Coolmay EX3G-43HB-24M, EX3G-43KH-24M, EX3G-70KH, EX3G-100HA, EX3G-50KH-24M Programming Manual

Page 1

COOLMAY EX3G PLC/HMI All in one Programming manual

COOLMAY

EX3G PLC/HMI All in one

Programming manual

(plc part: Difference comparing with Mitsubishi FX3G)

All right belongs to Shenzhen Coolmay Technology Co.,Ltd

V8.112

Page 2

2

Content

COOLMAY EX3G PLC/HMI All in one Programming manual

1. Overview

1.1 EX3G PLC/HMI Allin one Main Advantage:

1.2 Specification

1.3 Hardware description

2. PLC

2.1 PLC Programming notice

2.2 Soft element table

2.3 Special relay number and content

2.4 Special register number and content

2.5 Applied instructions【Sequence is according to instruct variety

2.6 Analog input

2.7 Analog output

2.8 PID instruction

2.9.Application of high speed counter

2.10.Application of high speed pulse

2.11 PLC Communication port User Manual

2.12 Network communication

2.13 Difference between EX3G and EX2N PLC/HMI All in one

3. HMI

3.1 HMI program software user introduction

3.2 HMI Display download

.........................................................................................................................................................

......................................................................................

..........................................................................................................................................

............................................................................................................................

1.3.1 EX3G-43HA/HB structure description and dimension

1.3.2 EX3G-43(50)KH structure description and dimension

1.3.3 EX3G-70KH structure description and dimension

1.3.4 EX3G-100HA structure description and dimension

1.3.5 Introduction of each interface and indicator

.................................................................................................................................................................

......................................................................................................................

..................................................................................................................................

.......................................................................................................

...................................................................................................

........................................................................................................................................

2.6.1 Analog input (temperature)

2.6.2 Analog input reading 1 (for software version 26210 and 26220)

2.6.3 Analog input reading 2 (for Main software version 26220)

2.6.4 Analog input reading 3 (for Main software version 26230 and above)

2.6.5 Analog input sampling

2.6.6 Demo example

......................................................................................................................................

2.10.1 high speed pulse output

2.10.2 Circular interpolation

2.10.3 Continuous interpolation function

2.11.1 Serial port 2: RS485(A B)/RS232

2.11.2 Serial port 3:RS485 (A1 B1)/RS232

2.11.3 Modbus Communication address number

...............................................................................................................................................................

3.1.1HMI Program software installation

3.1.2 New build HMI program

3.2.1 Online download step (USB download line download)

3.2.2 U disk download step (43HB series don’t support)

.........................................................................................................................

....................................................................................................................................

...................................................................................................................

.......................................................................................................................

......................................................................................................

.............................................................................................................

......................................................................................................

........................................................................................................

..........................................................................................................

.............................................................................................................

..........................................................................................

...........................................................................................

..........................................................................................

...........................................................................................

...........................................................................................

..........................................................................................................

..............................................................................

......................................................................................

..............................................................................

..............................................................

..............................................................

....................................................................

..................................................................

...................................................

】

.........................................

.................................................

................................

............................................................

...........................................................

.................................................................

1

1

2

3

3

4

5

6

7

8

8

8

10

13

17

24

24

26

27

27

28

29

30

30

30

31

31

32

34

37

37

44

51

55

57

61

61

61

61

62

62

65

Page 3

COOLMAY EX3G PLC/HMI All in one Programming manual

3

3.3 Introduction when HMI is with com port for MODBUS RTU protocol

3.3.1 HMI as master

3.3.2 HMI as slave

3.4 Other HMI usage.

..........................................................................................................................

............................................................................................................................

................................................................................................................................

............................................

66

66

68

69

Page 4

COOLMAY EX3G PLC/HMI All in one Programming manual

1

1. Overview

1.1 EX3G PLC/HMI Allin one Main Advantage:

◆Powerful, compatible with FX3G/FX3U/FX3S PLC, high processing speed.

◆Upper computer programming software compatible with Works 2/GX Developer8.86

◆Military level 32 bit CPU adopted, which is faster and more adapted to industrial environment of high

electromagnetic interference.

◆Special encryption, prevent illegal reading thoroughly. 8-bit encryption, 12345678 as password can

thoroughly prevent reading of ladder logic program.

◆Clock supported, rechargeable battery adopted.

◆Default With one HMI Downloading port, two PLC programming ports: one MiniB USB port with faster

downloading speed; one Rs232 programming port with 8 mouse hole sockets.

◆Support Mitsubishi programming port protocol/Modbus protocol/Rs protocol/BD board protocol,

PLC communication with each other and other devices is easily achieved.

◆EX3G-70KH/100HA,PLC is optional to add 1 rs485 or 2rs485(one of rs485 is changed from default

rs232)/CAN/ethernet (which can’t exist to hmi ethernet port)/WIFI(which will occupy default rs232port);

HMI is optional to add 1RS232 or RS485/ethernet (which can’t exist to plc ethernet port);

43HB(HA)/43(50)KH(A) PLC is optional to add 2 RS485;HMI is optional to add 1 RS232,used for external

hmi and inverters.

◆High speed counter.regularly single phase 6 channels 60KHz/ AB(Z) Phase 2 channels 60KHz + 1 channel

10KHz. EX3G-43HB regularly single phase 8 10KHz;

◆High speed pulse, regular as 8 channels Y0-Y3 in 100KHz,Y4-Y7 in 10KHz

Note: High speed counter+High speed pulse should be less 480KHz.

◆Support multiple types analog individually or mixed ones for analog output and input.

EX3G-70KH/100HA is up to 16AD/8DA,EX3G-43HB(HA)/43(50)KH is up to 4AD/2DA.Precision of

AD/DA is 12bit.Temperature/current/voltage for input. current/voltage for output.

◆EX3G-70KH/100HA is up to 30DI/30DO(MR:28 at most),DO is optional to choose

MR(max:5A)/MT(max:500mA)or mixed MRT;EX3G-43HB(HA)/43(50)KH is up to 12DI/12DO,DO is

optional to choose MR(max:5A)/MT(max:2A).

◆Convenient for wiring, adopting 3.81mm pluggable terminals.

◆Easy installation. DIN-Rail (35mm width) installation and fixed hole installation.

◆32K steps program capacity, 32k registers of hold on when power off, support interrupt,linear&circular

interpolation,PID and self-tuning,high powerful.

◆Flexible, can be customized accordingly.

Page 5

2

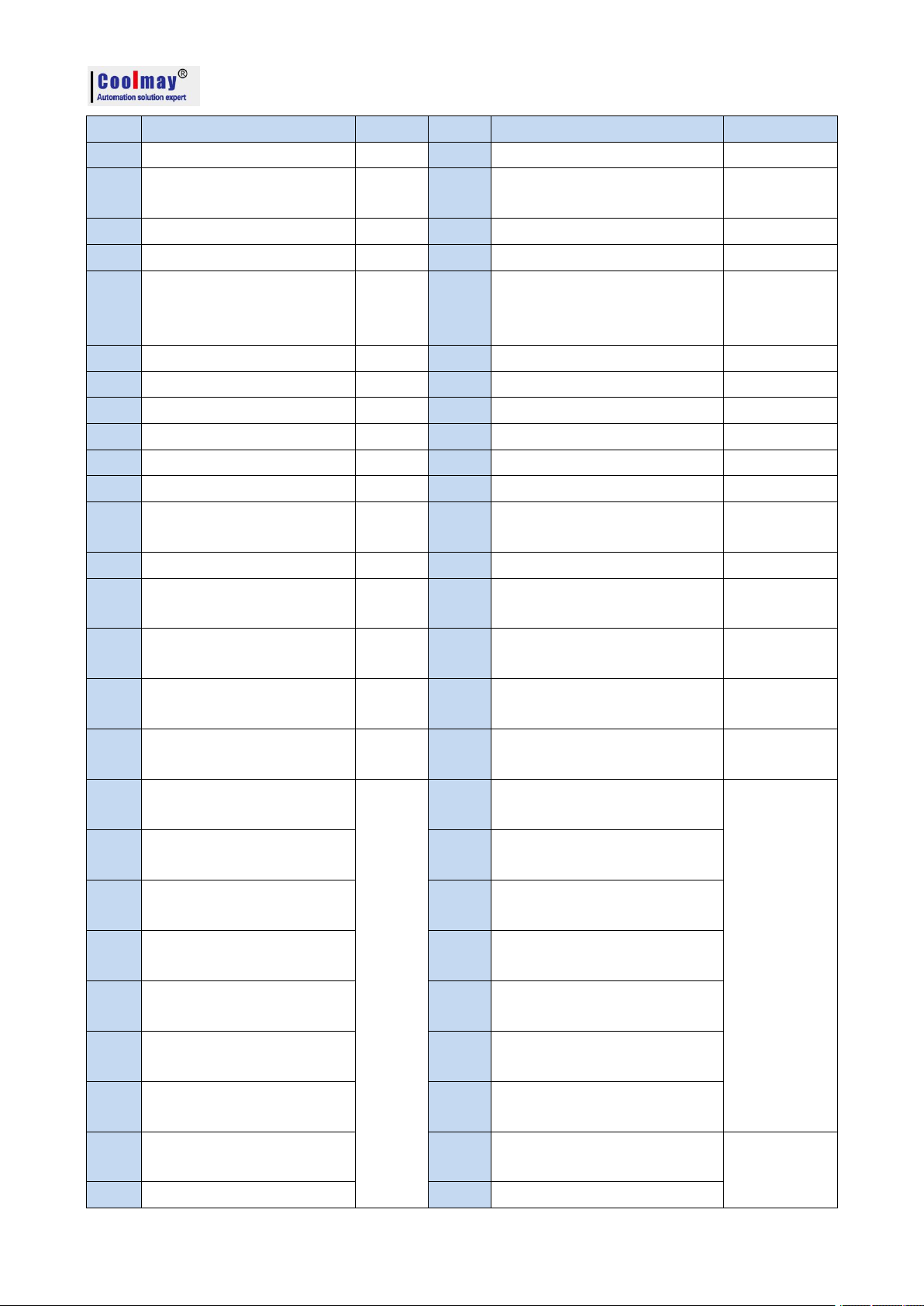

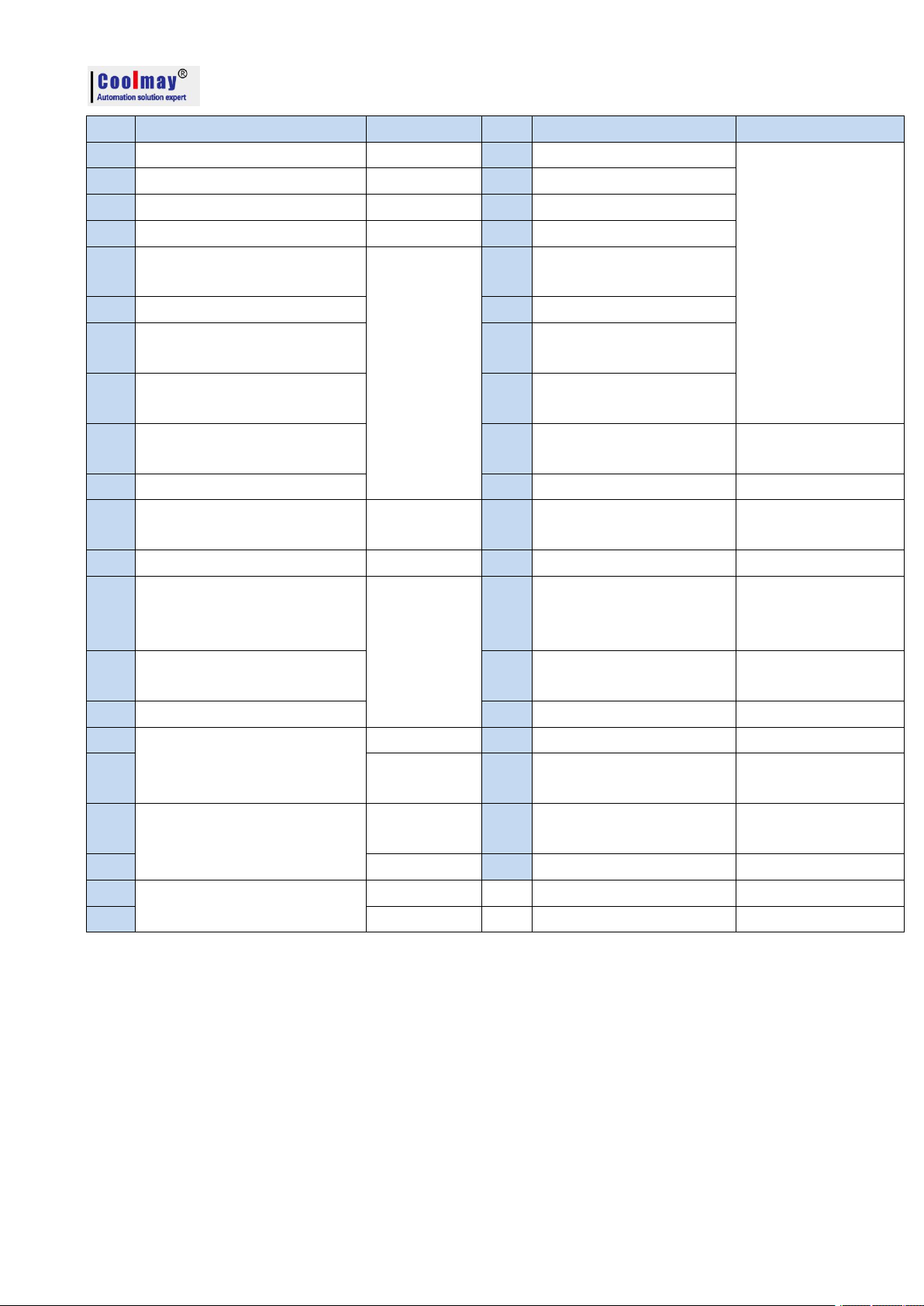

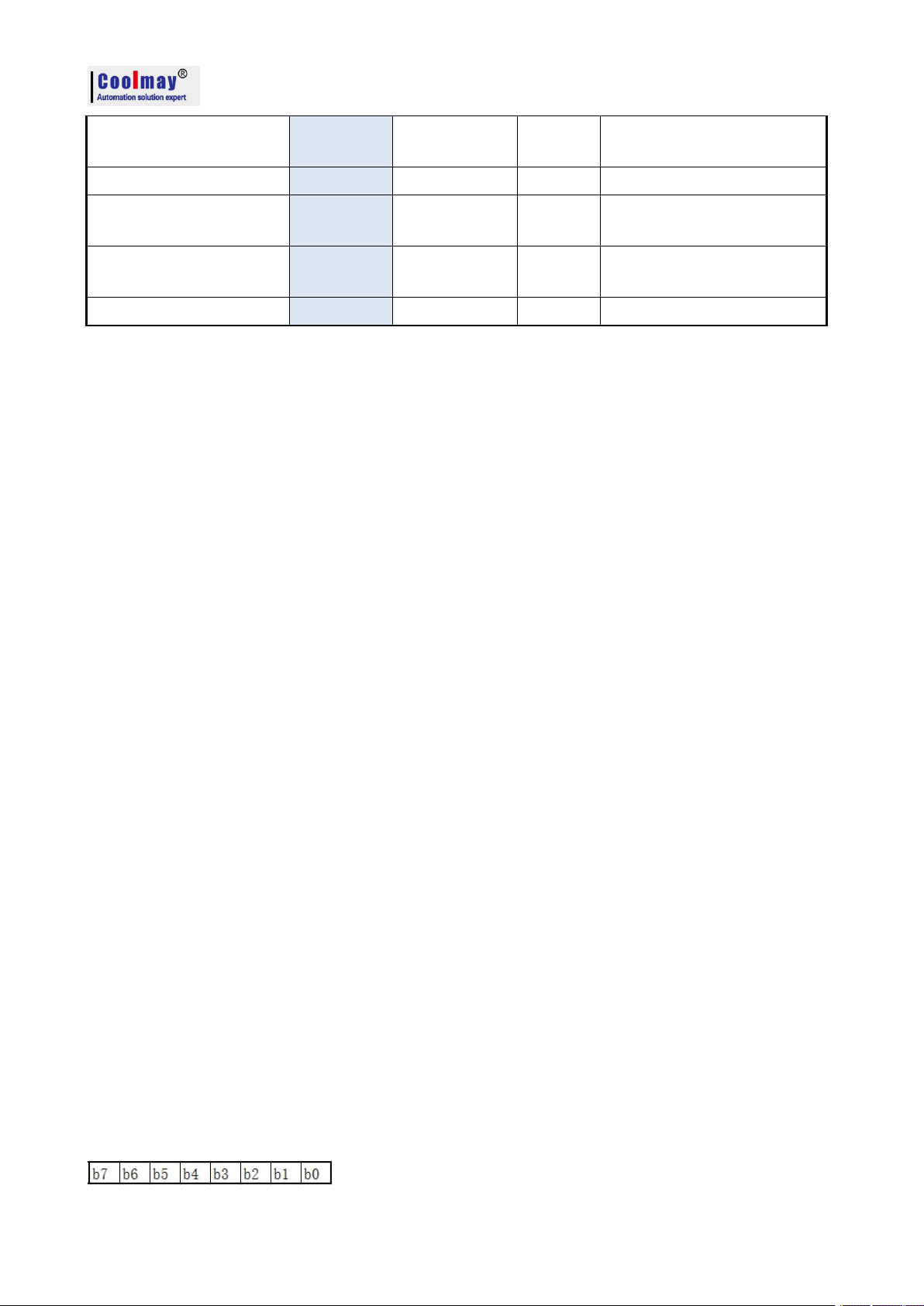

1.2 Specification

Artical

EX3G-43HB-24M

EX3G-43(50)KH-24M

EX3G-70KH

EX3G-100HA

Image

Dimension

134*102*30mm

150*93*32mm

226*163*35.6mm

275*194*36mm

Cutout size

119*93mm

143*86mm

218*153mm

261*180mm

Power

Consumption

4-6W

4-6W/5-7W

6-7W

6-8W

Features

Support Interrupt,linear arc interpolation,PID auto-tuning,32k program capacity, 32k retentive register

HMI

Display

60K colors

Display size

97*56mm

97*56/108*65mm

154*87mm

222*133mm

Resolution

(

pixels

)

480*272

43KH:480*272

50KH:800*480

70KH:800*480

1024*600

RAM

32MB

64MB

128MB

ROM

128MB

Operation

system

without system

WINCE 5.0

WINCE 7.0

CPU

ARM9 216MHz

ARM9 400MHz

CORTEX A8

720MHz-1GHz;

COM port

1 TP download port

1 TP download port,1 USB 2.0 port

1 RS232 optional

1 RS485 or RS232 optional

Can’t coexist with PLC ethernet port

Software

CoolMayHMI V5.**(newest vesion pls see Http://coolmay.net)

PLC

Digital I/O

Up to12DI/12DO

Up to 30DI/30DO(At most 28 relay outputs)

I/O level

MT Output: NPN MR output: NO contact Input: Passive NPN, public terminal isolated

Output type

MR/MOS

Maximum load: MOS is 2A; MR is 5A

MR/MT/MRT

Maximum load: MT is 500mA; MR is 5A

High-speed

counting

Single phase 6channel

10KHz or AB(Z) 3

channel 10KHz

Normally 6 single phase 60KHz Or 2channel ABl(Z) phase 60KHz+1 channel 10KHz;

High-speed

pulse

8 channel 10KHz

8channels,Y0-Y3 is 100KHz,Y4-Y7 is 10KHz

;

Note: High speed counter+High speed pulse should be less 480KHz.

Analog I/O

Analog input type is EKSTJ type thermocouple (supports

negative temperature) / PT100 / PT1000 / NTC10K /

NTC50K / NTC100K / 0 ~ 10V/0~5V/0~20mA/4~20mA

or mix type and other special specifications

Analog input type is EKSTJ type thermocouple (supports

negative temperature) / PT100 / PT1000 / NTC10K /

NTC50K / NTC100K / -5V ~ 5V / -10V ~ 10V / 0 ~

10V/0~5V/0~20mA/4~20mA or mix type and other

special specifications

AO: 0-10V/0-5V/0-20mA/4-20mA or mixed

At most 4AD/2DA

At most 16AD/8DA

COM port

2 programming ports(1 MiniB type USB port,faster downloading speed;1 Rs232 port

)

2 RS485 optional

1 rs485 or 2rs485(one of rs485 is changed from default

rs232)/CAN(2.0A/B)/ethernet (which can’t exist to hmi

ethernet port)/WIFI(which will occupy default rs232port)

optional

Software

Compatible with Mitsubishi GX Developer8.86 and WORKS 2

Regular models:EX3G-43HB/43KH/50KH-16MR/24MR/24MT(-4AD2DA-485P/232H)

EX3G-70KH100HA-16MR/24MR/44MT/44MRT(-16AD8DA-485P/232H)

*EX3G-70HA/100HA: If with 30DI/30DO,the maximum analogs are 5AD/2DA;If with 24DI/20DO,the maximum analogs are

16AD/8DA; Detailed info.refer to:《Coolmay HMI/PLC All-in-on Programming Manual》 《HMI/PLC All-in-one User Manual》

《

CoolMay HMI User Manual

》 《

EX3G PLC/HMI Programming Manual

》 《

EX3G PLC/HMI User Manual

》

COOLMAY EX3G PLC/HMI All in one Programming manual

Page 6

3

1.3 Hardware description

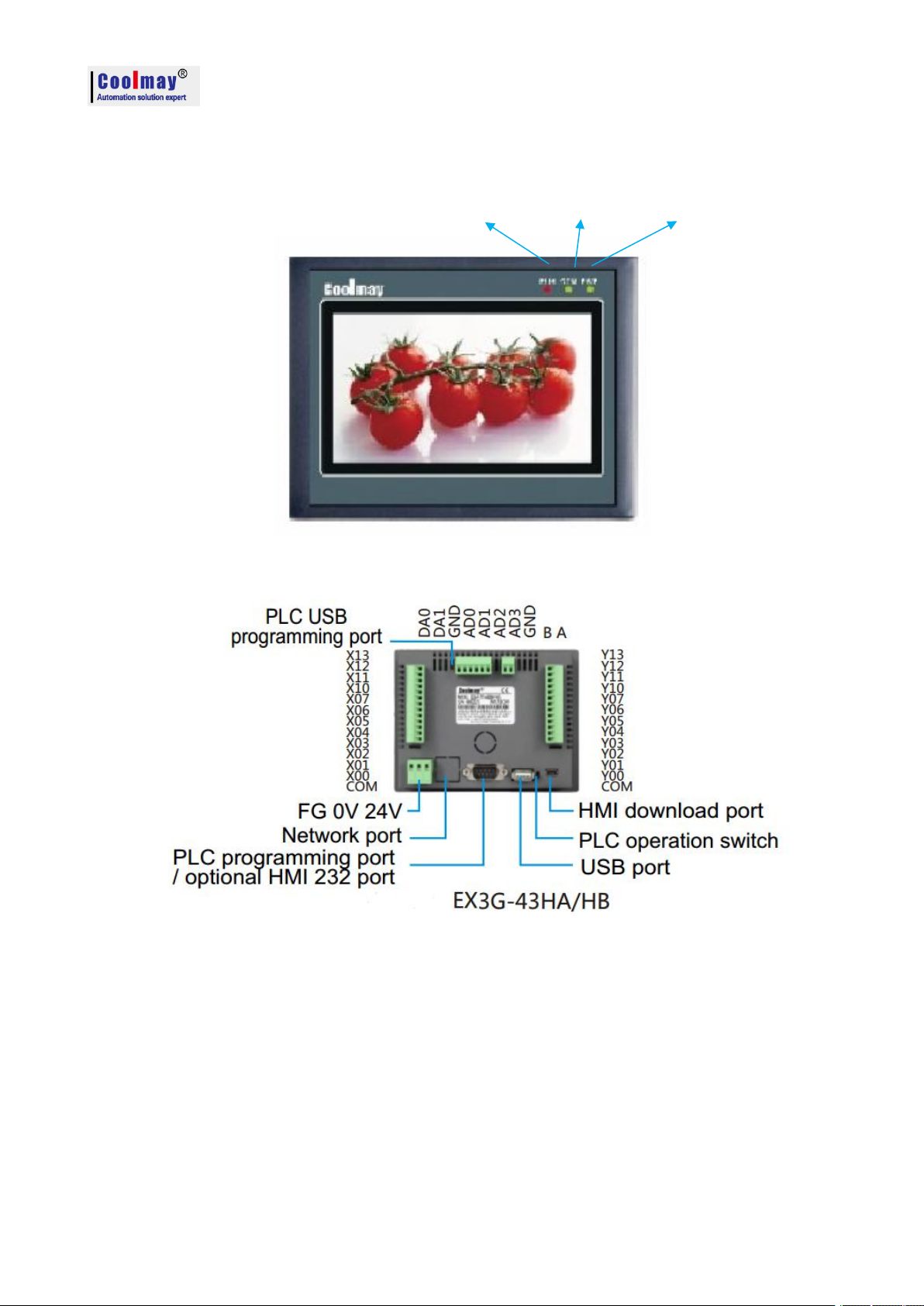

1.3.1 EX3G-43HA/HB structure description and dimension

PLC Run light Com port of plc and hmi Power light

COOLMAY EX3G PLC/HMI All in one Programming manual

* Dimension(mm):134*102*30

* Cutout size(mm): 119*93

* Installation: Clip installation

* Display size(mm): 97*56

Page 7

COOLMAY EX3G PLC/HMI All in one Programming manual

4

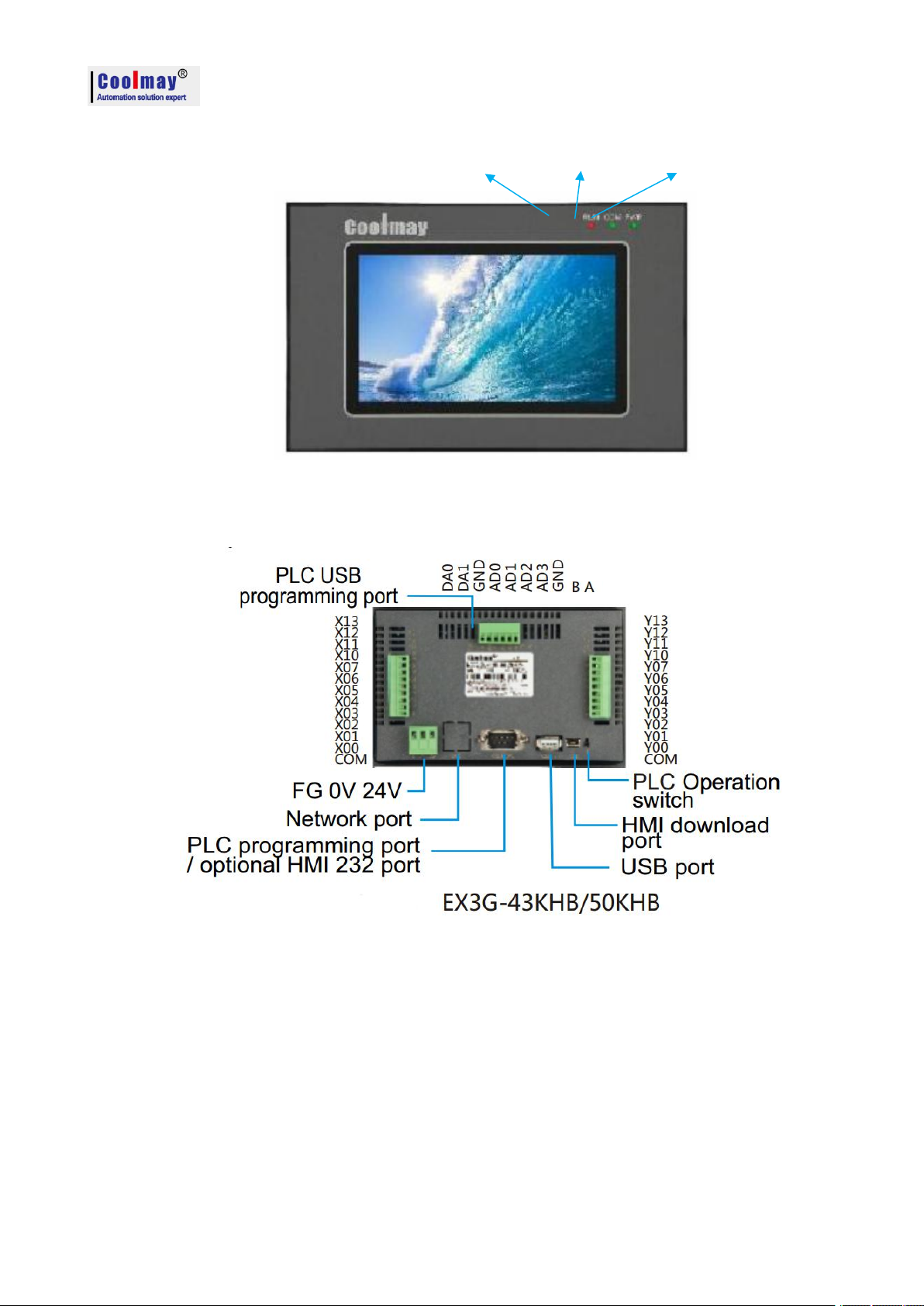

1.3.2 EX3G-43(50)KH structure description and dimension

PLC Run light Com port of plc and hmi Power light

* Dimension(mm):150*93*32

* Cutout size(mm):143*86

* Installation: Clip installation

* Display size(mm): EX3G-43KH:97*56

EX3G-50KH:108*65

Page 8

COOLMAY EX3G PLC/HMI All in one Programming manual

5

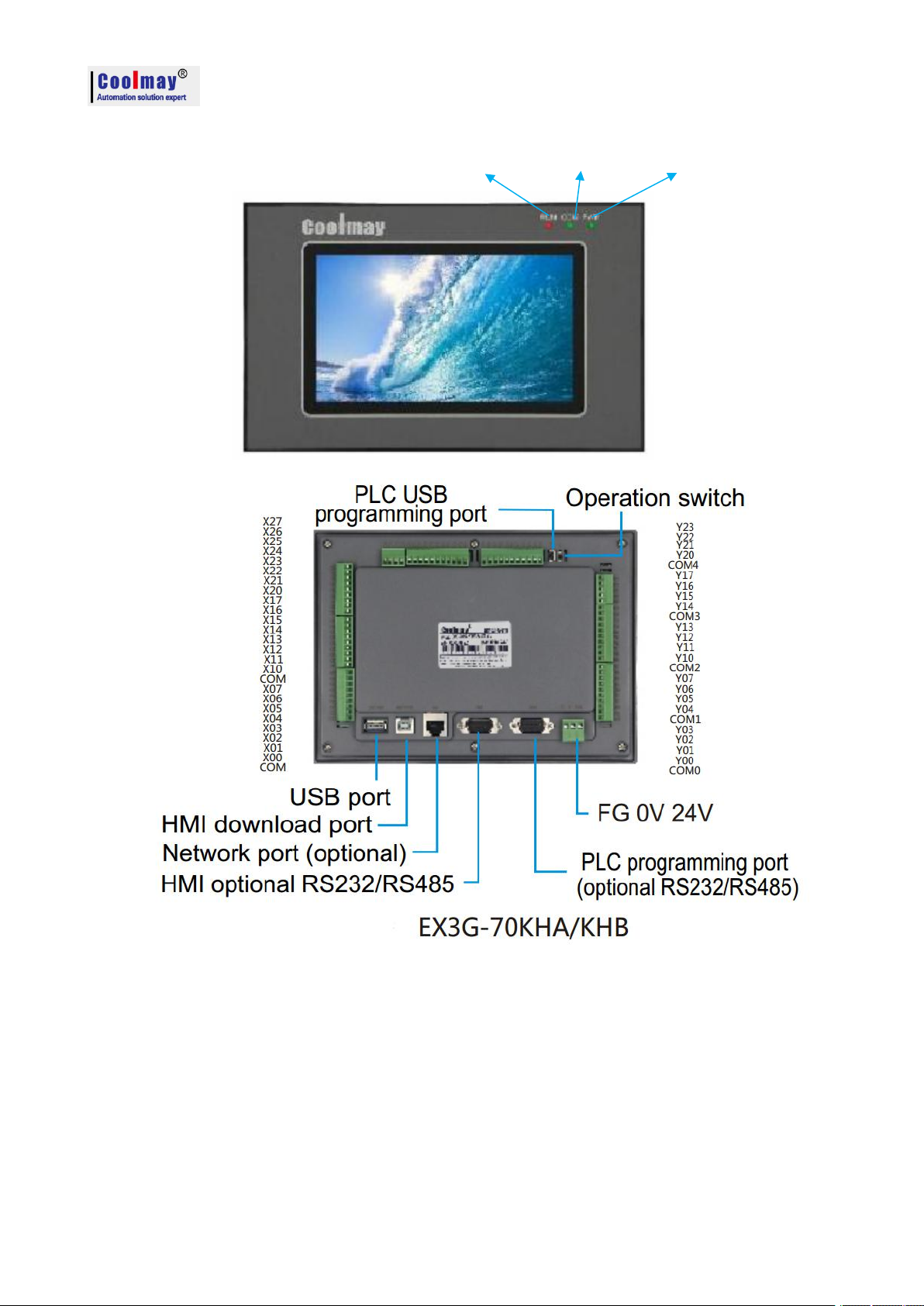

1.3.3 EX3G-70KH structure description and dimension

PLC Run light Com port of plc and hmi Power light

* Dimension(mm):226*163*35.6

* Cutout size(mm): 218*153

* Installation: Clip installation

* Display size(mm): 154*87

Page 9

COOLMAY EX3G PLC/HMI All in one Programming manual

6

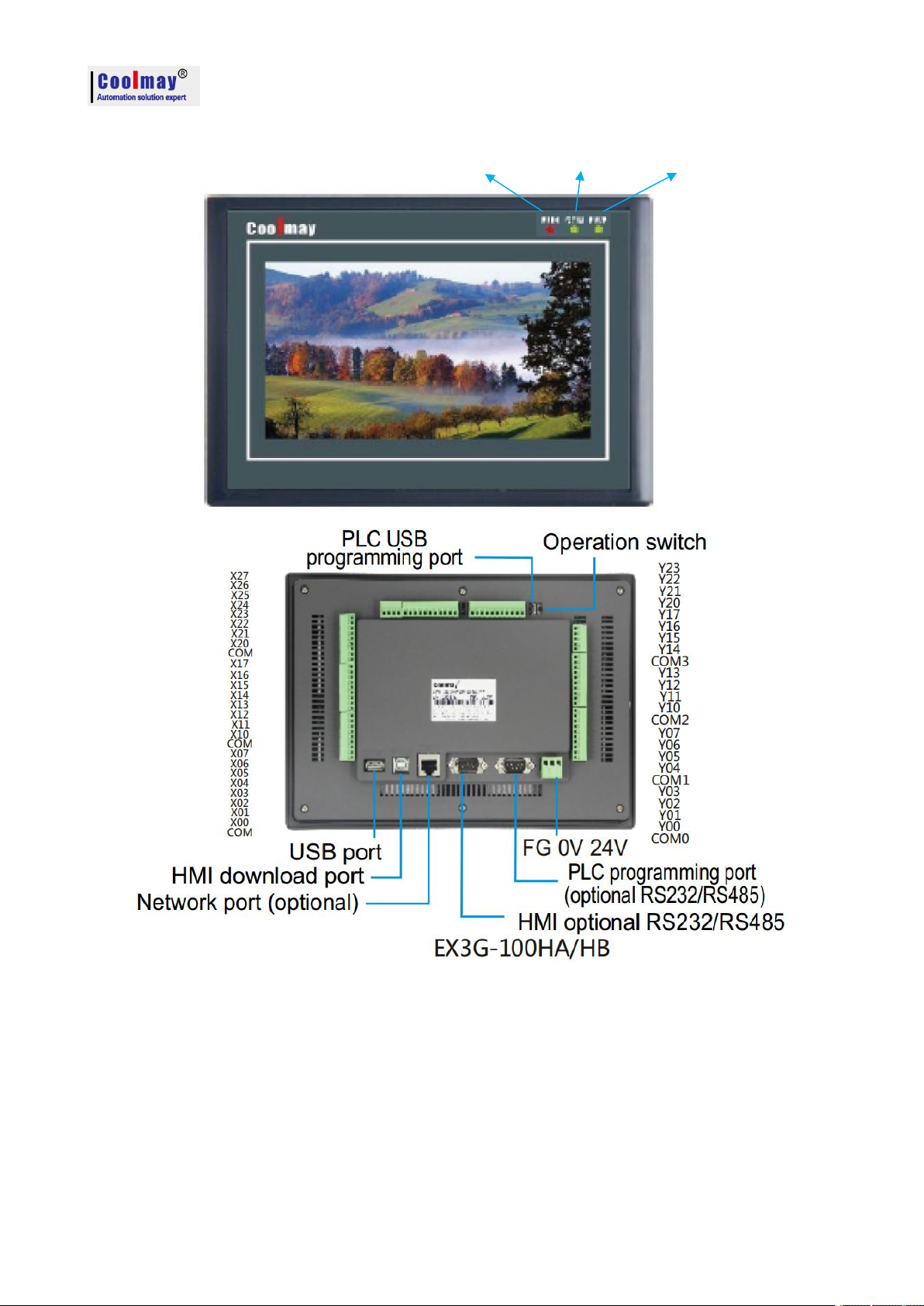

1.3.4 EX3G-100HA structure description and dimension

PLC Run light Com port of plc and hmi Power light

* Dimension(mm):275*194*36

* Cutout size(mm): 261*180

* Installation: Clip installation

* Display size(mm): 222*133

Page 10

COOLMAY EX3G PLC/HMI All in one Programming manual

7

1.3.5 Introduction of each interface and indicator

POWER: Power indicator, connected to the power light

RUN: PLC running status indicator. This light is on when the PLC is running.

COM: touch screen and PLC communication status indicator, when the two communicate, the light is on

Power terminal: The positive and negative terminals of the DC24V switching power supply are respectively

connected to the DC24V and 0V of the power supply terminal.

PLC programming port: two PLC programming ports (MiniB type usb port / RS232), PLC program can be

downloaded through 232 programming line or USB cable download

Touch screen programming port: download touch screen configuration program

USB interface: mainly can be directly inserted into the U disk of the file system FAT 32, can also be inserted

into the mouse.

For other hardware information, refer to "EX3G Series HMI/PLC All-in-One User Manual"

Page 11

COOLMAY EX3G PLC/HMI All in one Programming manual

8

2. PLC

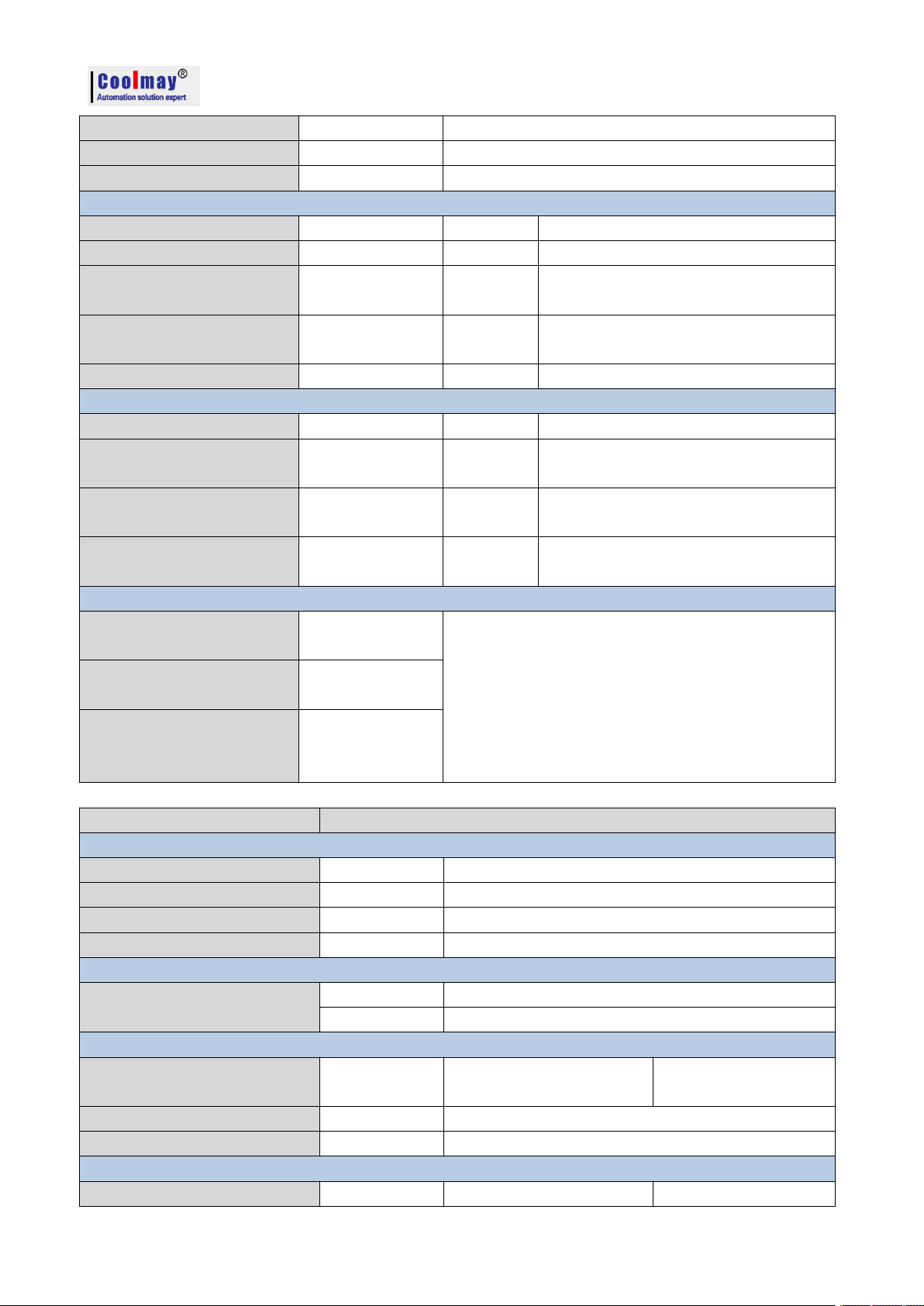

Name

Contents

I/O relay

Input relay

X000~X047

40points

Soft element number is octal

Total 80points for I/O

Output relay

Y000~Y047

40points

Auxiliary relay

General

M0~M383

384 points

EEPROM hold

M384~M1535

1152 points

General*1

M1536~M7679*2

6144 points

Special*3

M8000~M8511

512 points

Status

Initial state (EEPROM hold)

S0~S9

10 points

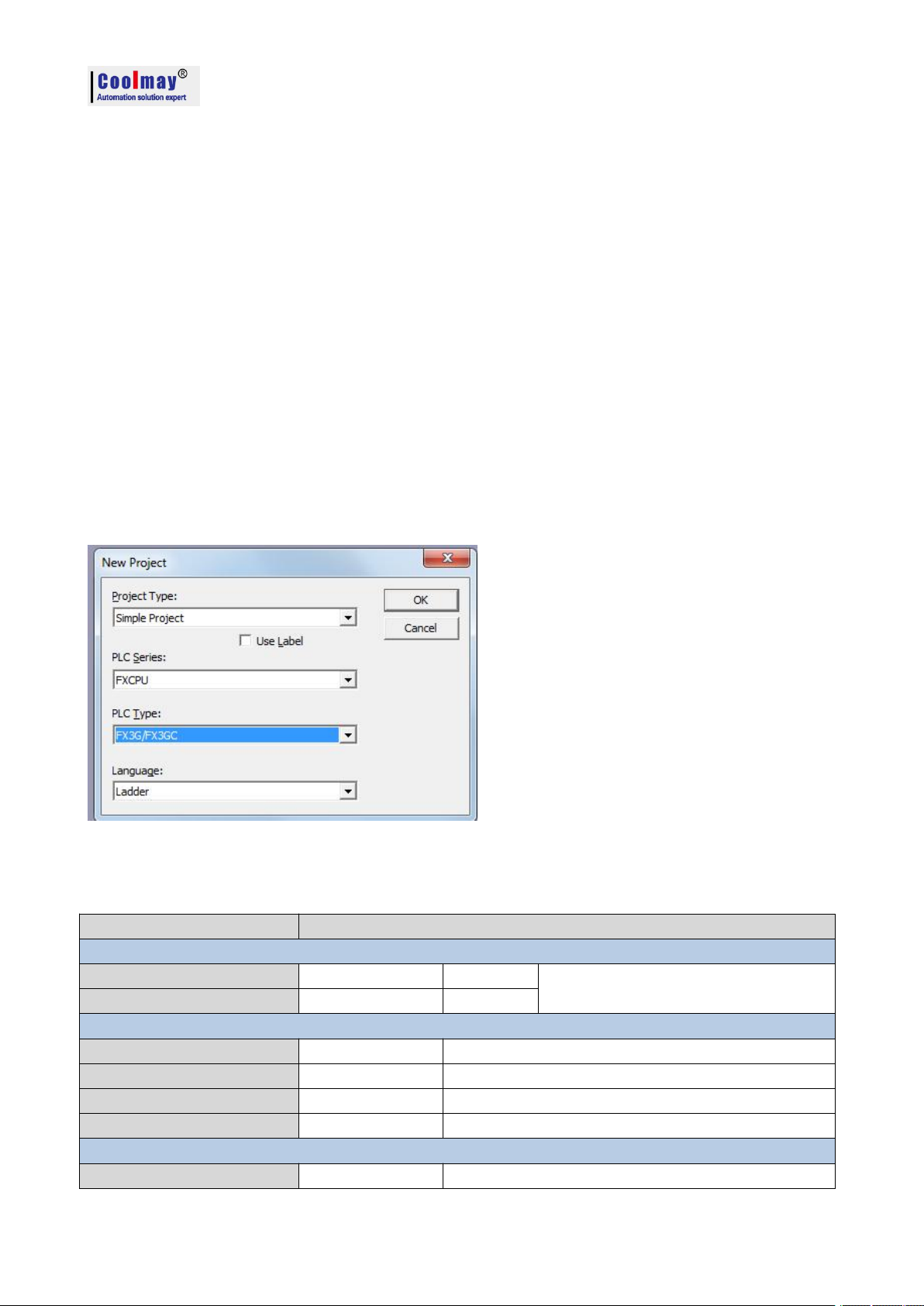

2.1 PLC Programming notice

The PLC is compatible with GX 8.86/Works 2 and below. If you use other versions of the software,

incompatibility may occur.

When the PLC program is downloaded, there is a prompt error: Cannot specify the com port,

GX 8.86 software: Online - Transfer settings change com port;

Works 2: All targets - Change the com port in all connected targets;

If communication error occurs, cable is abnormal If prompted, remove it by powering off, detecting the cable,

detecting whether the power is normal, or replacing the computer.

In the Works 2 software version, choose the figure : (Note: the label is forbidden)

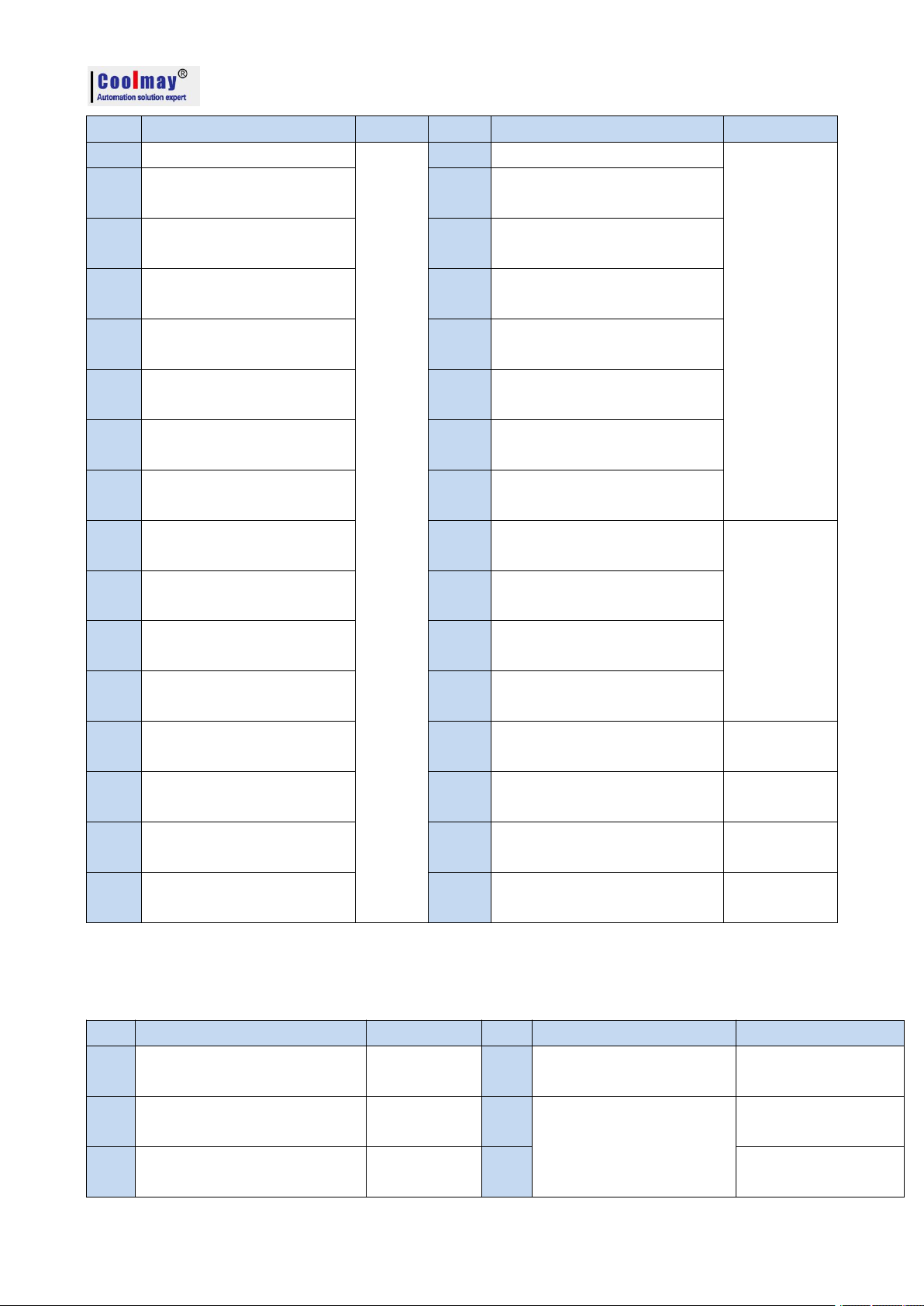

2.2 Soft element table

Page 12

COOLMAY EX3G PLC/HMI All in one Programming manual

9

EEPROM hold

S10~S899

890 points

Signal Alert (EEPROM hold)

S900~S999

100 points

General*1

S1000~S4095

3096 points

Timer (ON delay timer)

100ms

T0~T191

200 points

0.1~3,276.7s

10ms

※1

T200~T245

46 points

0.01~327.67s

1ms accumulative

(EEPROM hold)

T246~T249

4 points

0.001~32.767s

100ms accumulative

(EEPROM hold)

T250~T255

6 points

0.1~3,276.7s

1ms

T256~T319

64 points

0.001~32.767s

Counter

General up counter (16bit)

C0~C15

16 points

0~32,767 counter

EEPROM hold up counter

(16 bit)

C16~C199

184 points

0~32,767counter

General bi-direction (32 bit)

C200~C219

20 points

-2,147,483,648~+2,147,483,647

counter

EEPROM hold bi-direction

(32 bit)

C220~C234

15 points

-2,147,483,648~+2,147,483,647

counter

High-speed counter

Single-phase single counter input

Bi-direction (32 bit) (EEPROM hold)

C235~C245

-2,147,483,648~+2,147,483,647 Counter

Software counter

Single phase:at most 6 channel, 60kHz

Double phase:double frequency:at most 2-3 channels,60KHz

M8198 is 4 times frequency sign of C251.

Quad frequency:at most 2-3 channels,24kHz

M8199 is 4 times frequency sign of C253.

Single-phase double counter input

Bi-direction (32 bit) (EEPROM hold)

C246~C250

Double –phase double counter

input

Bi-direction (32 bit)(EEPROM hold)

C251~C255

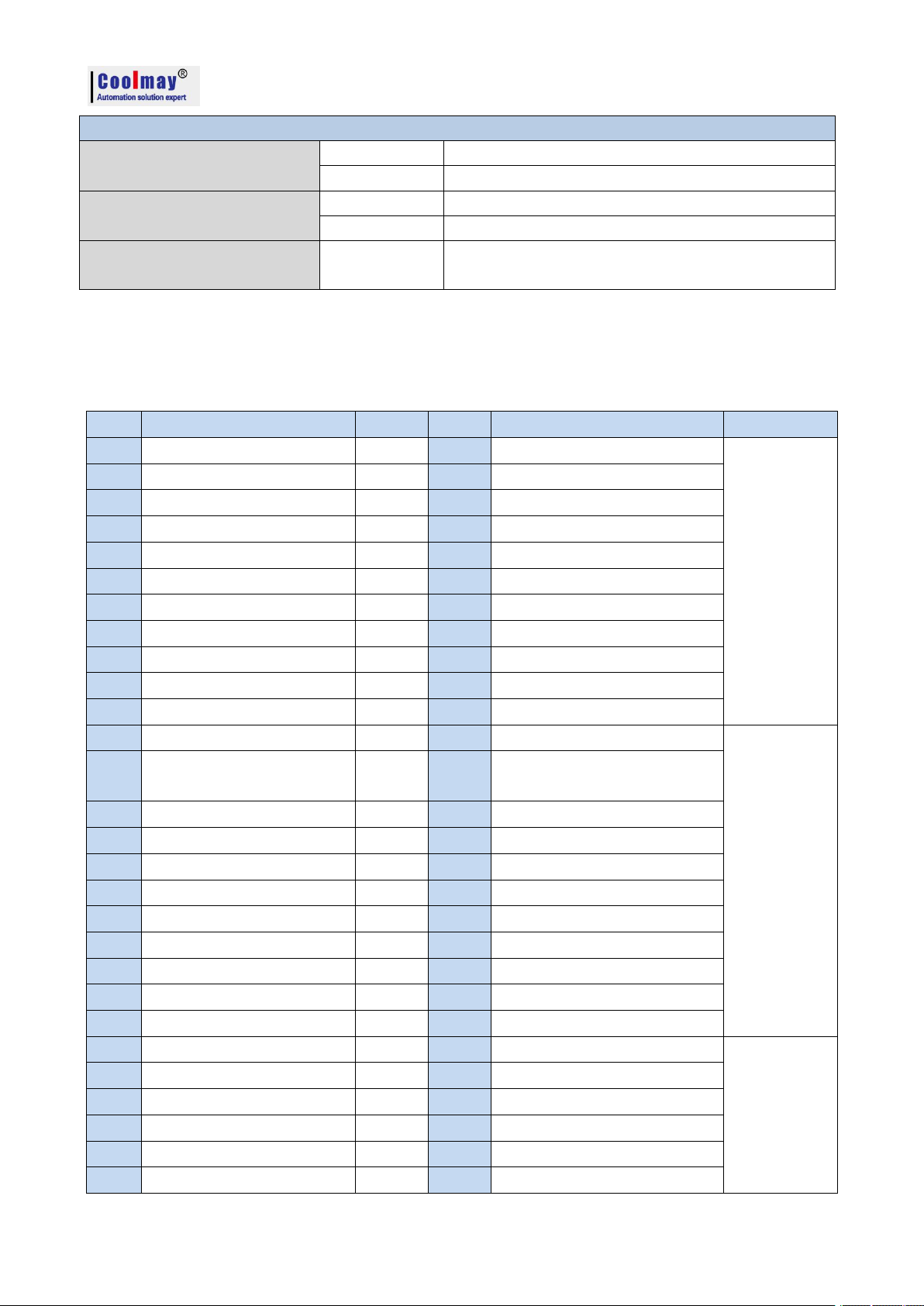

Name

Contents

Data register(32 bit when using in pair)

General(16bit)

D0~D127

128 points

EEPROM hold (16 bit)

D128~D7999

7872 points

Special (16 bit)

D8000~D8511

512 points

Index (16 bit)

V0~V7,Z0~Z7

16 points

Extended register·extended file register

Extended register(16 bit)

R0~R22999

23000points Maintain when power off not supported

R23000~R23999

1000points for system internal

Pointer

JUMP、CALL branch

P0~P255

P0~P1280

256 points

1281 points(26232 and above)

CJ instruct、CALL instruct

Input interrupt

I0□□~I5□□

6points

Timer interrupt

I6□□~I8□□

3points

Nest

Master control

N0~N7

8points

MC instruct

Page 13

COOLMAY EX3G PLC/HMI All in one Programming manual

10

Constant

Decimal (K)

16 bit

-32,768~+32,767

32 bit

-2,147,483,648~+2,147,483,647

Hexadecimal (H)

16 bit

0~FFFF

32 bit

0~FFFFFFFF

Real number(E)*3

32 bit

-1.0×2128~-1.0×2-126,0,1.0×2-126~1.0×2128

Can be in the form of a decimal point and index

Num

Content

Remarks

Num

Content

Remarks

M8000

In RUN,Normally closed

M8224

C224 Increase/decrease counting action

ON:decrease action

OFF:increase action

M8001

In RUN,Normally open

M8225

C225 Increase/decrease counting action

M8002

After RUN, Output a scan cycle ON

M8226

C226 Increase/decrease counting action

M8003

After RUN, Output a scan cycle OFF

M8227

C227 Increase/decrease counting action

M8011

Oscillating in 10ms cycle

M8228

C228 Increase/decrease counting action

M8012

Oscillating in 100ms cycle

M8229

C229 Increase/decrease counting action

M8013

Oscillating in 1s cycle

M8230

C230 Increase/decrease counting action

M8014

Oscillating in 1min cycle

M8231

C231 Increase/decrease counting action

M8020

Zero flag

M8232

C232 Increase/decrease counting action

M8021

Borrowing flag

M8233

C233 Increase/decrease counting action

M8022

Carry flag

M8234

C234 Increase/decrease counting action

M8024

Specify BMOV direction

M8235

C235 Increase/decrease counting action

ON:decrease action

OFF:increase action

M8028

During instruction execution,allow

interrupt

M8236

C236 Increase/decrease counting action

M8029

Instruction execution end flag

M8237

C237 Increase/decrease counting action

M8031

Non-retentive memory is cleared

M8238

C238 Increase/decrease counting action

M8032

Retentive memory is cleared

M8239

C239 Increase/decrease counting action

M8033

Memory retention stop

M8240

C240 Increase/decrease counting action

M8034

Prohibit all output

M8241

C241 Increase/decrease counting action

M8035

Forced RUN mode

M8242

C242 Increase/decrease counting action

M8036

Force RUN command

M8243

C243 Increase/decrease counting action

M8037

Force STOP command

M8244

C244 Increase/decrease counting action

M8045

Prohibit reset of all outputs

M8245

C245 Increase/decrease counting action

M8046

STL state action

M8246

C246 Increase/decrease counting action

ON:decrease action

OFF:increase action

M8047

STL effective control

M8247

C247 Increase/decrease counting action

M8048

Signal alarm action

M8248

C248 Increase/decrease counting action

M8049

Signal alarm is effective

M8249

C249 Increase/decrease counting action

M8050

Input interrupt (I00 is prohibited)

M8250

C250 Increase/decrease counting action

M8051

Input interrupt (I10 is prohibited)

M8251

C251 Increase/decrease counting action

*1: The 10ms timer will be affected by the scan cycle. If the scan period is 12ms, the timer becomes 12ms and is executed once.

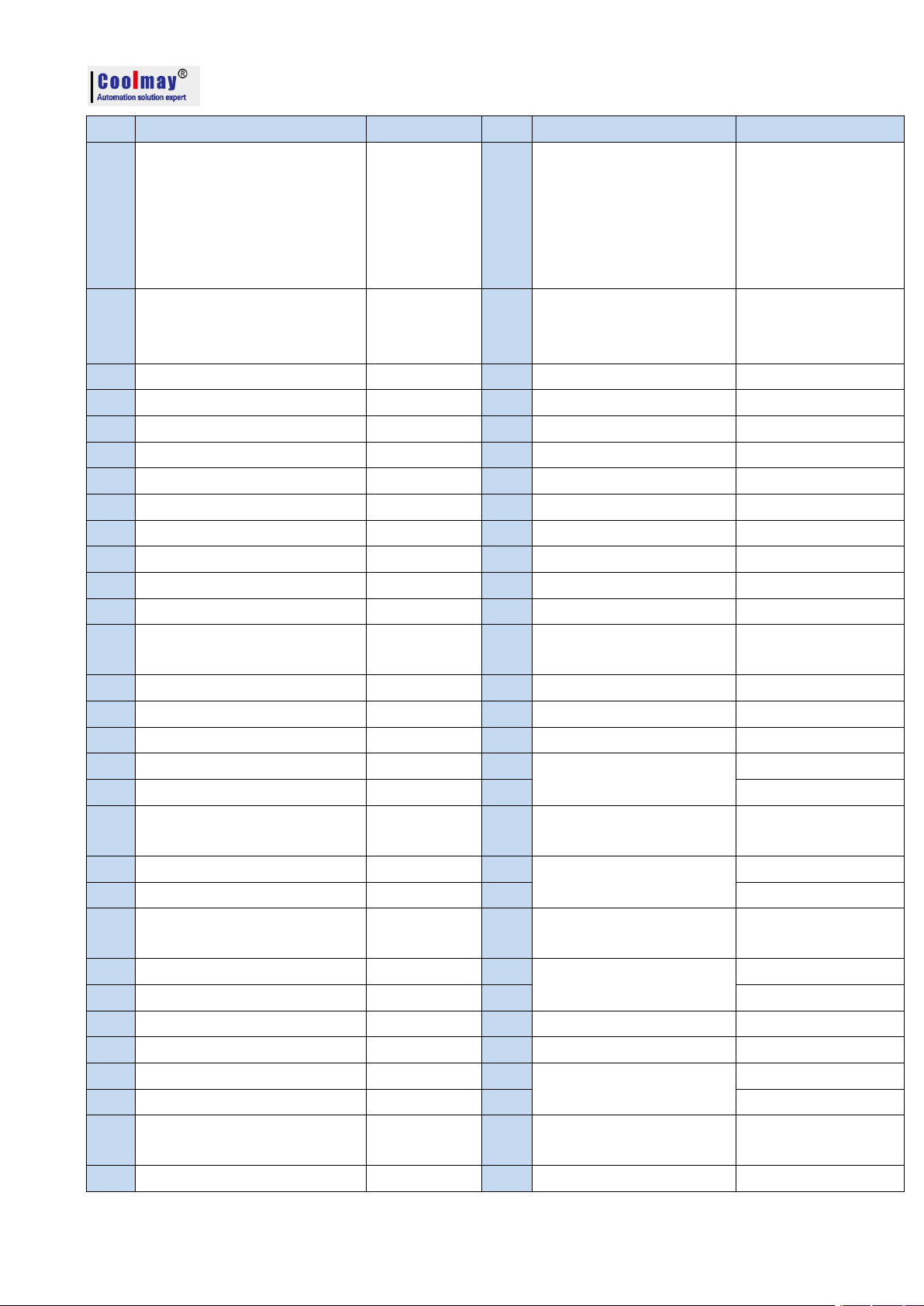

2.3 Special relay number and content

Page 14

COOLMAY EX3G PLC/HMI All in one Programming manual

11

Num

Content

Remarks

Num

Content

Remarks

M8052

Input interrupt (I20 is prohibited)

M8252

C252 Increase/decrease counting action

M8053

Input interrupt (I30 is prohibited)

M8253

C253 Increase/decrease counting action

M8054

Input interrupt (I40 is prohibited)

M8254

C254 Increase/decrease counting action

M8055

Input interrupt (I50 is prohibited)

M8255

C255 Increase/decrease counting action

M8056

Timer interrupt (I6 is prohibited)

M8340

1stpulse operation monitoring

M8057

Timer interrupt (I7 is prohibited)

M8342

Interpolation mode

26233 and lower

version

M8058

Timer interrupt (I8 is prohibited)

M8343

Interpolation mode

M8059

Counter interrupt is prohibited

M8344

Interpolation relative/absolute

coordinate

M8060

I/O Constitute error

M8348

Interpolation counterclockwise

26233and lower

version

M8061

PLC hardware error

M8341

Y000 clear signal output function is valid

26234 and higher

version

M8062

Serial communication error 0

M8342

Y000 specify the origin return direction

M8063

Serial communication error 1

M8343

Y000 forward limit

M8064

Parameter error

M8344

Y000 reverse limit

M8065

Grammatical error

M8345

Y000 near-point DOG signal logic

inversion

M8066

Loop error

M8346

Y000 zero signal logic inversion

M8067

Operation error

M8347

Y000 interrupt signal logic inversion

M8068

Operation error latch

M8348

Y000 positioning command driver

M8069

I/O bus detection

M8349

1st pulse stop

M8075

Sample tracking preparation start

command

M8350

2ndpulse operation monitoring

M8076

Sample tracking execution start

command

M8351

Y001 clear signal output function is valid

M8077

Sample tracking execution

M8352

Y001 specify the origin return direction

M8078

Sample tracking execution end

control

M8353

Y001 forward limit

M8079

Sampling tracking system area

M8354

Y001 reverse limit

M8120

Can't use

M8355

Y001 near-point DOG signal logic

inversion

M8121

RS/RS2 command sends standby

Serial Port 2

refer to

chapter

2.11

M8356

Y001 zero signal logic inversion

M8122

RS/RS2 command to send request

M8357

Y001 interrupt signal logic inversion

M8123

RS/RS2 command reception end

M8358

Y001 positioning command driver

M8124

RS/RS2 command data in reception

M8359

2nd pulse stop

M8125

MODBUS and Mitsubishi function

enablement

M8360

3rdpulse operation monitoring

M8128

RD3A/WR3A Receive Completed

M8361

Y002 clear signal output function is valid

M8129

RD3A/WR3A communication

timeout

M8362

Y002 specify the origin return direction

M8151

5thpulse operation monitoring

M8363

Y002 forward limit

Page 15

COOLMAY EX3G PLC/HMI All in one Programming manual

12

Num

Content

Remarks

Num

Content

Remarks

M8152

6thpulse operation monitoring

M8364

Y002 reverse limit

M8153

7thpulse operation monitoring

M8365

Y002 near-point DOG signal logic

inversion

M8154

8thpulse operation monitoring

M8366

Y002 zero signal logic inversion

M8160

XCH's SWAP function

M8367

Y002 interrupt signal logic inversion

M8161

8-bit processing mode

Software

26234 and

higher

M8368

Y002 positioning command driver

M8170

Input X000 pulse capture

M8369

3rd pulse stop

M8171

Input X001 pulse capture

M8370

4thpulse operation monitoring

M8172

Input X002 pulse capture

M8371

Y003 clear signal output function is valid

M8173

Input X003 pulse capture

M8372

Y003 specify the origin return direction

M8174

Input X004 pulse capture

M8373

Y003 forward limit

M8175

Input X005 pulse capture

M8374

Y003 forward limit

M8176

Input X006 pulse capture

M8375

Y003 near-point DOG signal logic

inversion

M8177

Input X007 pulse capture

M8376

Y003 zero signal logic inversion

M8192

Programming port protocol and

other protocol enablement

Serial port3

M8377

Y003 interrupt signal logic inversion

M8196

Programming port protocol and

other protocol enablement

Serial port2

M8378

Y003 positioning command driver

M8198

4 times frequency of C251, C252,

C254

M8379

4th pulse stop

M8199

4 times frequency of C253

M8396

C254 function corresponds to input

phase

Refer to chapter

2.9.1

M8200

C200 Increase/decrease counting

action

ON:decreas

e action

OFF:increas

e action

M8401

RS2 command sends standby

Serial port 3

Refer to chapter

2.11.2

M8201

C201 Increase/decrease counting

action

M8402

RS2 command to send request

M8202

C202 Increase/decrease counting

action

M8403

RS2 command reception end

M8203

C203 Increase/decrease counting

action

M8404

RS2 command data in reception

M8204

C204 Increase/decrease counting

action

M8405

RS2 command data setting ready

M8205

C205 Increase/decrease counting

action

M8408

RD3A/WR3A Receive Completed

M8206

C206 Increase/decrease counting

action

M8409

RD3A/WR3A communication timeout

M8207

C207 Increase/decrease counting

action

M8421

RS2 command sends standby

CAN

communication

Refer to chapter

M8208

C208 Increase/decrease counting

M8422

RS2 command to send request

Page 16

COOLMAY EX3G PLC/HMI All in one Programming manual

13

Num

Content

Remarks

Num

Content

Remarks

2.11.4

action

M8209

C209 Increase/decrease counting

action

M8423

RS2 command reception end

M8210

C210 Increase/decrease counting

action

M8424

RS2 command data in reception

M8211

C211 Increase/decrease counting

action

M8425

RS2 command data send completed

M8212

C212 Increase/decrease counting

action

M8426

RS command master-slave and

multi-machine mode

M8213

C213 Increase/decrease counting

action

M8427

CAN data standard frame and extended

frame

M8214

C214 Increase/decrease counting

action

M8428

CAN communication MODBUS response

correct

M8215

C215 Increase/decrease counting

action

M8429

Communication timeout

M8216

C216 Increase/decrease counting

action

M8432

Interpolation mode

26235 and higher

version

M8217

C217 Increase/decrease counting

action

M8433

Interpolation mode

M8218

C218 Increase/decrease counting

action

M8434

Interpolation relative/absolute

coordinate

M8219

C219 Increase/decrease counting

action

M8435

Interpolation counterclockwise

M8220

C220 Increase/decrease counting

action

M8450

5th pulse stop

M8221

C221 Increase/decrease counting

action

M8451

6th pulse stop

M8222

C222 Increase/decrease counting

action

M8452

7th pulse stop

M8223

C223 Increase/decrease counting

action

M8453

8th pulse stop

Num

Content

Remarks

Num

Content

Remarks

D8000

Watchdog timer

D8148

5th- 8thpulse acceleration and

deceleration time

D8001

PLC type and system version

Main version

number

D8160

8thposition pulse amount

Low

D8002

PLC memory capacity

2...2K steps

;

4...4K steps

;

D8161

High

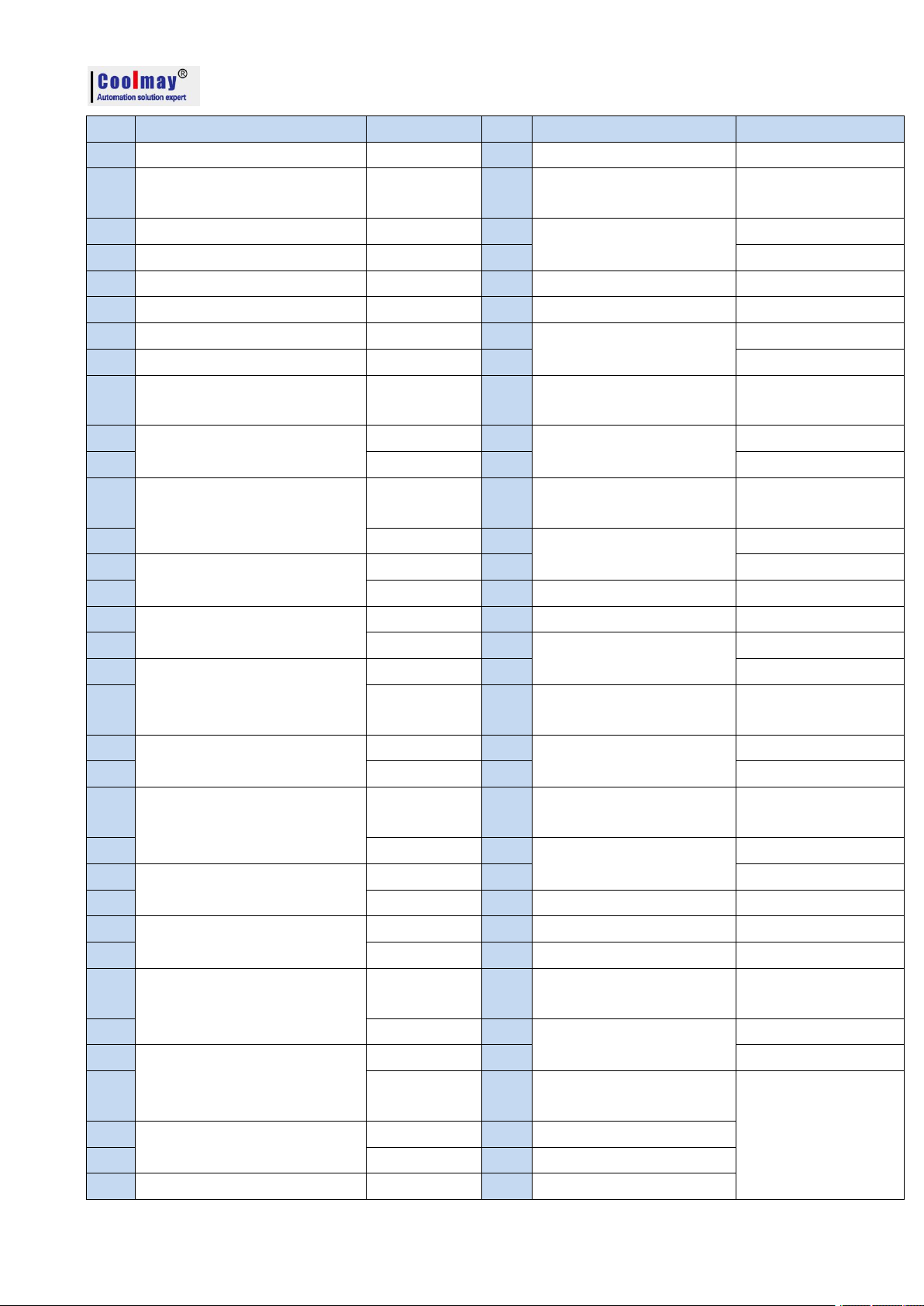

2.4 Special register number and content

Page 17

COOLMAY EX3G PLC/HMI All in one Programming manual

14

Num

Content

Remarks

Num

Content

Remarks

8...8K steps

;

When 16K steps

and above,

D8002=8,D8102 is

corresponded to

16,32,64

D8003

Memory type

10H:Programmable

controller built-in

memory

D8169

Restrict access status

D8010

Scan current value

D8182

Z1 Register contents

D8011

Scan time minimum

D8183

V1 Register contents

D8012

Scan time maximum

D8184

Z2 Register contents

D8013

Second

D8185

V2 Register contents

D8014

Minute

D8186

Z3 Register contents

D8015

Hour

D8187

V3 Register contents

D8016

Date

D8188

Z4 Register contents

D8017

Month

D8189

V4 Register contents

D8018

Year

D8190

Z5 Register contents

D8019

Week

D8191

V5 Register contents

D8020

Input filter adjustment (0-60ms) initial

10

D8192

Z6 Register contents

D8030

AD0 analog input value

D8193

V6 Register contents

D8031

AD1 analog input value

D8194

Z7 Register contents

D8032

AD2 analog input value

D8195

V7 Register contents

D8033

AD3 analog input value

D8340

1stposition pulse amount

Low

D8034

AD4 analog input value

D8341

High

D8035

AD5 analog input value

D8342

Y0 deviation speed

Initial value:0

D8036

AD6 analog input value

D8343

1stpulse maximum speed

Low

D8037

AD7 analog input value

D8344

High

D8038

AD8 analog input value

D8345

Y0 crawling speed

Initial value: 1000

D8039

AD9 analog input value

D8346

5th-8thpulse maximum speed

Low

D8040

AD10 analog input value

D8347

High

D8041

AD11 analog input value

D8348

1stpulse acceleration time

D8042

AD12 analog input value

D8349

1stpulse deceleration time

D8043

AD13 analog input value

D8350

2ndposition pulse amount

Low

D8044

AD14 analog input value

D8351

High

D8045

AD15 analog input value

D8352

Y1 deviation speed

Initial value:0

D8050

DA0 analog output value

D8353

2ndpulse maximum speed

Low

Page 18

COOLMAY EX3G PLC/HMI All in one Programming manual

15

Num

Content

Remarks

Num

Content

Remarks

D8051

DA1 analog output value

D8354

High

D8052

DA2 analog output value

D8355

Y1 crawling speed

Initial value: 1000

D8053

DA3 analog output value

D8356

Y1 Origin return speed

Initial value:50000

Low

D8054

DA4 analog output value

D8357

High

D8055

DA5 analog output value

D8358

2ndpulse acceleration time

D8056

DA6 analog output value

D8359

2ndpulse deceleration time

D8057

DA7 analog output value

D8360

3rdposition pulse amount

Low

D8058

When DA is current,Bit setting

Refer to 2.7

D8361

High

D8059

Constant scan time

D8362

Y2 deviation speed

Initial value:0

D8074

X0 Rising edge ring counter value

[1/6μs unit]

Low

D8363

3rdpulse maximum speed

Low

D8075

High

D8364

High

D8076

X0 falling edge ring counter value

[1/6μs unit]

Low

D8365

Y2 crawling speed

Initial value: 1000

D8077

High

D8366

Y2 Origin return speed

Initial value:50000

Low

D8078

X0 pulse width / pulse period

[10μs unit]

Low

D8367

High

D8079

High

D8368

3rdpulse acceleration time

D8080

X1 Rising edge ring counter value

[1/6μs unit]

Low

D8369

3rdpulse deceleration time

D8081

High

D8370

4thposition pulse amount

Low

D8082

X1 falling edge ring counter value

[1/6μs unit]

Low

D8371

High

D8083

High

D8372

Y3 deviation speed

Initial value:0

D8084

X1 pulse width / pulse period

[10μs unit]

Low

D8373

4thpulse maximum speed

Low

D8085

High

D8374

High

D8086

X3 Rising edge ring counter value

[1/6μs unit]

Low

D8375

Y3 crawling speed

Initial value:1000

D8087

High

D8376

Y3 Origin return speed

Initial value:50000

Low

D8088

X3 falling edge ring counter value

[1/6μs unit]

Low

D8377

High

D8089

High

D8378

4thpulse acceleration time

D8090

X3 pulse width / pulse period

[10μs unit]

Low

D8379

4thpulse deceleration time

D8091

High

D8395

Network setting function

Refer to chapter 2.12

D8092

X4 Rising edge ring counter value

[1/6μs unit]

Low

D8397

ADPRW command serial port

position

Refer to chapter 2.11.1

D8093

High

D8398

0~2147483647(1ms) Ring count for

incremental actions

D8094

X4 falling edge ring counter value

[1/6μs unit]

Low

D8399

D8095

High

D8400

Modbus RTU protocol

Communication parameters

Serial port3

Refer to chapter 2.11.2

D8096

X4 pulse width / pulse period

[10μs unit]

Low

D8401

Communication mode

D8097

High

D8406

Number of intervals

D8101

PLC type and system version

Secondary version

D8409

overtime time

Page 19

COOLMAY EX3G PLC/HMI All in one Programming manual

16

Num

Content

Remarks

Num

Content

Remarks

number

D8102

PLC memory capacity

16...16K steps

D8410

RS2 header 1, 2 <initial value: STX>

D8108

Number of special modules connected

D8411

RS2 header 3, 4

D8109

Y number of output refresh error

D8412

RS2 trailer 1, 2 <initial value: ETX>

D8120

Modbus RTU protocol Communication

parameters

Serial port2

Refer to chapter

2.11

D8413

RS2 trailer 3, 4

D8121

Master and slave station number

D8414

Master and slave station number

D8122

RS command to send data remaining

points

D8415

RS2 receives the summation

calculation result

D8123

RS command to receive points

monitoring

D8416

RS2 sends summation

D8124

RS header <initial value: STX>

D8420

Communication parameters

CAN communication

Refer to chapter 2.11.4

D8125

RS trailer <initial value: ETX>

D8421

Communication mode

D8126

When the serial port 2 uses the ADPRW

command, the value is 0.

26232 lower

D8426

Number of intervals

D8126

Serial port 2 interval period number

26232 and higher

D8429

overtime time

D8127

Specify the starting number of the

communication request of the lower

computer

Serial port2

Refer to chapter

2.11

D8430

RS2 header 1, 2 <initial value: STX>

D8128

Specify the number of data requested

by the lower computer communication

D8431

RS2 header 3, 4

D8129

Set timeout

D8432

RS2 trailer 1, 2 <initial value: ETX>

D8140

5thposition pulse amount

Low

D8433

RS2 trailer 3, 4

D8141

High

D8434

RS2 receives the summation

receive data

D8142

6thposition pulse amount

Low

D8435

RS2 receives the summation

calculation result

D8143

High

D8436

RS2 sends summation

D8144

7thposition pulse amount

Low

D8145

High

Special relay and register not supported

※ Special relay not supported

M8004~M8010,

M8015~M8019,

M8024~M8027,

M8030,

M8038~M8039,

M8040~M8044,

M8060~M8074,

Page 20

COOLMAY EX3G PLC/HMI All in one Programming manual

17

1

Data move instructions

2

Data conversion instructions

3

Comparison instructions

4

Arithmetic operation instructions

5

Logical operation instructions

6

Special function instructions

7

Rotate instructions

8

Shift instruction

9

Data operation instructions

10

Character string operation instructions

11

Program flow control instructions

12

I/O refresh instructions

13

Real time clock control instructions

14

Pulse output/positioning control instructions

15

Serial communication

16

Special block/unit control instructions

17

Extension register/extension file register control instructions

18

Other handy instruct

M8084~M8119

M8130~M8159

M8161~M8169

M8178~M8191

,

,

,

,

M8256~M8339,

M8370~M8395

,

M8430~M8511.

special register not supported

※

D8004~D8009

D8042~D8067

D8069~D8073

D8105~D8119

D8150~D8168

D8200~D8329

,

,

,

,

,

,

D8468~D8511.

Specific functions please refer to《Mitsubishi FX3G programming manual

》

2.5 Applied instructions【Sequence is according to instruct variety】

(Contrast with MITSUBISHI FX3G PLC)

Applied instruction can be divided into the following 18 kinds.

Page 21

COOLMAY EX3G PLC/HMI All in one Programming manual

18

1. Data move instructions

Mnemonic

FNC No.

Function

Support

MOV

12

Move

★

SMOV

13

Shift Move

★

CML

14

Compliment

★

BMOV

15

Block Move

★

FMOV

16

Fill Move

★

PRUN

81

Parallel Run (Octal Mode)

★

XCH

17

Exchange

★

SWAP

147

Byte Swap

★

EMOV

112

Floating Point Move

★

HCMOV

189

High Speed Counter Move

★

2. Data conversion instructions

Mnemonic

FNC No.

Function

Support

BCD

18

Conversion to Binary Coded Decimal

★

BIN19Conversion to Binary

★

GRY

170

Decimal to Gray Code Conversion

★

GBIN

171

Gray Code to Decimal Conversion

★

FLT

49

Conversion to Floating Point

★

INT

129

Floating Point to Integer Conversion

★

EBCD

118

Floating Point to Scientific Notation

Conversion

★

EBIN

119

Scientific Notation to Floating Point

Conversion

★

RAD

136

Floating Point Degree to Radian

Conversion

★

DEG

137

Floating Point Radian to degree Conversion

★

3.

Comparison instructions

Mnemonic

FNC No.

Function

Support

LD=

224

Contact compare LD

(S1)=(S2)

★

LD>

225

Contact compare LD

(S1)>(S2)

★

LD<

226

Contact compare LD

(S1)<(S2)

★

LD<>

228

Contact compare LD

(S1)≠(S2)

★

LD<=

229

Contact compare LD

(S1)≦(S2)

★

LD>=

230

Contact compare LD

(S1)≧(S2)

★

AND=

232

Contact compare AND

(S1)=(S2)

★

AND>

233

Contact compare AND

(S1)>(S2)

★

AND<

234

Contact compare AND

(S1)<(S2)

★

AND<>

236

Contact compare AND

(S1)≠(S2)

★

AND<=

237

Contact compare AND

(S1)≦(S2)

★

Page 22

COOLMAY EX3G PLC/HMI All in one Programming manual

19

AND>=

238

Contact compare AND

(S1)≧(S2)

★

OR=

240

Contact compare OR

(S1)=(S2)

★

OR>

241

Contact compare OR

(S1)>(S2)

★

OR<

242

Contact compare OR

(S1)<(S2)

★

OR<>

244

Contact compare OR (S1)≠(S2)

★

OR<=

245

Contact compare OR (S1)≦(S2)

★

OR>=

246

Contact compare OR (S1)≧(S2)

★

CMP

10

Compare

★

ZCP

11

Zone Compare

★

ECMP

110

Floating Point Compare

★

EZCP

111

Floating Point Zone Compare

★

HSCS

53

High speed counter set

★

HSCR

54

High speed counter reset

★

HSZ

55

High Speed Counter Zone Compare

★

HSCT

280

High speed counter table compare

★

BKCMP=

194

Block compare (S1)=(S2)

★

BKCMP>

195

Block compare (S1)>(S2)

★

BKCMP<

196

Block compare (S1)<(S2)

★

BKCMP<>

197

Block compare (S1)≠(S2)

★

BKCMP<=

198

Block compare (S1)≦(S2)

★

BKCMP>=

199

Block compare (S1)≧(S2)

★

4. Arithmetic operation instructions

Mnemonic

FNC No.

Function

Support

ADD

20

Addition

★

SUB

21

Subtraction

★

MUL

22

Multiplication

★

DIV

23

Division

★

EADD

120

Floating Point Addition

★

ESUB

121

Floating Point Subtraction

★

EMUL

122

Floating Point Multiplication

★

EDIV

123

Floating Point Division

★

BK+

192

Block Data Addition

★

BK-

193

Block Data Subtraction

★

INC

24

Increase

★

DEC

25

Decrement

★

5. Logical operation instructions

Mnemonic

FNC No.

Function

Support

WAND

26

Word AND

★

WOR

27

Word OR

★

WXOR

28

Word Exclusive OR

★

Page 23

COOLMAY EX3G PLC/HMI All in one Programming manual

20

6. Special function instructions

Mnemonic

FNC No.

Function

Support

SQR

48

Square Root

★

ESQR

127

Floating Point Square Root

★

EXP

124

Floating Point Exponent

★

LOGE

125

Floating Point Natural Logarithm

★

LOG10

126

Floating Point Common Logarithm

★

SIN

130

Floating Point Sine

★

COS

131

Floating Point Cosine

★

TAN

132

Floating Point Tangent

★

ASIN

133

Floating Point Arc Sine

★

ACOS

134

Floating Point Arc Cosine

★

ATAN

135

Floating Point Arc Tangent

★

RND

184

Random Number Generation

★

7. Rotate instructions

Mnemonic

FNC No.

Function

Support

ROR

30

Rotation Right

★

ROL

31

Rotation Left

★

RCR

32

Rotation right With Carry

★

RCL

33

Rotation Left with Carry

★

8. Shift instructions

Mnemonic

FNC No.

Function

Support

SFTR

34

Bit Shift Right

★

SFTL

35

Bit Shift Left

★

SFR

213

Bit Shift Right with Carry

★

SFL

214

Bit Shift Left with Carry

★

WSFR

36

Word Shift Right

★

WSFL

37

Word Shift left

★

SFWR

38

Shift Write [FIFO/FILO Control]

★

SFRD

39

Shift Read [FIFO Control]

★

POP

212

Shift Last Data Read [FILO Control]

★

9. Data operation instructions

Mnemonic

FNC No.

Function

Support

ZRST

40

Zone Reset

★

DECO

41

Decode

★

ENCO

42

Encode

★

MEAN

45

Mean

★

WSUM

140

Sum of Word Data

★

SUM

43

Sum of Active Bits

★

BON

44

Check Specified Bit Status

★

Page 24

COOLMAY EX3G PLC/HMI All in one Programming manual

21

NEG

29

Negation

★

ENEG

128

Floating Point Negation

★

WTOB

141

WORD to BYTE

★

BTOW

142

BYTE to WORD

★

UNI

143

4-bit Linking of Word Data

★

DIS

144

4-bit Grouping of Word Data

★

CCD

84

Check Code

★

CRC

188

Cyclic Redundancy Check

★

LIMIT

256

Limit Control

★

BAND

257

Dead Band Control

★

ZONE

258

Zone control

★

SCL

259

Scaling (Coordinate by Point Data)

★

SCL2

269

Scaling 2 (Coordinate by X/Y Data)

★

SORT

69

Sort Tabulated Data

★

SORT2

149

Sort Tabulated Data 2

★

SER61Search a Data Stack

★

FDEL

210

Deleting Data from Tables

★

FINS

211

Inserting Data to Tables

★

10. String processing instruction

Mnemonic

FNC No.

Function

Support

ESTR

116

Floating Point to Character String Conversion

★

EVAL

117

Character String to Floating Point Conversion

★

STR

200

BIN to Character String Conversion

★

VAL

201

Character String to BIN Conversion

★

DABIN

260

Decimal ASCII to BIN Conversion

★

BINDA

261

BIN to Decimal ASCII Conversion

★

ASCI

82

Hexadecimal to ASCII Conversion

★

HEX

83

ASCII to Hexadecimal Conversion

★

$MOV

209

Character String Transfer

★

$+

202

Link Character Strings

★

LEN

203

Character String Length Detection

★

RIGH

204

Extracting Character String Data From the Right

★

LEFT

205

Extracting Character String Data from the Left

★

MIDR

206

Random Selection of Character Strings

★

MIDW

207

Random Replacement of Character Strings

★

INSTR

208

Character string search

★

COMRD

182

Read Device Comment Data

★

11. Program flow control instructions

Mnemonic

FNC No.

Function

Support

CJ00Conditional Jump

★

CALL

01

Call Subroutine

★

Page 25

COOLMAY EX3G PLC/HMI All in one Programming manual

22

SRET

02

Subroutine Return

★

IRET

03

Interrupt Return

★

EI04Enable Interrupt

★

DI05Disable Interrupt

★

FEND

06

Main Routine Program End

★

FOR

08

Start a FOR/NEXT Loop

★

NEXT

09

End a FOR/NEXT Loop

★

12. I/O refresh instructions

Mnemonic

FNC No.

Function

Support

REF50Refresh

★

REFF

51

Refresh and Filter Adjust

★

13. Real time clock control instructions

Mnemonic

FNC No.

Function

Support

TCMP

160

RTC Data Compare

★

TZCP

161

RTC Data Zone Compare

★

TADD

162

RTC Data Addition

★

TSUB

163

RTC Data Subtraction

★

TRD

166

Read RTC data

★

TWR

167

Set RTC data

★

HTOS

164

Hour to Second Conversion

★

STOH

165

Second to Hour Conversion

★

14. Pulse output/positioning control instruction

Mnemonic

FNC No.

Function

Support

ABS

155

Absolute Current Value Read

★

DSZR

150

DOG Search Zero Return

★

ZRN

156

Zero Return

★

TBL

152

Batch Data Positioning Mode

★

DVIT

151

Interrupt Positioning

★

DRVI

158

Drive to Increment

★

DRVA

159

Drive to Absolute

★

PLSV

157

Variable Speed Pulse Output

★

PLSY

57

Pulse Y Output

★

PLSR

59

Acceleration/Deceleration Setup

★

15. Serial communication instructions

Mnemonic

FNC No.

Function

Support

RS80Serial Communication

★

R(S2)

87

Serial Communication 2

★

IVCK

270

Inverter Status Check

IVDR

271

Inverter Drive

Page 26

COOLMAY EX3G PLC/HMI All in one Programming manual

23

IVRD

272

Inverter Parameter Read

IVWR

273

Inverter Parameter Write

IVBWR

274

Inverter Parameter Block Write

IVMC

275

Inverter multiple command

ADPRW

276

MODBUS read and write

★

16. Special block/unit control instructions

Mnemonic

FNC No.

Function

Support

FROM

78

Read From a Special Function Block

★

TO

79

Write To a Special Function Block

★

RD3A

176

Read form Dedicated Analog Block

★

WR3A

177

Write to Dedicated Analog Block

★

RBFM

278

Divided BFM Read

WBFM

279

Divided BFM Write

17. Extension register/extension file register control instructions

Mnemonic

FNC No.

Function

Support

LOADR

290

Load From ER

SAVER

291

Save to ER

RWER

294

Rewrite to ER

INITR

292

Initialize R and ER

INITER

295

Initialize ER

LOGR

293

Logging R and ER

18. Other handy instructions

Mnemonic

FNC No.

Function

Support

WDT

07

Watchdog Timer Refresh

★

ALT66Alternate State

★

ANS46Timed Annunciator Set

★

ANR

47

Annunciator Reset

★

HOUR

169

Hour Meter

★

RAMP

67

Ramp Variable Value

★

SPD56Speed Detection

★

PWM

58

Pulse Width Modulation

★

DUTY

186

Timing Pulse Generation

★

PID88PID Control Loop

★

ZPUSH

102

Batch Store of Index Register

★

ZPOP

103

Batch POP of Index Register

★

TTMR

64

Teaching timer

★

STMR

65

Special timer

★

ABSD

62

Absolute Drum Sequencer

★

INCD

63

Incremental Drum Sequencer

★

ROTC

68

Rotary Table Control

★

Page 27

COOLMAY EX3G PLC/HMI All in one Programming manual

24

IST60Initial state

★

MTR

52

Input Matrix

★

TKY

70

Ten Key Input

★

HKY

71

Hexadecimal Input

★

DSW

72

Digital switch (thumbwheel input)

★

SEGD

73

Seven Segment Decoder

★

SEGL

74

Seven Segment With Latch

★

ARWS

75

Arrow Switch

★

ASC76ASCII code data input

★

PR77Print (ASCII Code)

★

VRRD

85

Volume Read

★

VRSC

86

Volume Scale

★

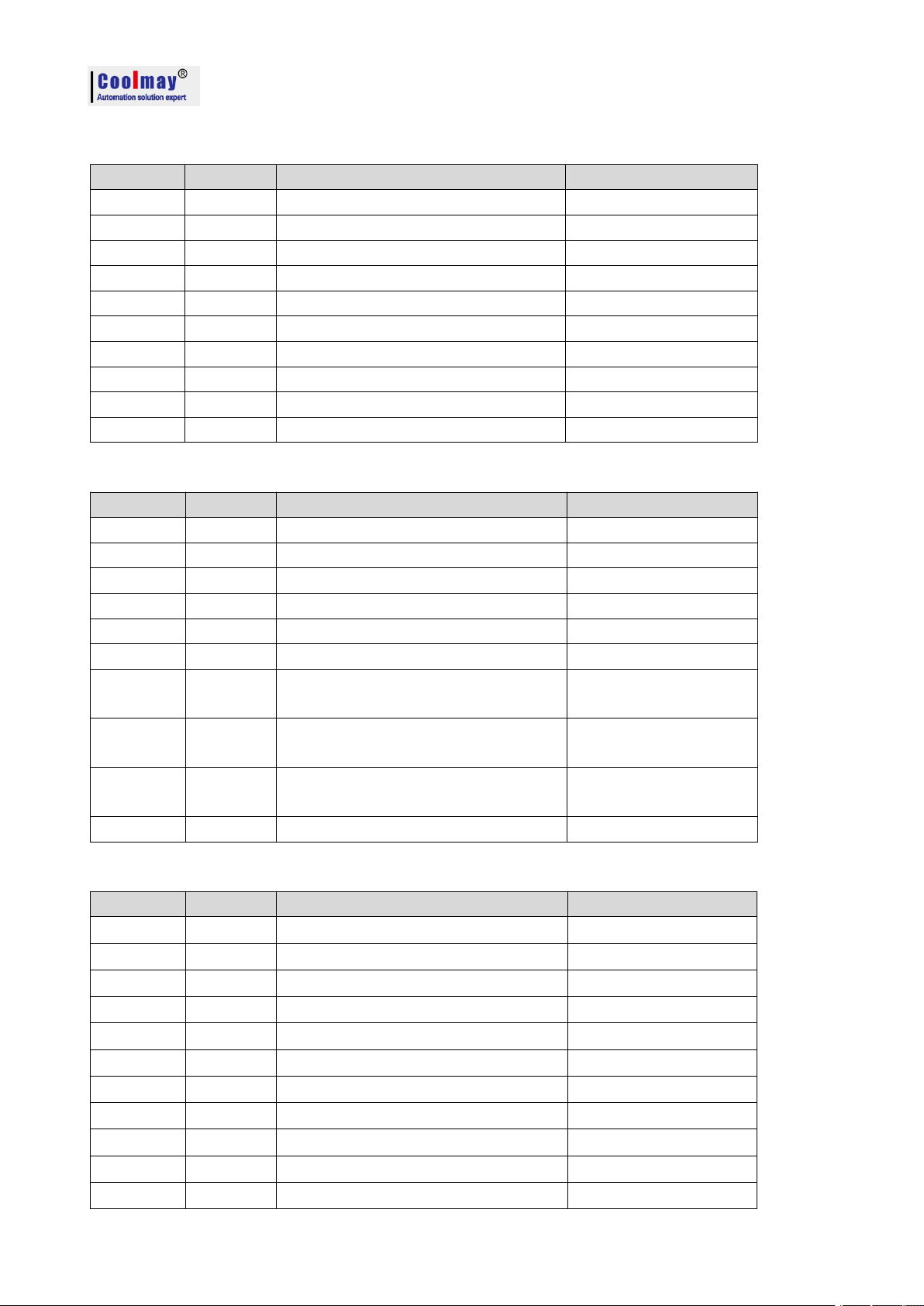

Input signal

Range

Register value

Resolution

Accuracy

(Total Measuring range)

K-type thermocouple

0~1100℃

Room temperature

~11000

0.1℃

1%

PT100

-200~350℃

-2000~3500

0.1℃

1%

NTC10K

-48~210℃

-480~2100

0.1℃

1%

Voltage

0~10V/0-5V

0~4000

2.5mV

1%

Current Type1

0~20mA

0~4000

5uA

1%

Current Type2

4~20mA

0~4000

4uA

1%

Input signal

Range

Register value

Resolution

Accuracy

(Total Measuring range)

K-type thermocouple

0~1100℃

Room temperature

~11000

0.1℃

1%

K-type thermocouple

(Negative temp)

-210~1200℃

-2100~12000

0.1℃

1%

T-type thermocouple

0~420℃

Room temperature

~4200

0.1℃

1%

T-type thermocouple

-210~420℃

-2100~4200

0.1℃

1%

2.6 Analog input

This section refers to the software version query, the version number is stored in the special register

D8001, D8101, if necessary, please query the value of D8001.

Input precision of coolmay CX3G/FX3GC PLC and EX3G plc hmi all-in-one is 12-bit, directly read the

corresponded register value of each analog while using. Environment temperature is only used in

thermocouple.

2.6.1 Analog input (temperature)

Below table for software version 26210

Below table for software version 26220

Page 28

25

(Negative temp)

PT100/PT1000

-200~350℃

-2000~3500

0.1℃

1%

NTC

-48~210℃

-480~2100

0.1℃

1%

Voltage

0~10V/0-5V

0~4000

2.5mV

1%

Current Type1

0~20mA

0~4000

5uA

1%

Current Type2

4~20mA

0~4000

4uA

1%

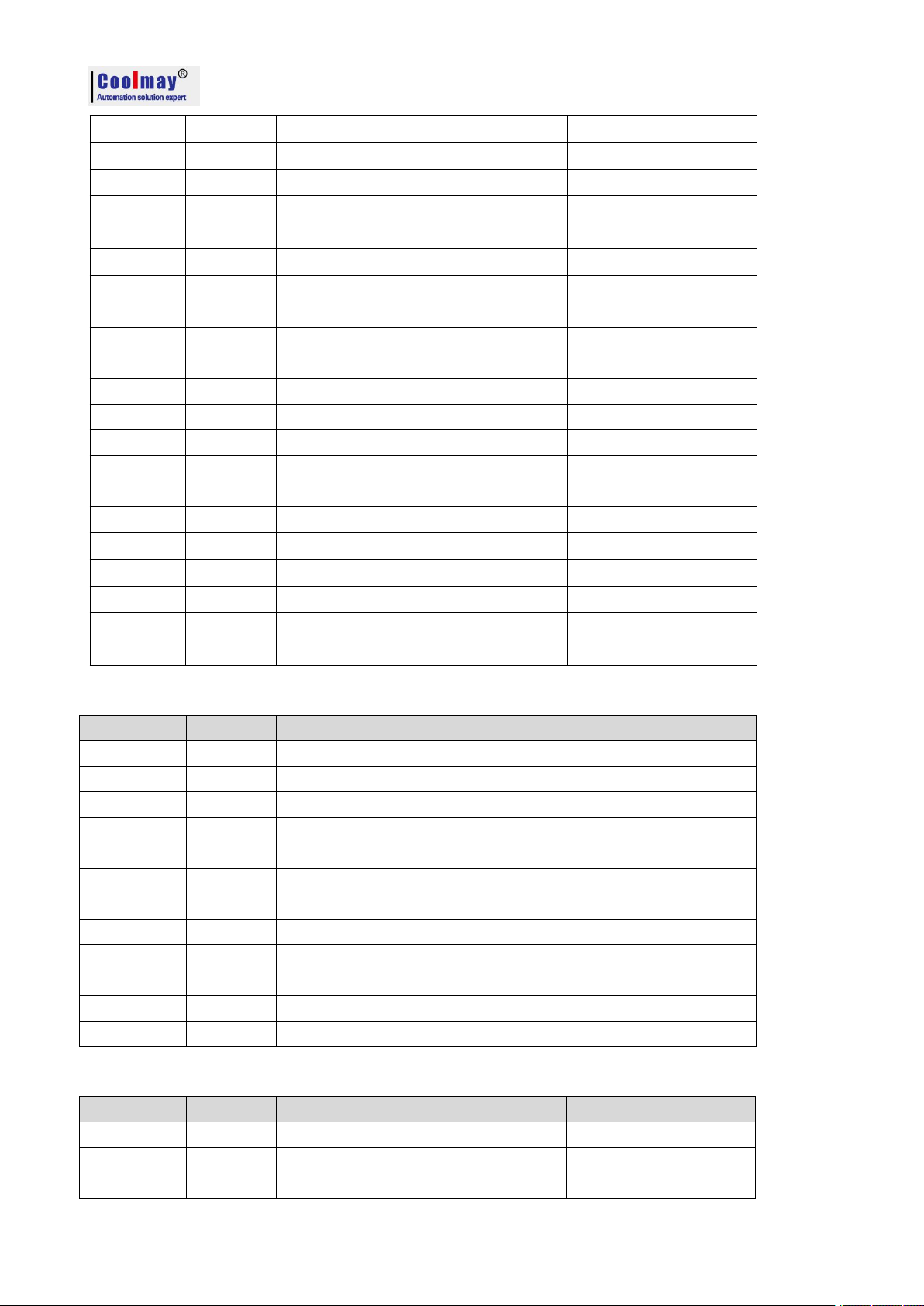

Below table for software version 26230 and above

Input signal

Range

Register value

Resolution

Accuracy

(Total Measuring

range)

K-type thermocouple

0~1100℃

Room temperature

~11000

0.1℃

1%

K-type thermocouple

(Negative temp)

-210~1200℃

-2100~12000

0.1℃

1%

T-type thermocouple

0~420℃

Room temperature

~4200

0.1℃

1%

T-type thermocouple

(Negative temp)

-210~420℃

-2100~4200

0.1℃

1%

S-type thermocouple

0~1710℃

Room temperature

~17100

0.1℃

1%

S-type thermocouple

(Negative temp)

-26~1710℃

-260~17100

0.1℃

1%

J-type thermocouple

0~800℃

Room temperature

~8000

0.1℃

1%

J-type thermocouple

(Negative temp)

-90~950℃

-900~9500

0.1℃

1%

E-type thermocouple

0~600℃

Room temperature

~6000

0.1℃

1%

E-type thermocouple

(Negative temp)

-110~730℃

-1100~7300

0.1℃

1%

PT100/PT1000

-200~500℃

-2000~5000

0.1℃

1%

NTC50K/100K

-48~210℃

-480~2100

0.1℃

1%

NTC10K

-48~110℃

-480~1100

0.1℃

1%

Voltage

0~10V/0-5V/

-10~10V/-5~5V

0~4000

2.5mV

1%

Current Type1

0~20mA

0~4000

5uA

1%

Current Type2

4~20mA

0~4000

4uA

1%

COOLMAY EX3G PLC/HMI All in one Programming manual

customers’s need when ordering.

The transmitter which is integrated inside PLC is one of the above table or mixed ones, it is up to

Page 29

COOLMAY EX3G PLC/HMI All in one Programming manual

26

NO

Register Value

AD0

R23680

AD1

R23681

AD2

R23682

AD3

R23683

Environment temperature

R23684

AD4

R23685

AD5

R23686

AD6

R23687

AD7

R23688

AD8

R23689

AD9

R23690

AD10

R23691

AD11

R23692

AD12

R23693

AD13

R23694

AD14

R23695

NO

PT100

NTC10K

0~10V/0-5V/0~20mA

4~20mA

AD0

R23640

R23660

D8030

R23620

AD1

R23641

R23661

D8031

R23621

AD2

R23642

R23662

D8032

R23622

AD3

R23643

R23663

D8033

R23623

AD4

R23644

R23664

D8034

R23624

AD5

R23645

R23665

D8035

R23625

AD6

R23646

R23666

D8036

R23626

AD7

R23647

R23667

D8037

R23627

AD8

R23648

R23668

D8038

R23628

AD9

R23649

R23669

D8039

R23629

AD10

R23650

R23670

D8040

R23630

AD11

R23651

R23671

D8041

R23631

AD12

R23652

R23672

D8042

R23632

2.6.2 Analog input reading 1 (for software version 26210 and 26220)

Support FROM instruction or register directly read. Such as: FROM K0 K0 D400 K16, read out 16

analog input, 0-10V.

K type thermocouple (1~4 channel) are in the 4 registers from R23680, the 5this temperature

compensation, R23684 reveals the environment temperature. The below keep the same, that is to say that

read thermocouple (6~16 channels) are the 11 registers from R23685

A decimal points should be retained for temperature. Namely 182=18.2℃.

Other types of registers read values are shown below table:

Page 30

COOLMAY EX3G PLC/HMI All in one Programming manual

27

AD13

R23653

R23673

D8043

R23633

AD14

R23654

R23674

D8044

R23634

AD15

R23655

R23675

D8045

R23635

No

K type(negative

temperature)

T type

T type(negative

temperature)

AD0

R23720

R23700

R23740

AD1

R23721

R23701

R23741

AD2

R23722

R23702

R23742

AD3

R23723

R23703

R23743

AD4(Environment

temperature)

R23724

R23704

R23744

AD5

R23725

R23705

R23745

AD6

R23726

R23706

R23746

AD7

R23727

R23707

R23747

AD8

R23728

R23708

R23748

AD9

R23729

R23709

R23749

AD10

R23730

R23710

R23750

AD11

R23731

R23711

R23751

AD12

R23732

R23712

R23752

AD13

R23733

R23713

R23753

AD14

R23734

R23714

R23754

AD15

R23735

R23715

R23755

NO

Register Value

AD0

D8030

AD1

D8031

AD2

D8032

AD3

D8033

AD4 (environment temp)

D8034

AD5

D8035

AD6

D8036

When 4~20mA,<3.8mA,value is 32760,which is the disconnection value.

2.6.3 Analog input reading 2 (for Main software version 26220)

Thermocouple K (negative temperature), T type, T type (negative temperature) register read values are

shown as below table:

2.6.4 Analog input reading 3 (for Main software version 26230 and above)

input, 0~10V.

constant scan time is changed to D8059, and it is started by M8039 (version 26232 and above);

Support FROM instructions or register read directly. Such as: FROM K0 K0 D400 K16 read 16 analog

The register is directly read: D[8030]~D[8045] is the output value set for the corresponding type, the

Page 31

COOLMAY EX3G PLC/HMI All in one Programming manual

28

AD7

D8037

AD8

D8038

AD9

D8039

AD10

D8040

AD11

D8041

AD12

D8042

AD13

D8043

AD14

D8044

AD15

D8045

NO

Register Value

AD0

R23660

AD1

R23661

AD2

R23662

AD3

R23663

AD4

R23664

AD5

R23665

AD6

R23666

AD7

R23667

AD8

R23668

AD9

R23669

AD10

R23670

AD11

R23671

AD12

R23672

AD13

R23673

AD14

R23674

AD15

R23675

When the analog input has a thermocouple type, it can only do up to 15 channels, of which AD4 is the

ambient temperature of the thermocouple. You can do 16 channels without the thermocouple type.

Tthermistor NTC is shown as below table:

negative temperature amplification).

sampled values.

2.6.5 Analog input sampling

one time and change the 1stanalog input value for one time. The larger R23600~R23615 value is, the result

is more stable.

R23960 starts with a zero correction value and default is 0 (Namely, size correction).

R23980 starts with a negative temperature amplification. The default is 4633 (temporarily only have

The 16 registers starting from R23620 are 0~10V or 0~20mA corresponding values, that is, real-time

Filtering cycles=( R23600~R23615)* PLC scanning time, if R23600=1, One PLC scan cycle sample

R23600~R23615 is filtering cycles, default is 100 (range 2~20000), data can’t be equal to or less than 0;

D8073 is smoothing filter coefficients of all analog input, range: 0~999

Page 32

COOLMAY EX3G PLC/HMI All in one Programming manual

29

2.6.6 Demo example

Below is an example of EX3G 1 channel temperature analog AD0 acquisition. The program reads the

values as follows:

Connect the signal terminal of the temperature sensor to the AD0 input of the PLC and the other end to

the GND of the analog input port.

When the PLC is running, the value of the data register D8030 corresponding to AD0 will be

transmitted to D0, the value of D0 will be put into D10 after floating point operation, and then the floating

point number division operation will be performed on D10, and then operation result will be put into D20,

the result D20 is the actual Temperature value.

In the ladder diagram, you can also directly divide the value of D8030.

Note: When the input is 0-10V analog, the actual analog value = register reading / 400;

When the input is temperature, the actual temperature value = register reading/10;

When the input is 0-20mA analog, the actual analog value = register reading / 200;

When the input is 4-20 mA analog, the actual analog value = register reading / 250 + 4.

The analog correction is corrected for the size. The following figure is an example of correcting the

AD0 temperature after acquisition:

If the current temperature is 37.9℃,the actual test is 47.9°C, the error is 10°C, you need to modify

the size correction register, show as below:

Page 33

COOLMAY EX3G PLC/HMI All in one Programming manual

30

Counter type

No.

Input assignment

Single phase single

counter input

X000

X001

X002

X003

X004

X005

X006

X007

C235

U/D

C236

U/D

DA register

Range

Output type

DA0

D8050

0-4000

When

D8058.0~D8058.7=0

Means 0~20mA;

When

D8058.0~D8058.7=1

Means 4~20mA。

DA1

D8051

0-4000

DA2

D8052

0-4000

DA3

D8053

0-4000

DA4

D8054

0-4000

DA5

D8055

0-4000

DA6

D8056

0-4000

DA7

D8057

0-4000

In the above figure, when M0 is closed, the value -100 is transmitted to the correction register

R23960, and now you can see that the value of the actual measured temperature D20 is close to the

actual temperature which is 37.9 °C.

2.7 Analog output

Analog output range 0~4000, precision is 12 bit. Support TO instruction or register assignment operation

directly.

Adopts TO K0 K0 D500 K8, 8 channels 0~10V or 0~20mA analog output.

Register assignment operation directly: D8050~D8057.

When the analog output is current, the bit of D8058 needs to be set:

When the default D8058.0~D8058.7=0, it means 0~20mA; when D8058.0~D8058.7=1, it means

4~20mA.

Example:Below shows the 0-10V voltage analog output.

red pen is connected to the DA0 terminal, and the black pen is connected to the GND terminal. The multimeter

is displaying 5V voltage value.

2.8 PID instruction

Detailed information please refer to <Mitsubishi FX3G Programming Manual>

The self-tuning method in the PID instruction has only a step response mode. The step value is S0+22.

2.9.Application of high speed counter

2.9.1Assignment table of built-in high speed counter

At this point, use a multimeter to check the voltage of the DA0 terminal, that is, the multimeter's

Page 34

COOLMAY EX3G PLC/HMI All in one Programming manual

31

C237

U/D

C238

U/D

C239

U/D

C240

U/D

C241

U/D

R

C242

U/D

R

C243

U/D

R

C244

U/DRS

C245

U/DRS

Single phase

double counter

input

C246

U

D

C247

UDR

C248

UDR

C248(OP)*1

U

D

C249

UDR

S

C250

UDR

S

AB phase double

counter input

C251

A

B

C252

ABR

C253

ABR

C253(OP)*1

A

B

C254(OP)*1

A

B

C255

ABR

S

U: up counter D: down counter

A: A phase input B:B phase input

R: External reset input S: External start input

Single phase: at most 6 channels, max frequency is 60KHz

AB(Z) phase:

2 times frequency: 2 channels 60KHz+1 way 10KHz;

4 times frequency: 2 channels 24KHz; M8198 is C251 4 times frequency signal;M8199 is C253 4 times

frequency signal.

* High speed input C254:

When M8396=0, the original C254 is AB phase corresponded to X3 X4.

When M8396=1, C254 changes to AB phase corresponded to X6 X7.

2.10.Application of high speed pulse

2.10.1 high speed pulse output

Coolmay CX3G default has 8 channels high speed pulse, Y0-Y3 each 100KHz, Y4-Y7 each

10KHz,variable speed supported, the initial/final speed of start/stop is 0, diagram as below: (take accelerate

and decelerate time D8148 as an example).

Page 35

COOLMAY EX3G PLC/HMI All in one Programming manual

32

26233 Version and lower

Interpolation mode

M8343

M8342

Line Interpolation

0

1

Center interpolation

1

0

Radius interpolation

1

1

26235 Version and higher

Interpolation mode

M8343

M8342

Line Interpolation

0

1

Center interpolation

1

0

Radius interpolation

1

1

Pulse point

Function

Description

Y0Y1Y2Y3Y4Y5Y6

Y7

Pulse operation

monitoring

M8340

M8350

M8360

M8370

M8151

M8152

M8153

M8154

Position pulse(32bit)

D8340

D8341

D8350

D8351

D8360

D8361

D8370

D8371

D8140

D8141

D8142

D8143

D8144

D8145

D8160

D8161

accelerate / decelerate

time

D8348

D8349

D8358

D8359

D8368

D8369

D8378

D8379

D8148

D8148

D8148

D8148

Pulse stop bit

M8349

M8359

M8369

M8379

M8450

M8451

M8452

M8453

Maximum speed

D8343

D8344

D8353

D8354

D8363

D8364

D8373

D8374

D8146

D8147

D8146

D8147

D8146

D8147

D8146

D8147

Acceleration/deceleration time T calculation= (target speed-current speed) * acceleration/deceleration

time÷maximum speed.

For example, target speed = 50000, current speed = 20000, acceleration time 100 (ms), maximum speed =

100,000, T = 30 ms.

CX3G: 8 channels of pulse, the last 4 channels of acceleration and deceleration = D8148, the maximum

speed is D8146, D8147.

PLSY, ZRN, PLSV, DRVI, DRVA, DVIT, DSZR, only Y0-Y3 supports DVIT (interrupt positioning),

DSZR (originary return with DOG search) instructions.

The original FX3G pulse program can be used directly.

All the instruction support 8 channels pulse, except DVIT、DSZR which support 4 channels.

2.10.2 Circular interpolation

The special flags when setting the interpolation route are as shown in the following table: ( No interpolation function in

26234 version)

The direction and coordinates of the center and radius interpolation are as shown in the following table: ( No

interpolation function in 26234 version)

Page 36

COOLMAY EX3G PLC/HMI All in one Programming manual

33

26233 Version and lower

Clockwise

M8348=0

Counterclockwise

M8348=1

Relative position

M8344=0

Absolute position

M8344=1

26235 Version and higher

Clockwise

M8348=0

Counterclockwise

M8348=1

Relative position

M8344=0

Absolute position

M8344=1

S. represents the pulse frequency, that is, the speed of the interpolation motion.

M8348=0,clockwise; M8348=1,anticlockwise.

M8344=0,relative position; M8344=1,absolute position.

D8340 shows the current address of X axis,D8350 shows the current address of Y axis.

In CoolMay 3G PLC,interpolation motion still adopts DPLSR for pulse output.

Description of the Operand:

S.+2 represents the X-axis target address.

S.+4 represents the Y-axis target address.

D.: Specify the Y number with pulse output (currently only Y0 is supported), and the default Y1 is

another axis.

X axis: Y0 pulse, Y4 direction

Y axis: Y1 pulse, Y5 direction

In the center interpolation mode:

S.+6 represents the center X coordinate address.

S.+8 represents the center Y coordinate address.

In radius interpolation mode:

S.+6 represents the radius length. When it is positive, the path is a small circle; when it is a negative value,

the path is a large circle.

For example: DPLSR D100 D102 D104 Y000

In the linear interpolation: D100 speed, D102 is the X-axis target address, and D104 is the Y-axis target

address.Y0 and Y1 respectively pulse the X-axis and Y-axis.

Page 37

COOLMAY EX3G PLC/HMI All in one Programming manual

34

In the Center interpolation: D100 speed, D102 is the X-axis target address, D104 is the Y-axis target address,

and D106 is the center X address. D108 is the center Y address. Y0 and Y1 respectively pulse the X-axis and

Y-axis.

Note 1: The current address of X and Y must be on the same circle as the destination address.

Note 2: When the current address coincides with the target address, it indicates that the motion track is a full

circle.

In the radius interpolation: D100 speed, D102 is the X-axis target address, D104 is the Y-axis target address,

and D106 is the radius length. Y0 and Y1 respectively pulse the X-axis and Y-axis.

2.10.3 Continuous interpolation function

M8436 is the flag for the normal interpolation mode and continuous interpolation mode.

M8436=0: regular interpolation mode;

M8436=1: continuous interpolation mode;

In CoolMay 3G PLC 26236 and higher version, continuous interpolation motion uses DPLSR for pulse

output.

Page 38

COOLMAY EX3G PLC/HMI All in one Programming manual

35

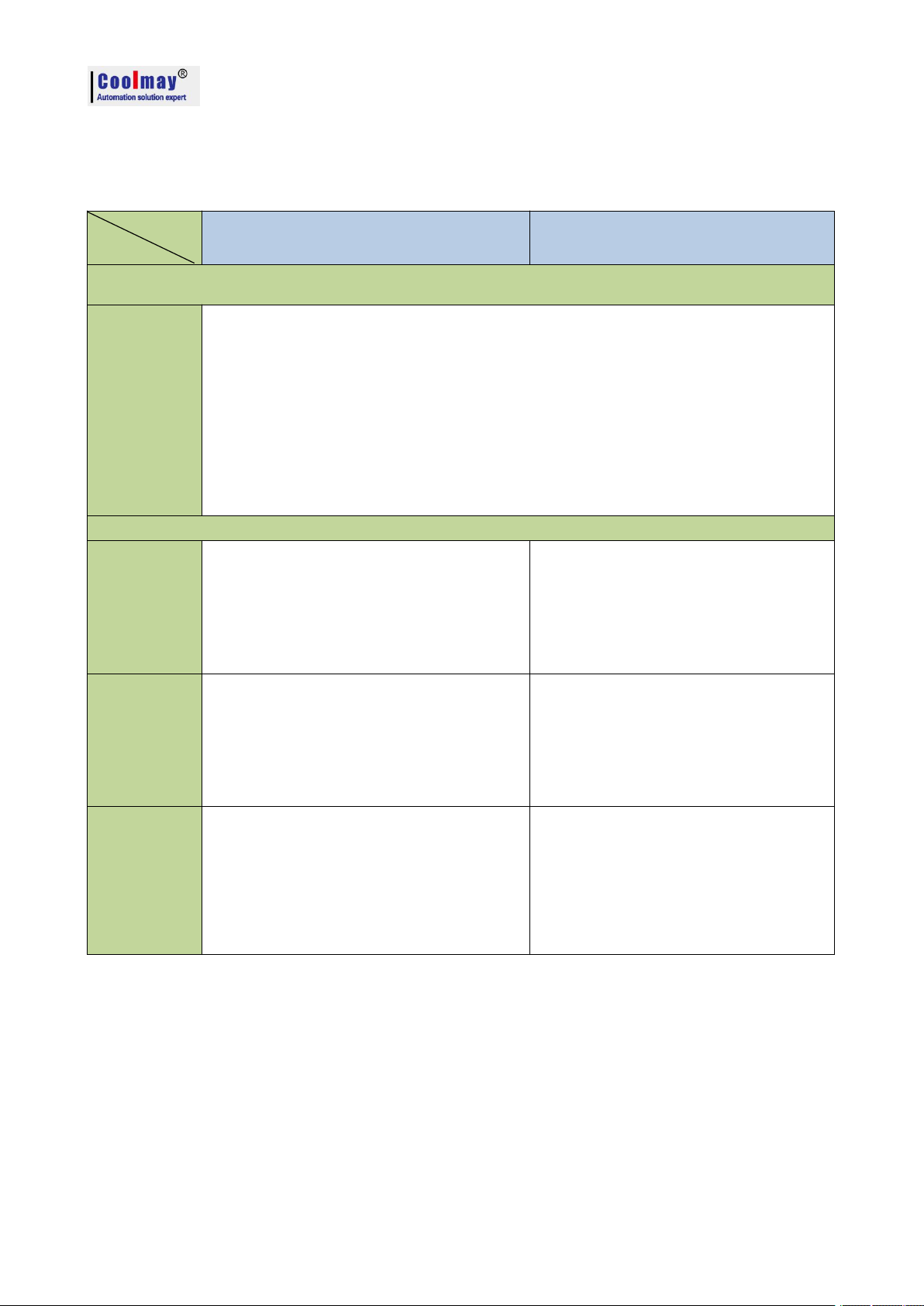

32bit

position

b31~b28

b27~b24

b23~b20

b19~b16

b15~b12

b11~b8