 Hoffman box added to Part Numbers iii, 2

05 Added Throttle Enable O11, changed operation of Hydrosync shift 10, 17

Deleted obsolete part numbers 1

iii

Page 4

T245 Control System Manual

This page is intentionally left blank.

iv

Page 5

T245 Control System Manual

Contents

1. Introduction..........................................................................................................................1

1.1. Part Numbers ...........................................................................................................1

2. Physical Installation .............................................................................................................3

2.1. Receiver/Controller..................................................................................................3

2.2. Receiver Antenna.....................................................................................................3

2.3. Platform Holster Magnet..........................................................................................4

3. Considerations for Electrowelding ......................................................................................5

4. Electrical Connections .........................................................................................................6

5. Fuses, Configuration Jumpers............................................................................................11

5.1. R1300+ Board........................................................................................................11

5.2. S20 Board ..............................................................................................................11

6. Setting Up the Radio Receiver..................................................................................................12

6.1. Unique Identifier (Radio ID)......................................................................................12

6.2. No-Link Data Mode...................................................................................................13

6.3. Checksum Mode ........................................................................................................13

6.4. Changing Switch Settings..........................................................................................13

7. Operations..........................................................................................................................14

7.1. Receiver/Controller................................................................................................14

7.1.1. Error Codes ................................................................................................14

7.2. T245/T45 Radio Transmitter .................................................................................14

7.2.1. Switching The Transmitter ON and OFF...................................................14

7.2.2. Operator Controls: .....................................................................................15

7.2.3. Tilt Failsafe ................................................................................................16

7.2.4. Low Battery Indicator ................................................................................16

7.2.5. Battery Charging and Replacement ...........................................................16

7.2.6. Transmitter Light Summary.......................................................................17

7.2.7. Numeric Display ........................................................................................17

7.3. T247/T47 Cable Remote........................................................................................18

7.4. Emergency Override Panel ....................................................................................19

8. Proportional Drive Adjustments ........................................................................................20

9. Factory Parameters.............................................................................................................25

9.1. Types of Factory Parameters..................................................................................25

9.2. Changing the Factory Parameters ..........................................................................25

9.3. List of Factory Parameters .....................................................................................26

PWM Drive Frequency Parameters .......................................................................29

Boom Load Moment Limit....................................................................................29

Boom Derating Factors..........................................................................................29

Emergency Override Panel Function Speed ..........................................................29

Auger Shake Speed................................................................................................29

v

Page 6

T245 Control System Manual

Digger Transmission Type.....................................................................................29

Bucket/Pole-Claw Speed Ratio..............................................................................29

10. Warranty .................................................................................................................................30

vi

Page 7

T245 Control System Manual

1. Introduction

The T45 Control System consists of a custom Receiver/Controller (grey

box), an optional T245 Radio Transmitter and/or an optional T247 Cable Remote. An

interface is also provided for an optional user-supplied Emergency Override Panel. The

main components of the Receiver/Controller are an R1300+ (TPCB-1225-10) circuit

board, an S20 (TPCB-1458-03) board, and a DEX-900 radio receiver.

The Receiver/Controller’s software is custom-designed for many applications.

Various sensors mounted on the machine chassis send feedback information to the

Receiver/Controller. This feedback information together with the operator commands

determine the drive outputs to the Apitech™ electric-over-hydraulic valves. A

sophisticated computer program, permanently encoded into the firmware chips of the

Receiver/Controller, governs the mapping of inputs to outputs.

Features of the computer program include safety interlocks to prevent injury to

personnel as well as damage to the machine. The program incorporates a “restart” check

which ensures that functions do not actuate unexpectedly due to operator panel switches

being left “on” by accident.

All wiring to the Receiver/Controller is through waterproof circular M.S.

connectors on the outside of the fibreglass enclosure, to ensure that the NEMA 4X rating

of the enclosure is preserved. This manual describes considerations which should be

taken during installation and operation, and gives procedures for “tuning” the system to

match the exact characteristics of your hydraulic valves

.

1.1. Part Numbers

The list below gives the part numbers of the major components of the T245

Control System. You will need these numbers for reference and ordering spare parts.

Component OMNEX Part

Number

R2305 Receiver (supports T245, T47 and

T247; replaces R1302 and R1305)

Factory Key for Receiver/Controller ACAB-1355-02 19444-1

User Key for Receiver/Controller ACAB-1355-01 Y1619

Shock Mount Kit for

Receiver/Controller

ASSY-1992-01 19425-1

AKIT-1498-01 Y1616

Versalift Part

Number

Antenna Kit for Receiver/Controller A0005 19292-1

Output Cable with 54-pin Connector, 6

feet

Emergency Override Panel Interface ACAB-1734-01 —

ACAB-1733-01 —

1

Page 8

T245 Control System Manual

1. Introduction

The T45 Control System consists of a custom Receiver/Controller (grey

box), an optional T245 Radio Transmitter and/or an optional T247 Cable Remote. An

interface is also provided for an optional user-supplied Emergency Override Panel. The

main components of the Receiver/Controller are an R1300+ (TPCB-1225-10) circuit

board, an S20 (TPCB-1458-03) board, and a DEX-900 radio receiver.

The Receiver/Controller’s software is custom-designed for many applications.

Various sensors mounted on the machine chassis send feedback information to the

Receiver/Controller. This feedback information together with the operator commands

determine the drive outputs to the Apitech™ electric-over-hydraulic valves. A

sophisticated computer program, permanently encoded into the firmware chips of the

Receiver/Controller, governs the mapping of inputs to outputs.

Features of the computer program include safety interlocks to prevent injury to

personnel as well as damage to the machine. The program incorporates a “restart” check

which ensures that functions do not actuate unexpectedly due to operator panel switches

being left “on” by accident.

All wiring to the Receiver/Controller is through waterproof circular M.S.

connectors on the outside of the fibreglass enclosure, to ensure that the NEMA 4X rating

of the enclosure is preserved. This manual describes considerations which should be

taken during installation and operation, and gives procedures for “tuning” the system to

match the exact characteristics of your hydraulic valves. CAUTION: Changes or modifications

not expressly approved by the party responsible for compliance could void the user's authority

to operate the equipment.

1.1. Part Numbers

The list below gives the part numbers of the major components of the T245

Control System. You will need these numbers for reference and ordering spare parts.

Component OMNEX Part

Number

R2305 Receiver (supports T245, T47 and

T247; replaces R1302 and R1305)

Factory Key for Receiver/Controller ACAB-1355-02 19444-1

User Key for Receiver/Controller ACAB-1355-01 Y1619

Shock Mount Kit for

Receiver/Controller

ASSY-1992-01 19425-1

AKIT-1498-01 Y1616

Versalift Part

Number

Antenna Kit for Receiver/Controller A0005 19292-1

Output Cable with 54-pin Connector, 6

feet

Emergency Override Panel Interface ACAB-1734-01 —

ACAB-1733-01 —

1

Page 9

T245 Control System Manual

2. Physical Installation

2.1. Receiver/Controller

The Receiver/Controller should be mounted with the connectors down, and in a

location so that the enclosure door may be opened conveniently for access to the inside.

Shock mounts must be used to mount the enclosure!

should the enclosure be directly bolted to the machine. Figure 1 below illustrates how the

shock mounts should be installed:

Figure 1

The Receiver/Controller enclosure is sealed and has a NEMA-4 rating. When

installing, ensure that nothing is done to compromise the watertightness of the enclosure.

When performing maintenance it may be necessary to gain access to the inside of the

enclosure; take care to re-close the door securely when you are done.

Enclosure Mounting

Under no circumstances

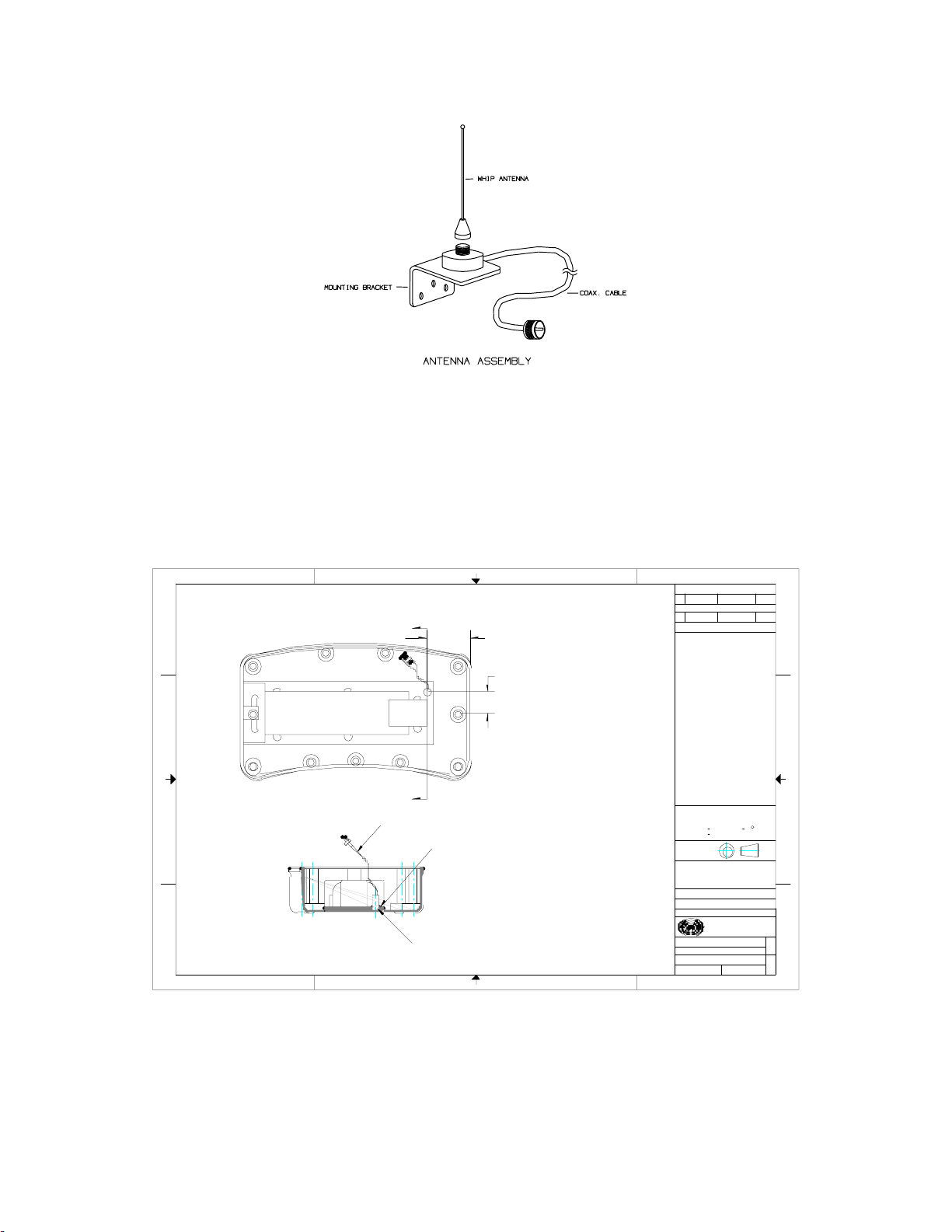

2.2. Receiver Antenna

The receiver antenna should be mounted pointing up and as high as possible,

preferably with a large metal surface below it but no metal above or to the side. The

antenna must be mounted on the outside of the machine; do not mount it inside an

operator’s cab or in a toolbox. Assemble the antenna as shown in Figure 2 below, and

thread (finger-tight only) the connector onto the matching receptacle on the

Receiver/Controller.

3

Page 10

T245 Control System Manual

Figure 2

Antenna Assembly

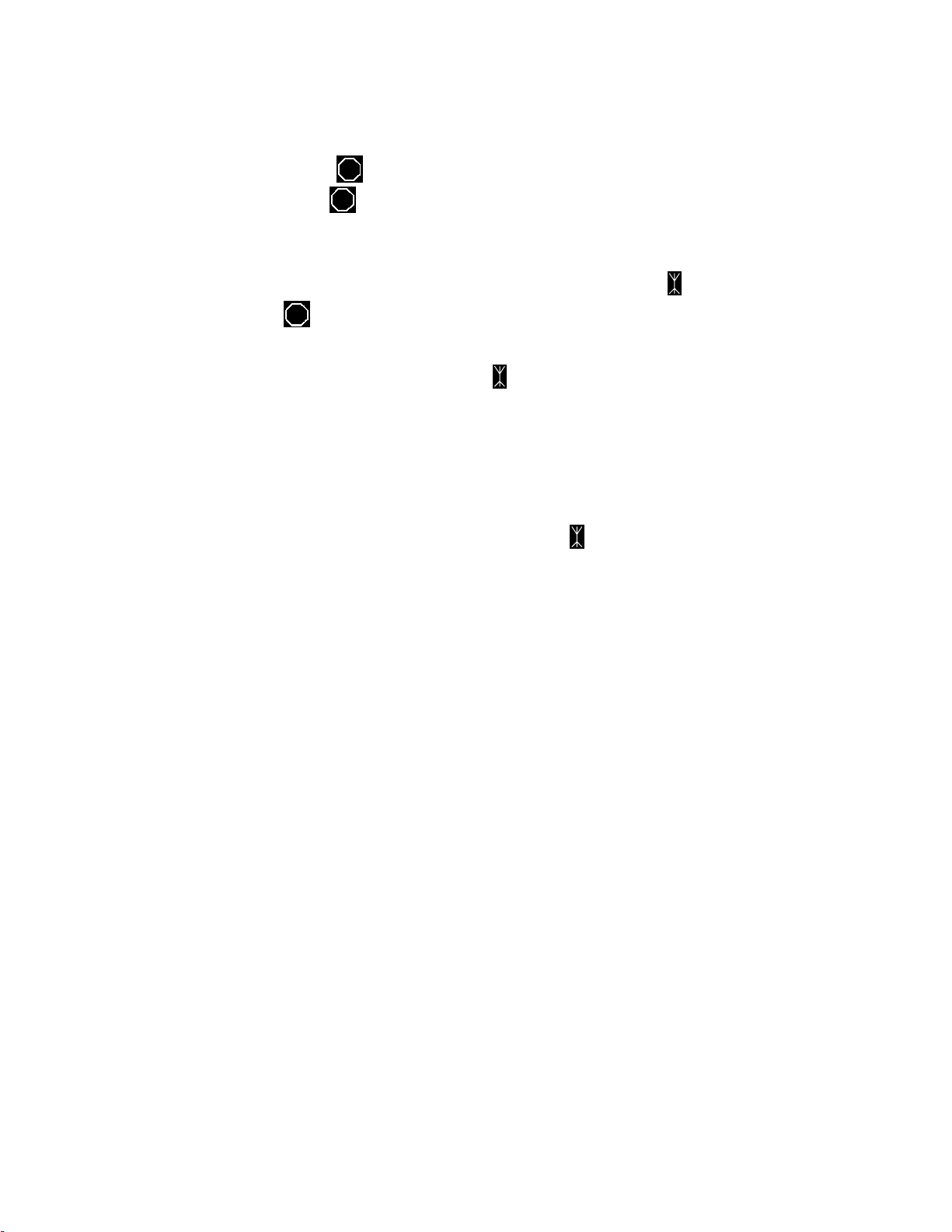

2.3. Platform Holster Magnet

The magnet which indicates to the T245 Radio Transmitter that it is in the

platform holster should be mounted with the plastic face up, towards the T245. The

drawing below is an internal view of the T245 bottom half, indicating where the magnetic

switch is.

4321

SWITCH , MAGNATIC REED

D

A

2.200

(P/N: SX-MPS9WGN)

INSTALLATION INSTRUCTION.

1.100

C

A

B

A

SECTION A-A

4321

18 AWG 3.75" WHT.

2 PLACES.

SILICONE SEALING

ALL WAY AROUND.

DRILL 3.5 DIA. HOLE ON T45 BOTTOM ONLY,

(PRESS FIT)

NOT DRILL ON BATTERY BOTTOM.

REVISIONS

REV DATE: APPROVED: ECO

1 05-12-99

DESCRIPTION:

T45 Bot. Versalift -Iss1

DATE:REV APPROVED: ECO

DESCRIPTION:

GENERAL NOTES:

1. MATERIAL: SWITCH, MAGNETIC REED

INSTALLATION INSTRUTION.

UNLESS OTHERWISE SPECIFIED

DIMENSIONS ARE IN INCHES

TOLERANCES

DECIMALS ANGULAR

.XX + .05 + 0.5

.XXX + .010

DO NOT SCALE DRAWING

THIRD ANGLE

PROJECTION:

THESE DESIGNS AND SPECIFICATIONS ARE THE

PROPERTY OF OMNEX CONTROL SYSTEMS INC.

AND SHALL NOT BE COPIED OR USED FOR

MANUFACTURING WITHOUT ITS WRITTEN

CONSENT.

CHECKED:

DRAWN:

DESIGNED:

TITLE:

PART #:

DRAWING #:

SCALE:

DATE:

R T F 05-12-99

DATE:

G. C. 05-12-99

DATE:

W. H. 05-12-99

OMNEX

Control Systems Inc.

T45 Bot. Versalift -Iss1

ASUB-1327-03

DSUB-1327-03

SHEET: OF

1 : 2 1 1

D

C

B

REV

A

1

SIZE

B

Figure 3

T245 Magnetic Switch

4

Page 11

T245 Control System Manual

3. Considerations for Electrowelding

The electronics in the T245 Control System can be damaged by the high currents

and voltages employed in electrowelding. If electrowelding must be performed after the

Control System has been installed, observe the following precautions to reduce the risk of

damage:

• Do not connect the ground clip to a point on the chassis close to the

enclosures.

• Disconnect the harnesses to the enclosures and sensors at the M.S. connectors.

Also disconnect the battery (PTO switch) and ground connections going into

the enclosures.

• Do not strike an arc close to the enclosures and sensors, or wiring leading into

the enclosures and sensors.

• Do not weld to the sensors.

5

Page 12

T245 Control System Manual

4. Electrical Connections

The Receiver/Controller has two circular M.S. connectors for connection to your

chassis wiring. A 54-pin M.S. connector is used for power and function outputs. A 16pin M.S. connector is provided for connection to the T47 Cable Remote or Emergency

Override Panel. The following tables specify the assignment of each pin, with

corresponding markings on the circuit boards for reference. The wire numbers refer to

the old-style Output Cable and not the new Custom Output Harness.

Main Connector (Power and Functions):

Function Wire # 54-pin (32A10P)

M.S. Pin

Ground 48,38 A, AF J15 (R1300), J3 (S20)

Power for Electronics (Battery Positive) 39 AG J12 (R1300), J1 (S20)

Power for Function Outputs (Batt. +) yellow

+green

Dump Valve Output (drives power out

when radio signal is being received

from transmitter)

Engine START 24 D D2 (R1300)

Engine STOP 47 E D1 (R1300)

Winch DOWN 29 F 1+ (R1300)

Winch UP 25 G 1- (R1300)

Digger DIG 46 H 2+ (R1300)

Digger CLEAN 45 J 2- (R1300)

Lower Boom LOWER 5 K 3+ (R1300)

49 C J13 (R1300), J2 (S20)

B J14 (R1300)

Board References

Lower Boom RAISE 14 L 3- (R1300)

Intermediate Boom EXTEND 23 M 4+ (R1300)

Intermediate Boom RETRACT 26 N 4- (R1300)

Upper Boom EXTEND 3 O 5+ (R1300)

Upper Boom RETRACT 22 P 5- (R1300)

Pole Guide/Platform LOWER 44 R 6+ (R1300)

Pole Guide/Platform RAISE 30 S 6- (R1300)

Boom Rotate CCW 6 T O1 (S20)

Boom Rotate CW 13 U O2 (S20)

6

Page 13

T245 Control System Manual

Function Wire # 54-pin (32A10P)

M.S. Pin

Pole Guide/Platform OPEN 12 V O3 (S20)

Pole Guide/Platform CLOSE 21 W O4 (S20)

Digger Shift HIGH 27 X O5 (S20)

Digger Shift LOW 4 Y O6 (S20)

Auger LATCH 2 Z D4 (R1300)

Auger UNLATCH 20 a D5 (R1300)

Throttle UP 31 b D6 (R1300)

Throttle DOWN 7 c D7 (R1300)

Emergency Power 9 d D3 (R1300)

Electronic Throttle Output (pulse-width

modulated signal; formerly 0 to 5V)

Hydraulic Tool Valve 43 f D8 (R1300)

Upper Boom Extended Switch (N.O.

contact)

1 e O9 (S20)

32 g J2 pin 6 (R1300)

Board References

Intermediate Boom Retracted Switch

(N.O. contact)

Upper Boom Retracted Switch (N.O.

contact)

(not used) — k —

Auger Overstow Switch (N.O. contact)

Input

(spare switch input) 15 n J2 pin 3 (R1300)

(spare switch input) 17 p J2 pin 4 (R1300)

Boom Stowed Switch (N.O. Contact)

Input

+5V Power for N.O. Switches 42 r J2 pin 1 (R1300)

+5V for Proportional Pressure and

Angle Sensors

Angle Sensor Input

(-20.0° = 0.5V, +80.0° = 4.5V)

28 h J2 pin 7 (R1300)

8 j J2 pin 8 (R1300)

33 m J2 pin 2 (R1300)

11 q J2 pin 5 (R1300)

34 s J3 pin 1 (R1300)

16 t J3 pin 3 (R1300)

7

Page 14

T245 Control System Manual

Function Wire # 54-pin (32A10P)

M.S. Pin

Lift Cylinder Piston-Side Pressure

Sensor Input (0 PSI = 0.5V, 3000 PSI =

4.5V)

Lift Cylinder Rod-Side Pressure Sensor

Input (0 PSI = 0.5V, 3000 PSI = 4.5V)

Ground for Proportional Pressure and

Angle Sensors

(spare 0-5V proportional input) — x J40 pin 2 (R1300)

(spare 0-5V proportional input) — y J40 pin 3 (R1300)

(spare 0-5V proportional input) — z J40 pin 4 (R1300)

(spare 0-5V proportional input) 18 AA J40 pin 5 (R1300)

(spare pulse input) 36 AB P1 (S20)

(spare pulse input) 41 AC P2 (S20)

Turret Brake Release 37 AD O7 (S20)

10 u J3 pin 4 (R1300)

19 v J3 pin 5 (R1300)

35 w J3 pin 6 (R1300)

Board References

Throttle Enable 50 AE O11 (S20)

There are two separate power (+12V) and ground pins on the Main Connector. If

you are using the old-style Output Cable or are making your own wire harness, the two

ground pins (A and AF) should be connected to a good ground point at the battery or on

the chassis. The two power pins (AG and B) should be connected to a good switched

source, usually at the vehicle’s PTO switch. While the Receiver/Controller contains

internal fusing, it is highly recommended that in-line fuses be used to protect the wiring

harness in case of short circuits;

The Dump Valve Output (pin C) is a safety feature, and must be used to control a

dump valve in the hydraulic pressure circuit.

energized, the dump valve must divert the hydraulic flow back to tank

hydraulically-powered movements stop. Only when this output is energized (driving

+12V out) should the machine have hydraulic power.

The rest of the output functions except for the Electronic Throttle Output (pin e)

are designed to drive either proportional or on/off solenoids at up to 3A each. Note that

the total simultaneous load must not, of course, exceed the ratings of the power fuses

(both inside the Receiver/Controller and your harness fuses). As the power distribution is

complex, please contact OMNEX for information before changing the fuse ratings from

their original values.

use a 3A fuse for pin AG, and a 15A fuse for pin B

Whenever this output becomes de-

so that all

.

8

Page 15

T245 Control System Manual

To control the engine throttle, use pin e for electronic throttles which take pulsewidth modulated signals (such as Caterpillar ECUs)

†

, or wire pins b and c to direction-

control relays for motor-driven throttles.

The Switch Inputs (pins m, n, p and q) are best switched to the +5V Power

supplied from pin r, although they will work fine if switched to +12V. The +5V from pin

r is preferred because it is already protected against short circuits. Do not feed +12V

back into pin r.

The proportional sensors must be powered from pin s (+5V) and pin w

(ground).

Do not power them from +12V or any other ground.

T47 Cable Control / Override Panel Connector:

Function Wire # 16-pin (24-5S)

Board References

M.S. Pin

Ground 14 A J15 (R1300), J3 (S20)

Power to T47 13 B J41 (R1300)

Wired Remote Interface A 4 C J1 pin 5 (R1300),

CN4 pin 4 (S20)

Wired Remote Interface B 5 D J1 pin 2 (R1300),

CN4 pin 3 (S20)

E-Stop A 11 E J41 (R1300)

E-Stop B 15 F CN8 pin 8 (S20)

T47 ON Switch /

Override Panel ENABLE Button

6 G CN8 pin 4 (S20),

CN3 pin 2 (S20),

J2 pin 9 (R1300)

Ground 10 H J15 (R1300), J3 (S20)

Override Panel Boom Rotate CCW 3 J J10 pin 2 (R1300)

Override Panel Boom Rotate CW 1 K J10 pin 3 (R1300)

Override Panel Intermediate Boom

16 L J10 pin 4 (R1300)

EXTEND

Override Panel Intermediate Boom

2 M J10 pin 5 (R1300)

RETRACT

Override Panel Upper Boom EXTEND 9 N J10 pin 6 (R1300)

†

An external module may be used to convert the pulse-width modulated signal to a 0 to 5V signal for

Navistar

®

, Ford, and GMC ECUs. Contact OMNEX for details.

9

Page 16

T245 Control System Manual

Function Wire # 16-pin (24-5S)

M.S. Pin

Override Panel Upper Boom

RETRACT

Override Panel Lower Boom LOWER 8 R J10 pin 8 (R1300)

Override Panel Lower Boom RAISE 7 S J10 pin 9 (R1300)

In systems which include a T247 or T47 Cable Remote, the 16-pin connector is

used for connection to the Cable Remote. However, in systems without a T247/T47, a

truck-mounted Emergency Override Panel must be provided; use either the old-style

Emergency Override Panel Interface Cable or the new Custom Emergency Override Panel

Harness to make connections from the 16-pin connector to this Panel.

Override Panel must provide a normally-closed Emergency-Stop button across pins

E and F.

Emergency Override Panel must also provide a momentary, normally-open contact

between pin B and pin G; this is the override button which the operator must press

and hold to override the T45 Radio Transmitter.

override switches (pins J through S). Pins C and D are not used for the Emergency

Override Panel.

The emergency-stop circuit must be closed to operate the machine.

17 P J10 pin 7 (R1300)

Pin B is also the common to all the

Board References

The Emergency

The

10

Page 17

T245 Control System Manual

5. Fuses, Configuration Jumpers

The R1300+ and S20 circuit boards have a number of fuses and configuration

jumpers which must be specific values for operation.

5.1. R1300+ Board

F2 = 10A

F3 = 15A

F4 = 1A

F5 = (omit)

JP1 (MAIN BYPASS) = OFF

JP4 (RADIO STATUS) = OFF

JP2 (INPUTS 1) = GND

JP3 (INPUTS 2) = GND

J25/J29/J34 = (no jumper installed)

J26 (PWM PWR) jumpered to J22

J28 (OUT PWR) jumpered to J23

J27 (DIGITAL PWR) jumpered to J24

SW1 = (all positions OFF)

SW2 = (all positions OFF)

5.2. S20 Board

F4 = 10A

F5 = 1A

F6 = 1A

11

Page 18

T245 Control System Manual

6. Setting Up the Radio Receiver

If you have purchased the optional T245/T45 Radio Transmitter, you will need to

verify that the Radio Receiver is set up to respond to your particular Radio Transmitter.

This section describes how to set the banks of configuration switches (see Figure 4) on

the front of the DEX-900 or REX-900 Radio Receiver (mounted to the S20 Board inside

the enclosure lid).

1

8

16

9

1

8

16

9

Figure 4

Radio Receivers

6.1. Unique Identifier (Radio ID)

Each T245/T45 Radio Transmitter is identified by a unique Radio ID. The

DEX-900 or REX-900 in your Receiver must be set up to match the ID of your

transmitter. On the back plate (to which the metal guard is attached) is affixed a serial

number and ID Code label, an example of which is shown in Figure 5. The ID code

consists of two parts, SW 1 and SW 2, corresponding to switch banks labelled “ID” 1

through 8 (SW 1) and 9 through 16 (SW 2) on the DEX-900 and REX-900.

Figure 5

The ID Code is punched as holes in the label, with the position of the hole

indicating the position of each of the small switch handles on the REX-900. Left to right

corresponds to 1 through 8, and 9 through 16. On the label, “1” means ON and “0”

means OFF. On the REX-900, ON is towards the ANTENNA connector (as marked on

each bank of switches), and OFF is towards the EXPANSION connector. Thus, to match

the REX-900 to the transmitter ID code given in the example label of Figure 5, you must

set switches 1 through 8 to OFF, ON, ON, OFF, OFF, ON, OFF, ON, and switches 9

through 16 to ON, ON, ON, ON, OFF, OFF, OFF, ON.

Radio Transmitter ID Label

12

Page 19

T245 Control System Manual

6.2. No-Link Data Mode

The third bank of switches (“MODE” 1 through 8) on the DEX-900 and REX-900

is used to select various features on the radio receiver.

Receiver/Controller, only position 5 should be ON.

REX-900 to clear all its output data whenever there is no link or signal from the Radio

Transmitter of the right ID.

For the Versalift

This sets the DEX-900 or

6.3. Checksum Mode

The DEX-900 has a fourth bank of switches (“MODE” 9 through 16) for selecting

additional features.

ON.

This sets the DEX-900 to use checksums when transferring data to and from the

R1300+ board.

For the Versalift Receiver/Controller, only position 5 should be

6.4. Changing Switch Settings

To change the switch settings, use a ballpoint pen or small screwdriver to move

the switch levers. When you have set the levers to the right positions, turn the system

power off (usually by shutting off the vehicle’s PTO switch) and back on again. The

DEX-900 or REX-900 will take about 5 seconds to process your changes and then turn on

its red ON lamp.

DEX-900/REX-900 switches, for the changes to take effect.

You must switch the power off and on whenever you change the

13

Page 20

T245 Control System Manual

7. Operations

This chapter briefly describes how to operate the T245 Control System. These

instructions are intended to give you an understanding of basic operating principles; this

is not a complete Operator’s Manual. Once installation has been completed and checked,

we recommend that you read this section carefully and operate the system to become

accustomed to the controls.

7.1. Receiver/Controller

The Receiver/Controller does not contain an on/off switch. It is functional as

soon as power is applied; power should be switched though an external switch, such as

the vehicle’s PTO switch.

7.1.1. Error Codes

The Receiver/Controller constantly monitors its safety systems. If a fault is

detected, the Receiver/Controller will disable all control functions and begin flashing all

of the VALUE lights in its Configuration Panel (see Figure 7) together with one of the

numbered OUTPUT lights. The codes are as follows:

OUTPUT Light Flashing Fault Indicated and Remedy

1_ One or both power relay contacts have welded closed.

Replace both relays if they are the plug-in types; if not, the

R1300+ board must be replaced.

2_ REX-900 receiver stop-circuitry fault. Replace the

REX-900.

7.2. T245/T45 Radio Transmitter

A description of transmitter operation follows.

7.2.1. Switching The Transmitter ON and OFF

The T245/T45 Radio Transmitter has three LED lights to indicate

its operating status, and a toggle switch to turn it on and off. It has built-in safety features

to both protect you against unexpected movement of the controlled machine, and selfcheck its emergency stop circuit, when powering up. The operation of its status lights

and power-on sequence is as follows:

To switch ON the transmitter:

1. Move the POWER switch to the ON position. The red

indicate you must test the EMERGENCY STOP button.

14

STOP

light will flash to

Page 21

T245 Control System Manual

2. The EMERGENCY STOP button test is two-part; the transmitter needs to see

both states (pressed and released) of the button before it will allow you to

operate. If the

button. If the

button. When the test is done, the button will be released.

3. The transmitter now checks to ensure that all switches and joysticks are in

STOP

light is flashing slowly, press the EMERGENCY STOP

STOP

light is flashing quickly, release the EMERGENCY STOP

their “off” or “neutral” positions. If they are not, the green

and red

STOP

lights will flash together to indicate that you must switch off any

(transmit) light

functions which are on.

4. During normal operation, the green

light is on solid if no functions are

switched on, and flashes if one or more functions are active.

Be sure to switch off the transmitter when you are finished operating. Besides

depleting the battery, an active, unattended transmitter is a safety hazard!

7.2.2. Operator Controls

Once the transmitter is switched on and the green

light is on, all joysticks and

toggle switches are active. The label indicates which machine functions are affected by

each control. To operate the dual-axis joystick functions or the centre paddle, you must

press and hold one of the joystick deadman triggers.

The Throttle Enable output will turn ON 4 seconds after a REMOTE START is

received. It will turn OFF after an E-Stop or ENGINE STOP.

The DIGGER SHIFT function behaves slightly differently depending on whether

you have a Two-Speed digger transmission or a Hydrasync digger. With a Hydrasync

digger, you can shift “on the fly” and the shift occurs immediately when you activate

DIGGER SHIFT (the Control System will toggle between HIGH and LOW speed). When

in HIGH speed the Control System will pulse the HIGH output ON for 1 second and OFF

for 4 seconds. It will continue to pulse until a shift into LOW speed or an E-Stop. With a

Two-Speed digger, activating DIGGER SHIFT will start an automatic 3-second shift

sequence: The digger motor is stopped (if it is moving) for 1 second, a shift command is

applied to the transmission for 1 second, and another 1-second delay occurs before the

digger motor can be restarted. You do not need to hold the toggle switch for the entire

sequence. Thus, you can be digging with the DIG/CLEAN paddle, toggle DIGGER

SHIFT and the auger will automatically stop, shift, and resume with you having to let go

of the DIG/CLEAN paddle.

The AUGER UNLATCH function will only operate if the Upper Boom is

retracted. The AUGER UNLATCH function will automatically shift the digger into low

and stop all auger movements. Once the digger is shifted into low, the auger is unlatched

for 8 seconds after which the auger will automatically re-latch.

15

Page 22

T245 Control System Manual

7.2.3. Tilt Failsafe

The transmitter is equipped with a tilt sensor which automatically engages the

EMERGENCY STOP if the transmitter is tipped more than 90° from its normal

horizontal operating position. This is a failsafe mechanism that protects the operator in

case he or she falls or is struck by the machine itself. To resume operation from a tilt

condition, press and release the EMERGENCY STOP button after righting the

transmitter.

7.2.4. Low Battery Indicator

The

(battery) light is the “low battery” indicator. When the battery voltage

is acceptable, the lamp will be off. If the voltage becomes too low, the lamp will begin to

blink and the battery should be recharged, or replaced, as soon as possible. The control

system will not become erratic with a low battery; it will simply cease to operate when

the voltage falls below the minimum operating level.

7.2.5. Battery Charging and Replacement

®

9.6V rechargeable power tool battery. A

Makita

The Transmitter is powered by a Makita

®

charger is available for purchase from OMNEX. Call 1-800-663-8806 to order.

To charge the battery please follow the instructions included with the charger. To

remove the battery from the transmitter, grasp the lip on the battery door and pull it down

and out to open the door. Tilt the case to allow the battery to slide out. The battery is

keyed to prevent incorrect installation (see Figure 6 below).

Figure 6

Battery Replacement

16

Page 23

T245 Control System Manual

7.2.6. Transmitter Light Summary

The following table describes all the conditions indicated by various states of the

three transmitter lights. Note that the transmitter performs some self-diagnostics, and can

indicate joystick and radio failures in addition to the “usual” operating status.

Legend: z = LED on, ~ = LED flashing slowly, = LED flashing quickly,

{ = LED off, N/A = Not Applicable

STOP

LED LED

{{ {

{{ ~

{{

N/A

N/A

N/A

N/A

~

~~

~ ~

~~

z{

~{

{/~

N/A N/A Low Battery Replace/Recharge Battery

LED

z

Description Action Required

Battery Dead; Power Off Charge Battery; Turn Power On

E-Stop Test Press E-STOP Button

E-Stop Test Part two Release E-STOP Button

Functions not all off on

EMERGENCY STOP

release

All Okay, all functions off OK, continue as required

All Okay, 1+ functions on OK, continue as required

Emergency Stop E-STOP Button Pressed

Module failure: Joystick Cycle Power--if not remedied, call

Module failure: Radio Cycle Power--if not remedied, call

Set all functions off

service

service

7.2.7. Numeric Display

The transmitter contains a three-digit numeric display to further indicate operating

status. It can display numbers between 0.0 and 99.9, and is lighted for night viewing.

There are several quantities that the display can show, indicated by “pointers” to three

marks (LOAD %, BOOM ANGLE, DIAG) at the right edge of the display:

Mark Pointed To Quantity Shown

LOAD %

BOOM ANGLE

DIAG

BOOM ANGLE and

Percentage of allowable boom load.

The absolute value of the boom angle, in degrees.

The voltage, 0.0 to 5.0, at the piston-side pressure sensor.

The voltage, 0.0 to 5.0, at the rod-side pressure sensor.

DIAG

Additionally, the display can have a digit between 0 and 9 in the right-most

position, with the left three digits showing diagnostic information as follows:

Legend (Right Digit) Information Shown (Left Three Digits)

0 This special mode shows the Boom De-rating Factor being

17

Page 24

T245 Control System Manual

Legend (Right Digit) Information Shown (Left Three Digits)

adjusted and will only appear in Factory Setup mode. Please

9. Factory Parameters

see

1 Boom Extension Switches†:

100 = Upper Boom Extended,

10 = Intermediate Boom Retracted,

1 = Upper Boom Retracted

2 Boom Stow Switches:

100 = Auger Overstow,

10 = Boom Stowed

To change between these displays, press the DISPLAY button. The display will

always start at LOAD % after releasing the transmitter’s EMERGENCY STOP. Holding

the DISPLAY button for more than two seconds will also return the display to LOAD %.

The display will only work when the transmitter is switched on and its

EMERGENCY STOP is released (the

STOP

light must not be on or flashing); otherwise,

the display will show three dashes (“- - -”) in place of numbers. If the T247 Cable

Remote is plugged in and switched on, the display on the T245/T45 Transmitter will stop

working and the information will be displayed on the T247’s display instead.

for more information.

The display in the newer T245 will operate whenever the T245 is in control of the

VXD, with a range of about 1200 feet (line-of-sight). The display in the older T45 will

operate within a 100-foot (approximate) radius of the Receiver/Controller’s antenna;

however, the remote control of the machine will operate over a range of about 1200 feet.

Should the display in the older T45 stop working because you are too far from the

machine, you can still safely operate the controls but you will not be able to read the

status information.

7.3. T247/T47 Cable Remote

If you have purchased the optional T247 or T47 Cable Remote, you may operate

the Control System with all of the electronic safety features afforded with the Radio

Transmitter, but via a hardwire (cable). To activate the T247/T47 Cable Remote, release

the red Emergency Stop button and switch on the POWER switch—the control of the

machine is now taken away from the Radio Transmitter and given to the Cable Remote.

All control functions operate as in the Radio Transmitter.

Note that for safety, the Cable Remote’s Emergency Stop button must be released

even when operating from the Radio Transmitter (Cable Remote POWER switch turned

off); this allows someone to stop the machine at the Cable Remote.

†

If more than one switch is on, the values are added. Hence, the display “1011” indicates that the Upper

Boom Extended switch is on, the Intermediate Boom Retracted switch is off, and the Upper Boom

Retracted switch is on.

18

Page 25

T245 Control System Manual

The numeric display in the T247 Cable Remote does not have any distance

limitation as in the T45. The display will work as long as the T247’s cable is connected,

the T247’s POWER switch is turned on and the EMERGENCY STOP is released.

7.4. Emergency Override Panel

If you have not purchased the T247/T47 Cable Remote, you must have an

Emergency Override Panel connected in place of the Cable Remote. To operate from the

Emergency Override Panel, make sure the Emergency Stop button on the Panel is

released and press and hold the ENABLE button while operating the toggle switches on

the Panel.

19

Page 26

T245 Control System Manual

8. Proportional Drive Adjustments

Each proportional valve output can be adjusted to match the characteristics of the

individual valve. There are proportional functions which come out of the R1300+ circuit

board, as well as out of the S20.

The proportional outputs from the S20 are numbered O1 through O16, and the

proportional outputs from the R1300+ are numbered 1+ through 6-; their assigned

functions are indicated in the table below.

Proportional

Output

1+ (R1300) Solid 1+ Winch DOWN

1- (R1300) Solid 1- Winch UP

2+ (R1300) Solid 2+ Digger DIG

2- (R1300) Solid 2- Digger CLEAN

3+ (R1300) Solid 3+ Lower Boom LOWER

3- (R1300) Solid 3- Lower Boom RAISE

4+ (R1300) Solid 4+ Intermediate Boom EXTEND

4- (R1300) Solid 4- Intermediate Boom RETRACT

5+ (R1300) Solid 5+ Upper Boom EXTEND

5- (R1300) Solid 5- Upper Boom RETRACT

6+ (R1300) Solid 6+ Pole Guide/Platform LOWER

6- (R1300) Solid 6- Pole Guide/Platform RAISE

O1 (S20) Flashing 1+ Boom Rotate CCW

Set-Up Panel

Indicator

Function

O2 (S20) Flashing 1- Boom Rotate CW

O3 (S20) Flashing 2+ Pole Guide/Platform OPEN

O4 (S20) Flashing 2- Pole Guide/Platform CLOSE

O5 (S20) Flashing 3+ Digger Shift HIGH (normally set for on/off behaviour)

O6 (S20) Flashing 3- Digger Shift LOW (normally set for on/off behaviour)

O7 (S20) Flashing 4+ (Do not adjust—used for Turret Brake Release)

O8 (S20) Flashing 4- (spare proportional output)

O9 (S20) Flashing 5+ Electronic Throttle (PWM output signal)

O10 (S20) Flashing 5- (not used)

20

Page 27

T245 Control System Manual

Proportional

Output

O11 (S20) Flashing 6+ (not used)

O12 (S20) Flashing 6- (not used)

O13 (S20) Solid 1 (not used)

O14 (S20) Solid 2 (not used)

O15 (S20) Solid 3 (not used)

O16 (S20) Solid 4 (not used)

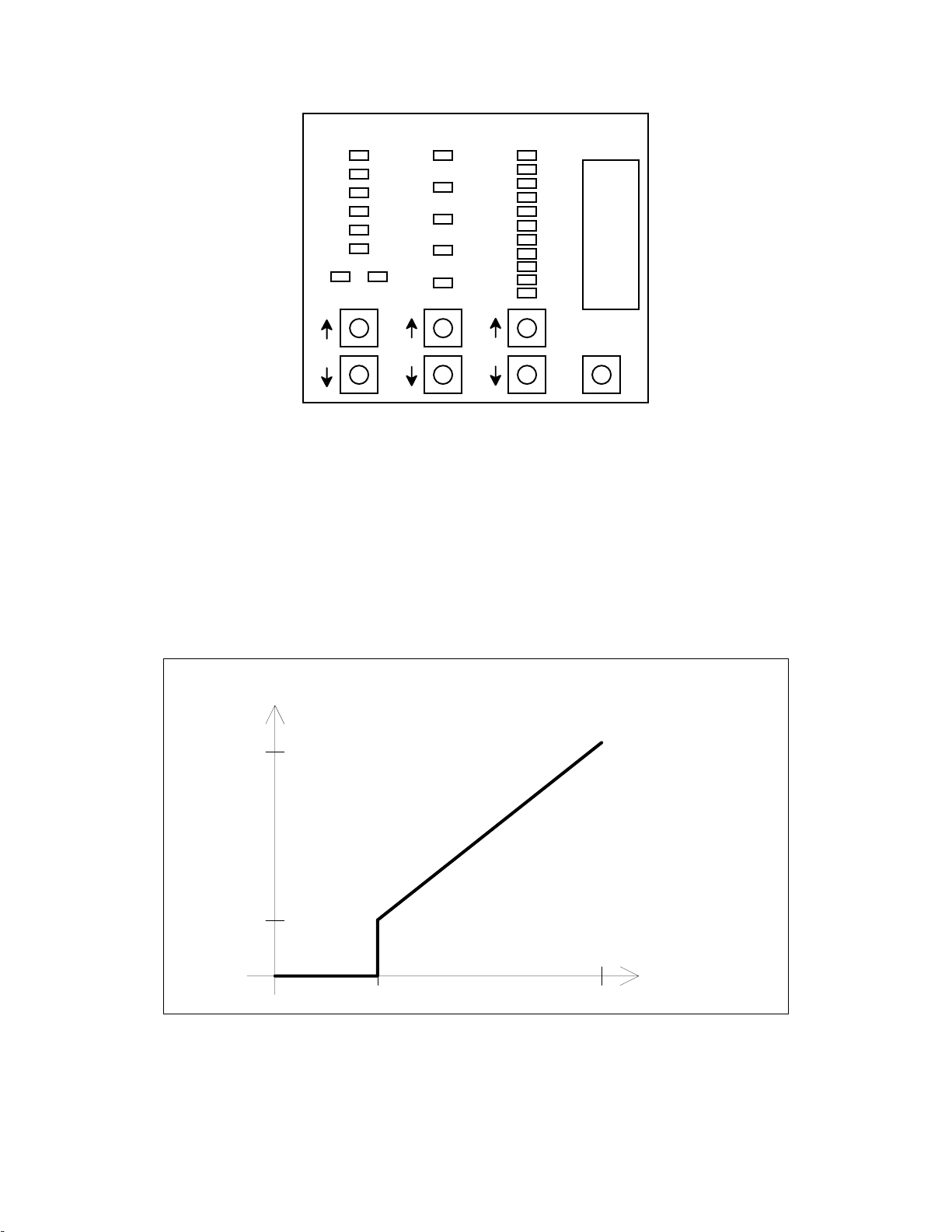

Built-in to the R1300+ is a Set-Up Panel (see Figure 7) consisting of three

columns of indicator lights, seven push buttons, and a socket for a plug-in “key”. As

shown in the diagram below, there are five configurable parameters (centre column of

lights) for each proportional (pulse-width modulation, PWM) output: Threshold,

Start PWM, Max PWM, Ramp Up, and Ramp Down.

The Set-Up Panel has “Output” lights 1+ to 6- which correspond directly to the

proportional outputs of the R1300+. For adjustment of the proportional outputs of the

S20, the Output lights are re-used as per the “Set-Up Panel Indicator” column in the

above table.

Set-Up Panel

Indicator

Function

The 12 R1300+ proportional outputs are indicated by the lights in the “Output”

column as follows: When the “1_” and “+” lights are solidly on, the 1+ parameter is

being output is being adjusted. The “1_” and “-” lights indicate 1-, and so on. The table

above lists these as “Solid 1+” through “Solid 6-“.

The first 12 S20 proportional outputs (O1 through O12) are indicated by flashing

“1+” through flashing “6-”. The table above lists these as “Flashing 1+” through

“Flashing 6-”.

The last 4 outputs (O13 through O16) of the S20 are indicated by the “1_” through

“4_” lights solidly on with both the “+” and “-” lights off. The table above lists these as

“Solid 1” through “Solid 4”.

21

Page 28

T245 Control System Manual

Output Param Value

1_

2_

3_

4_

5_

6_

+-

Threshold

Start PWM

Max PWM

Ramp Up

Ramp Down

MAX

MIN

Key

Store

Figure 7

R1300+ Set-Up Panel

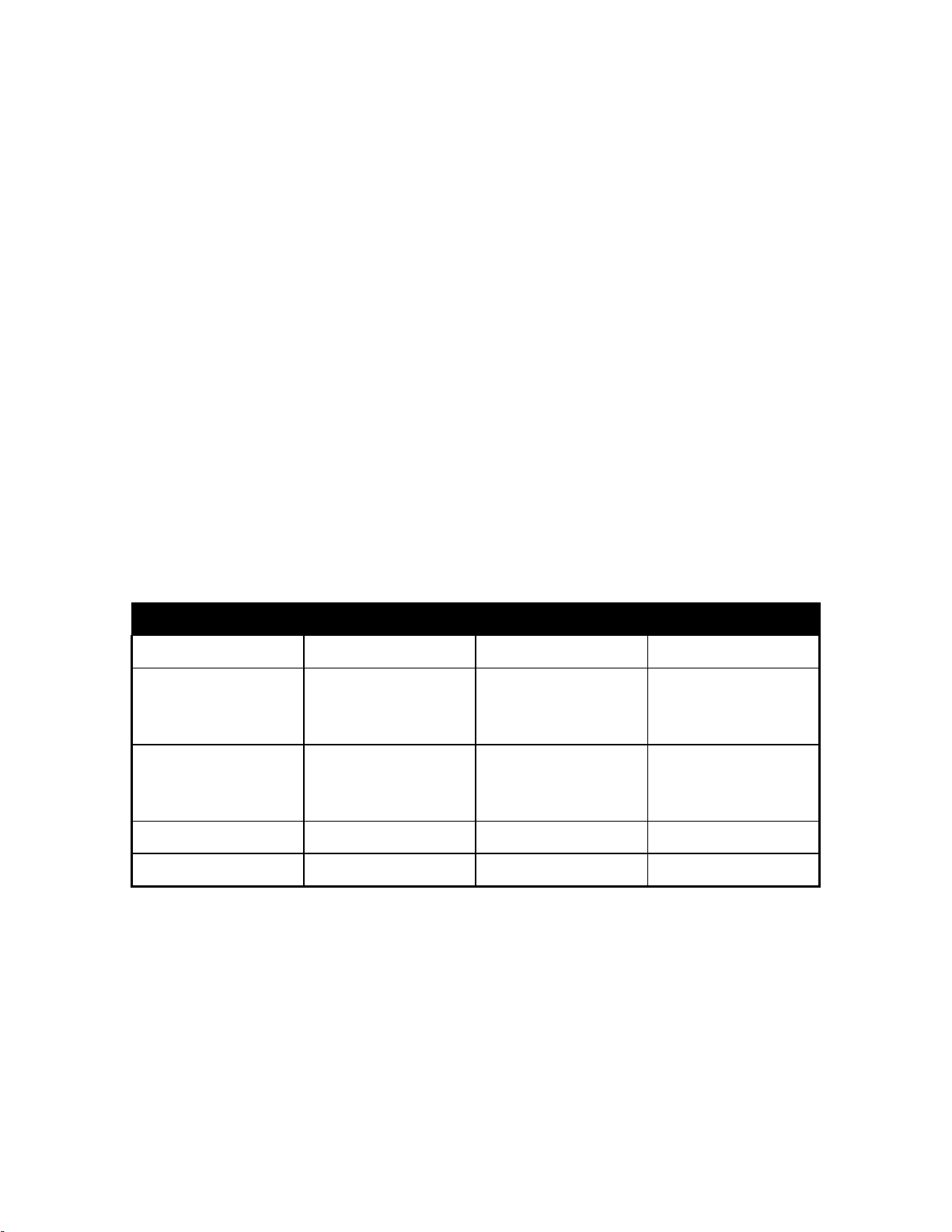

The Ramp parameters control how fast the output builds up or down to the final

value according to a first-order difference equation. The separate Ramp Up and

Ramp Down time constants allow you to tune the valve response for smooth, non-jerky

actuation. The Threshold, Start PWM, and Max PWM parameters control the transferfunction from input (joystick position) to PWM-output value, as shown in Figure 8. The

joystick position can go from 0 to 127. The threshold is simply the deadband beyond

which the joystick must move in order to actuate the PWM output. The PWM output

starts at Start PWM as soon as the joystick has exceeded the threshold, and maps linearly

with joystick position up to Max PWM.

PWM Output

Max PWM

Start PWM

0

0

Threshold 127

Figure 8

Proportional (PWM) Output Function

Joystick Posit

22

Page 29

T245 Control System Manual

In order to customize various parameters for the PWM outputs, the configuration

panel must be “enabled” by plugging in the Factory Key or User Key (supplied); you will

then be in Proportional Drive Setup mode. The display will initially be displaying

“Output” 1 +, no “Param” lights will be illuminated, and the “Value” lights will be

displaying the Start PWM and Max PWM as solid lights. Also, a flashing “Value” light

will show the actual function output value. The flashing light will move as the

corresponding joystick is moved, and you will also see the green light next to the 1+

output on J6 go brighter and dimmer.

To select the output pin you want to change parameters for, press the buttons

under the “Output” lights. To change a parameter, press the buttons under the “Param”

lights until the desired parameter is lit up (Threshold, Start PWM, Max PWM, Ramp Up,

Ramp Down). The “Value” lights will now indicate where the selected parameter is

currently set, in relation to the MAX and MIN values allowed for that particular

parameter (see table below). Press the buttons below the “Value” lights to raise or lower

the parameter; if the value of the parameter is “in between” two lights, the two adjacent

lights will both be on at once, each with relative brightness corresponding to how far in

between the two lights the value is. To change a parameter a long way, press and hold the

button and it will auto-repeat as on a computer keyboard.

The table below indicates the minimum, maximum, and increment values for each

of the proportional drive adjustments. The default values for each parameter are specific

to each proportional output and are not listed.

Parameter Minimum Maximum Increment

Threshold 0 (out of 127) 40 (out of 127) 1

Start PWM 0% lesser of 100% and

Max PWM

Minimum setting

Max PWM greater of 0% and

Start PWM

Maximum setting

Ramp Up 0 ms 1054 ms 34 ms

Ramp Down 0 ms 1054 ms 34 ms

100% 1%

1%

23

Page 30

T245 Control System Manual

As you are adjusting any of the parameters, you can “try” the new setting right

away by moving the joystick and watching the hydraulic/pneumatic response. A very

good way to tune the proportional parameters is to have someone watch the override

handles on the hydraulic valves (or the cylinder or bellows in a pneumatic system) as you

operate the joystick from “just-on” to “full-on”; for best metering action, adjust the Start

PWM and Max PWM such that the whole travel of the joystick corresponds to full travel

of the override handle, with no “dead” region at the start or end of the joystick travel.

Note: It is very important that the proportional drive frequency be correct for the

type of valve installed in your system. Please see the next chapter for information

on how to set the drive frequency, and make sure it is correct before attempting to

adjust the PWM output parameters.

When you are satisfied with the way the parameters are set up, press the “Store”

button. All of the lights will come on to indicate that the new parameters have been

stored. If you wish not to save the changes you have made, simply unplug the key. Then,

you can plug the key back in and start again from the original settings. If you have stored

a set of new parameters which are so far off from values which the machine will operate

with, press and hold the “Store” button until all the lights begin to flash. Release the

button and all of the Proportional Drive parameters will be reset to factory-default values.

Important

set-up procedure. Leaving the key in may allow someone to change the parameters

accidentally, as well as allow the long-term vibration of the vehicle to damage the key.

: The key should not be left plugged in after you have completed the

24

Page 31

T245 Control System Manual

9. Factory Parameters

The Control System has a number of “Factory Parameters” which may be

configured to match the model of valves installed in the machine, and to set the load

limit. They are called “Factory Parameters” because they are usually set at your factory

before the machine is shipped to the end customer. In the application, the first 4

Factory Parameters are PWM drive frequencies for the various “banks” of proportional

outputs, and the rest of the Factory Parameters set boom load moment limits and speeds

of special functions.

In the general discussion below, reference is made to “up to 48 Factory

Parameters”, which means more parameters may be added in the future, if required.

9.1. Types of Factory Parameters

There are only two types of factory parameters. The first type of parameter is a

“multiple-choice” selection; the “PWM Drive Frequency for S20 Proportional Outputs

O1 through O8” parameter is an example of a multiple-choice parameter—you set it by

selecting one of 5 different frequencies.

The second type of factory parameter is a “variable-value” adjustment with a

minimum and maximum value. Examples of such a parameter are the Boom Derating

factors; you set between 20% and 150% in 2% increments.

9.2. Changing the Factory Parameters

To change or view the Factory Parameters, use the following procedure:

1. Plug the Factory Key (the User Key will not allow you to enter Factory Setup Mode)

into the R1300 Controller board’s Set-up Panel; you will be in Proportional Drive

Setup mode. Enter Factory Setup mode by momentarily pressing the two lower lefthand buttons together; the light display will change.

2. There can be up to 48 Factory Parameters. Pressing the up and down buttons at the

bottom of the “Output” column changes the parameter you are accessing. The first 12

are indicated by the lights in the “Output” column as follows: When the “1_” and “+”

lights are on, the first parameter is being accessed. The “1_” and “-” lights indicate

the second parameter, “2+” indicates the third, “2-” indicates the fourth, etc. down to

“6-” which is the 12th parameter. The next 12 parameters are indicated by flashing

“1+” through flashing “6-”.

The next 6 parameters are indicated by the “1_” through “6_” lights solidly on with

both the “+” and “-” lights off. The next 6 are indicated by “1_” through “6_” solidly

on with both the “+” and “-” lights on.

The next 6 parameters are indicated by flashing “1_” through flashing “6_” with both

the “+” and “-” lights off. The last 6 parameters are indicated by flashing “1_”

through flashing “6_” with both the “+” and “-” lights also flashing.

25

Page 32

T245 Control System Manual

3. To change or view a particular Factory Parameter, press the up or down Output

buttons until you reach the desired parameter (see table below). Note that if you press

the up button when you are already at the “top” (parameter 1, solid “1+”), the display

will “wrap around” to the last parameter (parameter 48, flashing “6±”). A similar

wrap-around happens when you press the down button when you are already at the

last parameter.

4. The display will show one light on in the “Param” column if the selected parameter is

a “multiple-choice” type, or one or two lights in the “Value” bar graph if the

parameter is a “variable-value” type. You change the multiple-choice selection using

the buttons under the “Param” lights, and the variable-value using the buttons under

the “Value” lights. For multiple-choice parameters, the top Param light (“Threshold”)

through the bottom light (“Ramp Down”) are referred to in the table as choices “A”

through “E”.

When changing a variable-value parameter, note that the top Value light (“MAX”)

corresponds to the maximum value allowed for that parameter (see table below), and

the bottom (“MIN”) corresponds to the minimum value allowed. Each single press of

the Value up or down buttons will change the parameter by the increment value for

that parameter. Holding down either button will cause it to automatically repeat, and

is useful when you need to change a value a long way from where it is.

If you are adjusting either of the Boom Derating Factors, the numeric display on the

T45 or T47 will show the value (in percent) of the parameter you are adjusting, with

no pointers (LOAD %, DIAG1, DIAG2) showing.

5. When you are done changing the parameters, press the Store button to save the new

Factory Parameters. If you do not want to save your changes, remove the Factory

Key. If you want to restore the Factory Parameters to the preprogrammed factorydefault settings, press and hold the Store button until all the lights begin flashing; only

the Factory Parameters are affected--the Proportional Drive Settings can only be reset

by holding the Store button in Proportional Drive Setup Mode.

6. You can now remove the Factory Key or simultaneously press the two lower-left hand

buttons again to get back to Proportional Drive Setup mode.

9.3. List of Factory Parameters

The following table lists the Control System Factory Parameters. For each

parameter, the corresponding light display in the Output column is shown, together with

the Minimum, Maximum, Adjustment Increment, and Default Value. The last two

columns in the table indicate other adjustment restrictions for the parameter; some

parameters may be constrained by the values of other parameters.

An explanation of the parameters whose function is not immediately obvious

follows the table.

26

Page 33

T245 Control System Manual

Parameter Display Type Min. Max. Increm. Default Cannot Go Below Cannot Go Above

PWM Drive Frequency

for R1300 Proportional

Outputs 1+/- through

4+/-

PWM Drive Frequency

for R1300 Proportional

Outputs 5+/- and 6+/-

PWM Drive Frequency

for S20 Proportional

Outputs O1 through O8

PWM Drive Frequency

for S20 Proportional

Outputs O9 through O16

Solid 1+ Mult.-

Choice

Solid 1- Mult.-

Choice

Solid 2+ Mult.-

Choice

Solid 2- Mult.-

Choice

A = 33 Hz

B = 50 Hz

C = 80 Hz

D = 125 Hz

E = 250 Hz

A = 33 Hz

B = 50 Hz

C = 80 Hz

D = 125 Hz

E = 250 Hz

A = 33 Hz

B = 50 Hz

C = 80 Hz

D = 125 Hz

E = 250 Hz

A = 33 Hz

B = 50 Hz

C = 80 Hz

D = 125 Hz

E = 250 Hz

AN/A N/A

AN/A N/A

AN/A N/A

EN/A N/A

Boom Load Moment

Limit

Boom Derating Factor,

Ground Operation (%)

Solid 3+ Mult.-

Choice

Solid 3- Variable

Value

A = 2500000 inch-lbs A N/A N/A

20 150 2 84 N/A N/A

27

Page 34

T245 Control System Manual

Parameter Display Type Min. Max. Increm. Default Cannot Go Below Cannot Go Above

Boom Derating Factor,

Platform Operation (%)

Emergency Override

Panel Function Speed

(%)

Auger Shake Speed (%) Solid 5+ Variable

Digger Transmission

Type

Bucket/Pole-Claw Speed

Ratio

Solid 4+ Variable

Value

Solid 4- Variable

Value

Value

Solid 5- Mult.-

Choice

Solid 6+ Variable

Value

20 150 2 66 N/A N/A

5 100 5 25 N/A N/A

5 100 5 100 N/A N/A

A = Two-Speed

B = Hydrasync

25 75 5 30 N/A N/A

AN/A N/A

28

Page 35

T245 Control System Manual

PWM Drive Frequency Parameters

These 4 parameters allow you to use the Receiver/Controller in heterogeneous

valve systems. Grouping valves requiring different drive frequencies into separate banks,

you can provide each valve with the drive frequency most suited to it.

Boom Load Moment Limit

This parameter allows you to select from up to five load moment limits to match

the exact model of digger derrick on which you are installing the Control System.

Boom Derating Factors

These parameters are used to multiply (in percent) the

to determine the actual load limit for the boom. There are two separate factors; one

Limit

is for ground operation and the other for platform operation.

When you are adjusting these parameters, the T245/T45 or T247 numeric display

will show the value (in percent) of the parameter you are adjusting, with no pointers

(

LOAD %, DIAG1, DIAG2

Emergency Override Panel Function Speed

This parameter determines the speed of the proportional functions when operated

from the toggle switches on the Emergency Override Panel.

Auger Shake Speed

This parameter determines the speed of the digger when operated from the Auger

Shake toggle switch.

Digger Transmission Type

This parameter is used to determine if the auger must be stopped while shifting

speeds. Hydrasync diggers can be shifted “on the fly”, while two-speed diggers cannot.

When the Two-Speed digger is selected, the DIGGER SHIFT functions will

automatically stop the auger, perform a shift, and then restart the auger.

) showing

Boom Load Moment

Bucket/Pole-Claw Speed Ratio

When the T245 Transmitter is holstered in the bucket, the bucket speed will be

automatically set to this percentage of the pole-claw speed.

29

Page 36

T245 Control System Manual

10. Warranty

OMNEX Control Systems Inc. Warrants to the original purchaser that the OMNEX

products are free from defects in materials and workmanship under normal use and

service for a period of

OR PARTS SUBJECT TO UNAUTHORIZED REPAIR OR MODIFICATION) and

labor from the date of delivery as evidenced by a copy of the receipt. OMNEX’s entire

liability and your exclusive remedy shall be, at OMNEX’s option, either the (a) repair or

(b) replacement of the OMNEX product which is returned within the warranty period to

OMNEX freight

receipt and with the

accident, abuse or misapplication, OMNEX shall have no responsibility to repair or

replace the product under warranty. In no event shall OMNEX be responsible for

incidental or consequential damage caused by defects in its products, whether such

damage occurs or is discovered before or after replacement or repair and whether or not

such damage is caused by the negligence of OMNEX Control Systems Inc.

Neither OMNEX nor its Distributors shall be liable for any delay or failure of the

performance of any of its obligations under this agreement caused by acts of God, labor

disputes, embargoes, boycotts, shortage of parts or any cause beyond its reasonable

control.

ONE YEAR,

collect

by the OMNEX

return authorization

parts (EXCLUDING: SWITCHES, CRYSTALS,

APPROVED

of OMNEX. If failure has resulted from

carrier with a copy of the purchase

Neither OMNEX nor its Distributors shall be responsible for incurred costs associated

with border clearance or with the delay of the OMNEX products in transit to OMNEX.

Any charges associated with the return of the OMNEX products may be subject to billing

to the original purchaser in the event that the OMNEX products are NOT covered by the

warranty as noted above.

30

Loading...

Loading...