Page 1

DFI 1650

COMMUNICATIONS GUIDE

Page 2

Table of Contents

Chapter 1 Introduction................................................................................................................................... 1

1.1 About This Manual...............................................................................................................................1

1.1.1 Scope............................................................................................................................................1

1.1.2 Conventions ..................................................................................................................................1

1.2 Related Documents.............................................................................................................................1

1.3 What is the DFI Series? ......................................................................................................................1

1.3.1 Features........................................................................................................................................1

1.3.2 Chassis Models.............................................................................................................................1

1.3.3 Channel Types.............................................................................................................................. 2

1.4 What is Calibration? ............................................................................................................................2

1.4.1 Overview ....................................................................................................................................... 2

1.4.2 Benefits .........................................................................................................................................2

1.4.3 Information Stored ........................................................................................................................ 2

Chapter 2 Getting Started Quickly ................................................................................................................3

2.1 Introduction..........................................................................................................................................3

2.2 Locate Required Parts and Information...............................................................................................3

2.3 Connect the Instrument to the Computer's RS-232 Serial Port ..........................................................3

2.4 Turn on the Instrument ........................................................................................................................ 3

2.5 Configure a Terminal Emulator Program ............................................................................................4

2.6 Establish Communications .................................................................................................................. 4

2.6.1 Example 1 .....................................................................................................................................4

2.6.2 Example 2 .....................................................................................................................................4

Chapter 3 Command Format ........................................................................................................................4

3.1 Introduction..........................................................................................................................................4

3.2 Baud Rate, Start Bits, Stop Bits and Parity ......................................................................................... 4

3.3 Differences between Instruments........................................................................................................4

3.4 Two Types of Commands ...................................................................................................................5

3.4.1 System Commands.......................................................................................................................5

3.4.2 Channel Commands ..................................................................................................................... 5

3.5 Addressing........................................................................................................................................... 5

3.6 Command Format................................................................................................................................5

3.6.1 Format........................................................................................................................................... 5

3.6.2 Command Codes..........................................................................................................................6

3.6.3 Attention Character.......................................................................................................................6

3.7 Response Format ................................................................................................................................6

Chapter 4 RS-232 Installation Notes ............................................................................................................6

4.1 Introduction..........................................................................................................................................6

4.2 System Connector Pinout.................................................................................................................... 6

4.3 Operation Notes ..................................................................................................................................7

4.4 Typical Wiring Diagrams......................................................................................................................7

Chapter 5 RS422/RS-485 Installation Notes ................................................................................................ 8

5.1 Introduction..........................................................................................................................................8

5.2 Installation Overview ........................................................................................................................... 8

5.3 System Connector Pinout.................................................................................................................... 8

5.4 RS-422 Wiring ..................................................................................................................................... 9

5.5 RS-485 Wiring ..................................................................................................................................... 9

5.6 Addressing........................................................................................................................................... 9

5.6.1 Determine Address ..................................................................................................................... 10

5.6.2 Change Address ......................................................................................................................... 10

Chapter 6 Application Programs ................................................................................................................. 10

6.1 Introduction........................................................................................................................................10

6.2 HyperTerminal ...................................................................................................................................10

6.2.1 Start the Program........................................................................................................................10

6.2.2 Create a New Connection........................................................................................................... 10

6.2.3 Establish Communications .........................................................................................................12

6.3 WinWedge .........................................................................................................................................12

CF 126 ii Nov 2001

Page 3

6.4 QBasic I QuickBasic ..........................................................................................................................12

6.5 Visual BASIC 5 or 6........................................................................................................................... 12

6.5.1 MSCOMM Active X Control ........................................................................................................12

6.5.2 Third party Active X controls and DLLs ......................................................................................13

6.6 C and C++ ......................................................................................................................................... 13

6.6.1 Win32 API ...................................................................................................................................13

6.6.2 Third-party Libraries.................................................................................................................... 13

6.7 LabVIEW ...........................................................................................................................................13

6.8 Trademarks .......................................................................................................................................13

Chapter 7 System Commands....................................................................................................................14

7.1 Introduction........................................................................................................................................14

7.2 Listings.......................................................................................................................................... 14

7.3 Descriptions.......................................................................................................................................14

Chapter 8 Strain-Gage Input Channel Commands.....................................................................................23

8.1 Introduction........................................................................................................................................23

8.2 Descriptions.......................................................................................................................................23

Chapter 9 AC-AC LVDT Input Channel Commands...................................................................................30

9.1 Introduction........................................................................................................................................30

9.2 Descriptions.......................................................................................................................................30

Chapter 10 High-Level Input Channel Commands ..................................................................................... 36

10.1 Introduction......................................................................................................................................36

10.2 Descriptions.....................................................................................................................................36

Chapter 11 Relay Output Channel Commands ..........................................................................................43

11.1 Introduction......................................................................................................................................43

11.2 Descriptions.....................................................................................................................................44

Chapter 12 DAC Output Channel Commands............................................................................................46

12.1 Introduction......................................................................................................................................46

12.2 Descriptions.....................................................................................................................................46

Chapter 13 Split-Display Virtual Channel Commands ................................................................................ 48

13.1 Introduction......................................................................................................................................48

13.2 Descriptions.....................................................................................................................................48

Chapter 14 Mathematics Virtual Channel Commands................................................................................ 50

14.1 Introduction......................................................................................................................................50

14.2 Descriptions.....................................................................................................................................50

Warranty and Repair Policy ........................................................................................................................52

CF 126 iii Nov 2001

Page 4

Chapter 1 Introduction

1.1 About This Manual

1.1.1 Scope

This manual contains information about the wiring and protocol used for serial communications SC series

instruments. This series includes the models DFI 1650, DFI 1650PT, and DFI 1650-3004.

Nearly all of the DFI’s features available via its front panel switches, indicators, display and rear panel

connectors are also available through its serial communications interface. This guide is primarily intended

for those DFI users already familiar with RS-232 and RS-422/RS- 485 serial communications interfaces

and who wish to use the DFI remotely using them. If you are not familiar with serial communications terms

such as "baud rate" and "ASCII character", you may wish to review the subject before using this guide.

The information and programs contained in this manual are believed to be correct, however no warranty

is expressed or implied including fitness for a particular purpose. The capabilities of the instrument are

continuously being improved upon, and the information in this manual is subject to change without notice.

1.1.2 Conventions

This manual uses the following conventions to present information:

[TEXT IN BRACKETS] The label of a front panel button.

DISPLAY

->

DATA

↵

1.2 Related Documents

Instruction Manual

The Serial Communications Guide explains the setup, features and operation of 3rd generation DFI

instruments.

1.3 What is the DFI Series?

The DFI Series of Signal Conditioners/Indicators are versatile, multi-channel devices designed to operate

with many different types of sensors. Several different 9 chassis types, Input channels, and Output

channels are available to allow the configuration of a DFI instrument to meet a variety of measurement

and control needs. The operation of a DFI instrument is based on digital technology to provide improved

accuracy, superior ease of setup, and a wealth of features.

1.3.1 Features

The main features of the DFI Series are:

• Four alarm limits (optional sixteen), with versatile setup (not available on Model DFI 1550).

• Automatic setup, calibration, and scaling of strain-gage sensors through the use of Signature

Calibration TM

• Field selectable, digital, low-pass filtering ("damping") on each Input channel

• Up to ±50,000 part resolution

• Field selectable five-, six- or seven-digit (9,999,999 maximum) display

• RS-232 communications standard (RS-485 optional)

• Local or remote setup using the RS-232 or RS-422/RS-485 port

• Push-button on/off tare feature

• No knobs or adjustments

1.3.2 Chassis Models

Several models (i.e. chassis types) are available:

Text that appears on the display, such as error messages or menu items.

Indicates that what follows is an item from a sub-menu, such as SYSTEM

MENU -> DIAGNOSTICS.

Commands sent to or replies from the instrument

The carriage-return character, ASCII code decimal 13

CF 126 1 Nov 2001

Page 5

• DFI 1550: 1 to 4 physical channels, 3/8 DIN case, no limits or peak detector

• DFI 1650: 1 to 4 physical channels, 3/8 DIN case

• DFI 1650PT: 1 to 4 physical channels, portable case

• DFI 1650-3004: 1 to 14 physical channels, 19" rack mount case, 1 to 3 quad-Iine displays

1.3.3 Channel Types

Channels can be one of three types: Input, Output, or Virtual

Input Channels Input channels are hardware circuit boards with a unique channel number. Currently,

they are available for the following types of sensors:

• Strain-gage sensors, such as unamplified pressure transducers and load cells

• Sensors with voltage outputs

• Sensors with current outputs

• AC-AC LVDTs (Linear Variable Displacement Transducers)

• DC-DC LVDTs

Output Channels Output channels are hardware circuit boards with a unique channel number. They

include:

• Relay Output channels, which can add additional limits to the standard four (N/A on DFI 1550).

• DAC Output channels, which provide additional voltage or current outputs.

Virtual Channels Virtual channels are software-based devices that occupy a channel number, but not a

physical slot, in an instrument.

• Split Display Virtual channels allow the displaying of any two channel's track, peak or valley

values at the same time.

• Mathematics Virtual channels run small programs written in an interpretive language called

SensoCode. This provides great flexibility which allows the DFI Series to do many jobs which

otherwise requires a personal computer or PLC.

1.4 What is Calibration?

1.4.1 Overview

A small integrated circuit is located either inside the transducer, in an in-Iine package between the

instrument and the transducer, or in the connector of a cable. All data necessary to set up the transducer

with the instrument are stored (even linearity data), and setup is automatic when a new transducer is

connected to the instrument.

The Strain Gage Input channel of the DFI Series is designed to operate with Signature Calibration. It will

automatically set itself up with transducers that contain the memory device, but can also be set up using a

front-panel interactive procedure. The Signature Calibration module can also be programmed from the

instrument's front panel.

Calibration is only available with un-amplified strain-gage transducers.

1.4.2 Benefits

The benefits are:

• The transducer's Calibration Record is always located where it is needed most - with the

transducer.

• The instrument is always set up correctly with the transducer.

• Interchanging of transducers and instruments is a quick process.

• A User Calibration Data area that can be altered by customers to fit their requirements.

• A Factory Calibration Sheet Data area, unalterable by the customer, can be copied back into the

User Calibration Data.

1.4.3 Information Stored

The following information is stored inside transducers equipped with Calibration:

CF 126 2 Nov 2001

Page 6

• Full-scale mV/V: The full-scale millivolt-per-volt (mV/V) rating of the transducer when its full load

is applied; also called "calibration factor".

• Shunt-Cal mV/V: The millivolt-per-volt output of the transducer when the shunt calibration resistor

is placed across its -SIGNAL and -EXCITATION leads.

• Shunt Resistance: The resistance value, in Ohms, that was used to obtain the shunt-cal mV/V

value above.

• Full-Scale Value: The full-scale value of the transducer, in engineering units.

• Engineering Units: The engineering units that the transducer is calibrated in (i.e. pounds, grams,

Pascals, inches of water, etc.)

• Serial Number: The serial number of the transducer.

• Excitation Voltage: The magnitude and type of signal used to excite the transducer.

• Linearization Points (optional): These can be used by an instrument using Shunt Calibration or

Millivolt-per-Volt Calibration to correct any non-linearity in the transducer and thus improve the

accuracy of the system. An additional "multiple-point calibration" can be purchased with the

transducer that allows linearity correction information to be placed into its Calibration module.

Chapter 2 Getting Started Quickly

2.1 Introduction

This chapter explains how to quickly establish communications with a DFI Series instrument equipped

with the standard RS-232 interface. It assumes that you are very familiar with serial communications and

have access to a terminal emulator program.

Most computers are equipped with either a standard 25-pin male or an IBM 9-pin male RS-232 serial

connector.

Remember that all personal computer serial ports have male connectors! Parallel printer ports have

female connectors.

RS-422 or RS-485 serial ports are NOT STANDARD EQUIPMENT on PC computers!

2.2 Locate Required Parts and Information

The following items are required quickly establish communications with a DFI Series instrument equipped

with the standard RS-232 interface.

• DFI Series instrument

• A computer that is running a terminal emulator program that you are familiar with.

• 25-pin D-sub pass-through male/female cable, such Radio Shack pin 26-240.

• If your computer's serial port has a 9-pin D-sub male connector, an adapter to convert the

computer's male 9-pin RS-232 port to a standard male 25-pin port. Example: Radio Shack pin 26-

209.

• The Customer Information Sheet that shipped with your instrument. Examine it to confirm that the

instrument is equipped with the standard RS-232 interface.

• Power cord for the instrument.

2.3 Connect the Instrument to the Computer's RS-232 Serial Port

Connect the 25-pin serial cable (female connector) or 25-pin serial cable plus 9-pin adapter (female

connector) to the computer's RS-232 serial port (male connector). Determine if this port is called out as

COM 1 or COM2.

Connect the 25-pin cable (male connector) to the instrument's System connector (female connector).

In nearly all situations, a gender changer device is not required! Do not connect the serial

communications cable to your computer's female printer port.

2.4 Turn on the Instrument

Connect the power cord between the instrument power source and the instrument, and turn the OnlOff

switch on the back of the instrument to the On position.

CF 126 3 Nov 2001

Page 7

The instrument enters its INITIALIZE mode that lasts a few seconds per channel. When the instrument

enters its normal operating mode (RUN mode), you will see the following format on the front panel

display:

1 c ШШШШШ. PSIG ◊

2.5 Configure a Terminal Emulator Program

Start your favorite terminal emulator program. Configure it to communicate with the serial port you have

connected the instrument to (usually COM1 or COM2), at 9600 baud, no parity bits, 8 data bits and 1 stop

bits ("9600,8,N, 1"). Disable any hardware or software handshaking or flow control such as (RTS/CTS

handshaking, DSR/DTR handshaking or Xon/Xoff flow control.

2.6 Establish Communications

The following examples assume that the two-character address of the instrument is the factory default of

"00" (ASCII code decimal 30, ASCII code decimal 30).

2.6.1 Example 1

All instruments will respond to the "RR: Read Revision" command. Type the following command into your

terminal emulator software, followed by the Enter key:

#00RR↵

You should see a reply from the instrument similar to:

084-1500-01 2.07

2.6.2 Example 2

The "FI: Display Characters" command can be used to send a message to the instruments display. For

example, type the following command into your terminal emulator program:

#00FIHELLO, WORLD↵

The instrument will acknowledge with "OK" and the characters "HELLO, WORLD!" III should be displayed

on the instrument's front panel.

Chapter 3 Command Format

3.1 Introduction

All DFI instruments have a standard DB-25 type female connector that is used for both serial

communications and other control functions. One of two communications hardware interfaces is available:

RS-232 or RS-485. Instruments equipped with the RS-485 two-wire interface can also be used in an RS422 four-wire type setup; thus this interface is sometimes called RS-422/RS-485. Regardless of the type

of hardware interface used, the SC uses the same software command set, the general format of which is

described in this chapter.

3.2 Baud Rate, Start Bits, Stop Bits and Parity

DFI Instruments always use 8 data bits, one start bit and one stop bit and no parity bits (often described

as "N81 ") for serial communications. Baud rates of 300, 1200, 2400, 4800, 9600, 19200 or 38400 baud

are available. As shipped from the factory, DFI Instruments are set to communicate at 9600 baud. The

baud rate can be viewed from the front panel but can only be changed over the serial communications

link. For details on changing the baud rate, see "W1 Write Baud Rate".

3.3 Differences between Instruments

The commands described in this guide may not be available on all versions of DFI series instruments.

For example, since the model DFI 1550 does not have "limits" or "peak/valley" functions, commands

CF 126 4 Nov 2001

Page 8

relating to this functionality will not work with it. If a command is not available on such an instrument, it will

be mentioned in the description for that command.

Likewise, if your instrument is not equipped with an optional Relay/DAC channel, commands relating to

relays and DAC outputs will not work on your instrument.

3.4 Two Types of Commands

3.4.1 System Commands

System commands are commands that apply to the entire instrument. For example, since the instrument

has one serial communications port all commands that apply to serial communications are system

commands.

3.4.2 Channel Commands

Channel commands are those that affect the operation of only one particular channel. For example, if the

full-scale range of a Strain Gage Input channel is altered, it applies only to a single channel of the

instrument and not the entire instrument.

3.5 Addressing

Every instrument on the communications loop must have a unique two-character address. As shipped

from the factory, every DFI has an address of "00" (ASCII codes decimal 30, decimal 30). This address

can only be viewed, not changed, from the front panel. An instrument's address can only be changed over

the serial communications link. For details on addressing, see "Addressing".

3.6 Command Format

3.6.1 Format

An example command is shown below:

#0002WK0169.89↵

where:

# is called the attention character, which alerts all instruments that a command is being

transmitted to them. This character is ASCII code decimal 35.

00 is the two-character address of the SC to be communicated with. Each character must

be a number or an uppercase letter.

02 is the two-numeric-ASCll-character channel number to which this command will apply.

When using system commands that affect the entire instrument, the channel number can

be "00" (zero, zero) or it can be omitted altogether.

WO is the two-character command to be executed. A list of the valid system commands is

given at the beginning of "System Commands". Lists of the valid channel commands are

given at the beginning of the remaining chapters.

01 is an optional two numeric character parameter number needed by some commands.

69.89 is the optional argument to be written to the instrument.

↵ represents the carriage return (ASCII code decimal 13), which indicates the end of the

command.

For example, the system command string “#00W12400”, followed by a carriage return, will cause the

instrument addressed as "00" to process the "W1 " command with a data value of "2400". The W1 system

command changes the baud rate 2400 baud.

An example of a channel command string is “#0301F1”, This command, followed by a carriage return,

causes the instrument addressed as "03" to process the "F1" command on channel "01 ". The "F1"

command activates the tare function, and thus this command string activates the tare function for channel

01.

CF 126 5 Nov 2001

Page 9

3.6.2 Command Codes

The first character of each two-character command code signifies if that command is a function command

("F"), a read operating parameter command ("R"), or a write operating parameter command ("W"). Read

and write commands can be used instead of the front panel setup menus to configure the operation of the

instrument. Function commands are used as an alternative to the front panel to gather data from the

instrument or to cause it to perform an operation.

3.6.3 Attention Character

All characters received before the "#" (ASCII code decimal 35) attention character are ignored. Therefore,

one or more instruments can share a single communications link with other "foreign instruments" (within

the physical limits of the RS-232 8 or RS-422/RS-485 interface, of course) as long as the host or the

"foreign instruments" do not use the "#" character.

When the "#" attention character is sent, the instrument enters its receive mode and will attempt to parse

out the rest of the characters before the carriage return as a possible message. If another attention

character is received in the middle of a message, the previous incomplete message is ignored. If the

instrument receives a garbled character, or if the character received has an ASCII value larger than 127,

then the entire message sent is ignored.

3.7 Response Format

An instrument will give a response over the serial communications link for every valid and invalid

command given that uses its unique two-character address. There are four types of responses used:

• "OK", which is sent after an instrument has accepted the data presented with a write operating

parameter ("W") command, or when a function ("F") command has been completed.

• "ERROR", which is sent when an instrument has been asked to perform an invalid command, or

when invalid information is given with a write operating parameter ("W") command.

• "N/A", which is sent when you are requesting information from the instrument which is not

applicable to its present configuration. For example, requesting limit setup information from a DFI

1550 will cause this message to be sent.

• a floating point number as the result of a read operating parameter ("R") or function ("F")

command.

• other ASCII strings, such as serial numbers, dates, the front panel contents, etc.

To signal the end of a response the instrument will transmit a carriage-return (ASCII code decimal 13) if

the Auto-Linefeed function is off, or a linefeed/carriage- return (ASCII codes decimal 10, decimal 13)

when the Auto-Linefeed is on. The Auto-Linefeed status can be viewed from the front panel but can only

be changed over the serial communications link using the "W2 Write Automatic Line-feed Set- ting"

system command.

Chapter 4 RS-232 Installation Notes

4.1 Introduction

This chapter provides wiring examples and hardware information for RS-232 communications. "DTE"

(Data Terminal Equipment) will be used to refer to the personal computer, programmable controller,

terminal, data acquisition system, etc. to which the instrument is connected.

4.2 System Connector Pinout

The table below lists the pins on the System Connector used for RS-232 communication. Other pins on

the System Connector may be used for other purposes.

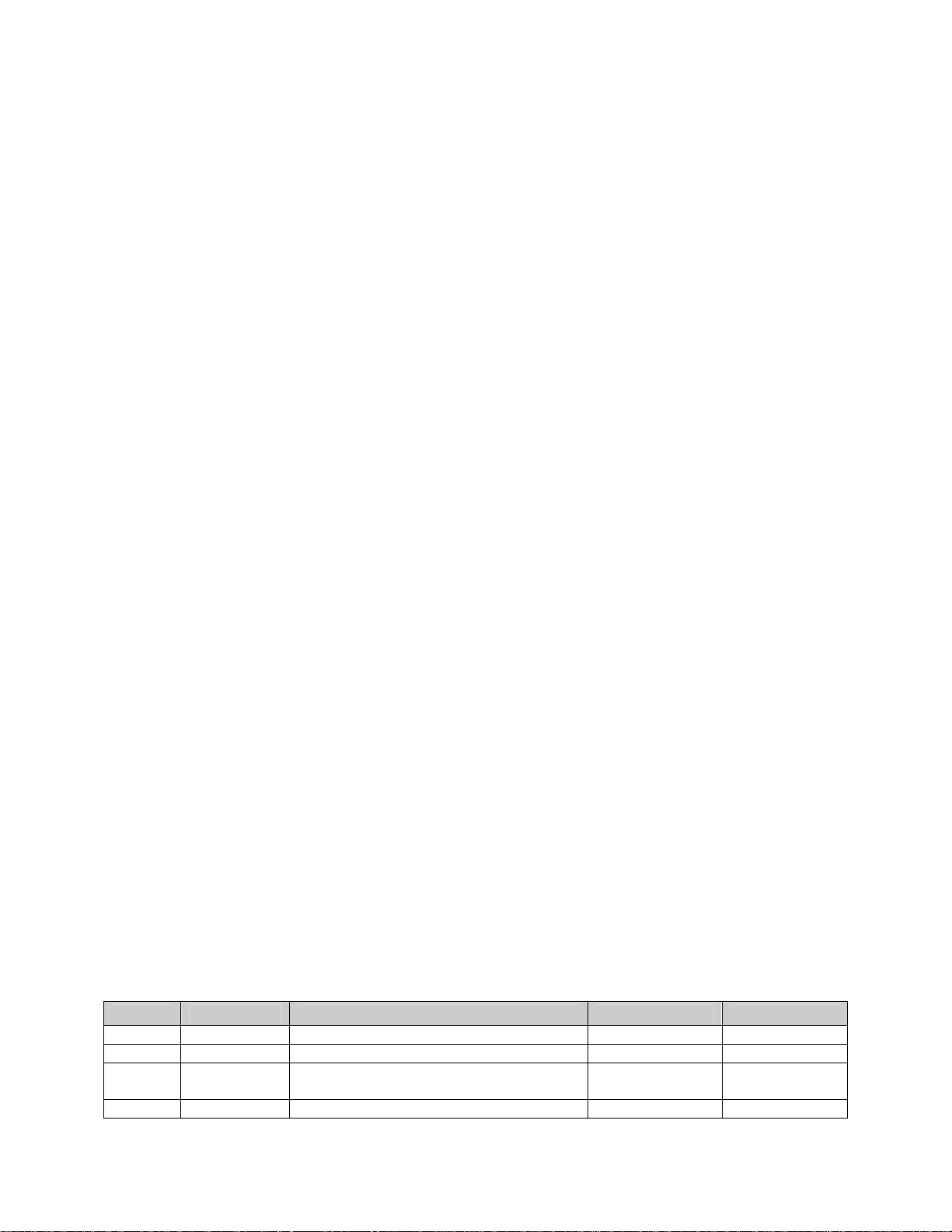

Table 4-1: System Connector Pins used for RS-232

Pin Name Function Input/Output Reference Pin

2 RS-232 IN RS-232 Data In Input 7

3 RS-232 OUT RS-232 Data Out Output 7

4 CTS RS-232 Clear to Send (connected to pin

N/A N/A

5)

5 RTS RS-232 Request to Send (connected to N/A N/A

CF 126 6 Nov 2001

Page 10

pin 4)

6 DSR RS-232 Data Set Ready Output 7

7 GND RS-232/RS-485 reference Reference 8 DCD RS-232 Data Carrier Detect (not

N/A N/A

connected)

20 DTR RS-232 Data Terminal Ready (not

N/A N/C

connected)

22 RI RS-232 Ring Indicator (not connected) N/A N/C

The RS-232 communications pins are electrically isolated from the rest of the instrument.

The RS-232 and RS-485 interfaces are exclusive; an instrument cannot have both.

4.3 Operation Notes

If the DTE wishes to send a command to the instrument, it should first wait for the DSR line (pin 6) to be

high. Then, the DTE can send the command string (which starts with the '#' character and ends in a

Carriage Return). See "Command Format" for further information.

If the address sent by the DTE matches the address of the instrument and the command string is valid,

then the instrument pulls the DSR line low to indicate that it is busy processing the command string. After

the instrument has finished processing the command string, it will pull the DSR line high (to indicate that

new commands will be accepted) and will send the response.

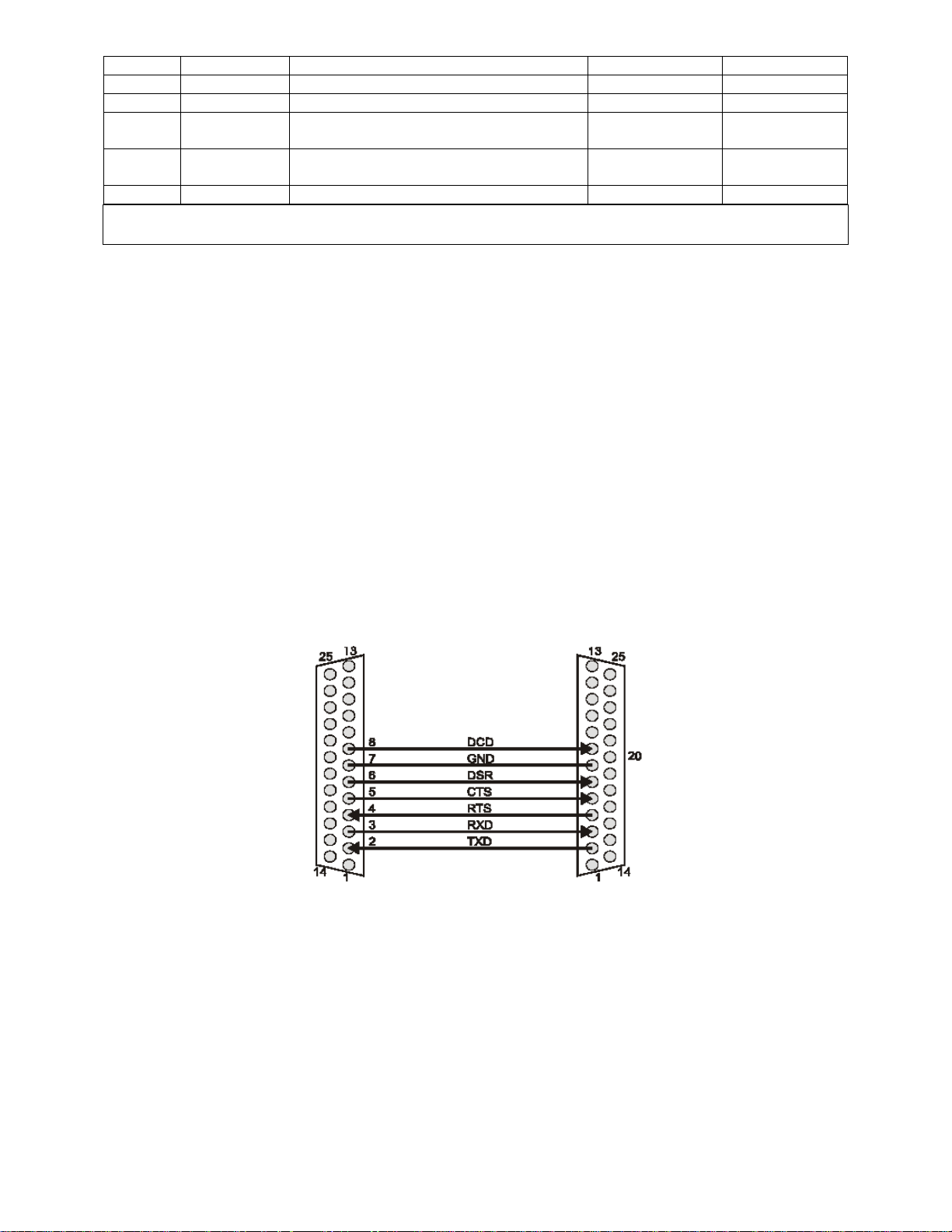

4.4 Typical Wiring Diagrams

Most computers are equipped with either a standard 25-pin male or an IBM 9-pin male RS-232 serial

connector.

Remember that all personal computer serial ports have male connectors! ~ Parallel printer ports have

female connectors. In nearly all situations, a gender changer device is not required!

Model DFI Computer or Terminal

DB 25 connector DB-25 connector

DCE DTE

Figure 4-1: Wiring to 25-pin DTE

CF 126 7 Nov 2001

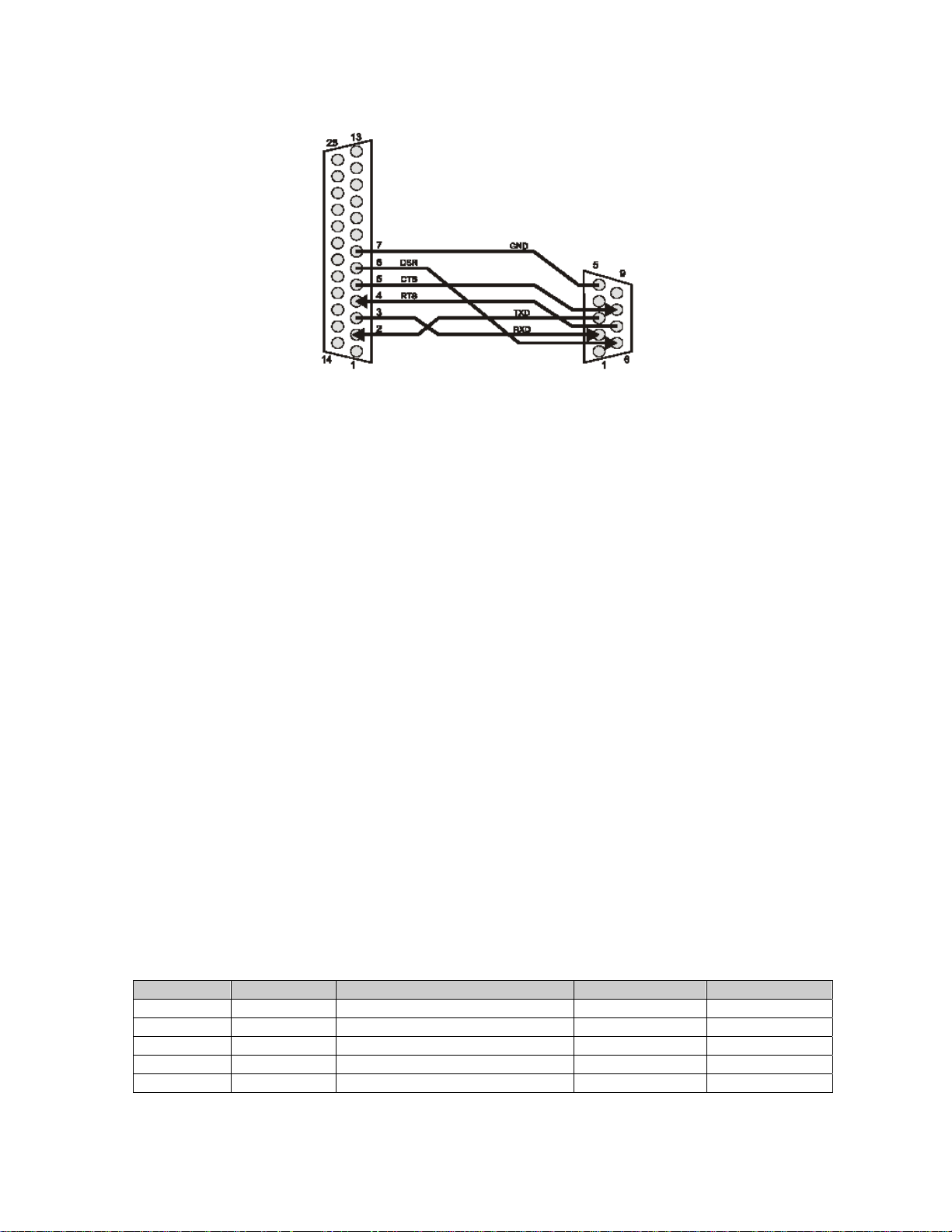

Page 11

Model DFI Computer or Terminal

DB-25 connector DB-9 connector

DCE DTE

Figure 4-2: Wiring to 9-pin DTE

Chapter 5 RS422/RS-485 Installation Notes

5.1 Introduction

This chapter provides wiring examples and hardware information for RS-422/RS-485 communications.

"Bus master" will be used to refer to the personal computer, programmable controller, terminal, data

acquisition system, etc. to which the instrument is connected.

5.2 Installation Overview

Every slave instrument on the communications bus must have a unique 2-character address. Before

wiring multiple instruments into an RS-422/RS-485 communications bus, it is recommended that you read

this document thoroughly and then follow the sequence given below to avoid problems during installation.

1. Determine if the bus master has an RS-422 interface or a RS-485 interface. Wire up one, and

only one, slave instrument to the communications loop z according to the wiring diagrams in this

chapter.

2. Determine the address used by this DFI instrument (factory default is "00") by using the front

panel setup menus. This procedure is explained in (I) "Addressing". Use this address to establish

communications with this instrument.

3. Change this instrument's address to another unique value, such as "01 ", using the "W4"

command as explained in "Addressing".

4. Wire the next instrument to the communications loop and repeat steps 2-4 until the last unit is online.

5.3 System Connector Pinout

The table below lists the pins on the System Connector used for RS-422/RS-485 communication. Other

pins on the System Connector may be used for other purposes.

Table 5-1: System Connector Pins used for RS-422/RS-485

Pin Name Function Input/Output Reference Pin

7 GND RS-422/RS-485 reference Reference 12 (-) TX RS-485 Transmit - Output 7

13 (+) TX RS-485 Transmit + Output 7

24 (-) RX RS-485 Receive - Input 7

25 (+) RX RS-485 Receive + Input 7

CF 126 8 Nov 2001

Page 12

The RS-485 communications pins are electrically isolated from the rest of the instrument.

The RS-232 and RS-485 interfaces are exclusive; an instrument cannot have both.

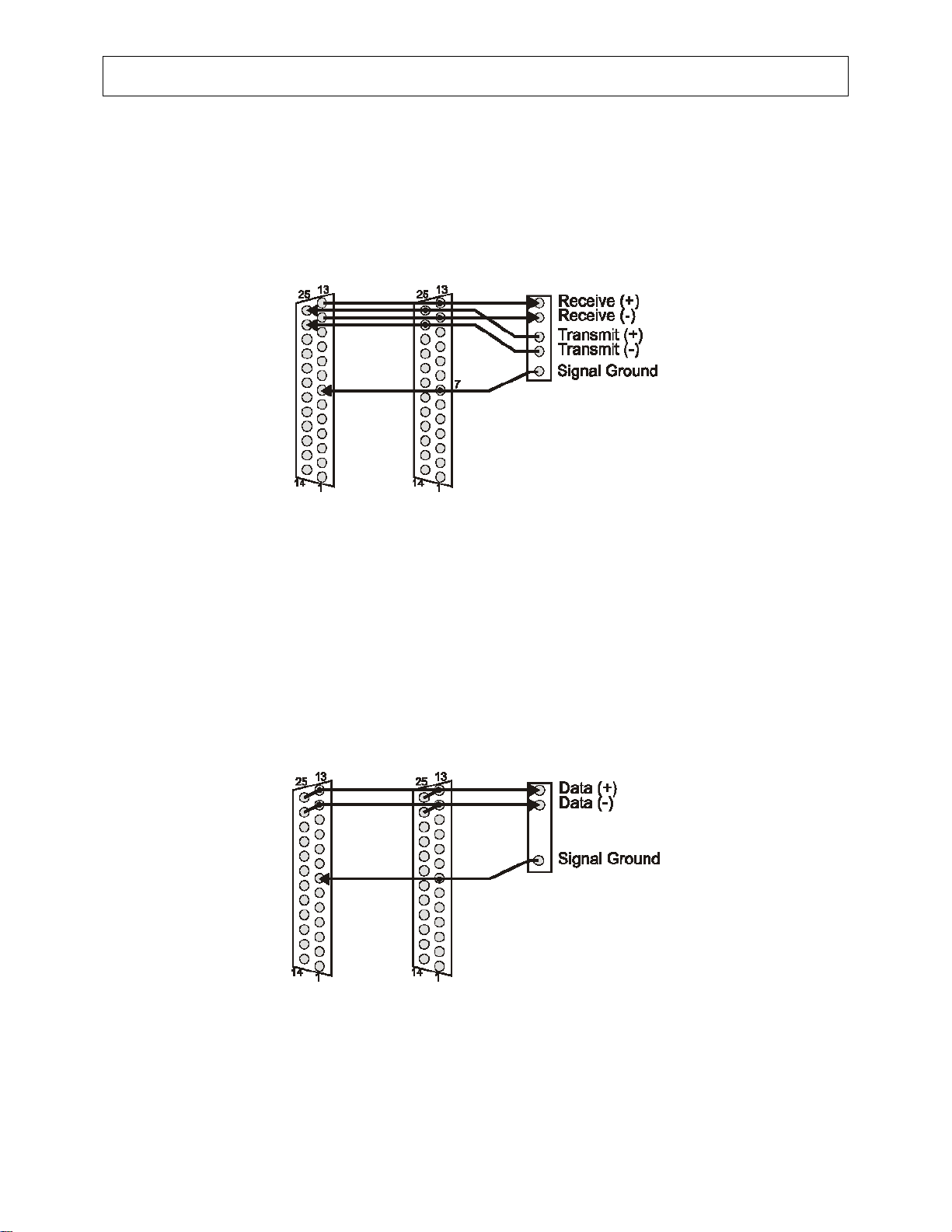

5.4 RS-422 Wiring

RS-422 uses two pairs of wires to communicate between one bus master and up to 10 slave devices. It is

a full-duplex system, i.e. the bus master can transmit and receive data from the slaves at the same time.

Model DFI Model DFI Controller

DDB-25 connector DB-25 connector RS-422

Slave Slave Bus Master

Figure 5-1:RS-422 Wiring

5.5 RS-485 Wiring

An RS-485 balanced differential communications bus uses one pair of wires to allow up to 32 devices to

send and receive data. A two-wire RS-485 system is a half-duplex system, which means that no device

can transmit and receive data at the same time, and that only one device can "drive" or "talk" on the bus

at a time. An SC Instrument is configured as a two-wire RS-485 device when "Transmit (+)" (pin 13) is

connected to "Receive (+)" (pin 25), and "Transmit (-)" (pin 12) and "Receive (-)" (pin 24) are connected

together.

Model DFI Model DFI Controller

DB-25 connector DB-25 connector RS-485

Slave Slave Bus Master

Figure 5-2: RS-485 Wiring

5.6 Addressing

Every DFI instrument on the RS-422/RS-485 communications bus must have a unique 2-character

address. Each instrument as shipped from the factory has its address set at "00" (i.e. ASCII code 30

decimal, 30 decimal).

CF 126 9 Nov 2001

Page 13

5.6.1 Determine Address

To determine what address the instrument is using from the front panel:

1) Enter the setup menus by pressing [UP] and [DOWN] together. The display will read “SETUP”

and then “CHANNEL 01 MENU” (which is the top-most item on the setup menus).

2) Press and release [DOWN] until the display reads “SERIAL COM.MENU”. Press [ENTER] to

enter the SERIAL COM. menu.

3) Press and release [DOWN] until the display reads “ADDRESS". Press [ENTER] and the display

will show this DFI’s address, for example “ADDRESS 00”. The address cannot be changed from

the front panel, only from the serial port.

4) Press [EXIT] to exit the menus and restart the instrument.

5.6.2 Change Address

To change the address of a DFI instrument:

1) Establish communication with the instrument, using its present address. For F example, if the

DFI's present address is "00", the command string “#00F0” followed by a carriage return will

cause the instrument to transmit the contents of the display. If the instrument's response appears

garbled, this may be caused by improper wiring or bus termination, having two or more

instruments on the bus with identical addresses, or having the bus master's baud rate not match

that of the instrument. DFI instruments ship from the factory set at 9600 baud.

2) Use the "W4" command to change the DFI's address. For example, if you wish to change the

address of a DFI from "00" to "01 ", send it the command string “00W401” followed by a carriage

return.

Chapter 6 Application Programs

6.1 Introduction

This chapter provides several programming examples and hints for using serial communications with

various applications and programming languages.

Cooper Instruments can also be a source of application information for your specific needs.

Many other programs and languages than the ones listed here allow communication between Cooper

instruments and your computer. Cooper Instruments is not affiliated with any of these companies and

cannot provide technical support for their products.

6.2 HyperTerminal

HyperTerminal is a terminal emulator program that has shipped with Microsoft Windows operating

systems starting with Windows 95. Characters coming in over the port are sent to your screen, and

whatever you type is transmitted out. Although HyperTerminal is generally not useful for data acquisition

or control applications, it can be used to communications verification and experimentation.

6.2.1 Start the Program

If HyperTerminal is installed on your computer, it will be located under either "Start Menu -> Programs ->

Accessories -> Communications -> HyperTerminal" or "Start Menu -> Programs -> Accessories ->

HyperTerminal". If it is not installed, consult your system administrator.

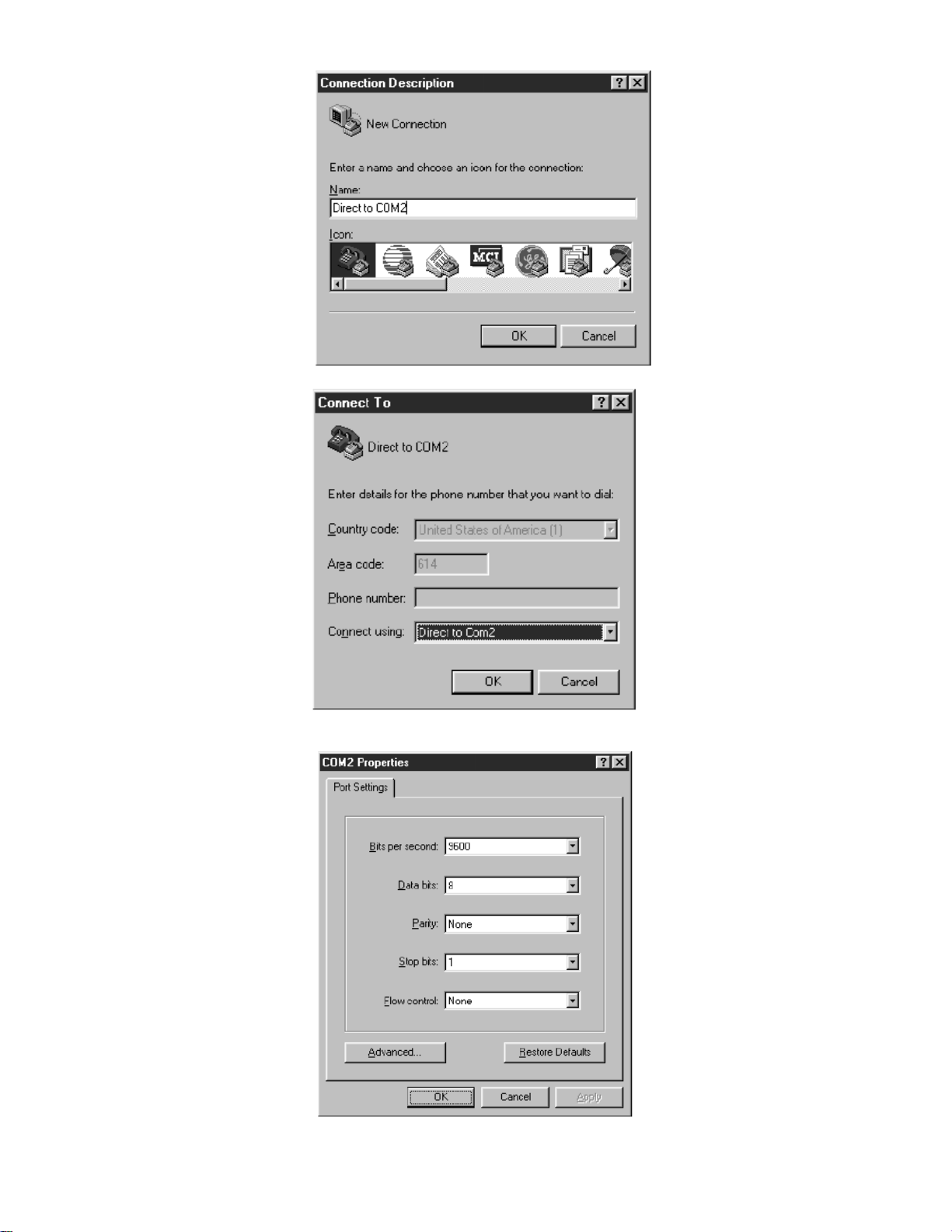

6.2.2 Create a New Connection

If you see a dialog box, which asks:

"You need to install a modem before you can make a connection. Would you like to do this now?"

respond "No".

Create a new connection setup as shown on the screenshot below. Select a descriptive name you will

remember such as "Direct to COM2"

CF 126 10 Nov 2001

Page 14

Next, select the serial port you wish to connect with.

Finally, configure the serial port parameters as shown below.

CF 126 11 Nov 2001

Page 15

If HyperTerminal reports "Unable to open Com 2" (or whatever port you are using} some other application

on your computer is currently using the port. It could be a printer, a mouse or another terminal emulation

program.

6.2.3 Establish Communications

Type “#00RR” (you will not see these characters on the screen) then press enter to transmit this

command to the instrument. If all goes well, the instrument should respond with a message in the form of

“084-1500-01 2.07”.

6.3 WinWedge

WinWedge (a.k.a. SoftwareWedge for Windows) by TALTech is a Microsoft Windows applications that

allows you to input data from a device connected to a serial port on your computer directly into any other

Windows program. The data is transferred into another Windows program (such as Microsoft Excel,

Corel Quattro Pro or Lotus 1-2-3) either as keystrokes or by using DDE (Dynamic Data Exchange).

WinWedge is easy to use for novice users and also is available in a "professional" version for more

demanding tasks. Information about WinWedge can be found at

http://www.winwedge.com

6.4 QBasic I QuickBasic

Microsoft includes a copy of QBasic (a version of QuickBasic with reduced functionality) with MS-DOS 5.0

and above, Windows 95, Windows 98, Windows NT 3.51 and Windows NT 4.0. Microsoft intended to

release QBasic with Windows 2000, but forgot to place it onto the installation CD (Microsoft support

article 0258265); they suggest copying QBasic manually from a Windows NT 4.0 computer.

Both QBasic and QuickBasic can only access ports COM1 and COM2.

Two sample programs for Microsoft QuickBasic can be located on Sensotec's web site at:

http://www.sensotec.com/scprograms/084-1031-00.zip

Note than QuickBasic's "LINE INPUT #" statement will not work when it receives a line-feed/carriagereturn combination. Therefore, you must disable the instrument's Auto Line-Feed function as explained in

"W2 Write Automatic Line-feed Setting".

6.5 Visual BASIC 5 or 6

6.5.1 MSCOMM Active X Control

Microsoft provides the MSComm ActiveX control along with Visual Basic; the file MSCOMM32.OCX is

copied and registered onto your computer when Visual Basic is installed. Some developers have been

able to use the MsComm control in VB without problems. Others, however, have encountered one or

more of the following issues:

• If you deploy your application onto a computer that does not have Visual Basic installed, you will

have to register the MSComm control manually on the other computer. Copy the file

MSCOMM32.OCX into the Windows\System directory then using the Windows "Start -> Run"

menu item type "REGSVR32 C:\Windows\System\MSCOMM32.OCX". This fix does not always

work.

• Memory leaks when using the MsComm control. See Microsoft support document Q171472.

• When another application created with Visual Basic re-installs the MsComm control and the

Visual Basic Development Environment is installed onto the same machine afterwards, you may

not be able to use the MsComm control in your VB programs. See Microsoft support document

Q177799.

For these reasons, Cooper recommends the use of a third-party Active X control or DLL for serial

communications with Visual Basic.

CF 126 12 Nov 2001

Page 16

6.5.2 Third party Active X controls and DLLs

Because of the above problems with the MsComm control, you may wish to use a third-party Active X

control for serial communications. One such product is CommX from Greenleaf software. Their web site is

located at:

http://www.greenleafsoftware.com

Several vendors offer DLL libraries for serial communications. MarshallSoft Computing offers 16-bit and

32-bit DLLs available as a shareware download. Their web site is:

http://www.marshallsoft.com

6.6 C and C++

6.6.1 Win32 API

One way of using serial communications with a C or C++ program is with the serial communications

functions of the Win32 API developed by Microsoft. These functions include CreateFile (), ReadFile () and

WriteFile (). Sample source code that demonstrates the use of these functions is available on Sensotec's

web site at:

http://www.sensotec.com/scprograms/084-1198-00.zip

The sample program was compiled with the Borland C++ compiler. Although the program is a console

mode program, the communications functions can also be used with a GUI program.

The advantage of using the Win32 API for communications is that access to it is free with your CIC++

compiler. The disadvantages are that these functions are complicated, not well documented, and do not

always work in a consistent way across Win32 operating systems.

6.6.2 Third-party Libraries

Another way of using serial communications with a CIC++ program is by purchasing a third-party library

such as CommLib from Greenleaf Software. The advantages of third-party libraries is their ease of use,

quality documentation, quantity of example code, technical support and source-code compatibility across

past, present and future operating systems.

Information about CommLib can be found at Greenleaf's web site at:

http://www.greenleafsoftware.com

6.7 LabVIEW

LabVIEW from National Instruments is a program development application, which uses a LabVIEW, uses

a graphical programming language to create programs in block diagram form. A low-cost student version

of LabVIEW is also available.

Information about LabVIEW can be found at National Instrument's web site at:

http://www.natinst.com

LabVIEW applications can use either the Serial Port VIs or VISA Vis for serial communications. A

package (Sensotec pin 084-1173-00) containing samples illustrating the use of both is available on

Sensotec's web site at

http://www.sensotec.com/scprograms/084-1173-00.zip

6.8 Trademarks

"Microsoft" and "Windows" are trademarks of the Microsoft Corporation.

"WinWedge" and "SoftwareWedge" are trademarks of TAL Technologies.

"Corel" and "Quattro" are registered trademarks of Corel Corporation.

"Lotus" is a registered trademark of Lotus Development Corporation.

CF 126 13 Nov 2001

Page 17

"CommLib" and "CommX" are trademarks of Greenleaf Software Inc.

"National Instruments" and "LabVIEW" are trademarks of National Instruments Corporation.

"MARSHALLSOFT" is a registered trademark of MarshallSoft Computing, Inc.

Chapter 7 System Commands

7.1 Introduction

System commands affect the operation of the entire instrument.

7.2 Listings

Following are the Commands listed in this section.

F0 Transmit Front Panel Display

F6 Transmit Limit Status

F8 Clear Latched Limits

FI Display Received Characters

FL Transmit Multiple Readings

FR Reset

W1 Write Baud Rate

W2 Write Automatic Line-feed Setting

W4 Write Address

RA/WA Read/Write Limit Set Point

RB/WB Read/Write Limit Return Point

RC/WC Read/Write Limit Operation

WI Write Continuous Transmit Setting

RL/WL Read/Write Multiple Readings Setup

RP/WP Read/Write Dual-Line Display Operation

RQ/WQ Read/Write Power Up Display Value

RR Read Firmware Revision

RS/WS Read/Write Channel to Display

ZM Read Scan Time

ZX Temporarily Suppress Continuous Transmissions

ZY Read Configuration

7.3 Descriptions

F0 Transmit Front Panel Display

Purpose To transmit the contents of the front panel display

Usage

Example

“#

aaF0↵”

# is the 'pound' or 'hash' character (ASCII decimal 35).

aa is the two-character instrument address.

↵ is the 'carriage return' character (ASCII decimal 13).

#00F0↵

Reply “02HI 5670.5 LBS” (typical)

Remarks This function is used to verify that communications with the instrument have been

established rather than reading data. Data is usually desired from a particular channel

number regardless of which channel the display happens to be monitoring.

The “S” and “T” display symbols are transmitted as “

“”and “” symbols are not transmitted.

HI” and “LO” respectively. The

F6 Transmit Limit Status

Purpose To transmit which of the limits have been activated

Usage

CF 126 14 Nov 2001

“#

aaF6↵”

# is the 'pound' or 'hash' character (ASCII decimal 35).

aa is the two-character instrument address.

↵ is the 'carriage return' character (ASCII decimal 13).

Page 18

Example

Reply The floating-point value in the reply is created by adding together the values for each

If “#00F6↵“ is sent when limits 02 and 04 are activated, the reply will be “10.”

activated limit as shown below.

Limit number

01 1.

02 2.

03 4.

04 8.

05 16.

06 32.

07 64.

08 128.

09 256.

10 512.

11 1024.

12 2048.

13 4096.

14 8192.

15 16384.

16 32768.

This command does not apply to instruments not equipped with limits, such as the DFI

1550.

Value

F8 Clear Latched Limits

Purpose Deactivate all latched limits

Usage

Example

Reply “OK” or “N/A”

Remarks Manually deactivates a limit that has been activated and has its “LIMIT.LATCHING” menu

“

aaF8↵”

# is the 'pound' or 'hash' character (ASCII decimal 35).

aa is the two-character instrument address.

↵ is the 'carriage return' character (ASCII decimal 13).

“00F8↵”

item set to “

button or by using the Function Input #2 pin on the rear panel System Connector.

This command does not apply to instruments not equipped with limits, such as the Model

DFI 1550.

ON”. Latched limits may also be cleared by pressing the front panel [CLEAR]

FI Display Received Characters

Purpose Display text momentarily on the display.

Usage

Example

Reply “OK”

Remarks Lower case characters are converted to upper case characters.

#

aaFIn↵”

# is the 'pound' or 'hash' character (ASCII decimal 35).

aa is the two-character instrument address.

n is the text to be displayed.

↵ is the 'carriage return' character (ASCII decimal 13).

“#

00FIHELLO WORLD↵”

The text stays on the display for about 3 seconds.

This function can be used to verify that serial communications to the instrument is

working. For RS-232 instruments, using this command can ensure that the "GND" and

"TXD" pins on the computer are properly connected to the instrument.

This command does not apply to the DFI 1650.

CF 126 15 Nov 2001

Page 19

FL Transmit Multiple Readings

Purpose Transmit a set of multiple readings as defined with the "WL" command

Usage

Example

Reply A series of ASCll-floating-point values, separated by the 'comma' character (decimal 44).

Remarks See "RL/WL Read/Write Multiple Readings Setup" for more information.

#aa

FL↵”

# is the 'pound' or 'hash' character (ASCII decimal 35).

aa is the two-character instrument address.

↵ is the 'carriage return' character (ASCII decimal 13).

Suppose that the command “#00WL01110212↵“ has been previously sent. Sending

“#00FL↵“ might result in a reply of “-001.2, 0051.3, 000.05, 100.31↵”

The format of each transmitted reading is the one that would be used to display the

readings on the front panel. Because some types of channels (such as Relay Output

channels) do not acquire or calculate data, the data read from these channels will be zero.

See "WI Write Continuous Transmit Setting" for information on how to execute this

command as quickly as possible.

FR Reset

Purpose Resets the instrument as if the power switch had been toggled

Usage

Example

Reply none

Remarks "Do not pass 'GO!' Do not collect $200." -Monopoly

“aa

FR↵”

# is the 'pound' or 'hash' character (ASCII decimal 35).

aa is the two-character instrument address,

↵ is the 'carriage return' character (ASCII decimal 13).

“00FR↵”

W1 Write Baud Rate

Purpose Writes a new baud rate for serial communications

Usage

# is the 'pound' or 'hash' character (ASCII decimal 35).

Example

Reply “OK” (at new baud rate) or “ERROR" (at present baud rate).

Remarks As shipped from the factory, DFI instruments are set to communicate at 9600 baud.

“aa

W1n↵”

aa is the two-character instrument address.

n may be 300,600,1200,2400, 4800,9600,19200 or 38400.

↵ is the 'carriage return' character (ASCII decimal 13).

Sending “#00W138400↵” will cause the instrument to communicate at 38400 baud. The

instrument will reply with “OK” at this new baud rate.

To determine what baud rate the instrument is using from the front panel:

1) Enter the setup menus by pressing [UP] and [DOWN] together. The display will read

“

SETUP” and then “CHANNEL 01 MENU” (which is the top-most item on the setup menus).

2) Press and release [DOWN] until the display reads “

[ENTER] to enter the SERIAL COM. menu.

3) Press and release [DOWN] until the display reads “

the display will show the baud rate. The baud rate cannot be changed from the front

panel, only from the serial port.

4) Press [EXIT] to exit the menus and restart the instrument.

SERIAL COM. MENU” Press

BAUD RATE". Press [ENTER] and

W2 Write Automatic Line-feed Setting

Purpose Enables or disables use of the line-feed character (ASCII decimal 10) in replies.

Usage

“aa

W2n↵”

#is the 'pound' or 'hash' character (ASCII decimal 35).

CF 126 16 Nov 2001

Page 20

aa is the two-character instrument address.

n is the argument defined below.

↵ is the 'carriage return' character (ASCII decimal 13).

Argument “0” disables the auto line-feed function. Each reply ends only with a carriage return.

“1” enables the auto line-feed function (default). Each reply ends with a line-feed/carriagereturn combination.

Example

“#00W20↵”

Reply “OK” or “ERROR”

W4 Write Address

Purpose Writes a new baud rate for serial communications

Usage

"#aa

W4nn. ↵"

# is the 'pound' or 'hash' character (ASCII decimal 35).

aa is the old two-character instrument address.

nn is the new two-character instrument address.

↵ is the 'carriage return' character (ASCII decimal 13).

Example

“#00W402↵”

Reply "OK" or "ERROR".

Remarks Each character of the new address must be alphanumeric.

Lower-case characters are converted to upper case.

As shipped from the factory, DFI instruments are set to communicate at address 00.

To determine what address the instrument is using from the front panel:

1) Enter the setup menus by pressing [UP] and [DOWN] together. The display will read

"

SETUP" and then "CHANNEL 01 MENU" (which is the top-most item on the setup menus).

2) Press and release [DOWN] until the display reads "

SERIAL COM. MENU". Press

[ENTER] to enter the SERIAL COM. menu.

3) Press and release [DOWN] until the display reads "

ADDRESS".

Press [ENTER] and the display will show the address. The address cannot be changed

from the front panel, only from the serial port.

4) Press [EXIT] to exit the menus and restart the instrument.

RA/WA Read/write Limit Set Point

Purpose Reads or writes the SET POINT of a limit.

Usage

“aa

RApp↵”to read, “aaWAappn↵“ to write.

# is the 'pound' or 'hash' character (ASCII decimal 35).

aa is the two-character instrument address.

pp is the two-numeric-character limit number.

n is the limit SET POINT value.

↵ is the 'carriage return' character (ASCII decimal 13).

Example

Sending “#00WA01325.2↵“ will change the SET POINT of Limit 1 to 325.2.

Reply When writing: "OK", "ERROR" or "N/A"

When reading: a floating-point value, or "N/A".

Remarks This command does not apply to instruments not equipped with limits, such as the DFI

1550.

RB/WB Read/write Limit Return Point

Purpose Reads or writes the RETURN POINT of a limit.

Usage

“aa

RBpp↵” to read, “#aaWBppn↵” to write.

# is the 'pound' or 'hash' character (ASCII decimal 35).

aa is the two-character instrument address.

pp is the two-numeric-character limit number.

n is the limit RETURN POINT value.

↵ is the 'carriage return' character (ASCII decimal 13).

CF 126 17 Nov 2001

Page 21

Example

Reply When writing: "OK", "ERROR" or "N/A"

Remarks This command does not apply to instruments not equipped with limits, such as the DFI

Sending “00WB04415.5↵“ will change the RETURN POINT of Limit 4 to 415.5.

When reading: an floating-point value or "N/A"

1550.

RC/WC Read/write Limit Operation

Purpose Reads or writes the operation of a limit.

Usage

Argument The argument is created by adding together the values of the desired options as shown.

Example It is desired to have Limit 1 to operate as follows:

Reply When writing: "OK", "ERROR" or "N/A".

Remarks This command does not apply to instruments not equipped with limits, such as the DFI

“#aa

RCpp↵” to read, “#aaWCppn↵” to write.

# is the 'pound' or 'hash' character (ASCII decimal 35).

aa is the two-character instrument address.

pp is the two-numeric-character limit number.

n is the argument defined below.

↵ is the 'carriage return' character (ASCII decimal 13).

Channel

01 256. OFF 0.

02 512. ON 1.

03 768.

04 1024.

05 1280. Latching

06 1536. OFF 0.

07 1792. ON 2.

08 2048.

09 2304. Source

10 2560. TRACK 0.

11 2816. PEAK 4.

12 3072. VALLEY 8.

13 3328.

14 3584.

15 3840.

16 4096. Energize

17 4352. signal<setpoint 0.

18 4608. signal>setpoint 16.

19 4864. signal inside 32.

20 5120. signal outside 48.

21 5376.

22 5632.

23 5888.

Sending "#00WC01273↵" will change Limit 1 operation accordingly.

When reading: a floating-point value described above or "N/A".

1550.

Value Enable Value

Value

Value

Value

Limit will monitor channel 01 = 256

Source of limit is track value = 0

Enable limit operation = 1

Do not latch limit after it activates = 0

Activate when signal > setpoint = 16

WI Write Continuous Transmit Setting

Purpose Enable of disable continuous transmission

Usage

“aaWIn↵”

# is the 'pound' or 'hash' character (ASCII decimal 35).

CF 126 18 Nov 2001

Page 22

aa is the two-character instrument address.

n is the argument defined below.

↵ is the 'carriage return' character (ASCII decimal 13).

Argument "0" disables continuous transmission (default). The instrument will only transmit when

requested.

"1" enables continuous transmission of the front panel display. This is equivalent to

sending the system command "F0 Transmit Front Panel Display" repeatedly. The

instrument will respond to other commands normally.

"2" performs the system command "FL Transmit Multiple Readings" repeatedly. The

instrument will respond to other commands normally.

Examples

Reply "OK" or "ERROR".

Remarks Some terminal emulator programs running under Microsoft Windows operating systems

Sending “#00WI1↵“ will cause the instrument to transmit the front panel display

contents as quickly as possible. The instrument will reply with "OK" before

commencing transmissions.

(such as HyperTerminal) may appear to "lockup" the computer after enabling

continuous transmissions with baud rates greater than 2400 baud. This is because

Windows is so busy reading and displaying the received characters that it will not

accept keyboard or mouse input.

It is a bad idea to use continuous transmission with two-wire RS-485 communications.

RL/WL Read/write Multiple Readings Setup

Purpose Read or Write how to reply to the "FL Transmit Multiple Readings" command.

Usage

Argument A list of up to 15 codes each of which indicates a channel's data value to be transmitted.

Example

“#aaRL↵” to read, “aaWLn↵” to write.

# is the 'pound' or 'hash' character (ASCII decimal 35).

aa is the two-character instrument address.

n is the argument defined below.

↵ is the 'carriage return' character (ASCII decimal 13).

Each code consists of two hexadecimal characters. The code is created by first adding

together the values of the desired options as shown in decimal and then converting the

result into hexadecimal.

Channel

01 1. TRACK 0.

02 2. PEAK 16.

03 3. VALLEY 32.

04 4.

05 5.

06 6.

07 7.

08 8.

09 9.

10 10.

11 11.

12 12.

13 13.

14 14.

15 15.

16 64.

17 65.

18 66.

19 67.

20 68.

21 69.

22 70.

23 71.

Sending “00WL031323↵” will cause the "FL Transmit Multiple Readings" command to

Value Source Value

CF 126 19 Nov 2001

Page 23

reply with the track, peak and valley values of channel 03. The instrument will reply with

"OK".

Reply When writing: "OK", "ERROR" or "N/A".

When reading: a list of hexadecimal characters as explained above.

Remarks See "FL Transmit Multiple Readings" and "WI Write Continuous Transmit Setting" for

more information.

RP/WP Read/write Dual-Line Display Operation

Purpose Read or Write the operation of the dual-Iine display

Usage

Parameters&

Arguments

Example

Reply When writing: "OK" or "ERROR"

Remarks Not available on the DFI 1650.

“#aa

RPpp↵” to read, “#aaWPppn↵” to write.

# is the 'pound' or 'hash' character (ASCII decimal 35).

aa is the two-character instrument address.

pp is one of the two-character parameters given below.

n is the argument.

↵ is the 'carriage return' character (ASCII decimal 13).

Using pp="00" reads/writes the lower line's display mode.

When writing this parameter:

n=0 blanks the lower-Iine

n=1 displays the limit indicators

n=2 displays the channel specified with parameter "80"

Using pp="01" reads/writes the channel displayed on the lower line. When writing this

parameter, n is the channel to be displayed. See ***ken for encoding information.

Using pp="80" reads/writes display operation.

When writing this parameter:

n=0 enables the display (default)

n=1 disables the display. The display will be blanked after power up until a front

panel button is pressed.

Sending “#00WP0001↵” will cause the lower line to display the limit indicators. The

instrument will reply with "OK".

When reading: a numeric value

RQ/WQ Read/write Power-Up Display Value

Purpose Read or Write which channel and data value is displayed when the instrument is

powered up.

Usage

Argument A number that selects a channel's value. This number is created by adding together the

“aa

RQ↵” to read, “#aaWQn↵” to write.

# is the 'pound' or 'hash' character (ASCII decimal 35).

aa is the two-character instrument address.

n is the argument defined below.

↵ is the 'carriage return' character {ASCII decimal 13).

values of the desired options as shown.

Channel

01 1. TRACK 0.

02 2. PEAK 16.

03 3. VALLEY 32.

04 4.

05 5.

06 6.

07 7.

08 8.

09 9.

10 10.

Value Source Value

CF 126 20 Nov 2001

Page 24

11 11.

12 12.

13 13.

14 14.

15 15.

16 64.

17 65.

18 66.

19 67.

20 68.

21 69.

22 70.

23 71.

Example If the instrument is setup to display channel 01 's track value on power up, sending

“#00RQ↵” will generate a reply of "1".

Reply When writing: “OK" or "ERROR".

When reading: a number corresponding to a channel number and data value as shown

above.

Remarks See also "RS/WS Read/Write Channel to Display".

RR Read Firmware Revision

Purpose Read the internal firmware revision information

Usage

Example

Reply A text string such as

Remarks This command is useful when establishing or debugging communications because it

“#aa

RR↵”

# is the 'pound' or 'hash' character (ASCII decimal 35).

aa is the two-character instrument address.

↵ is the 'carriage return' character (ASCII decimal 13).

“#00RR↵”

084-1501-01 2.08

generates a consistent reply.

RS/WS Read/Write Channel to Display

Purpose Read or Write which channel and data value are displayed

Usage

Argument "UP" increments the number of the channel to be displayed, or

“#aaRS↵”to read, “#aaWS↵”to write.

# is the 'pound' or 'hash' character (ASCII decimal 35).

aa is the two-character instrument address.

n is the argument defined below.

↵ is the 'carriage return' character (ASCII decimal 13).

"DN" decrements the number of the channel to be displayed, or

a number which selects a channel's value. This number is created by adding together

the values of the desired options as shown.

Channel

01 1. TRACK 0.

02 2. PEAK 16.

03 3. VALLEY 32.

04 4.

05 5.

06 6.

07 7.

08 8.

09 9.

10 10.

11 11.

Value Source Value

CF 126 21 Nov 2001

Page 25

12 12.

13 13.

14 14.

15 15.

16 64.

17 65.

18 66.

19 67.

20 68.

21 69.

22 70.

23 71.

Examples

Reply When writing: "OK" or "ERROR".

Remarks Any changes made to the channel number and data value are lost when the instrument

Sending “#00WS01↵” will cause the display to show channel 01 's tracking value. The

instrument will reply with "OK".

Sending “#00WSUP↵” will increment the channel number shown on the display. The

instrument will reply with "OK".

When reading: a numeric value corresponding to a channel number and data value as

explained above.

is reset.

ZM Read Scan Time

Purpose Read how much time it last took for the instrument to service all channels.

Usage

Example

Reply The number of seconds that it last took for the chassis to ser- vice all of the channels.

Remarks This command can provide information about how fast the instrument can service the

“#aa

ZM↵”

# is the 'pound' or 'hash' character (ASCII decimal 35).

aa is the two-character instrument address.

↵ is the 'carriage return' character (ASCII decimal 13).

“#00ZM↵”

limits.

ZX Temporarily Suppress Continuous Transmissions

Purpose Temporarily suppress or allow continuous transmissions

Usage

Example

Reply "OK" or "ERROR"

Remarks If this command is used to suppress continuous transmissions enabled by the "WI Write

“#aa

ZMn↵”

# is the 'pound' or 'hash' character (ASCII decimal 35).

aa is the two-character instrument address.

n is "0" to suppress continuous transmissions, "1" to allow them (power-up setting).

↵ is the 'carriage return' character (ASCII decimal 13).

“#00ZM1↵”

Continuous Transmit Setting" system command, resetting the instrument will allow

them.

See "WI Write Continuous Transmit Setting" for more information.

ZY Read Configuration

Purpose Reads a list of the types of channels installed in the instrument.

Usage

Example If an instrument is configured with a dual-Iine display (card type 04), one Strain Gage

“#aa

ZY↵”

# is the 'pound' or 'hash' character (ASCII decimal 35).

aa is the two-character instrument address.

↵ is the 'carriage return' character (ASCII decimal 13).

channel (card type 65), four Mathematics channels (card type AE) and two Split Display

channels (card type AB), sending “#00ZY↵” will generate a reply of

“0465AEAEAEAEABAB1CA9”

CF 126 22 Nov 2001

Page 26

Reply A list card types, followed by a CRC check.

The list of card types consists of a series of two hexadecimal - characters for every

installed channel in the instrument. Note that the display is considered to be an installed

channel with a channel number of "00".

The CRC check consists of four hexadecimal characters, which is the 16-bit Cyclic

Redundancy Check of the ASCII characters 8 in the reply. The polynomial used is

Remarks This command is intended for internal factory use.

The number of channels installed in the instrument (not including the display) can be

determined by counting the number of characters in the reply.

NumChannels=NumCharacters

2

–3

Chapter 8 Strain-Gage Input Channel Commands

8.1 Introduction

These commands affect the operation of Strain-Gage Input channels.

8.2 Descriptions

F0 Transmit Track Data

Purpose To transmit the channel's tracking data value

Usage

Example

Reply “5670.5” (typical)

Remarks The input channel continuously reads the transducer. This function transmits the most

“#aacc

# is the 'pound' or 'hash' character (ASCII decimal 35). aa is the two-character instrument

address. cc is the two-character channel number

↵ s the 'carriage return' character (ASCII decimal 13).

“#0001F0↵”

recent reading.

F0↵”

F1 Activate Tare

Purpose To reset the channel's data values to zero.

Usage

Example

Reply "OK"

“aacc

F1↵”

# is the 'pound' or 'hash' character (ASCII decimal 35).

aa is the two-character instrument address. cc is the two-character channel number

↵ Is the 'carriage return' character (ASCII decimal 13).

“#0001F1↵”

F2 Deactivate Tare

Purpose To remove the offset from the channel's data values which was applied when tare was

activated.

Usage

Example

Reply "OK"

“aacc

F2↵”

# is the 'pound' or 'hash' character (ASCII decimal 35).

aa is the two-character instrument address.

cc is the two-character channel number

↵ is the 'carriage return' character (ASCII decimal 13).

“#0001F2↵”

CF 126 23 Nov 2001

Page 27

F5 Apply Shunt Resistor and Transmit Reading

Purpose To apply the channel's internal shunt resistor to the transducer and transmit a reading.

Usage

Example

Reply A numeric data reading or "N/A"

Remarks This can be used as a quick check to verify that the transducer is operating properly

“#aaccF5↵”

# is the 'pound' or 'hash' character (ASCII decimal 35).

aa is the two-character instrument address.

cc is the two-character channel number

↵ is the 'carriage return' character (ASCII decimal 13).

“#0001F5↵”

F9 Transmit Peak Data

Purpose To transmit the channel's peak data value

Usage

Example

Reply “12602.5” (typical) or "N/A"

Remarks This command is not available on the DFI 1550

“#aacc

# is the 'pound' or 'hash' character (ASCII decimal 35).

aa is the two-character instrument address.

cc is the two-character channel number

↵ is the 'carriage return' character (ASCII decimal 13).

“0001F9↵”

F9↵”

FA Transmit Valley Data

Purpose To transmit the channel's valley data value

Usage

Example

Reply "-0012.5" (typical) or "N/A"

Remarks This command is not available on the DFI 1550.

“#aacc

# is the 'pound' or 'hash' character (ASCII decimal 35).

aa is the two-character instrument address. cc is the two-character channel number

↵ is the 'carriage return' character (ASCII decimal 13).

“#0001FA↵”

FA↵”

FB Clear Peak and Valley Data

Purpose To reset the channel's peak and valley data values to the track value.

Usage

Example

Reply "OK" or "N/A"

Remarks This command is not available on the DFI 1550.

“#aacc

# is the 'pound' or 'hash' character (ASCII decimal 35).

aa is the two-character instrument address. cc is the two-character channel number

↵ is the 'carriage return' character (ASCII decimal 13).

“#0001FB↵”

FB↵”

FE Transmit Transducer Serial Number

Purpose To transmit the serial number of the Signature-Calibration- equipped transducer attached

to the channel.

Usage

Example

Reply "872945" (typical) or "NONE"

Remarks If the transducer attached to the channel does not have a Signature Model, then its serial

“aacc

FE↵”

# is the 'pound' or 'hash' character (ASCII decimal 35).

aa is the two-character instrument address.

cc is the two-character channel number

↵ is the 'carriage return' character (ASCII decimal 13).

“#0001FE↵”

number can't be determined.

CF 126 24 Nov 2001

Page 28

FF Transmit Analog-to-Digital Converter Reading

Purpose To transmit the Analog-to-Digital converter reading as a percentage from -100% to +100%

of the AID converter’s full scale

Usage

Example

Reply “872945" (typical)

Remarks none

“#aacc

# is the 'pound' or 'hash' character (ASCII decimal 35).

aa is the two-character instrument address. cc is the two-character channel number

↵ is the 'carriage return' character (ASCII decimal 13 ).

“#0001FF↵”

FF↵”

FH Write DAC Control Value

Purpose To control the channel's Digital-to-Analog Converter (DAC) manually or automatically.

Usage

Argument "AUTO" returns the DAC to its normal automatic operation (power-on default). That is, it is

Example

Reply "OK" or "ERROR"

Remarks You might wish to force a channel's DAC to a certain output to help calibrate the attached

“#aacc

# is the 'pound' or 'hash' character (ASCII decimal 35)

aa is the two-character instrument address

cc is the two-character channel number

n is the argument defined below

↵ is the 'carriage return' character (ASCII decimal 13 ).

controlled by the "DAC. CHANNEL", “DAC. SOURCE", "DAC. ZERO-SCALE" and "DAC.

FULL-SCALE" menu items.

If the argument is a numeric value between -1 and +1, the DAC is forced to manual

control and the value is used to drive the DAC from -100% to +100% of its output.

“#0001FH.5↵ will force channel 01 's DAC to +50% of full-scale.

data acquisition system or other device.

FHn↵”

R5/W5 Read/write Full-Scale Value

Purpose Reads or writes the channel's "FULL SCALE VALUE" menu item

Usage

# is the 'pound' or 'hash' character (ASCII decimal 35).

Example

Reply When writing: "OK" or "ERROR".

“#aacc

aa is the two-character instrument address. cc is the two-character channel number

n is the full-scale value in engineering units.

↵ is the 'carriage return' character (ASCII decimal 13).

“ 0001W520000↵”

When reading: an ASCll-floating-point value.

Changing this value has no effect until the channel is recalibrated to the transducer.

R5↵” to read, “aaccW5n↵” to write

R6/W6 Read/write Units Label

Purpose Reads or writes the channel's "DISPLAY. UNITS" menu item

Usage

Example

Reply When writing: "OK" or "ERROR".

“#aacc

# is the 'pound' or 'hash' character (ASCII decimal 35).