Coolerado C60, M30 User Manual

COOLERADO CORPORATION 4430 GLENCOE STREET, DENVER, COLORADO 80216

INSTALLATION AND SERVICE PROVIDER

COMPANY______________________________________

ADDRESS_______________________________________

_______________________________________________

_______________________________________________

_______________________________________________

TELEPHONE_____________________________________

Coolerado Installation Manual

M30, M50A, C60

Version 2013-4

Date: 4-9-2014

WWW.COOLERADO.COM

Customer Information

Installer Information

Name

Company

Address Line 1

Address Line 1

Address Line 2

Address Line 2

City City

State / Prov.

State / Prov.

Postal Code

Postal Code

Phone #

Phone #

Installation Date:

Installation Information

Air Filters installed (Y/N)

Water Filter Installed (Y/N)

Water Hardness

Type of Air Filter Installed

Type of Water Filter Install

Size of Air Filter Installed

Make of Water Filter

Water Pressure @ unit

Plenum Air Pressure Measurements

Conditioned Air

Exhaust Air

Outside Air Temp

Outside Humidity Level

Conditioned Air Temp

Power

Line Voltage

Line Amperage

Phase

Control Voltage

Equipment Information

Unit Model #

Unit Serial #

Thermostat Make

Thermostat Model #

Initial Installation Start-up Data Sheet

MUST BE COMPLETED AFTER INITIAL INSTALLATION

Page 2 of 50

Table of Contents

Safety Considerations 4

Installation Recommendations 4

Installation Steps

Step 1 – Check Equipment and Job Site 5

Step 2 – Inspect Filters and Heat Exchanges 6

Step 3 – Clearance Requirements 7

Step 4 – Install on Solid and Level Foundation 7

Step 5 – Drain Connections 8

Step 6 – Outdoor Intake Air 9

Step 7 – Conditioned Air Ducts 9

Step 8 – Working Air Ducts 11

Step 9 – Water Supply Connections 13

Step 10 – Electrical Power Connection 15

Step 11 – Thermostat Wiring 16

Step 12 – Control Board Set-up and Operation 17

Step 13 – Thermostat 17

Step 14 – HMX Wet Out Logic 18

Step 15 - Operational Startup 19

Step 16 – Final Checks 19

Post Installation / Seasonal Start-up 20

Normal Operating Procedure 20

Seasonal Shutdown 20

Care and Maintenance 21

Appendix

Appendix 1 – Coolerado Water Quality Requirements 23

Appendix 2 - Wiring and Control Diagram 24

Appendix 3 – Coolerado Thermostat Wiring Picture 25

Appendix 4 – Multiple Unit Control Diagram 26

Appendix 5 – Water Control Board / Indicators / Dip Switch Settings 27

Appendix 6 – Thermostat Operations for (TEC2145-4) 28

Appendix 7 – Thermostat Programming (TEC2145-4) 29

Appendix 8 – M30 Dimensional Specifications 30

Appendix 9 – M30 Air Flow Performance Table 31

Appendix 10 – M50A Dimensional Specifications 32

Appendix 11 – M50A Air Flow Performance Table 33

Appendix 12 – M50A Curb Mount Unit 34

Appendix 12 – C60 Dimensional Specifications 36

Appendix 13 – C60 Air Flow Performance Table 37

Appendix 14 – Water Pressure Charts 38

Appendix 15 – Limited Warranty 40

Appendix 16 – Installation Check List 42

Appendix 17 – Preventative Maintenance, (PM) Checklist 47

Appendix 18 – Troubleshooting 48

Page 3 of 50

Page 4 of 50

Coolerado Installation

SAFETY CONSIDERATIONS

Improper installation, adjustment, alteration, service,

maintenance, or use can cause explosion, fire, electrical

shock, or other conditions, which may cause death, personal

injury, or property damage.

Use this product only in a manner intended by

manufacturer.

Ensure the fan has completely stopped prior to

changing filters.

Before servicing or cleaning, other than changing

filters, ensure power to the unit is disconnected and

locked out.

Keep body, hands, and foreign objects away from air

intake while unit is in operation.

To avoid fire hazard, do not block any air intake.

Do not use the unit cabinet as a platform or attempt

to sit, stand, or climb or store.

Do not use the unit’s fan with any solid state speed

control device.

Consult a qualified installer, service agency, or your product

distributor for more information, or assistance. The qualified

installer or agency must use only factory-authorized kits or

accessories when modifying this product. Refer to the

individual instructions packaged with the kits or accessories

when installing.

WARNING: Follow all safety codes. Wear safety glasses,

protective clothing, and work gloves.

Read these instructions thoroughly and follow all warnings

or cautions included in literature and attached to the unit.

These instructions are intended as a general guide and do

not supersede local codes in any way. Authorities having

jurisdiction should be consulted before installation.

Recognize safety information, symbols and words:

(DANGER) will identify serious hazards, which will result in

severe personal injury or death.

(CAUTION) will identify unsafe practices, which would result

in minor personal injury or poor unit performance, product

damage and property damage.

(NOTE) will be used to highlight suggestions, which will

result in enhanced installation, reliability, or operation.

INSTALLATION RECOMMENDATIONS

NOTE: Any restrictions to air movement, either for intake

air, conditioned air, or exhaust air, will reduce the capacity

and efficiency of the unit.

NOTE: Working air (exhaust) will always be heavier than

ambient air until it fully mixes and comes to equilibrium

with outside air.

1.) The unit may be installed either indoors or outdoors.

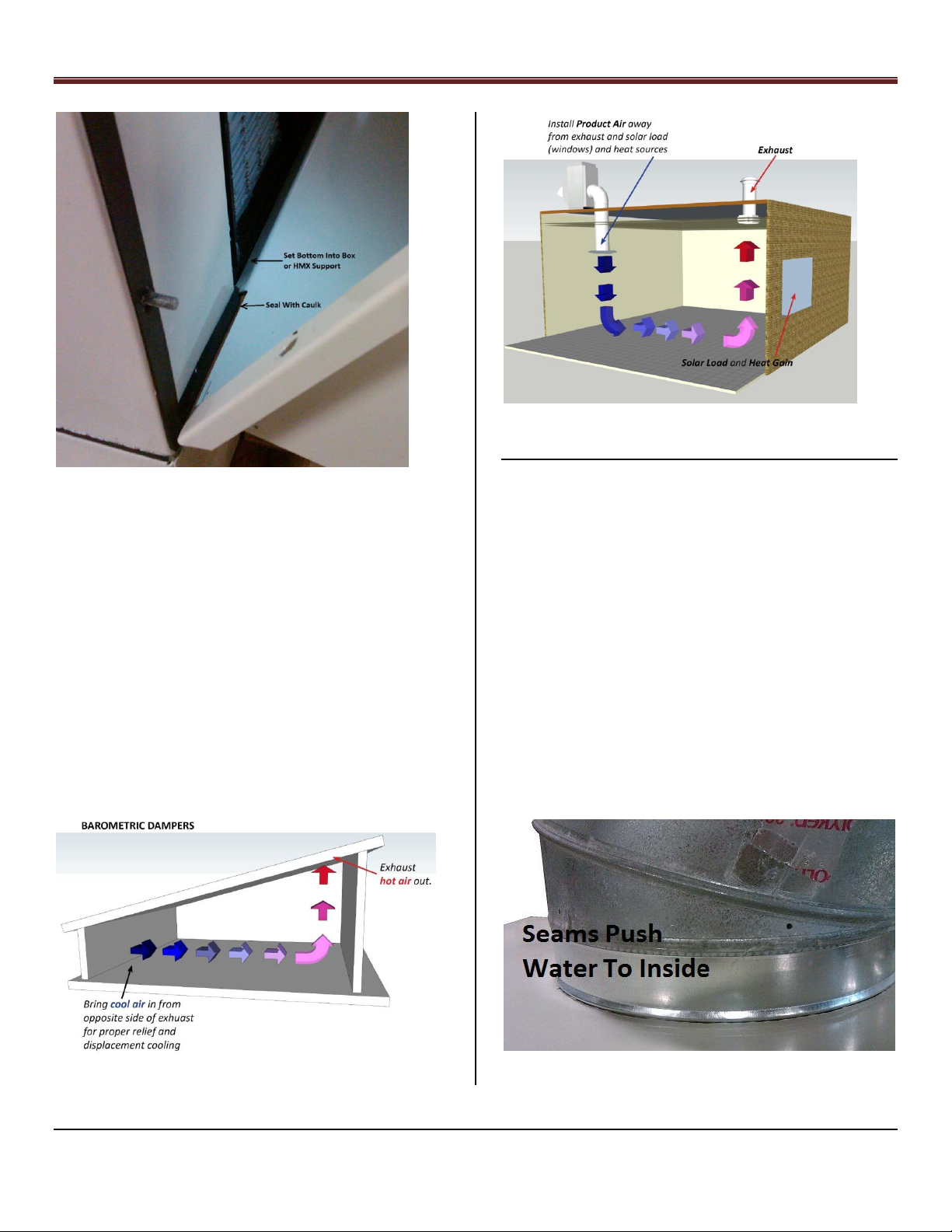

2.) Flexible duct connectors should be installed between

any rigid ductwork and the unit to allow for leveling

requirement and to mitigate vibration.

3.) If unit is installed indoors, install an emergency drain

pan that extends beyond the unit by at least 6” (152

mm) on all sides along with separate overflow drain

in accordance with local plumbing codes.

4.) Be sure to provide adequate support for the unit and

associated ductwork.

5.) Be sure that there is no exposure to flammable

vapors, excessive dust, or other contaminants in the

air.

6.) To obtain the greatest cooling capacity, air will need

to flow into and out of the unit as freely as possible.

7.) Humid working air must be allowed to flow freely

away from the unit and directed away from the

unit’s intake air supply. If ducted, ensure adequate

condensate drains are available.

8.) The intake air opening must be kept free from

obstruction and allowed to draw in fresh dry air.

9.) The conditioned air must be unobstructed to the

building or space to be cooled.

10.) All ductwork must be properly sealed and insulated.

11.) Keep all ductwork runs as short as possible between

the unit and conditioned space.

12.) If exhaust ducts are needed they must be sealed.

13.) If unit is installed outdoors, install rain shields as

needed.

14.) In unheated environments, provide adequate freeze

protection for system water supply and drain.

Page 5 of 50

Coolerado Installation

15.) Ensure level mounting to allow the internal water

distribution to work correctly.

16.) If the potable water supply is considered moderately

hard, hard or very hard include a sodium-based

water softener, see Appendix 1.

Note: Make any necessary duct modifications to implement

seasonal Duct Blocks during initial installation.

It is recommended that off-season duct blocking devices be

installed as part of the end-of-season shutdown procedures.

Step 1—Check Equipment and Job Site

Caution: Take the necessary precautions and use

appropriate equipment to move and install.

INSPECT PACKAGING OF EQUIPMENT BEFORE ACCEPTANCE

Check the unit for any signs of shipping damage before

accepting equipment from the freight carrier. If shipment is

damaged do not accept shipment or it may become yours as

is. If damaged, file an immediate claim with the shipping

company. No return shipment will be accepted without

written return authorization.

UNPACK UNIT

Move to final location. Remove carton or packaging, taking

care not to damage unit.

INSPECT EQUIPMENT

Check the unit for any signs of shipping damage. Fan should

spin freely and all covers and parts should be secured

properly. To reduce the shipping footprint on a C60, the

conditioned air plenum may be shipped wrapped to the inlet

of the unit rather than bolted on. If shipment is damaged or

incomplete, file a claim with the shipment company as soon

as possible. No return shipment will be accepted without

return authorization.

CHECK BUILDING UTILITIES AND GEOMETRY

Check for plumbing vent location

Check for exhaust vents and fumes from heaters

Check water location and hookup

Check for location of sanitary sewer drain

Check for storm sewer

Do the downspouts connect to the storm sewer

drain?

Check power

Check control connections

Check water hardness

LOCATION OF EQUIPMENT

Select a location for the unit as close as possible to the supply

air diffuser and away from any building exhaust or sources of

high humidity levels.

Note: If tying into existing HVAC equipment check for

complete functionality before starting any work.

NOTE: Prevailing winds and building geometry must be

taken into consideration in determining air inlet and

exhaust locations. Additional ductwork for either the intake

or exhaust may be required to assure proper separation of

the air

streams.

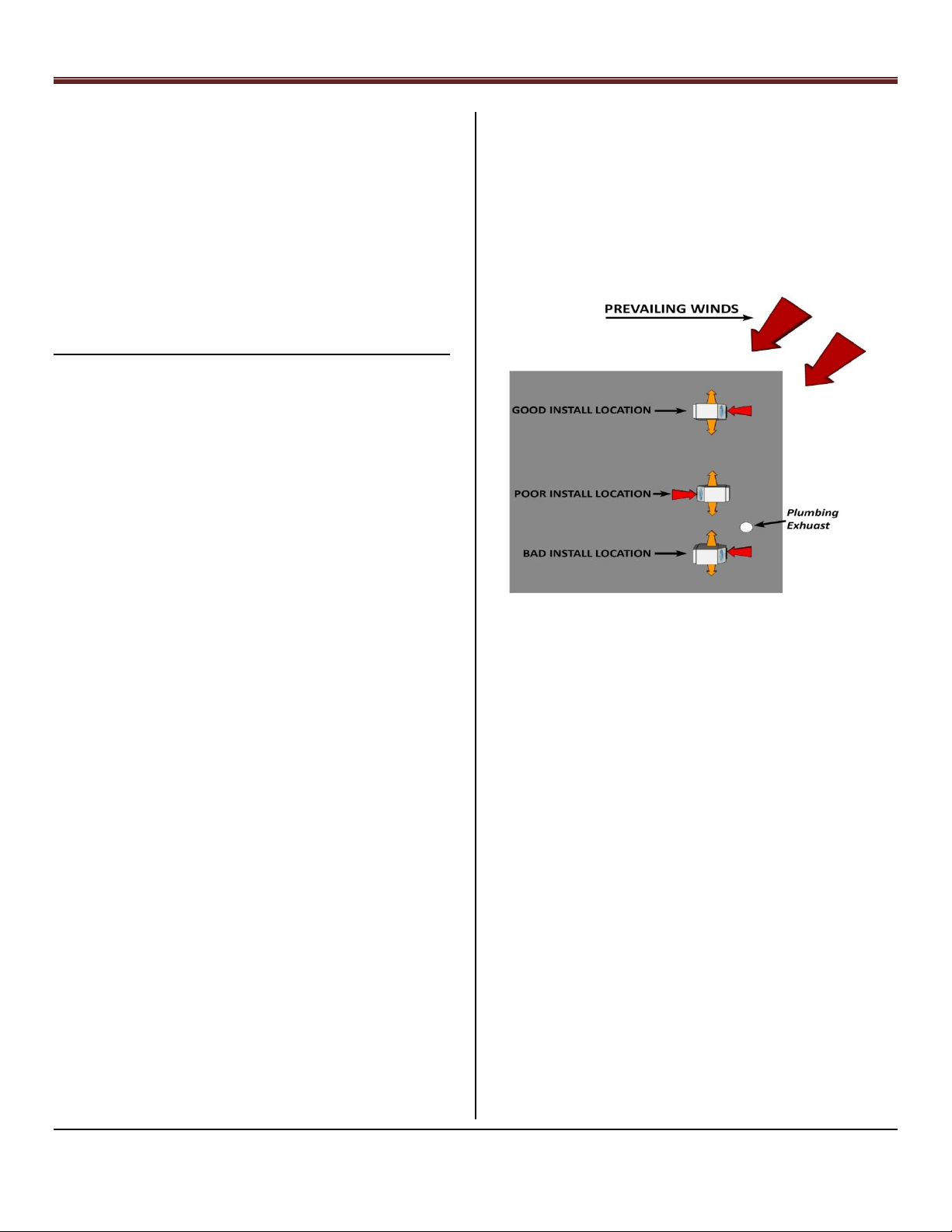

Prevailing wind consideration, Figure 1

NOTE: Inlet hoods should not be located near driveways,

parking lots, gas meters, oil fill pipes, dryer vents or other

areas. Avoid areas where objectionable vapors,

contaminants, or excess particles could be drawn into the

unit. Humid working air must be directed into a free air

outdoor space and away from any condensing surface.

NOTE: Humidity sources include the Working Air exhausts

from the unit itself or from adjacent units, cooling towers,

open drains, grass, bushes, trees, swampy areas, swimming

pools, water features, plumbing vents, etc.

DANGER: Do not expose the unit intake air to flammable

liquids or vapors and away from excessive dust sources.

LIFTING EQUIPMENT

Forklift / crane

Crane

Straps and spreader bar

Upper security banding (as seen below)

The lifting point above the unit must be at least 4’ (1.2 m) or a

spreader bar is needed to prevent squeezing box.

Page 6 of 50

Coolerado Installation

Model

Pleated Filter Size

M30

2”x20”x25” pleated (50x500x625mm), nominal

1.75”x19.5”x24. 5” (44.5x495x622mm), actual

M50

2”x20”x25” pleated (50x500x625 mm), nominal

1.75”x19.5”x24. 5” (44.5x495x622mm), actual

C60

2”x20”x25” pleated (50x500x625 mm), nominal

1.75”x19.5”x24. 5” (44.5x495x622mm), actual

Care should be taken not to rack or torque the units

when moving units or lifting units into position as this

may cause poor door fitting, Heat and Mass Exchanger

racking and leaking, air leaks, etc.

M50A Lifting Lugs, Figure 2

Lifting Straps/Banding, Figure 3

Step 2— Inspect Filters and Heat Exchangers

1.) Inspect the unit’s filters for damage or debris.

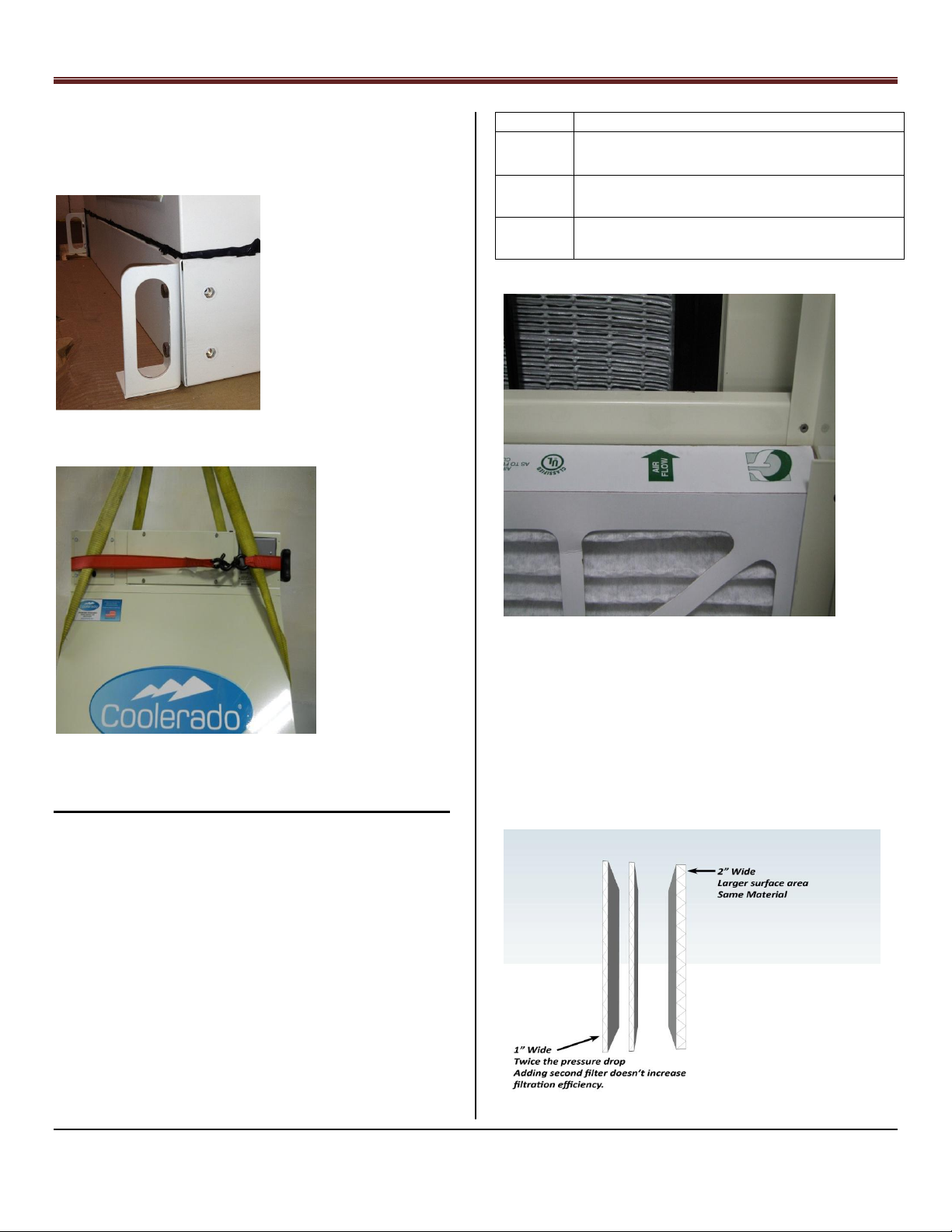

Filter Flow Arrow, Figure 4

NOTE: One 1” (25 mm) thick filter can be used in place of 2”

(50 mm) filters but will need to be changed twice as often.

CAUTION: Do not substitute the recommended 2” (50 mm)

filter with two 1” (25 mm) filters, this will significantly

reduce the airflow through the unit. See Figure 5

DANGER: Do not expose the intake air to flammable liquids

or vapors.

2.) Spin the fan for freedom of movement.

3.) Remove filters and inspect heat and mass

exchangers (ensure flow arrow on filter is correct).

4.) Inspect surfactant soap container for proper level.

5.) Units are shipped with filters.

Page 7 of 50

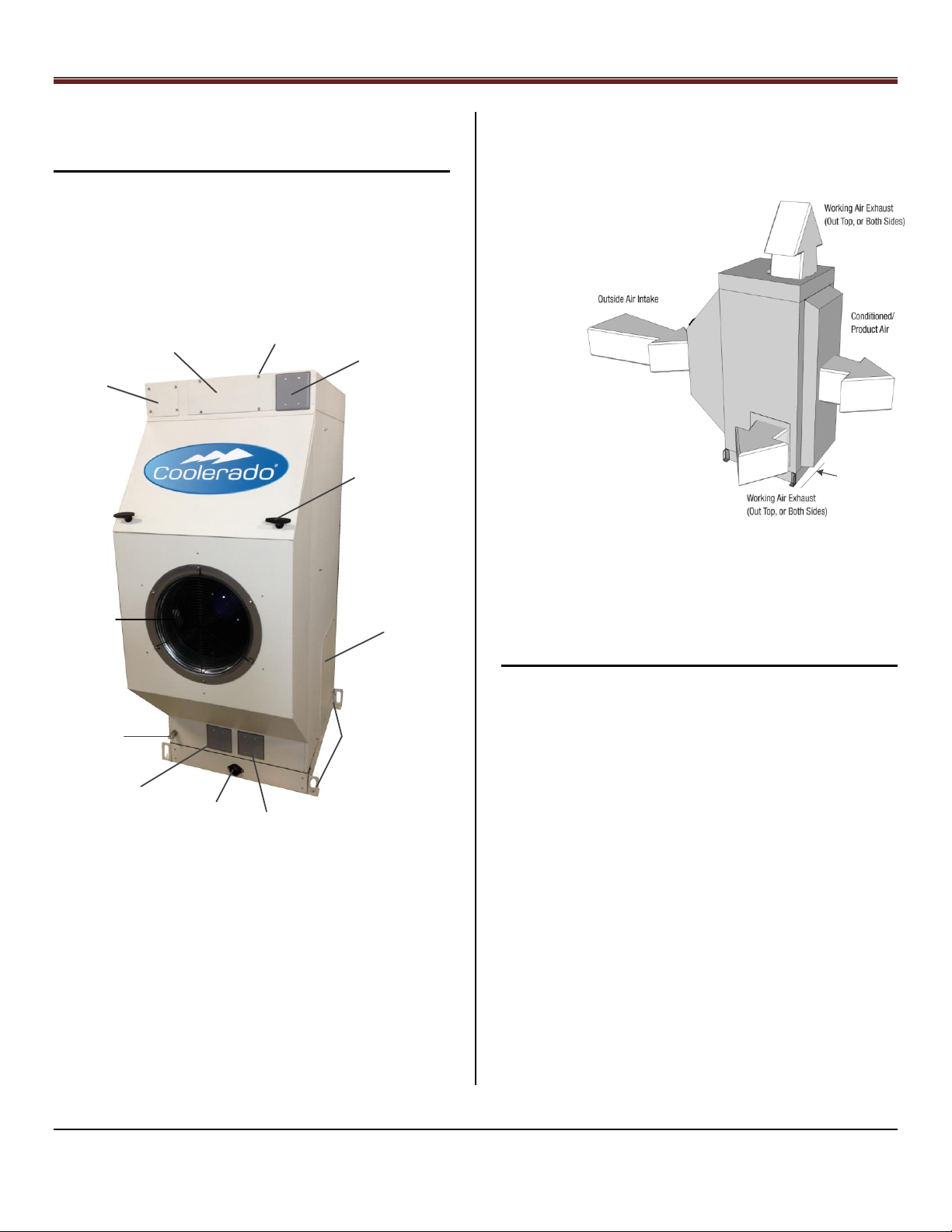

Coolerado Installation

Pre-Cut 16" (406 mm)

Diameter Exhaust In Top

High Voltage Power

Factory Wired

Connections

Soap

Pump

Control Wiring,

Low Voltage

Do Not Block

Filter Access Door

Filter Access

Door Handles

Pre-Cut 16" x 16"

(406 x 406 mm)

Louver/ Cover

Lifting Lugs

Drain

Water In

Low Voltage Wire

Terminals In

High Voltage Wire

Terminals In

Outdoor

Air In

Clearances:

Sides: 0" if exhausted from the top.

24"(600 mm) if exhausted from both

sides. A baffle maybe needed between

M50's to reduce mixing with intake air.

Outside Air Intake, fan side: 24" (600

mm).

Conditioned Air Plenum side: 12" (300

mm).

Top: 6" (150 mm) for installation if not

exhausting out the top.

Do Not Cut

Below 6" (150

mm) From Base

of Unit

Filter image, Figure 5

Step 3—Clearance Requirements

1.) Inspect clearances and position unit for installation –

see Appendices 8, 10 or 12 for unit dimensions and

clearance details per model.

2.) Familiarize yourself with the unit’s connection and

service points. See Figure 6.

NOTE: Take precautions no to block service areas of unit,

and that ductwork connections have enough flexibility for

leveling or seasonal re-leveling purposes.

Identifying System Components, M50A, Figure 6

NOTE: Ensure unit is positioned so that filters, soap pump

and electrical service areas are easily accessible for

maintenance and seasonal changes.

NOTE: Figure 7 shows the working exhaust air from the top.

For units using side working air exhaust.

CAUTION: Ensure a minimum of 24” (610 mm) clearance for

side mounted working air exhaust.

Clearance Requirements, Figure 7

Step 4— Install on a Solid and Level Foundation

1.) Mount the unit on a solid and level foundation with

proper sub-base and drainage to ensure the unit will

not shift during its lifetime.

2.) Take the proper precautions when mounting the

unit to reduce noise and vibration.

3.) If mounted on rafters use appropriately sized

vibration damping springs and duct isolation

attachments.

4.) If installed on a roof, in an attic or somewhere else

where structural support may be an issue, consult

with a structural engineer and comply with local

code requirements.

The base of the C60 and M30 units can be attached to for tie

down purposes with screws that are less than 1” (25 mm) in

length and located within 1” (25 mm) of the bottom of the

base, see Appendices 8, 10 and 12.

The M50A comes with lifting lugs at bottom four (4) corners

with ¼” (6.35 mm) x 20 mounting bolts that can also be used

for installation attachment to a frame.

Page 8 of 50

Coolerado Installation

M50A Leveling Feet, Figure 8

If unit is installed indoors, install an emergency drain pan that

extends beyond the unit by at least 6” (150 mm) on all sides

along with separate overflow drain directed to a sink or

outside location where the leak can be seen and in

accordance with local plumbing codes, see Figure 9.

Step 5 – Drain Connections

NOTE: The units drain connection is located underneath the

unit’s intake air plenum.

1.) Install system drain piping

A drain line must be connected to the:

o M30 or C60 - 1½” (38.1 mm) ABS female slip

connection

o M50A - can be 1 ½” (38.1 mm) pipe over

If local or state codes allow drain water to be

outside; 1 ¼” (31.75 mm) inside or 40mm

deeper inside

used for Irrigation it must be drained away from

the pad to eliminate any settling that will

prevent the unit from remaining level. If this

occurs, the drain line must slope a minimum of

1/8” per foot (10.4 mm/meter).

Overflow/Drain Example, Figure 9

LEVEL UNIT

The weight of the wet unit will require a stable base. During

installation, the unit must be properly supported and leveled

to stay stable over time. The water delivery to all areas inside

the unit depends on the unit being level within 1/16” per foot

(5.2 mm/meter) in both directions. Caution: Failure to do so

will void system warranty.

The M50A comes with leveling screws in a box wrapped with

the unit.

Pooling of water near the unit will also allow

excess humidity to be drawn into the unit, which

will reduce the cooling performance of the unit.

CAUTION: Do not discharge to roof top drains that drain to

parking lots or alleys. (The continual flow of water will cause

a slick green algae growth).

Drain Connection, Figure 10

CAUTION: Foundation racks or solid drainage

footing/concrete pads must be used on ground installations

to ensure the unit remains level and secure. Proper

preparation of ground is necessary to maintain level footing

over time.

CAUTION: Do not place unit directly underneath roof, eaves

or drip lines without adequate gutters.

If the unit drain line is connected to an internal building

sanitary sewer drain line, it must feed into a 1-1/4” (40mm),

(or larger) plumbing drain line that meets all plumbing code

requirements. The drain line must be vented as it enters the

building sanitary sewer drain line.

Page 9 of 50

Coolerado Installation

Model

Intake Duct Size

Intake Duct Size

M30

16 inches, (20” at fan inlet)

400 mm, (508 mm

at fan inlet)

M50

20 inches

500 mm

C60

22 inches, (20” at fan inlet)

560 mm, (508 mm

at fan inlet)

Step 6—Outdoor Intake Air

NOTE: The intake air duct must not be located near the units

working air duct.

1.) Install and inspect ductwork if needed.

The intake air can enter the unit directly or through a

properly sized duct. Use intake sizes from Table 1:

Intake Duct Sizes, Table 1

NOTE: If the unit is installed in a building (attic or other) a

duct may be needed to draw fresh intake air into the unit

from outside the building.

NOTE: The free open area of the intake grill must equal the

duct area. Failure to do so may cause excessive pressure

drop across the grill, see duct sizes in Table 1.

NOTE: If rigid duct is used to connect to the unit’s intake air,

it must be designed to be easily removed to allow service

access.

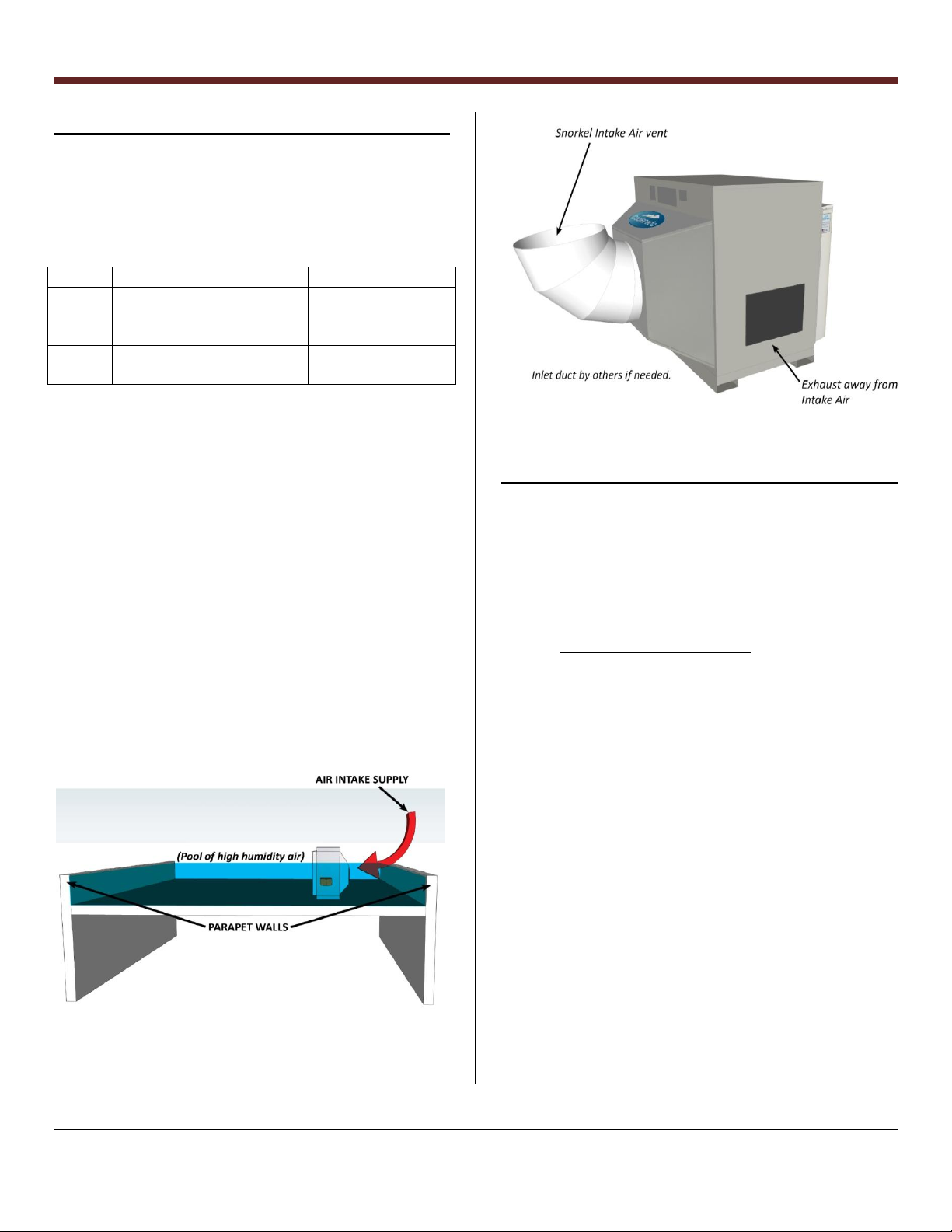

NOTE: In some roof top installations, parapet walls can trap

the heavy cool humid working air below the walls causing

the intake air to have a high humidity resulting in higher

conditioned air temperatures. In these situations the intake

air may need to be brought from a higher location, see

Figure 11.

Intake Snorkel, Figure 12

Step 7 –Conditioned Air Duct

1.) Install properly sized, sealed and insulated

conditioned, R6 minimum, air duct to unit.

2.) For all units the conditioned air plenum is shipped

without pre-cut duct openings. This allows the

installer to add the ducts where desired on location.

Duct openings should only be cut into the front of

the supply plenum. DO NOT CUT OPENING IN THE

BOTTOM OF SUPPLY PLENUM or within 2” (20mm)

of the bottom. Coat and seal any exposed metal, see

Appendices 8, 10 and 12.

NOTE: Seasonal shut off dampers or easily accessible duct

blocks should be installed for easy winterization

changeover.

NOTE: A flexible duct connector should be installed between

the unit and any rigid ductwork to allow for seasonal

leveling and to mitigate vibration.

Recommendations for reducing temperature loss and

creating displacement ventilation conditions:

High Parapet Walls, Figure 11

1.) The air pressure at the units conditioned air plenum

should be 0.01 to 0.15 inches of water column (2.5

Pa to 37 Pa) greater than the working air exhaust

plenum under full air-flow. This will prevent water

migration from the exhaust side to the conditioned

air-side and provide adequate working air.

2.) Seal duct work.

3.) If the conditioned air ducts are located external to

the building or in an attic space, a minimum of R6

Page 10 of 50

Coolerado Installation

insulation is required. Follow local building and

insulation code requirements.

4.) Size ducts to about 0.08 inches of water column per

100 feet (66 Pa per 100 m) of duct.

5.) Maximize the trunk duct and minimize the length of

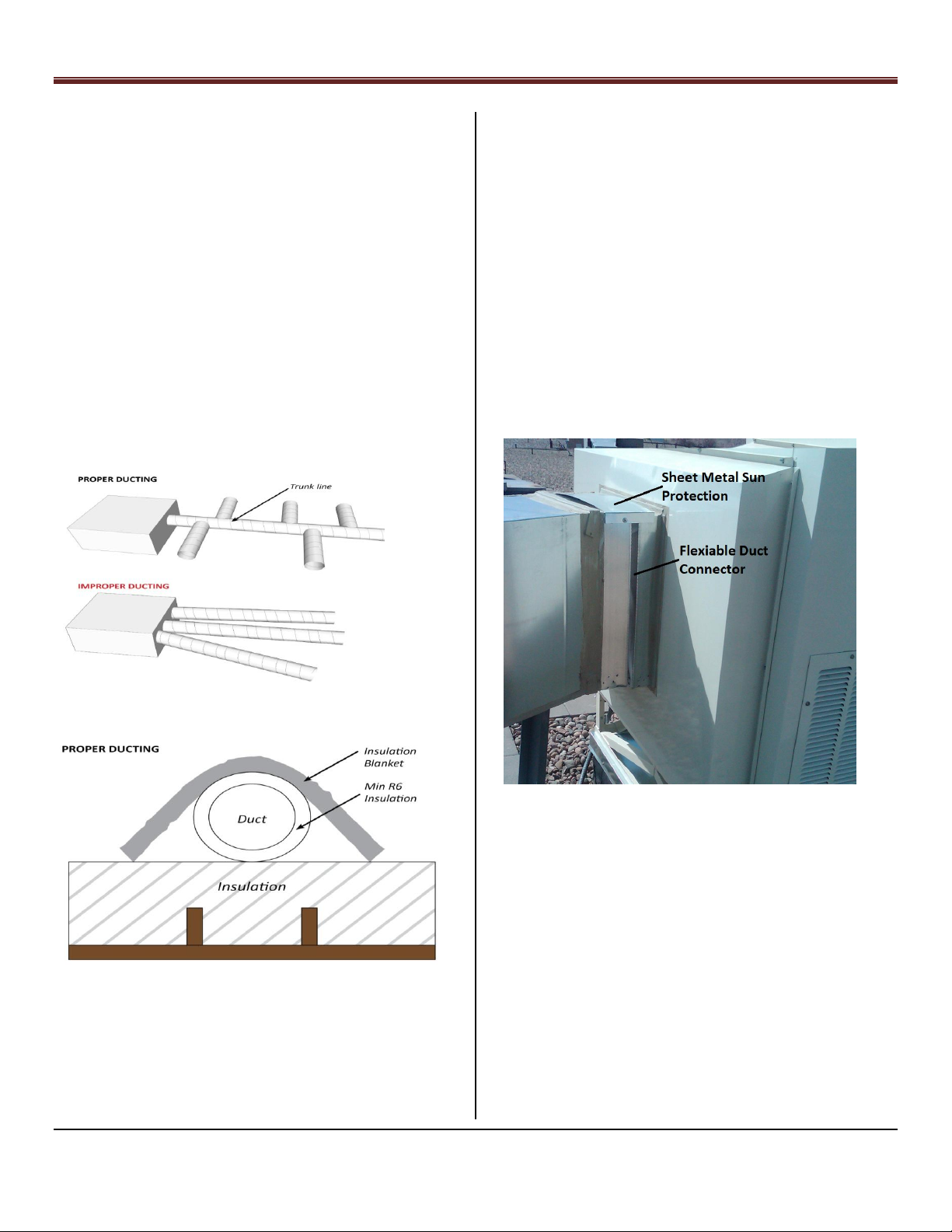

duct branches, see Figure 13.

6.) Too many air-drops can cause excessive temperature

losses.

7.) Large, non-mixing type diffusers (positioned low) are

recommended.

8.) High ceiling installations should direct the air down

at low velocities, less than 200 ft/min (60 m/min),

preferably 50 ft/min (15 m/min). Do not mix air, see

Figure 18.

NOTE: Adjust barometric dampers to optimize air

distribution.

Diffuser location examples:

Installation of a room diffuser might have the

conditioned air delivered at the opposite side of the

room from the door and sweep toward the door to a

barometric duct in the ceiling, see Figure 17.

A room with a window may have the diffuser

installed on the opposite side from the window, with

cooled air sweeping the room toward the window

and removing the hot air above the window, see

Figure 18.

NOTE: Avoid sharp bends and sudden reductions in ducting

as pressure drop will occur, impeding air-flow.

Ductwork Example, Figure 13

Duct Insulation, Figure 14

NOTE: Additional duct insulation may be required in high

heat gain areas such as attics, see Figure 14.

CAUTION: To get proper air movement it is sometimes

necessary to install several barometric dampers and/or

building exhaust fans.

Example Conditioned Air Plenum Duct Connection Figure,

15.

Page 11 of 50

Coolerado Installation

M30 and C60 Conditioned Air Plenum Inside Box, Figure 16

NOTE: Set the conditioned air plenum inside the box or the

HMX frame so that water will be directed into the box

rather than to the outside. Seal outside edge at bottom of

plenum, see Figure 16.

NOTE: The conditioned air plenum is not insulated in the

factory. Insulate plenum after duct holes have been cut out.

In outside installations, the plenum should be fully insulated

and sealed to reduce air temperature increases within the

plenum. Any increase in the conditioned supply air

temperature will result in an increased building temperature

and run time.

NOTE: Barometric Dampers and /or building exhaust fans

are installed to relieve conditioned space pressure at the

highest temperature locations.

Installation Example, Figure 18

Step 8 – Working Air Ducts, (unit exhaust)

1.) If installed outside with good ventilation install

louvers.

2.) If units are located inside or multiple units are

mounted side by side requiring a common working

air duct:

a. Seal ducts to prevent condensation from leaking

from the ducts

b. Provision must be made for the duct to drain

condensation back to the unit. Connect to an

appropriate drain if ducting is lower than unit.

Duct joints should be constructed to drain water

such that it will not catch in seams.

c. Ducts may be cut in the top or on either side of

any of the units, see Appendices 8, 10 and 12.

Barometric Damper Example, Figure 17

Top Mounted Exhaust Example, Figure 19

Page 12 of 50

Coolerado Installation

CAUTION: All duct connections to the unit’s must be able to

drain back into the unit, ensure duct flanges mount to the

inside of the cabinet to prevent leakage of condensate. See

Figure 19 for an example.

CAUTION: Failure to prevent sunlight from reaching the heat

exchanger will allow degradation of the heat exchanger

material and possibly allow green algae growth if there is

enough dissolved nutrients in the water supply and or air.

The Clean HMX material will not support mold or algae

growth.

CAUTION: A bird screen must be installed over the outlet

exhaust out let to keep birds and squirrels out.

Considerations: The working air is always cooler than the

outside air. This air can be used to cool the back of solar

panels or directed to condenser coils (Most applications that

will not be affected by moisture).

CAUTION: Working air being drawn into the intake air will

seriously impact the temperature performance of the unit

and add significant humidity to the inside of the building.

When installing the unit on the roof or ground, use working

air louvers with protective screening (these louvers are sold

separately). Using louvers other than those supplied by

Coolerado may void the warranty.

NOTE: At least 24 inches (600 mm) should be left between

side louvers and any object to allow free air-flow.

Additionally, this will allow access for the louver panel

(which houses a filter pad that prevents water from spitting

from louver).

Exhaust Louvers, Figure 20

M50A and C60 units are shipped with precut holes for

louvers. The M30 units require that holes be cut to accept the

louvers. Side louvers should be cut low in the box so the

heavy working air falls away from the intake air.

To install these louvers in an M30, cut a 16 “ x 16 “ (406 mm x

406 mm) hole on one or both sides of the unit.

NOTE: One side is sufficient to allow for working air exhaust

on an M30 model, but two (2) are required for the M50A’s

and C60’s.

CAUTION: The working air expels excess water, minerals and

salts at all times it is in operation. Any holes cut into this

section or screws attached must be coated on the inside

with a high quality duct sealer to prevent corrosion. In most

cases the HMX’s will need to be removed to adequately seal

any punctures to the inside of the working air section and

prevent rusting of the box. This may void warranty if not

properly sealed.

Side Cover and Louver Attachment:

To seal the side covers or louver very little torque is needed

to tighten the screws. Over tightening will cause warping of

the cover or louver. Eight (8) 10 – 32 stainless steel screws

are used to hold the louvers or covers on. The unit comes

with matching blind rivets mounted in the box.

NOTE: Side louvers may have some condensation and excess

water carry over from the working air (which may contain

minerals) and should be located where mineral buildup

outside the unit will not be a problem.

Inside Cover, Figure 21

Page 13 of 50

Coolerado Installation

Model

Number of HMX’s

M30

3

M50A

5

C60

6

Step 9 – Water Supply Connections

Note: Do not turn water on unit till Step 15.

See Appendix 14 for line size and pressure charts.

CAUTION: Clean potable water should be connected to the

Coolerado air conditioner, see Appendix 1 Coolerado Water

Quality Requirements for more details.

Water lines should be insulated from heat sources such as the

sun to prevent overheating and scaling of the water. If the

water line insulation will see sun light at any point it should

be UV protected material. When hard water is heated it

increases its scaling potential such as in a water heater.

The instantaneous water flow rate to the HMX’s is the water

required when turned on by the water control board. The

water is turned off most of the time. A clean and consistent

water supply capable of instantaneous, dynamic flows of 51

GPH (gallons per hour) (193 LPH (liters per hour)) will be

required for the model M30, 85 GPH (322 LPH) M50, and 102

GPH (386 LPH) C60, for proper operation of the units.

The water connection is a ½” (12.7 mm) FNPT at the unit

base. The water pressure at this connection must be between

25 psi (172 kPa) and 80 psi (550 kPa). For your convenience,

Appendix 14 provides water pressure drop information. Note

that the water pressure will decrease 1 psi for every 27.7”

(9.8 kPa for every 1 m) of height do to gravity. So for a 30’

(9.14 m) rise, the water pressure will decrease by 13 psi (90

kPa), this does not include pressure drop due to friction in the

piping and pipe fittings.

Note: A Water Pressure Switch has been installed on the

water line inside the unit that will disconnect the fan control

wire turning the fan off until the water pressure rises again,

see Figure 24. This same switch is also on the M50A post 1028-2013 but will cut the cool call preventing the wetting out

of the unit and the fan from running.

This means a dirty water filter or low water main pressure will

turn the fan off. If the water main pressure is low a booster

pump may be required.

CAUTION: Dynamic water supply pressure of between 25 PSI

(172 kPa) and 80 PSI (550 kPa) is required at the unit.

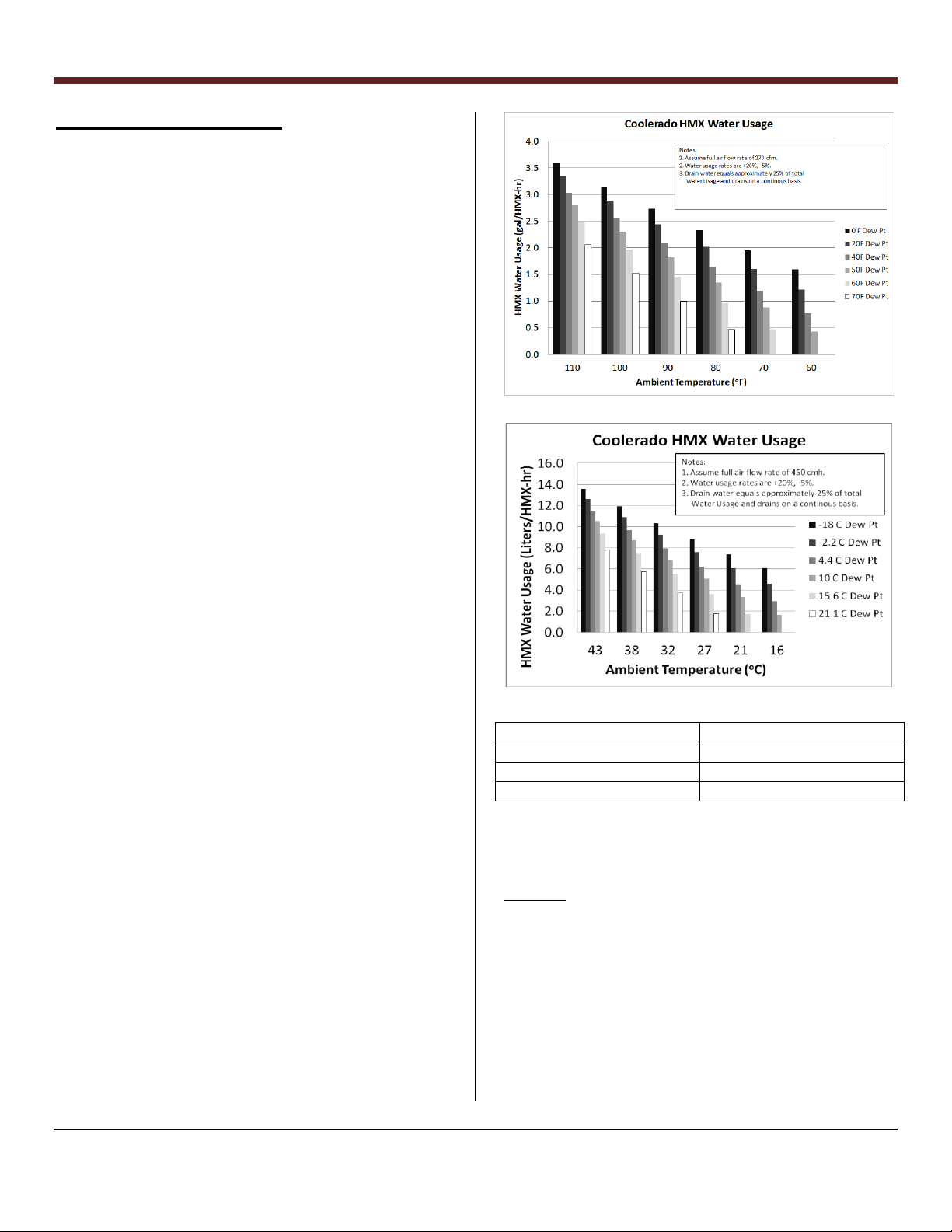

Water Consumption:

Water Consumption Table (per HMX), Figure 22.

WATER FILTER

WARNING: INSTALL the IN-LINE 30 micron WATER FILTER

supplied with units. The water filter should be installed

upstream (before) any solenoid valves or water pressure

regulator on the Coolerado unit so that these devices will be

protected by the water filter.

CAUTION: Failure to install an in line water filter will void

system warranty.

NOTE: In addition to water pressure, water quality has a

major impact on performance. Reducing undissolved

particulates increases performance and longevity of systems

heat exchangers.

Page 14 of 50

Coolerado Installation

Check Valve, CV

Booster

Pump

Pressure

Tank

Pressure

Gauge

Ball Valve

Union

Relief Valve

Pressure

Sensor

Circuit Breaker

Disconnect (110VAC, 20 amp)

Control for Booster Pump

Need 25 psi (172 kPa)

Minimum at Coolerado Unit

By Contractor

CV

Header

Soap Tee

Solenoid

Valve

Regulator

Low Water

Pressure Switch

Filter Door

Fan Switch

Soap

Bottle

Fan

The filter will need to be changed when the pressure drop

increases to the point not enough water pressure is available

for the units. How fast a water filter needs to be replaced

depends on the amount of un-dissolved minerals or debris

that is in the water.

NOTE: If incoming water pressure is excessive 80 psig (550

kPa), a pressure-reducing valve should be installed to the

incoming water supply line.

WATER PRESSURE REQUIREMENTS

Note: If incoming water pressure is ever less than 25 psig

(172 kPa) when the unit is running, a water pressure booster

pump may be required. Water district water line pressure is

often loss from due to irrigation activities especially at

night.

Low Water Pressure:

In certain locations, a reduction or potential loss of water

pressure can occur due to high demand conditions on the

municipal or district water supply. Install a booster pump to

ensure water pressure is maintained. If required, mount

booster equipment near ground level, see Figure 23.

Water Booster, Figure 23.

NOTE: Use a minimum of 1/2” (12.7 mm) diameter supply

water line, which should be free draining for winter shut

down.

BACK FLOW PREVENTION

Water Distribution System – M50A, Figure 24

Freeze protection can be done manually:

1. Install supply water shut off valve between the

water supply line and the unit.

2. Install a drainage valve downstream of the manual

water valve. The drain valve should be located within

a conditioned space.

3. Slope the line from the unit to the drain valve for

proper draining and freeze protection.

4. To drain the line and water distribution system it

must be turned on for a few minutes to allow the

water to drain and air to pulled into the system. This

is done by turning the thermostat to require a cool

call.

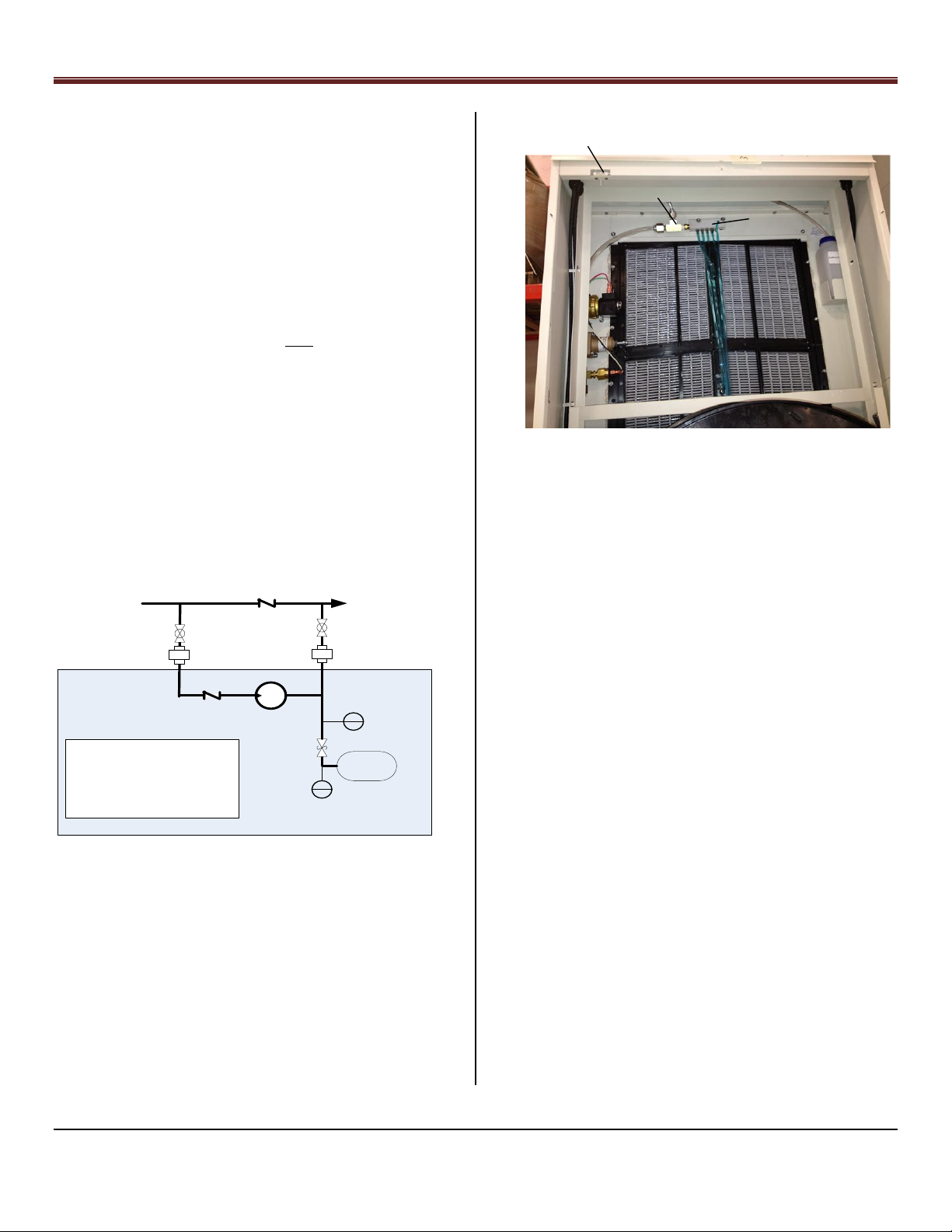

WATER DISTRIBUTION SYSTEM

The water distribution system, (located inside the unit) is a

combination pressure regulator, 24 VAC solenoid valve and

water distributions manifold. The valve is designed to

deliverer the correct water flow to each of the systems heat

exchangers.

NOTE: The unit is equipped with a self-draining water

regulating valve designed with a vacuum break in the HMX.

Page 15 of 50

Loading...

Loading...