Page 1

Coolmay Multi-channel temperature

control module CM-4TM

User Manual

Shenzhen coolmay Technology Co. Ltd

Page 2

Contents

Introduction to use the manual

Descriptions of symbols in the communication manual

Safety Instructions

Operation Precautions

....................................................................................................

............................................................................................

Chapter 1 Product Introduction

1.1 Characters

1.2 Components and accessories

1.3 Components and features

1.3.1 Front

1.3.2 Bottom - wiring part

.....................................................................................................................

........................................................................................................................................

...............................................................................................................

Chapter 2 Product Specifications

2.1 Specification

.................................................................................................................

..............................................................................

.................................

..........................................................................

.................................................................................

.........................................................................................

......................................................................

Chapter 3 Wiring diagram and module connection diagram

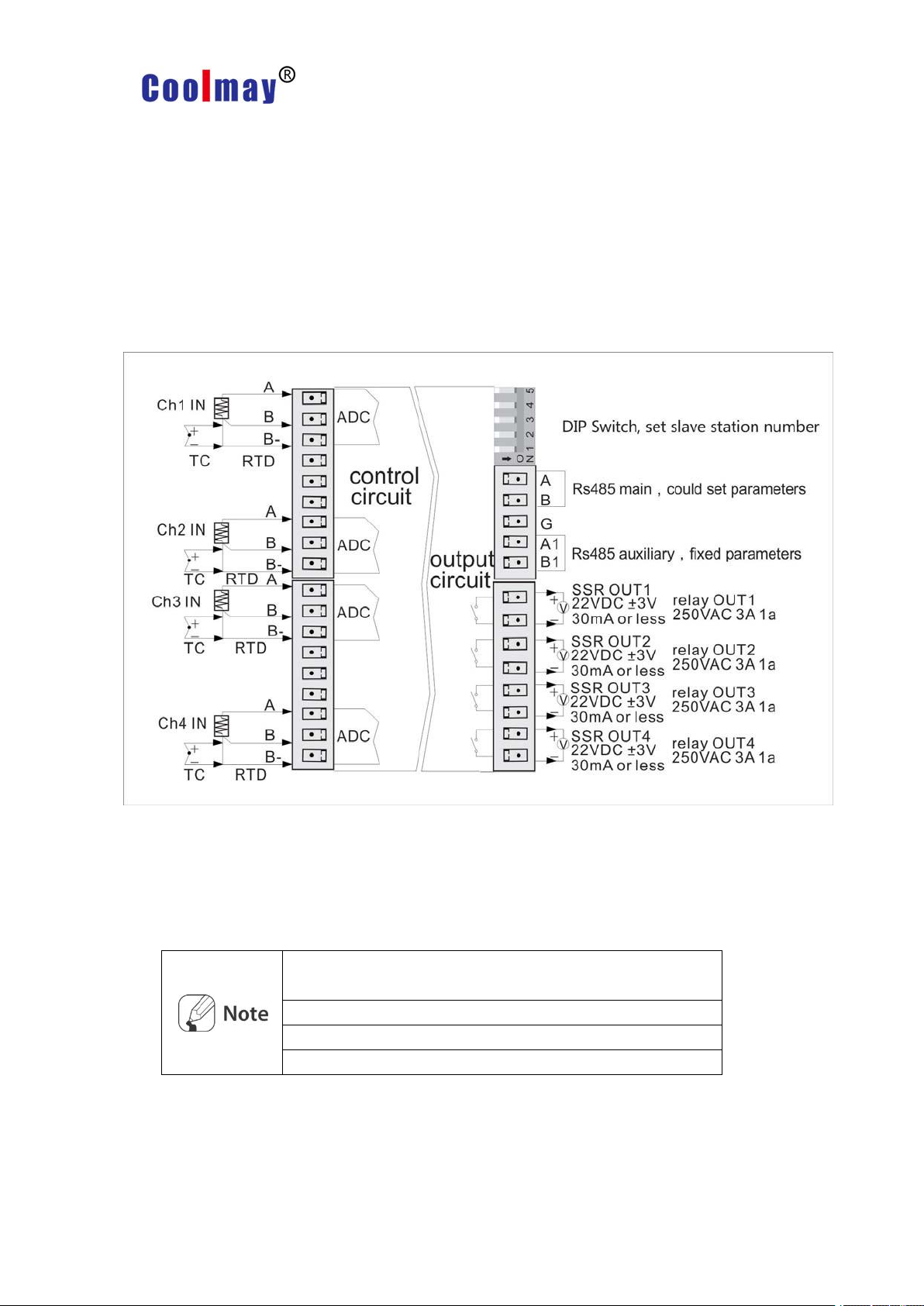

3.1 Wiring diagram -front view

........................................................................................

......................

I

I

II

III

1

1

2

3

3

4

5

5

7

7

3.2 Wiring precautions

3.2.1 Sensor connection

3.2.2 Power connection

3.2.3 Communication connection

3.3 Preparation and start

3.3.1 Overall sequence of operations

3.3.2 Set value status when power-on

......................................................................................................

................................................................................................................

.................................................................................................................

.................................................................................................

..................................................................................................

..........................................................................................

........................................................................................

Chapter 4 Parameter settings and functions

4.1 Input

4.1.1 Input type and temperature range

4.1.2 Input type setting

4.1.3 Input sensor temperature unit setting

4.1.4 Input deviation correction setting

4.1.5 Input digital filter setting

4.1.6 SV Upper/lower limit setting

4.2 Control output

4.2.1 Control output operation setting

4.2.2 MV Upper/lower limit setting

4.2.3 Slope setting

4.2.4 Automatic/manual control settings

..............................................................................................................................

....................................................................................

.................................................................................................................

..............................................................................

......................................................................................

.....................................................................................................

...........................................................................................

............................................................................................................

.......................................................................................

.............................................................................................

........................................................................................................................

...................................................................................

................................................

8

8

9

9

9

9

9

28

28

28

29

29

30

30

31

32

32

34

35

36

4.3 Temperature control

.................................................................................................

38

Page 3

4.3.1 Temperature control method setting

4.3.2 ON/OFF control

4.3.3 PID control

4.3.4 Self-tuning

...................................................................................................................

...........................................................................................................................

............................................................................................................................

................................................................................

38

38

39

41

4.4 Communication

4.4.1 Communication address setting

4.4.2 Communication speed setting

4.4.3 Communication Parity Bit Setting

4.4.4 Communication stop bit setting

4.4.5 Communication response waiting time setting

4.4.6 Enabling/Disabling Communication Write Settings

4.5 Additional features

4.5.1 Monitoring function

4.5.2 Run/Stop Settings

4.5.3 Multi-segment SV

4.5.4 Error Detection Function

4.5.5 Parameter initialization functions

Chapter 5 Troubleshooting method

5.1 error display

..........................................................................................................

.......................................................................................

..........................................................................................

.....................................................................................

........................................................................................

....................................................................................................

.............................................................................................................

...............................................................................................................

................................................................................................................

....................................................................................................

......................................................................................

................................................................

................................................................................................................

5.2 Communication troubleshooting method

5.3 Control troubleshooting methods

........................................................................

...............................................................

.......................................................

...........................................................

43

43

44

45

45

45

46

46

46

47

47

48

49

51

51

51

52

Chapter 6 Modbus RTU protocol

6.1 Read coil status (Func 01-01H)

6.2 Read Input Status (Func 02-02H)

6.3 Read hold memory (Func 03-03H)

6.4 Read input memory(Func 04-04H

6.5 Preset a single memory(Func 06-06H

6.6 Preset multiple memories(Func 16-10H

6.7 Exception response - error code

Chapter 7 Modbus mapping table

7.1 Read coil status / force single coil(Func: 01/05,RW:R/W

7.2 Read input status(Func: 02,RW:R

7.3 Read input memory(Func: 04,RW:R

7.4 Read input memory(Func: 04,RW:R

......................................................................

..............................................................................

..........................................................................

........................................................................

...................................................................

)

...........................................................

)

.......................................................

)

...........................................................................

....................................................................

......................

)

...............................................................

)

...........................................................

)

...........................................................

)

7.5 Read Hold Memory (Func 03) / Preset Single Memory ( Func 06) / Preset

Multiple Memory ( Func 16)

7.5.1 Monitoring function [ Func: 03/06/16, RW: R/W]

...........................................................................................

.........................................................

53

53

54

55

57

58

59

60

62

62

62

63

64

65

65

Page 4

7.5.2 Operation (control operation) function (Func: 03/06/16, RW: R/W)

7.5.3 Master output function (Func: 03/06/16, RW: R/W)

7.5.4 Initial setting function (Func: 03/06/16, RW: R/W)

7.5.5 Set the master output function (Func: 03/06/16, RW: R/W)

7.5.6 Setting options (communication settings) function (Func: 03/06/16, RW: R/W).70

....................................................

......................................................

.........................

...................................

65

66

67

69

Page 5

Thank you for purchasing Coolmay products.

Symbol

Description

Special function supplement.

Warning sign, failure to follow this warning may

result in accident or death

Attention signs, failure to follow this warning

may result in malfunction or product damage

Related function use examples

※

1

comment mark

This user manual includes the instructions and methods of the product. Please

read it before using.

Introduction to use the manual

◆

Please read carefully before using the product

◆

The purpose of this manual is to introduce the functions of this product in detail, and

is not responsible for other purposes..

◆

This manual can not be edited or copied without authorization.

◆

This manual is not included with the product. Please download it from our website

www.coolmay.com

◆

The contents of this manual may differ due to product changes or other reasons

without prior notice.

◆

Please leave us messages if you have any suggestions for this manual.

Descriptions of symbols in the communication manual

I

Page 6

Safety Instructions

Warning sign, failure to follow this warning may

result in accident or death

Caution signs, failure to follow this warning may

result in malfunction or product damage

Following these safety precautions ensures safe and correct use of the product and

helps prevent accidents and reduce risk.

Safety instructions are divided into two categories: warning and caution:

◆ When using large instruments (such as nuclear power, medical machinery,

surveying, railway, aviation, combustion equipment, entertainment machinery, etc.,

including safety facilities) that have an impact on life or property, please make sure to

perform double safety measures before using. Otherwise, fire, life-threatening, property

damage may occur.

◆ Installed on the panel, otherwise it may cause electric shock.

◆ Make sure to disconnect the power supply while checking or repairing, otherwise it

may cause electric shock.

◆ Please check the polarity of the power supply before powering up, otherwise it may

cause fire.

◆ Please do not disassemble or modify the product. If you need internal inspection or

repair, please contact our company. Otherwise, it may cause fire, electric shock and

product damage.

◆ Do not use this product outdoors, otherwise may result in short product life or

electric shock.

◆ Use AWG 20 (0.5mm2) or better cable when connecting, otherwise it may cause

fire.

◆ Use this product within the rated specifications, otherwise it may damage the

II

Page 7

product or cause fire.

◆ Do not connect a load that exceeds the rated range, otherwise it may damage the

product or cause fire.

◆ Do not use detergents such as water or oil to clean the product. Wipe it with a dry

towel, otherwise may damage the product or cause fire.

◆ Do not use this product in a place that is flammable, explosive, humid, direct

sunlight, high temperature, strong vibration or shock, otherwise it may cause fire or

explosion hazard.

◆ Do not allow dust or wiring residue to go into the product, as this may cause fire or

damage to the product.

◆ Please check if the polarity of the sensor is connected correctly before using,

otherwise it may cause fire or explosion hazard.

Operation Precautions

Please read the precautions carefully before using, otherwise it may cause damage

to the product or accident.

Power supply voltage and use environment

◆ Use the voltage within the rated range.

◆ Ambient temperature: -10℃

◆ Power on the product for 20 minutes before using.

◆ Install a switch or circuit breaker to control the power supply voltage of the product.

◆ Install the switch or circuit breaker near the product for easy operation.

◆ Please install and use this product in a well ventilated environment, if necessary,

install a cooling fan.

◆ Please use the product in the environment as below.

~

50℃.

Indoor, altitude below 2000m, pollution level 2, installation category II

III

Page 8

Input sensor

◆ If it is unavoidable to avoid the temperature detected by the sensor due to

environmental factors, please use the deviation correction to minimize the error.

◆ When using a thermocouple sensor, please use the compensation wire of the rated

range when extending the wire. Otherwise, the joint between the thermocouple and the

extension wire will be thermally deformed, resulting in inaccurate measurement

temperature.

◆ If using a RTD sensor, connect three terminals and use three cables with the same

material, thickness and length. Otherwise, thermal deformation may occur, resulting in

inaccurate measurement temperature.。

◆ When changing the input sensor, please disconnect the power supply, connect the

new sensor, and then power on the PC to modify the relevant parameters.

◆ Install the filter on the controller. In addition, install the shield wire near the power

supply.

Noise impact

◆ Product power line and high-voltage line are separately routed to prevent impulse

noise interference.

◆ Please try to avoid high frequency noise interference in the environment, such as

welding machine, sewing machine, high-capacity SCR controller and high-capacity motor.

◆ Do not use this product in accessories of high frequency broadcast, TV and wireless

equipment.

Communication

◆ Use twisted pair cable for communication cable and ferrule on both sides of the

cable to reduce external noise interference.

◆ Do not arrange communication cables on the AC power accessories.

◆ Pleease use independent power supply voltage (24VDC) for communication

converter.

IV

Page 9

Chapter 1 Product Introduction

Chapter 1 Product Introduction

1.1 Characters

CM-4TM temperature controller module realized high-speed sampling (cycle: 100ms),

side connection can expand up to 31 modules. It communicates with PC through RS485,

and a variety of convenient and simple functions can achieve precise temperature control.

◆ Up to 124 simultaneous control

◆ Insulation strength per channel - dielectric strength 1,000VAC

◆ Up to 31 modules (124 channels / 62 channels) can be connected. The expansion

modules used do not need additional communication and power supply.

◆ High-speed sampling period: 100ms

◆ Heating/cooling simultaneous control

◆ Sensor status can be monitored by current transformer (CT)

◆ Communicate with PC via RS485 (Modbus RTU)

◆ Connector wiring is convenient for wiring and maintenance: Sensor input interface,

control output interface, power/communication connector use pluggable terminal

◆ Multi-channel inputs / multiple ranges

◆ Applications: Hot runner systems, electronic furnaces, reflow soldering, catapults

and extruders

1

Page 10

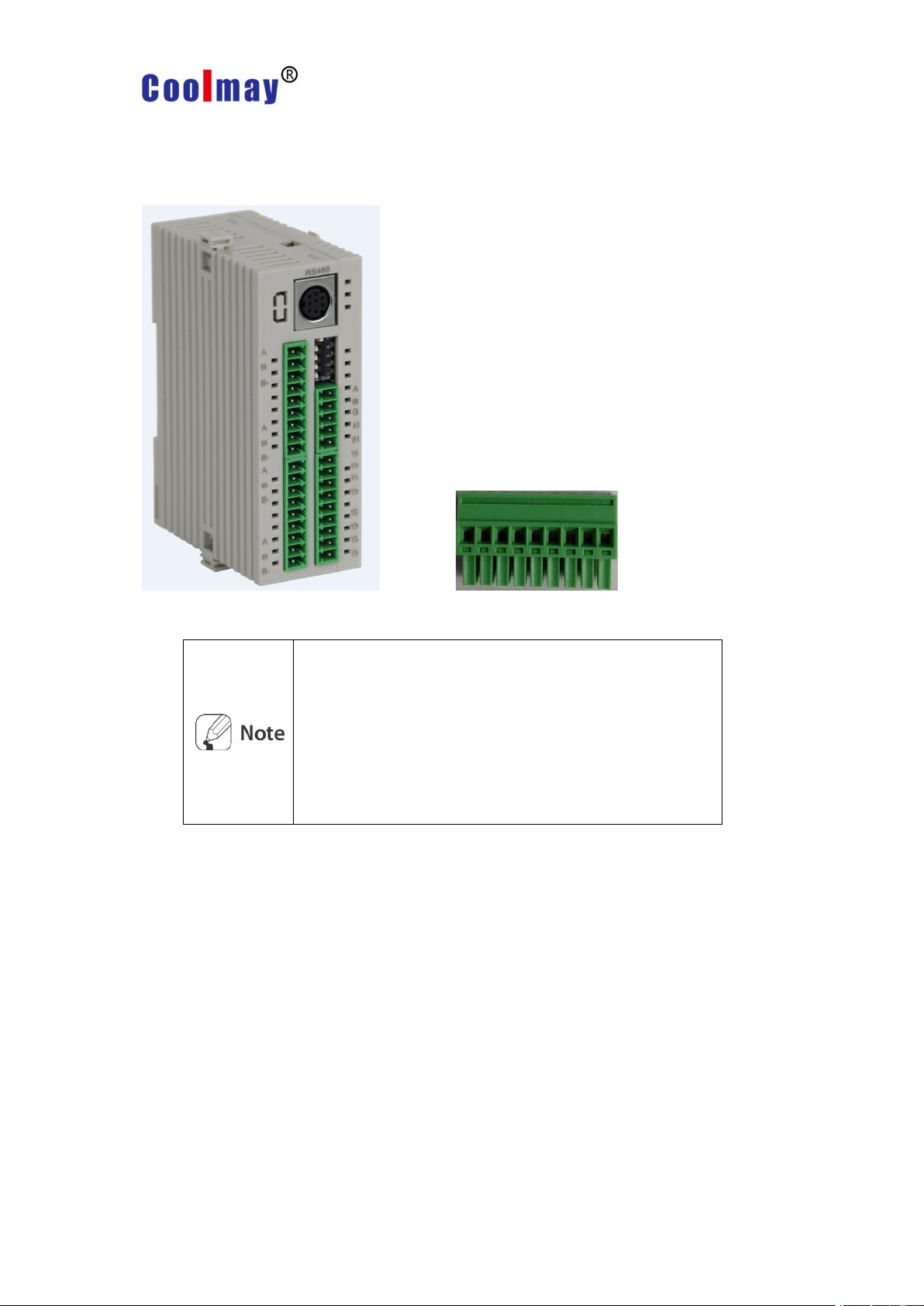

1.2 Components and accessories

Please confirm whether the components are complete after

your purchase. If any defects or damage, please contact the

sales for after-sale services.

Please note that the power/communication connector is only

included in the basic module.

Please visit the official website www.coolmay.com to download

the user manual.

Components

Chapter 1 Product Introduction

Body Terminals

2

Page 11

1.3 Components and features

Status

LED display

Power on

※1

Output

control

Self tuning

※2

Power LED

※3

Green

Green

Green

CH1 LED

2400bps-flicker

ON-red

flicker

CH2 LED

4800bps-flicker

ON-red

flicker

CH3 LED

9600bps-flicker

ON-red

flicker

CH4 LED

19200bps-flicker

ON-red

flicker

38400bps-flicker

1.3.1 Front

Chapter 1 Product Introduction

LED display

※1. After the power is on, the LED indicator will flash once in sequence, then locate the

corresponding frequency with communication speed set earlier. The LED flashes for 5

seconds (cycle: 1 second).

*2. The corresponding LED will flash while self tuning (cycle 1 second).

*3: The power LED flickers while communicating with the outside (cycle 1 second).

3

Page 12

1.3.2 Bottom - wiring part

Chapter 1 Product Introduction

4

Page 13

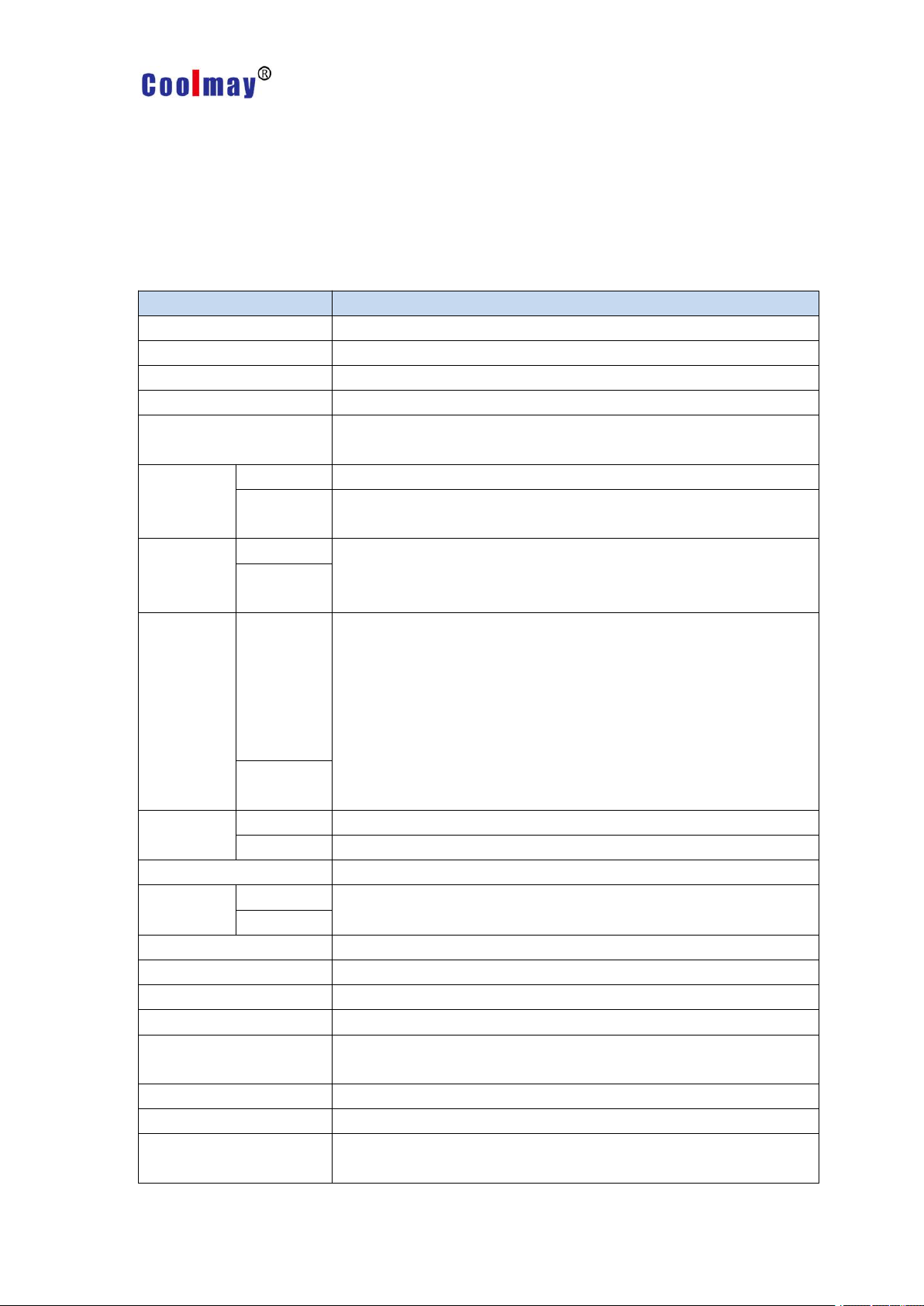

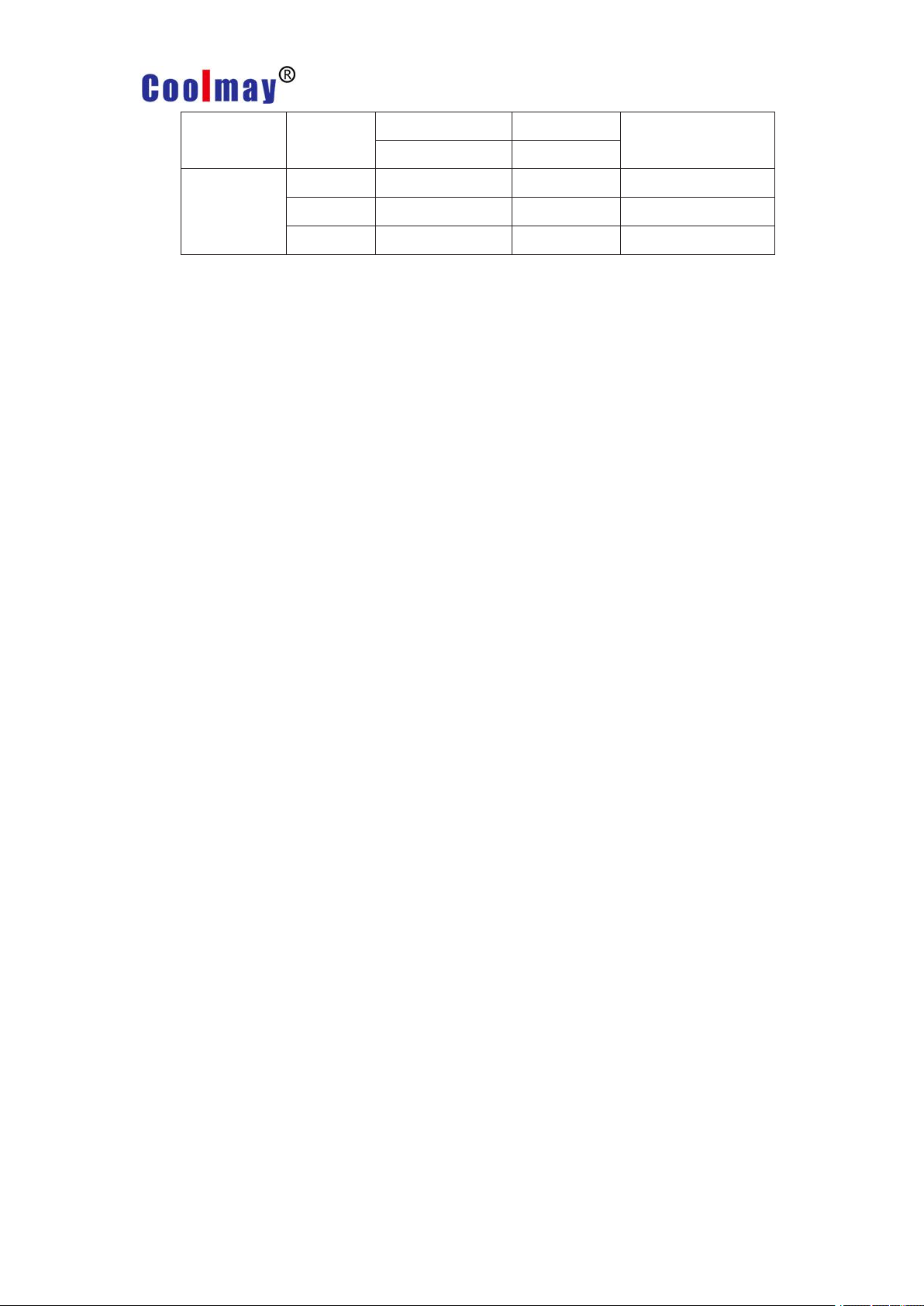

Chapter 2 Product Specifications

Item

CM-4TM

Channels

4 channels----Each channel insulation, dielectric strength1,000VAC

Voltage

24VDC

Voltage range

Nominal voltage * 90% ~ 110%

Power

Max.5W (max load)

Display type

Non-display type - modify parameters and real-time monitoring (PC

or PLC) via external device

Input

RTD

DPt100Ω, JPt100Ω 3 line(resistance: Max. 5Ω)

Thermocou

ple

K, J, E, T, L, N, U, R, S, B, C, G and PLII (13 types)

Display

precision

RTD

(PV±0.5% or ±1℃ greater) < ±1 bit

Thermocou

ple ※1

Temperatur

e effect

※2

RTD

(PV±0.5% or ±2℃ greater) < ±1 bit,

(If thermocouple input, ±5℃ when lower than -100℃ ),

thermocouple L ,U, C, G, R, S, B: (PV±0.5% or ±5℃ greater) < ±1bit

Thermocou

ple

Control

output

Relay

250VAC 3 A 1a

SSR

22VDC ±3V Max.30mA

Communication output

RS485 (Modbus RTU protocol)

Control

mode

Heat, cool

ON/OFF control, P, PI, PD, PID control

Heat & cool

Lag

RTD/thermocouple: 1~100℃/℉(0.1~100.0℃/℉) optional

Proportional band (P)

0.1 ~ 999.9℃

Integral time (I)

0 ~ 9999 sec.

Derivative time (D)

0 ~ 9999 sec.

Control cycle

0.1~120.0 seconds (relay output, SSR drive voltage output type

product)

Hand reset

0.0 ~ 100.0%

Sampling cycle

100ms(4 channels can be sampled simultaneously)

Proof voltage

1000VAC 50/60Hz last 1 minute (between input and power

terminals)

2.1 Specification

Chapter 2 Product Specifications

5

Page 14

Chapter 2 Product Specifications

Item

CM-4TM

Vibration resistance

5 ~ 55Hz (1 minute cycle) amplitude 0.75mm X, Y, Z every direction

2 hours

Relay life

Mechanical

> 10,000,000 times

Electric

> 100,000 times (250VAC 3A resistive load)

Insulation resistance

> 100MΩ (based on 500VDC)

Anti-interface

Interference simulator square wave interference (pulse width 1μs)

±0.5kV

Environmental

temperature

-10 ~ 50℃, Storage: -20 ~ 60℃

Environmental humidity

35 ~ 85%RH, Storage: 35 ~ 85%RH

Attachments

Expansion connector

Power/communication connector [Basic Module only]

Insulation type

Double or reinforced insulation (dielectric strength between the input

and power sections: 1kV)

Certificate

CE, UL

Weight

Approx. 135 ~ 152g

Model

Weight

CM-4TM

Approx. 130g

*1. Thermocouples K, T, N, J, E are below -100 °C and L, U, Platinel II: ±2 °C ± 1 or less. When

the thermocouple B is below 400 °C, the detection accuracy cannot be guaranteed. When R, S

is below 200 °C, it is equal to C, G: 3 °C ± 1 or less.

*2. It is suitable for the situation beyond normal temperature (23 °C ± 5 °C).

Net weight of product refers to the table below.

6

Page 15

Chapter 3 Wiring diagram and module connection diagram

Connecting the power/communication terminals,notice the

polarity of the terminals.

Use AWG 28-16 wires for sensors or compensation wires.

When SSR output, recommend AWG 24 and above cables.

When Relay output, recommend AWG 20 and above cables.

Chapter 3 Wiring diagram and module

connection diagram

3.1 Wiring diagram -front view

When wiring the thermocouple type, connect B, B-; When wiring the two-wire

resistors, connect A and B; When wiring the three-wire resistor, connect A, B,

B-.

7

Page 16

Chapter 3 Wiring diagram and module connection diagram

3.2 Wiring precautions

◆Incorrect connection of the input terminal and output terminal may result in damage to

the product.

◆Please use the sensor type supported by this product.

◆Make sure the SSR or load is within the rated range.

◆Make sure the communication cable is properly connected to the communication

terminals (A, B).

◆Be sure to connect the polarity (+, -) of the terminal correctly.

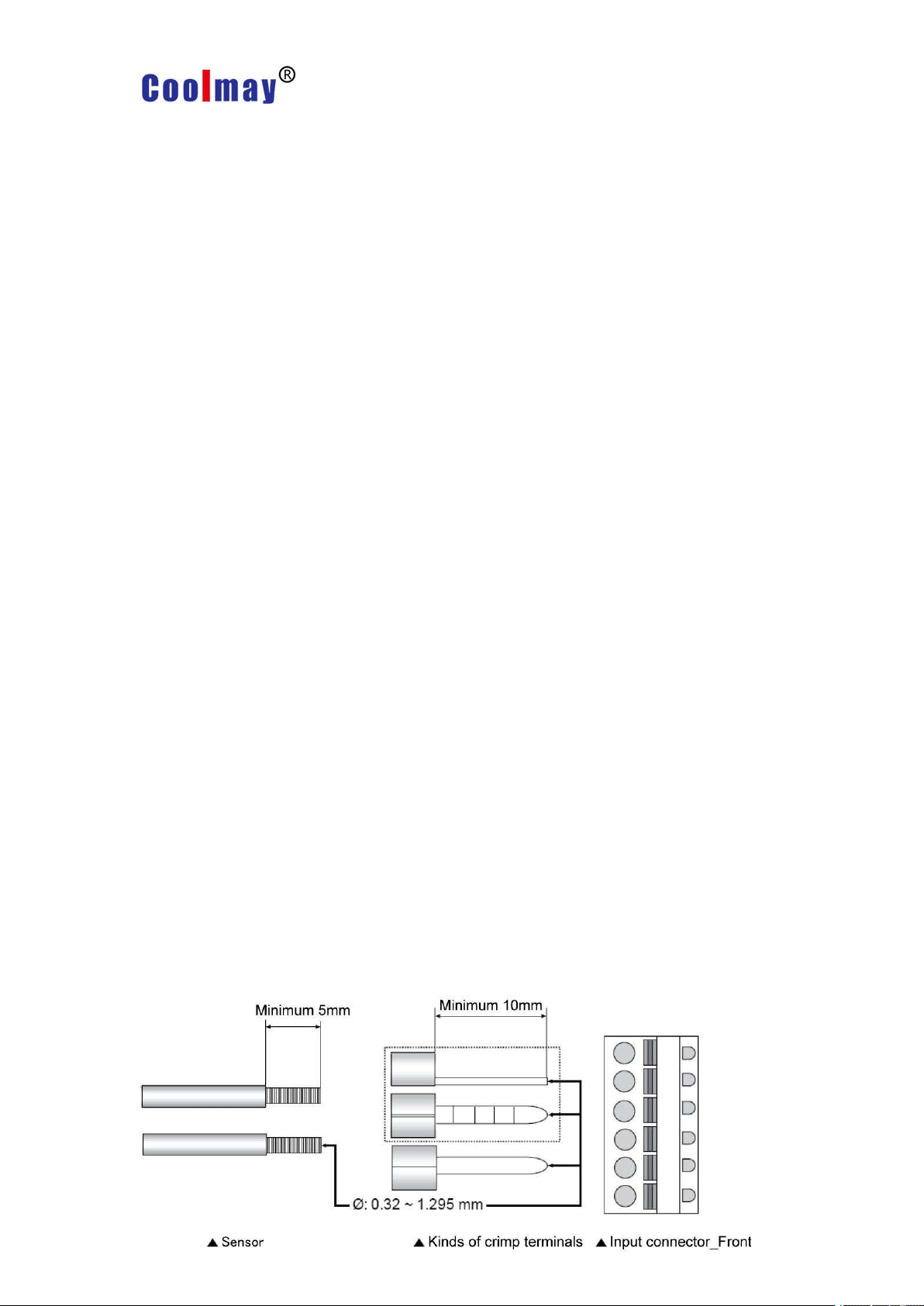

3.2.1 Sensor connection

Compensation wire connection

When using a thermocouple sensor, if you extend the wire, use the same size

compensation wire if you use different specifications.

The compensation wire may have a temperature error. Try to choose a

high-performance compensation wire for more accurate temperature measurement.

Measurement error

◆Do not connect the positive and negative polarity of the sensor.

◆Please pay attention to maintain the distance between the load and the sensor.

◆Make sure the sensor is securely connected to the terminal.

AC power wiring

Do not install the sensor near an AC power source.

Input sensor (or compensation wire) connection

8

Page 17

Chapter 3 Wiring diagram and module connection diagram

Make sure the sensor cable is fully inserted into the terminal.

Sensor/crimp terminal connection spec AWG28~16 (DI:

0.32~1.295mm).

Fix the sensor to make the measurement more accurate.

Use AWG 24 ~ 12 specifications for the power cord.

First calculate general power according to the usage and then

connect the corresponding power.

Setting type

Factory

default

Value before

power-on

Value after

power-on

Com address(CH1)※1

auto/ manual

auto

auto

auto

400004(0003H)

manual

manual

Run/stop

Run

Run

Run

400051(0032H)

Stop

Stop

3.2.2 Power connection

Power supply wiring, please refer to 1.3.2 Bottom-power wiring

3.2.3 Communication connection

For the communication connection, please refer to 1.3.1 introduction.

3.3 Preparation and start

3.3.1 Overall sequence of operations

Perform the following steps before operating the CM -4TM for the first time.

1. All external devices, sensors and loads are connected to the CM -4TM terminals.

2. Modify the relevant parameters (PC, GP, etc.) through the external connection device.

3. Load the set parameters into the CM -4TM.

4. After setting the SV value, perform auto-tuning. Use this product after self-tuning.品。

3.3.2 Set value status when power-on

9

Page 18

Chapter 3 Wiring diagram and module connection diagram

PID/ONOFF

PID

PID

Keep presets

ONOFF

Keep presets

MV

0.0

Preset MV

Keep presets

0.0

Stop MV

Keep presets

0.0

Sensor Error MV

Keep presets

※1:The communication addresses involved in this manual are the addresses of

channel 1 (CH1). For the address of channel 2-channel 4, please refer to

Chapters 6 and 7..

10

Page 19

Chapter 4 Parameter settings and functions

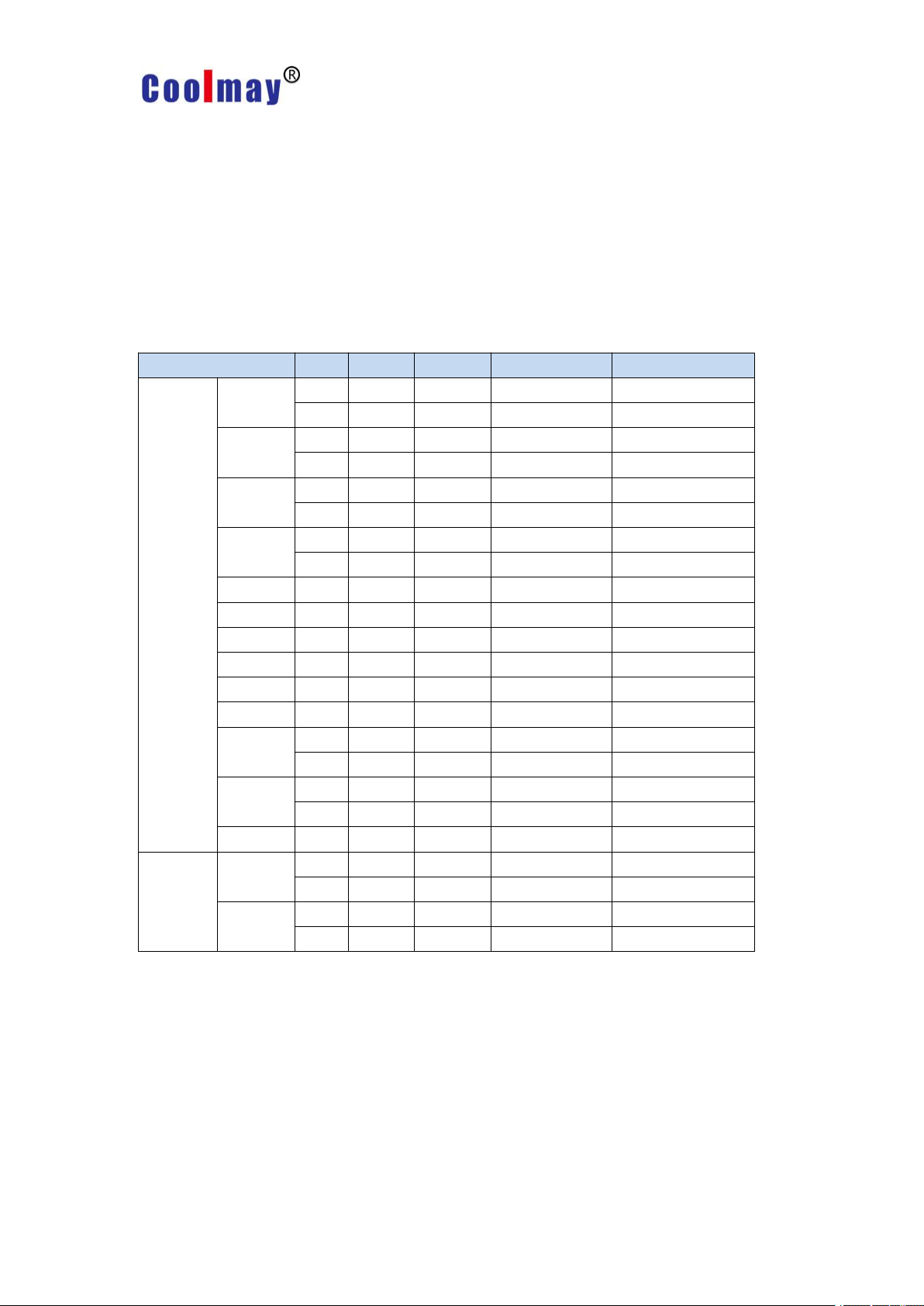

28

Input type

No.

Decimal

Parameter

Input range (℃)

Input range (℉)

Thermoco

uple

K(CA)

01K(CA).H

-200 ~ 1350

-328 ~ 2462

1

0.1

K(CA).L

-200.0 ~ 1350.0

-328.0 ~ 2462.0

J(IC)

21J(IC).H

-200 ~ 800

-328 ~ 1472

3

0.1

J(IC).L

-200.0 ~ 800.0

-328.0 ~ 1472.0

E(CR)

41E(CR).H

-200 ~ 800

-328 ~ 1472

5

0.1

E(CR).L

-200.0 ~ 800.0

-328.0 ~1472.0

T(CC)

61T(CC).H

-200 ~ 400

-328 ~ 752

7

0.1

T(CC).L

-200.0 ~ 400.0

-328.0 ~ 752.0

B(PR)81

B(PR)

0 ~ 1800

32 ~ 3272

R(PR)91

R(PR)

0 ~ 1750

32 ~ 3182

S(PR)101

S(PR)

0 ~ 1750

32 ~ 3182

N(NN)111

N(NN)

-200 ~ 1300

-328 ~ 2372

C(TT)※1121C(TT)

0 ~ 2300

32 ~ 4172

G(TT)※2131G(TT)

0 ~ 2300

32 ~ 4172

L(IC)

141L(IC).H

-200 ~ 900

-328 ~ 1652

15

0.1

L(IC).L

-200.0 ~ 900.0

-328.0 ~ 1652.0

U(CC)

161U(CC).H

-200 ~ 400

-328 ~ 752

17

0.1

U(CC).L

-200.0 ~ 400.0

-328.0 ~ 752.0

Platinel II

181PLII

0 ~ 1400

32 ~ 2552

RTD

JPt100 Ω

191JPt100.H

-200 ~ 600

-328 ~ 1112

20

0.1

JPt100 .L

-200.0 ~ 600.0

-328.0 ~ 1112.0

DPt100 Ω

211DPt100.H

-200 ~ 600

-328 ~ 1112

22

0.1

DPt100. L

-200.0 ~ 600.0

-328.0 ~ 1112.0

Chapter 4 Parameter settings and functions

4.1 Input

4.1.1 Input type and temperature range

※1: C(TT): The same temperature sensor as W5 (TT).

※2: G(TT): The same temperature sensor as W(TT).

The sensor feeds the detected temperature back to the thermostat and then controls

the temperature through the thermostat.

SV (set value) is only allowed to be set within the input range.

Page 20

Chapter 4 Parameter settings and functions

29

Parameter

group

Parameter

Setting

range

Factory

default

Unit

Com

address

Initial set

function

CH1 Input type

Refer

to4.1.1

K(CA).H

−

400151(0096H)

When input type is changed, the upper and lower input range will automatically change to the

selected sensor input range, reset these parameters (SV, multi-segment SV setting,

SV-0~SV-3 and input deviation correction are initialized) to ensure that the measurement

environment remains unchanged.

If the measured range is above or below the input range, HHHH (above), LLLL (lower)

will be displayed, and OPEN will be displayed when the sensor is not connected or

disconnected.

Parameter group

Parameter

Setting range

Factory

default

Unit

Com

address

Initial set function

CH1 Temp unit

℃/℉

℃

-

400152(0097H)

When the temperature unit is changed, the input type remains

the same, but SV, multi-segment SV setting, SV-0~SV-3, SV

upper/lower limit and input deviation correction are initialized.

4.1.2 Input type setting

This product supports a variety of sensors, users can choose thermocouple or

thermal resistance according to demand.

Different sensors can be used for each individual channel. Example): CH1 input type

= KCA.H, CH2 input type = JIC.H

4.1.3 Input sensor temperature unit setting

When the input sensor type is set, the temperature unit can be set according to the

actual demand.

Page 21

Chapter 4 Parameter settings and functions

30

Parameter

group

Parameter

Setting range

Factory

default

Unit

Com address

Initial set

function

CH1

Input deviation

-999~999(H)

-999.9

~

999.9(L)

0

bit

400153(0098H

)

For example, the temperature is displayed at 78 ° C,

but the actual temperature is 80 ° C.

In this case, you can set the input deviation value to

2 and the display temperature to 80 °C.

● Make sure the actual temperature detected is correcr,

otherwise it will cause a larger error.

● Most sensors have sensitivity grading, and higher

sensitivity sensors are relatively expensive. Therefore,

most sensors with medium sensitivity measure the

sensitivity difference of each sensor and then set the

input deviation value to ensure more accurate

measurement temperature.

Parameter

group

Parameter

Setting

range

Factory

default

Unit

Communic

ation

address

Initial setting

CH1input digital

0.1~120.0

0.1

Sec

400154(0099H)

4.1.4 Input deviation correction setting

This function is used to correct the deviation caused by the thermocouple and

Thermal resistance sensor, rather than the deviation caused by the product.

The input deviation correction is mainly used when the sensor cannot be directly

connected to the measurement target. This function can be used to correct the resulting

temperature deviation.

4.1.5 Input digital filter setting

This feature allows the product to achieve high-precision temperature control. If the

PV (display value) is not accurate due to noise components, interference, or input signal

instability, the input digital filtering function can be used to achieve more precise

temperature control.

Page 22

Chapter 4 Parameter settings and functions

31

functions

filtering

When the input digital filter is set to 0.4s, the input digital filter will

take 0.4s (400ms) as the sampling period.

When using input digital filtering, the PV (display value) may

differ from the actual measurement.

Parameter group

Parameter

Setting range

Factory

default

Unit

Com address

Default setting

function

SV Lower limit set

See the

explanation

below

-200

℃/

℉

400155(009AH)

SV Upper limit set

1350

400156(009BH)

If the upper/lower limits are set to exceed the sensor range, the set

value

will not be saved and the value before the setting will remain

unchanged.

SV (set value) is valid only in the upper and lower limits of SV.

The SV lower limit does not exceed the SV upper limit.

When the sensor input type is changed, it will be automatically

changed to the sensor temperature range used. The user needs

to reset the upper/lower limit values.

4.1.6 SV Upper/lower limit setting

The SV (set value) can be set to use the upper and lower limits to prevent product

damage or accidents due to excessive or low set temperatures.

* SV lower limit: sensor lower limit range ~ SV upper limit value - 1 bit

* SV upper limit: SV lower limit value + 1 bit ~ sensor upper limit range

Page 23

Chapter 4 Parameter settings and functions

32

Parameter

group

Parameter

Setting range

Factory

default

Unit

Com address

Default

setting

function

CH1

Operating

mode

0:heating 1:cooling

2:heating & cooling

heating

-

400157(009CH

)

Control output operation amount (MV) Control output operation amount(MV)

4.2 Control output

4.2.1 Control output operation setting

General temperature control includes heating, cooling or heating & cooling; heating

control and cooling control are two opposite operations; the PID value will change as the

control object changes.

Heating control

Heating control mode: When PV (display value) is lower than SV (set value), the

output control load (heater) operates.

Cooling control

Cooling control mode: When the PV (display value) is higher than SV (set value), the

output control load (cooler) operates.

Heating & Cooling Control

Heating & Cooling Control: Heating & Cooling controls the same load action.

The heating & cooling mode can control the same object with different PID values,

and can also set the same PID value control.

It is also possible to select the relay output, SSR output or current output depending

Page 24

Chapter 4 Parameter settings and functions

33

Paramet

er group

Associated

parameter

Parame

ter

Setting range

Factory

default

Unit

Communicati

on address

Master

output

functions

PID-PID

PID-ON/OFF

ON/OFF-PID

CH1

dead

zone

- proportional

band ~

+

proportional

band

0.0

bit

400108(006BH)

ON/OFF-ON/OFF

-999 ~ 0 ~ 999

0

If the input is displayed in decimal, the display range is –999.9 ~ 999.9.

When the proportional bands are different, the smaller one takes

precedence.

There is a decimal point when the sensor type (input.H, input.L) is set to

input.L

Cooling load, temperature drop

Cooling output control

temperature

gontrol

l

temperature rises, Heating load

Heating output control

Input sensor (feedback)

on the application (note that only the standard SSR can be used to control the SSR output

in OUT2.

Overlap/dead zone

In heating and cooling control, the SV (setpoint) overlaps between the heating and

cooling dead zones.

According to the SV value, DP is set to a positive value, and there is no control in the

dead zone interval. Therefore, the control operation amount MV is 0 in the dead zone

interval.

The overlap (heating and cooling simultaneous operation) zone is set to a negative

value according

Set to 0 when no overlap/dead zone is used.

Page 25

Chapter 4 Parameter settings and functions

34

Paramet

er

Associated

parameter

parameter

Setting range

Factory

Default

Unit

Com address

Master

output

function

Cooling

Heating

CH1 MV Lower limits

0.0 ~ (MV Upper

0.0

%

400114(0071H)

CH1 MV Upper limits

(MV Lower limits+ 0.1) ~

100.0

100.0

400115(0072H)

Heating&Cooling

CH1 MV Lower limits

-100.0 ~ 0.0

-100.0

%

400114(0071H)

CH1 MV Upper limits

0.0 ~ 100.0

100.0

400115(0072H)

The amount of operation during the self-tuning process

The amount of operation during manual control includes: the amount of operation when

the

control is stopped; the amount of operation when the sensor is faulty; and the initial

amount of operation when the controller is manually controlled.

The upper/lower limit of the MV does not apply to the ON/OFF

mode in standard mode (heating or cooling).

MV Upper limits

MV Upper limits

MV Lower limits

MV Lower limits

Cooling gontrol

<Standard control (heating control)>

<

Heating and cooling control>

4.2.2 MV Upper/lower limit setting

The setting of the MV upper/lower limit limits the amount of operation of the

thermostat, which is beneficial to safety control.

For heating and cooling control, the cooling MV is prefixed with “-”, so the upper

heating limit is controlled to + value and the lower cooling limit is controlled to - value.

Page 26

Chapter 4 Parameter settings and functions

35

Paramete

r group

Parameter

Setting range

Factory

default

Unit

Communicati

on address

Control

operation

CH1 rising slope

setting

0 (OFF) ~ 9999

0

-

400116(0073H)

CH1 falling slope

setting

0 (OFF) ~ 9999

0

-

400117(0074H)

CH1 slope time

unit

0:SEC (s)

1:MIN (m)

2:HOUR (h)

MIN

-

400118(0075H)

For ceramic or ceramic furnaces, heating too fast may

damage the porcelain in the ceramic furnace, and the

slope heating function can achieve slow heating.

When SV (set value) is operated based on the slope setting value based on PV (display value)

and the value of SV or slope is changed, the SV operation amount changes according to the

corresponding change amount.

Determine the SV control object and set the corresponding slope according to the SV variation.

(hereinafter referred to as RAMP SV)

The amount of change in the rise and fall of the slope can be set separately.

The alarm output and slope depend on the SV value.

This function can't be used when the slope is set to 0.

Running Status

Slop

e

Slope function

All modes=0invalid

OPEN, HHHH,LLLL, Autotuning,

Auto>Manual,

RUN>STOP

Arbitrary value

invalid

OPEN, HHHH, LLLL, after Auto-tuning, PV = SV

Arbitrary value

invalid

Power on, SV change, control switch STOP switch to RUN,

Control Switch Manual Switch to Auto, Slope or Slope Time Unit Change

≠0

invalid

4.2.3 Slope setting

The slope is a function related to SV (set value) that prevents the rate of SV from

being limited due to a sudden change (increase or decrease) in the temperature of the

controlled object.

Slope state in different modes

Page 27

Chapter 4 Parameter settings and functions

36

Parameter Group

Associated

parameter

Parameter

Setting range

Factory

default

Unit

Com address

Master

control output

function

PID

CH1 operation

volume

0:Auto-MV:

1:Manual-MV

Auto-MV:

-

400202(00C9H)

Parameter Group

Parameter

Setting range

Factory

Default

Unit

Com address

Monitoring

function

CH1 automatic -

manual control

0: automatic; 1: manual

Auto

-

400004(0003H)

Auto/manual function can be switched freely by controlling the switch.

Auto/manual control remains unchanged when the product is powered down or shut down.

During operation, AT (auto-tuning) can be switched to manual control.

In stop mode, manual control is activated.

If SBA (sensor disconnection alarm) occurs during control, the sensor error operation

amount will be used. In this state, it can be switched to manual control, and the manual

control operation

amount can also be modified.

It is possible to switch to manual/automatic control during control operations.

Priority: Manual Control > Stop > Disconnect (sensor disconnection).

4.2.4 Automatic/manual control settings

Automatic control: When PID control, the operation amount is automatically controlled

according to the SV value. Manual control: In this mode, the user can freely set the

operation amount according to the requirements.

The stop function can be set by setting the digital input terminals (DI1, DI2).

Manual control of the amount of operation

When switching from automatic control to manual control, the initial operation amount

can be set.

AUTO-MV: When switching from manual control to automatic control, the amount of

operation is initialized.

PRESET-MV: Use the set operation amount as the initial value.

Page 28

Chapter 4 Parameter settings and functions

37

Parameter

Group

Associated

parameter

Parameter

Setting range

Factory

default

Unit

Com address

Master contr

ol output fun

ction

Heating, cooling, PID

CH1 Manual operation

Initial operation

0.0 ~ 100.0

0.0

%

400203(00CAH)

Heating&cooling,PID

-100.0 (Cooling) ~

0.0

~ 100.0 (Heating)

0.0

0.1~ -100.0When heating and cooling control, the heating

operation amount is set from

0.1 to 100.0, and the cooling operation amount is set from

0.1 to -100.0.

※ When the power is turned back on after the power is turned off, the operation amount is

controlled to output the value before the power is turned off.

Initial operation amount during manual control

If the manual operation amount is set to PR.MV (manual preset MV), the initial MV can

be manually modified.

Page 29

38

4.3 Temperature control

Parameter

Group

Associated

parameter

Parameter

Setting range

Factory default

Unit

Com address

Initial

setting

function

heating, cooling

CH1

control way

0:PID:1:ON/OFF

0:PID

-

400158(009DH)

heating&cooling

0:PID-PID

1:PID-ON/OFF

2:ON/ OFF-PID

3:ON/OFF- ON/OFF

0:PID-PID

-

Parameter

Group

Associated

parameter

Parameter

Setting

range

Factory

Default

Com address

Master control

output function

Heating

&

Cooling

Heating

CH1 Heating hysteresis

1~100

2

400110(006DH)

CH1 Heating deviation

0~100

0

400111(006EH)

Cooling

CH1 Cooling hysteresis

1~100

2

400112(006FH)

CH1 Cooling deviation

0~100

0

400113(0070H)

4.3.1 Temperature control method setting

The temperature control method can be set by parameters.

4.3.2 ON/OFF control

Chapter 4 Parameter settings and functions

The ON or OFF state is controlled by comparing PV (display value) and SV (set

value).

Hysteresis value setting

When the ON/OFF control output is used, the ON hysteresis and OFF deviation

values can be set.

When the hysteresis value is set too low, it may cause frequent movements and cause

interference (noise, vibration, etc.). In order to reduce interference, the appropriate ON and

OFF offsets are set according to the heating and cooling capacity and thermal

characteristics, the response frequency between the controller and the sensor, the

installation environment and other relevant factors.

Page 30

Chapter 4 Parameter settings and functions

39

Parameter

group

Associated

parameter

Parameter

Setting range

Factory

defualt

Unit

Com address

Master

control output

function

Heating, PID

CH1 Heating

proportional band

0.1 ~

999.9

10

C

400102(0065H)

Cooling, PID

CH1 Cooling

proportional

band

400103(0066H)

Control

Control

(Heating)

(Cooling)

<heating control>

<cooling control>

heating control

4.3.3 PID control

PID is a combination of proportional band (P), integral (I), and differential (D). The

control time is longer than ON/OFF, but the control accuracy is high.

Proportional band (P) control reduces oscillations; integral (I) controls correct for

deviations; and differential (D) controls provide fast response to interference. Through the

combined control of these three, precise temperature control can be achieved.

PID control application

Proportional (P) control: When PID control is selected, the integration and derivative time are set to 0.

Proportional-Integral (PI) Control: When PID control is selected, the derivative time is set to 0.

Proportional-Derivative (PD) Control: When PID control is selected, the integration time is set to 0. When

using the multi-segment SV function, the PID values of SV0 ~ SV3 are the same.

Proportional band settings

When PV (display value) is within the proportional band (P) range, ON/OFF needs to

adjust the proportional period (T), so the time period of proportional control is called the

proportional band.

Page 31

Chapter 4 Parameter settings and functions

40

Parameter

group

Associated

parameter

Parameter

Setting

range

Factory

defualt

Unit

Com address

Master control

output function

Heating, PID

CH1 Heating

integration time

0 ~ 9999

0

Sec.

400104(0067H)

Cooling, PID

CH1 Heating

Integration time

400105(0068H)

This function is not used if the integration time is set to 0.

The integration time setting is too short. The correction action for

interference is weak, but it is not easy to produce overshoot.

Parameter

group

Associated

parameter

Parameter

Setting range

Factory

defualt

Unit

Com address

Master

control output

function

Heating, PID

CH1 Heating

differential time

0 ~ 9999

0

Sec.

400106(0069H)

Cooling, PID

CH1 Cooling

differential time

400107(006AH)

This function can't be used if the integration time is set to 0.

Parameter

group

Associated

parameter

Parameter

Setting

range

Factory default

Unit

Com address

Initial

setting

function

Heating, PID

CH1 Heating control

cycle

0.1 ~

120.0

20.0(Relay)

2.0(SSR)

Sec.

400160(009FH)

Cooling, PID

CH1 Cooling control

cycle

400161(00A0H

)

Integration time setting

When there is a certain deviation, the time that the combined action and the

proportional action work together is the integration time.

Derivative time setting

The time required for the differential action and the proportional control of the deviation

on the slope is the differential time.

Control cycle setting

Under the control of the relay or SSR output, the output is kept for a fixed amount of

time (the percentage of the manipulated variable during the control period) remains off.

When the output ON/OFF changes to the proportional period control within the preset

period. The SSR control output responds faster than the relay output, so the period

required for control is shorter and easier to achieve sensitive temperature control.

Page 32

Chapter 4 Parameter settings and functions

41

If heating and cooling control is used, set the heating and cooling

control cycles separately.

The deviation function can only be used in proportional control. If

the integration time is set to 0, the manual correction parameter

value can be modified.

Manual adjustment cannot be set during heating and cooling

control, the parameter is automatically set to 0%

Only applicable integration time is set to 0 (only in P or PD control)

Automatically change to standard control (P, PD control) when

switching heating and cooling control is 50%

Parameter

group

Associated

parameter

Parameter

Setting

range

Factory

defualt

Unit

Com address

Master

control output

function

PID

CH1 Manual

reset

0.0 ~ 100.0

50.0

%

400109(006CH)

Deviation correction / manual reset setting

When only proportional control (P, PD control) is used, the heat capacity of the control

object and the heat capacity of the heater affect the heating and cooling time. Therefore,

there may be a certain deviation in the final control temperature, which can be corrected

manually.

Manual reset adjustment based on control results

Set the deviation to 50% for stable control

The deviation is 50% when PV=SV; the deviation exceeds 50% when PV<SV; the

deviation is less than 50% when PV>SV.

4.3.4 Self-tuning

During PID control, the required PID value is automatically adjusted according to the

thermal characteristics and response speed of the control object, so that the product can

respond quickly and accurately control the temperature.

Auto-tuning ON/OFF setting

The PID value is automatically saved after the auto-tuning is completed, and the user can

also set the PID value according to the usage environment.

Page 33

Chapter 4 Parameter settings and functions

42

Parameter

group

Associated

parameter

parameter

Predete

r- mined

area

Factory

default

Unit

communicati

on address

Master output

function

PID

CH1 PID

0:OFF

1:ON

OFF

-

400101(0064H)

If you change to manual control during auto-tuning, auto-tuning will

end automatically

If a sensor error prompt occurs during auto-tuning, the auto-tuning

ends and the PID value before tuning is maintained.

Even if the temperature is higher or lower than the input range, the

operation continues during the auto-tuning process.

During the auto-tuning process, related parameters can only be

viewed and cannot be modified.

When auto-tuning is in progress, if the digital input (DI-1, DI-2) is

run/stop or auto/manual, and the sensor has an error, the

auto-tuning ends automatically.

Auto-tuning is not available during manual control

default

setting

Features

PID

CH1 PID

type

0:Tun1

1:Tun2

Tun1

-

400159(009EH)

In cooling mode, Tun2 is based on 70% of 0°C.

Example: If the SV is -100, the Tun2 execution

benchmark is -70 °C.

During the self-tuning process, the LED output lamp flashes once every 1 second, and

after the end, the LED output lamp goes out, and the auto-tuning state is automatically

changed from ON to OFF.

Self-tuning mode setting

Auto-tuning is based on the use of optional Tun1 mode (SV) or Tun2 mode (70% of

SV).

Tun1 mode [TUN1]: Automatically adjusts the PID value based on SV.

Tun2 mode [TUN2]: Self-tuning PID value based on 70% of SV.

Page 34

Chapter 4 Parameter settings and functions

43

Types

Description

Applicable

standard

Meets EIA RS 485-standard

Maximum

connection

31 (address: 01 ~ 31)

way of

communication

2-wire half duplex

Communication

synchronization

asynchronous(Asynchronous)

Communication

effective distance

Max. 800m

BPS(Communicati

on rate)

2400, 4800, 9600, 19200, 38400 bps

Communication

response time

5 ms ~ 99 ms

Start bit

1 bit(fixed)

Data bit

8 bit(fixed)

Parity bit

None, odd, even

Stop bit

1, 2bit

protocol

Modbus RTU

Dail

switch

54321

4.4 Communication

Function for setting parameters and monitoring data after the controller is connected

to an external device (PC, GP, etc.)

There is no duplicate address in the same communication line, and the communication

cable must use twisted pair to support RS485 communication.

interface

4.4.1 Communication address setting

Each product can be set to a unique address

◆

◆Set the communication address using the communication address setting switch

◆Setting range: 01 ~ 31

◆Factory default 01

Page 35

Chapter 4 Parameter settings and functions

44

When it is set to all OFF, that is, 0, communication

will not be possible.

LED

BPS (Bits/second)

2400

4800

9600

19200

38400

Communication ports A and B can be used for communication of

multiple modules. After changing the communication speed, you

need to power on again (power OFF → power ON)

OFF

00000

ON

11111

Parameter

group

parameter

Predetermined

area

Factory

default

Unit

commuication

address

Setting

Options

(communica

tion setting)

function

Bit per

second

0:2400, 1:4800,

2:9600,3:19200

4:38400

9600

bps

400301(012CH)

For example: In the example, dial 1, 2, 4, and 5 of the DIP switch to OFF, indicating that

the module's communication address is 03H.

For example, dial 1 and 5 of the DIP switch to turn ON, 2, 3, and 4 to OFF, indicating that

the module's communication address is 11H.

4.4.2 Communication speed setting

Can set the data transmission speed

At power-on, the LED corresponding to the current set frequency flashes for 5 seconds (1

second period). For the specific LED lamp position, please refer to 1.3.1

Page 36

Chapter 4 Parameter settings and functions

45

Communication ports A1, B1 are only suitable for single module

communication, and the speed is fixed at 9600 bps.

Make sure that the address of each module is unique. If there is an

overlapping address, the modules with overlapping addresses will

not communicate properly, and may even affect the normal

communication of all products.

SV (Set value)

Description

0:NONE

Do not use parity bits

1:Even

Set an even parity bit

2:Odd

Set 1 odd parity bit

Parameter

group

parameter

Predetermin

-ed area

Factory

default

Unit

commuication

address

Setting

Options

(communica

tion setting)

function

Parity bit

0:NONE,

1:EVEN,

2:ODD

NONE

-

400302(012DH)

Parameter

group

Param

e-ter

Predeter

m-ined

area

Factory

default

Unit

commuicatio

n address

Setting Options

(communication

setting) function

Stop

bit

0:1bit

1:2bit

2

-

400303(012E)

4.4.3 Communication Parity Bit Setting

The check digit is an additional bit for each character in the transmitted data. It is used to

verify the data loss and corruption. This parameter can be set to enable or disable the

check digit option.

4.4.4 Communication stop bit setting

Can set a stop character for transferring data

4.4.5 Communication response waiting time setting

When setting communication with (PC, PLC, etc.), in order to reduce communication

errors, you can set the response waiting time and start working normally after the

response time.

Page 37

Chapter 4 Parameter settings and functions

46

Parameter

group

Paramete

r

Predeter

m-ined

area

Factory

default

Unit

commuicati

on address

Setting Options

(communication

setting) function

Communic

-ation

response

time

5~99

20

-

400304(012FH)

Setting the communication waiting time too short

may cause communication errors.

Parameter

group

Param

eter

Setting

range

Factory

default

Unit

communication

address

Setting Options

Commu

nication

write

0:allow

1:forbid

allow

-

400305(0130H)

The communication write function

does not affect the read parameters.

4.4.6 Enabling/Disabling Communication Write Settings

It is possible to set functions that are allowed or prohibited by communication with PC, GP,

PLC, etc.

4.5 Additional features

4.5.1 Monitoring function

Monitor control output operation

Monitor and display the current control output operation amount.

Monitor heating operation

◆ Monitor and display the current heating operation amount.

◆ The user can also control the temperature by manually adjusting the amount of

operation.

◆Measurement range: 0.0 ~ 100.0%.

Monitor refrigeration operations

◆ Monitor and display the current cooling operation.

◆ The user can also control the temperature by manually adjusting the amount of

operation.

◆Measurement range: 0.0 ~ 100.0%.

Page 38

Chapter 4 Parameter settings and functions

47

When the RUN/STOP function is set to the stop state, the STOP

status remains valid even if the power is turned off again.

Displays the current control output operation amount (Stop.MV)

when the stop function is in effect, and keeps

When power is restored after stopping, the initial operation amount

is also the maximum operation amount.

Re-powering after RUN/STOP setting is still valid

Paramet

er

group

Associated

parameter

Param

eter

Setting range

Factory

default

Unit

Communica

tion address

Master

control

Output

Features

Heati

ng,

Cooli

ng

PID

CH1

stop

Operati

on

volume

0.0 ~ 100.0

0.0

%

400205(00CCH)

ON/OFF

0.0(OFF) ~ 100.0(ON)

Heati

ng&

Cooli

ng

PID

-100.0(Cooling) ~

100.0(heating)

0.0

ON/OFF

-100.0(Cooling ON)

/0.0(OFF) /

100.0(heating ON)

When set to STOP mode, ON/OFF control and PID control ignore

the set operation amount

4.5.2 Run/Stop Settings

◆ In the operation mode, the control output can be forced to run or stop.

◆ The control output stops after the STOP command is sent.

◆ Control the run/stop function by setting the digital input terminals (DI-1, DI-2).

Control output stop

When the control output is stopped, select between 0.0 (OFF) and 100.0 (ON) under

ON/OFF control.

Under PID control, the control output operation can be selected between 0.0 ~ 100.0.

4.5.3 Multi-segment SV

The multi-segment SV function allows the user to set multiple SV values and save them to

the SV0 ~ SV3 parameters. The desired SV value can be selected via the external digital

input (DI-1, DI-2) terminals.

Supports up to 4 SV values, which can be set individually.

Number of multi-segment SVs

The multi-segment SV value can be set according to the number of control objects.

Page 39

Chapter 4 Parameter settings and functions

48

SV amount

SV parameters

0:1EA

SV-0

1:2EA

SV-0, SV-1

2:4EA

SV-0, SV-1, SV-2, SV-3

Select the SV value according to the

actual use

Parameter

group

Associated

parameter

Param

e-ter

Setting

range

Factory

default

Unit

Communic

ati-on

address

Master control

Output

Features

-

CH1

Multi

channel

SV

0:1EA;

1:2EA;

2:4EA;

0

-

400201(00C8H)

operating

(control

operation)

Features

Multi-channel

SV

CH1Mu

lti-chan

-nel SV

0:SV-0

1:SV-1

2:SV-0

3:SV-1

SV-0

400052(0033H)

operating

(control

operation)

Features

Multi-channel

SV

CH1

SV-0

setting

value

SV Lower

limit ~ SV

Upper limit

0

℃,℉

400053(0034H)

Multi-channel

SV

CH1

SV-1

setting

value

SV Lower

limit ~ SV

Upper limit

0

℃,℉

400054(0035H)

Multi-channel

SV

CH1

SV-2

setting

value

SV Lower

limit ~ SV

Upper limit

0

℃,℉

400055(0036H)

Multi-channel

SV

CH1

SV-3

setting

value

SV Lower

limit ~ SV

Upper limit

0

℃,℉

400056(0037H)

Multi-segment SV selection

Select the SV value according to your needs.

Multi-segment SV operation

Set the amount of operation corresponding to each SV value

4.5.4 Error Detection Function

Page 40

Chapter 4 Parameter settings and functions

49

When power is turned on, or in the standard heating/cooling mode,

HHHH is displayed when the control output is 0%, and LLLL is displayed

when the control output is 100%.

When power is turned on, or in the standard heating/cooling mode, the

heating output is 0%, the HHHH is displayed when the cooling output is

100%, the heating output is 100%, and the LLLL is displayed when the

cooling output is 0%.

Manually control the output priority order: Heating (Cooling)_MV >

Stop_MV > Sensor Error _MV

Automatic control output priority: Stop _MV > Sensor Error _MV >

Heating (Refrigeration) _MV

Parameter

groups

Parameter

Setting range

Factory

default

Unit

Communica

te address

Setting

Options

functions

(communicati

on setting)

Parameter

initialization

1:YES

0:NO

NO

-

400306(0131H)

When the thermostat detects an input signal error, it sends and displays this

information.

The following conditions may cause an error condition, and when an error occurs, the

LED flashes in a 0.5 second cycle.

Sensor input exceeds the upper temperature range;

◆

Sensor input is below the lower temperature range;

◆

◆Sensor disconnected or not connected.

Once the error alarm is removed (sensor connected / restored to temperature range),

the device will continue to operate normally

Sensor error MV

This function is used to control the sensor error during output, the user can set

ON/OFF, MV setting, etc.

The MV value is controlled by ON/OFF or PID and is based on the MV control value.

4.5.5 Parameter initialization functions

This feature restores all parameters to their factory defaults.

Page 41

Chapter 4 Parameter settings and functions

50

If Yes is selected in the parameter, all parameters will be restored to

factory defaults.

However, the communication parameters are not initialized.

Page 42

Chapter 5 Troubleshooting method

51

CM-4TM

LED condition

When disconnecting

sensor input

When the

temperature range is

exceeded

PWR LED

Red light on

CH1 LED

Red light flashes(0.5 second period)

CH2 LED

Red light flashes(0.5 second period)

CH3 LED

Red light flashes(0.5 second period)

CH4 LED

Red light flashes(0.5 second period)

Communication

output (decimal

number)

Communication

output‘31000’

Communication

output'30000'(upper

limit)

Communication

output‘-30000’(lower

limit)

For PC only

display‘OPEN’

display'HHHH (upper

limit)'

display‘LLLL (lower

limit)’

Chapter 5 Troubleshooting method

5.1 error display

The display LED flashes in a 0.5 second bit period, or the external communication

connection device displays an error message.

OPEN indicates that the sensor is disconnected or not connected:

Power off check the sensor connection status. If the sensor is not broken, short the + and

- poles with a wire and select the thermocouple sensor to see if the temperature controller

displays room temperature. If the room temperature is not displayed, the thermostat may

be damaged. Please contact our technical support department.

Make sure the sensor is connected correctly and select the corresponding input type

5.2 Communication troubleshooting method

When using this product to connect to a communication external device without response

or abnormal data:

■ Make sure that the communication converter is normal.

■ Do not route the AC power cord with the communication cable.

■ Please supply power separately for the converter and the product.

■ If the product is damaged due to internal circuits or strong interference, please contact

our technical support department. In addition, the external interference of the product

should be shielded as much as possible, and the internal circuit of the product may be

Page 43

Chapter 5 Troubleshooting method

52

damaged due to continuous interference signals.

When the product is not properly connected to the external device:

■ Check that the converter is properly powered.

■ Check that the communication settings are correct.

■ Check that the product is properly connected to the external device.

5.3 Control troubleshooting methods

The control output does not work when using the product:

■ Check that the product front panel output LEDs are working properly.

■ If the output LED does not work, check each parameter. If the output LED is working

properly, check that the controller output terminals (relay, SSR) are properly connected.

Page 44

Chapter 6 Modbus RTU protocol

53

Slave

address

function

initial address

Number of data

Error

check(CRC16)

High

Low

High

Low

Low

High

1Byte

1Byte

1Byte

1Byte

1Byte

1Byte

1Byte

1Byte

Salve

address

function

Number

of bytes

data

data

data

Error

check(CRC16)

Low

High

1Byte

1Byte

1Byte

1Byte

1Byte

1Byte

1Byte

1Byte

Salve

address

function

initial address

Numbers of data

Error

check(CRC16)

High

Low

High

Low

Low

High

11 H

01 H

00 H

00 H

00 H

0A H

** H

** H

Chapter 6 Modbus RTU protocol

6.1 Read coil status (Func 01-01H)

Read the output of the slave device (refer to OX state) ON/OFF state

1. Inquiry (master side)

CRC16

2. Answer (salve side)

CRC16

For example:

When the master side reads the output status of 10 coils 000001 (0000H) to 000010

(0009H) from the slave side (address 17) (ON: 1, OFF: 0).

Inquiry(master side)

If the value of the slave side coil 000008 (0007H)~000001 (0000H) is

"ON-ON-OFF-OFF-ON-ON-OFF-ON",The value of 000010(0009H)~000009(0008H) is

"OFF-ON".

Page 45

Chapter 6 Modbus RTU protocol

54

Slave

address

function

Number

of bytes

Data

(000008-00000

1)

Data

(000010-00000

9)

Error

check(CRC16)

Low

High

11 H

01 H

02 H

CD H

01 H

**H

**H

Slave

address

function

initial address

Numbers of data

Error

check(CRC16)

High

Low

High

Low

Low

High

1Byte

1Byte

1Byte

1Byte

1Byte

1Byte

1Byte

1Byte

Slave

address

function

Number

of bytes

Data

Data

Data

Error

check(CRC16)

Low

High

1Byte

1Byte

1Byte

1Byte

1Byte

1Byte

1Byte

1Byte

Slave

address

function

initial address

Numbers of data

Error

check(CRC16)

High

Low

High

Low

Low

High

11 H

02 H

00 H

00 H

00 H

0A H

** H

** H

answer(slave side)

6.2 Read Input Status (Func 02-02H)

Read the input of the slave device (refer to 1X state) ON/OFF state

Inquiry(master side)

CRC16

2 answer(slave side)

CRC16

The master side reads the output state of the ten coils 10001 (0000H) to 100010 (0009H)

from the slave side (address 17) (ON: 1, OFF: 0).

Inquiry (master side)

If the value of the slave side coil 100008 (0007H) ~100001 (0000H) is

"ON-ON-OFF-OFF-ON-ON-OFF-ON",

Page 46

Chapter 6 Modbus RTU protocol

55

Slave

address

function

Number

of bytes

data

(100008-10000

1)

data

(100010-10000

9)

Error

check(CRC16)

Low

High

11 H

01 H

02 H

CD H

01 H

** H

** H

Slave

address

function

initial address

Numbers of data

Error

check(CRC16)

High

Low

High

Low

Low

High

1Byte

1Byte

1Byte

1Byte

1Byte

1Byte

1Byte

1Byte

Slave

addre

s-s

Func

t-ion

Numbe

r of

bytes

data

data

data

Error

check(CRC16)

Hig

h

Low

High

Low

High

Low

Low

High

1Byte

1Byt

e

1Byte

1Byte1Byt

e

1Byt

e

1Byt

e

1Byt

e

1Byt

e

1Byte

1Byte

The value of 000010(0009H)~000009(0008H) is "OFF-ON".

answer(salve side)

6.3 Read hold memory (Func 03-03H)

Read binary data from the device holding memory (refer to 4X state)

1. Inquiry (master side)

CRC16

2. answer(salve side)

CRC16

Examples:

The master side reads the values of the two holding memories 400001 (0000H) to 400002

(0001H) from the slave side (address 17).

Inquiry (master side)

Page 47

Chapter 6 Modbus RTU protocol

56

Slave

address

function

initial address

Numbers of data

Error

check(CRC16)

High

Low

High

Low

Low

High

11 H

03 H

00 H

00 H

00 H

02 H

** H

** H

Slave

addres

s

functio

n

Numbe

r of

bytes

data

data

Error

check(CRC16)

High

Low

High

Low

Low

High

11 H

03 H

04 H

02 H

2B H

00 H

64 H

** H

** H

If the values from the side 400001 (0000H) ~ 400002 (0001H) are "555 (22B H)" and "100

(64 H)" respectively.

answer(salve side)

Page 48

Chapter 6 Modbus RTU protocol

57

Slave

address

Functio

n

Initial address

Data quantity

Error check

(CRC16)

High

Low

High

Low

Low

High

1Byte

1Byte

1Byte

1Byte

1Byte

1Byte

1Byte

1Byte

Slave

address

Functio

n

Number

of bytes

Data

Data

Data

Error check

(CRC16)

Low

High

1Byte

1Byte

1Byte

1Byte

1Byte

1Byte

1Byte

1Byte

Slave

address

Functio

n

Initial address

Data quantity

Error check

(CRC16)

High

Low

High

Low

Low

High

11 H

04 H

00 H

00 H

00 H

02 H

** H

** H

Slave

addres

Functio

n

Numbe

r of

Data

Data

Error

check(CRC16)

6.4 Read input memory(Func 04-04H

Read binary data from the input memory of slave device (refer to 3X state)。

)

1. Inquiry (master side)

CRC16

2. Answer(slave side)

CRC16

For example:

The master side reads the values of the two input memories 300001 (0000H) to 300002

(0001H) from the slave side (address 17).

Inquiry (master side)

If the values of the slave side 300001 (0000H) ~ 300002 (0001H) are "10 (A H)" and "20

(14 H)", respectively.

Answer (slave side)

Page 49

Chapter 6 Modbus RTU protocol

58

s

byte

High

Low

High

Low

Low

High

11 H

04 H

04 H

00 H

0A H

00 H

14 H

** H

** H

Slave

address

Functio

n

Memory address

Preset data

Error check

(CRC16)

High

Low

High

Low

Low

High

1Byte

1Byte

1Byte

1Byte

1Byte

1Byte

1Byte

1Byte

Slave

address

Functio

n

Memory address

Preset data

Error check

(CRC16)

High

Low

High

Low

Low

High

1Byte

1Byte

1Byte

1Byte

1Byte

1Byte

1Byte

1Byte

Slave

address

Functio

n

Initial address

Preset data

Error check

(CRC16)

High

Low

High

Low

Low

High

11 H

06 H

00 H

00 H

00 H

0A H

** H

** H

6.5 Preset a single memory(Func 06-06H

Binary data written to a single memory (refer to the 4X state) from the slave device.

1. Inquire(master side)

CRC16

2. Answer(slave side)

)

CRC16

For example:

The master side writes "10 (A H)" to the holding memory 400001 (0000H) of the slave side

(address 17).

Inquiry (master side)

Page 50

59

Answer(slave side)

Slave

address

Functio

n

Initial address

Preset data

Error check

(CRC16)

High

Low

High

Low

Low

High

11 H

06 H

00 H

00 H

00 H

0A H

** H

** H

Slav

e

addr

ess

Func

tion

Initial

address

Memory

quantity

Num

ber

of

byte

Data

Data

Error check

(CRC16)

High

Low

High

Low

High

Low

High

Low

Low

High

1Byt

e

1Byt

e

1Byt

e

1Byt

e