Page 1

DFI INFINITY

SERIAL COMMUNICATIONS GUIDE

www.cooperinstruments.com

PH: 540-349-4746 • FAX: 540-347-4755

Page 2

TABLE OF CONTENTS

1. INTRODUCTION ....................................................................................................................................... 1

2. HARDWARE.............................................................................................................................................. 1

2.1 Definition of Terms....................................................................................................................... 1

2.2 RS-232 Hardware ........................................................................................................................1

2.3 RS-485 Hardware ........................................................................................................................4

3. USING THE CONFIGURATION AND COMMUNICATIONS DISKETTES............................................... 7

3.1 Pushbutton Communications Setup ............................................................................................7

3.2 Diskette-Driven Computer Control............................................................................................... 8

4. DEFINITIONS ............................................................................................................................................ 8

4.1 Meter Or DCE ..............................................................................................................................8

4.2 Computer Or DTE........................................................................................................................8

4.3 Point-To-Point..............................................................................................................................8

4.4 Multipoint (Multi-Drop) .................................................................................................................8

4.5 Simplex ........................................................................................................................................ 8

4.6 Half Duplex ..................................................................................................................................8

4.7 Full Duplex................................................................................................................................... 9

4.8 RS-232 (CCITT V.24) .................................................................................................................. 9

4.9 RTS..............................................................................................................................................9

4.10 RS-422......................................................................................................................................... 9

4.11 RS-485......................................................................................................................................... 9

4.12 ASCII............................................................................................................................................ 9

4.13 HEX ASCII ...................................................................................................................................9

4.14 Transmission Voltage Levels.....................................................................................................10

4.15 Recognition Character ............................................................................................................... 11

4.16 RAM ........................................................................................................................................... 11

4.17 EEPROM ...................................................................................................................................11

5. BAUD RATES ......................................................................................................................................... 11

6. CHARACTER WAVEFORM.................................................................................................................... 11

7. CLASSES OF OPERATION ...................................................................................................................12

7.1 Point-To-Point............................................................................................................................ 12

7.1.1 Continuous Mode ..................................................................................................................12

7.1.2 Command Mode....................................................................................................................12

7.2 Multipoint....................................................................................................................................13

7.2.1 Command Mode....................................................................................................................13

7.2.2 Alarm Mode ........................................................................................................................... 13

7.3 The Meter As A Remote Display ...............................................................................................13

7.4 The Meter As A Double Tasking Remote Meter........................................................................ 14

7.4.1 Command Structure For Double Tasking.............................................................................. 14

8. COMMAND AND RESPONSE STRUCTURE ........................................................................................15

8.1 Message String.......................................................................................................................... 15

8.1.1 “Data” and “Non Data”...........................................................................................................15

8.1.2 Brackets and Spaces ............................................................................................................15

8.2 Commands and Structure..........................................................................................................15

8.2.1 Read Communications Configuration Command.................................................................. 15

8.2.2 General Command Structure ................................................................................................16

8.2.3 Command Formats................................................................................................................ 16

8.2.4 Command Suffix.................................................................................................................... 17

8.3 Response Structure ...................................................................................................................22

8.3.1 No Error ................................................................................................................................. 22

8.3.2 Echo Mode (See Sections 10.19 And 11.25) ........................................................................22

8.3.3 No Echo Mode....................................................................................................................... 22

8.4 Data Length Corresponding To The Response Structure ......................................................... 23

8.5 Error Response.......................................................................................................................... 23

CF 125 INFINITY SC GUIDE ii M1519/N/0605

Page 3

8.5.1

Error Response Format......................................................................................................... 23

8.5.2 Error Message ....................................................................................................................... 24

8.5.3 Description.............................................................................................................................24

8.6 Status Character Formats..........................................................................................................25

8.6.1 Alarm Status Characters ....................................................................................................... 25

8.6.2 Peak/Valley (HI/LO) Status Characters................................................................................. 26

8.7 “V01” Or “External Print” Response Data Format ..................................................................... 26

8.8 “^AE” Response Format ............................................................................................................ 27

8.9 Examples: Temperature/Process/Strain/Universal Meters........................................................ 27

8.10 Examples: Rate Meter/Totalizers/Batch .................................................................................... 28

9. METER BUS RESPONSE....................................................................................................................... 30

9.1 Point-To-Point or Multipoint Command Mode ...........................................................................30

9.1.1 Meter’s Response Time ........................................................................................................30

9.2 Point-To-Point Continuous Mode ..............................................................................................31

9.2.1 Meter’s Response Time ........................................................................................................31

9.2.2 Communicating With The Meter When In Continuous Mode................................................31

9.3 Multipoint Alarm Mode Response.............................................................................................. 32

9.3.1 Meter’s Response Time ........................................................................................................32

9.4 External Print Command............................................................................................................32

9.4.1 Meter’s Response Time ........................................................................................................33

9.5 Watchdog Timer For Communication........................................................................................ 33

10. Data Formats Associated With Commands (“P”, “G”, “R”, “W”) Process, Strain Gauge,

Temperature Or Universal Meters........................................................................................................ 33

10.1 Lockout Bytes ............................................................................................................................34

10.2 Input Type (“Input”) .................................................................................................................... 35

10.3 Reading Configuration (“RDG.CNF”)......................................................................................... 37

10.4 Reading, Input, Or Output Scale Factor (“RD SC”, “IN SC”, “OUT SC”)................................... 37

10.5 Reading Offset (“RDG OF”), Input Offset (“INP OF”), or Output Offset (“OUT OF”) ................. 38

10.6 Input Configuration (“IN CNF”)...................................................................................................39

10.7 Setting Decimal Point Location and Roundoff (“DEC PT”, “CNT BY”) ...................................... 40

10.8 Filter Configuration And Number Of Samples In The Average (“FIL.CNF”, “FIL TI”)................ 41

10.9 Setpoint 1 and 2 Configuration (“SP CNF”) ............................................................................... 41

10.10 Alarm (Setpoints 3 And 4) Configuration (“AL CNF”)............................................................ 42

10.11 Alarm Functions (“AL FNC”).................................................................................................. 43

10.12 Alarm Delay: (“AL RDG”)....................................................................................................... 43

10.13 Setpoint 1 and 2 Hysteresis (“SP DB”).................................................................................. 44

10.14 Alarm (SP 3 AND SP 4) Hysteresis (“AL DB”) ...................................................................... 44

10.15 Output Configuration and Display Flashing Controls (“OUT.CNF”) ...................................... 44

10.16 Serial Communications Configuration (“SER.CNF”) ............................................................. 45

10.17 RS-485 Meter “ADDRES”...................................................................................................... 46

10.18 Data Format (“DAT FT”) ........................................................................................................46

10.19 Communications Bus Format (“BUS FT”) .............................................................................47

10.20 Number Of Readings Between Each Transmission (“SER CNT”)........................................ 48

10.21 Recognition Character...........................................................................................................48

10.22 Units Of Measure...................................................................................................................48

10.23 TX/RX Turnaround Delay (SERIAL DELAY)......................................................................... 49

10.24 Setpoint Value (“SP1”, “SP2”, “SP3”, “SP4”)......................................................................... 49

10.25 Block Read or Write ..............................................................................................................50

10.25.1 BLOCK A........................................................................................................................... 51

10.25.2 BLOCK B........................................................................................................................... 51

10.25.3 BLOCK C ..........................................................................................................................51

10.25.4 EXAMPLE: ........................................................................................................................52

11. DATA FORMATS ASSOCIATED WITH COMMANDS FOR RATE METER/TOTALIZERS AND

BATCH METERS .................................................................................................................................... 52

11.1 Lockout Bytes (“L1 CNF”, “L2 CNF”, “L3 CNF”) ........................................................................ 52

11.2 Mode.......................................................................................................................................... 54

CF 125 INFINITY SC GUIDE iii M1519/N/0605

Page 4

11.3

Display Mode .............................................................................................................................54

11.4 Configuration 1 (“CNFG 1”) .......................................................................................................55

11.5 Configuration 2 (“CNFG 2”) .......................................................................................................55

11.6 Configuration 3 (“CNFG 3”) .......................................................................................................56

11.7 Configuration 4 (“CNFG 4”) .......................................................................................................58

11. 8 Average Configuration (“AVG.CNF”) For Rate And Square Root Rate Modes Only ................58

11.9 Measurement Time (“GATE T”) For Rate and Square Root Rate Modes Only ........................59

11.10 Pulsed Setpoint Number .......................................................................................................59

11.11 Alarm Time (“AL TI”).............................................................................................................. 60

11.12 Input Scale And Offset (“IN.SC.OF”)..................................................................................... 60

11.13 Batch Decimal Point (“BAT DP”), Rate Decimal Point (“RTE DP”), Total Decimal Point (“TOT

DP”) 61

11.14 Batch Load (“B LOAD”), Batch Scale (“BAT SC”), Rate Offset (“RTE OF”), Rate Scale (“RTE

SC”), Total Offset (“TOT OF”), Total Scale (“TOT SC”).......................................................................... 62

11.15 Scale Operator ......................................................................................................................63

11.16 Setpoint 1 Through 4 Values (“SP1”, “SP2”, “SP3”, “SP4”) ..................................................63

11.17 Setpoint 5 Value (“SP5”) .......................................................................................................63

11.18 Set Time (“SET TI”) ...............................................................................................................64

11.19 Output Scale.......................................................................................................................... 64

11.20 Output Offset .........................................................................................................................65

11.21 Raw Measurement Values; Batch Count (“BATCH”), Batch Number (“BAT NO”), Total And

Time 65

11.22 Baud Rate (“BAUD”)..............................................................................................................66

11.23 Serial Communications Configuration (“SER.CNF”) ............................................................. 66

11.24 Data Format (“DAT FT”) ........................................................................................................67

11.25 Communication Bus Format (“BUS FT”) ............................................................................... 68

11.26 RS-485 Meter Address (“ADDRES”)..................................................................................... 68

11.27 Time Between Each Transmission (“SER TI”) ...................................................................... 68

11.28 Recognition Character...........................................................................................................69

11.29 Units Of Measure...................................................................................................................69

11.30 TX/RX Turnaround Delay (SERIAL DELAY)......................................................................... 69

11.31 Calibration Items ...................................................................................................................70

11.32 Block Read Or Write.............................................................................................................. 70

11.32.1 Block A (For G, P, R, W Commands) ...............................................................................71

11.32.2 Block B For Batch Meter And Square-Root Meter............................................................ 71

11.32.3 Block B For Rate Meter..................................................................................................... 72

11.32.4 Block C For Batch Mode Only.......................................................................................... 73

11.32.5 Block D For Batch, Square-Root And Rate Modes........................................................... 73

11.32.6 Block E For Batch, Square-Root And Rate Modes........................................................... 73

11.32.7 Example ............................................................................................................................ 74

CF 125 INFINITY SC GUIDE iv M1519/N/0605

Page 5

1. INTRODUCTION

This guide is intended to facilitate digital communication between your computer (or other controlling device)

and one or more meters.

This digital-communications guide is provided for use with any of the meters OWNER’S GUIDES for Process,

Strain gauge, Temperature, Universal, Rate meter/totalizer, Batch controller or Clock, which provide details of all

applicable inputs, connections, option, push button controls and programming procedures.

2. HARDWARE

2.1 Definition of Terms

RX: Received line on RS-232

TX: Transmit line on RS-232

RTS: Request to send

ARX: First pair received line on RS-422/485 = +RX

ATX: First pair transmit line on RS-422/485 = +TX

BRX: Second pair received line on RS-422/485 = -RX

BTX: Second pair transmit line on RS-422/485 = -TX

Gnd: Ground

2.2 RS-232 Hardware

INSTALLATION: The RS-232 card in approximately 1” high and 5” long, refer to Figure 2-1A. If you have an

older option card refer to Figure 2-1B.

It is installed with the meter removed from its case (Refer to Section 5 of your meter’s Owner’s Guide for

instructions on how to open the meter).

P11 inserts into J11 of the main board located next to the transformer (Refer to Figure 2-2). You should install

the option board in such a way the pin “1A” of “P11” is aligned with pin “1A” of “J11”.

The board is held in position by a plastic guide on the rear of the display board and plastic assembly at the rear

of the meter.

The 6-pin telephone jack, P4, is available at the rear of the meter case, and accepts a type RJ-11 or RJ-12

telephone plug (Refer to Figure 2-3).

Logic signals are opto-isolated, and drive power is obtained from a galvanically-isolated transformer winding so

that the ±7 V signal levels from the meter can be slaved to the external controller (computer) ground; earthing

that ground is recommended.

Refer to Figure 2-1A. When interfacing the meter to devices that do not have handshaking lines, i.e. RTS/CTS,

the S3-E Jumper should be installed. However, when interfacing to a PC, the S3-E should be removed.

CF 125 INFINITY SC GUIDE 1 M1519/N/0605

Page 6

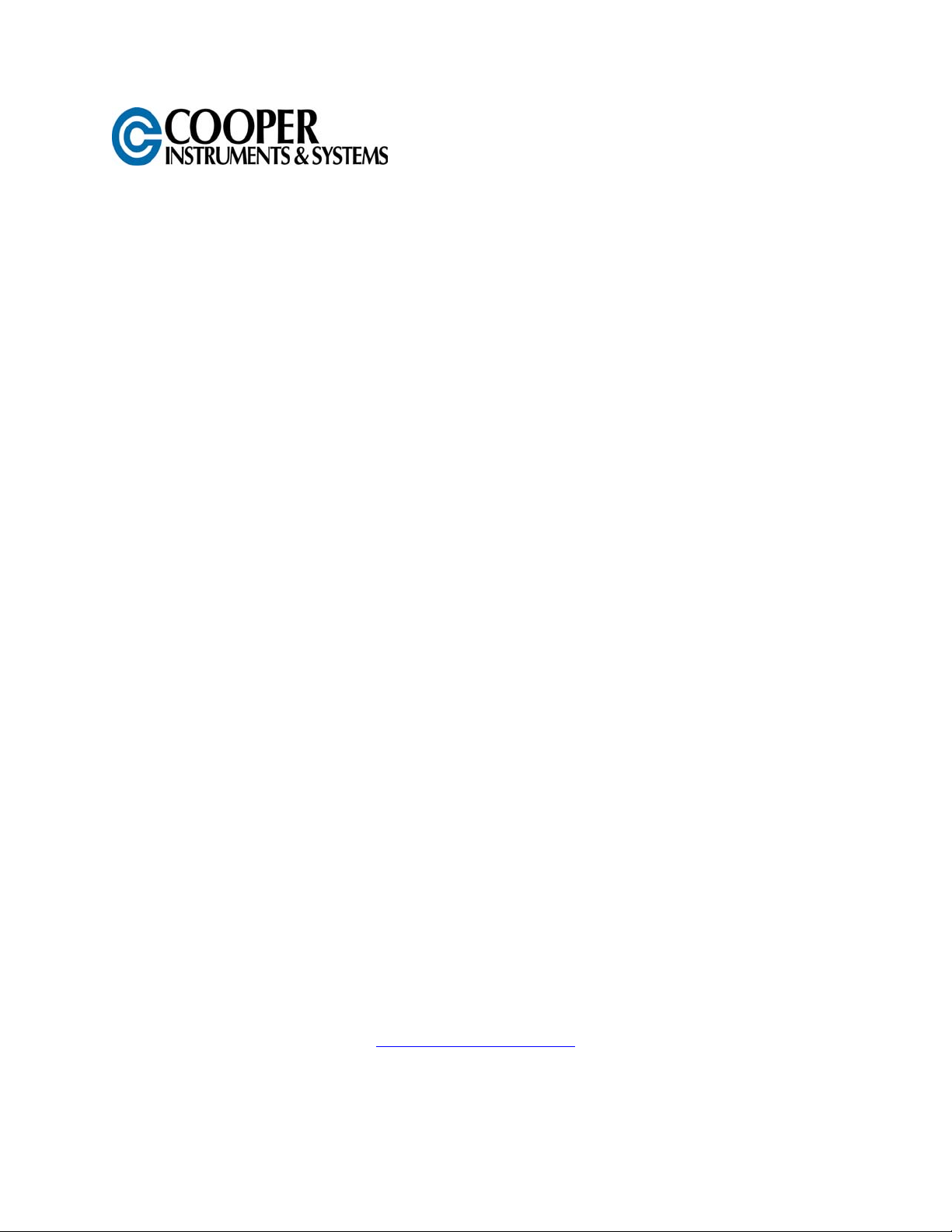

Figure 2-1A. RS-232 Option Board

Figure 2-1B Older RS-232 Option Board

Refer to Figure 2-1B. When interfacing the meter to devices that do not have handshaking lines, i.e. RTS/CTS,

the S1-A jumper should be installed. However, when interfacing to a PC, the S1-A should be removed.

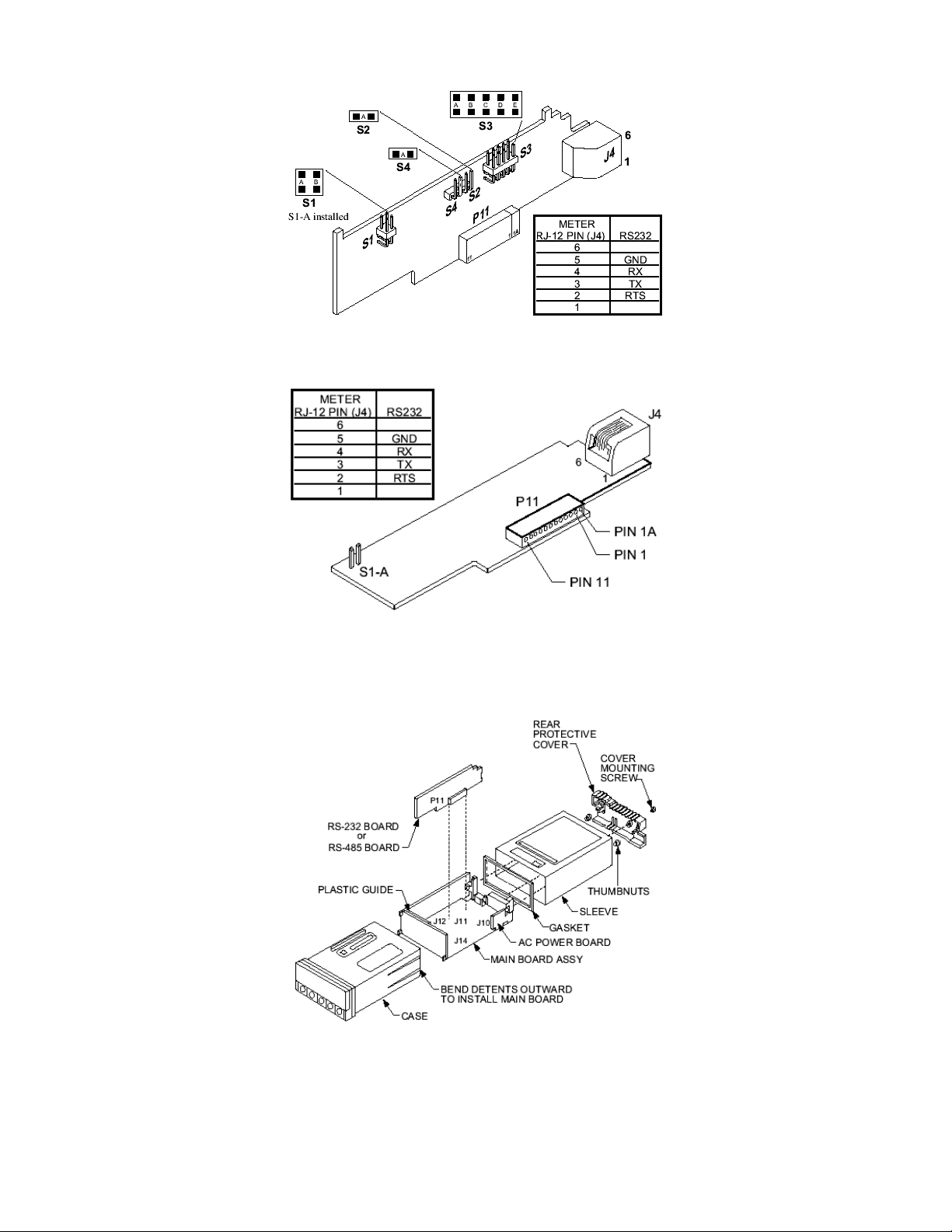

Figure 2-2. Main Board with the RS-232/RS-485 Option Board

CF 125 INFINITY SC GUIDE 2 M1519/N/0605

Page 7

Figure 2-3. Rear of Meter with J4 Connection

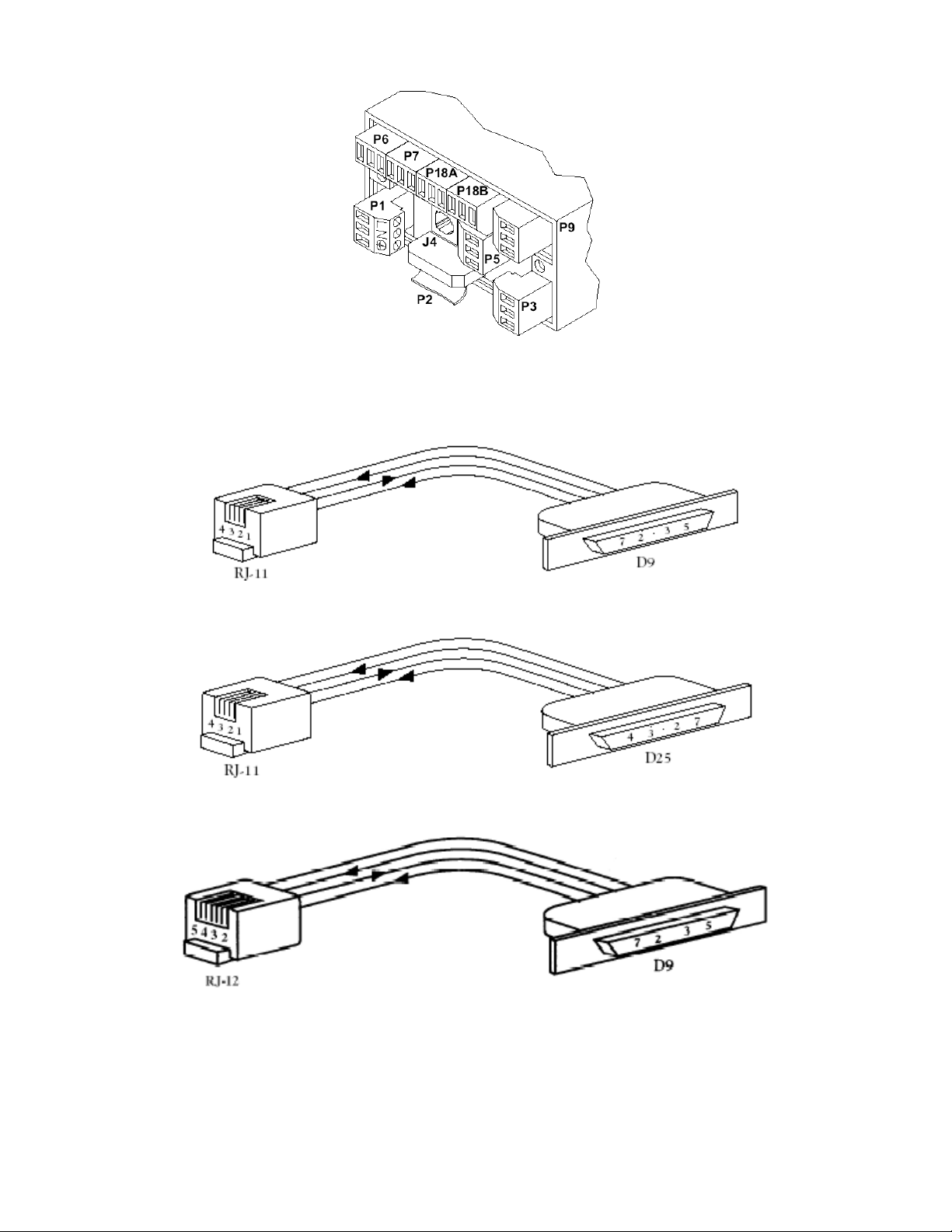

Figures 2-4A and Figure 2-4B show the four-wire RS-232 connections between the host computer/controller

using either a 9-pin or 25-pin “D” connector and the meter (point-to-point full duplex, with RTS handshake).

Figure 2-4A. RJ-11 to D9 Connector

Figure 2-4B. RJ-11 to D25 Connector

Figure 2-4C. RJ-12 to D9 Connector

Table 2.1 shows the pin connection assignments between the RS-232 connection on the meter and the 9-pin or

25-pin “D” connectors of your computer.

CF 125 INFINITY SC GUIDE 3 M1519/N/0605

Page 8

Table 2.1. Meter Hookup (RS-232) to the Computer

METER

PIN SIGNAL/

FUNCTION

RTS, meter from computer 1 2 7 4

TX, meter = RX, computer 2 3 2 3

RX, meter = TX, computer 3 4 3 2

Return 4 5 5 7

NC (not connected) 1,6 (all others)

Table 2.2 shows the pin connection assignments between the RS-232 connection on the meter and the 9-pin or

25-pin “D” connectors of your printer.

Table 2.2. Meter Hookup (RS-232) to the Printer

(DCE)

RJ-11 RJ-12 D9 D25

COMPUTER

(DTE)

PIN SIGNAL/

FUNCTION RJ-11 RJ-12

RTS, meter 1 2 Data Terminal Ready (DTR)

TX, meter 2 3 Received Data (RXD)

RX, meter 3 4 Not Connected

Return 4 5 Signal Return

NC (not connected) 1,6

METER

PRINTER

FUNCTIONS

2.3 RS-485 Hardware

INSTALLATION: The RS-485 card (refer to Figure 2-5A, or if you have an older option card refer to Figure 25B) is the same size and plugs in the same ways as the RS-232 card, refer to Section 2.2.

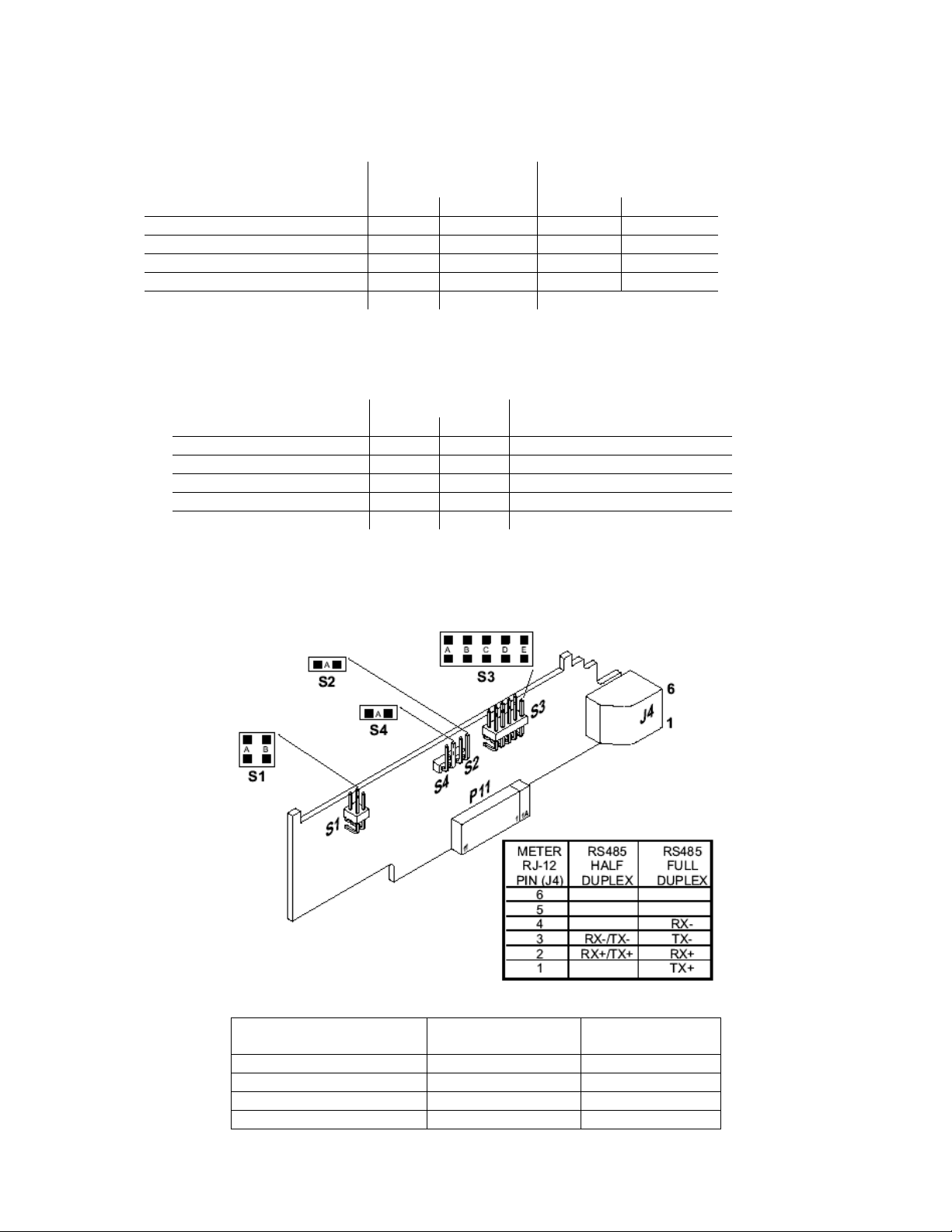

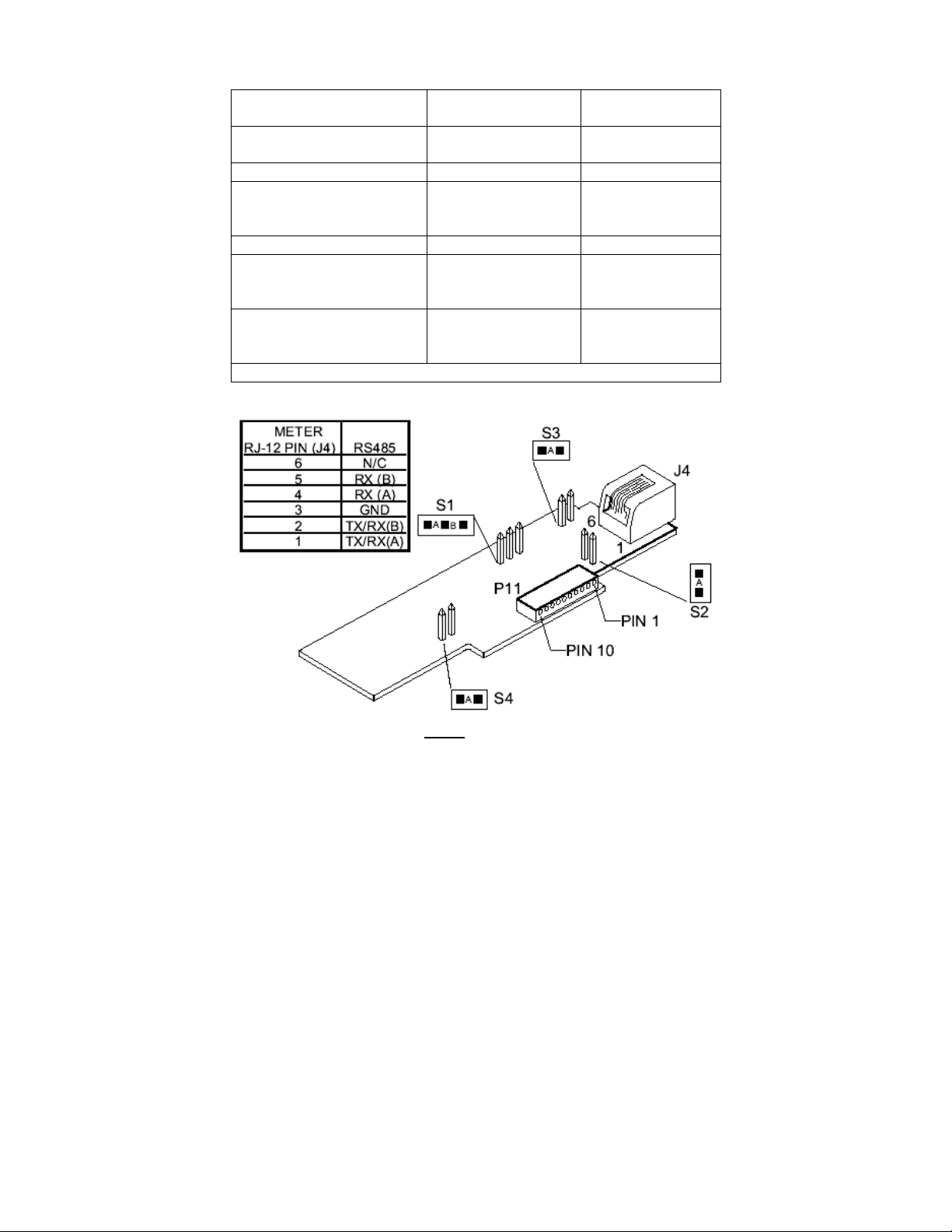

Figure 2-5A. RS-485 Option Board

JUMPER

S1-A OPEN OPEN

S1-B CLOSE OPEN

S2-A CLOSE CLOSE

S3-A * *

CF 125 INFINITY SC GUIDE 4 M1519/N/0605

RS485

HALF DUPLEX

RS485

FULL DUPLEX

Page 9

JUMPER

RS485

HALF DUPLEX

RS485

FULL DUPLEX

(CLOSE FOR TERMINAL

RESISTOR)

S3-B CLOSE OPEN

S3-C

(CLOSE FOR TERMINAL

* *

RESISTOR)

S3-D CLOSE OPEN

S3-E

(CLOSE FOR RTS

OPEN OPEN

TRUE)

S4

(CLOSE FOR

* *

CONTINUOUS MODE)

Note: * means optional, select as required.

Figure 2-5B. Older

RS-485 Option Board

Figure 2-5B shows the card outline and the pin designators for the connectors.

There are 4 jumper-selected features.

Putting a jumper in S1-A adjust for HALF DUPLEX (see Definitions in Section 4)

A jumper in S1-B allows for FULL DUPLEX.

A jumper in S2 adds an impedance-matching 121 ohms across the HALF DUPLEX lines.

A jumper in S3 to impedance-match the other pair of wires, for FULL DUPLEX.

For normal RS-485 operation: remove S4.

For continuous transmission: install S4 and set BUS format menu item as follows:

BUS.4=0

BUS.5=0

BUS.7=0

CF 125 INFINITY SC GUIDE 5 M1519/N/0605

Page 10

Logic symbols are opto-isolated, and drive power is obtained from a galvanically-isolated transformer winding so

that the differential signals (minimum ±2 V) will not be altered by an external ground; earthing of the external

transceiver power supply is recommended to limit common-mode voltage.

The RS-485 hardware may be operated point-to-point (e.g., as RS-422 equipment), OR in multipoint, sharing

the bus wires with up to 32 other meters.

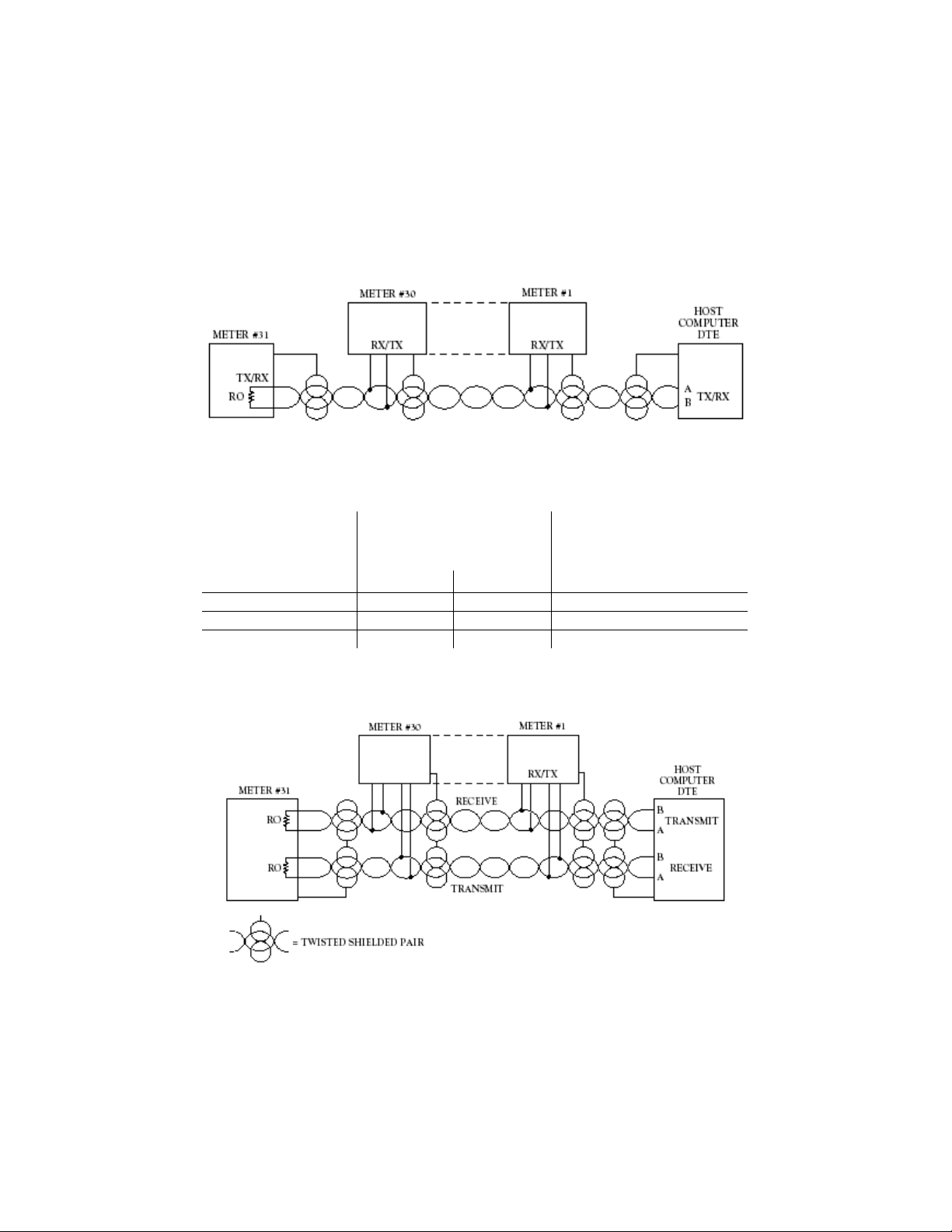

The RS-485 cabling may be a single pair of wires (usually with a shield) for HALF DUPLEX (Figure 2-6), or two

such pairs for FULL DUPLEX (Figure 2-7). The configurations shown are for bus operation, with tap-offs for

each meter.

Figure 2-6. Multipoint, Half-Duplex RS-485 Connection

Table 2.3-Half-Duplex Hookup (RS-485) to the Computer

PIN SIGNAL/

FUNCTION

METER (DCE)

RJ-12

COMPUTER (DTE)

D9/D25

NEW OLDER

RS-485 RS-485 BD

RX+/TX+=RX 2 1 (SEE MFG DWG)

RX-/TX-=TX 3 2 (SEE MFG DWG)

N/C or RTN - 3 (SEE MFG DWG)

RS-422/RS-485 multipoint interconnections between the computer (DTE) and the meter (DCE) are less well

defined because different computer/controller manufacturers use different pins on their D9 or D25 connectors.

Figure 2-7. Multipoint Full-Duplex RS-485 Connection

CF 125 INFINITY SC GUIDE 6 M1519/N/0605

Page 11

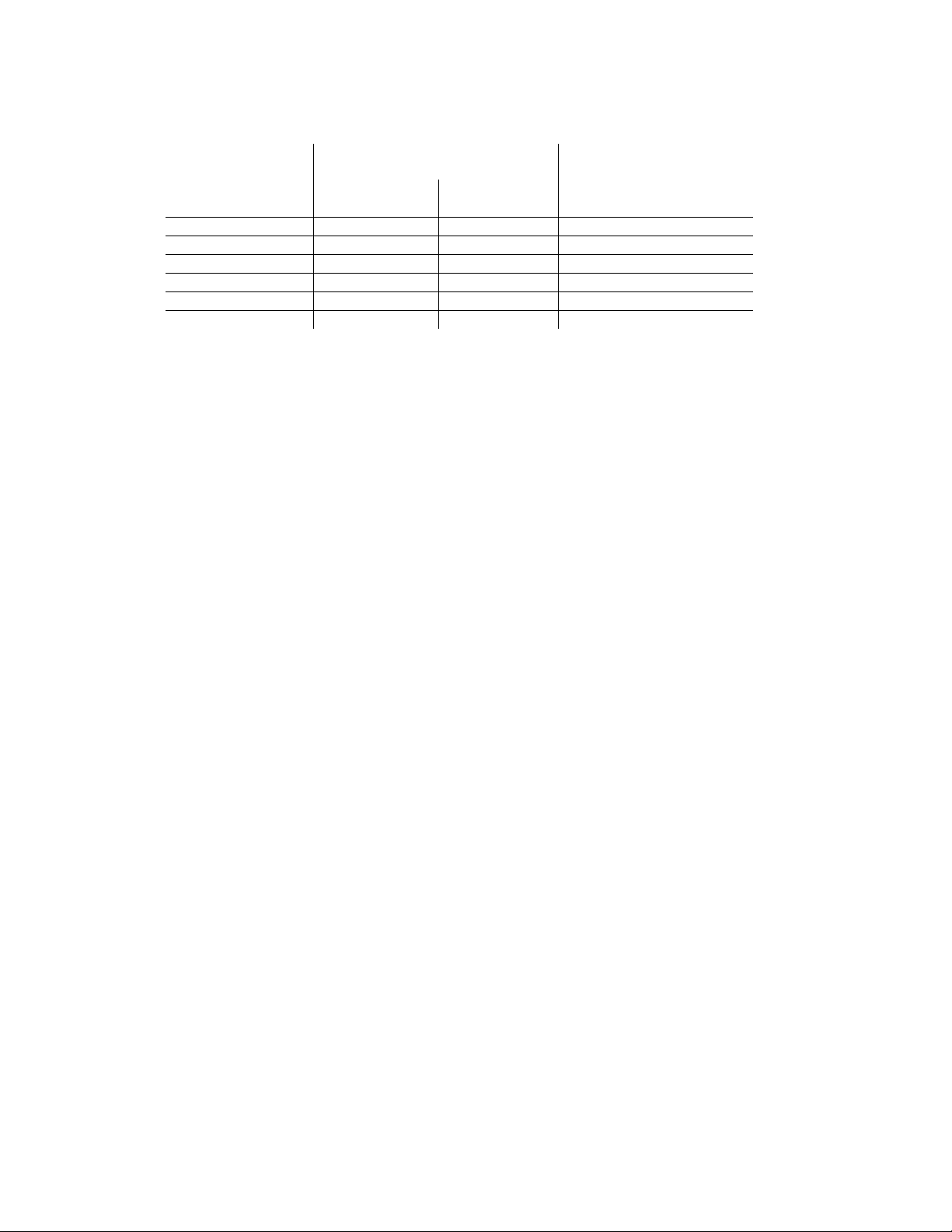

Table 2.4. Full-Duplex Hookup to the Computer

PIN SIGNAL/

FUNCTION

+TX 1 1 (SEE MFG DWG)

-TX 3 2 (SEE MFG DWG)

+RX 2 4 (SEE MFG DWG)

-RX 4 5 (SEE MFG DWG)

N/C or RTN - 3 (SEE MFG DWG)

N/C - 6

Both HALF DUPLEX (Figure 2-6) and FULL DUPLEX RS-485 (Figure 2-7) communications require a 6-wire RJ12 plug to be connected to the RJ-12 jack at the rear of the meter.

Unlike RS-232, there presently is no established standard D9 or D25 connector pin-out for RS-485; refer to your

computer or controller manual to insure the right cable connections.

NOTE: If communications with your meter has failed, it is recommended that you check for the receive portion of

the RS-485 board on DTE (computer). These lines should be pulled up for +RX and pulled down for –RX with

resistors with a resistance value from 330 ohms 1k ohms.

METER (DCE)

RJ-12

NEW OLDER

RS-485 RS-485 BD

COMPUTER (DTE)

D9/D25

3. USING THE CONFIGURATION AND COMMUNICATIONS DISKETTES

NOTE: Configuration and Communications Diskettes are furnished only with the Process, Strain, Temperature,

and Universal meters. These diskettes are not offered with the rate meter/totalizers, or batch controllers.

The diskettes provide computer-screen prompts for communication setup, control of your meter, and data

acquisition.

Although the diskette program provides for selection of many meter features, it is not designed to assist the

generation of custom-designed control and data acquisition programs: that information is given starting with

Section 4, covering the protocol, coding and format for all of the meter commands and responses.

3.1 Pushbutton Communications Setup

Although the diskette program can automatically search for the baud rate, parity and stop-bit settings that have

been set into the meter, the search is shorter if these are set to factory-preset values via the front-panel

pushbuttons.

To enter these values, first unlock the communications bits by setting all “L4 CNF” bits to equal “0”.

Next, press the ‘MENU’ button until “BAUD” is displayed, then press the ‘MIN’ button to see the previously-set

value of the baud rate (nominally “9600”). Press the ‘MAX’ button to rotate around to this nominal value, unless

some other baud rate has been selected.

Now press the ‘MENU’ button to store this choice and display “SERCNF”. Press the ‘MIN’ button to see

“SER.1=0” for no parity, “SER.1=1” for odd parity (the factory preset setting), or “SER.1=2” for even parity. If

your computer uses different parity, set the appropriate choice by pressing the ‘MAX’ button, and advance to

“SER.2” by pressing the ‘MIN’ button.

Setting “SER.2=0” picks the factory preset value of one stop bit; setting “SER.2=1” selects two stop bits.

(Note: the combination of no parity and single stop bit has fewer bits than the chosen standard. Therefore, the

meter automatically selects two stop bits when you select no parity.)

CF 125 INFINITY SC GUIDE 7 M1519/N/0605

Page 12

Pressing the ‘MENU’ button saves your choices and advances to “ADDRES”. This is used to set in an RS-485

device from address 0 to 199 and is accomplished by pressing the ‘MIN’ button to advance the digit position and

pressing ‘MAX’ button to change values. Note: For RS-232, skip over this by pressing the ‘MENU’ button.

If the communication link is in place, no more pushbutton programming is needed: the computer takes over at

this point. Follow the prompts and selections on that screen.

3.2 Diskette-Driven Computer Control

The next three communications bytes will now be set via the communications link. If not already in place,

complete the link by plugging in the telephone jack (using the furnished male/male cable and optional computercard-to-telephone-jack adapter as required.) Apply power.

Refer to the DISKETTE instructions and your computer screen. The DISKETTE program will prompt your

selections of message format. At the end of this programming, the link will advance your meter to the RUN

mode and your measurements will begin.

If the system performance is satisfactory with the diskette-driven controls, you may SKIP the rest of this Guide

(which is dedicated to the data needed for custom control and data acquisition program generation).

4. DEFINITIONS

This guide uses some abbreviations and compact wording to signify devices and concepts with detailed

descriptions. Significant items are:

4.1 Meter Or DCE

The term “METER” signifies one or more meters (or devices with compatible communications) which respond to

the commands (requests) of a controller device such as a computer. Such meters are classified as “DCE”

devices, from the older “Data Communication Equipment” telephone specifications.

4.2 Computer Or DTE

These descriptors signify the device controlling the communications, such as a computer (“HOST” device) or

programmable controller. Telephony specifications refer to controllers as “Data Terminal Equipment” or DTEs.

4.3 Point-To-Point

Direct connection between two (and only two) devices for data exchange, such as the meter and your digital

computer. No addresses are used unless the meter is programmed for a “one-meter bus”.

4.4 Multipoint (Multi-Drop)

Shared wiring for the DTE and more than on DCE, designates a “BUS”. Several panel meters and a personal

computer can share a bus, with the computer service as the controller. The controller can acquire data by

transmitting the preassigned address for a meter followed by a command for the meter to send selected

information. When used with the meter, up to 31 meters can share a bus (with addresses from 01 to decimal

199); all meters receive the data when the address is “00”.

4.5 Simplex

A channel (path, typically a twisted pair of wires) with unidirectional data flow.

4.6 Half Duplex

A channel (e.g., twisted pair) with bi-directional data flow, but only in one direction at a time.

CF 125 INFINITY SC GUIDE 8 M1519/N/0605

Page 13

4.7 Full Duplex

Two channels (e.g., two twisted pairs) with bi-directional data flow at any time (one simplex channel in each

direction).

4.8 RS-232 (CCITT V.24)

Bipolar ±5 to ±15 V point-to-point transmission for short distances and moderate data rates. The meter operates

with full-duplex RS-232, with two wires (RX and TX), plus a common ground, to transmit baud in either direction.

A third signal wire, Request To Send, is referenced to the same ground wire and is used by the computer (DTE)

to control transmissions of the meter (DCE).

Receiver sensitivity is ±3 V and impedance of 3 to 7 kilohms. (Although RS-232 is nominally for only one driver

and one receiver on the line, custom high-impedance versions exist for limited multipoint use.)

4.9 RTS

A designator for the “Request To Send” control signal from the computer, carried on a wire separate from that of

the data, and used by the meter to permit or inhibit transmissions in Continuous Mode RS-232. The other

control line of RS-232, CTS, is not used in meter communications.

4.10 RS-422

Unipolar-voltage (3.6 to 6 V supplies) simplex drive of a bus with ±2 V-differential signals (neither wire at

ground) for long distances and/or high data rate. Receiver sensitivity 200 mV, common-mode voltage range ±3

V, and impedance 4 kilohms or more. A maximum of one driver and 10 receivers allowed, with no driver

protection against bus contention. Duplex operation requires another set of hardware.

4.11 RS-485

This is the extension of RS-422 to a half or full duplex bus of up to 32 devices, with multiple drivers and drivercontention protection. Receiver impedance is now 12 kilohms or more.

4.12 ASCII

Table 4.1 shows the ASCII (American Standard Code for Information Interchange) symbols that can be encoded

in 7-bit binary code (DB0 through DB6). When organized in table form, these 7 bits may be regarded as the

symbol address, the most significant 3 bits determining the column and the last four bits determining the row.

These symbols include all the decimal numerals, letters, punctuation marks, common abbreviations and control

characters, including non-printed symbols such as Carriage Return and Line Feed.

The 7-bit symbol code (or address) is called a “character”, and digital communication with the meter is made

with a string of these characters.

When transmitted, each character is preceded by a start bit (BAUD) and followed by one or two stop bits plus an

optional parity bit, making a train of 10 or 11 baud for each transmitted character. If you are building a system

from the UART up (Universal Asynchronous Receiver/Transmitter), that device must be informed of the number

of data bits, parity, stop bit length, etc., so that it properly decodes the incoming stream into the bytes that your

program can recognize (check the UART or plug-in board literature for required control signals).

As dictated by FORMAT statements, a symbol may be sent by transmitting just its table address (one character,

plain ASCII) or by HEX-ASCII, which uses two characters, one for each of the two hex address nibbles (0

through 7 for column nibble, 0 through F for the row nibble, shown on top and left-hand side of Table 4.1).

4.13 HEX ASCII

Storage in most digital devices is in groups of 8 bits, called bytes. Each byte has a most-significant nibble (the

left most 4 bits) and a least-significant nibble.

CF 125 INFINITY SC GUIDE 9 M1519/N/0605

Page 14

To make the best use of the available storage, all possible bit sequences should be used, so each nibble can

have 16 different values (not just the ten of decimal notation). These 6 values are symbolized by 0-9 and A-F,

the hexadecimal code.

The meter transmits almost all data (shown in format statements as <data>) in this HEX-ASCII form: each byte

is broken into its two nibbles, each nibble is given its HEX symbol, and the ASCII character (table address) for

each of those two HEX symbols is then transmitted (most significant nibble first).

The transmitter and receiver must know whether a number or a non-numerical symbol is being sent by HEXASCII: this is the reason for standard FORMATs in the meter commands and responses. To illustrate this

requirement, if you decode two adjacent characters as “0110100” (the code for the symbol “4”) and “1000001”

(the code for the symbol “A”), do you print “4A” or do you print the symbol whose hex table address is 4A, the

letter “J”? The format statements tell you which is which.

The responses to “V” and “X” commands encode the numerical <data> in HEX-ASCII, but use decimal (BCD)

nibbles (4 bits per decimal digit), storing these two BCD digits per byte (rather than 8 bits of straight binary).

Decoding to decimal is then simplified for receiving devices such as printers.

“V” and “X” commands also use a single plain ASCII character for each “-“, “.”, and units-of-measure symbols, in

contrast to the “G, P, R or W” commands and responses, which encode everything in HEX-ASCII, 2 characters

to the byte.

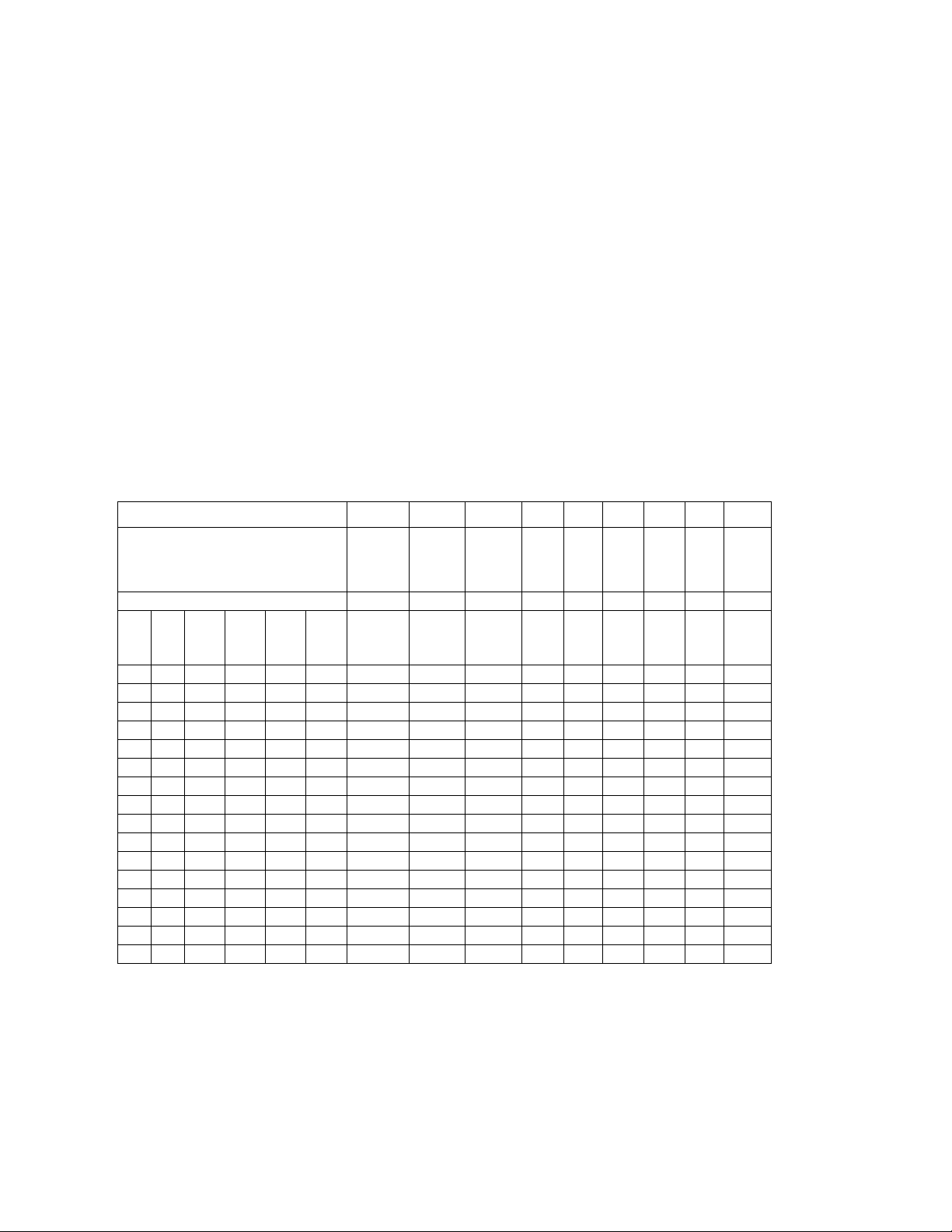

Table 4.1. The ASCII Character Code

COL 0 1 2 3 4 5 6 7

DB6= 0 0 0 0 1 1 1 1

ROW

H

D

D

D

D

E

E

B

B

B

X

C

3

2

1

0 0 0 0 0 0 NUL DLE SP 0 @ P ‘ p

1 1 0 0 0 1 SOH DC1 ! 1 A Q a q

2 2 0 0 1 0 STX DC2 “ 2 B R b r

3 3 0 0 1 1 ETX DC3 # 3 C S c s

4 4 0 1 0 0 EOT DC4 $ 4 D T d t

5 5 0 1 0 1 ENQ NAK % 5 E U e u

6 6 0 1 1 0 ACK SYN & 6 F V f v

7 7 0 1 1 1 BEL ETB ‘ 7 G W g w

8 8 1 0 0 0 BS CAN ( 8 H X h x

9 9 1 0 0 1 HT EM ) 9 I Y i y

A 10 1 0 1 0 LF SUB * : J Z j z

B 11 1 0 1 1 VT ESC + ; K [ k {

C 12 1 1 0 0 FF FS , < L \ l l

D 13 1 1 0 1 CR GS - = M ] m }

E 14 1 1 1 0 SO RS . > N ^ n ~

F 15 1 1 1 1 SI US / ? O - o DEL

Non-numeric symbols (e.g., letters) or unprinted characters that are sent in hex data strings are transmitted as

the two characters of their hex address; e.g., “*” is “2A”, Carriage Return is “0D”, Line feed is “0A”, XON=DC1 is

“11”, and XOFF=DC2 is “13”.

DB5= 0 0 1 1 0 0 1 1

DB4= 0 1 0 1 0 1 0 1

D

B

0

4.14 Transmission Voltage Levels

The voltage levels accepted by the meter are those of the standards, and the meter outputs are well regulated

and well within the standards. The two wires carrying the signal are designated “A” and “B”; for RS-232, “B” is

taken as the 0 V ground.

CF 125 INFINITY SC GUIDE 10 M1519/N/0605

Page 15

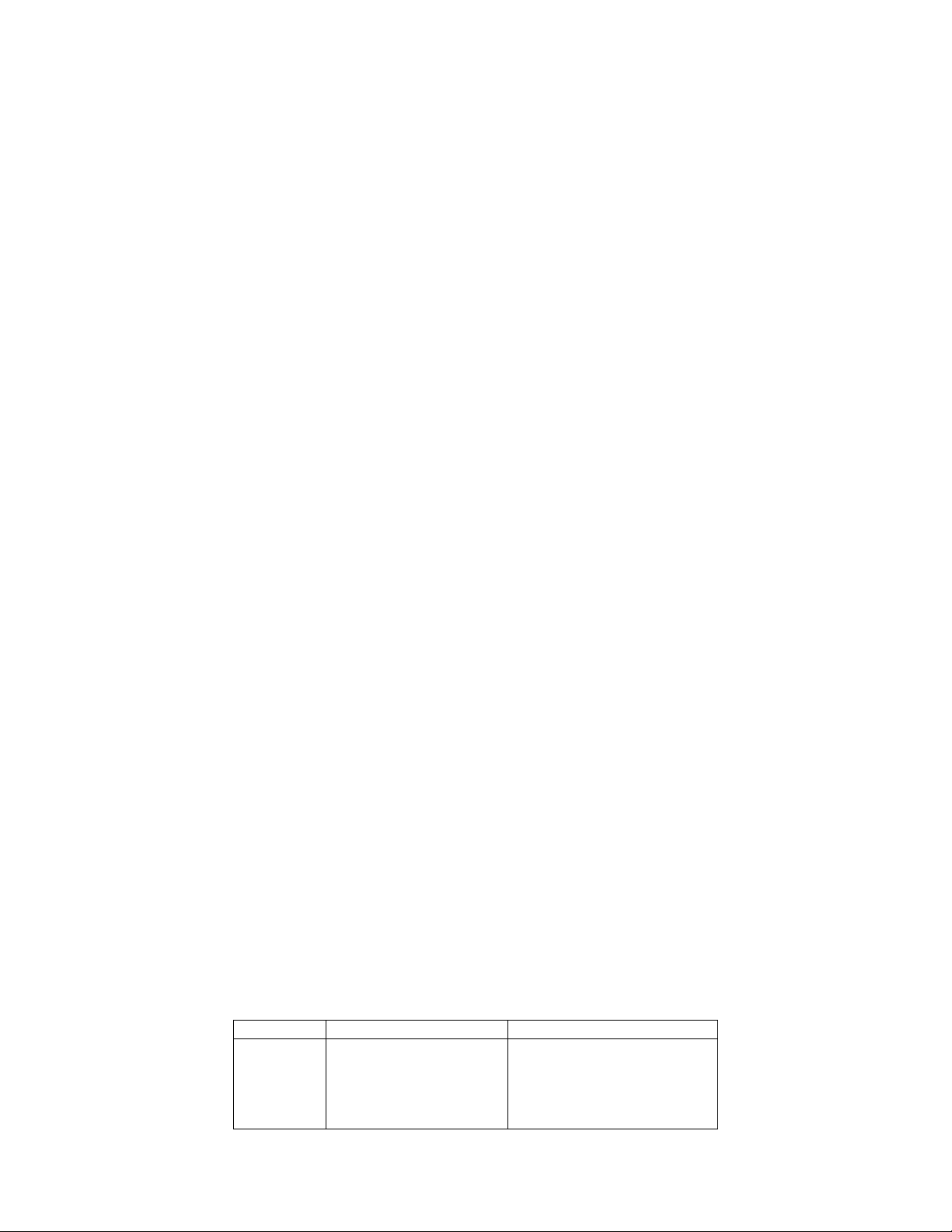

Table 4.2 Meter Receiving Voltages

“1” BIT/MARK

OPTION TYPE

RS-232

RS-422 OR 485

Table 4.3. Meter Transmitting Voltages

OPTION TYPE

RS-232

RS-422 or 485

The RS-422/485 transmissions from the meter are 3-state, and both receive and transmit are zener-protected.

OR STOP BIT

-3 > A > -15 V

A< (B-0.2 V)

“1” BIT/MARK

OR STOP BIT

-6 > A > -7 V

A < (B-2 V)

“0” BIT/SPACE OR

START BIT

+3 < A < +15 V

A > (B+0.2 V)

“0” BIT/SPACE OR

START BIT

+6 < A < +7 V

A > (B+2 V)

4.15 Recognition Character

A selectable symbol (e.g., the asterisk, *) transmitted as the first character of each message from the computer,

which is used for message security: the meter ignores messages without this symbol.

4.16 RAM

The acronym for “Random Access Memory”. For the meter, the storage for the data and instructions for the

immediately occurring operation. When given a “RESET1” or “soft” reset, the meter restarts its operation from

the data in RAM. “PUT” commands insert information from the computer into RAM, and “GET” commands

transmit RAM information to the computer.

4.17 EEPROM

The acronym for “Electrically Erasable Programmable Read-Only Memory”. For the meter, the non-volatile

memory for the setup and configuration data is retained independent of power or resets. Upon a “RESET2” or

“hard” reset (e.g., after any BLOCK WRITE command), the data in the EEPROM is copied into RAM, discarding

whatever data had been running. “WRITE” commands insert information from the computer into EEPROM, and

“READ” commands transmit EEPROM data to the computer.

5. BAUD RATES

The meter can operate at any rate from 300 to 19,200 in 2:1 steps. Following are the baud rates used by the

meter:

300, 600, 1200, 2400, 4800, 9600, and 19200.

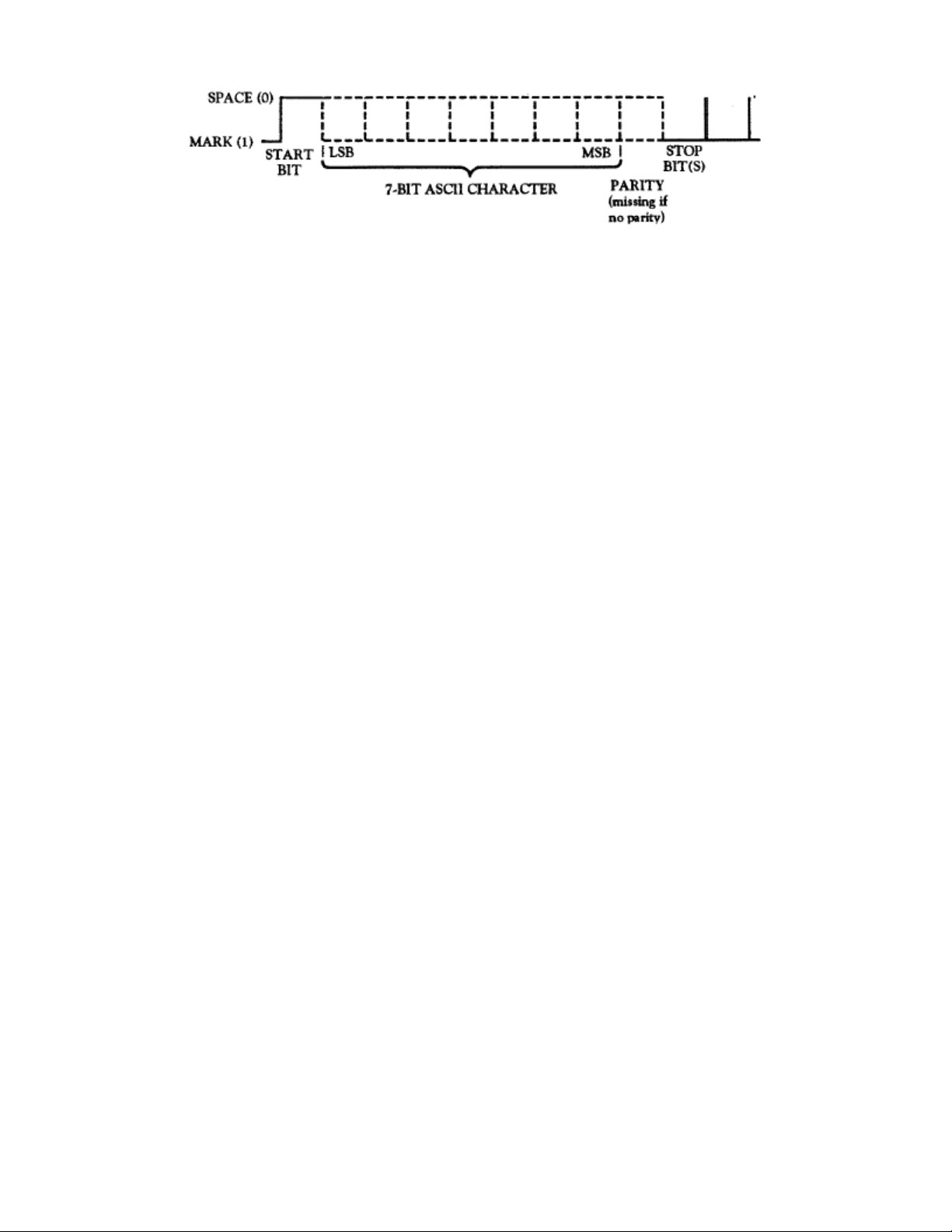

6. CHARACTER WAVEFORM

Ten or eleven bits are used for each character: a start bit, 7 bits for the ASCII character, one parity bit, and

either one or two stop bits. If the parity bit is chosen as “none” (absent), the stop length is automatically set at

two bits by the meter (to keep the minimum character length to ten bits).

Figure 6-1 shows the mark/space sequence.

CF 125 INFINITY SC GUIDE 11 M1519/N/0605

Page 16

Figure 6-1. Character Waveform

The rising edge of the start bit of the next character may occur at any time after the end of the last stop bit.

7. CLASSES OF OPERATION

There are two (2) classes of operation associated with meter serial communications: Point-to-point and

Multipoint. (Refer to section 10.19 for Process, Temperature, Strain Gauge and Universal meters and Section

11.25 for Rate Meter, Totalizer and Batch meters.)

7.1 Point-To-Point

No device address is included in the command or response message when operating in this class. There are

two (2) modes associated with this class; CONTINUOUS and COMMAND.

7.1.1 Continuous Mode

For RS-232, the computer can direct the meter to repeatedly transmit the data and status information in the

format specified by the communications setup (which includes a selectable parameter to space out the

transmissions for data logging purposes).

Continuous mode is not used on RS-422/485, because no RTS line is present to prevent bus contention.

However, you can use one meter using a RS-485 board by configuring the meter for point-to-point continuous

mode, and configure it so that it is enabled at all times. This will result in allowing for transmission to be sent for

longer distances to such devices as large remote displays.

Control of the continuous mode is by RTS level. Either message or character control can be specified. In the

former case, RTS polarity is checked by the meter before a message is begun, but, once started, the

transmission continues to the end of the specified message. In the latter case, RTS polarity is checked before

each character transmission, so that the meter message can be interrupted after any character.

The specified data and status are transmitted for each new measurement (if so requested), provided that the

selected baud rate and message length are adequate. If the message transmission takes longer, complete

messages are sent as fast as possible, skipping any readings overlapped by a message transmission.

7.1.1.1 Message Handshake The RTS line from the host controller is checked when the device is ready to send measurement data. If the

RTS is true, it sends the complete message data without interruption eve if RTS goes false in the middle of

transmission. If RTS is false, it skips sending the data completely and continues with the next measurement.

7.1.1.2 Character Handshake The device checks the RTS input before sending each character and sends characters only while RTS is true. It

always completes sending the data before transferring the late reading to the output buffer.

7.1.2 Command Mode

In this mode, no handshake line is used, but instead a simple command from the host requests that the device

transmit its latest measurement message.

CF 125 INFINITY SC GUIDE 12 M1519/N/0605

Page 17

7.2 Multipoint

A device address from 0 to 199 is included in the COMMAND or RESPONSE message. By using the

addressing capabilities, collision on the bus can be avoided. If “00” is used for the address on multiple units,

they will all receive the COMMAND but will not respond. This is issued to avoid collisions on the bus. There are

two (2) modes available in the class; COMMAND MODE and ALARM MODE.

NOTE: NO RTS handshaking is available with Multipoint.

7.2.1 Command Mode

Each device, when it receives an addressed command, checks the received address. If it matches its own preselected address, the device responds by fulfilling the command. After a programmed turnaround delay time, it

may transmit either an acknowledgement and/or the requested data, or may have no response. If the address

does not match, the command is ignored. The programmed turnaround time delay allows for line reflections to

dissipate and for the transmitting host controller to switch to the receive mode. The turnaround time delay

choices are 0,30,100 and 300 milliseconds with a 3 ms uncertainty.

7.2.2 Alarm Mode

All devices can be put into the alarm mode simultaneously by a single address 00 command. In the alarm

mode, the bus is quiet until one of the devices detects and alarm condition. It then transmits its address onto

the bus and goes out of the alarm mode. When other devices detect a character on the bus, they too go out of

the alarm mode. The host program, which may have been performing an unrelated task, is then interrupted by

receipt of a character and after a short delay, starts polling all devices. It begins with the received address

device. All devices are polled in case two or more have reached an alarm condition at or near the same time. If

this happens, it can cause bus contention, corrupted characters or framing errors. However, none of these

results in system failure because any bus activity causes all devices to exit the alarm mode and the host

program to perform the alarm poll. After identifying the alarm device(s), the alarm can be reset and the host

controller can put the devices back into the alarm mode. It is suggested that the host controller polls all of the

devices when ready to send the common alarm mode and sends it only if all alarms are inactive. This reduces

the probability of two or more devices being ready to transmit on the bus simultaneously when the alarm mode

is entered due to existing alarm conditions.

7.3 The Meter As A Remote Display

NOTE: The Remote Display Mode pertains only to the Process, Strain Gauge, Temperature and Universal

meters. This feature is not available in the Rate meter/Totalizer or Batch controller units.

The meter has the capability to become a remote display. While in this mode, it can accept any word with 1 to 6

letters (7 including one decimal point). Valid characters are: numbers from 0-9, uppercase letters from A-Z,

space, period, “/”, “-“, “+”, “,” and “*”. Upon receiving the proper commands from the host controller, the meter

will switch to the REMOTE DISPLAY mode and display whatever has been transmitted to it.

NOTE: The meter will continue to operate normally during this mode.

As an example, try to write, “Hello my name is Bob” to the meter number 25 decimal (19 hex) on the RS-485

network. Assume “*” is the meter’s recognition character.

Transmit according to the following steps:

1) *19Y01HELLO<CR>

2) *19Y01MY<CR>

3) *19Y01NAME<CR>

4) *19Y01IS BOB<CR>

(You would want to generate a proper delay between each step.)

To go back to “RUN” mode, use the following command:

*19D03<CR>

(See Section 8 for more information on commands).

CF 125 INFINITY SC GUIDE 13 M1519/N/0605

Page 18

7.4 The Meter As A Double Tasking Remote Meter

The Process, Strain Gauge, Temperature and Universal meters can be configured as a double tasking remote

indicator/controller. This is accomplished by transmitting any value (In HEX format Only!) from “-99999 to

999999” (and any decimal point position between 1 to 6) to the meter. The value transmitted will be the meter’s

Reading Value, which allows you to display any value desired and assign a setpoint as well as set up the value

of this setpoint. The meter can also be configured to output this value via the optional analog or BCD output

boards. The double tasking is accomplished during this operation, the meter will continue to operate normally

and the Filtered Value is the value used for normal operation.

NOTE: For comparing the transmitted value with any setpoint, the decimal point of the value should be equal to

the meter’s decimal point position.

7.4.1 Command Structure For Double Tasking

The general command structure for this mode is as follows:

*[nn]Y02<DATA><CR>

Where: * =The recognition character

nn =Device address (Required for multipoint mode only)

Y02 =Command index

DATA =3 byte Hexadecimal based (24 bits) value as:

First 20 bits are the absolute value (Maximum is 999999 when positive and 99999 when negative)

Bits 21, 22, 23 are assigned to the decimal point as shown below:

BIT NO.

23 22 21

0

0

0

0

1

1

1

1

*10 to the power of the value

Bit 24 is the polarity sign

0=Positive

1=Negative

EXAMPLE: To send a value of “-23.468” to the meter, you must first send the meter number which is 15 HEX

with “*” as the recognition character. The following is the itemized list of the required variables that must be sent

via HEXADECIMAL:

Absolute value is 23468 and its HEX equivalent is “5BAC” Decimal value will be “100 BINARY” and HEX

equivalent is “4HEX”.

Sign is negative and must be sent as “1” and therefore bits 21, 22, 23, and 24 (or most significant nibble will be

1100 binary or “C” HEX. Combine this with value and you have “DATA” with a Hexadecimal equivalent of

“C05BAC”.

The complete command for this example is as follows:

“*15Y02C05BAC<CR>”

0

0

1

1

0

0

1

1

0

1

0

1

0

1

0

1

DECIMAL VALUE*

Not used

-0

-1

-2

-3

-4

-5

Not used

CF 125 INFINITY SC GUIDE 14 M1519/N/0605

Page 19

8. COMMAND AND RESPONSE STRUCTURE

8.1 Message String

8.1.1 “Data” and “Non Data”

Each of the many types of messages between computer or printer and the meter is transmitted or received as a

string of ASCII characters. There characters are classified as “DATA” and NON DATA”.

“DATA” is the string of measurement or non-measurement values (see Section 8.2 and 8.3) and can be

classified as:

<data>: hexadecimal based values. Each nibble is converted to the ASCII character and transmitted or

received.

>: is alphanumeric plain ASCII characters and need not be converted. It is used in Remote Display Mode.

<data

<value> is data which is transmitted against “X”, “V01” or external print commands. These are in decimal base,

and each digit is converted to the ASCII character and transmitted along with decimal point and sign.

“NON DATA” items are: recognition character (*), device address (nn), command prefix letter (c), command

suffix (cc), space (S or SP), carriage return (CR), line feed (LF), checksum (hh), and units of measure (uuu).

Checksum, device address, and command suffix (cc) items are hexadecimal base, and each nibble will be

converted to the ASCII character and transmitted. The rest of the “NON DATA” items are plain ASCII characters

and need not be converted (see examples in Section 8.8).

8.1.2 Brackets and Spaces

In the following text the position reserved for each ASCII character is represented by a lower-case letter.

If there must always be an ASCII character put into the message at that position, no brackets are used.

Angle brackets, “<” and “>”, are used to enclose names (or acronyms). In the actual message these names will

be replaced by the ASCII value of that name (the number of those ASCII characters is not usually the same as

the number of letters of the name inside the angle brackets).

The occurrence of non-printing ASCII characters is also indicated by angle brackets (e.g., “<CR>”).

Square brackets, “[“ and “]”, enclose items which are optional, i.e. the message is still valid when those are

omitted.

8.2 Commands and Structure

The meter responds to over 150 different commands from the computer. This section gives the format and lists

all commands by COMMAND CLASS and COMMAND SUFFIX.

8.2.1 Read Communications Configuration Command

To have the meter report its current communication parameters, the special command “^AE” is provided when

transmitted to the meter with the correct baud rate, parity information, stop bit(s), and address (if multipoint). The

meter will return 4 bytes (9 characters including carriage return) of information as follows:

Byte #1 = Recognition character

Byte #2 = Meter address

Byte #3 = Bus Format

Byte #4 = Communications Configuration

NOTE: This “Read Only” command is the only one without a leading recognition character.

Command format:

^AE<CR> for point-to-point,

or

^AE[nn]<CR> for multipoint

CF 125 INFINITY SC GUIDE 15 M1519/N/0605

Page 20

where nn = device address from 01 to C7 (hex) = 01 to 199 decimal.

NOTE: Response detail is given in Section 8.8 and 8.9.

8.2.2 General Command Structure

The meter can be commanded to “read”, i.e. to transmit (send) data from either the nonvolatile memory

(EEPROM) or from the volatile working memory (RAM). The meter can also be commanded to “write”, i.e. store

new values for data processing or meter control.

There are different command types associated in communicating with your meter as follows:

Type (1) Commands which return non-measurement data from the meter are “R” and “G”.

Type (2) Commands which return measurement data from the meter are “X” and “V”.

Type (3) Commands which return status character data from the meter is “U”.

Type (4) Commands send non0measurement data to the meter are “P”, “W”, and “Y” (for Process, Strain

Gauge, Temperature and Universal meters only).

Type (5) Commands for disable, enable, and reset are “D”, “E”, and “Z”.

Table 8.1 Command Prefix Letters (Command Classes)

COMMAND PREFIX

(COMMAND CLASS)

^AE Special read, communications parameters

P (Put) Write HEX data into RAM

W (Write) Write HEX data into EEPROM

G (Get) Read HEX data from RAM

R (Read) Read HEX data from EEPROM

U Read status byte

V Read measurement data string in decimal format

X Read measurement data values in decimal format

D Disable

E Enable

Z Reset

Y (temp/process/strain

meters only)

Write characters or values to the meter

MEANING

8.2.3 Command Formats

For “P” and “W” Command classes:

a) Point-to-point mode:

*ccc<data>[hh]<CR>

b) Multipoint mode:

*nnccc[<data>][hh]<CR>

For “G” and “R” Command classes:

a) Point-to-point mode:

*ccc[hh]<CR>

b) Multipoint mode:

*nnccc[hh]<CR>

For “X”, “V”, “U”, “D”, “E” and “Z” Command classes:

a) Point-to-point mode:

*ccc[hh]<CR>

CF 125 INFINITY SC GUIDE 16 M1519/N/0605

Page 21

b) Multipoint mode:

*nnccc[hh]<CR>

For “Y” Command (Process, Strain Gauge, Temperature and Universal meters only):

Remote Display

a) Point-to-point mode:

*Y01<data

b) Multipoint mode:

*nnY01<data><CR>

Remote Indicator Controller

a) Point-to-point mode:

*Y02<data><CR>

b) Multipoint mode:

*nnY02<data><CR>

Where “*” is the selected Recognition Character, you may select any ASCII table symbol from “!” (hex address

“21”) to the right-hand brace (hex “7D”) except for the caret “^”, “A”, “E”, which are reserved for bus format

request.

“[nn]” are the two ASCII characters for the device Bus Address. Use values from “00” to hex “C7” (199 decimal).

“ccc” stands for the HEX-ASCII COMMAND CLASS letter (one of twelve given in Table 8.1) followed by the two

HEX-ASCII COMMAND SUFFIX characters identifying the meter data, feature or menu items to which the

command is directed (given in Table 8.2).

“<data>” is the string of characters containing the variable information the computer is sending to the meter.

These data (whether BCD or binary) are encoded into HEX-ASCII characters, two characters to the byte, except

for the “Y01”, “write to the display” command: here, the desired display upper-case letters, numbers or (limited)

symbols are transmitted by plain ASCII characters. Square brackets (indicating optional status) enclose this

<data> string, since some commands contain no data.

“[hh]” is the optional CHECKSUM BYTE, two HEX-ASCII characters equal to the modulo 256 sum of all the

preceding bytes including the serial recognition character. Each addition to this sum uses the ASCII 7 bits plus

the parity bit as the most significant bit. Any carry (overflow) bits are discarded. The checksum is transmitted

most-significant character first.

Message errors can be discovered by computing the checksum from the received bytes and comparing that

total with the transmitted checksum. However, most systems have a good signal-to-noise ratio, so that

checksum errors are rare and the procedure is infrequently used.

><CR>

8.2.4 Command Suffix

The two HEX characters following the command class letter are used to specify the data, features or menu

items that the command affects. Table 8.2 gives the command letter, suffix, feature affected, and the number of

data characters included in the command.

“00” is not used (reserved for the all-device bus address).

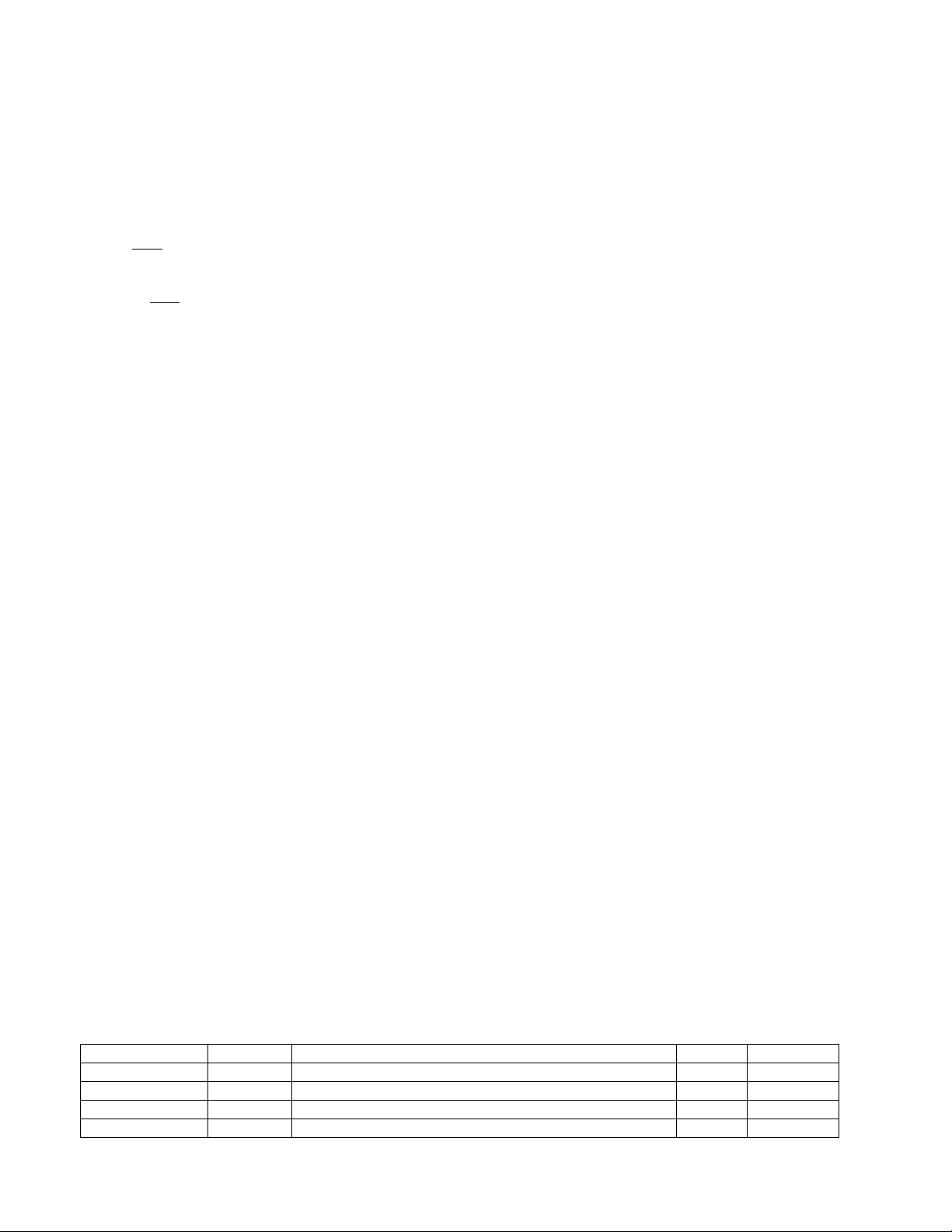

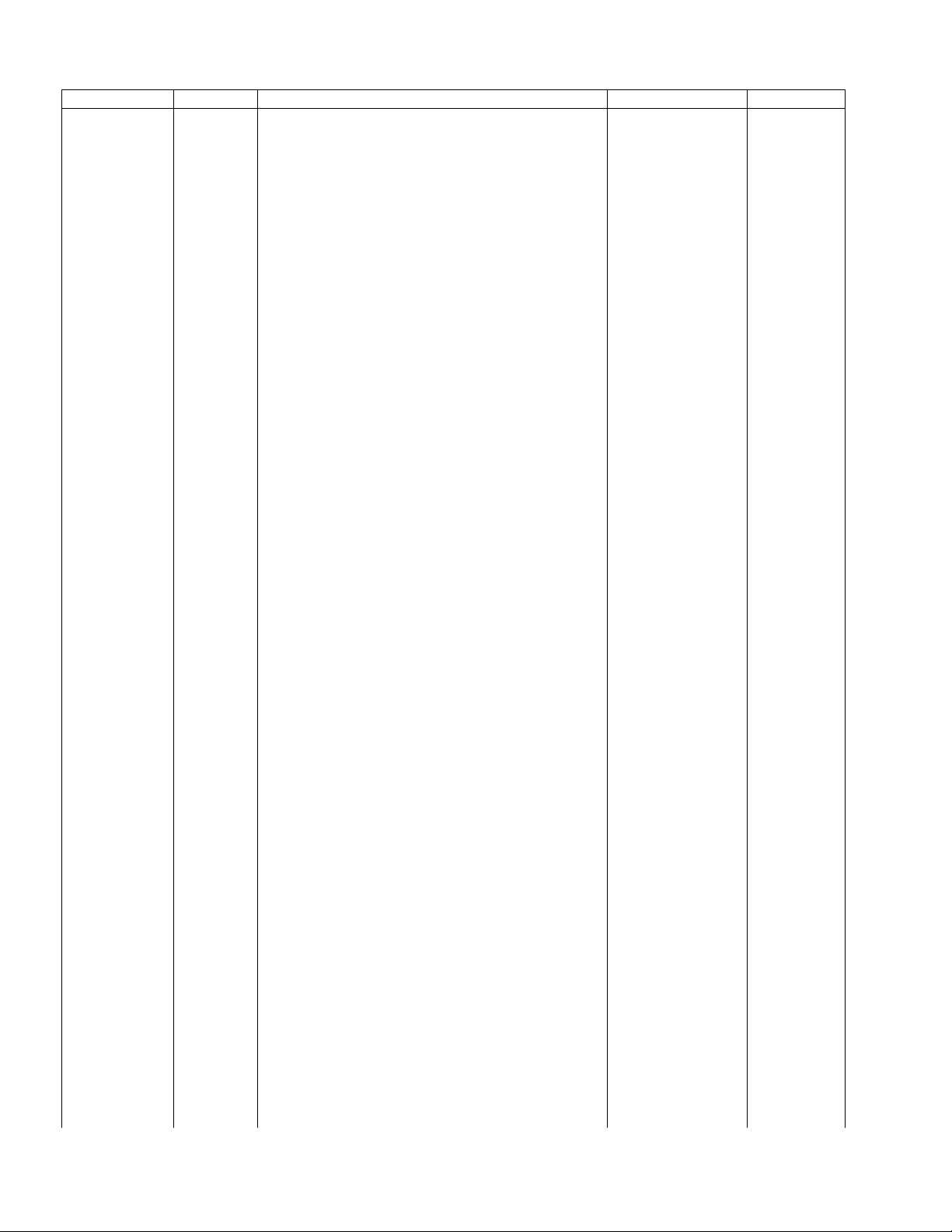

Table 8.2. Command Letters and Suffixes for Temperature/Process/Strain/Universal Meters

Command Suffix Item affected #Char Section

D 01 Disable alarms (SP#3 and SP#4) 0 8.2.3

E 01 Enable alarms (SP#3 and SP#4) 0 8.2.3

R,W 01 L1 CNF, Lockout byte #1 2 10.1

U 01 Setpoints and Alarm statue 0 8.2.3

CF 125 INFINITY SC GUIDE 17 M1519/N/0605

Page 22

Command Suffix Item affected #Char Section

V 01 Read data string 0 8.2.3

X 01 Read unfiltered value 0 8.2.3

Y 01 Write value to display 6 8.2.3

Z 01 Reset latched alarms 0 8.2.3

D 02 Disable setpoints 1 and 2 0 8.2.3

E 02 Enable setpoints 1 and 2 0 8.2.3

R, W 02 L2 CNF, Lockout byte #2 2 10.1

U 02 Peak/Valley (HI/LO) status 0 8.2.3

X 02 Read peak (HI) value 0 8.2.3

X Y02 Write value to meter 7 8.2.3

Z 02 Reset averaging filter 0 8.2.3

D 03 Disable display of remote value 0 8.2.3

E 03 Set alarm mode 0 7.2.2

R, W 03 L3 CNF, lockout byte #3 2 10.1

U 03 Microprocessor Revision 0 8.2.3

X 03 Read valley (LO) value 0 8.2.3

Z 03 Soft reset (RESET1, from RAM) 0 8.2.3

D 04 Hold displayed value 0 8.2.3

E 04 Display “RUN” 0 8.2.3

R, W 04 L4 CNF, lockout byte #4 2 10.1

X 04 Read filtered value 0 8.2.3

Z 04 Hard reset (RESET2, from EEPROM) 0 8.2.3

D 05 Reset tare, valid only on strain meter 0 8.2.3

E 05 TARE, valid only on strain meter 0 8.2.3

G, P, R, W 05 INPUT, type and range 2 10.1

Z 05 Reset Peak/Valley (HI/LO) 0 8.2.3

G, P, R, W 07 RDG.CNF display controls 2 10.3

G, P, R, W 08 RDG SC, display scale factor 6 10.4

G, P, R, W 09 RDG OF, display offset 6 10.5

G, P, R, W 0A IN CNF, meter features 2 10.6

G, P, R, W 0B INP SC, input scale factor 6 10.4

G, P, R, W 0C DEC PT and CNT BY (roundoff) 2 10.7

G, P, R, W 0E FIL.CNF and FIL TI, filter #’s 2 10.8

G, P, R, W 10 SP CNF, control setpoints 1 and 2 2 10.9

G, P, R, W 11 AL CNF, control setpoints 3 and 4 2 10.10

G, P, R, W 12 AL FNC, alarm function 2 10.11

G, P, R, W 13 AL RDG, # readings delayed 2 10.12

R, W 14 SP DB, setpoint hysteresis 4 10.13

R, W 15 AL DB, alarm hysteresis 4 10.14

G, P, R, W 16 OUT.CNF, analog out and flashing 2 10.15

G, P, R, W 17 OUT SC, analog out scale 6 10.4

R, W 18 SER.CNF, communications configuration 2 10.16

G, P, R, W 1A ADDRES, RS-485 device # address 2 10.17

G, P, R, W 1B DAT FT, communication data format 2 10.18

G, P, R, W 1C BUS FT, communications BUS format 2 10.19

R, W 1D SER CNT, # of readings between each transmission 4 10.20

G, P, R, W 1E SER.RCG, recognition character 2 10.21

G, P, R, W 1F SER.UOM, units of measure 6 10.22

R, W 20 SER.DLY, communication turnaround delay 2 10.23

G, P, R, W 21 SP 1, setpoint 1 value 6 10.24

G, P, R, W 22 SP 2, setpoint 2 value 6 10.24

G, P, R, W 23 SP 3, setpoint 3 value 6 10.24

G, P, R, W 24 SP 4, setpoint 4 value 6 10.24

G, P, R, W 25 INP OF, input offset 6 10.5

G, P, R, W 26 OUT OF, analog output offset 6 10.5

CF 125 INFINITY SC GUIDE 18 M1519/N/0605

Page 23

Command Suffix Item affected #Char Section

G, P, R, W 40 RAM or EEPROM BLOCK A 60 10.25.1

G, P, R, W 41 RAM or EEPROM BLOCK B 38 10.25.2

R, W 42 EEPROM BLOCK C 20 10.25.3

R, W 43 EEPROM BLOCK D -

R, W 44 EEPROM BLOCK E -

R, W 45 EEPROM BLOCK F -

NOTES:

Each BLOCK is the string of HEX-ASCII data that is produced by he concatenation of the data for single items

listed below:

BLOCK A=

26+17+25+0B+09+08+24+23+22+21

BLOCK B=

1E+1F+20+1A+18+13+12+11+10+05+0C+16+07+1C+1B+0E+0A

BLOCK C=

1D+15+14+04+03+02+01

BLOCKS D, E AND F are meter factory calibration values described in the separate “METER CALIBRATION

MANUAL”. (Adjustment of these values should be made with care, preferably using a well-equipped calibration

laboratory.)

Suffixes 06, 0D, 0F, and 19 are not used: the meter will respond to these with an error message.

The meter, upon completion of a BLOCK PUT (into RAM) Command, goes to soft reset, “RESET1”, which does

not copy EEPROM data into RAM.

Upon completion of a BLOCK WRITE (into EEPROM) Command, however, the meter goes to hard reset,

“RESET2”, copying the data from EEPROM into the working RAM. Single PUT (or WRITE) commands do not

interrupt the measurement process of the meter, even when the changes are to scale or offset values.

<data> encoding for W

rite and Put Commands will be described in Section 10 with each Read and Get

response.

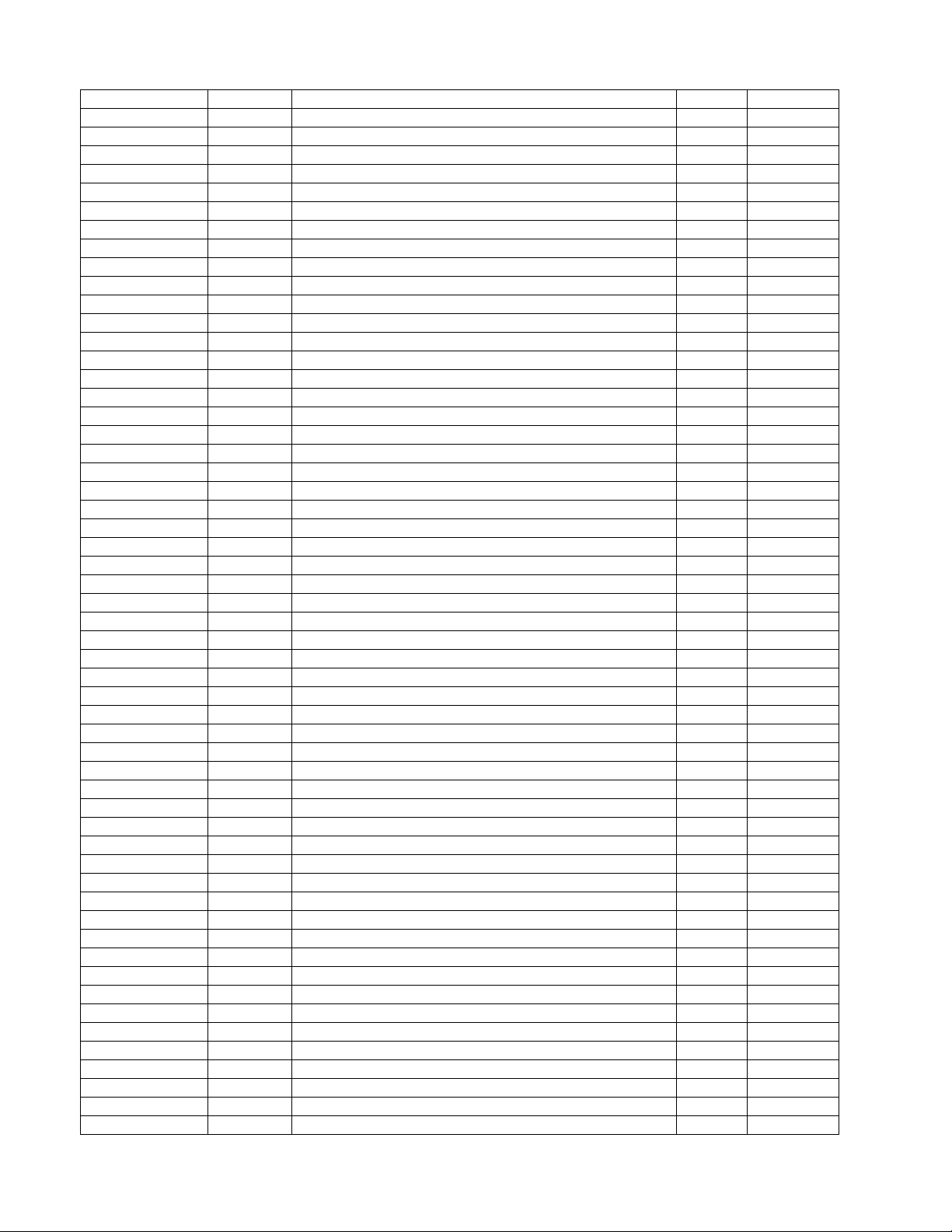

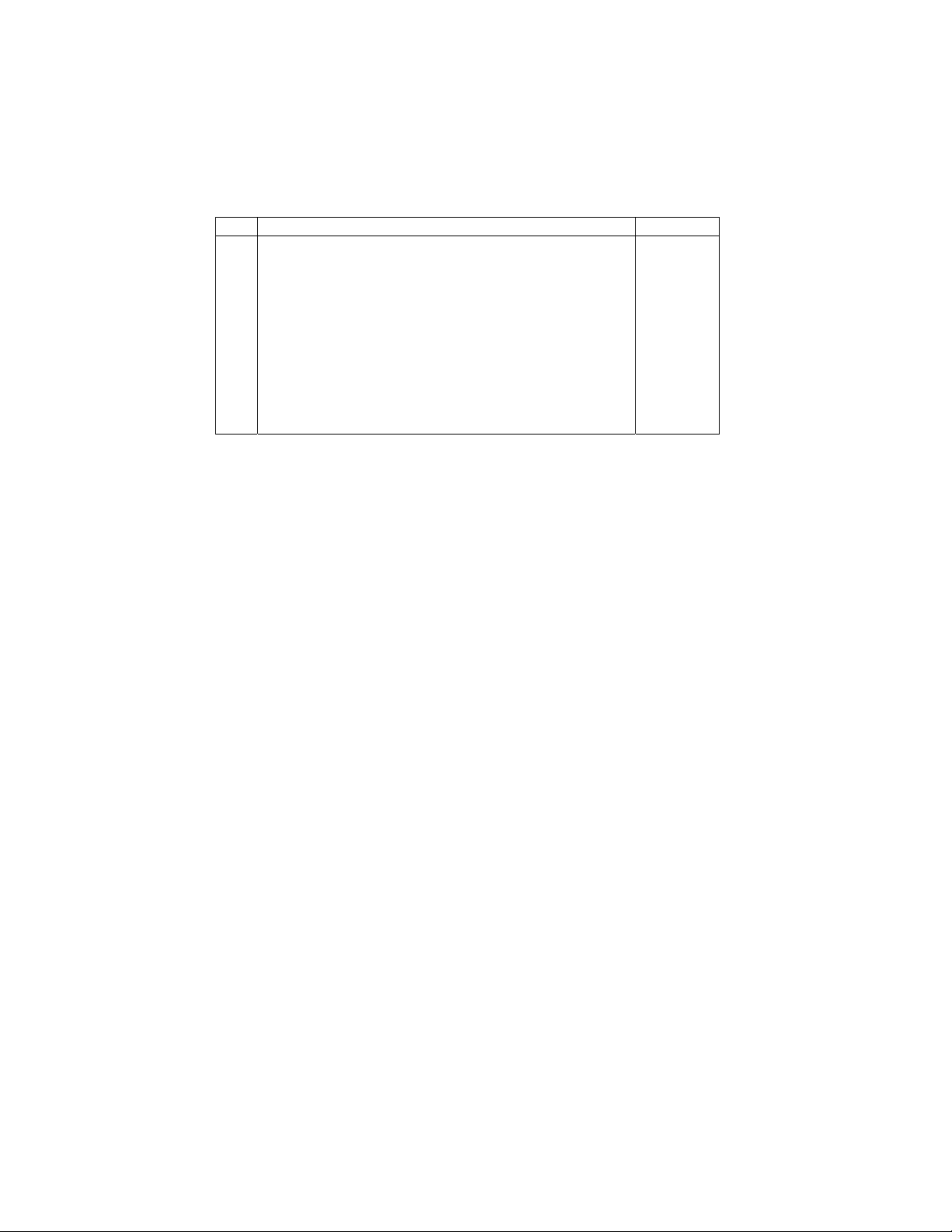

Table 8.3. Command Letters and Suffixes for Rate Meter/Totalizers

COMMAND SUFFIX ITEM AFFECTED # CHAR SECTION

D 01 Disable setpoints (SP1-SP5) - 8.2.3

E 01 Enable setpoints (SP1-SP5) - 8.2.3

G,P,R,W 01 Setpoint 1 value 6 11.16

U 01 Setpoints status 1 8.2.3

V 01 Read data string Variable 8.2.3

X 01 Read batch (rate) value 7 8.2.3

Z 01 Reset A - 8.2.3

D 02 Display hold - 8.2.3

E 02 Display RUN - 8.2.3

G,P,R,W 02 Setpoint 2 value 6 11.16

X 02 Read No. of batches (AV.RTE) 7 8.2.3

Z 02 Reset B - 8.2.3

D 03 Display brightness is 50% of normal - 8.2.3

E 03 Display brightness is normal - 8.2.3

G,P,R,W 03 Setpoint 3 value 6 11.16

U 03 Microprocessor Revision 1 8.2.3

X 03 Read TOTAL value 7 8.2.3

Z 03 Reset C - 8.2.3

D 04 Stop (only in Batch mode) - 8.2.3

CF 125 INFINITY SC GUIDE 19 M1519/N/0605

Page 24

COMMAND SUFFIX ITEM AFFECTED # CHAR SECTION

E 04 Set alarm mode - 7.2.2

G,P,R,W 04 Setpoint 4 value 6 11.16

X 04 Read time value 8 8.2.3

Z 04 Reset LATCHED setpoints - 8.2.3

E 05 Start (Batch mode only) - 8.2.3

G,P,R,W 05 Setpoint 5 value 6 11.17

Z 05 Power On reset (Hard reset) - 8.2.3

G,P,R,W 06 L1 CNF (Lockout byte 1) 2 11.1

G,P,R,W 07 L2 CNF (Lockout byte 2) 2 11.1

G,P,R,W 08 L3 CNF (Lockout byte 3) 2 11.1

R,W 09 MODE (operational mode) 2 11.2

G,P,R,W 0A CONFG 1 (Configuration 1) 2 11.4

G,P,R,W 0B CONFG 2 (Configuration 2) 2 11.5

G,P,R,W 0C CONFG 3 (Configuration 3) 6 11.6

G,P,R,W 0D CONFG 4 (Configuration 4) 2 11.7

G,P,R,W 0E AV.CNF (Average configuration only available

2 11.8

for rate or square-root rate)

G,P,R,W 11 Bat DP (Batch decimal point ) or

2 11.13

RTE DP (Rate decimal point)

G,P,R,W 12 B.LOAD (Batch load) or

6 11.14

RTE OF (Rate Offset)

G,P,R,W 13 BAT SC (Batch Scale) or

6 11.14

RTE SC (Rate Scale)

G,P,R,W 14 TOT DP (Total decimal point) 2 11.13

G,P,R,W 15 TOT OF (Total offset) 6 11.14

G,P,R,W 16 TOT SC (Total Scale) 6 11.14

G,P,R,W 17 AL TI (Alarm time) 4 11.11

G,P,R,W 18 GATE T (Gate time) 2 11.9

R,W 19 Baud rate 2 11.22

R,W 1A SER.CNF (Serial Communication Configuration) 2 11.23

G,P,R,W 1B DAT FT (Communication Bus Format) 2 11.24

G,P,R,W 1C BUS FT (Communications Bus Format) 2 11.25

G,P,R,W 1D ADDRES (RS-485 device # address) 2 11.26

G,P,R,W 1E SER TI (time between each transmission) 4 11.27

R,W 1F SET TI (Set time) 6 11.18

G,P,R,W 20 Pulsed setpoint number 2 11.10

G,P,R,W 21 Scale operator 2 11.15

G,P,R,W 22 Input Scale 6 11.12

G,P,R,W 23 Input Offset 6 11.12

G,P,R,W 24 Communication Recognition character 2 11.28

R,W 25 Communication Turnaround Delay 2 11.30

G,P,R,W 26 Output scale 6 11.19

G,P,R,W 27 Output Offset 6 11.20

G,P,R,W 28 Time value 6 11.21

G,P,R,W 29 Total raw value 8 11.21

G,P,R,W 2A Batch raw value (In Batch mode only) 8 11.21

G,P,R,W 2B # of Batches raw value (In Batch mode only) 6 11.21

G,P,R,W 2C Unit of measure #1 6 11.29

G,P,R,W 2D Unit of measure #2 6 11.29

R,W 2E Clock frequency calibration 2 11.31

R,W 2F Analog out Volt zero calibration 4 11.31

R,W 30 Analog out Volt span calibration 4 11.31

R,W 31 Analog out current zero calibration 4 11.31

R,W 32 Analog out current span calibration 4 11.31

G,P 33 Display mode 2 11.3

G,P,R,W 40 RAM or EEPROM Block A Batch: 76 Rate

11.32

(SQ RT): 78

CF 125 INFINITY SC GUIDE 20 M1519/N/0605

Page 25

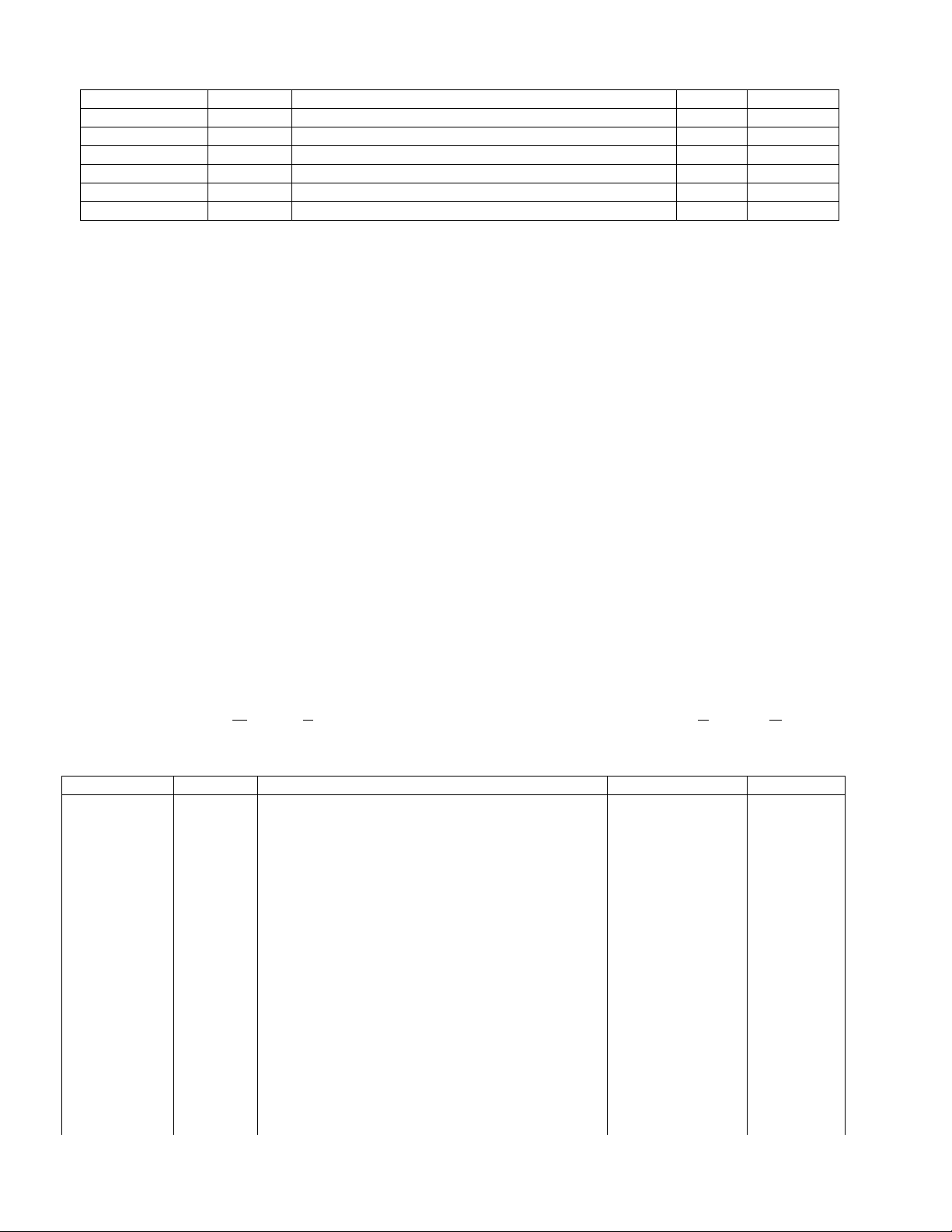

COMMAND SUFFIX ITEM AFFECTED # CHAR SECTION

G,P 41 RAM Block B Batch and (SQ

11.32

RT): 34

Rate:36

R,W 41 EEPROM Block B Batch and (SQ

11.32

RT): 50

Rate: 52

G,P,R,W

42 RAM or EEPROM Block C (only for Batch

22 11.32

mode)

R,W 43 EEPROM Block D 12 11.32

R,W 44 EEPROM Block E 18 11.32

NOTES:

1. Each BLOCK is the string o HEX-ASCII data that is produced by the concatenation of the data for single

items listed below.

a) For BATCH mode:

Block A (for G,P,R,W commands)=

16+15+14+13+12+11+0D+0C+0B+0A+08+07+06+05+04+03+02+01

Block B (for G and P commands)=

25+24+23+22+21+20+1E+1D+1C+1B+17

Block B (for R and W commands):

27+26+25+24+23+22+21+20+1E+1D+1C+1B+1A+19+17

Block C (for G,P,R,W commands):

2B+2A+29

Block D (for R and W commands):

2D+2C

Block E (for R and W commands):

32+31+30+2F+2E

b) For Rate mode and Square-root mode:

Block A (for G,P,R,W commands):

16+15+14+13+12+11+0E+0D+0C+0B+0A+08+07+06+05+04+03+02+01

Block B (for G and P commands):

For rate mode:

25+24+23+22+21+20+1E+1D+1C+1B+18+17

For square-root mode:

27+26+25+24+23+22+21+20+1E+1D+1C+1B+1A+19+17

Block C:

Not available

Block D (for R and W commands):

2D+2C

Block E (R and W commands):

32+31+30+2F+2E

CF 125 INFINITY SC GUIDE 21 M1519/N/0605

Page 26

2. Suffixes 0E and 0F are not used: the meter will respond to these with an error message.

3. The meter, upon completion of a BLOCK PUT (into RAM) Command, goes to soft reset which does not copy

EEPROM data into RAM.

4. Upon completion of a BLOCK WRITE (into EEPROM) Command, however, the meter goes to hard reset

copying the data from EEPROM into the working RAM. Single PUT (or WRITE) commands to not interrupt the

measurement process of the meter, even when the changes are to scale or offset values.

5. <data> encoding for Write and Put Commands will be described in Section 11 with each Read and Get

response.

8.3 Response Structure

The meter transmits different response formats according to the type of command it receives, e.g. if it is in echo

or no-echo mode and if an error has occurred or not.

8.3.1 No Error

8.3.2 Echo Mode (See Sections 10.19 And 11.25)

For type (1) Command:

[nn]ccc<data>[hh]<CR>[<LF>]

For type (2) Command:

a) Response for “V01” Command for the Process, Strain Gauge, Temperature, or Universal meters.

[nn][V01][Sa[b]][S<value>][S<value>][S<value>][S<value>][<SP>uuu][hh]<CR>[<LF>]

b) Response for “V01” Command for the rate meter/totalizer or batch meters

[nn][V01][Sa][S<value>][SP<uuu>][S<value>][ SP<uuu>][S<value>][SP<uuu>][S<value>][hh]<CR>[<LF>]

c) Response for “X” Command

[nn][ccc]<value>[hh]<CR>[<LF>]

For type (3) Command:

[nn][ccc]<d>[hh]<CR>[<LF>]

For type (4) Command:

a) For “P” and “W” Command:

[nn][ccc][hh]<CR>[<LF>]

(b) For “Y” Command (Process, Strain Gauge, Temperature and Universal meters only):

[nn][Y01<CR>[<LF>]

For type (5) Command:

[nn]ccc[hh]<CR>[<LF>]

8.3.3 No Echo Mode

For Commands “P”, “W”, “D”, “E”, “Z”, and “Y”

No response will be transmitted

For type (1) Commands:

<data>[hh]<CR>[<LF>]

For type (2) Commands:

a) For “V01” Command:

1) For the Process, Strain Gauge, Temperature and Universal meters:

[Sa[b][S<value>[S<value][S<value>][S<value][<SP>uuu][hh]<CR>[<LF>]

CF 125 INFINITY SC GUIDE 22 M1519/N/0605

Page 27

2) For the Rate meter/totalizer or Batch meters:

[Sa][S<value>][SP<uuu>][S<value>][SP<uuu>][S<value>][SP<uuu>][S<value>][hh]<CR>[<LF>]

b) For “X” Command:

<value>[hh]<CR>[<LF>]

For Type (3) Commands:

<d>[hh]<CR>[<LF>]

Where “nn” is the meter’s address HEX format and is omitted from the response format if the communication is

in the point-to-point mode. “ccc” is the three (3) character command prefix letter and it’s suffix number. “d” is

one ASCII character.

“[hh]” is the optional checksum “CR” is carriage return “[<LF>]” is optional line feed.

“Sa[b]]” is the optional alarm status character followed by the optional peak/valley status character. Alarm

status character is preceded by the chosen plain-ASCII separator character, <S> or <CR>, depending on how

you want this data displayed.

“S<value>” is the separator followed by the decimal-digit measurement value, with plain-ASCII minus sign (if

any) and decimal point.

“[S<value>]” is the optional inclusion of the separator followed by any one of the three added decimal-digit

values listed above.

“[<SP>uuu]” is the optional three units-of-measure characters (letters or other printable plain-ASCII symbols)

preceded by a space; “<CR>” is the terminating plain-ASCII Carriage Return character.

[<LF>] optional line feed.

NOTE: A positive overflow in any one of the <value>s results in the transmission of “?+999999” for that value;

negative overflow sends “?-999999”.

8.4 Data Length Corresponding To The Response Structure

For “R” and “G” Commands:

Data is equivalent to the “W” and “P” Commands respectively (see Table 8-2).

For “V01” and “X” Commands:

a) Value has 7 characters (like 724.352 or –233.45), unless overflow occurs in which case it consists of 8

characters (see note above)

b) Status characters “a” or “b” are each one character.

For “U” commands:

Data is one character.

8.5 Error Response

The meter is capable of detecting the different errors during the communication process and will transmit an

indicating message to the host controller.

8.5.1 Error Response Format

1. Echo mode

[nn]?ee<CR>[<LF>]

2. No echo mode

CF 125 INFINITY SC GUIDE 23 M1519/N/0605

Page 28

?ee<CR>[<LF>]

where “?ee” is the special code indicating an error has occurred as follows:

8.5.2 Error Message

Table 8.4 Error messages

ERROR MESSAGE CODE

1 Command Error ?43

2 Format Error ?46

3 Checksum Error ?48

4 Parity Error ?50

5 Calibration/Write Lockout Error ?4C

6 EEPROM Write Lockout Error ?45

7 Serial Device Address Error ?56

8 Decimal Point Error ?56

9 Serial Recognition Error ?56

10 Invalid Character(s) used in <data> with Y01

Command

?56

8.5.3 Description

1. COMMAND ERROR occurs when:

Command prefix letter is not valid

Command suffix is not valid

2. FORMAT ERROR occurs when:

Length of the message is either shorter or longer than it should be.

Any other character than “0-F” used for hexadecimal values

3. CALIBRATION LOCKOUT ERROR occurs if jumper “S3C” (on the Main Board of the Process, Strain Gauge,

Temperature or Universal meters) or S1A (on the Main Board of the rate meter/totalizer or batch meter) on the

Main Board has been removed to prohibit any changes in calibration.

4. EEPROM WRITE LOCKOUT ERROR occurs if any write (“W”) Command has been issued to the meter and

the jumper position “S3A” on the Main Board of the meter has been removed

or

External pin 10 on the rear connector “P2” of the meter has been grounded.

5. SERIAL RECOGNITION CHARACTER ERROR occurs if a new value is between 0 to 1F (hex) or larger than

7F (hex). “^“, “A”, “E”, are not valid since those are used in the special communication command “^AE”.

6. SERIAL DEVICE ADDRESS ERROR occurs if the new value is larger than 199 decimal.

7. For Process, Strain Gauge, Temperature or Universal meters, DECIMAL POINT ERRORS occur if:

New value is 0 or larger than 6 (3 when the meter is in the Thermocouple or RTD modes)

New value causes the reading offset to overflow, i.e., larger than 999999or less than -99999.

New value causes any of the setpoints to overflow, i.e., larger than 999999 or smaller than -99999.

8. For Rate meter/totalizer or Batch meters, DECIMAL POINT ERRORS occur if:

New offset values cannot be accommodated on the display with the current decimal point position.

New setpoint values cannot be accommodated on the display with the current decimal point position.

IMPORTANT NOTES:

1. The meter will not respond to a command if the command’s recognition character does not match the meter’s

recognition character.

CF 125 INFINITY SC GUIDE 24 M1519/N/0605

Page 29

2. When in multipoint mode, the meter will test the command’s address with the one previously assigned after

the recognition character has been matched. The meter will not respond to the command if addresses do not

match, even if an error has occurred.

3. If the meter is in the Menu or Setpoint mode and receives any transmitted data, it quits that routine, displays

“SERIAL” for up to two seconds, completes its Communication job, and then resets the meter, i.e., hard reset

(RESET 2) from Menu, or soft reset (RESET 1) from Setpoint. (The Rate meter/totalizer or Batch meter resets

respectively, but displays the mode before reverting to RUN.)

4. Any attempt to use push buttons when meter is in Transmit/Receive mode will be denied and followed by the

display of “SERIAL”, indicating that Communication is in process.

8.6 Status Character Formats

The meter upon receiving U01 or U02 Command will transmit alarm or peak/valley status characters

respectively.

8.6.1 Alarm Status Characters

Table 8.5 shows the transmitted character for each of the sixteen possible setpoint/alarm states for Process,

Strain Gauge, Temperature, or Universal meters. (Note the binary progression).

Table 8.5 Temperature/Process/Strain/Universal Meter Alarm Status Characters

CHARACTER SP#4 SP#3 SP#2 SP#1