Page 1

DCI 120

20Hz Bridge/Strain Recorder

DCI 120-10

10mV, 20 Hz, Bridge Recorder

DCI 120-25

25mV, 20 Hz, Bridge Recorder

DCI 120-100

100mV, 20 Hz, Bridge Recorder

DCI 120-1000

1000mV, 20 Hz, Bridge Recorder

Configuring the Data Logger

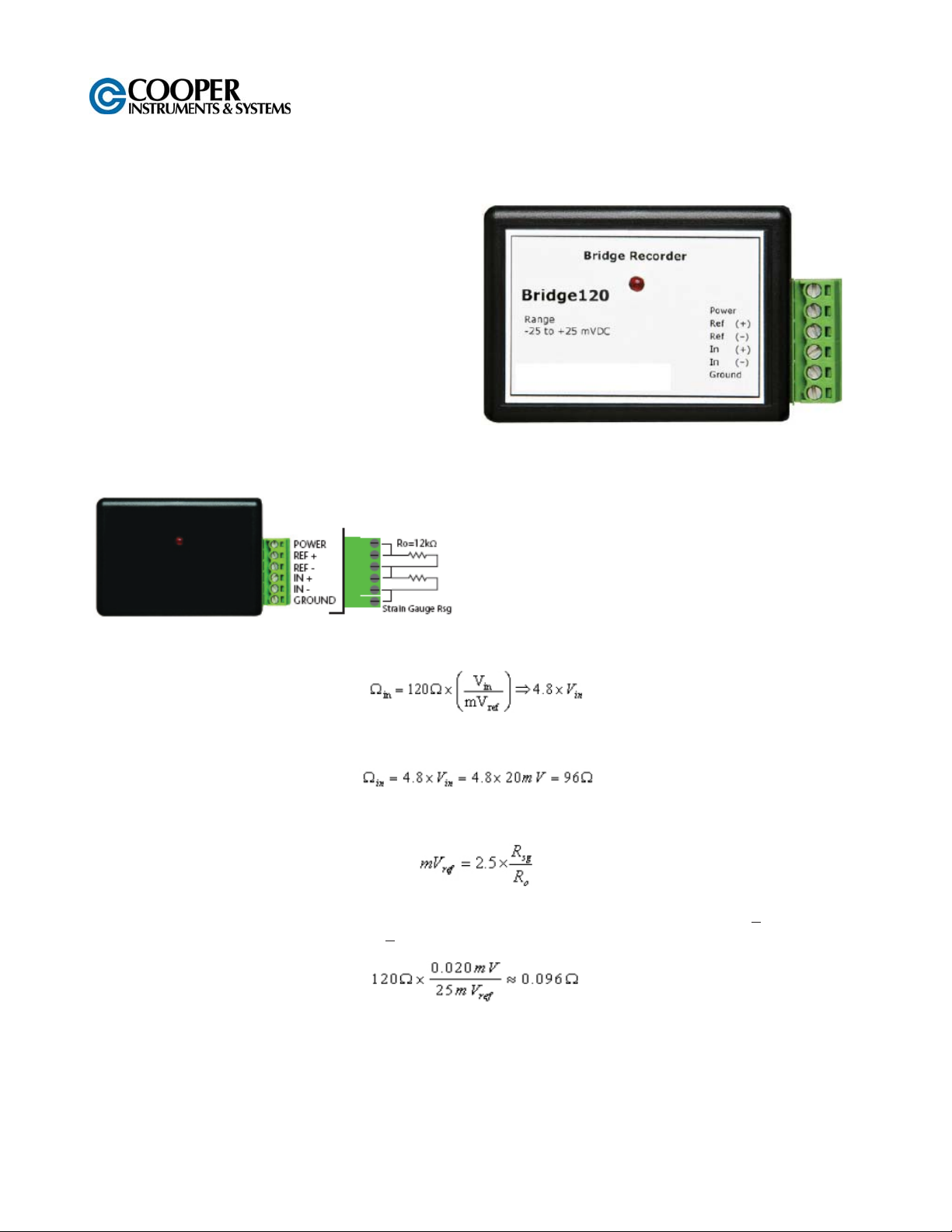

Voltage Divider Configuration

The Voltage Divider configuration is a simple and frequently used setup to measure bridge strain.

1. Jumper between POWER and REF+

2. Place a 12kΩ resistor between REF+ and REF-

3. Jumper between REF- and IN+

4. Place the strain gage between IN+ and IN-

5. Jumper between IN- and GROUND

Conversions

To convert the Voltage values into Ohms, use the following formula:

Example: The software reports a voltage of 20mV in the circuit described above. The strain gage resistance is

therefore:

The resistor Ro between REF+ and REF- and the strain gage value form the mV reference (mVref). This may

be expressed as:

The Bridge120-25 has a resolution of about 2μV. If the resistance of the strain gage changes by +.1, the device

would measure a change of approximately +

approximately:

Note: The maximum voltage must be kept within the specified input range. See data sheet for details.

20μV. Conversely, this voltage resolution translates in Ohms to

Product Notes

LEDs

Once started, the LED will flash at the selected reading rate to indicate that the device is running.

CF 179 1 Rev A 2008.07.08

Page 2

Installation Guide

Installing the Interface cable

- IFC200, IFC202 or IFC300; Refer to the “Quick Start Guide” included in the package.

- IFC110, IFC102 or IFC103; Plug the serial cable into the port and verify it is secure.

- USB-1 or USB-101; Install the USB drivers from the CD provided in the kit, than plug the USB cable into the

computer and the serial cable into the serial port.

Installing the software

Insert the Software CD in the CD-ROM Drive. If the autorun does not appear, locate the drive on the computer

and double click on Autorun.exe. Follow the instructions provided in the Wizard.

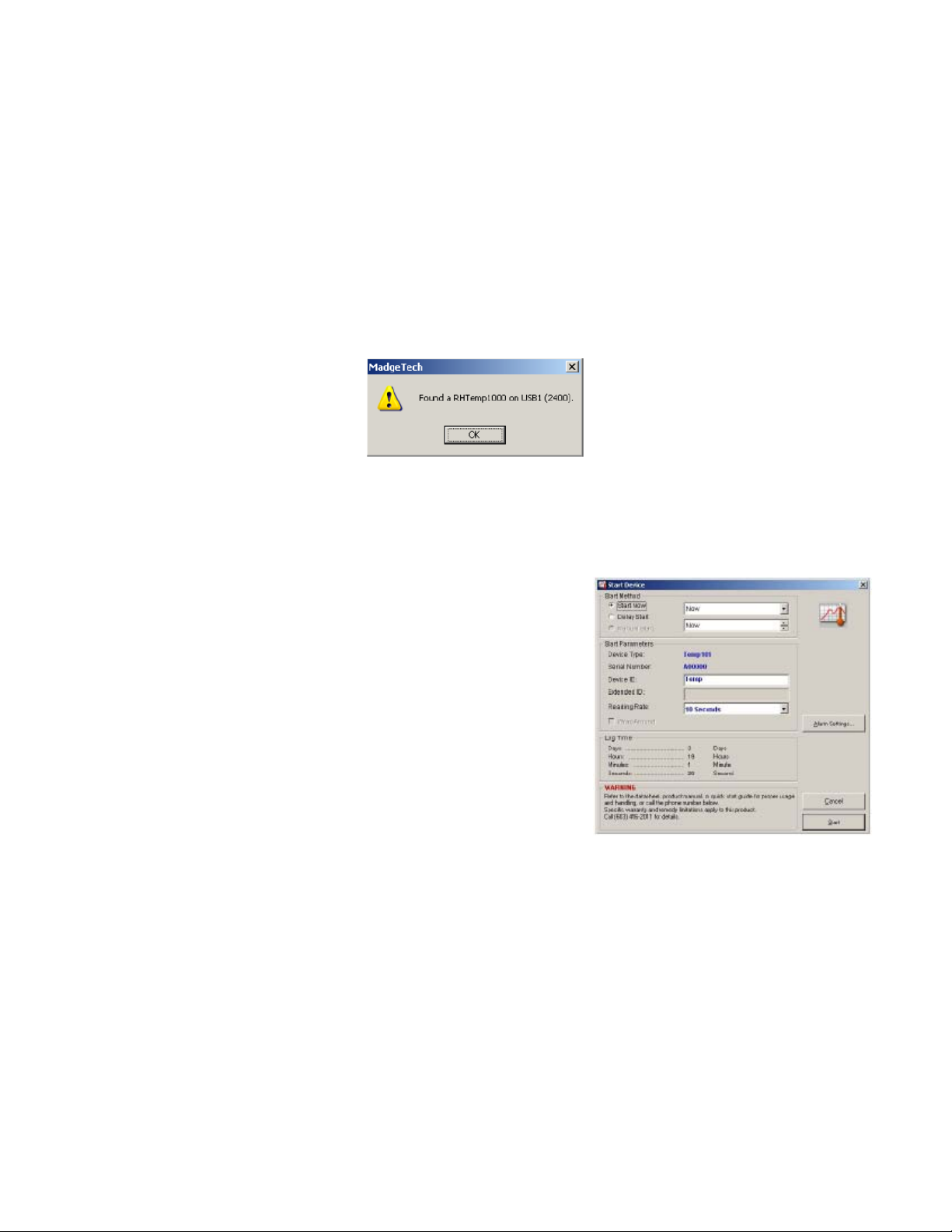

Connecting the data logger

- Once the software is installed and running, plug the interface cable into the data logger.

- Click the Communication Menu, then Auto Configure Port.

- After a moment, a box similar to the following will appear;

- Click OK. The Device Status box will appear. Click OK.

- At this point, communications have been configured for your logger. These settings can be found under the

Communication Menu.

Note: For additional installation instructions refer to your “Data Logger & Software Operating Manual”.

Device Operation

Starting the data logger

- Click Device Menu then Start Device.

- Choose the desired start method.

- Choose the start parameters by selecting a Reading Rate suitable

for your application.

- Enter in any other desired parameters and click Start.

- A box will appear stating the data logger has been started. Click OK.

- Disconnect the data logger from the interface cable and place it in the

environment to measure.

Note: The device will stop recording data when the end of

memory is reached or the device is stopped. At this point the

device cannot be restarted until it has been re-armed by the

computer.

Downloading data from a data logger

- Connect the data logger to the interface cable.

- Click the Device Menu then Read Device Data. This will offload all recorded data onto the PC.

Device Maintenance

Battery Replacement

Materials:

Small Phillips Head Screwdriver

Replacement Battery (LTC-7PN)

- Puncture the center of the back label with the screw driver and unscrew the enclosure.

- Remove the battery by pulling it perpendicular to the circuit board.

- Insert the new battery into the terminals and verify it is secure.

- Screw the enclosure back together securely.

Note: Be sure not to over tighten the screws or strip the threads.

WARNING: FIRE, EXPLOSION, AND SEVERE BURN HAZARD. DO NOT SHORT CIRCUIT, CHARGE,

FORCE OVER DISCHARGE, DISASSEMBLE, CRUSH, PENETRATE OR INCINERATE. BATTERY MAY

LEAK OR EXPLODE IF HEATED ABOVE 80°C (176°F).

CF 179 2 Rev A 2008.07.08

Page 3

Recalibration

DCI 120 standard calibration values:

Logger Voltage 10mV 25mV 100mV 1000mV

Strain (V)

0V and

9-10mV

0V and

22.5-25mV

0V and

90-100mV

0V and

900-1000mV

Part Number DCI 120

Range

Resolution

Accuracy

Memory 32,767

Sample Rate 20Hz to 12 hours

Units

Required Interface Package IFC110 or IFC200

Baud rate 57,600

Typical Battery Life 25 days

Operating Environment –40 to +80°C, 0 to 95%RH (non-condensing)

Material ABS plastic

Dimensions 0.8” x 1.7” x 2.7” (20mm x 42mm x 68mm)

Approvals CE

See Table Below*

V, mV, μV,

Engineering Units specified through software

*DCI 120 Range, Resolution and Accuracy

Nominal Range +10mV +25mV +100mV +1000mV

Measurement Range +15mV +37.5mV +120mV +1200mV

Resolution 1μV 2.5μV 5μV 50μV

Accuracy +0.25%FSR +0.10%FSR +0.05%FSR +0.01%FSR

Input Range 0 to 2.5V 0 to 2.5V 0 to 2.5V 0 to 2.5V

Reference Voltage 2.5V 2.5V 2.5V 2.5V

Specifications subject to change.

WARRANTY REPAIR POLICY

LIMITED WARRANTY ON PRODUCTS

Any of our products which, normal operating conditions, proves defective in material or in workmanship within

one year from the date of shipment by Cooper, will be repaired or replaced free of charge provided that you

obtain a return material authorization from Cooper and send the defective product, transportation charges

prepaid with notice of the defect, and establish that the product has been properly installed, maintained, and

operated within the limits of rated and normal usage. Replacement or required product will be shipped F.O.B.

our plant. The terms of this warranty do not extend to any product or part thereof which, under normal usage,

has an inherently shorter useful life than one year. The replacement warranty detailed here is the buyer’s

exclusive remedy, and will satisfy all obligations of Cooper whether based on contract, negligence, or otherwise.

Cooper is not responsible for any incidental or consequential loss or damage which might result from a failure of

any and all other warranties, express or implied, including implied warranty of merchantability or fitness for

particular purpose. Any unauthorized disassembly or attempt to repair voids this warranty.

OBTAINING SERVICE UNDER WARRANTY

Advance authorization is required prior to the return to Cooper. Before returning the item, contact the Repair

Department c/o Cooper Instruments at (540) 349-4746 for a Return Material Authorization number. Shipment to

Cooper shall be at buyer’s expense and repaired or replacement items will be shipped F.O.B. our plant in

Warrenton, Virginia. Non-verified problems or defects may be subject to an evaluation charge. Please return

the original calibration data with the unit.

REPAIR WARRANTY

All repairs of Cooper products are warranted for a period of 90 days from date of shipment. This warranty

applies only to those items that were found defective and repaired, it does not apply to products in which no

defect was found and returned as is or merely recalibrated. Out of warranty products may be capable of being

returned to the exact original specifications or dimensions.

* Technical description of the defect: In order to properly repair a product, it is absolutely necessary for Cooper

to receive information specifying the reason the product is being returned. Specific test data, written

observations on the failure and the specific corrective action you require are needed.

CF 179 3 Rev A 2008.07.08

Loading...

Loading...