Page 1

DCM 437

CURRENT BRIDGE AMPLIFIER

USER’S GUIDE

www.cooperinstruments.com

PH: 540-349-4746 • FAX: 540-347-4755

Page 2

Features

• Complete Strain Gage Bridge Signal Conditioner

• 4-20 mA or 0-20 mA Output

• Output Capable of Driving 1000 ohm Loop

• Bridge Balance with 68% Tare Offset Capability

• High Gain Amplifier; Can Accept Live Load Signals as Low as 3 mV and Provide 16 mA Output Span

• Sufficient Excitation Current for Five Load Cells

• Powered by 10 to 36 VDC Unregulated

• Rugged Epoxy Encapsulated Design

Applications

• Weighing with Load Cells

• Process Control Add-on Loops

Description

The Model DCM 437 is a self-contained, DC powered signal conditioner for bridge type instrumentation. It contains

a precision differential amplifier with filtered output and a highly regulated, low noise, adjustable output bridge

excitation source. What sets the DCM 437 apart is a Bridge Balance pot and high gain capability to accurately

condition load cell weighing systems with large tare offsets and small live load signals. The unit is completely

encapsulated for use in rugged environments.

CF 27 2 4/2001

Page 3

Specifications

Output Current Span

Input for 16 mA Span

Zero Adjust

Temperature Coefficient

0° to 55°C

Hysteresis 50 microamp maximum

Amplifier

Cell Sensitivity

(10 Volts Excitation)

Linearity 0.005% typical

Temperature Stability 50 ppm/°C

Hysteresis 0.1% of span maximum

Input Bias Current 150 pA maximum

Input Noise: DC to 10 Hz 4 microvolts P-P maximum

Common Mode Input 0 to +7.5 Volts

Common Mode Rejection

DC to 60 Hz

Output

Current 0 to 20 mA

Loop Resistance 0 to 1000 ohm

Compliance 20 Volts maximum

Frequency Response 10 Hertz, 2 Pole Filter

Response Time to 0.1% 90 ms typical

Bridge Excitation Supply

Adjustment Range 5 to 15 Volts

Load Current 150 mA maximum

Stability 100 ppm/°C maximum

Hysteresis 0.1%

Bridge Balance Adjust- (Tare Weight)

With 350 Load Cell

3mV/V Sensitivity

Power Requirements

Input power supply is DC isolated from the amplifier and is reverse polarity protected.

Input Voltage 10 to 36 Volts DC

Input Current

with 150mA B+ load

with one 350 ohm Bridge

120 Hertz Ripple allowed

on input supply

Isolation 700 Volts DC & .0033 mF

NOTE: Specifications apply 0°C to 55°C and 10 to 36 Volts DC input.

Getting Started with the Model DCM 437

This procedure is for large tare weights, i.e. greater than about 10% of the cell’s full scale rating.

I. Hook Up Procedure

A. Connect the + out of your load cell to the + INPUT, pin 10.

B. Connect the - out of your load cell to the - INPUT, pin 9.

Note: If the ±SENSE are not used in your application, the connections in step C & D need to be followed. If the

± SENSE are going to be used, do not jumper them as described in steps C & D.

C. Connect +Excitation, pin 6, to the + excitation of your load cell and jumper the + SENSE, pin 5, to

+Excitation, pin 6.

D. Connect -Excitation, pin 4, to the - excitation of your load cell and jumper the - SENSE, pin 3, to -Excitation,

pin 4.

4 to 20 mA; 0 to 20 mA

3 mV to 62 mV

12 mA

1 microamp/°C typical

4 microamp/°C maximum

0.3 mV/V to 6.2 mV/V

90 dB minimum

± 68% of Full Scale

0.17A @ 36V to 0.7A @10V

0.1A @ 36V to 0.35A @10V

1 Volt P-P at 10 Volts input

2 Volts above 12 Volts input

CF 27 3 4/2001

Page 4

E. Determine the voltage of the power supply to be used and adjust within the 10 to 36 volt range if necessary

before connecting to the power pins, 1 and 2.

F. Verify that the hook up procedure is complete.

G. Turn on the power supply and check the bridge excitation supply.

II. Calibration Procedure

A. Set the GAIN SWITCH position 1 ON and all others OFF.

B. Short the signal input pins 9 and 10 together with a clip lead. Adjust the COARSE and FINE OFFSET pots,

C and B, for zero or 4 mA output current.

Note: Some PLC models do not accept negative inputs. The maximum negative current is 1 mA.

C. Remove the short between the signal input pins, 9 and 10. Adjust the BRIDGE BALANCE pot for zero or 4

mA output current.

D. Set the GAIN SWITCH to the expected load cell output.

E. Adjust the BRIDGE BALANCE pot for zero or 4 mA output current.

F. Apply the live load to the cell and adjust the GAIN, pot D, for the desired output current.

G. Remove live load and use the COARSE and FINE OFFSET pots to set the zero or 4 mA output current.

H. Repeat steps E. to G. until the desired settings are obtained.

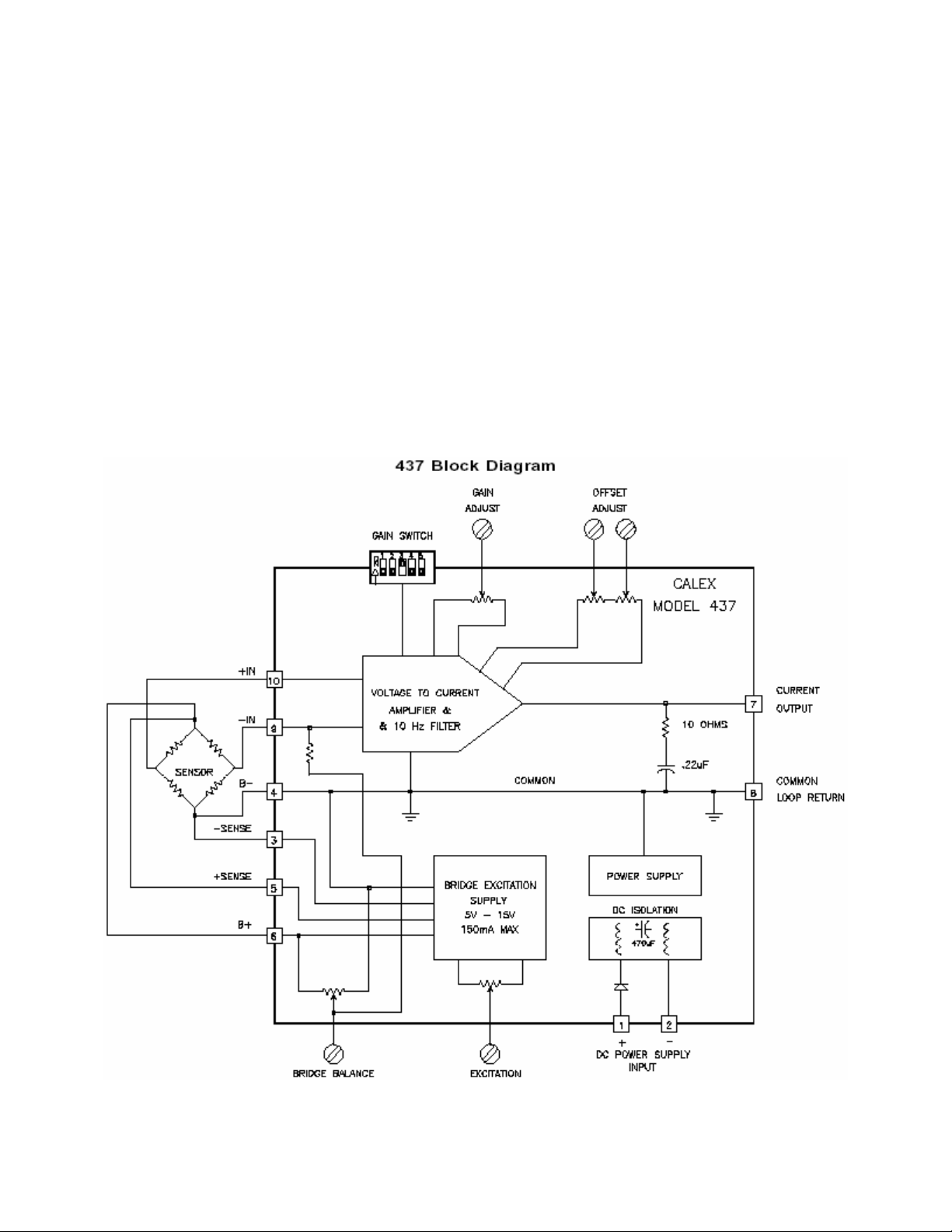

Amplifier

The built-in amplifier is a true differential input, low noise, low drift, instrumentation amplifier. It has a high common

mode rejection ratio (CMRR) and is provided with an output offset that is potentiometer adjustable. The output

offset pots adjust the output zero current up to 12 mA. The zero current can also be adjusted for 0 to 20 mA output.

The instrumentation amplifier has a gain DIP switch which changes the gain by factors of two and a gain

potentiometer for fine adjustments.

The amplifier accepts input signals of 3 mV to 62 mV. The amplifier can withstand input voltages up to 15 Volts

without damage. The output of the amplifier is filtered to be 3 dB down at 10 Hz using a double pole Butterworth

filter to minimize the effects of high frequency electrical and physical noise on the system.

The DCM 437 has a Bridge Balance pot, which is connected internally to the amplifier - INPUT.

Transducer Excitation

Transducer excitation is provided by an adjustable, well-regulated, low noise power supply. The excitation voltage

is adjustable by means of a molded-in potentiometer, which allows the output voltage to be varied from 5 to 15

Volts. It is capable of supplying up to 150 mA to easily drive five 350-ohm load cells at 10 Volts.

The +Excitation supply has remote sensing provisions for 6 wire configurations. The sense lines minimize variations

in output voltage with changes in load current or lead resistance. The supply output, +Excitation, may be connected

through a 300-ohm safety barrier and the sense lines will regulate the voltage across a 350-ohm bridge between 5

and 8 volts.

The supply has short circuit protection to protect it against short-term faults. The output recovers automatically from

short circuit conditions once the short is removed.

CF 27 4 4/2001

Page 5

Bridge Balance

The Bridge Balance pot provides up to 68% of full-scale tare weight adjustment when using a 350-ohm, 3mV/V load

cell. The DCM 437 can then be adjusted to provide full span output with only about 10% of the cell’s range.

DCM 437 Gain Switch

Bridge Output Signal for:

Mechanical Specifications

Gain Switch

Position “ON”:

1

2

3

4

5

0 to 20 mA 4 to 20 mA

50mV to 62.5mV 40mV to 50mV

25mV to 50 mV 20mV to 40mV

12.5mV to 25mV 10mV to 20mV

6.25mV to 12.5mV 5mV to 10mV

3.125mV to 6.25mV 2.5mV to 5mV

CF 27 5 4/2001

Page 6

Terminal Strip Assignments

Screw

Terminal

1

2

3

4

5

Function

+DC POWER

- DC POWER

-SENSE

-EXCITATION

+SENSE

Screw

Terminal

6

7

8

9

10

Function

+EXCITION

CURRENT OUTPUT

AMPLIFIER CMN

-INPUT

+INPUT

WARRANTY REPAIR POLICY

Limited Warranty on Products

Any Cooper Instruments product which, under normal operating conditions, proves defective in material or in workmanship

within one year of the date of shipment by Cooper will be repaired or replaced free of charge provided that a return

material authorization is obtained from Cooper and the defective product is sent, transportation charges prepaid, with

notice of the defect, and it is established that the product has been properly installed, maintained, and operated within the

limits of rated and normal usage. Replacement or repaired product will be shipped F.O.B. from our plant. The terms of

this warranty do not extend to any product or part thereof which, under normal usage, has an inherently shorter useful life

than one year. The replacement warranty detailed here is the buyer’s exclusive remedy, and will satisfy all obligations of

Cooper whether based on contract, negligence, or otherwise. Cooper is not responsible for any incidental or

consequential loss or damage which might result from a failure of any and all other warranties, express or implied,

including implied warranty of merchantability or fitness for particular purpose. Any unauthorized disassembly or attempt to

repair voids this warranty.

Obtaining Service under Warranty

Advance authorization is required prior to the return to Cooper Instruments. Before returning the item, contact the Repair

Department c/o Cooper Instruments at (540) 349-4746 for a Return Material Authorization number. Shipment to Cooper

shall be at buyer’s expense and repaired or replacement items will be shipped F.O.B. from our plant in Warrenton,

Virginia. Non-verified problems or defects may be subject to a $100 evaluation charge. Please return the original

calibration data with the unit.

Repair Warranty

All repairs of Cooper products are warranted for a period of 90 days from date of shipment. This warranty applies only to

those items that were found defective and repaired; it does not apply to products in which no defect was found and

returned as is or merely recalibrated. It may be possible for out-of-warranty products to be returned to the exact original

specifications or dimensions.

*Technical description of the defect: In order to properly repair a product, it is absolutely necessary for Cooper to receive

information specifying the reason the product is being returned. Specific test data, written observations on the failure and

the specific corrective action you require are needed.

CF 27 6 4/2001

Loading...

Loading...