Cool Energy EcoStore Heat Pump Water Heater

0 | P a g e

EcoStore - Air Source Heat Pump Water Heater

EcoStore

Cool Energy EcoStore Heat Pump Water Heater

1 | P a g e

INTRODUCTION

Thank you for purchasing this equipment which will give many years trouble free use with the correct installation

and care. In the unusual occurrence that problems occur with the installation or continued use please contact the

installer in the first instance to provide all the backup required to ensure these products meet the high standard

met by our products.

These

instru

ctions

are addressed

to both the

installer and

the final

user,

who

respectively

must install

and

use

the heat pump water

heater. Failure

to meet the

provisions

contained in this manual will

result

in the

cancellation

of the

warranty.

These

instructions include

essential

and important information for

safe

and proper installation, and

are an

integral part of the

product.

As a consequence,

all

technical documents

must

be

kept with care

and must always accompany

the product.

All

the

data and instructions contained

in

this manual refer

to the

current technological

level.

Please always refer

to the

instructions contained

in

this manual when installi

ng the equipment.

The operations described

in

these instructions

require

specialized knowledge, achievable

through a

comprehensive and proven professional training in system installation.

As a consequence,

we

recommend that you only perform the installation operations described

herein if you meet th

e

technical requirements listed

above.

The instructions are provided in schematic form; due to possible writing/printing

errors, and to

possible technical changes,

we decline all responsibility

as

to the

correctness

of the contents.

The diagrams used are

purely

INDICATIVE,

have

no

pretense

of

completeness

and

are

not intended

to

replace

the design.

Cool Energy EcoStore Heat Pump Water Heater

2 | P a g e

INDEX

1

GENERAL

NOTICE

..............................................................................................................................04

1.1

F

IELD OF US

E

.................................................................................................................................................................................04

1.2

PRODUCT NAME………………………..

..............................................................................................................................................04

1.3

SAFETY INFORMATION……………………….

.......................................................................................................................................04

1.4

C

ERTIFICATIONS

AND

MARKINGS

...............................................................................................................................................05

1.5

M

EANING OF

THE SYMBOLS USED HEREIN

................................................................................................................................05

1.6

D

ELIVERY AND PACK

AGING

.........................................................................................................................................................05

1.7

T

RANSPORT ……

.........................................................................................................................................................................05

1.8

M

EASUR

ING

.................................................................................................................................................................................06

1.9

T

EMPERATURE UNIT SHIFT

...................................................................................................................................................... .....06

2

TECHNICAL AND DIMENSIONAL

SPECIFICAT

IONS......................................................................

06

2.1

O

PERAT

ING PRINCIPL

E

.......................................................................................................................................................... .....06

2.2

E

NERGY EFFICIENCY

.................................................................................................................................................................07

2.3

H

OT WATER TEMPERATURE

.....................................................................................................................................................07

2.4

M

AIN COMPONENTS

...............................................................................................................................................................08

2.4.1

T

ANK

.........................................................................................................................................................................................08

2.4.2

HEAT PUMP UNIT

.......................................................................................................................................................................08

2.4.3

A

NTI-CORROSION PROTECTION

...............................................................................................................................................08

2.4.4

T

HERMAL INSULATION

AND COAT

ING

.....................................................................................................................................09

2.5

D

IMEN

SIONAL CHARACTERISTIC

S

............................................................................................................................................10

T

ECHNICAL

DATA TA

BLE

..........................................................................................................................................................10

3

INSTALLATION AND FIRST START-UP ..........................................................................................

11

3.1

H

YDRAULIC CONNECTION

......................................................................................................................................................11

3.1.1

H

YDRAULIC

SAFETY UNIT

.......................................................................................................................................................12

3.1.2

P

RESS

URE REDUCER

................................................................................................................................................................12

3.1.3

E

XPANSION TANK

...................................................................................................................................................................12

3.2

U

NIT FILLING

.........................................................................................................................................................................12

3.3

D

UCT

.......................................................................................................................................................................................12

3.4

E

LECTRICAL CONNECTION

......................................................................................................................................................14

4

USAGE IN

STRUCTIONS

...................................................................................................................

14

4.1

S

WITCH-ON

..................................................................................................................................................................................14

4.2

E

LECTRONIC CON

TROL

................................................................................................................................................................14

4.2.1

D

ISPLAY

...................................................................................................................................................................................14

4.3

O

PPERATING IN

STRUCTIO

N

........................................................................................................................................................16

4.3.1

O

PERATIONS BEFORE

TURNING ON

THE PRODUC

T

................................................................................................................

16

4.3.2

M

ODE

.......................................................................................................................................................................................16

4.3.3

H

EAT SOURCE

SHIFT

................................................................................................................................................................16

4.4

B

ASIC

FUNCTION

.......................................................................................................................................................................17

Cool Energy EcoStore Heat Pump Water Heater

3 | P a g e

4.4.1

W

EEKLY DISINFECT

FUNCTIO

N

................................................................................................................................................17

4.4.2

V

ACATION MOD

E

:....................................................................................................................................................................17

4.4.3

P

OWER ON AND POWER OFF

.................................................................................................................................................17

4.4.4

L

OCK AND UNLOCK

.................................................................................................................................................................17

4.4.5

Q

UERY FUNCTION

...................................................................................................................................................................18

4.5

S

E

TTING

.....................................................................................................................................................................................19

4.5.1

T

EMPER ATURE SETTIN

G

...........................................................................................................................................................19

4.5.2

C

LOCK SETTIN

G

........................................................................................................................................................................19

4.5.3

T

IMER

SETTING

.........................................................................................................................................................................19

4.5.4

C

ANCEL

....................................................................................................................................................................................20

4.5.5

D

ISINFECT MODE

.....................................................................................................................................................................21

4.5.6

V

ACATION MOD

E

.....................................................................................................................................................................22

4.6

C

OMBINATION BUTTON

..............................................................................................................................................................23

4.7

A

UT

O-RE

START

............................................................................................................................................................................23

4.8

S

CREEM AUTO LOCK

....................................................................................................................................................................24

4.9

E

RROR

...........................................................................................................................................................................................24

4.9.1

E

RROR CO

DE TROUBLE SHOOTING TABLE

.............................................................................................................................24

4.10

FAQ .............................................................................................................................................................................................26

4.11

H

YDRAULIC

SAFETY UNIT EFFICIENCY CHE

CK

.............................................................................................................................27

4.12

U

NIT

EMPTYING

...........................................................................................................................................................................27

4.13

R

ESTART AFTER A

LONG-TERM STOP

...........................................................................................................................................27

5

MAINTENANCE INSTRUCTIONS

....................................................................................................

27

5.1

G

ENERAL

......................................................................................................................................................................................27

5.2

F

ALSE ERRORS OF OPERP

ATION

..................................................................................................................................................28

5.3

V

ISUALIZED

TEMPER

ATURE

.........................................................................................................................................................28

5.4

HEAT PUMP UNIT MAINTENANCE

.................................................................................................................................................28

5.5

C

LEANING THE

ASPIRATION

AIR FILTER

......................................................................................................................................28

5.6

W

ATER

CIRCUIT

/

C

ONDENSATE DISCHARGE

............................................................................................................................29

5.7

A

IR CIRCUIT SUPP

LY

.....................................................................................................................................................................29

5.8

D

ESCALING AND LIME SCALE DEPOSIT REMOVAL

......................................................................................................................29

5.9

A

NODE

VERIFICATION

..................................................................................................................................................................30

5.10

R

EPLACE

AND/OR CONTROL THE

ELECTRICAL

RESISTANCE

.......................................................................................................31

5.11

O

UTSIDE CLEANI

NG

.....................................................................................................................................................................32

5.12

G

ENERAL NOTES

..........................................................................................................................................................................32

5.13

A

FT

ER-SALE

SERVICE

....................................................................................................................................................................32

6

MEASURES TO BE

ADOPTED IN CASE OF

MALFUN

CTIONS .....................................................32

7

INSTALLATION EXAMPLES…

..................................................................................................

34

8 COMMISSIONING SHEET AND SERVICE RECORD

..........................................................

35

Cool Energy EcoStore Heat Pump Water Heater

4 | P a g e

1

GENERAL

NOTICE

1.1

Field of

use

The heat

pump water

heater

for the production of hot

water is

only intended to be

used

for sanitary

water

heating,

without

exceeding

the

usage

restrictions

specified herein.

To

this

purpose

it must

be

hydraulically connected

to

a sanitary water delivery network. It

requires a

power su

pply to operate.

Never use

the heat pump for

any purposes

other than

those specified herein.

Any other

use is

to be

deemed

as

inappropriate and

forbidden.

The

manufacturer cannot be

held

responsible

for

any installation errors and inappr opriate

equi

pment

use.

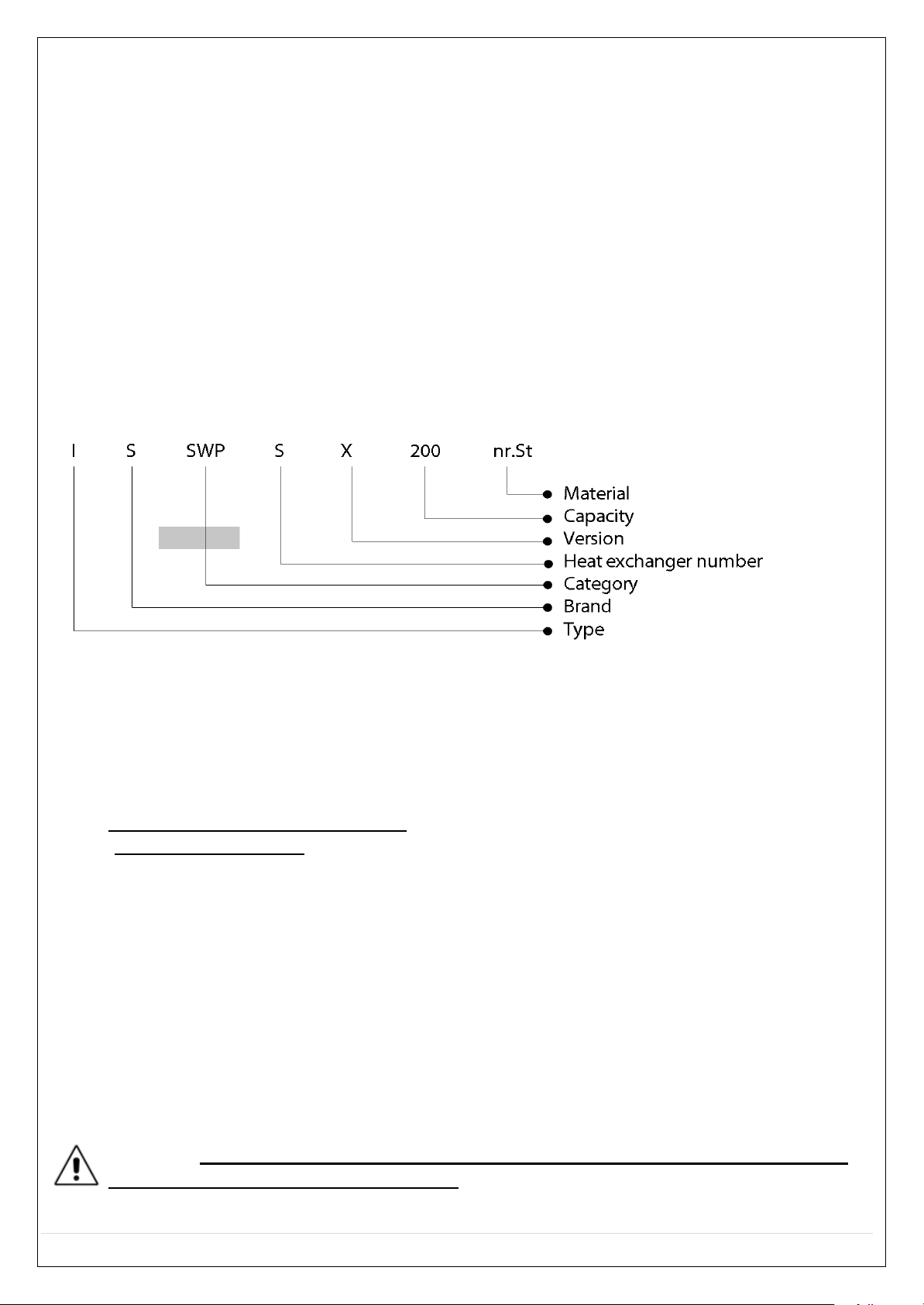

1.2

Product

nameplate – EcoStore CE-ES200 / CE-ES300

1.3

Safety Precautions

The purchaser shall take care

of the

installation. The Manufacturer shall

not be

liable

for

any damage

s

caused

by wrong installation and/or

noncompliance

with the instructions contained in this

use

and

maintenance booklet, and

in

particular

with

those prescribing

that:

• the

electrical connection must comply

with the

provisions specified

in the

relevant

para

graph;

• Uthe

supplied

nylon

electrical protectorsU must be properly installed;

• “Uthe

hydraulic safety

unit”U

must be

properly installed, intact

and

in good working order;

• installation and

maintenance

must be performed by qualified

personnel,

in

compliance with

the

regulations

in force;

• before st

arting any

maintenance

or repair

operations

on components containing any cooling

fluid, a qualified technician must remove

an

appropriate

amount of the

latter,

to

ensure

the risk-

free execution

of the

operations

in qu

estion.

The refrigerant

must be handled and

disposed

of

in

compliance with the relevant

regulations and

must not be

dispersed

into the environment!

(The R134a

refrigerant

is CFC-free,

not

flammable and

not harmful for the

ozone

layer);

• the

maintenance

regu

lations must be obse

rved;

• the equipment

must be installed

in

an appropriate

room (to

avoid

being

exposed

to frost)

• the

maximum overpressure, when using

the

tank, must be

respected;

• the

maximum

temper

ature, when usin

g the ta nk, must be respected

.

CAUTION! UFAILURE

TO

COMPLY

WITH

THE ABOVE PROVISIONS WILL RESULT

IN THEU

U

CANCELLATION OF ANY WARRANTY RIGHT.

This

equipment

complies

with the

provisions contained

in the

EEC

Directives

in force.

Cool Energy EcoStore Heat Pump Water Heater

5 | P a g e

1.4

Certifications and

Markings

The

verification

has

been performed

with

reference

to the following

technical standards:

UNI EN

16147;

EN

12102;

EN

60335-1;

EN

60335-2-21;

EN

60335-2-40;

EN

55014-1;

EN

55014-2;

EN

61000-3-2;

EN

61000-3-3;

EN

50366.

1.5

Meaning of the symbols used

herein

Symbol

Meaning

Failure to comply with the provision in question may result in injuries and/o

r

damages

to people,

objects, plants or animals.

1.6

Delivery and

pack

aging

The

heat pump water heater

is supplied

in an environment-friendly and

easy

to handle cardboard

packaging

with protective

inserts. Make sure

that the

packaging

material is

disposed

of properly

in

compliance

with the

environment-related regulations

in force.

S

hould the heat pump for

sanitary

water show any clear

damages, absolutely

avoid mounting or

installing it.

Immediately

inform the supplier.

1.7

Transport

When

storing and transporting it,

always

keep the heat pump water heater vertical

(straight)

in its

original packaging.

For

short

stretches

it

can

be

inclined

by

45°,

provided utmost

care is taken

when

transporting it.

Due

to the forward

inclination,

when usin

g forklift

trucks

or other

means

of

transport proceed sl

owly and fasten the equipment to prevent it from

tipping.

After

transporting the equipment in

inclined

position,

before starting

it you

need to wait for about 3

hours,

to

ensure

the appropriate settling of the

lubricating oil in the cooling circuit

and avoid

damages.

Position the heat pump,

after removing the packaging and the bracket

supplied

for

transp

ortation.

For short moves use

the

special handles situated

on the

side

part of the pr

oduct.

Cool Energy EcoStore Heat Pump Water Heater

6 | P a g e

1.8 Measuring

The measuring units used in this manual for the relevant physical magnitudes are those of the

International

System(SI).

1.9

Temperature unit

shift

Press

ENTER

for

3 seconds

to

unlock

the buttons.

P

ressing

the

E-HEATER

key for 10

seconds

they can shift the temperature from

display unit

from

‘°F’

to

‘°C’ or

from

‘°C’

to ‘°F’

The

default

is ‘°C’.

When

it

is sh

ifted

to

display

‘°F’ , it still will

display

‘°C’

while it operates spot check.

2

TECHNICAL AND DIMENSIONAL

SPECIF

ICATIONS

2.1

Operating

principle

The air-water

heat pump

uses

the

energy

of the air existing in the environment.

The

air required fo

r

the proper operation of the

heat

pump

can be

drawn from the

outside through a window

(mini

mum

temperature

-20°C)

or from the surroun

ding environment

or from other

environments

through ducts.

The

air drawn from the environment

is sucked

through a fan and the heat

existing

in air

is

absorbed

during the

passage

in

a heat exchanger (evaporator).

In the

evaporator

the

heat taken

from the

air

is

caused

to evaporate at low

pressure

by the refrigerant (the working fluid in the refrigerant circuit,

is as in a household fridge).

The vaporized

coolant is

sucked

by a

compressor

and raised to a

higher level of pressure (as

in

a bicycle

pump)

and temperature.

In

a second heat exchanger

(condenser)

the higher

temperature

heat

is absorbed

and

transferred

to the

water;

this

way

the

Cool Energy EcoStore Heat Pump Water Heater

7 | P a g e

vaporized

refrigerant fluid

switches back

to the liquid

state as a

consequence

of thermal

dissipation.

The

liquid

refrigerant, fl

owi

ng through a choking component

(expansion valve), undergoes

a low

pressure expansion and, after

returning to the

evaporator,

it

can again draw heat

from the

surrounding

environment.

The

hot

water heat

pump

operates at ambient temperatures ranging between

-20°C and +43°C.

The hot water heat pump is a

connection-ready

equipment whose function

is

heating drinkable

water;

it

basically consists

of the water tank and of the

refrigerant,

air and water circuit

components,

as well

as

of

all

the co

ntrol,

adjustment

and

monitoring

devices required

for

automatic

operation.

> Use of the environment energy

Refrigerators, washing machines,

heating

systems and

other equipment/electric

appliances

generate

heat that in most

cases

is not reused. Instead

of being

dispersed

into the environment, generating

pollution, the hot air in question can suitably be

used

to heat sanitary water: a

sensible

and

environment-friendly

solution.

An

important benefit

is

the

air

dehumidification

resulting

from

heat suction, decreasing

the

degree

of

humidity in

cellars and

laundries.

This has

two

beneficial effects: environment

prote ction

and

production of

cheap

hot

sanitary

water.

2.2

Energy efficiency

> Free energy

The necessary energy

for the heating of

sanitary

water

comes

for 2/3 from the air and 1/3 from the

electric

power supply.

> Coo

ling through

the heat pump for

hot

sanitary

water

After heat subtract

ion,

the lower-temperature output air can be

used

during

summer

to cool th

e

environment where

the

heat

pump

is

installed.

This provides a

double

benefit,

while

ensuring

optimum

energy

efficiency.

> multi

use of

energy

The heat pump can be beneficially installed in stores, workshops, commercial, residential

applications etc. to get hot

sanitary water and,

if needed, cooled air.

2.3

Hot water

temperature

Setting water temperature

target

range:

38÷

65°C.

Cool Energy EcoStore Heat Pump Water Heater

8 | P a g e

Using renewable energies and ensuring

optimum

energy efficiency,

the

heat

pump

provides an

environment-friendly

and efficient

solution to

heat water throughout the

year.

2.4

Main

components

2.4.1 Tank

The tank consists

of a water-tight Stainless Steel AISI316L

cylindrical inner vessel.

2.4.2

Heat pu

mp unit

The

refrigerant

circuit

is

located

in the upper

section

of the

water heater and co

nsist of:

•

Refrigerant

fluid R134a;

•

Rotary

compressor;

•

Thermostatic expansion

valve;

•

Solenoid valve

for the

de-frosting

cycle;

•

Combined filter, drier and collector

of the

refrigerating

circuit;

•

High-powe r blade

evaporator;

•

Electronic axial

fan;

•

Average-sized Cu cooling

pipes;

•

Thermal exchanger co oper

pipe wounded

around

the inner vessel ( in

this

way a

contact between

the

refrigerant gas

and

the

drinkable water

is

impossible);

•

Condensation drain plastic pipe.

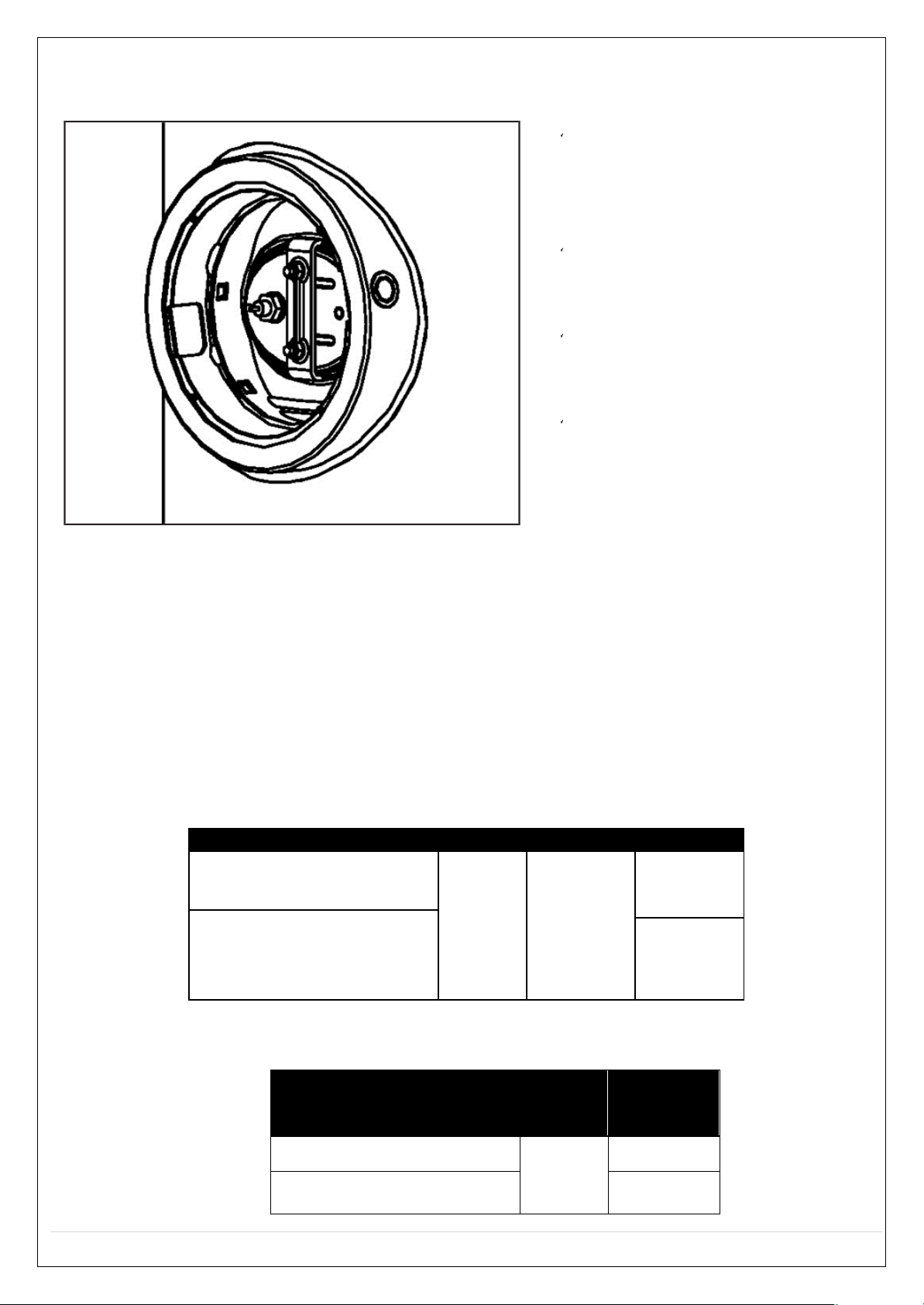

2.4.3

Anti-corrosion

protection

The

protection

against corrosion

is

performed by

an

integrated

electronic

anode.

Data:

Electronic

• Feeding

90 - 253Vac 50 - 60Hz

•

Maximal

absorpti on 3

•

Maximal

output voltage 20Vdc

•

Maximal

output current 15mAdc

• Working temperature

-10 – 85°C.

•

Protection

level IP44

• Size 85x55x26mm

Electrode

•

Protection

electrode

activated

titanium diam. 3mm

• Fastening 1/2”

•

Screwi

ng up max.

25

Nm

•

Working

temperature

-10 – 100°C.

Co

nnection

•

Power

cable double

insulation cable tmax 105°C.

•

Protection

cable flat

cable 2x0,50mm red/black (red cable:

electrode)

•

Electrode

connection

bush

diam. 3mm

• T

ank

connection

eyelet

diam.

5mm.

Cool Energy EcoStore Heat Pump Water Heater

9 | P a g e

Positioning

All fastening, connection and

maintenance operations must be

performed when the device

is not

powered.

Be sure

that the

device has a

proper

position, far

away

from water, direct

heat sources,

etc.

Do not open the container of th

e

device,

inside there are no sp

are

parts.

Do not invert the connections

electrode-tank.

2.4.4

Thermal insulation and

coating

Thermal insulation

is ensured

by a highly

biological, CFC-free

rigid

polyurethane

foam

(PUR)

coating.

The

full

compressed foam coating allows

to

minimize energy

losses.

The external coating

is made

of a soft PVC material.

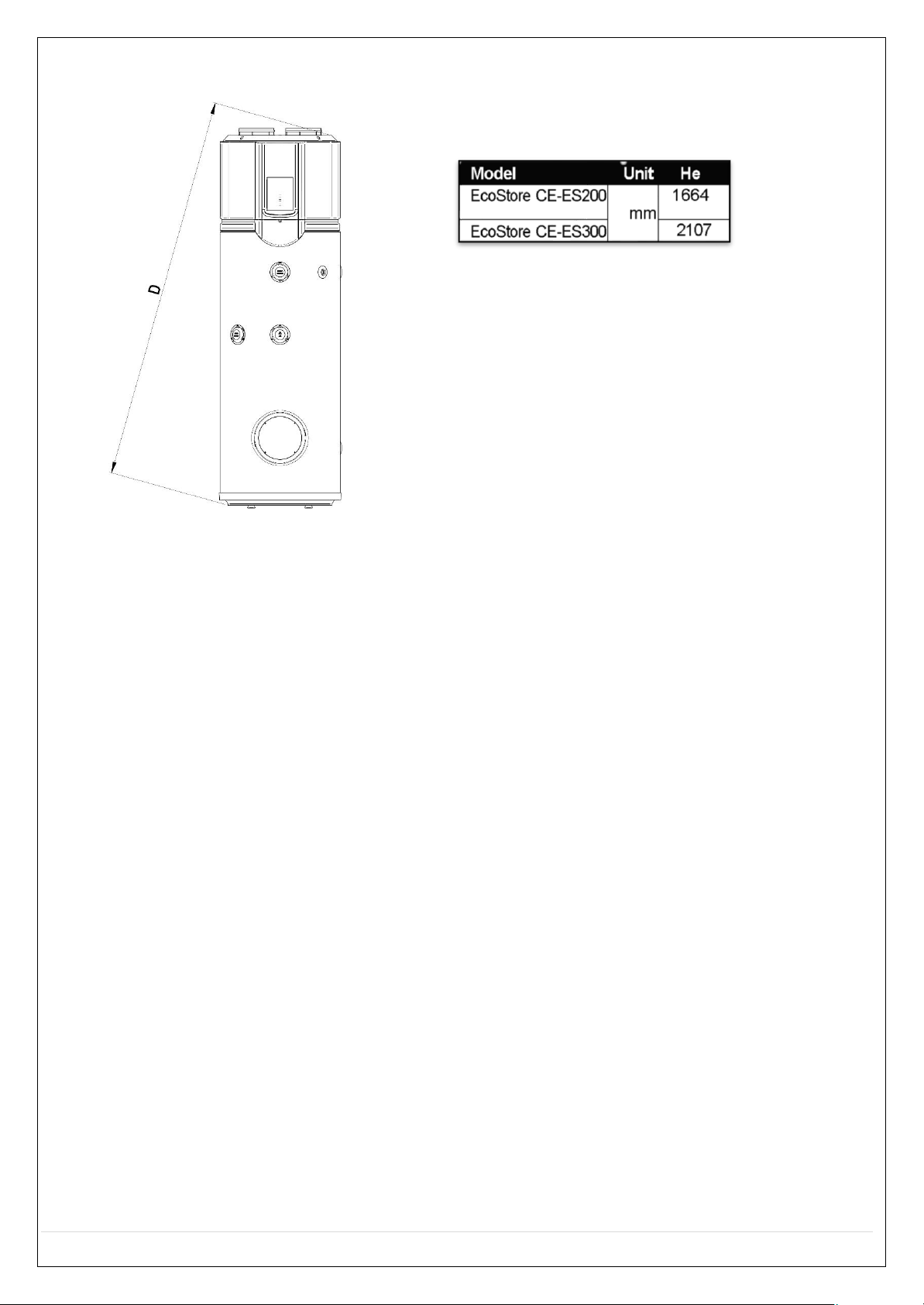

2.5

Dimensional char

acteristics

The technical and

dimensional characteristics

of the equipment

are

indicated

in

Fig.

1.

The electrical characteristic data

of

each

model

can be

found on the equipment itself.

Heating exchanger su

rface:

Model

Unit 0 H

EcoStore 200

mm

650

1586

EcoStore 300

2107

Model

Unit

Lower

heating

exchange

r

EcoStore 200

m

2

0.6

EcoStore 200

1.3

Cool Energy EcoStore Heat Pump Water Heater

10 | P a g e

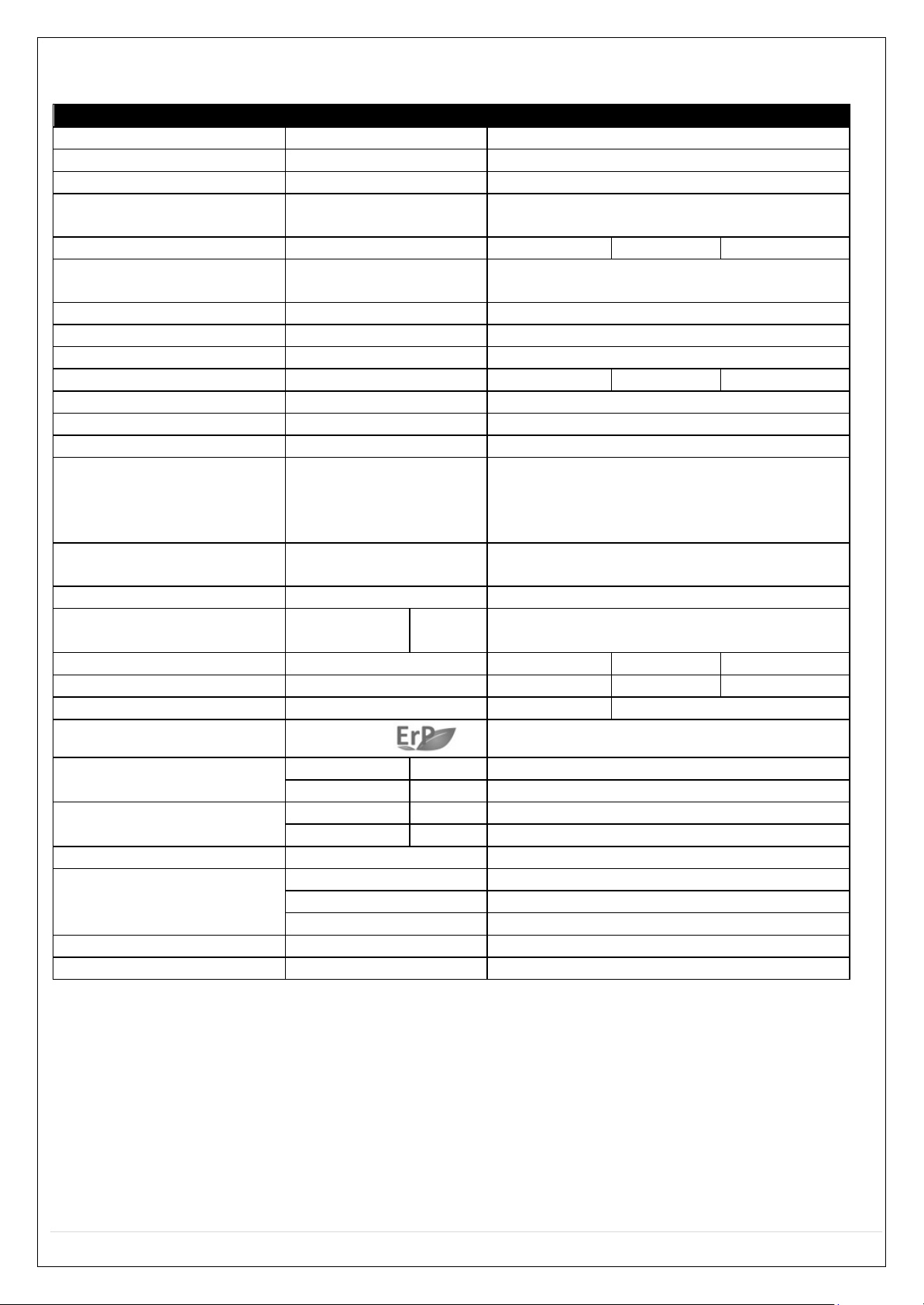

Technical data

table

Model

EcoStore 200

EcoStore 300

Type

Air Source Heat Pump

Use

Water Heater

Temp.

Ԩ

Standard 55°C ( 38°C bis ~ 65°C)

Storage

material

(DIN

4753)

AISI 316 / EN

1.4404

Storage size L

200

300

Insulation

thickness

mm

B2 / DIN

4102

50

Power su

pply

Ph-V

-Hz 1 –

230 – 50

Ambient temperature

Ԩ

-20°C

min /

max.

+43°C

Noise

level

dB(A)

53

Refrigerant type / quantity

kg

R134a/1.02

R134a/1.2

Refrigerant design pressure

MPa

3.0/1.2

Tank design

pressure

MPa

0.6

Control

Electronic

Program

Economy

E

-Heater

Vacancy

Disinfect

Protection

TCO1, TCO2,

de-frosting automatic

Air

flow m3/h

414

Compress

or

Input

kW

0.62

COP

A15/W1

5-60

2,76 3,1

COP A 15/W

15-45

3,86

4,34

ErP Test

Profile

L

XL

Erp Energy Class

Class

A+

Fan

Input

W

68

r/

min

620/530/465

Water pipe

Rp

1"

Rp

1"

Condenser Diameter

Copper 0 8x0,5

E-heater

No.

1

Material

Nicolay

800

kW

0.9

Tank protection

Electronic Anode

(DIN

4753)

Electrical protection IP21

Cool Energy EcoStore Heat Pump Water Heater

11 | P a g e

3

INSTALLATION AND

FIRST

START-UP

(qualified personnel

only)

CAUTION!

•

The installation

room must be 20 m3 or larger and have

suitable

air e

xchange and not be subject

to sub zero conditions.

• The equipment must be installed in

compliance

with the national installation

regulations.

•

Operations involving

the hot water heat pump

must

only be

performed

by competent /

qualified personnel!

•

Observe the safety regula

tions.

• The

installation environment,

electrical

and

hydraulic systems of

the equipment m

ust comply

with local regulations in

force.

•

You need

to

install

the

equipment

at the

prescribed distance

from the

room walls

and

ceiling, to ensure easy

maintenance.

•

The surface on

which the equipment is to be

installed must be able to

bear

its weight.

•

The equipment ventilation

openings

must not be obstructed.

•

The chosen environment must

be

suitable

for the

equipment IP degree,

in

accordan

ce

with the

regulations in

force;

•

The ambient temperature

(or the

temperature

of the input air)

must range between

-

20°C and +43°C.

• If

possible, install the equipment in a room allowing to exploit the

excess

heat

generated

by

tumble-driers, refrigerators, freezers,

etc.

• Air

must be neither

excessively purified nor too

contaminated with

dust.

•

There must be a

suitable drain connection to discharge cond

ensa

tion from the unit.

CAUTION! UThe equipment is

not

intended

to be

used

by any

persons ( including

children

)U

U

having reduced sensory

or mental faculties, or lacking experience or knowledge,

unless

theyU

U

are under the supervision

of a

person in charge

of

their safety, or they have received

properU

U

instructions regarding equipment

usage.

Children must

be watched to ensure

that

they don't play with the

equipment.

3.1

Hydraulic connection

Installations must conform to local

regu

lations in force. We recommend the integration of a

magnetic filter for the cold feed water supply. The link

pipes

(hot water,

recycle,

in-out

exchanger)

must

be perfectly isolated according

to the

energy norms

in

order

to avoid

heating

dispers

ions.

We recommend

that you install the equipment

close

to the

main

hot

water

drawing point, to prevent

heat

dispersions

along

pipes,

and if possible, near a drain, for

easier

emptying and condensate

discharge

Cool Energy EcoStore Heat Pump Water Heater

12 | P a g e

3.1.1

Hydraulic safety

unit

(manda

tory)

You

must install a

hydrauli c safety

unit (Supplied in G3 Kit)

complying with

EN 1487

or with

equivalent local standards

in

force;

•

Check

valve;

•

Check valve

control de

vice;

•

Safety valve;

•

Hydraulic load

interrupting

device.

The above components are required to

safely

run the supplied equipment. The rated calibration

pressure

of the hydraulic

safety

unit must be of

0.6 MPa

(6

bar). Pay

attention while installing the

hydraulic safety

unit,

avoiding forcing or altering it. Water may drip from the hydraulic safety un

it

discharge connector (see paragraphs

“USAGE INSTRUCTIONS

(user) - Water dripping from th

e

hydraulic

safety unit”).

This

opening must

be left

exposed

to the atmosp

here.

You

need to install a

discharge

pipe, with a constant downward

slope, in a

condensate-

and

ice-free area. There

must be

no

obstructions

in the

pipe,

to

avoid overpressures.

3.1.2

Pressure

reducer

Should the network

pressure exceed 0.6 MPa

(6

bar),

you need to install an appropriate pressure

reducer upstream

of the

hydraulic safety unit,

ensuring

the

indicated operating

range.

3.1.3

Expansion

tank

To prevent any

overpressures

that might

damage

the equipment, frequently triggering the safety

unit and causing water

dripping,

Uit is mandatoryU that you install an adequate

expansion

vess

el.

Install it in

accordance

with the instructions provided by the manufacturer. The expansion

tank is

required

to

keep pressure

constant and avoid harmful

pressure shocks

or

accidental overpressures.

3.2

Unit

filling

WARNING: USwitching on the equipment when

it

is

not filled with water will seriously

damageU

U

the refrigerating units and the electrical

heating element.

WARNING:

UIn the

presence

of water with a

hardness degree >20°TH (where 1°TH=Frenc

hU

U

degree=10mg CaCo3/l)

it

is

mandatory that you install a

softener

to

reduce

limestoneU

U

scaling inside

the

boiler

and

keep

the

electrical resistance

and the

hydraulic safety

unit inU

U

good

working

order.

To

fill the equipment,

you need to:

•

open

the

main water supply

or the equipment

water supply valve;

• open a hot

water

tap

(e.g. ba

throom,

wash basin, etc.)

to allow the water to flow out; when the

water

outflow from the tap

is

constant

the equipment will

be full;

Cool Energy EcoStore Heat Pump Water Heater

13 | P a g e

•

check

that

there are

no

leaks

from the

various hydraulic

connections;

UNote******

We

recommend

that

you flush

the pipes before connecting the unit

Only proceed

with the

electrical connection after

performing

this

operation

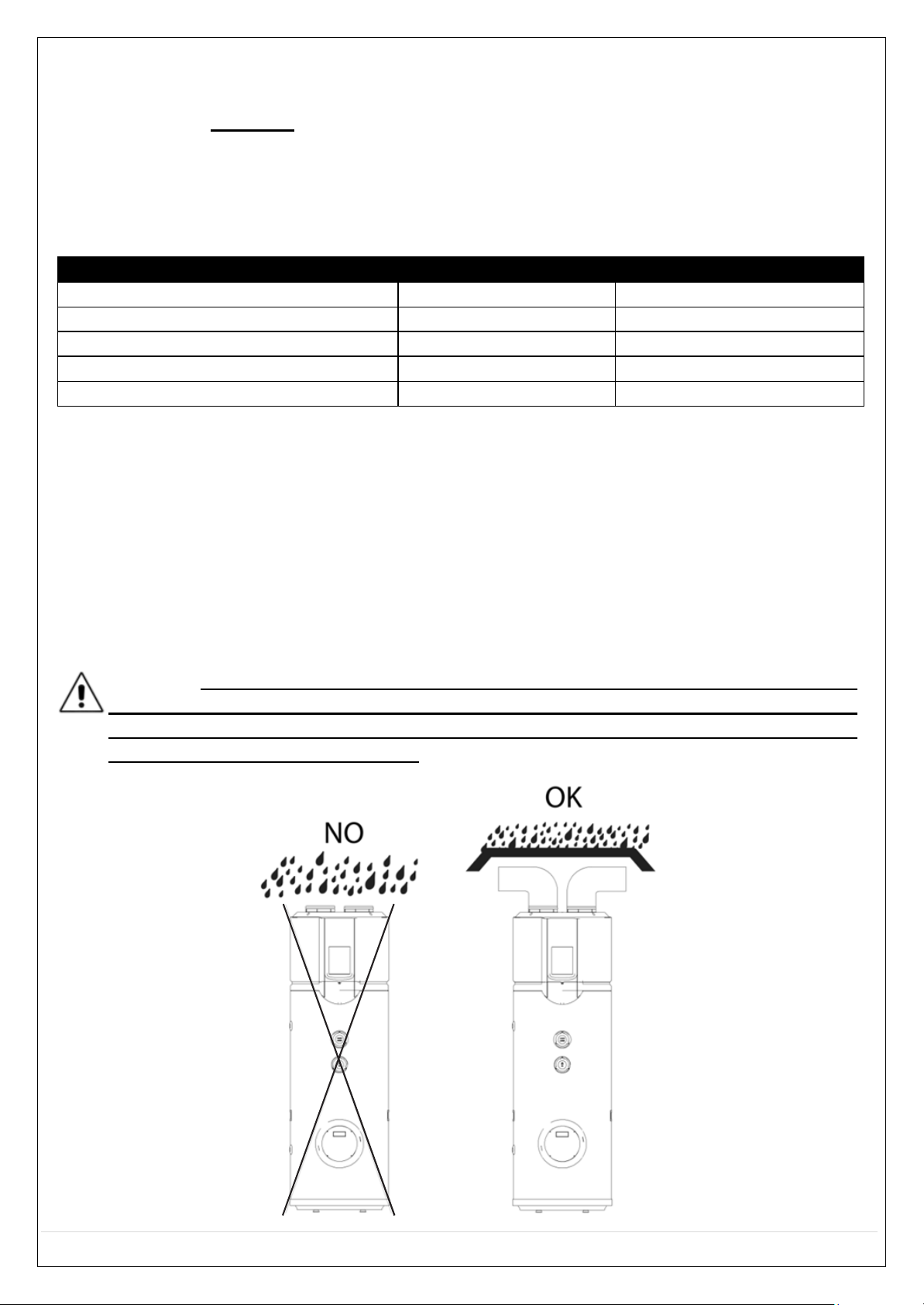

3.3 Duct

DUCT

ROUND

DUCT

RECTANGLE

DUCT

Dimension (mm)

190

190x190

Straight-li ne pressure

drop (Pa/m)

≤2

≤2

Straight-line

length (m)

≤5

≤5

Bent pressure

drop (Pa/m)

≤2

≤2

Bent’s

qty.

≤5

≤5

•

Too much resistance of duct will

decrease air-flow-rate,

which will lead to capacity of

unit decreased.

•

T

otal duct length ideally

should be

no

more

than 5m and 3 x 90 degree bends or the

maximum static pressure should be

within

25Pa.

•

For

unit air outlet with duct, when unit operating,

condensate

will be generated around

outside

of duct.

please pay

attention to the

drainage

work, we

suggest

to wrap the thermal

insulated layer around outside

of the duct.

• It

is recommended

to install the unit in the indoor

space,

it

is

not allowed to install the unit

at the

rainy space.

WARNING: UIn case of rain entering

to

internal components of the unit, the component

mightU

U

be damaged

or

causing physical da nger.

In

terms

of

the unit connect with duct reaching

toU

U

outdoor, a reliable water-resistant measure must be conduct on the duct,

to

prevent

waterU

U

from dropping into in

ternal of the unit.

Cool Energy EcoStore Heat Pump Water Heater

14 | P a g e

3.4

Electrical connection

WARNING:

UThe

equipment is

already

factory-wired

and

is equipped

with a plug for theU

U

connection to an outlet ha

ving appropriate electrical characterist

ics.

U

Verify

that the

mains voltage complies

with the

value specified

in the

labe l applied on

theU

U

equipment, and

that

the mains can supply

a sutable pressure and flow.

To disconnect

the equipment from the

mains

you

need

to

use a

two-pole

switch

complying with the

EN standards

(contact opening 3mm, preferably equipped with

fuses).

The connection must be

established by inserting the plug into the appropriate outlet, that must comply with the regulations

in force.

WARNING: USwitching on the equipment when

it

is not filled with wa

ter will seriously

damageU

U

the

refrigerating units and the electrical

resistance.

WARNING:

UIf

the supply cable is

damaged,

it

must be replaced by the manufacturer or by it

sU

U

technical support service,

or

anyway by a person having a s

imilar

qualification,

to preventU

U

any

risk.

4

USAGE INSTRUCTIONS

(User)

4.1 Switch-on

WARNING: UBefore switching on the equipment, always

verify the correctness of the

electricalU

U

connection; also check

that the tank

is

filled with water, to

avoid seriously damaging

theU

U

refrigerating

unit

and the electrical

heating elements.

4.2

Electronic co

ntrol

The

heat pump water

heater is

equipped with an

electronic

regulation

system

for the management

of the

temperature and

of the

complementary E-Heater.

4.2.1 Display

Cool Energy EcoStore Heat Pump Water Heater

15 | P a g e

Water Temperature setting

Cool Energy EcoStore Heat Pump Water Heater

16 | P a g e

4.3

Operating instr

uctions

4.3.1

Operations before turning on the

product

• When the product

is

turned on for the first time, all indicators on the UI will turn on for 3

seconds,

and in the

same

time an

acoustic

sound will be

heard.

After a minute without any

other

operation,

all

buttons are

blocked apart from

UNLOCK

button.

Press

it for 3

seconds

to

unlock

the buttons.

• When the tank will be full and all the

settings

set,

press

the ON/OFF button and start the

equipment.

• When the equipment is working, if no operation is going to be done and there is no

malfunction for 30

seconds,

the

display

will be locked apart from the error

codes

and alarm

li

ghts.

Press any

button to

unlock

the display.

4.3.2 Mode

Modes

will

be automatically selected

by unit.

Manually mode

selection

is

unavailable. Se

tti

ng

water temperature

target

range: 38

- 65°C. Max 55°C is recommended for good efficiency.

E-heater

running

ambient temperature range:

-20 - 45°C.

Heat

pump running

ambient temperature range:

minus7 -

45°C.

Ambient Te

mp.

TA<-7

-7≤ TA<-2

-2≤TA<2

2≤TA<7

7≤TA<35

35≤TA<43

Max.

Temp.

(Heat pump)

-

42

47

55

65

60

Max.

Temp.

(E-heater)

65

65

65

65

65

65

4.3.3

Heat source shift

The

default

heating source is heat

pump.

• If ambient

is

range out of heat pump,

heat pump will stop r

unning, the unit will shif

t

automatically to activate

E-heater

and show the icon LA ( );on the display, then if the

ambient

temperature goes

into the running

range

of

heat

pump

again,

it will

stop E-

heater

and

shift

automatically

to

heat

pump

again, and

the

icon LA( )

will

be exti

nguished.

• If the target setting water temperature is higher than

Max

temp (Heat

pump),

the unit

will

activate

heat pump firstly to the

Max. temperature,

then stop heat pump,

activate E-heater

to

continuall y

heat water

to the target temperature.

• If

manually activate

the

E-heater

running mode when heat pump running,

E-heater

and heat

pump will work together until the

water temperature gets

to target

temperature.

So

if want

to

heat quickly, please

manually activate

E-heater.

NOTE: E-heater

will

be activated once

for the

current heating

progress,

if want to

apply

E-heater

again, please push

.

• If

system occurs some malfunctions,

error

code "E7" and

will be shown on the

display, then

heat pump will stop running, and the unit will activate automatically

E-heater as

the backup

heat source,

but the

code "E7"

and will be shown until power off.

Note: If only the electric element is used

as

a heating

source,

only one part of the cylinders

content will

be heated; the

water temperature must be set at a higher

value

that the

one

for the

Cool Energy EcoStore Heat Pump Water Heater

17 | P a g e

running of the

heat

pump.

•

Defrosting

during

water-heating.

In heat pump running

period,

if the evaporator frosted in lower ambient temperature, the

system

will

defrost automatically

to

keep effective performance(circa 3~10

min.).

At defrosting

time,

the

fan

motor will

stop,

but

compressor

will still run.

•

COP

The

COP (Coefficient of Performance)

varies when the environmental temperature varies.

Normally,

lower is

the

environmental temperature, higher

will

be

the

water

heating.

• When the environmental temperature is inferior to

2°C,

the heat pump and the electric

element

work together

order

to

reach

the

planned temperature

(see

the chart).

4.4

Basic

function

4.4.1

We

ekly disinfect

function

Under disinfection mode unit immediately start to heat water up to

65°C

to kill the potential

legionella

bacteria inside

water of tank, “ ” icon will light on the

display screen

during

disinfection

;

Unit will quit

disinfection mode

if

water temperature

is higher

than

65°C

and extinguish

“ ”icon.

4.4.2

Vacatio n mo

de:

After

pressing "Vacation"

button, Unit will

automatically

heat water to

15°C

for the

purpose

of energy

saving

during

vacation

days.

4.4.3

Power On and power

Off

Press “ON/OFF”

( ) button after all the above have finished and the

system

will run

as

the

setti

ng. And simply press

the

same

button to

stop

it.

4.4.4

Lock and

unlock

In order to prevent wrong

operation, a special lock

function

has been design.

If there

is

no operation

for 1 minute, the unit will

be locked automatically,

and display

the

lock sign (Lock

indicator lights

up)

.

When

the unit is

locked,

no

keys can be operated.

Pres s for 3

second

to

unlock

the bu

tton

Cool Energy EcoStore Heat Pump Water Heater

18 | P a g e

4.4.5

Query

function

For the

convenience

of maintenance and debug, query function is available by

Press 2 buttons

together. +

,

then

system

running

parameters

will be shown one by one

with following sequence

by

each pushing

of “ “o “ ”

button.

N.

TEMP./DASYS

EXPLENATION

1 t 5 U T

emp.

T5U

2 t 5 L Temp.

T5L

3

t 3 T

emp.

T3

4

t 4 Temp.

T4

5

t P Temp.

Tp

6

t h Te

mp.

Th

7

C E Current Com

pressor

8 1

Last

error

9

2

Previous 1st error or prot

ection

code

10 3

Previous 2st error or prot

ection

code

11

Software

number

Cool Energy EcoStore Heat Pump Water Heater

19 | P a g e

4.5 Setting

4.5.1

Temperature

setting

The

temperature displayed

is

the

water temperature

in the

upper

part of tank.

Method for

temperature

set:

Press

the button to increase the

temperature, press the button to

decrease.

Confirm

setting.

4.5.2

Clock

setting

The clock

is for a 24-hour system and the initial time is

00:00. To make

a better

use

of this unit,

it is

recommended

to

set

the time for

accurate local

time. Every

time powered off, the

clock

will be reset

to initial time 00:00.

Method for time set:

Press

button for 5 sec to enter clock

setting. Then icon will be

lightened and the hour

value

of

clock

will

flash

slowly

Set

the hour

value

of

clock.

Confirm

the hour setting.

Then

the minute

value

of

clock

will

flash

slowly.

Set

the minute

value

of clock.

Confirm

the minute se

tti

ng

and

quit clock

setting.

4.5.3

Timer

setting

User

can set up running start time and stop

time on a

specifically

by the timer function.

The

least

numbers

of timer is

10

minutes.

Cool Energy EcoStore Heat Pump Water Heater

20 | P a g e

Method for timer set:

E

nter timer setting.

Select

timer

( )which needs

to be

set. The timer icon will flash slowly if it is

select

ed.

Confirm

the

selected se

tti

ng

timer.

Then

will

be lightened .

Then

the hour

value

of timer will

flash

slowly.

Set

the hour

value

of

timer.

Confirm

the hour

value

of

timer. Then

the

minute

value

of timer will

flash slow

ly.

Set

the minute

value

of timer.

Confirm

the minute

value

of

timer.

Then

ON or

OFF

icon following the setting timer

will flash

slowly.

Set

the

action (ON

or

OFF)

of the timer.

Confirm

the

action (ON

or

OFF)

of the timer.

ON

/OFF

ON

OFF

The

display

screen

will automatically display

different value at by different action. It

will

display

the last set

temperature and icon

if the action

is ON,

and will display-- if

the action is OFF.

Set

the water temperature of the se

tting

timer.

Confirm and complete

the timer.

Then

repeat

this process

to

set another

timer.

Cool Energy EcoStore Heat Pump Water Heater

21 | P a g e

Method for

cancel

timer setting:

Enter

timer se

tting.

Select timer ( )which

needs

to be

cancel.

The timer icon will

flash slowly

if it

is

selected.

Confirm

to cancel the timer. Then repeat

selecting

timer and

cancelling.

If the timer has

not been

set,

when

press

button the

display will show

.

After complete

canc

elling

timer, press button fo

r

3sec

to quit timer

cancelli

ng.

Method for

check

timer setting:

Select

time ( )which

needs

to be

checked.

The

timer icon will

flash

slowly if it

is

selected, and the timer

action(ON

or

OFF)

and

set clock will be

shown.

If the action

is ON,

target temperature will be shown. And if the

action

is OFF,

icon will

be shown.

Press

button for

3sec

or no

button

pressin

g for

30sec

to quit timer checking.

If there is

confliction

between Timer and

Manually

ON:

1. The

moment of

Manually ON has

priority;

2. The

moment of timer

OFF has

prio

rity;

4.5.4 Cancel

To cancel setting, quit setting,

clear al

arm,

etc.

press

button.

To clear alarm

buzzer, need to

press

same

button for 1sec.

Cool Energy EcoStore Heat Pump Water Heater

22 | P a g e

4.5.5

Disinfect

mode

Manually

turn on

disinfect

function:

Icon will fl

ash

Confirm

manually activate disinfec

tion

function, then the unit will heat up water to

65°C at least for

disinfection.

Disinfect Clock

Setting:

Press

button for

3 sec. To enter

in

the hour settings of Disinfect moda

lity.

The

icon

flashes,

the icon lightens

and

the hour indicator st

arts

to

flash slowly.

Set

the hour

value

of clock.

Confirm the hour setting.

Then

the minute

value

of

clock

will

flash

slowly.

Set

the minute

value

of clock.

Confirm the disinfect clock setting and qu

it

out.

Unit will automatically st

art

disinfection function at the

above-set

clock

every 7 days.

If

user

don't

set disinfect

clock,

unit will automatical ly start disinfection

function at

23:00 every 7 days.

If unit is

OFF

or

under

disinfe

ct

mode, press

will

lead

to

show

on the

display.

Cool Energy EcoStore Heat Pump Water Heater

23 | P a g e

4.5.6

Vacation

mode

Method for

Vacation mode setting:

Enter Vacation setting. Icon

wi

ll

flash.

Icon will

be

lightened.

will

show

the

last

setting

vacation

days.

Set vacation

days.

The days range is 1~99

days.

Confirm

Vacation setting and quit out. The

unit will

immediately

go into Vacati

on mode.

In vacation mode, the setting target water temperature is

15°C as

default and will

show the

remaining

vacation days.

On the

last

day of

vacation,

unit will automatically start disinfecting function,

and automatically reset the target temperature to the last one before

vacation. If unit

has

already

been under vacation mode or

OFF, press

will lead to

show

invalid icon on th

e

display.

4.6

Combination

button

ICON DESCRI

PTION

Clear error

code

+

Press

the two buttons at the

same time

to

clear

all

stored error

& protec t codes,

and

the

buzzer

will

buzz one

time.

Query

mode

+

Press

the two buttons at the

same time

for

1sec

to go into

query

mode.

Under

query mode

user can check unit

setting & running parameters by

pressing

toggles.

Press

button for

1s or no button operation for

30s,

then quit

query

mode.

4.7 Auto-restart

If electricity

power failed, unit

can memorize all setting

parameters,

unit will

be back

to the previou

s

setting

when power

recover.

4.8

Screen auto lock

If there is no operation of button for

30s, screen

will be locked

(extinguished) except for error code

and alarm light.

Press any

button will

unlock

the

screen(l

ighten).

Cool Energy EcoStore Heat Pump Water Heater

24 | P a g e

4.9 Error

If some errors happen, the

buzzer

will

buzz 3

times

every

other

minute.

Press

for

1 sec

to stop

the

buzzer

but the

alarm icon

will

keep glittering.

When an error is

verified,

although in

some

conditions it

may

function, it

cann

ot

reach

the expected

efficiency.

Please

contact

the

supp

lier.

4.9.1

Error code shooting

table

DISPLAY

MALFUNCTION DE

SCRIPT

ION

CORRECTIVE

ACTION

E0

Error

of

sensor T5U(upper

water

temperature

sensor)

Maybe

the

connection between se

nsor

and PCB

has released

or

sensor has

been

broken.

Contact a

qualified person

to

service

the

unit.

E1

Error

of

sensor T5L(lower

water

temperature

sensor)

Maybe

the

connection between se

nsor

and PCB

has released

or

sensor has

been

broken.

Contact a

qualified person

to

service

the

unit.

E2

Tank and Wired

Controller

communication

error

Maybe

the

connection

between

controller

and

PCB

has releas ed or

PCB

has been

broken.

Contact a

qualified person

to

service

the

unit.

E4

Evaporator temperature

sensor T3

error

Maybe

the

connection between se

nsor

and PCB

has released

or

sensor has

been

broken.

Contact a

qualified person

to

service

the

unit.

E5

Ambient

temperature

sensor T4

error

Maybe

the

connection between se

nsor

and PCB

has released

or

sensor has

been

broken.

Contact a

qualified person

to

service

the

unit.

E6

Compressor discharge

temperature

sensor TP

error

Maybe

the

connection between se

nsor

and PCB

has released

or

sensor has

been

broken.

Contact a

qualified person

to

service

the

unit.

E7

Heat Pump system

error

If any

of

P3/P4/P2/P1

continuously

appear 3 times

within

single

heating

cycle, system

will

consider

it

as

“Heat

Pump system error”

Contact a

qualified person

to

service

the

unit.

Cool Energy EcoStore Heat Pump Water Heater

25 | P a g e

E8

Electric leakage

error

If PCB

current_induction_circuit

check

the

current difference between L,N

14mA, system consider

it

as

"electric

leakage

error"

Maybe some wires have been broken

or

bad wire

connection.

Contact a

qualified person

to

service

the

unit.

E9

Compressor su

cti

on temperature

sensor TH

error

Maybe

the

connection between

sensor

and PCB

has released

or

sensor has

been

broken.

Contact a

qualified person

to

service

the

unit.

EE

E-heater

open-circuit error(

IEH) C

urrent

difference E-heater

on

& e-heater

off

<1A)

Maybe

the E-heater has been broken

or

bad wire connection after

repair.

EF

Clock

chip error

Maybe

the

chip has been broken,

but

unit

can

work well without clock-

memory, so

it

is needed

to

reset

clock

when power

put on again.

If necessary, contact a

qualified person

to

service

the unit.

Ed

E-EPROM

chip error

Contact a

qualified person

to

service

the

unit.

P1

System

high

pressure

protection:

•

≥2.76 MPa,

active;

•

≤2.07 MPa,

inactive.

Maybe because

of

system blocked, air

or

water

or

more refrigerant

in sy

stem(after

repair), water temperature

sensor

malfunction, ect.

Contact a

qualified person

to

service

the

unit.

P2

High discharge temperature

protection

•

Tp > 115 °C,

protection active;

•

Tp < 90 °C,

protection

inactive.

Maybe because

of

system blocked, air

or

water

or

less

refrigerant(leakage)

in

system( after

repair), water

temperature

sensor

malfunction,

ect.

Contact a

qualified person

to

service

the

unit.

P3

Compressor abnormally

stopped

protection.

The

discharge temperature is

not so

higher than

evaporator

temperature

after compressor

running a term.

Maybe because

of

compressor broken

or

bad connection between

PCB

and

compressor.

Contact a

qualified person

to

service

the

unit.

P4

Compressor overloaded

protection (10

sec.

after compressor

startup, Curr

ent

checking starts:

•

an

only

compressor running, if it is

>10A, the

compress or

will be

stopped

and

protected.

•

Compressor+e-heater opened,

if it is

>IEH+10,the compressor

will be

stopped

and

protected.)

Maybe because

of

compressor br

oken,

system bl

ocked, air or

water

or more

refrigerant

in

system (after repair),

water

temperature

sensor malfunction, etc.

Cool Energy EcoStore Heat Pump Water Heater

26 | P a g e

When

the

ambient

temp

T4 is

out of

Heat Pump

running

range (-7~43

°C

)

Heat Pump

will stop,

unit will

show

LA

LA on the position of

clock

on

display

until

T4 back

to

(-7~ 43 °C ).

Only valid

for the unit without

e-heater.

Unit with

e-heater

will

never show

"LA".

It

is normal, and

no

necessary

to

repair.

CAUTION: UThe diagnostic codes listed above are the most common.

If a

diagnostic code

notU

U

listed above is

displayed, contact residential technical assistance referencing the number

on

U

the front of this

manual.

4.10

FAQ

D.

Why compressor can't

start

immediately after setting?

R.

Unit will wait for 3 min to

balan ce

the

pressure

of system

before start

compresso r again, it's a self-

protection logic of unit.

D.

Why sometimes

the

temperature shown on the

display panel decreased

while unit

is

running?

R.

When

the upper tank temperatur e

is

much higher than the bottom

part,

upper part hot water

will

be mixed by the bottom cold water which is continually flow from inlet tap water so that will

decrease

the upper part temperature.

D.

Why sometimes

the

temperature shown

on the

display decreased

but unit st

ill keep closed?

R.

To avoid unit

ON/OFF

frequently,

unit will activate heat source only when bottom tank

temperatur e

is lower

than se

tti

ng

temperature

for

at least 5

ºC.

D. Why sometimes

the

temperature shown

on the

display

will

decreased

dramatically?

R. Because

tank is

pressure-bearable

type, if there is

massive

hot demand,

hot water will quickly

tapped out from upper part of

tank as

well

as

cold

water

will

quickly

tapped into bottom part of bank,

if the cold water

surface emerge

the upper temperature

sensor,

temperature shown on the display

will

decreased

dramatically.

D.

Why sometimes

unit

shows "LA"

on

display?

R.

The heat

pump

available

running ambient

range is -7÷43°C,

if ambient

temperature

is

out of range,

system

will

show abovementioned signal

to let

user notice

it.

Q. Why does the display sometimes show nothing?

A. To preserve the life of the display. After no button press for 30 sec the display will turn off.

D. Why something there is nothing shown on the

display?

R.

If there

is

no operation on panel for 1 min, unit will lock the

panel, shows .

To unlock the panel,

please press the button for

3

second

s.

Cool Energy EcoStore Heat Pump Water Heater

27 | P a g e

4.11

Hydraulic safety unit efficiency

check

The hydraulic unit efficiency is very important to prevent any

overpressures

inside the tank

(tha

t

would damage

it), and

allows

the user to

safely

operate the equipment.

Periodically

check the

efficiency

of the hydraulic

safety

unit, according to the instructions provided by the manufacturer.

Follow the instru

ctions provided by the

manufacturer.

During the

check clean

the unit and remove

any limestone

scales.

4.12

Unit

emptying

Should

the unit be going to

remain unused

for a prolonged time, we

recommend

that you empty it

.

In this case

proceed

as

follows:

• cut off the

power supply and

the

main water

supply;

•

open a

hot

water

tap to allow

air

to flow in;

• turn the emptying knob on the

hydraulic safety unit to the

open

position;

• verify that the

discharge

connector of the hydraulic safety unit is connected to a drain as

specified

in

par.

3.1.1.

4.13

Restart after a long term stop

When

the unit

is restarted after a

long-term st

op (trail

running included), it

is normal

that outlet water

is unclean. Keep

the tap on

and

the

water

will

be clean

soon.

5

MAINTENANCE INSTRUCT

IONS

(qualified personnel

only)

WARNING:U

the

repair

and/or

maintenance operations must only be performed by

qualifiedU

U

personnel, exclusively

using genuine spare parts. Before

performing

any maintenanceU

U

operat

ions, disconnect the equipment from the mains.

U

Before performing

any

maintenance operations

we

recommend

that you

purchase

anyU

U

spare parts from the

authorized dealers or directly

from

the

Manufacturer.

5.1 General

•

Control regularly

the

connection between

the

supply

plug

and wi

ring.

• In

some

cold

areas

(under

0°),

if the system

is

not

used

for a long period, empty the boiler in

order

to

avoid

freezing.

• It

is advised

to

clean regularly

the

inside

part of the boiler

and

the

electric resistance

in order

to

preserve

the efficiency.

•

Control

the

magnesium anode and change

it if

needed.

•

Clean

the

air filters

each

month in

order

to

preserve

the

heating

performance.

•

Before

turning off the

system

for a long period

you must:

-

Remove

the

current

supply;

-

Drain

all the

water

from the

tank and

the pipes;

-

Close all valves;

-

Control regularly all inside

components.

Cool Energy EcoStore Heat Pump Water Heater

28 | P a g e

5.2

False errors of

operation

•

Due

to a start

caused

by a voltage

fall,

you must wait 3 minutes before the

reactivation

of the

compressor,

in

order

to

preserve its integrity.

•

If

the

auto

protection

is

activated and

the

system stops,

control

that:

-

When

the supply indicator is on, if the

system

is being forced to function

even

without the

normal

operative cond

itions; if the in-out air flow

is

blocked or if a strong wind blows

towards

the

air

exit.

•

De-frosting

When

there

is

humidity and cold,

the

condenser must be thawed and the

efficiency

of the air

heating

is lower:

the

system

will stop the water heating, will do the thaw and then will restart

the

air

heating.

•

During

the defrosting,

the

compressor co

ntinues to

work,

while the

fan

stops.

• The

defrosting

time varies between 3 and 10 minutes accordingly to the environmental

temperature and

frosting.

5.3

Visualized

temperature

•

When

the

system is stopped, a

reduction of the temperature

is

normal due to the

loss

of heat.

When

it

goes

bellow a few

degrees,

the

system is

automatically

activated.

• During the heating the water temperature could continue to

decrease

or could not increase

because