Cool Compact SKFME Series, 5 X GN 1/1, SKFZK Series, 15 X GN 1/1 Operating Manual

OPERATING MANUAL

Blast chiller - freezer

5 X GN 1/1 – 15 X GN 1/1

Series: SKFME / SKFZK

2

CONTENTS

Page

1.

PRELIMINARY REMARKS

3

2

PURPOSE OF USE

3

3.

GENERAL TIPS

3

4.

SAFETY REGULATIONS

4

5.

TECHNICAL DATA

4

6.

INSTALLATION

5

6.1

Transport and handling of the equipment

5

6.2

Unpacking and setting

5

6.3

Electrical connection

7

6.4

Connection of an external unit

8

6.4.1

Setting

8

6.4.2

Electrical connection

8

6.4.3

Connection of coolant hoses

8

6.5

Tips concerning installation

8

7.

USE

9

7.1

Equipment in the standby mode

9

7.2

Equipment in the cooling mode

9

7.3

Categories of food products

9

7.4

Automatic and individually set programs

9

7.5

Cycle in progress

10

7.6

Other functions

10

7.7

Machine in the heating mode

11

7.8

Combined mode (option)

11

7.9

Options

11

7.10

Alarms

12

7.11

Manual mode and Multilevel mode

12

7.12

USB

13

7.13

HACCP report

14

7.14

Help (option)

14

7.15

Modem (option)

14

8.

MAINTENANCE

16

8.1

Safety

16

8.2

Cleaning

16

8.3

Care

16

8.4

Non-standard maintenance work

17

9.

WARRANTY AND SERVICE

17

10.

SCRAPPING AND RECYCLING

17

11.

WIRING DIAGRAM

18-21

12.

DECLARATION OF CONFORMITY

22

3

1. PRELIMINARY REMARKS

Thank you for buying our blast chiller-freezer. All our products are subject to constant quality control.

Please read the manual carefully so as to be able to enable long and problem-free use of our products.

The operating manual is intended to provide the following information:

• general tips;

• safety regulations;

• technical data;

• installation;

• use;

• maintenance;

• guarantee and service;

• scrapping and recycling; and

• declaration of conformity.

2. PURPOSE OF USE

Blast chillers-freezers are used to quickly cool down certain food products so as to avoid growth of

bacteria in food and to maintain high quality of food.

Such equipment is used in two ways:

• Quick cooling in order to reduce the temperature from +90 °C to +3 °C in 90 minutes.

• Freezing in order to reduce the temperature from +90 °C to -18 °C in 240 minutes.

During the quick cooling, one can set the most appropriate cooling cycles for the specific food products

being cooled.

After the cycle is completed, the equipment switches to the storage mode. One must keep in mind that

the blast chiller-freezer is intended for storage of products for up to 2 days.

3. GENERAL TIPS

• The equipment is suitable only for quick cooling/blast freezing of food products.

• After the equipment is unpacked and the protections are removed, please check if the

equipment is not damaged. If any damage is found, please inform the supplier or installer

immediately.

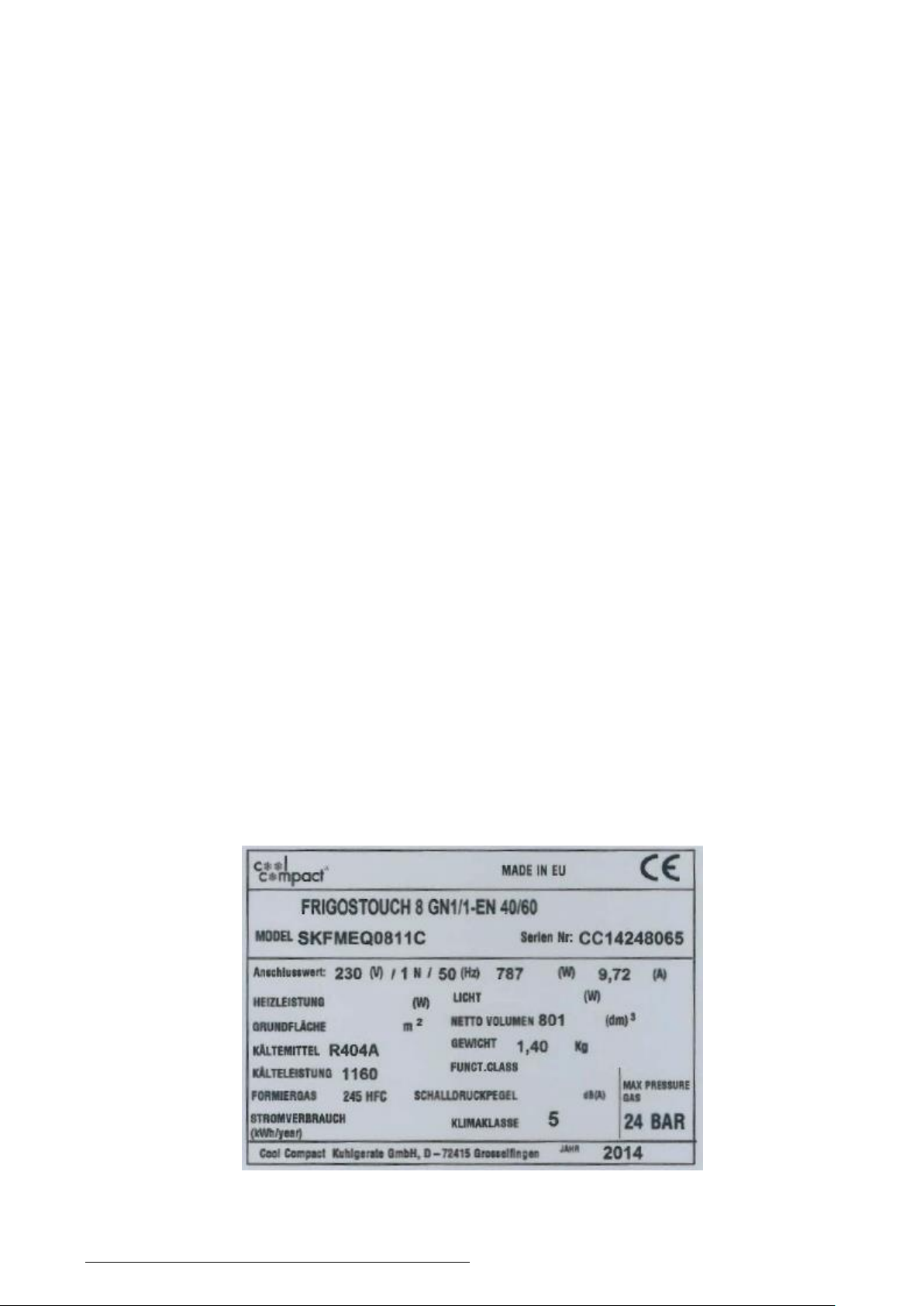

• Before works related to setting and installation are started, please check if the data pertaining

to the power and voltage of the electrical system given in the data plate correspond to the actual

local values. The data plate is located in the back of the equipment and on the back page of the

operating manual.

• In the event of a breakdown, the equipment must be switched off immediately.

Installation, startup, and maintenance of the blast chiller-freezer must be performed by qualified

companies that provide cooling services or by persons authorized by the manufacturer. In order to

ensure safe installation, use, and maintenance of the blast chiller, one must carefully read the

instructions contained in this manual and keep this manual in a place where it will be easily accessible

for the user.

4. SAFETY REGULATIONS

4

In the course of the design and the production of the blast chillers-freezers, particular attention was

paid to observance of the safety rules, which enable the user to use the equipment safely.

• In order to avoid accidental touching of live cables, the equipment is fitted with metal guards.

Such protections may be removed only by qualified personnel.

• In order to avoid accidental contact with moving parts, the blades of the fan on the condenser

and in the enclosure of the evaporator are covered with a protective grille.

• The electrical system complies with the CEI EN 60335-1:2002 standard.

As is the case with any electrical equipment, in order to avoid dangerous situations during installation

and during use, one must act in compliance with the applicable regulations.

• Before performing any maintenance, disconnect the equipment from the power supply network.

• Do not work with the equipment with wet hands or feet.

• Do not remove and do not tamper with protective devices while performing regular maintenance

work.

• Do not put any devices or kitchen tools into the cover of electrical and mechanical parts.

• Use appropriate and compatible equipment for maintenance.

• When not in use, the equipment should be switched off and the plug should be taken out of the

power socket.

Failure to observe the above rules may affect the safety of the equipment and of the user. The

manufacturer is not responsible for any changes to the original method of functioning of the equipment,

failure to observe the operating instructions, or changes to or installation of additional devices.

5. TECHNICAL DATA

In order to determine the technical characteristics of the blast chillers-freezers, it is recommended to

pay attention to the information contained in the data plate located on the back cover of the operating

manual.

A data plate is also provided in the back of the blast chiller and is intended for:

• identification of the product during the service based on its model, product number, and serial

number;

• providing information about the required electric power and supply voltage of the equipment;

• providing information about the type and quantity of the coolant.

•

5

The manufacturer is not responsible for improper use of the product.

The manufacturer also reserves the right to make the necessary and useful changes in its products that

the manufacturer finds necessary, without changing its basic functions.

6. INSTALLATION

Setting, installation, connection, and maintenance work on the blast chiller-freezers may be performed

only by a person who builds cooling equipment and/or a technically qualified and authorized

manufacturing company.

6.1. TRANSPORT AND HANDLING OF THE EQUIPMENT

In order to properly transport and then handle the blast chiller-freezer, one must comply with the

following instructions:

• In order to avoid damage to objects or injury of persons during transport of the equipment, one

must use appropriate means of transport and equipment.

• Check if the selected means of transport is appropriate for the weight of the blast chiller-freezer.

• Note: During transport of the equipment, it may not be turned upside down or laid on the side.

Such a position may cause damage to the equipment and hinder the cooling cycle.

6.2. UNPACKING AND SETTING

Before the equipment is installed, it must be unpacked carefully.

• Set a blast chiller-freezer that still has not been unpacked using an appropriate forklift in the

vicinity of the eventual place of installation.

• Cut the tape and pull the cardboard packaging upward. In order to avoid damage to the

equipment, do not use knives or other similar tools.

• Take out the wooden base and set the chiller in the final position.

• Take off the PVC protective film from all sides.

• Remove the plastic protection from the probe for measuring the temperature inside the product.

• Place the equipment in a level position in a well ventilated room.

• Avoid putting the equipment close to a direct source of heat or in an area directly exposed to

sunlight.

• The place where the equipment is to be set must be well ventilated and free from dust.

• The air humidity should be equal to a maximum of 70%.

• All uneven spots on the floor must be eliminated before the installation.

• Leave free space in the area where air is sucked into and exhausted out of the unit (around the

ventilation openings) in order to ensure proper ventilation.

• The ambient temperature should be in the range of +16 °C to +32 °C.

• The floor of the equipment must be sealed to prevent penetration of water from the outside! (It

must be sealed or covered with silicone.)

• Keep a distance of at least 50 cm on all sides in order to ensure proper circulation of air.

• All elements of the packaging of the equipment should be disposed of in compliance with

applicable regulations. In no case may they constitute a burden to the environment.

6

Data plate (on the back)

Control panel

Door

Legs with height adjustment

Unit chamber with a grate

air inlet cover

Removable condensate container

Door

7

6.3. ELECTRICAL CONNECTION

The equipment is delivered without the plug for connecting to the power supply line. This connection

must be made by qualified workers.

If the connection is made by the user or by unqualified workers, the manufacturer will be exempted from

any and all responsibility.

• Check the integrity of the power supply lines. In the event of damage, have a qualified specialist

perform the repair.

• The supply voltage must correspond to the values specified in the data place of the equipment.

• The electrical cable must have an integrated multi-pole main switch which opens all contacts,

including those in the zero conductor. The minimum distance between open contacts must be

equal to 3 mm and the cable must be connected to an appropriate overcurrent switch or fuse.

The selected parameters and settings must correspond to those shown on the data plate.

• The main switch must be located close to the equipment, easily acceptable, and enable its use

each time for the equipment.

• The ground cable made by the investor must be connected to the appropriate grounding

terminals (clamps) of the equipment.

• It is prohibited to use connections, multiple plug sockets, extension cables, and cables with not

permitted cross-section.

• Local standards must be complied with.

• The detailed information concerning the electrical connection can be found in the wiring diagram

in the operating instruction or on the back wall of the equipment.

• During normal operation of the equipment and during its maintenance, the installation cable

must not be stretched or crushed.

6.4. CONNECTION OF AN EXTERNAL UNIT

Two units should be connected in accordance with the following instruction.

Cooling unit Blast chiller-freezer

6.4.1. SETTING

Loading...

Loading...