Page 1

MODEL R1300

RADIO CONTROL SYSTEM

FOR

ALTEC AD108 TRAILER REEL

#74 - 1833 COAST MERIDIAN ROAD PORT COQUITLAM, B.C. V3C 6G5

PHONE (604)944-9247 FAX (604)944-9267

Page 2

CONTENTS

INSTALLATION

RECEIVER 3-4

ANTENNA 3

RECEIVER WIRING 4

OPERATION

TRANSMITTER 5

RECEIVER 6-7

BASIC TROUBLESHOOTING

Important User Information

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions:

(1) This device may not cause harmful interference, and (2) this device must accept any interference

received, including that which may cause undesired operation.

Changes or modifications not expressly approved by OMNEX Control Systems Inc. can void the users

authority to operate this equipment!

8-9

MOUNTING THE RECEIVER:

INSTALLATION

2

Page 3

Select a suitable location on the machine that will protect the receiver box fr om impact dam age. A loc ation

that protects the receiver from direct exposure to the weather is desirable. If the box must be located

outside, mount it with the power and antenna cables facing down to allow water to drain away.

! IMPORTANT:

The receiver box is supplied with rubber shock mounts to prevent damage from shock or vibration. Be

sure to install the shock mounts on machines that vibrate during operation or transport! Use only the

mounting flanges provided on the box. Do not drill into the receiver box!

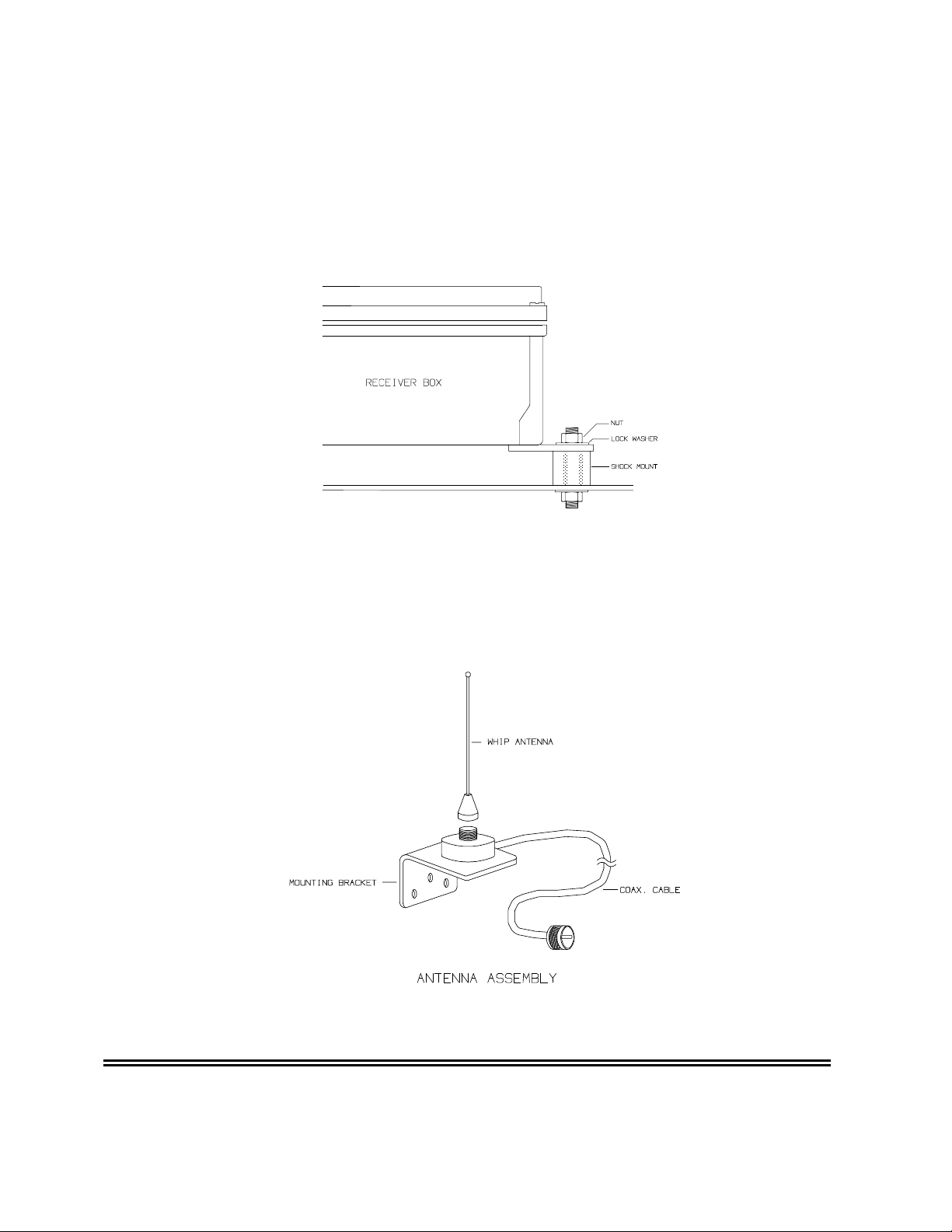

MOUNTING THE RECEIVER ANTENNA:

The receiver antenna assembly consists of a mounting bracket with attached coax. cable, and a

removable whip antenna. The mounting brack et should be located as high as possible on the outside of

the machine such that the whip antenna is vertical. The bracket m ay be bolted to the metal frame but do

not allow the antenna whip to contact metal parts.

RECEIVER WIRING:

INSTALLATION

3

Page 4

The receiver box is supplied with a 3 ft. "pigtail" cable that must be connected to the machine remote

control interface. The wires in the pigtail cable are individually labeled as to function. The following chart

relates the receiver connector wiring to the machine functions:

FUNCTION CONNNECTOR PIN #

Ground A

-B

+12 Volt Power In* C

-D

-E

Function Speed F

-G

Wheels FWD. H

Wheels REV. J

Reels PAY IN K

Reels PAY OUT L

Carriage LOAD M

Carriage UNLOAD N

Steer LEFT P

Steer RIGHT R

-S

-T

-U

-V

-W

-X

-Z

-a

-b

-c

ST/SIDE IN d

ST/SIDE OUT e

CB/SIDE IN f

CB/SIDE OUT g

-h

-j

-k

HI/LO ON m

-n

-p

+12 Volt Power In * r

-s

* Both power wires (C and r) must be connected to 12 volts for proper operation.

The receiver also contains a separate ground lug and wire. Connect the ground lug to a solid, clean

ground point on the machine.

OPERATION

TRANSMITTER:

Switching the Transmitter ON and OFF:

4

Page 5

To switch on the transmitter first release the red STOP button by turning clockwise, then momentarily

press the ON button. (The transmitter will not switch on if the STOP button is depressed). The ON light will

glow red indicating the transmitter is on and ready to use. The receiver will now respond to the function

switches. W hen finished operating depr ess the STO P button to switch of f the transm itter and dis able the

receiver output relays.

Enable Button:

The W heels and Reels switches will not operate unless the Enable button is also press ed "at the same

time".

Auto Shut-Off:

The transmitter incorporates an auto shut-off feature. If no control switches are operated over a three

minute period, the transmitter will switch off autom atically. The ON switch mus t then be pressed again to

resume operation.

Battery Indicator:

The ON light is also used to indicate battery level. When the light is solidly on, the battery level is

acceptable. If it blinks, the batteries require charging.

Charging the Transmitter Battery:

The transmitter is powered by a standard 9.6V Makita power tool battery, and a Makita charger is supplied

to re-charge the battery. Please read the instructions provided with the Makita c harger. To remove the

battery, grasp the ring on the battery door and turn counter-clockwise to release the locking m echanism.

The door may now be opened and the case tilted to allow the battery to slide out. (A slight "tap" is

sometimes necessary to dislodge the battery from the contact terminals.)

MAKITA BATTERY

OPERATION

RECEIVER:

The receiver will be operational when power is applied. It does not contain a power switch. Three LED

indicator lights on the lid are used to verify proper operation. The lights are labeled Power, ID and Link and

function as follows:

5

Page 6

POWER:

Indicates that 12 volt DC power is applied to the receiver.

ID:

Indicates that information f rom the transmitter is being suc cessfully received. If the light flickers

occasionally this indicates that interference is present on s om e fr equencies. T his is not a pr oblem

since this is a spread spectrum system and changes frequency many times each second.

LINK:

Indicates that the radio link between the transmitter and receiver is reliable. If the link is not

reliable, power is removed from the receiver output drivers.

CONFIGURING THE PROPORTIONAL SPEED OUTPUT:

The receiver contains a configuration panel that allows you to customize the operation of the function

speed control. The panel appears as shown below:

To enable the configuration panel, plug in the user configuration key supplied. The dis play will initially be

displaying "Output" 1 + , no "Param" lights will be illuminated, and the "Value" lights will be displaying the

Start PWM and MAX PWM as solid lights, and the ac tual speed output as a flashing light. The flashing

light will move as the speed dial on the transm itter is rotated. You will also see the green light next to the

1+ output go brighter and dimmer.

OPERATION

Note: You will notice that the control panel has 6 "output" lights. This is bec ause the r ec eiv er is c apable of

controlling the parameters for up to 6 proportional functions. In this particular application, however, only a

single proportional output is needed, and this has been assigned to output #1. Also, the Parameter setting

options: Threshold, Ramp Up and Ramp Down, will not apply to the simple potentiometer control provided

on the Altec system. (These are used in other applications that require joystick type controls). In

6

Page 7

this application, only the Start PWM and Max PWM will be of concern. These s et the endpoints (min and

max) of the speed potentiometer.

To change a parameter, press the buttons under the "Param " lights until the desir ed param eter is lit up. In

this application select only Start PW M or Max PWM. The other selections do not apply! The "Value" lights

will now show one solid light indicating where the selected parameter is cur rently set, in relation to the

MAX and MIN values allowed for that particular param eter. Press the buttons below the "Value" lights to

raise or lower the parameter. Note that the light may not move for each time you press a button, but that

the parameter is actually changing (there are not enough lights to show every step). To change a

parameter a long way, press and hold the button and it will auto-repeat as on a computer keyboard.

When you are happy with the way the parameters are set up, press the "Store" button. All of the lights will

come on to indicate that the new parameters have been stored. If you wish not to save the changes you

have made, simply unplug the key, then, you can plug the key back in and start again from the or iginal

settings. If you have stored a new set of parameters which are s o far off fr om values which the machine

will operate with, press and hold the "Store" button until all the lights begin to flash. Release the button and

all of the parameters will be reset to factory default values.

IMPORTANT: Do not leave the key plugged in after you have completed the set-up procedure. Leaving

the key may allow someone to change the parameters accidentally, as well as allow long term vibration to

damage the key.

BASIC TROUBLESHOOTING

The most com mon cause for a previously operating system not to respond is a low transm itter battery.

Always check the battery indicator light first. If it is blink ing, or does not light at all, replace the batter y with

a charged one and try again. If the battery indicator does not light with a good battery, a transmitter fault is

indicated requiring factory repair. The trans m itter contains no us er ser viceable parts . (Also rem em ber that

the transmitter will not operate if the red STOP button has been depressed. Check this!) If the battery

indicator lights and the system still does not res pond, proceed with the following steps to help isolate the

problem:

STEP ONE:

7

Page 8

Check the Power, ID and Link lights on the lid of receiver. With the transm itter switched OFF only the red

Power light should be on. When the transm itter is switched ON, the ID and Link lights should also come

on. If this is so, proceed to step two. If the lights do not operate, open the lid of the receiver box . Inside

you will find a radio receiver module on the lid and a circuit board inside. Located on the circ uit board are

two green lights labeled as DRIVE PW R and MICRO PW R (Do not be concerned with the flashing lights

on the configuration panel). When power is applied to the r eceiver, and the transm itter switched O N, both

these lights should be on. If so proceed to step two. If not, check the condition of 10 amp. fuses F2 and F3

on the circuit board. Disconnect power to the receiver before removing f uses! A fuse that keeps blowing

indicates a short circuit, check the wiring car efully. If the fuses are OK a c ircuit f ault on the c ircuit board is

indicated.

STEP TWO:

Observe the red and green lights on the red receiver module located on the inside of the lid. With the

transmitter switched OFF , only the red light should be on. If it is not a receiver fault is indicated. If the r ed

light is on, switch on the transmitter. The green light s hould now also be on. If it is pr oc eed to step thr ee. If

not, a fault could exist in either the transmitter or receiver.

STEP THREE:

Observe the green lights located in a long row along one side of the circuit board while operating the

various transmitter controls. Each machine function will have an associated light as indicated in the

following chart. W hen operating proportional functions , the lights will change in intensity. Digital f unctions

will just switch on or off.

MACHINE FUNCTIONS VS RECEIVER INDICATOR LIGHTS:

FUNCTION INDICATOR LIGHT

Function Speed 1+

Wheels FWD. 2+

Wheels REV 2-

Reels PAY IN 3+

Reels PAY OUT 3-

Carriage LOAD 4+

Carriage UNLOAD 4-

Steer LEFT 5+

Steer RIGHT 5-

ST/SIDE IN D1

ST/SIDE OUT D2

CB/SIDE IN D3

CB/SIDE OUT D4

HI/LO ON D8

WARRANTY

OMNEX CONTROL SYSTEMS INC. Warrants to the original purchaser that the OMNEX

radio remote control system is free from defects in materials and workmanship under normal use

and service for a period of ONE YEAR parts (EXCLUDING: SWITCHES, CRYSTALS, OR

8

Page 9

PARTS SUBJECTED TO UNAUTHORIZED REPAIR OR MODIFICATION) and labor

from the date of delivery as evidenced by a copy of the receipt. OMNEX's entire liability and

your exclusive remedy shall be, at OMNEX's option, either the (a) repair or (b) replacement of

the OMNEX radio control system, which is returned to OMNEX freight prepaid with a copy of

the receipt. If failure has resulted from accident, abuse or misapplication, OMNEX shall have no

responsibility to repair or replace. In no event shall OMNEX be responsible for incidental or

consequential damage caused by defects in its products, whether such damage occurs or is

discovered before or after replacement or repair, and whether or not such damage is caused by

the negligence of OMNEX CONTROL SYSTEMS INC.

Neither OMNEX nor its Distributor shall be liable for any delay or failure in the performance of

any of its obligations under this agreement caused by acts of God, strikes, other labor

disturbances, embargoes, boycotts, shortage of parts or any cause beyond its reasonable control.

9

Loading...

Loading...