Page 1

DCM 460 VOLTAGE BRIDGE AMPLIFIER

Description

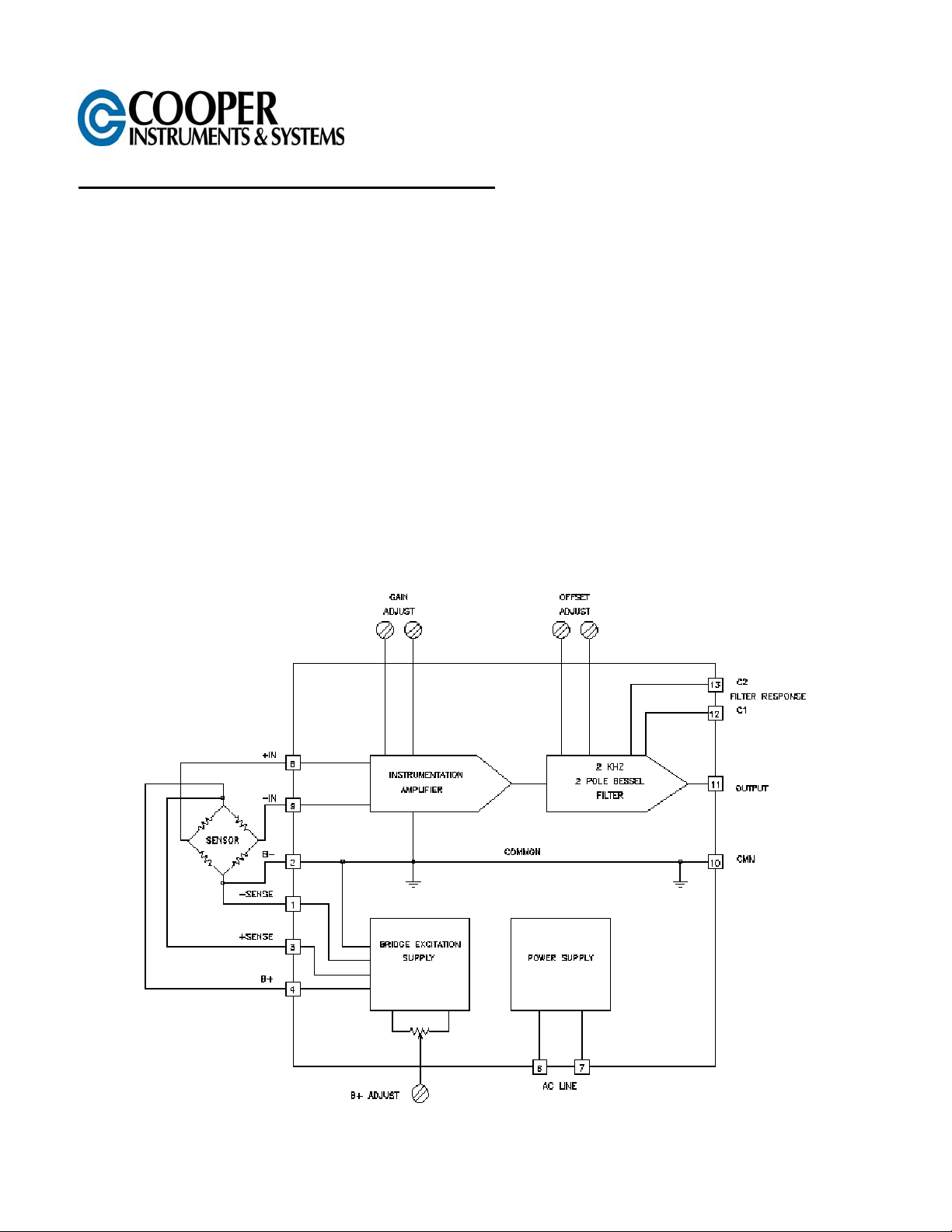

The DCM 460 Bridgesensor is a self-contained, AC powered, signal conditioning module for bridge type

instrumentation. It contains a precision differential instrumentation amplifier with filtered output and a highly

regulated, low noise, adjustable output bridge excitation source. The unit is completely encapsulated for use in

rugged environments. The output filter cutoff frequency is 2000Hz and may be lowered by adding two external

capacitors.

Features

• 2 kHz Frequency Response

• Rugged, Compact And Fully Encapsulated

• Complete System-just Add AC Power

• Ready To Use With Screwdriver Wiring

• Stable and Accurate

Applications

• Weighing With Load Cells

• Long Term Structural Monitoring

• Process Control Pressure Transducers

• Temperature Controls Using Thermocouples

• Strain Measurements

Figure 1. Simplified Block Diagram

CF 28 1 4/2001

Page 2

Specifications

(Typical @ 25°C unless noted)

Amplifier

Gain Range 40-250

Gain Temperature Coefficient 200 ppm/°C

Drift (RTI) 3 µV/°C

Input Bias Current ±30 nA

Input Impedance

Differential

Common Mode

Output Noise (RTO)

At gain=100

1 Hz to 2 kHz

Input Noise

Line Frequencies

Output Offset-Tare

Range

Drift

Common Mode Rejection

Gain=40 (DC-60 Hz)

Gain=250 (DC-60 Hz)

Rated Output (2k load) ±10V

Output Impedance

DC to 2 kHz

Dynamic Response

DC to –3 dB two pole

Bessel Filter

Common Mode Input Voltage ±6.5V

Bridge Supply

Input 115 VAC ±10% 50 to 60 Hz

Output Voltage 4 to 15 Volts

Output Current 120 mA

(see output voltage vs. current curve)

Load & Line Regulation 0.05%

VOUT=12V, IL=0 to 100 mA

Output Noise 0.5 mV RMS

Drift 200 ppm/°C max.

B+ Potentiometer Hysteresis 0.3% of output max.

Short Circuit Current 750 mA

Line Isolation 1,500 VDC

Mechanical

Operating Temperature 0°C to 70°C

Storage Temperature -25°C to +85°C

Weight 18 oz. (510 grams)

Size 3.75”L x 2.0”W x 2.87”H

3,000 megohms

6 megohms

2 mV P-P

15 µV P-P

-5V to +2V

±0.2 mV/°C

90 dB

100 dB

0.01 ohms to 1 ohm

2 kHz

(100, 220 & 230 VAC available)

9.53 x 5.1 x 7.62 (cm)

Getting Started with the DCM 460

I. Hook Up Procedure

A. Connect the +out of your load cell to the +INPUT, pin 8.

B. Connect the -out of your load cell to the -INPUT, pin 9.

Note: If the ± SENSE are not used in your load cell application, the connections in step C & D need to be

followed. If the ±SENSE are going to be used, do not jumper them as described in steps C & D.

C. Connect B+, pin 4, to the + excitation of your load cell and jumper the + SENSE, pin 3, to B+, pin 4.

D. Connect B-, pin 2, to the -excitation of your load cell and jumper the - SENSE, pin 1, to B -, pin 2.

E. Connect the VAC power supply to the AC input lines, pins 6 and 7.

II. Turn On Procedure

A. Verify that the hook up procedure is complete.

B. Verify the correct AC voltage is applied to the DCM 460; i.e. 100, 115, 220, 230.

CF 28 2 4/2001

Page 3

C. Turn on the AC source supply to the DCM 460.

D. Set the required EXCITATION supply voltage to the load cell by adjusting B+ ADJUST.

III. Calibration Procedure for Zero Voltage Adjustment

A. Jumper the + and - input terminals, pins 8 and 9, together.

B. Connect a voltmeter across the output, pins 11 and 10.

C. Adjust the COARSE OFFSET and the FINE OFFSET potentiometers for the desired ZERO voltage.

IV. Full Scale Voltage Adjustment

A. Remove the jumper between the + and - input terminals and apply a known load to your load cell, in

most cases it would be 100% of full scale.

B. Adjust the COARSE GAIN and FINE GAIN potentiometers for the desired FULL SCALE output.

C. Calibration is now complete. However, the user should recheck the ZERO & FULL SCALE voltage

output before continuing.

Figure 2. Safe Operating Curve

Figure 3. Typical Bridge Application

Transducer Excitation

Transducer bridge excitation is provided by an AC line powered, adjustable, well regulated, low noise power supply.

The excitation voltage is adjustable by means of a molded-in potentiometer which allows the output voltage to be

varied from 4 to 15 Volts. The output ripple is extremely low and the line and load regulation are 0.05%.

CF 28 3 4/2001

Page 4

The sense lines minimize variations in output voltage with changes in load current or lead resistance. It should be

noted that if the sense feature is not being used, terminal 1 must be connected to terminal 2. Terminals 3 and 4

must be connected also. The supply will provide up to 120 mA of output current. These features make the unit ideal

for most common strain gage bridge circuits of 120, 350, and 500 Ohms.

The supply has short circuit protection to protect it against short-term faults. The output recovers automatically from

short circuit conditions once the short is removed.

Safe Operating in the Unsafe Area

The curve (Figure 2) describes the region of safe operating output current at each voltage setting level. If excitation

is desired at the 4 Volt level with 120mA, this can be accomplished by using a resistor of at least 2 watts in size in

series with the bridge. The right value resistor would drop 11 Volts allowing 4 Volts at 120mA across the bridge

while minimizing internal heating of the DCM 460. The + sense line would regulate the supply to the required 4

Volts. Normal operation of single bridges at 10 Volts and under 100mA (all 125, 350, and 500 Ohm bridges) can be

accomplished within the safe operating area.

Instrumentation Amplifier

The built-in amplifier is a true differential input, low noise, low drift, instrumentation amplifier. It has a high common

mode rejection ratio (CMRR) and is provided with an output offset that is potentiometer adjustable. The minimum

gain setting of the amplifier is 40 and the maximum gain is 250. The amplifier can withstand input voltages up to 15

Volts without damage. The output of the amplifier is filtered to be 3dB down at 2kHz using a double pole Bessel

response filter. The output of the amplifier is 10 Volts at 5mA making it compatible with modern data acquisition

techniques and systems. Capacitors may be added to terminals 10, 11, 12, and 13 to lower the filter cutoff

frequency. This will reduce the DCM 460 output noise and system noise where the high frequency response is not

required.

Typical Bridge Application

Figure 3 shows a typical bridge application using a standard 350-Ohm bridge. This could be a strain gage, load cell,

pressure transducer, accelerometer, or other bridge based measurement.

Typical bridge output is 2 or 3 mV/Volt of excitation. With the power supply excitation voltage at 10 Volts an output

of 20 to 30 mV from the bridge can be obtained. The common mode voltage of the bridge (the instrumentation

amplifier input signal level) is 5 Volts. This is well within the 6.5 Volt common mode voltage range of the amplifier.

The built-in potentiometer set to a gain of 200 would achieve an output voltage of 4 to 6 Volts.

Assuming a standard 350-Ohm bridge is used, the current required from the excitation supply (set at 10 Volts)

would be 28.6mA. If the leads were long enough to have 10 Ohms of internal resistance there would be a drop of

over 0.286 Volts in both the plus and common side of the bridge. To eliminate this potential error (especially where

the current might vary during the course of a measurement) the sense lines are connected to measure and regulate

the voltage right at the bridge rather than at the output of the supply. The decision to use the sense leads or not

depends entirely on the lead length, its resistance, and the effect of that error on the measurement.

Application Suggestions

The DCM 460 is designed to eliminate many of the ordinary problems associated with bridge type measurements.

Since the whole system is in one case the common problem of ground loops or circulating currents caused by poor

wiring practices is eliminated. It is recommended that lead lengths be kept to a minimum. The use of shielded

twisted pairs for the input leads is recommended for most applications.

To minimize self-heating errors the use of minimum excitation power is suggested as is sufficient heatsinking of the

transducer whenever possible. For optimum stability a one-hour warm-up is recommended. Avoid large

temperature changes or stray magnetic fields.

The DCM 460 Bridgesensor is ready to wire into your system, have power applied, and start making measurements

for you.

CF 28 4 4/2001

Page 5

Filter Roll Off Frequency

The table in Figure 4 shows the values for C1 and C2 to set the 3 dB filter frequency. A printed circuit board is

included for convenient mounting of the two capacitors. Use X7R ceramic or foil type capacitors.

Filter

Frequency

C1

To Pin 11

C2

To Pin 10

2000 Hertz None None

200 Hertz 0.068 μF 0.022 μF

20 Hertz 0.68 μF 0.22 μF

9.4 Hertz 1.5 μF 0.47 μF

Figure 4. Filter Roll Off Frequency

Mechanical Specifications

Specifically designed for rugged field use the DCM 460 is completely encapsulated in epoxy using a vacuum

potting system to insure a complete seal against corrosive environments. It is similarly protected against shock and

vibration and will provide years of reliable and accurate operation.

CF 28 5 4/2001

Page 6

Figure 5. Case Dimension

Terminal Strip Assignments

Screw

Terminal

1 SENSE 8 +INPUT

2 B- 9 -INPUT

3 +SENSE 10 AMPLIFIER CMN

4 B+ 11 AMPLIFIER OUTPUT

5 NOT USED 12 FILTER-C1

6 AC 13 FILTER-C2

7 AC

Function

Screw

Terminal

Function

W ARRANTY REPAIR POLICY

Limited Warranty on Products

Any Cooper Instruments product which, under normal operating conditions, proves defective in material or in workmanship

within one year of the date of shipment by Cooper will be repaired or replaced free of charge provided that a return

material authorization is obtained from Cooper and the defective product is sent, transportation charges prepaid, with

notice of the defect, and it is established that the product has been properly installed, maintained, and operated within the

limits of rated and normal usage. Replacement or repaired product will be shipped F.O.B. from our plant. The terms of

this warranty do not extend to any product or part thereof which, under normal usage, has an inherently shorter useful life

than one year. The replacement warranty detailed here is the buyer’s exclusive remedy, and will satisfy all obligations of

Cooper whether based on contract, negligence, or otherwise. Cooper is not responsible for any incidental or

consequential loss or damage which might result from a failure of any and all other warranties, express or implied,

including implied warranty of merchantability or fitness for particular purpose. Any unauthorized disassembly or attempt to

repair voids this warranty.

Obtaining Service under Warranty

Advance authorization is required prior to the return to Cooper Instruments. Before returning the item, contact the Repair

Department c/o Cooper Instruments at (540) 349-4746 for a Return Material Authorization number. Shipment to Cooper

shall be at buyer’s expense and repaired or replacement items will be shipped F.O.B. from our plant in Warrenton,

Virginia. Non-verified problems or defects may be subject to a $100 evaluation charge. Please return the original

calibration data with the unit.

Repair Warranty

All repairs of Cooper products are warranted for a period of 90 days from date of shipment. This warranty applies only to

those items that were found defective and repaired; it does not apply to products in which no defect was found and

returned as is or merely recalibrated. It may be possible for out-of-warranty products to be returned to the exact original

specifications or dimensions.

*Technical description of the defect: In order to properly repair a product, it is absolutely necessary for Cooper to receive

information specifying the reason the product is being returned. Specific test data, written observations on the failure and

the specific corrective action you require are needed.

CF 28 6 4/2001

Loading...

Loading...