Cooper Duroflow 4500 series, Duroflow 4504, Duroflow 4506, Duroflow 4509, Duroflow 4512 Service Manual

Page 1

Price $5.00

DUROFLOW@

SERIES 4500

BLOWERS

1st Edition

Supersedes

D-9-620

BO11O

SERVICE MANUAL

#

COOPER

Gardner-Denver

Industrial Machine~

Page 2

Section One:

Section Two:

Section Three:

Section Four:

Section Five:

Section Six:

Section Seven:

Section Eight:

Section Nine:

Section Ten:

Section Eleven:

Section Twelve:

Section Thirteen:

DUROFLOW.

45 Series Blowers

Table of Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2

Suggested Equipment and Supplies for a Major Overhaul . . . . . . . . . . . . . . ...3

Teardown Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...5

Policy Replacement Items . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..9

Major Parts Cleanup Procedures.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...9

Major Parts Inspection Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...10

Assembly Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...11

SpurGear Blowers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...18

Operating Limitations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...19

Lubrication Recommendations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...20

Parts Lists, Sectional and Exploded Views . . . . . . . . . . . . . . . . . . . . . . . . . . ...21

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...23

Warranty Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...25

Page 3

SECTION ONE

Introduction

This manual was prepared as a guide for the person involved in the maintenance or overhaul of DuroFlow@ 45

Series Blowers utilizing splined rotor shafts and timing

gears. There are two versions, one of which uses spur

gears and the other, helical gears.

The helical gear version is the latest in the evolution of

DuroFlow blower technology. It differs from its predecessor, the spur gear version, only in the gear tooth

configuration and the addition of a Belleville spring

behind one timing gear. On the helical gear blower,

rotor timing is accomplished by varying the position of

a lock nut moving one timing gear axially against the

pressure of the Belleville spring washer. This slight

longitudinal movement of the drive gear in relation to

the idler gear changes the angular relationship between the two rotors.

In the spur gear version, rotor timing is accomplished

by selective assembly. A particular set of gears is

matched to a particular set of rotors in order to achieve

the proper angular relationship between the two

rotors.

This manual is concerned primarily with the helical

gear version,

which is currently in production.

Section Eight covers the differences in teardown and

reassembly procedure for the spur gear version.

Each of the four sizes of 45 Series blowers has four

configurations designated by the position of the drive

shaft as viewed from the drive end. The most common

configuration, designated vertical-top (VT), has the

drive rotor above the idler rotor and the airbox inlet

and discharge ducts are at the sides. In the vertical-

bottom (VB) configuration, the drive rotor is mounted

below the idler rotor. In the horizontal-left (H L)configuration, the drive rotor is to the left of the idler rotor

and the airbox inlet and discharge ducts are at the top

and bottom of the unit. In the horizontal-right (HR)

configuration, the drive rotor is mounted to the right

of the idler rotor.

The VT and HL configurations are identical except for

the position of the oil breather and the oil filler plug

and a change in the mounting plate in the HL. Likewise, the VB and the HR configurations correspond to

each other with the same differences as the VTand HL.

The VT-HL differs from the VB-HR in having a dif-

ferent oil flinger on the drive end which is mounted on

the drive shaft in the VB-HR version rather than on

the idler shaft as in the VT-HL. Both oil flingers are

identical in the VT-HL version, whereas the drive end

flinger is more deeply dished than thegear end fiinger

in the VB-HR versions.

Since the VT version is the most common of the

various configurations, the illustrations and the tear-

down and reassembly procedures in this manual refer

to the VT configuration. The person involved in

overhauling one of the other versions of the blower

should keep in mind the differences noted in the

preceding paragraphs.

In addition, if overhauling either the HL or HR

versions, it is advisable to use a holding fixture to

secure the blower to the workbench. This can be

obtained from DuroFlow or it can be fabricated as in

Fig. 4.

It is suggested that the appropriate sections of this

manual be read and fully comprehended before any

specific service operation is attempted. Further, the

importance of a clean and adequately outfitted

workshop cannot be overemphasized. The success of

any major blower service effort depends upon

recognition of the fact that virtually every part

contained in the assembly is highly precise, and

hence, is vulnerable to the damaging effects of dirt,

moisture and rough handling.

IMPORTANT NOTICE

In mid-1981, modifications to the 45 Series end plates were made that are not shown in the text of this manual.

Blowers now require only one conventional breather cap. This difference will not affect service procedures.

When properly mounted, the air breather ports on modified blowers are always facing downward, and no

longer require breather caps. If these vent ports are threaded, a breather vent will be inserted. DO NOT PLUG

OR OBSTRUCT THESE AIR VENT PASSAGEWAYS!!

The oil sump breathing is now accomplished through the oil fill port. A hexagonal bushing is inserted into the

oil fill hole, and the blowers’ only breather cap is placed in this bushing to vent the oil sump.

2

Page 4

A.

B.

c.

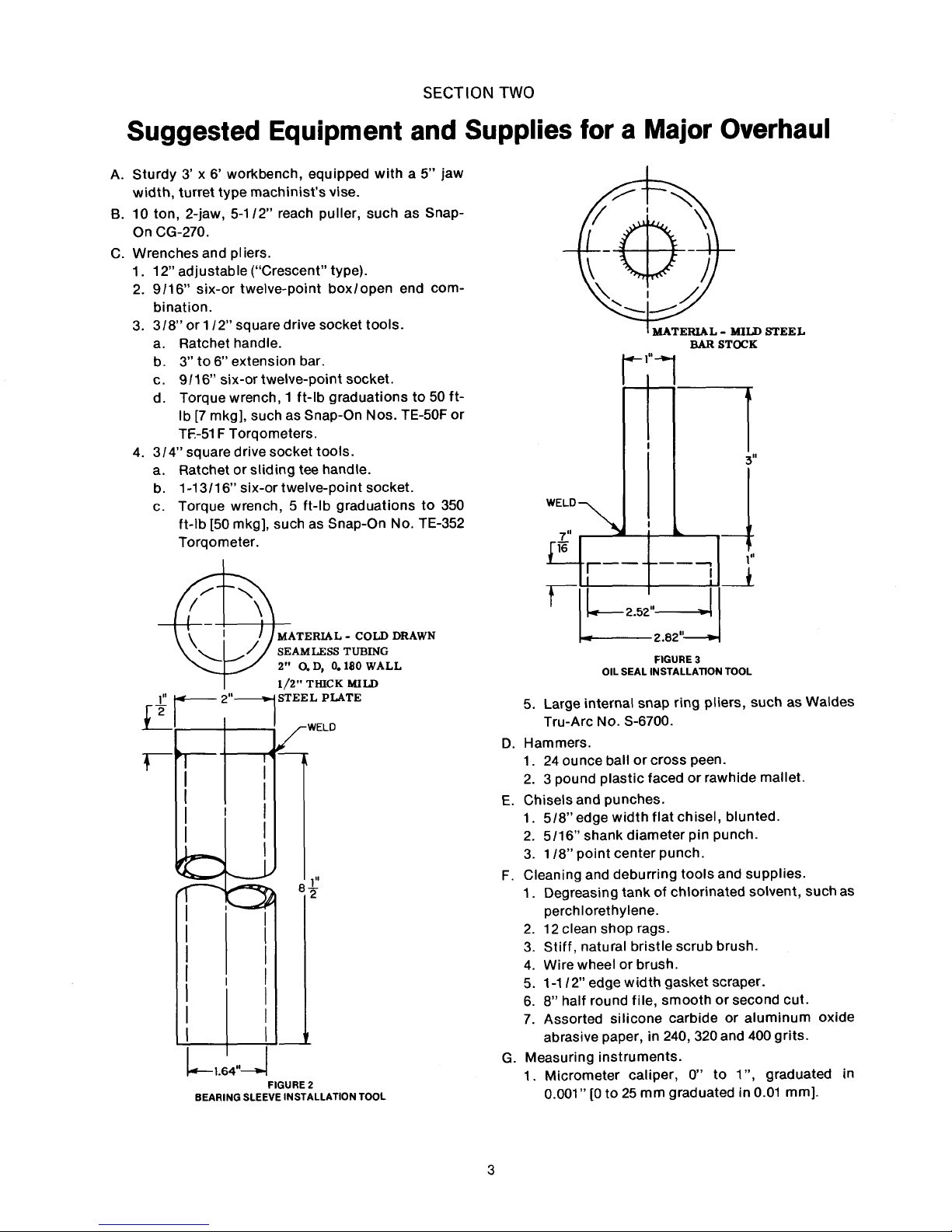

SECTION TWO

Suggested Equipment and Supplies for a Major Overhaul

Sturdy 3’ x 6’ workbench, equipped with a 5“ jaw

width, turret type machinist’s vise.

10 ton, 2-jaw, 5-1 /2” reach puller, such as SnapOn CG-270.

Wrenches and PIiers.

1. 12“ adjustable (“Crescent” type).

2. 9/16“ six-or twelve-point box/open end combination.

3. 3/8’ orl /2” square drive socket tools.

a. Ratchet handle.

b. 3“ to 6’ extension bar.

c. 9/16’ six-or twelve-point socket.

d. Torque wrench, 1 ft-lb graduations to 50 ft-

Ib [7 mkg], such as Snap-On Nos. TE-50F or

TE-51 F Torqometers.

4. 3/4” square drive socket tools.

a. Ratchet or sliding tee handle.

b. 1-13/16’ six-or twelve-point socket.

c. Torque wrench, 5 ft-lb graduations to 350

ft-lb [50 mkg], such as Snap-On No. TE-352

Torqometer.

Q

Iy

‘\

/:’

MATERIAL - COLD DRAWN

~ SEAMLESS TUBING

2“ O. D, 0.180 WALL

I

1/2” THICK MILD

~; r—2“-7sTEEL PLATE

I

T

3“

WELD

1

L J

——.

———=

252,, J J

&2.82”&

FIGURE 3

OIL SEAL INSTALLATION TOOL

5. Large internal snap ring pliers, such as Waldes

c!

!

I

zWELD

Tru-Arc No. S-6700.

~

i’–

I

I

I ‘~

I

I

I

,1

I

I

I _

Ld

1.64”

FIGURE 2

BEARING SLEEVE INSTALLATION TOOL

STEEL

D. Hammers.

1. 24 ounce ball or cross peen.

2. 3 pound plastic faced or rawhide mallet.

E. Chisels and punches.

1. 5/8” edge width flat chisel, blunted.

2. 5/16” shank diameter pin punch.

3. 118” point center punch.

F. Cleaning and deburring tools and supplies.

1.

2.

3.

4.

5.

6.

7.

Decreasing tank of chlorinated solvent, such as

perch lorethylene.

12 clean shop rags.

Stiff, natural bristle scrub brush.

Wire wheel or brush.

1-1 / 2“ edge width gasket scraper.

8“ half round file, smooth or second cut.

Assorted silicone carbide or aluminum oxide

abrasive paper, in 240, 320 and 400 grits.

G. Measuring instruments.

1. Micrometer caliper, O“ to 1“, graduated in

0.001” [0 to 25 mm graduated in 0.01 mm].

Page 5

2.

3.

4.

Depth micrometer, 1“ to 2“, graduated in 0.001”

[25 to 50 mm graduated in 0.01 mm].

Dial test indicator (lever contact arm type),

graduated in 0.0005” or 0.001” [0.01 or 0.02

mm], and equipped with magnetic base holder.

12“ x 1/2” feeler stock, 0.002” to 0.015“ in

0.001” increments, [0.04 to 0.40 mm], 2 strips

of each, such as Starrett Series 667.

H. Lubricants and compounds.

1. 2 quarts fresh motor oil, conforming to A.P. I.

Service Specs CC and SE (See Lubrication

Recommendations, Sec. Ten).

2. 1 pound fresh assembly lubricant, such as

molybdenum disulfide grease.

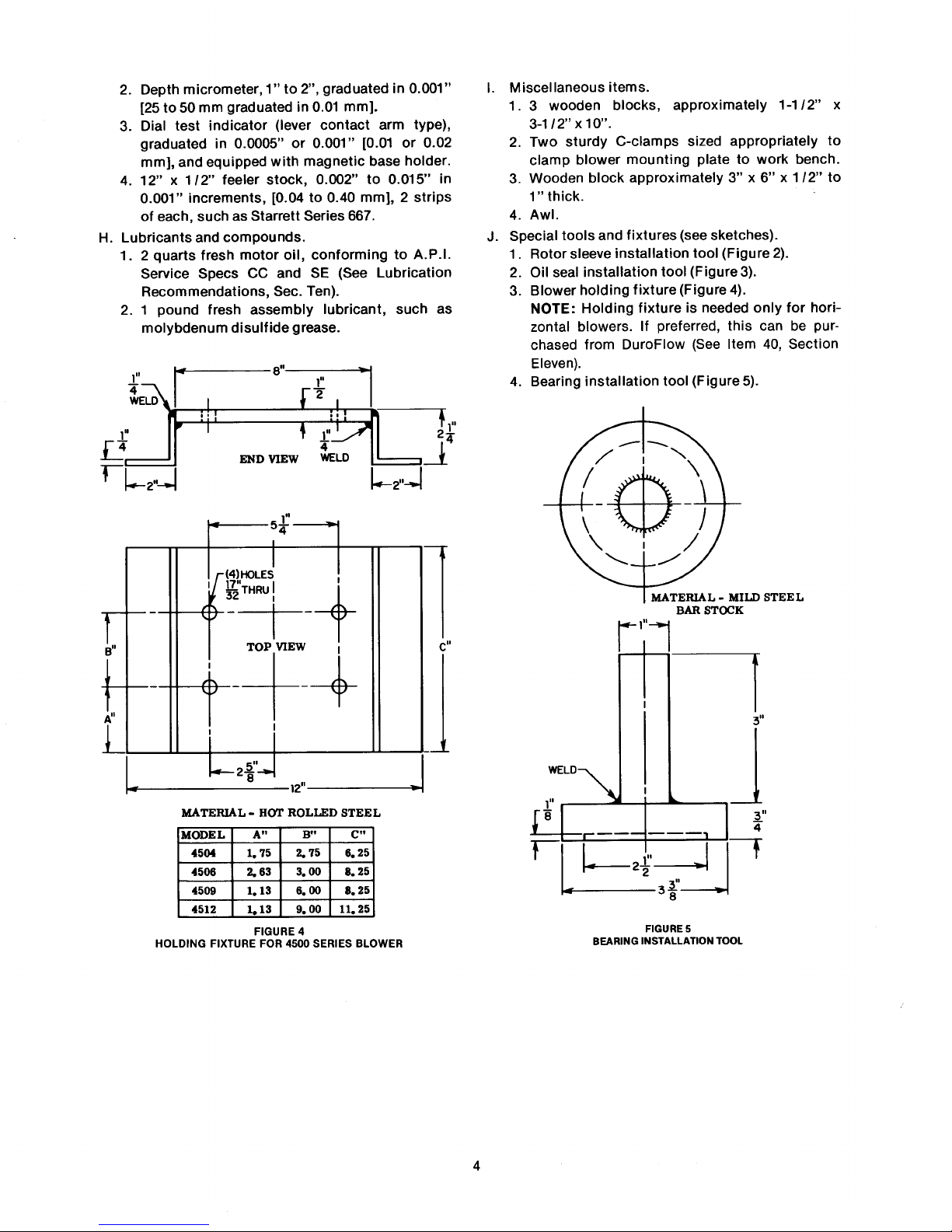

MATERIAL - HOT ROLLED STEEL

MODE L I A“

I

B“

I

c“

4504

I

1.75

Z75 I 6.25

1. Miscellaneous items.

1. 3 wooden blocks, approximately 1-1 /2” x

3-1/2’’ xlo’.

2. Two sturdy C-clamps sized appropriately to

clamp blower mounting plate to work bench.

3. Wooden block approximately 3“ x 6“ x 1 /2” to

1“ thick.

4. Awl.

J. Special tools and fixtures (see sketches).

1.

2.

3.

4.

Rotor sleeve installation tool (Figure’2).

Oil seal installation tool (Figure 3).

Blower holding fixture (Figure 4).

NOTE: Holding fixture is needed only for horizontal blowers. If preferred, this can be purchased from DuroFlow (See Item 40, Section

Eleven).

Bearing installation tool (Figure 5).

I

I

7

3“

WELD

I

1

,,

.1

,,

.——

E

1

‘2A<

FIGURE 4

HOLDING FIXTURE FOR 4500 SERIES BLOWER

FIGURE 5

BEARING INSTALLATION TOOL

Page 6

B.

SECTION THREE

Teardown Procedure

A. Preparation.

Before beginning the teardown sequence, the oil

should be drained from the unit. It is also sug-

gested that the usual accumulation of sludgy or

encrusted material be removed from the exterior.

This can best be accomplished by scouring with a

stiff bristle brush and soapy water, followed by a

pressure rinse with water. An acceptable alternative is steam cleaning, if the equipment is available. Because all salvable parts are made of cast

iron (or other ferrous alloy), virtually any heavy

duty, chemical cleaning agents—EXCEPT those

which are ACIDIC—are acceptable. It should be

noted, however, that when water (or steam) is used

in the cleaning process, the unit must be disassembled immediately, and blown dry with compressed air to prevent rusting of machined sur-

faces.

Teardown sequence.

NOTE: Numbers in parentheses ( ) refer to key

numbers in sectional and exploded assembly

drawings on pages 22 and 23.

1. Separation of the unit into basic subassem-

blies.

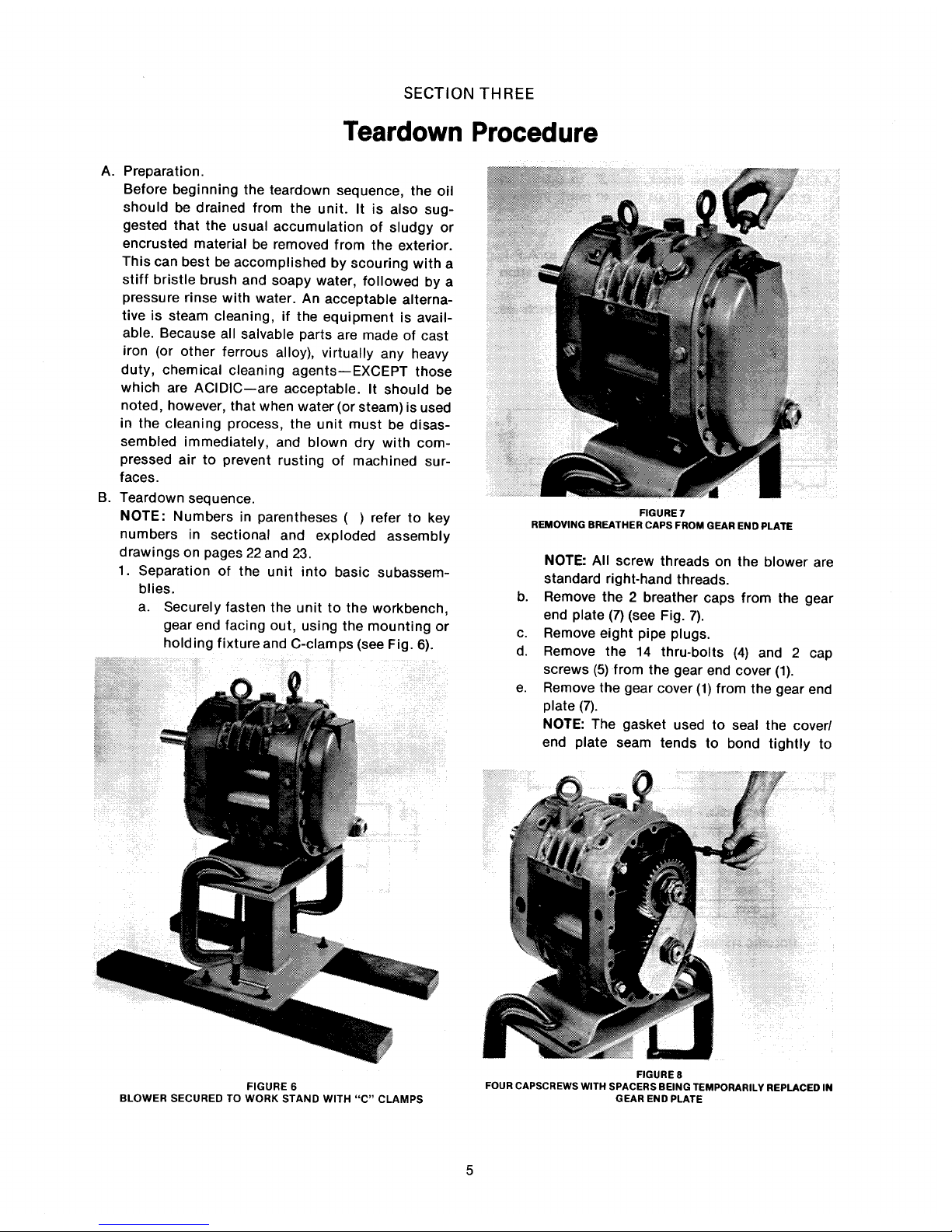

a. Securely fasten the unit to the workbench,

gear end facing out, using the mounting or

holding fixture and C-clamps (see Fig. 6).

FIGURE 6

BLOWER SECURED TO WORK STAND WITH “C” CLAMPS

b.

c.

d.

e.

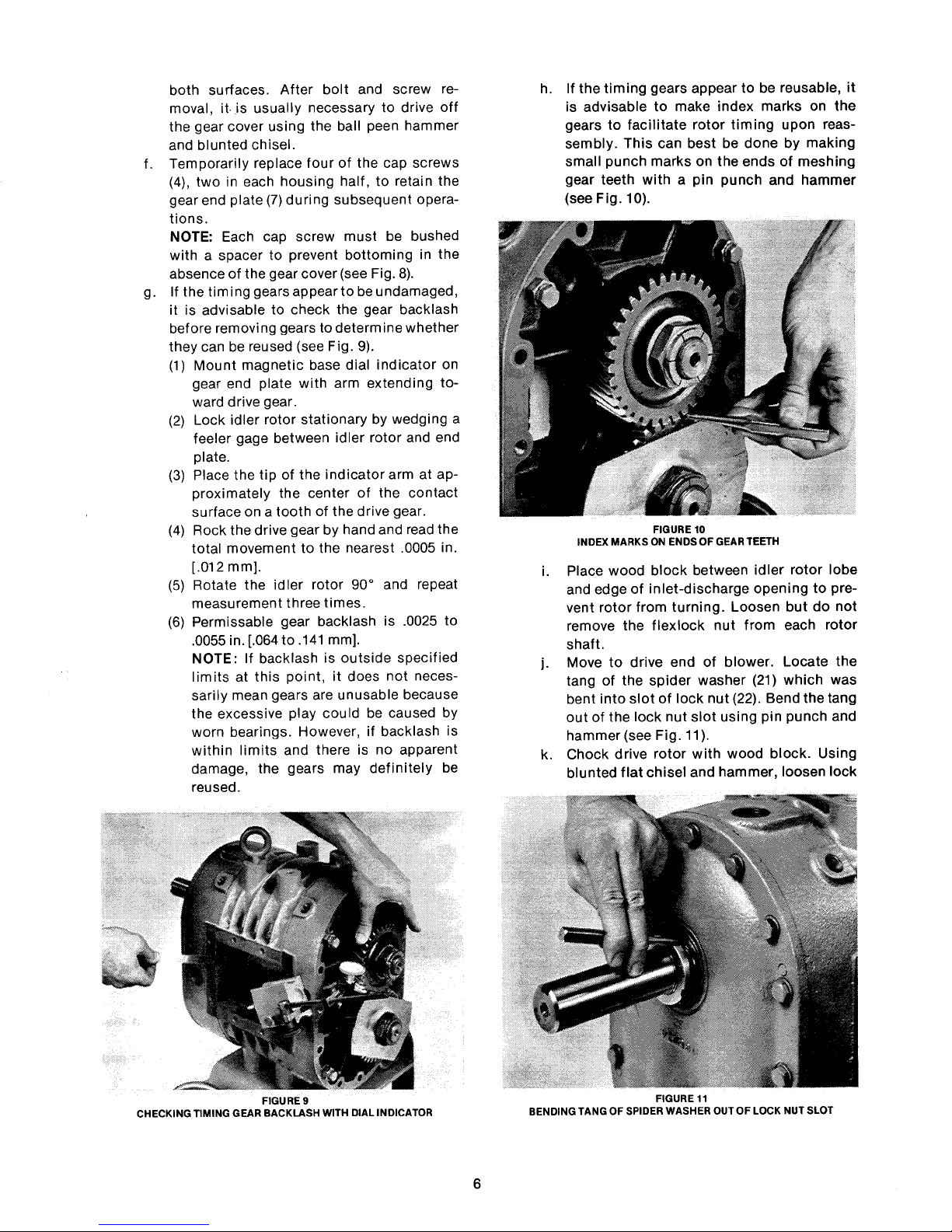

FIGURE 7

REMOVING BREATHER CAPS FROM GEAR END PLATE

NOTE All screw threads on the blower are

standard right-hand threads.

Remove the 2 breather caps from the gear

end plate (7) (see Fig. 7).

Remove eight pipe plugs.

Remove the 14 thru-bolts (4) and 2 cap

screws (5) from the gear end cover (l).

Remove the gear cover (1) from the gear end

plate (7).

NOTE: The gasket used to seal the cover/

end plate seam tends to bond tightly to

FIGURE 8

FOUR CAPSCREWS WITH SPACERS BEING TEMPORARILY REPLACED IN

GEAR END PLATE

5

Page 7

f.

9.

both surfaces. After bolt and screw removal, it. is usually necessary to drive off

the gear cover using the ball peen hammer

and blunted chisel.

Temporarily replace four of the cap screws

(4), two in each housing half, to retain the

gear end plate (7) during subsequent operations.

NOTE: Each cap screw must be bushed

with a spacer to prevent bottoming in the

absence of the gear cover (see Fig. 8).

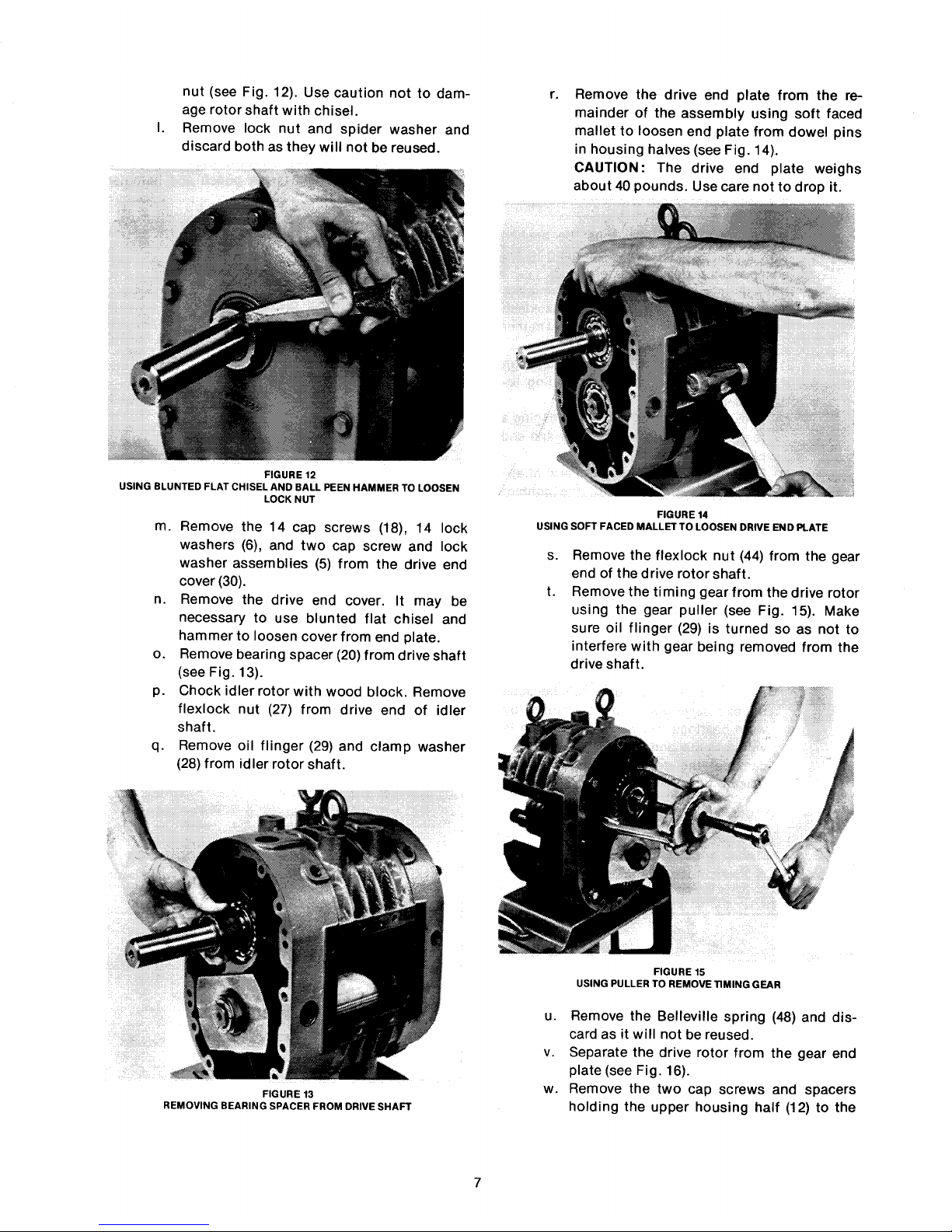

If the timing gears appear to be undamaged,

it is advisable to check the gear backlash

before removing gears to determine whether

they can be reused (see Fig. 9).

(1)

(2)

(3)

(4)

(5)

(6)

Mount magnetic base dial indicator on

gear end plate with arm extending toward drive gear.

Lock idler rotor stationary by wedging a

feeler gage between idler rotor and end

plate.

Place the tip of the indicator arm at approximately the center of the contact

surface on a tooth of the drive gear.

Rock the drive gear by hand and read the

total movement to the nearest .0005 in.

[.012 mm].

Rotate the idler rotor 90° and repeat

measurement three times.

Permissible gear backlash is .0025 to

.0055 in. [.064 to .141 mm].

NOTE: If backlash is outside specified

limits at this point, it does not neces-

sarily mean gears are unusable because

the excessive play could be caused by

worn bearings. However, if backlash is

within limits and there is no apparent

damage, the gears may definitely be

reused.

h. If the timing gears appear to be reusable, it

is advisable to make index marks on the

gears to facilitate rotor timing upon reassembly. This can best be done by making

small punch marks on the ends of meshing

gear teeth with a pin punch and hammer

(see Fig. 10).

FIGURE 10

INDEX MARKS ON ENDS OF GEAR TEETH

i. Place wood block between idler rotor lobe

and edge of inlet-discharge opening to prevent rotor from turning. Loosen but do not

remove the flexlock nut from each rotor

shaft.

j.

Move to drive end of blower. Locate the

tang of the spider washer (21) which was

bent into slot of lock nut (22). Bend the tang

out of the lock nut slot using pin punch and

hammer (see Fig. 11).

k. Chock drive rotor with wood block. Using

blunted flat chisel and hammer, loosen lock

FIGURE 9

CHECKING TIMING GEAR BACKLASH WITH DIAL INDICATOR

6

Page 8

nut (see Fig. 12). Use caution not to dam-

age rotor shaft with chisel.

1.

Remove lock nut and spider washer and

discard both as they will not be reused.

FIGURE 12

USING BLUNTED FLAT CHISEL AND BALL PEEN HAMMER TO LOOSEN

m

n.

o.

P.

q.

LOCK NUT

Remove the 14 cap screws (18), 14 lock

washers (6), and two cap screw and lock

washer assemblies (5) from the drive end

cover (30).

Remove the drive end cover. It may be

necessary to use blunted flat chisel and

hammer to loosen cover from end plate.

Remove bearing spacer (20) from drive shaft

(see Fig. 13).

Chock idler rotor with wood block. Remove

flexlock nut (27) from drive end of idler

shaft.

Remove oil flinger (29) and clamp washer

(28) from idler rotor shaft.

FIGURE 13

REMOVING BEARING SPACER FROM DRIVE SHAFT

r.

Remove the drive end plate from the remainder of the assembly using soft faced

mallet to loosen end plate from dowel pins

in housing halves (see Fig. 14).

CAUTION: The drive end plate weighs

about 40 pounds. Use care not to drop it.

FIGURE 14

USING SOFT FACED MALLET TO LOOSEN DRIVE END PLATE

s.

Remove the flexlock nut (44) from the gear

end of the drive rotor shaft.

t. Remove the timing gear from the drive rotor

using the gear puller (see Fig. 15). Make

sure oil flinger (29) is turned so as not to

interfere with gear being removed from the

drive shaft.

u.

v.

w

FIGURE 15

USING PULLER TO REMOVE TIMING GEAR

Remove the Belleville spring (48) and discard as it will not be reused.

Separate the drive rotor from the gear end

plate (see Fig. 16).

Remove the two cap screws and spacers

holding the upper housing half (12) to the

7

Page 9

x.

y.

z.

aa.

bb.

cc.

dd .

ee.

gear end plate and remove the upper housing half.

Remove the flexlock nut (44) from the idler

rotor shaft.

Remove the oil flinger (29).

Use gear puller to remove the idler gear (42)

from the idler rotor (32).

Remove the idler rotor from the gear end

plate.

Remove the two cap screws and spacers

holding the gear end plate to the lower

housing half (39).

Remove the gear end plate from the lower

housing half.

CAUTION: The gear end plate weighs

about 35 pounds. Use care not to drop it.

Loosen the C-clamps and invert the lower

housing half on the workbench.

Remove the four cap screws (37) and lock

replaced as a matter of service policy.

(1)

(2)

(3)

(4)

(5)

Securely fasten the rotor in the vise,

using 2 wood blocks to prevent marring

of the contoured surfaces.

Remove the seal ring (13) from the drive

end sleeve (14), using the awl to pry

apart the interlock, and then break the

ring from underneath.

Remove the seal ring (13) from the gear

end sleeve (11), as in Step 2.

Remove shims (15) from rotors.

Only as required in accordance with the

guidelines given under PREFACE, remove the sleeve(s) from the rotor shaft(s)

using the gear puller.

b. End plate subassembly.

PREFACE: Since all seals and bearings

should be replaced during overhaul as a

matter of service policy, both end plate

subassemblies must be completely disassembled internally.

washers (38), and separate the mounting

plate (40) from the lower housing half.

(1)

(2)

(3)

(4)

(5)

(6)

Remove the 2 retaining rings (26) from

their respective bearing sockets, using

the snap ring pliers.

Invert the end plate on the work bench,

and set on 2 oak blocks, so as to provide

3-1 /2” clearance between the plate and

bench, and to clear the edges of the

bearing sockets.

Remove the drive rotor bearing (9) or(l 7)

from its socket, using the ball peen

hammer and pin punch.

Remove the drive rotor oil seal (10) from

its socket, as in Step 3.

Remove the idler rotor bearing (9) or(17)

from its socket, as in Step 3.

Remove the idler rotor oil seal (10) from

FIGURE 16

REMOVING DRIVE ROTOR FROM GEAR END PLATE

2. Separation of the subassemblies into component parts.

a. Rotor subassembly.

PREFACE: Except in unusual cases, the 4

end plugs in each rotor casting need not be

removed or replaced.

Rotor sleeves need only be removed from

their respective shafts for the purpose of

rotor or sleeve salvage.

The 2 iron seal rings carried in the rotor

sleeves should always be removed and

c.

d.

its socket, as Step 3.

Housing half subassembly.

Except in unusual cases, the 4 dowel pins

(34) and 2 ferrules (35) in each housing half

end surface need not be removed or re-

placed. However, the 2 “O” rings (36) car-

ried on the ferrules of each housing half

shou Id always be replaced as a matter of

service policy.

Drive end cover.

(1)

(2)

Place cover on two wood blocks gasket

side up. With hammer and punch drive

out the seal (25). Discard seal as it will

be replaced.

Normally, there is no reason to remove

the two dowel pins (34) which are

pressed into the cover.

8

Page 10

SECTION FOUR

Policy Replacement Items

It is suggested that the following parts be replaced savings when possible consequences are considered.

each time the 45 Series blower is disassembled re- It is not necessary to order these parts individually, as

gardless of apparent or measured condition. This

DuroFlow offers a factory service parts kit for the 45

merely reflects sound service policy in that the reuse

Series, splined shaft blower.

of these parts cannot be justified on the basis of cost

Item No. Description Qty. Per Unit

Item No.

Description Qty. Per Unit

9

Roller Bearing

2

22

Lock Nut 1

10 Oil Seal

4

25 Oil Seal

1

13 Seal Ring 4

31

Gasket

2

15 Shim .002—.003— As

36

0 Ring

4

.005—.007—.01 O” Required

46 Gasket

2

17 Ball Bearing 2

48

Belleville Spring

1

21 Lock Washer 1

SECTION FIVE

Major Parts Cleanup Procedures

A. Rotors.

1.

2.

3.

4.

5.

6.

Dip in decreasing tank agitating and brushing

to remove grease and oil.

Sandblast or wirebrush as necessary to remove

scale from rotor lobes. If sandblasting, mask

bearing sleeves, bearing spacers, and shafts

with rubber hose or tape to prevent erosion.

Lightly wet polish the bearing sleeves, bearing

spacers, and rotor shafts with crocus cloth.

Any burrs on rotor or shaft should be removed

with a file.

Dip again in decreasing tank and blow dry with

compressed air.

If rotor is not to be inspected and reused immediately, dip in oil or rust preventative solu-

tion and seal in a clean plastic bag for storage.

B. End plates.

1.

2.

3.

4.

5.

6.

Dip in decreasing tank agitating and brushing

to remove grease and oil.

Sandblast or wirebrush as necessary to remove

scale. If sandblasting, place plugs in seal ring

bores to prevent erosion during blasting.

Lightly wet polish the seal ring bores with 400

grit abrasive paper.

Remove burrs with file.

Dip in decreasing tank and blow dry with compressed air.

If end plate is not to be inspected and reused

immediately, dip in oil or rust preventative

solution and seal in clean plastic bag for storage.

C. Housing halves.

1.

2.

3.

4.

5.

6.

Dip in decreasing tank agitating and brushing

to remove grease and oil.

Sandblast or wirebrush as necessary to remove

scale.

Wet polish the machined concave surface with

240 grit abrasive paper.

File burrs on machined surfaces.

Dip in decreasing tank and blow dry with compressed air. Use particular care to insure that

all foreign matter is purged from oil passages.

If housing is not to be inspected and reused

immediately, dip in oil or rust preventative

solution and seal in clean plastic bag for

storage.

D. Timing gears.

1.

2.

3.

4.

5.

Dip in decreasing tank to remove grease and oil.

Wirebrush as necessary to remove scale.

Remove nicks and burrs with file.

Dip in decreasing tank and blow dry with compressed air.

If gears are not to be inspected and reused immediately, dip in oil or rust preventative solution and seal in clean plastic bag for storage.

E. Covers.

1. Dip in decreasing tank agitating and brushing

to remove grease and oil.

Page 11

2.

3.

4.

5.

Scrape gasket surface to remove any remaining

F. Mounting plate, flingers, and external hardware.

pieces of gasket.

1. Dip in decreasing tank to remove grease and

File any burrs on gasket surface.

oil.

Dip in decreasing tank and blow dry with com-

2. File burrs from mounting surfaces of mounting

pressed air. plate.

If covers are not to be inspected and reused im- 3. If parts are not to be reused immediately, store

mediately, dip in oil or rust preventative solu- in clean plastic bag.

tion and seal in clean plastic bag.

SECTION SIX

Major Parts Inspection Procedures

A. Rotors.

The rotors are usually salvable if no significant

degeneration of the contoured or end surfaces has

occurred.

Occasionally, a hard object accidentally passes

through the blower causing localized gouging of

the lobes. This is not necessarily grounds for immediate rejection unless the gouging takes place

on the tip sealing vanes. Rotor end surfaces

should be checked for uniformity and smoothness

and should be free of burrs, eruptions, and other

irregularities. If there is evidence of rotor contact

with end plates, housings, or with each other, the

rotor lobe length and width should be measured.

The following table gives lengths and widths for the

various 45 series models (If specifications outside

these limits, contact factory for advice):

Models Length

Width

4504 3.982-3.986 in.

7.372-7.374 in.

[101.14 -101.24 mm]

[187.25 -187.30 mm]

4506 5.978-5.982 in.

7.372-7.374 in.

[151.84 -151.94 mm]

[187.25 -187.30 mm]

4509

8.976-8.982 in.

7.372-7.374 in.

[228.00 -228.14 mm] [187.25 -187.30 mm]

4512 11.971-11.977 in.

7.372-7.374 in.

B.

c.

[304.07 -304.22 mm]

[187.25 -187.30 mm]

End plates.

The end plates are usually salvable if the planar air

box and seal ring bore surfaces appear undamaged. As with the rotors, moderate localized goug-

ing of the air box surface is allowable but is not

usually found without more extensive damage to

surrounding areas. Ring bore condition, however,

is critical. No visible evidence of surface finish

disturbance is allowable. If seizure of the rotor

group had occurred during operation, the end

plates should be checked for cracks.

Housing halves.

The housing halves are usually salvable if the

D.

E.

F.

G.

cylindrical air box surfaces appear undamaged. As

with the end plates, the housing halves should be

checked for cracks if seizure had occurred during

operation.

Timing gears.

The timing gears are usually salvable if the meshing teeth show no evidence of profile degeneration. The gear teeth are cut with a slight spherical

crown so that small errors in axial rotor alignment

can be tolerated. This produces a tooth contact

pattern that is characteristically elliptical and

somewhat more polished than that of the surrounding tooth surface. To determine whether gear

tooth wear has gone beyond acceptable limits, it

is necessary to check the backlash when the pump

is reassembled.

Covers.

The gear end and drive end covers are nearly always salvable provided there are no cracks since

there are no wearing surfaces. The seal bore of

the drive end cover should be examined for

smoothness.

Mounting plate and external hardware.

The mounting plate is nearly always salvable provided it is not cracked or severely bent. If it is

bent, but can be straightened so that the mounting

holes line up, it may be reused. External hardware

can be reused provided the threads are good and

the heads of screws and plugs are not too severely

deformed. Exceptions to this are the spider type

lock washer and external lock nut on the drive

shaft which should always be replaced as a matter

of service policy. The oil gage plug and breather

filters should also be replaced.

Flingers.

Usually salvageable, but if any cracks or surface

damage around the center hole exists they should

be replaced.

10

Page 12

SECTION SEVEN

Assembly Procedure

A.

B.

Preparation.

All metallic parts should be rinsed in clean mineral

spirits to remove any residual traces of dirt or filings from deburring operations. It is also suggested that all tools to be used in the reassembly

operation also undergo a solvent wash, so as to

eliminate yet another

source of contain ination.

Following solvent wash, the parts and tools should

be blown dry with clean compressed air.

The elastic rotor shaft seals (1O)and (25) shou Id be

immersed in fresh motor oil of the type used in the

blower fora period of at least two (2) hours prior to

installation in the end plates. This will allow the

elastomers to absorb sufficient oil to prevent

accelerated early wear.

Reassembly sequence.

1. Rebuilding component parts into basic subassemblies.

a. Rotor subassembly.

If the sleeves were removed as described in

Section Ill, proceed as follows:

(1)

(2)

(3)

(4)

Lightly coat the gear end rotor shaft and

the bearing sleeve (11) bore with assembly lubricant.

Install the bearing sleeve (11) on the

gear end rotor shaft, using the rotor

sleeve instal Iation tool and ball peen

hammer to drive the sleeve tightly onto

its seat.

NOTE: The face of the seal ring end of

the sleeve is notched out in two places

to provide clearance for tips of the mat-

ing rotor lobes. Therefore, the sleeve

must be installed in such a position that

the valley sections of its rotor are both

totally encompassed by a notch on both

sides.

Lightly coat the drive end rotor shaft

and the bearing spacer (14) bore with

assembly lubricant.

Install the bearing spacer (14) on the

drive end rotor shaft, as in Step (2)

above.

If sleeves were not removed, or after reinstalling them:

(5) Coat the seal ring groove with assembly

lubricant. Install and couple the seal ring

(13) on the bearing sleeve (11).

(6) Install and couple the seal ring (13) on

the bearing spacer (14), as in Step (5)

above.

b. End plate subassembly.

(1)

(2)

(3)

(4)

(5)

Place one presoaked oil seal (10) on the

oil seal installation tool and instal I the

seal in the id Ier socket of one end plate

(7) or (33), metal side down, using the

bal I peen hammer to drive the seal

securely onto its seat.

Install another presoaked oi I seal in the

drive socket of the end plate, as in Step

(1) above.

Install the idler bearing (9) or(17) in the

idler socket of the end plate using the

bearing instal Iation tool and ball peen

hammer to drive the bearing tightly onto

its seat.

NOTE: Install roller bearings in gearend

plate and ball bearings in drive end plate

(drive end plate is thicker).

Install the drive bearing (9) or (17) in the

drive socket of the end plate, as in Step

(3) above.

Install the 2 retaining rings (26) in their

respective bearing sockets, bevelled

side out, using the snap pliers (see Fig.

17). Make certain the snap rings are

properly seated in their grooves.

FIGURE 17

INSTALLING RETAINING RING

c. Housing half subassembly.

Assuming that the 4 dowel pins (34) and 2

ferrules (35) were not removed, install the 2

“O” rings (36) on the ferrules (35).

d. Drive end cover (30).

11

Page 13

Invert cover and place on wood blocks

gasket side down. Wipe excess oil from O.D.

of presoaked seal (25). Place seal in its bore

with metal face up and tap with plastic

mallet to seat securely.

FIGURE 17A

MEASURING FROM AIRBOX SURFACE TO INNER RACE OF

BALL BEARING

2. Final assembly.

a. Place lower housing half assembly (39) on

bench with cylindrical air boxsurfacedown.

Place mounting plate (40) on housing half,

align holes, and

secure with four cap

screws (37) and four lock washers (38).

Torque cap screws to 50 to 60 ft-lb [7.0 to

8.3 mkg].

FIGURE 17B

MEASURING FROM END OF BEARING SPACER TO END OF ROTOR LOBE

b.

c.

Model

4504

4506

4509

4512

d.

NOTE: The lower housing half differs from

the upper housing half in that the lower half

has one through hole from end to end while

the upper half has two through holes.

Invert assembly and secure mounting plate

to workbench with “C” clamps.

The clearance between the air box surface

of the drive end plate and the drive end of

the rotors is controlled by placing shims of

the required number and thickness on the

drive end of each rotor between the bearing

spacer and the inner race of the ball bearing. The procedure for determining the shim

thickness required for each shaft is as follows. Using depth micrometer, measure the

distance from the planar air box surface to

the inner race of the double row ball bearing

reading to the nearest .0005 in. (see Fig.

17A). For the corresponding shaft, measure

from the outer end of the bearing spacer to

end of the rotor lobe reading to the nearest

.0005 in. (see Fig. 17B). The first measurement minus the second measurement plus

the appropriate drive end clearance specified in the table below is the total shim

thickness required. (If specifications are

outside these limits, contact factory.)

Drive End

Gear End

Minimum Clearance Minimum Clearance

.005 in. [.127 mm] .006 in. [.152 mm]

.005 in. [.127 mm]

.010 in. [.254 mm]

.007 in. [.178 mm] .014 in. [.356 mm]

.007 in. [.178 mm] .016 in. [.406 mm]

Assemble the required shim stacks, reading the micrometer caliper to the nearest

0.0005” across the total lamination of

shims to be used, so as to reduce additive

error.

NOTE: Always use the least number of

shims necessary to obtain the required

FIGURE 18

ASSEMBLING SHIMS TO DRIVE END OF DRIVE ROTOR SHAFT

12

Page 14

stack thickness, as this reduces the apparent loss later produced by retaining nut

compression.

e. Install the assembled shim stacks (15) on

their respective drive end rotor shafts (see

Fig. 18).

f. Install the drive end plate to the lower

housing half with two cap screws (18) using

a 1 /2-13 nut spacer under the head of each

cap screw (see Fig. 19).

Torque cap screws to approximately 30 ft-lb

[3.9 mkg].

FIGURE 19

TWO CAPSCREWS WITH SPACERS USED TO TEMPORARILY FASTEN

DRIVE END PLATE TO LOWER HOUSING HALF.

g.

h.

i.

Brush the bearing spacers on the drive ends

of both rotors with assembly lubricant.

Install the idler rotor to the drive end plate.

Use extreme care in starting the seal ring in

the bore as the ring can easily be broken.

Assemble the drive rotor to the end plate

j.

Install the upper housing half to the drive

end plate. Ferrule with “O” ring must mate

with counterbored hole in end plate. Secure

with two cap screws (18) using a 1 /2-13 nut

spacer under the head of each cap screw

(see Fig. 21). Torque cap screws to approximately 30 ft-lb [3.9 mkg].

FIGURE 21

TWO CAPSCREWS WITH SPACERS USED TO TEMPORARILY FASTEN

UPPER HOUSING HALF TO DRIVE END PLATE

k. Brush the bearing sleeves on the gear ends

of both rotors with assembly lubricant. install gear end plate using care to avoid

damage to the seal rings during assembly.

Secure end plate to housings using six cap

screws with 1 /2-13 nut spacers (see Fig.

22). Torque screws to approximately 30 ft-lb

[3.9 mkg].

1.

Lubricate threads on drive end of each shaft

with assembly lubricant.

FIGURE 22

SIX CAPSCREWS WITH SPACERS USED TO TEMPORARILY FASTEN GEAR

END PLATE TO UPPER AND LOWER HOUSING HALVES

13

Page 15

m. Assemble clamp washer (28) and oil flinger

punch, tighten lock nut sufficiently to com-

(29) to drive end of idler shaft (see Fig. 23).

Be sure that oil flinger is assembled concave side out.

FIGURE 23

ASSEMBLING CLAMP WASHER AND OIL FLINGER TO DRIVE END OF

n.

o.

P.

IDLER SHAFT

Assemble flexlock nut (27) to drive

end of

idler shaft. Place wood block between idler

rotor lobe and inlet or discharge duct to

prevent rotor from turning. Torque nut to

300 ft-lb [42 mkg] (see Fig. 24).

Assemble bearing spacer (20) to drive end

of drive shaft.

Assemble lock nut (22) to drive end of drive

shaft with chamfer facing toward pump

body. Using hammer and blunted flat

FIGURE 24

TIGHTENING LOCK NUTS WITH TORQUE WRENCH

press shim stack (see Fig. 25).

FIGURE 25

TIGHTENING LOCK NUT TO CHECK DRIVE END CLEARANCE

q. Check drive end plate to rotor lobe clear-

ance for

each rotor with feeler gages (see

Fig. 26). (Drive end clearance for each

model is specified in table following Step

c of Final Assembly procedure on page 12).

If clearance is not within specified limits for

each rotor, remove the drive end plate and

add or remove shims as necessary to adjust

clearance. Reassemble and recheck clearance.

r.

When drive end clearance is correct,

temporarily remove the snap rings (26) retaining the drive end bearings.

CAUTION: Failure to remove these rings may

result in damage to the double-row ball bearings during installation of the timing gears.

FIGURE 26

CHECKING DRIVE END CLEARANCE WITH FEELER GAGE

14

Page 16

s. Brush the gear end splines and threads of

both shafts with assembly lubricant. Assemble the idler gear (42) to the idler shaft

with the large diameter boss toward the

blower body. Use plastic or rawhide mallet

to start idler gear onto shaft.

t. Place oil finger on idler shaft with con-

cave side in toward gear.

u. Lubricate flexlock nut (44) and install on

idler shaft. Chock rotor with wood block to

prevent its turning. Tighten lock nut to seat

gear against bearing sleeve. Then back off

lock nut enough to permit oil flinger to turn

freel y.

v. Rotor timing procedure.

On the helical gear blower, rotor timing

(rotor to rotor clearance) is adjusted by a

system in which rotational motion of the

drive rotor is transferred to the idler rotor

by means of two meshed helical gears, each

splined to its respective rotor shaft. The

axial position of the idler gear is fixed as

the gear face butts against the bearing

sleeve and is held there by a lock nut. The

axial position of the drive gear is slightly

adjustable as the drive gear is clamped be-

tween a conical spring washer (Belleville

spring) and a lock nut. Axial movement of

the drive gear, accomplished by tightening

the lock nut against spring pressure,

changes the angular relationship between

the two rotors thereby changing their

timing.

(1) In order to time the rotors, it is first

necessary to start the gears on their

rotor shafts in proper relationship to

each other.

(2) Place Belleville Spring (48) on the drive

FIGURE 27

POSITIONING BELLEVILLE SPRING AND DRIVE GEAR BEFORE

ASSEMBLING TO DRIVE ROTOR SHAFT

FIGURE 28

ROTOR AND SPACER BLOCK POSITION FOR INDEXING GEARS

(AS VIEWED FROM GEAR END)

rotor shaft,

concave side out toward

(3a)

(3b)

gear (see Fig. 27).

If gears are being reused, align the index

marks made on the gears during tear-

down. Make sure that the wide land in

the drive gear spline is aligned with the

missing tooth on the drive rotor shaft.

Start drive gear on rotor shaft using

plastic or rawhide faced mallet far

enough to engage flexlock nut two turns

by hand.

If new gears are used, align rotors paral-

FIGURE 29

STARTING DRIVE GEAR ONTO SHAFT WITH SOFT FACED MALLET

15

Page 17

approximately 15” (l-1/2 teeth) while

w. When correct rotor timing has been estab-

idler gear and rotor remain stationary.

Iished, the other interior rotor and air box

Push drive gear onto shaft meshing it

clearances should be checked with feeler

with idler gear. Use mallet to move gear

gages (see Fig. 31).

onto shaft far enough to engage flexlock

nut two turns by hand (see Fig. 29).

(4) The two drive end snap rings (26) tem-

porarily removed on page 14 should now

be replaced.

(5) Drive gear onto shaft by turning flexlock

nut. When the inner faces of gears are

aligned, check rotor-to-rotor clearance at

arrows in Fig. 28. If clearance is greater

than .016” continue turning nut until

.016” is obtained. Rotors should then

turn freely.

(6) If tightening drive gear lock nut does not

free rotors, the gears have been improperly meshed. Remove drive gear, fit

a new Belleville spring, and repeat gear

Q

D

6A

cc

AB

ADB

c

D

c

B

A

m

A B

D

c

c

D

BCA

BA

DD

AB ~

indexing procedure (Item 3b above).

(7) Before making final timing adjustments,

(1)

torque idler gear lock nut to 300 ft-lb

[42 mkg].

(8) When rotors turn freely, it is still neces-

sary to adjust rotor clearances to be

equal on both sides. Refer to diagram in

Fig. 30. Use feeler gages placed between the rotor lobes at position A-A

and B-B to check clearance. Adjust

(2)

clearance by tightening flexlock nut on

drive rotor shaft. One-sixth of a turn of

the nut will change the clearance by

.005 in. [.13 mm]. Adjust so that clear-

ance at A-A is equal to B-B within

(3)

+ .001 in. [.025 mm]. Clearance must be

checked on both sides of each rotor

lobe near each end.

FIGURE 31

POSITIONS OF ROTORS FOR CHECKING INTERNAL CLEARANCE

-------- --

I-ltiul’lt 3U

POSITIONS OF ROTORS FOR CHECKING TIMING

Clearance between tip of one rotor lobe

and valley of other rotor (C-C and D-D)

should be a minimum of .0040 in. [.102

mm]. This is measured with the rotors

perpendicular to each other. It should be

checked several places along the length

of the rotor for each of the four lobe tip

to valley positions.

Clearance between the rotor tips and the

housing halves should be a minimum of

.0040 in. [.102 mm]. It should be

measured at several places along the

length of each of the four rotor lobes.

Gear end rotor to end plate clearance is

measured between the end of each rotor

lobe and the gear end plate. The gear

end clearance for each model is specified in the table on page 12. If the gear

end clearance is not within limits, recheck the drive end clearance (refer back

to Item q.), as gear end and drive end

clearance are interdependent.

CAUTION: These rotor-to-rotor and

rotor-to-air box clearances are extremely

critical. Even though the blower may

turn freely by hand when cold; under

operating conditions, the parts expand,

and the rotors are subject to slight deflection. If the clearances are not sufficient, the rotors may contact each other

or the housing with destructive results.

If the clearances are too great, the

16

Page 18

x.

y.

z.

aa.

blower may not develop the pressure or

airflow that is required to perform its

function.

Check gear backlash four places at 90°

intervals as described in the Teardown

Sequence (Section Ill, Item B., 1., g.).

NOTE: If any of the four readings are not

within the specified limits, do not proceed

further with assembly. If a new set of gears

does not solve the problem then consider

returning the unit to DuroFlow for credit

towards a remanufactured blower.

After correct gear backlash has been established, remove the six cap screws and

spacers used to tern porari Iy

secure the gear

end plate to the housing halves.

Assemble gasket (31) to gear end cover(1).

Assemble gasket and cover to gear end

99.

hh.

Insert 14 cap screws (18) and lock washers

(6) and two cap screw and lock washer as-

semblies (5) through holes in cover and end

plate. Torque all cap screws to 28 to 32 ft-lb

[3.9 to 4.4 mkg].

Assemble lock washer (21 ) to drive end of

drive shaft with tangs outward toward end

of shaft (see Fig. 33).

plate with 14 cap screws (4), 14 lock wash-

ers (6) and 2 cap screw and lock washer

assemblies (5). Torque all cap screws to 28

to 32 ft-lb [3.9 to 4.4 mkg] (see Fig. 32).

FIGURE 22

ASSEMBLING SPIDER WASHER AND LOCK NUT TO DRIVE SHAFT

ii. Reassemble lock nut (22) to drive shaft with

chamfer toward blower body. Tighten lock

nut securely with hammer and punch (see

Fig. 34).

NOTE: if blower rebuilding is to be performed on a regular basis, a special tool for

the drive rotor lock nut is suggested. A

detailed drawing for the fabrication of this

tool is available from DuroFlow upon request. if the special tool is used, torque

lock nut to 300 ft-lb [42 mkg].

FIGURE 32

ASSEMBLING GEAR END COVER AND GASKET TO END PLATE

bb.

cc.

dd .

ee.

ff .

Move back to d rive end of blower.

Remove lock nut (22) from drive rotor temporarily y.

Remove 4 cap screws(18) holding drive end

plate to upper and lower housing halves.

Assemble gasket (31) to drive end cover (30).

Assemble gasket and cover to drive end

plate.

FIGURE 34

TIGHTENING DRIVE SHAFT LOCK NUT SECURELY WITH BLUNTED

CHISEL AND BALL PEEN HAMMER

17

Page 19

jj. Choose the lock washer tang that best

aligns with a slot in the

lock nut (22). Bend

the tang into the lock nut to prevent lock

nut from backing off (see Fig. 35).

kk. Install oil gage plug (43) in gear end cover.

II. Install two oil breather caps (8) in gear end

cover.

mm. Install the other eight pipe plugs.

nn. If the unit is not to be installed immediately

cover the air inlet and outlet openings to

prevent the entry of foreign material.

SECTION EIGHT

Spur Gear Blowers

As

mentioned in Section 1, the former blower design

utilized spur tooth timing gears rather than helical

tooth gears

in the current design. The only change

(besides the gears) from the former model to the

current model is the addition of a Belleville spring

washer behind the drive rotor timing gear. Therefore,

when overhauling a blower with a reusable set of spur

gears and rotors, it is optional whether the spur gears

are reused or replaced with a set of helical gears and

Belleville spring. If it is desired to reuse the spur

gears, some steps in the teardown and reassembly

procedures will differ from those for the helical gear

type.

Rotor timing with the spur gears is controlled by

selective assembly (matching a particular rotor to a

particular gear). Therefore, it is essential each gear be

replaced on the shaft from which it was taken. After

checking the gear backlash and marking the ends of

the gear teeth for proper indexing as in Section Ill,

Item B., l.,g. and h.;

it is also necessary to mark the

drive gear and idler gear in some way so that they can

be differentiated upon reassembly. This can be done

with the center punch and hammer or with an etching

tool.

The reassembly procedure for a spur gear blower is

identical to that for the helical gear blower except for

the gear assembly and timing. With the spur gears,

assemble the idler gear as in Section Vll, Item B., 2.,

s. Assemble the drive gear to the drive shaft aligning

the gear idex marks which were made prior to

removing the timing gears. Chock the rotors with a

wood block and torque both flexlock nuts to 300 ft-lb

[42 mkg]. Check rotor timing with feeler gages as in

Section Vll, Item B., 2., v., (7). With spur gears the

rotor timing is notadjustable. If the timing is not within

limits, remove the spur gears and replace with a new

set of helical gears and Belleville spring.

18

Page 20

SECTION NINE

Operating Limitations

DuroFlow 45 Series blowers are designed to be

blower at speeds and pressures above the rated

operated at 4000 RPM maximum and no more than 2:1

maximum will cause premature bearing and seal wear

pressure ratio. The table below gives characteristic

and will void the warranty.

inlet airflow and horsepower requirements for various

CAUTION: Outlet temperatures should not exceed

speeds and pressures. Attempting to operate the

350”F.

OPERATING CHARACTERISTICS

(Data based on standard air at inlet (14.7 psi @ 60”F)

SPEED (RPM)

2000

2500

3000

3500

4000

MODEL Psl

CFM HP

CFM HP CFM HP

CFM HP CFM HP

4504 2

165

2.5

225 3 280 3.5 335

4.5 390 5.5

5

145

5 205 6.5 260 8 315 9 370 11

8 130

8 185

10

240 12

295 14 351 16.5

10 120

9.5 175

12.5

230 15 287

17.5

337

20.5

12 110

11.5

162 15 215 18.5 270 22 325 26

15

150

18 203 23 255 27

308

31.5

4506

2 260

4

340

5 430

6

513

6.5 600 8

5 235

8

320 10

400

12.5

485 14.5 565

16.5

8 215 12

295 16 380 19

460 22.5

540 26

10 200

14.5

285 19 365

23.5 445 28 530 32.5

12 185 17.5

265 23 350

28.5 435

33.5 515 39

15

250 28 349 35

415 41 495 48

4509 2

395 6

525 8 650

9.5 775 11.5

900 13.5

5

360

12.5

480 16

615

19

735 23

8

855 26

330 19

450 24 575 29

700 34

820 39

10

315

23.5

435 29.5 555 36 680 42 800 48

12 290 27

420 35 540 42

660 50 780 57

15

385 43 510 52

630 61 755 70

4512

2

540

8 705 10 870 12

1040 14 1205

16.5

5

480

16

650 20 820 25

980 30 1150 34

8

445

23

610 30 775 37

935 44 1100 51

10 420

28

580 37

745 45 905 54 1065 62

12 400

34 560 44 720 54

880 64 1040 74

15

520 54 680 66

845 78 1010 90

19

Page 21

SECTION TEN

Lubrication Recommendations

The blower gears and bearings are splash lubricated.

Proper oil level must be constantly maintained to pre-

vent overheating and damage to internal parts.

After installation of the blower, add oil through the oil

fill plug on top of the drive end plate. Fill only until oil

reaches the level midway in the oil gage plug sight

glass in the gear end cover. Approximate oil capacities

are given below.

Vertical-30 oz. [0.9L]

Oil level should be checked daily. Wait three minutes

after shutdown to allow oil to drain down before

reading level at sight glass. Top up if necessary

through oil fill plug. Every 500 hours of operation (or 6

months whichever occurs first) the oil should be

changed.

Oil used in DuroFlow blowers must meet or exceed the

requirements of SAE specifications SE and CC. The

viscosity used depends upon ambient air temperature

and severity of application, i.e., pressure ratio, as in

Horizontal-56 oz. [1.7L]

the following tabie;

AMBlENT AIR TEMPERATURE

–65 F to 40 F

40°F to 110°F

–54 C to 40C

4C to 43C

I

I I

l.Oto 1.7 P.R.

PRESSURE

0 to 10 psig pressure

SAE IOW SAE 20

0 to 10 in. Hgvacuum

1.7t02.0 P.R.

RATIO

10to 15 psig pressure

SAE 20W

SAE 40

10to 15 in. Hgvacuum

For applications outside these limits, consult

DuroFlow. Oils of different brands or types should not

be mixed.

10W4O or 15W40 multigrade oil is recommended for all

ordinary operating conditions.

20

Page 22

SECTION ELEVEN

Parts Lists, Sectional and Exploded Views

A list of current part numbers is available upon written request from DuroFlow. Alternatively,

replacement parts may be ordered by part number from the Parts List.

dbdb

@d @@b@@@

Sectional View

DuroFlow 45 Series Blowers

VARIABLE PARTS LIST

ITEM

NO.

NAME OF PART

4512

4509 4506 4504

1

12

23

24

32

39

40

46

Top Housing

Shaft Key

Drive Rotor

Idler Rotor

Bottom Housing

Mounting Plate

Gasket

135069

135431 135437

141534

135729 135720

135720 141562

180929 180928

180927 180926

180933

180932 180931

180930

135070

135432 135438

141535

135405

135436

135442 141541

135716

135717

135718 141539

21

Page 23

Item

No.

1

2

3

4

5

6

7’

8*

9

10

11

12

13

14

15

16’

17

18

19

20

21

22

23

24

Part

Name of Part

Number

Cover-GearEnd . . . .. . . . . . . . .. . . . 135075

SelfTappingScrew. . . . . . .. . .. . . . . . 129309

NamePlate. . . . . . .. . . . . .. . . . . . . . ,,, 143606

Capscrew. . . . . . . . . . . . . .. . . . . . . . . . 134674

Capscrew&L.W.Assy. 132579

Lockwasher. . . . . . . . . . . .. . . . . . .

2917

EndPlate-GearEnd .(137430) 180672

BreatherFilter..........,...,,,. 140887

RollerBearing......,,,,,,...,.. 138113

OilSeal. . . . . . . . . . . ... . . . .. . . . . . . . . 161200

BearingSleeve,. . . . . . . . . . . .. . . . . 138100

HousingHalf-Top ., ,.. Variable

SealRing . . .. . .. . . . . . . . . . .. . .. . . . 139986

BearingSpacer, . . . . . . . . . . . . . .. . . . 134662

Shim . . . . . . . . . . . . . ...135726-7-8and 159076-7

PipePlug(l”) . .(158285) 186545

BallBearing.........,,.,.,,,,,, 138116

Capscrew. . . . . . . . . . . . . .. . . . . . . . . . 134675

Oil Deflector.,,..............,,, 139466

BearingSpacer........,.....,.. 134671

Lockwasher. . . . . . . . . .. .. . . . . . . . 138257

Locknut . . . . . .. . . . . .. . .. . . . . . . . 128040

Key . . . . . . . . . . . . . .. . . . . . . . . . . . . Variable

Rotor-Drive., .,, ,,, . .. . . . . . . . . . Variable

Quantity

Per Blower

1

4

1

14

4

28

(1) 1

(2) 1

2

4

2

1

4

2

As Required

(2)2

2

14

1

1

1

1

1

1

Exploded View

DuroFlow 45 Series Blowers

(Consult DuroFlow for Truck

Mounted Blowers)

Item Part

Quantity

No. Name of Part Number

Per Blower

25

26

27

28

29..

30

31

32

33‘

34

35

36

37

38

39

40

41‘

42

43

44

45*

46

47

48

OilSeal. . . . . . . . . . .. . .. . . . . . . . . ...

SnapRing.....................,,,

FlexlockNut . . . . . . . . . . . . . .. .. . ,,,

ClampWasher, . . . . . . . . . . . . .. . . .

Finger. .. . . . . . . . . . . .. . .. . . . . .

Cover-DriveEnd. . . . . . . . . . . .. . . . .

Gasket . . . . . . . . . . . . . .. . . . . . . . . .

Rotor-idler, .. . . . . . . . . . .. . .. . . . .

EndPlate-DriveEnd. .(137429)

Dowel . . . . . . . . . . .. . .. . . . . . . . . . .

Ferrule . ., . ., .. . . . . .. . . . . . . . . .

“O’’Ring. . . . . . .. . . . . . . . . . . . . . . .. .

CapScrew . . . . . . . . . . . . . . . . . . . . . .,,

Lockwasher. . . . . . . . . . . . .. . . . . .

HousingHalf-Bottom . . ..

MountingPlate(Vertical)

PipePlug(318’’). .,, ,,, ,,, ,,, ,.. .

Gearldler L,H. . . . . .. . . . . . . . . . . . ..,,

Oil GagePlug. . . . . . . . . . .. . . . . . . . . .

FlexlockNut . . . . . . . . . . . . . .. . . .

PipePlug(112’’), ,,, ,,, ,,, ,, .. . . .

Gasket . . . . . . . . . . . . . .. . . . . . . . . . .,,

GearDriveR.H.,,,....,......,,,

BellevilleSpring .. . . . . .. . . . .. . .. ,,,

134870

125606

124793

135766

See

Below

135074

135715

Variable

180673

121880

119034

119058

100963

2675

Variable

Variable

21360

181377

137799

124793

9620

Variable

181378

181069

1

4

1

1

. .

1

2

(1; 1

10

4

4

4

4

1

1

(2) 2

or O

1

1

2

(4) O or 2

2

1

1

* Note - Part Number and/or quantity needed with old style end plates are in parenthesis.

** Flingers

- For V1/HL shaft configurations use 2-134652.

For VB/HR shaft configurations

use 1-134652 and 1-143095.

22

Page 24

SECTION TWELVE

Troubleshooting Guide—

DuroFlow Positive Displacement Rotary Blowers

Problem or Complaint

Probable Causes

Noisiness Rotor-to-Rotor Contact

Failing Bearing(s)

Failing Gears

Failing Lubricated Coupling or Joint

Loose Attached Hardware

Air Leakage

Belt Flutter

Poor Performance

Restricted Inlet

Down Stream Restriction

Excessive Air-to-Product Ratio

Usual Reasons or Sources

- Rotors Out of Time

- Excessive Pressure Ratio

- Failed Bearing(s)

- Failed Gears

- Faulty Installation

- Nonspec Oil

- Contaminated Oil

- Insufficient Oil

- Oversized Belt Drive

- Improperly Mounted Sheave

- Overtightened Belts

- Misaligned Direct Coupling

- Insufficient Backlash

- Nonspec Oil

- Contaminated Oil

- Insufficient Oil

- Severe Torsional Vibration

- Nonspec Grease

- Contaminated Grease

- Insufficient Grease

- Belt Guard

- Pump Mounting Bracket

- Frame Members

- In/Out Ducting Supports

- Improper Relief Valve Setting

- Blown Gaskets

- Loose Ducting Joints

- Insufficient Static Tension

- Long Span (Center-to-Center) Distance

- Sheave Misalignment

- Severe Torsional Vibration

- Clogged Filter Element

- Undersized Filtration Unit

- Undersized Inlet Pipe or Tubing

- Excessive Inlet Duct Length

- Collapsed Inlet Hose

- Clogged Silo Vent Filter Element

- Undersized Silo Vent Filter

- Undersized Outlet Pipe or Tubing

- Excessive Outlet Ducting Length

- Clogged Diffusion Pads (on Pneumatic Trailers)

- Material Bridging in Feed Hopper

- Insufficient Feeder Speed

- Material Caking at Inlet Nozzle

- Material Caking at Inlet Nozzle or Funnel

23

Page 25

Leaking Oil

End Cover Seams Not Tight

Oil Foaming

Chronic Fuse

Excessive Motor Amperage

Blowing or Circuit

Breaking

Overheat ing

Erroneous Pressure or Vacuum

- Loose Gauge Connection

Indication

- Gauge Movement Damaged

- Gauge Miscalibrated

- Gauge Tap Too Far from Unit Outlet Port

Air Leakage

- Improper Relief Valve Setting

- Blown Gaskets

- Loose Ducting Joints

Insufficient Rotor Speed

- Wrong Sheave Set

- Wrong Motor Speed

- Slipping Belts

- Insufficient Engine Speed

Excessive Rotor Clearances

- Abrasive Wear of Rotor Surfaces

- Rotors “Lag” Timed

Change in Conveyed Material

- Material More Difficult to Fluidize

- Material of Higher Density

- Moisture Content of Material Too High

Failed Oil Seals

- Foreign Material in Seal Bores

- Faulty Installation

- Nonspec Oil

- Contaminated Oil

- Overheated Rotor Shafts

- Through Bolts Loose

- Gaskets Torn

- Nonspec Oil

- Oil Cavities Overfilled

- Excessive Pressure Ratio

- Excessive Pump Speed

- Line Voltage Droop

- Air Density Increase

- Loose Electrical Connections

- Foreign Material in Air Box

Underrated Fuses

Premature Heater Strip Actuation

- Unusually High Ambient Temperature

- Underrated Heater Strips

Excessive Pressure Ratio

- Clogged Filter Element

- Undersized Filtration Unit

- Undersized Inlet Pipe or Tubing

- Excessive Inlet Duct Length

- Collapsed Inlet Hose

- Clogged Silo Vent Filter Element

- Undersized Silo Vent Filtration Element

- Undersized Outlet Pipe or Tubing

- Excessive Outlet Ducting Length

- Clogged Diffusion Pads (on Pneumatic Trailers)

- Wrong Sheave Set

- Wrong Motor Speed

- Slipping Belts

- Insufficient Engine Speed

Insufficient Rotor Speed

24

Page 26

SECTION THIRTEEN

WARRANTY

GARDNER-DENVER INDUSTRIAL MACHINERY

DUROFLOW

BLOWERS

1800 GARDNER EXPRESSWAY

QUINCY, IL 62305-4024

TEL: (217) 222-5400“ FAX (217) 223-5897

GENERALPROWSIONS AND LIMITATIONS

Industrial Machinery (the “Compan ‘) warrants to each

original retail purchaser (“Purchaser of its new roducts

from the Company or its authorized distributor that such

products are, at the time of delivery

to the Purchaser, made

with good material andworkmanship. No warranty ismade

with respect to:

1.

2.

3.

4.

5.

An product which has been repaired or altered in

Ksuc a way, in the Company’sjudgment, as to affect

the product adversely.

Any product which has, in the Company'sjudgment

been subject to negligence, accidentt unproper

storage, or improper installation or applicatlion.

Any product which has not been operated or maintained in accordance with normal practice and with

the recommendations of the Company.

Components or accessories manufactured, warranted and serviced by others.

Any reconditioned or prior owned product.

Claimsforitems described in(4) aboveshould be submitted

directly to the manufacturer.

WARRANTYPERIOD

The Company’s obligation under thiswarrantyis limited to

repairingor, atits option, replacin durin normalbusiness

hours at an authorized servicefacility of the Company, any

part which initsjudgment proved not towithin theapplicable Warranty Period asfollows:

BAREBLOWERS

Basic bare blowers consisting of all parts within, are war-

ranted for 12 month from date of initial use or

18 months

from date of shipment to the first purchaser, whichever

occurs first.

Any disassembly or partial disassembly of the blower, or

failure to return the "unopened"blower per Company instructions, will be cause for denial of warranty.

OTHER COMPONENTS

All other components are warranted for 12 months from

date of initial use or

18 months from date of shipment to first

purchaser, whichever comes first.

LABORTRANSPIRATION AND INSPECTION

The Company will provide labor, by Company repre-

sentative or authorized servicepersonnel, for repair or re-

placementof any product or art thereof which in the

Company's judgmentiS prove not to be as warranted.

Labor shall be limited to the amount specified in the

Company'slabor rate schedule.

Laborcosts in excess of the Companyrate schedule amounts

or labor providedby unauthorized service personnel is not

provide for by thISwarranty.

AUcosts oftransportation of roduct, labororpartsclaimed

not to be aswarrantedand,of repaired orreplacement parts

to or from such service facilities. shall be borne by the

Purchaser.The Company mayrequire the returnof anypart

claimed not to be as warranted to one of its facilities as

designated by Company, transportation prepaid by Purchaser, to establish a claim under this warranty.

Replacement parts provided under the terms of the warranty are warranted for the remainder of the WarrantyPeriod

of the product upon which installed to the same extent as if

such partswere original components thereof.

DISCLAIMER

THE FOREGOING WARRANTY ISEXCLUSIVE AND

IT IS EXPRESSLY AGREED THAT, EXCEPT AS TO

TITLE THE COMPANY MAKES NO OTHER WARRANTiES, EXPRESSED, IMPLIED OR STATUTORY,

INCLUDING ANY IMPLIED WARRANTY OF MERCHANTABILITY.

THE REMEDY PROVIDED UNDER THIS WARRANTY SHALL BE THE SOLE, EXCLUSIVE AND ONLY

REMEDY AVAILABLE TO PURCHASER AND IN NO

CASE SHALL THE COMPANY BE SUBJECT TO ANY

OTHER OBLIGATIONS OR LIABILITIES. UNDER

NO CIRCUMSTANCES SHALL THE COMPANY BE

LIABLE FOR SPECIAL, INDIRECT, INCIDENTAL OR

CONSEQUENTLAL DAMAGE, EXPENSES, LOSSES

OR DELAYS HOWSOEVER CAUSED.

No statement, representation, agreement, orunderstanding

oral or written, made by any agent, distributor, representative, or employee o. the Corn any whtch is not contamed in this Warrantywill be be g upon the Corn any

unless made in writing and executed by an officer o the

Company.

This warrantyshall not be effective asto any claim which is

not resented within 30 days after the date upon which the

product is claimed not to have been as warranted. Any

action for breach of this warranty must be commenced

withinone yearafter the date upon which the cause of action

occurred.

Any adjustmentmade pursuantto this warrantyshall notbe

construed asan admission bythe Company that anyproduct

was not aswarranted.

25

Page 27

#

COOPER

Gardner-Denver

Industrial Machinery

For additional information, contact Gardner-Denver Industrial Machinery

Division, 1800 Gardner Expressway, Quincy, Illinois 62305-4024

Telephone (217) 224-6600 FAX 217-224-7814 Telex 404332.

Specificationssubject to change without notice,

COPYRIGHT @ 1991 Cooper Industries, Inc.

Lithoin USA.

Loading...

Loading...