Cool Automation Cool Master 1000D, Cool Master 2000S, Cool Master 3000T, Cool Master 4000M, Cool Master 6000L Programmer's Reference Manual

...Page 1

CoolMaster Programmers Reference Manual (PRM)

CoolMaster

Interface

Adapter

for VRV, VRF

Air Conditioning

Systems

Cool Master 1000D

Cool Master 2000S

Cool Master 3000T

Cool Master 4000M

Cool Master 6000L

Cool Master 7000F

Cool Master 8000I(MH)

Cool Master 9000H

Cool Master G

Document Revision 4.08 12/16/2015

© 2015 Cool Automation LTD

www.coolautomation.com

Page 2

CoolMaster PRM

Table of Contents

2Contents

Part I

Part II

Part III

Part IV

Revisions History

RS232 Interface

................................................................................................................................... 51 Mechanical and Electrical Specification

................................................................................................................................... 62 Port Settings

General Protocol Definitions

................................................................................................................................... 71 Message format

................................................................................................................................... 72 Indoor Unit Addressing

Commands Reference

................................................................................................................................... 91 Cool Master Commands

.......................................................................................................................................................... 9alloff

.......................................................................................................................................................... 9allon

.......................................................................................................................................................... 10boot

.......................................................................................................................................................... 10cool

.......................................................................................................................................................... 10dry

.......................................................................................................................................................... 11heat

.......................................................................................................................................................... 11auto

.......................................................................................................................................................... 12fan

.......................................................................................................................................................... 12filt

.......................................................................................................................................................... 13fspeed

.......................................................................................................................................................... 13off

.......................................................................................................................................................... 14on

.......................................................................................................................................................... 15set

.......................................................................................................................................................... 16simul

.......................................................................................................................................................... 17stat

.......................................................................................................................................................... 18stat2

.......................................................................................................................................................... 19stat3,stat4

.......................................................................................................................................................... 21query

.......................................................................................................................................................... 22swing

.......................................................................................................................................................... 23temp

.......................................................................................................................................................... 24group

.......................................................................................................................................................... 24vam

.......................................................................................................................................................... 25lock

.......................................................................................................................................................... 26wh

.......................................................................................................................................................... 27feed

4

5

7

9

Part V

www.coolautomation.com

Firmware Update

28

................................................................................................................................... 281 Entering bootloader mode

................................................................................................................................... 282 Firmware Download

................................................................................................................................... 293 Reboot

© 2015 Cool Automation LTD

2

Page 3

CoolMaster PRM

3Contents

www.coolautomation.com

© 2015 Cool Automation LTD

3

Page 4

CoolMaster PRM

Rev 4.08

1 Revisions History

Document revision 4.08 Wednesday, December 16, 2015

· 4.08

set alive

· 4.07

CoolMaster 9000H Lock command support.

CoolMaster 4000M Feed command support.

· 4.06

set ignore r

CoolMaster 4000M wh support

CoolMaster 1000D lock support

· 4.05

CoolMaster G

· 4.04

lock

· 4.03

CoolMaster 4000M F/C support

CoolMaster 4000M VAM support

CoolMaster 7000F swing support

· 4.02

CoolMaster 6000L vam support

· 4.01

stat4

· 3.12

query h

temp XX[X].x[x]

· 3.11

CoolMaster 6000L

· 3.10

query

· 3.9

set baud

set slink

· 3.8

CoolMaster 1000D Fahrenheit support

20 groups limit

CoolMaster 8000I(MH)

· 3.7

PAC-YG66, PAC-YG63 support for CoolMaster 4000M

· 3.6

Centralized Address for 200S,3000T

· 3.5

CoolMaster 7000F

· 3.4

fixed compatibility notes

auto command, AutC, AutH

fspeed: t - top, m for CoolMaster 1000D

VAM and Auto modes in stat

· 3.3

added vam command

Revisions History

4

www.coolautomation.com

© 2015 Cool Automation LTD

Page 5

CoolMaster PRM

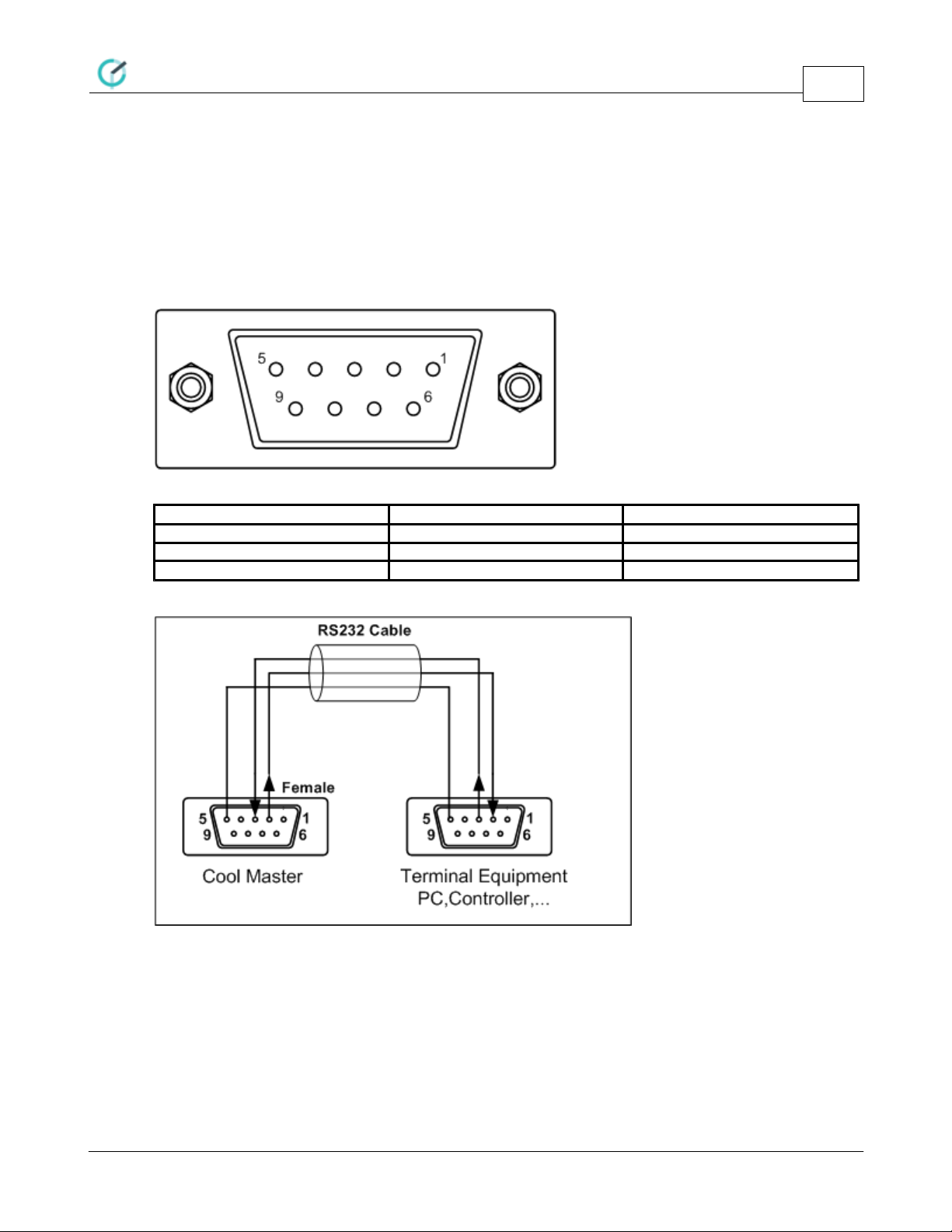

DB9 Pin

Signal Lvel

Description

2

±12V

TxD (Data from Cool Master)

3

±12V

RxD (Data to Cool Master)

5

GND

Ground

Rev 4.08

2 RS232 Interface

2.1 Mechanical and Electrical Specification

RS232 Interface connector used in Cool Master is D-Type 9-pin DB9 female connector.

Cool Master DB9 Connector front view

RS232 Interface

5

Connecting Cool Master to Home Automation Equipment

In the picture above it is assumed that Terminal Equipment DB9 connector has RxD line on pin 2 and

TxD line on pin 3. (This is a standard for PC). If a Terminal Equipment (Home Automation Controller)

has a reversed pin out ( RxD on pin 3 and TxD on pin 2), the crossed RS232 cable must be used to

connect TxD to RxD and RxD to TxD.

According to RS232 specification cable length should not exceed 25m. RS232 Cable supplied with

Cool Master is 1.5m length suitable for direct connection to PC RS232 serial port.

www.coolautomation.com

© 2015 Cool Automation LTD

Page 6

CoolMaster PRM

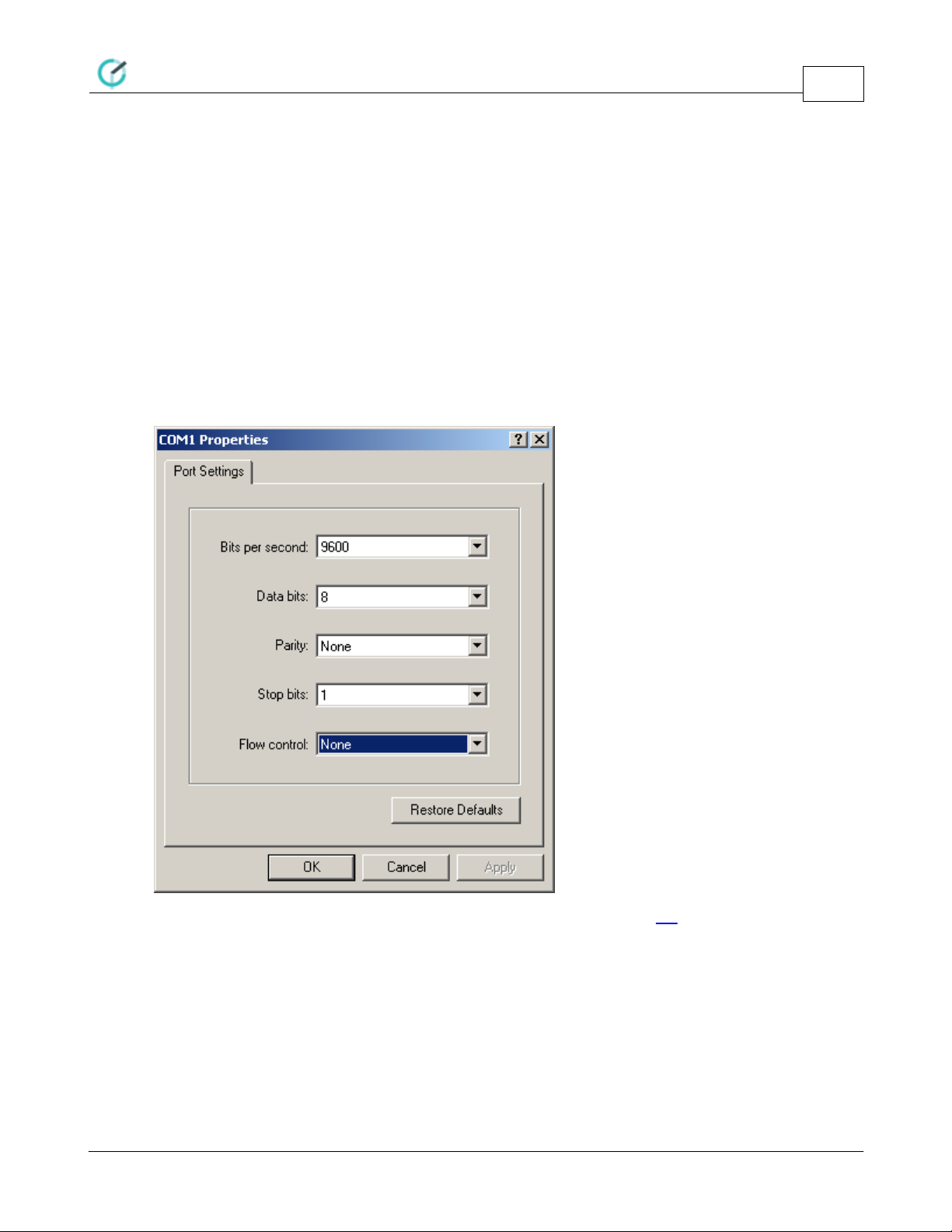

Baud Rate

9600

Data Bits

8

Parity Control

None

Stop Bits

1

Flow Control

None

2.2 Port Settings

For proper communication with Cool Master RS232 Port should be configured with following

parameters

Below is an example of COM port setup in HyperTerminal application

Rev 4.08

RS232 Interface

6

www.coolautomation.com

CoolMaster RS232 Port baud rate (bits per second) can be changed with set baud command.

© 2015 Cool Automation LTD

Page 7

CoolMaster PRM

>stat 101

command

PC to CoolMaster

101 ON 27C 00,00C Auto Dry OK

response

CoolMaster to PC

OK

exit code

>

prompt

Unknown command

Unrecognized command name

Bad parameters

Command has missing or wrong parameters

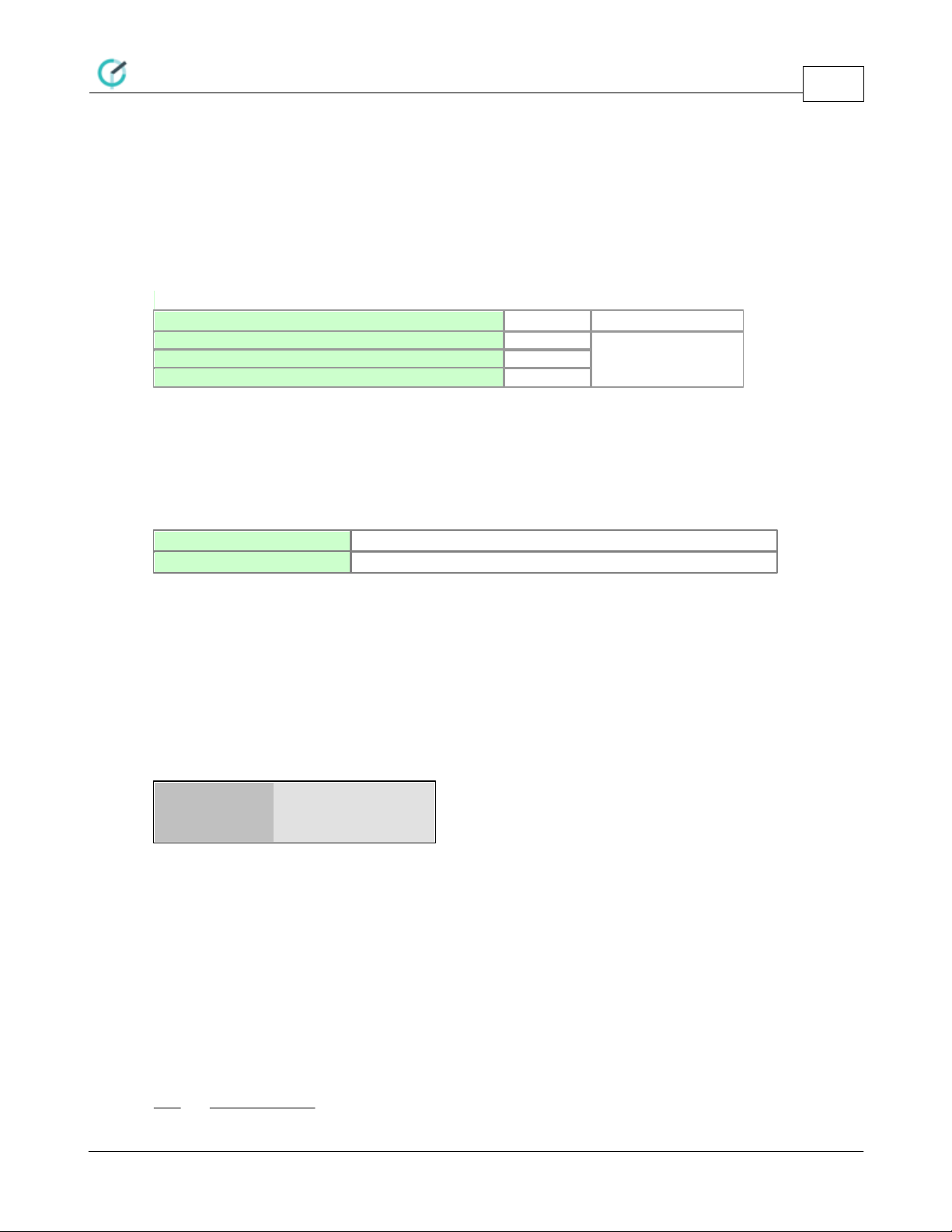

1

2

3

System Number

Unit Number in System

0-9, A-F

00-99 or FF

UID

Indoor Address

100

1-00

Rev 4.08

3 General Protocol Definitions

3.1 Message format

Communication between PC or Home Automation Controller and CoolMaster via RS232 interface is

based on text messages. Communication example is shown below

Command message sent to CoolMaster must be terminated by CR (carriage return 0x0D) LF (line feed

0x0A) sequence or a single CR character. Messages from CoolMaster (except prompt character) are

terminated by CR LF. Commands are case sensitive and should not contain leading or trailing spaces.

The only separator between command name and command parameter(s) is space character.

In case of wrong command CoolMaster response can be one of the following strings:

General Protocol Definitions

7

If command was executed CoolMaster will return optional response and exit code. Detailed information

is provided in topics describing specific commands.

3.2 Indoor Unit Addressing

To address specific indoor unit the UID parameter is used in CoolMaster commands. UID format is

three characters. First character is hexadecimal digit in range 0-9 or A-F to represent system numbers

0-9, 10-15 correspondingly or Z to specify centralized address mode.

UID Format:

· For CoolMaster 4000M System Number must be 0, Unit Number must be 01-50

· For CoolMaster 1000D System Number must be in range 1-4

· For CoolMaster 2000S, 3000T, 7000F,8000I(MH), 9000H System Number should not be 0

· For CoolMAster 6000L System Number must be 0, Unit Number must be 00-FF

· For CoolMaster G Unit Number must be in range 01-16

UID reflects the indoor unit address. For proper operation of CoolMaster all indoor units have to be

given addresses (depending on specific AC system type this can be done automatically by system or

has to be done manually by integrator). You should refer to specific AC system manuals to find out how

to set and quire indoor unit addresses.

Below are examples of accepted UID's.

www.coolautomation.com

© 2015 Cool Automation LTD

Page 8

CoolMaster PRM

101

1-01

201

2-01

310

3-10

F99

15-99

1

2

3

Centralized

Address Sign

Centralized

Address

Z

00-99

UID

Centralized Address

Z0101Z22

22

UID format for Centralized Address mode:

Example:

Centralized Address mode is currently supported for CoolMaster 2000S and 3000T.

Note: For backward compatibility Unit number in System can be represented by hexadecimal numbers couple in

range 00-0F equal to decimal 00-15. For example 10A represents Centralized Address 1-15. We recommend not

to use this option in future designs.

Rev 4.08

General Protocol Definitions

8

www.coolautomation.com

© 2015 Cool Automation LTD

Page 9

CoolMaster PRM

OK

Request Successfully Executed

Rev 4.08

4 Commands Reference

4.1 Cool Master Commands

alloff

allon

boot

cool

dry

heat

auto

fan

filt

fspeed

off

on

set

simul

stat

stat2

stat3

query

swing

temp

group

vam

lock

wh

feed

Commands Reference

9

4.1.1 alloff

SYNOPSIS

alloff

DESCRIPTION

Turn off all indoor units

EXAMPLE

>alloff

OK

EXIT CODE

4.1.2 allon

SYNOPSIS

allon

www.coolautomation.com

© 2015 Cool Automation LTD

Page 10

CoolMaster PRM

OK

Request Successfully Executed

OK

Request Successfully Executed

ERROR:1

Unit with specified UID not found

DESCRIPTION

Turn on all indoor units.

EXAMPLE

>allon

OK

EXIT CODE

4.1.3 boot

SYNOPSIS

DESCRIPTION

Switch CoolMaster to bootloader mode. Bootloader mode is used for Firmware Update. For details

please see the Firmware Update section.

EXAMPLE

>boot

reboot...

boot

Rev 4.08

Commands Reference

10

4.1.4 cool

SYNOPSIS

DESCRIPTION

Set indoor unit UID mode to COOL.

EXAMPLE

>cool 102

OK

EXIT CODE

4.1.5 dry

SYNOPSIS

cool <UID>

dry <UID>

www.coolautomation.com

© 2015 Cool Automation LTD

Page 11

CoolMaster PRM

OK

Request Successfully Executed

ERROR:1

Unit with specified UID not found

OK

Request Successfully Executed

ERROR:1

Unit with specified UID not found

OK

Request Successfully Executed

ERROR:1

Unit with specified UID not found

DESCRIPTION

Set indoor unit UID mode to DRY.

EXAMPLE

>dry 102

OK

EXIT CODE

4.1.6 heat

SYNOPSIS

DESCRIPTION

Set indoor unit UID mode to HEAT.

EXAMPLE

>heat 102

OK

heat <UID>

Rev 4.08

Commands Reference

11

EXIT CODE

4.1.7 auto

SYNOPSIS

DESCRIPTION

Set indoor unit UID mode to AUTO. Status report for the Indoor Unit in Auto mode can be

· Auto - Auto Mode

· AutC - Auto Mode Cooling

· AutH - Auto Mode Heating

EXAMPLE

>auto 102

OK

EXIT CODE

auto <UID>

www.coolautomation.com

© 2015 Cool Automation LTD

Page 12

CoolMaster PRM

CoolMaster 1000D

v 2.5.1

CoolMaster 2000S

v 2.8.6

CoolMaster 3000T

v 2.8.6.

CoolMaster 4000M

2.5.7

CoolMaster 6000L

any

CoolMaster 7000F

2.6.4

CoolMaster 8000I(MH)

2.7.3

CoolMaster 9000H

2.7.7

CoolMaster G

N.A.

OK

Request Successfully Executed

ERROR:1

Unit with specified UID not found

OK

Request Successfully Executed

ERROR:1

Unit with specified UID not found

CoolMaster 1000D

v 0.3.1

CoolMaster 2000S

v 2.0.9

COMPATIBILITY

4.1.8 fan

SYNOPSIS

DESCRIPTION

Set indoor unit UID mode to FAN.

EXAMPLE

>fan 102

OK

fan <UID>

Rev 4.08

Commands Reference

12

EXIT CODE

4.1.9 filt

SYNOPSIS

DESCRIPTION

Reset filter sign on indoor unit UID.

EXAMPLE

>filt 102

OK

EXIT CODE

COMPATIBILITY

filt <UID>

www.coolautomation.com

© 2015 Cool Automation LTD

Page 13

CoolMaster PRM

CoolMaster 3000T

any

CoolMaster 4000M

any

CoolMaster 6000L

N.A.

CoolMaster 7000F

N.A.

CoolMaster 8000I(MH)

any

CoolMaster 9000H

N.A.

CoolMaster G

N.A.

>fspeed 101 l

OK

Set unit 1-01 fan speed to low

>fspeed 101 m

OK

Set unit 1-01 fan speed to medium

>fspeed 101 h

OK

Set unit 1-01 fan speed to high

>fspeed 101 a

OK

Set unit 1-01 fan speed to auto

>fspeed 101 t

OK

Set unit 1-01 fan speed to top

OK

Request Successfully Executed

ERROR:1

Unit with specified UID not found

CoolMaster 1000D

any

Supported: l h

2.5.1

Supported: l m h

CoolMaster 2000S

any

Supported: l m h a

CoolMaster 3000T

any

Supported: l m h a

CoolMaster 4000M

any

Supported: l m h a t

CoolMaster 6000L

any

Supported: l m h a t

CoolMaster 7000F

any

Supported: l m h a

CoolMaster 8000I(MH)

any

Supported: l m h t

CoolMaster 9000H

any

Supported: l m h

CoolMaster G

any

Supported: l m h a

4.1.10 fspeed

SYNOPSIS

DESCRIPTION

Set indoor unit UID fan speed to low, medium, high, auto, top.

EXAMPLE

Rev 4.08

fspeed <UID> <l|m|h|a|t>

Commands Reference

13

EXIT CODE

COMPATIBILITY

4.1.11 off

SYNOPSIS

DESCRIPTION

Turn off indoor unit UID.

EXAMPLE

off <UID>

www.coolautomation.com

© 2015 Cool Automation LTD

Page 14

CoolMaster PRM

OK

Request Successfully Executed

ERROR:1

Unit with specified UID not found

OK

Request Successfully Executed

ERROR:1

Unit with specified UID not found

Rev 4.08

Commands Reference

>off 102

OK

EXIT CODE

EXTENSIONS

CoolMaster 4000M PAC-YG Support

In CoolMaster 4000M v2.5.6 or higher to control PAC-YG66 digital I/O device following off command

format is used

off <UID> [N]

N is digital output number 1..6

>off 012 2

OK

>off 012 6

OK

14

4.1.12 on

SYNOPSIS

DESCRIPTION

Turn on indoor unit UID.

EXAMPLE

>on 102

OK

EXIT CODE

EXTENSIONS

In CoolMaster 4000M v2.5.6 or higher to control PAC-YG66 digital I/O device following on command

format is used

on <UID>

CoolMaster 4000M PAC-YG Support

on <UID> [N]

N is digital output number 1..6

www.coolautomation.com

© 2015 Cool Automation LTD

Page 15

CoolMaster PRM

Configuration

Option

Access

Mode

Description

S/N

Read

CoolMaster Unit Serial Number

myid

R/W

CoolMaster Unit own Centralized Address

version

Read

Firmware Version

echo

R/W

0-Disable 1-Enable Commands echo

baud

R/W

RS232 Port baud rate. Can be 1200, 2400, 4800, 9600, 18200, 38400,

57600, 115200. Default is 9600

deg C/F

R/W

Temperature scale: C-Celsius, F-Fahrenheit. Set command is set deg C

or set deg F

slink

R/W

A/C line link type for CoolMaster 8000I(MH). Can be O (for Old) or N (for

New)

master

R/W

1-Master 0-Slave. For CoolMaster 6000L/1000D

lcd

R/W

LCD size

simul

R/W

Number of Indoor units permanently simulated. If simul is not zero

CoolMaster will simulate given number of units after reset.

CS count

Read

Check Sum errors counter

TO count

Read

Timeout errors counter

Collisio

Read

Collision Counter

NA Count

Read

NAK Counter

MB CRC

Read

Modbus bad CRC counter (Coolgate Only)

modaddr

R/W

Modbus Address (Coolgate Only)

ignore

R/W

Ignore flags: r - Ignore modbus Illegal Data Address (Coolgate Only)

alive

R/W

Keep Alive Time in seconds for all Indoors. Min value=300, if value is set to 0,

then Keep Alive is Disabled.

S/N : 0041

myid : 0A

version : 2.1.4

echo : 1

Query configuration

>on 012 2

OK

>on 012 6

OK

4.1.13 set

SYNOPSIS

DESCRIPTION

Query or set CoolMaster configuration. Without parameters set command will list all supported

configuration options and their values. To change option use format with option and value. Some

options are read only and can not be changed.

Rev 4.08

set [<option> <value>]

Commands Reference

15

Notes:

· baud change takes effect only after power reset.

· ignore flag 'r' allows reading of the consecutive Indoor status holding and input registers (address

range:0x1001-0xF640) even if there are non-existent Indoor Units in between. Non-existent Indoor

registers are filled with 0xFFFF.

EXAMPLE

www.coolautomation.com

© 2015 Cool Automation LTD

Page 16

CoolMaster PRM

baud 232: 9600

lcd : 8

simul : 0

CS count: 0

TO count: 0

Collisio: 0

NA Count: 0

MB CRC : 0

modaddr : 80

ignore : r

alive : 300 sec

OK

>set echo 0

OK

Set echo option (disable echo)

OK

Request Successfully Executed

deg C/F

v 2.5.6 CoolMaster 1000D

v 2.8.3 CoolMaster 4000M

baud

v 2.5.8

slink

v 2.5.7 CoolMaster 8000I(MH) only

master

CoolMaster 6000L/1000D

ignore r

v 2.8.9 CoolGate only

alive

v 2.9.3

>simul 20

OK

Simulate 20 Indoor Units

>simul 0

OK

Terminate simulation mode

OK

Request Successfully Executed

EXIT CODE

COMPATIBILITY

Rev 4.08

Commands Reference

16

4.1.14 simul

SYNOPSIS

simul <N>

DESCRIPTION

Simulate N indoor units. Simulation mode can be used to debug Home Automation Controller software

without connecting CoolMaster to Air Conditioning system line. To exit simulation mode set N to zero or

restart CoolMaster.

EXAMPLE

www.coolautomation.com

EXIT CODE

© 2015 Cool Automation LTD

Page 17

CoolMaster PRM

Position in String

Example

Format

Description

0-2

109

NNN

Indoor unit Centralized Address

4-6ONON or OFF

On/Off Status

8-10

23C

NNC***

Set Temperature ºC

12-17

24,08C

NN,NNC***

Room Temperature ºC

19-22

Auto

Low,Med,High,Auto,Top

Fan Speed

24-27

Cool

Cool,Heat,Fan,Dry,Auto

Auto,Bps,HExc*

AutC,AutH,Norm**

Operation Mode

29-32

OK

OK or Xn, Xnn, nnnn

OK or Failure code

OK

Request Successfully Executed

ERROR:1

Unit with specified UID not found

4.1.15 stat

SYNOPSIS

DESCRIPTION

Get Indoor unit(s) status. Specific indoor unit can be addressed by UID. If no UID provided in request,

response will contain information about all units

EXAMPLE

>stat

100 ON 12C 12,41C High Cool OK

101 OFF 32C 04,93C Low Dry OK

102 ON 07C 08,27C High Dry OK

103 OFF 01C 26,84C Med Dry OK

104 ON 04C 24,08C High Dry OK

105 OFF 11C 07,23C Low Dry OK

106 ON 11C 14,91C Auto Dry OK

107 ON 27C 12,94C Med Cool OK

OK

>stat 101

101 OFF 32C 04,93C Low Dry OK

OK

stat [UID]

Rev 4.08

Commands Reference

17

RESPONSE

* - See vam command

** - See auto command

*** - In Fahrenheit mode Temperature is printed as NNNF, see example below:

101 ON 101F 057F Low Cool OK

EXIT CODE

COMPATIBILITY

This command is obsolete and is supported only for backward compatibility.

EXTENSIONS

CoolMaster 4000M PAC-YG Support

In CoolMaster 4000M v2.5.6 or higher for PAC-YG66 (digital I/O extender) and PAC-YG63 (analog I/O

extender), stat,stat2,stat3 commands output format will differ from the mentioned above.

www.coolautomation.com

© 2015 Cool Automation LTD

Page 18

CoolMaster PRM

Position in String

Example

Format

Description

0-2

012

NNN

PAC-YG66 Centralized Address

4-6

DIG

DIG

PAC-YG66 Identification

8-16

IN:001111

IN:XXXXXX

6 Digital inputs 1-6 status. X can be 0 or 1

18-27

OUT:0000001

OUT:XXXXXXX

6 Digital outputs 1-6 status. X can be 0 or 1

29-30

OK

OK or nnnn

OK or Failure code

Position in String

Example

Format

Description

0-2

011

NNN

PAC-YG63 Centralized Address

4-6

ANA

ANA

PAC-YG63 Identification

8-12

007.5

NNN.n

Analog input 1 value

13-17

278.8

NNN.n

Analog input 2 value

19-20

OK

OK or nnnn

OK or Failure code

· PAC-YG66. CoolMaster 4000M v2.5.6

Rev 4.08

>stat 012

012 DIG IN:001111 OUT:000001 OK

OK

· PAC-YG63. CoolMaster 4000M v2.5.6

>stat 011

011 ANA 007.5 278.8 OK

OK

Commands Reference

18

4.1.16 stat2

SYNOPSIS

DESCRIPTION

Get Indoor unit(s) status. Specific indoor unit can be addressed by UID. If no UID provided in request,

response will contain information about all units. stat2 compared to stat1 has additional Filter Reset

Sign indication

EXAMPLE

>stat2

100 ON 12C 12,41C High Cool OK 0

101 OFF 32C 04,93C Low Dry OK 1

102 ON 07C 08,27C High Dry OK 0

103 OFF 01C 26,84C Med Dry OK 0

104 ON 04C 24,08C High Dry OK 0

105 OFF 11C 07,23C Low Dry OK 0

106 ON 11C 14,91C Auto Dry OK 0

107 ON 27C 12,94C Med Cool OK 1

OK

>stat2 101

101 OFF 32C 04,93C Low Dry OK 0

OK

stat2 [UID]

www.coolautomation.com

© 2015 Cool Automation LTD

Page 19

CoolMaster PRM

Position in String

Example

Format

Description

0-2

109

NNN

Indoor unit Centralized Address

4-6ONON or OFF

On/Off Status

8-10

23C

NNC***

Set Temperature ºC

12-17

24,08C

NN,NNC***

Room Temperature ºC

20-23

Auto

Low,Med,High,Auto,Top

Fan Speed

25-28

Cool

Cool,Heat,Fan,Dry,Auto

Auto,Bps,HExc

AutC,AutH

Operation Mode

30-31/32/33

OK

OK or Xn, Xnn, nnnn

OK or Failure code

33/34/35

0

0 or 1

Filter Reset Sign present

OK

Request Successfully Executed

ERROR:1

Unit with specified UID not found

CoolMaster 1000D

v 0.3.1

CoolMaster 2000S

any

CoolMaster 3000T

any

CoolMaster 4000M

any

CoolMaster 6000L

any

CoolMaster 7000F

any

CoolMaster 8000I(MH)

any

CoolMaster 9000H

any

CoolMaster G

any

RESPONSE

* - See vam command

** - See auto command

*** - In Fahrenheit mode Temperature is printed as NNNF, see example below:

Rev 4.08

Commands Reference

101 ON 101F 057F Low Cool OK 0

EXIT CODE

COMPATIBILITY

19

SEE ALSO

CoolMaster 4000M PAC-YG Support

4.1.17 stat3,stat4

SYNOPSIS

stat3 [UID]

stat4 [UID]

DESCRIPTION

Get Indoor unit(s) status. Specific indoor unit can be addressed by UID. If no UID provided in request,

response will contain information about all units. stat3 compared to stat2 has no fractional part in the

room temperature presentation. stat4 compared to stat3 has additional THERMOSTAT_ON column.

EXAMPLE

>stat3

100 ON 12C 12C High Cool OK 0

101 OFF 32C 04C Low Dry OK 1

102 ON 07C 08C High Dry OK 0

OK

>stat4

www.coolautomation.com

© 2015 Cool Automation LTD

Page 20

CoolMaster PRM

Position in String

Example

Format

Description

0-2

109

NNN

Indoor unit Centralized Address

4-6ONON or OFF

On/Off Status

8-10

23C

NNC****

Set Temperature ºC

12-14

24C

NNC****

Room Temperature ºC

16-19

Auto

Low,Med,High,Auto,Top

Fan Speed

21-24

Cool

Cool,Heat,Fan,Dry,Auto

Auto,Bps,HExc

AutC,AutH

Operation Mode

26-27/28/29

OK

OK or Xn, Xnn, nnnn

OK or Failure code

stat3

***00 or 1

Filter Reset Sign present

stat4

***00 or 1

THERMOSTAT_ON (1-On, 0-Off)

OK

Request Successfully Executed

ERROR:1

Unit with specified UID not found

CoolMaster 1000D

v 2.0.9

CoolMaster 2000S

v 2.0.9

CoolMaster 3000T

v 2.0.9

CoolMaster 4000M

v 2.4.5

CoolMaster 6000L

any

CoolMaster 7000F

any

CoolMaster 8000I(MH)

any

CoolMaster 9000H

any

CoolMaster G

any

CoolMaster 1000D

v 2.7.8

CoolMaster 2000S

N.A.

CoolMaster 3000T

N.A.

CoolMaster 4000M

N.A.

CoolMaster 6000L

N.A.

CoolMaster 7000F

N.A.

CoolMaster 8000I(MH)

N.A.

Rev 4.08

100 OFF 01C 26C Med Dry OK 0 0

101 ON 04C 24C High Dry OK 0 1

102 OFF 11C 07C Low Dry OK 0 0

OK

>stat3 101

101 OFF 32C 04C Low Dry OK 0

OK

RESPONSE

Commands Reference

20

* - See vam command

** - See auto command

*** - Depends on Failure code format

**** - In Fahrenheit mode Temperature is printed as NNNF, see example below:

101 ON 101F 057F Low Cool OK 0

EXIT CODE

COMPATIBILITY

stat3

stat4

www.coolautomation.com

© 2015 Cool Automation LTD

Page 21

CoolMaster PRM

CoolMaster 9000H

N.A.

CoolMaster G

N.A.

Letter

Parameter

Result

o

on/off

0 - off

1 - on

m

mode

0 - Cool

1 - Heat

2 - Auto

3 - Dry

4 - Haux

5 - Fan

f

fan speed

0 - Low

1 - Medium

2 - High

3 - Auto

4 - Top

t

set temperature

e

failure code

0-OK, else failure code

same as in stat2

command

a

ambient temperature

h

set temperature with

0.01 precision

s

swing

0 - No Swing

a - auto

h - horizontal

3 - 30º

4 - 45º

6 - 60º

v - vertical

SEE ALSO

CoolMaster 4000M PAC-YG Support

4.1.18 query

SYNOPSIS

DESCRIPTION

Query on/off, operation mode, fan speed, set temperature, failure code or ambient temperature for unit

UID. Query result is provided in numeric or alpha-numeric (for failure code) format.

Rev 4.08

query <UID> <o|m|f|t|e|a|h>

Commands Reference

21

www.coolautomation.com

This command is intended for systems with low parsing capabilities.

EXAMPLE

>query 100 o

1

OK

>query 100 m

0

OK

© 2015 Cool Automation LTD

Page 22

CoolMaster PRM

OK

Request Successfully Executed

ERROR:1

Unit with specified UID not found

CoolMaster

v 2.6.1

query h

Only CoolMaster 1000D v 2.6.9

query s

v 2.8.4

>swing 101 a

OK

Set unit 1-01 swing to auto

>swing 101 h

OK

Set unit 1-01 swing to horizontal

>swing 101 3

OK

Set unit 1-01 swing to 30º

>swing 101 4

OK

Set unit 1-01 swing to 45º

>swing 101 6

OK

Set unit 1-01 swing to 60º

>swing 101 v

Set unit 1-01 swing to vertical

Rev 4.08

>query 100 t

25

OK

>query 100 a

27

OK

>query 100 f

2

OK

>query 100 e

U4

>query 101 e

0

OK

>query 101 h

20.50

OK

EXIT CODE

Commands Reference

22

COMPATIBILITY

4.1.19 swing

SYNOPSIS

DESCRIPTION

Set indoor unit <UID> swing to auto, horizontal, 30º, 45º, 60º or vertical. Not all indoor unit types

support swing.

EXAMPLE

swing <UID> <a|h|3|4|6|v>

www.coolautomation.com

© 2015 Cool Automation LTD

Page 23

CoolMaster PRM

OK

OK

Request Successfully Executed

ERROR:1

Unit with specified UID not found

CoolMaster 1000D

v2.5.1

CoolMaster 2000S

v2.3.1

CoolMaster 3000T

v2.3.1

CoolMaster 4000M

v2.3.1

CoolMaster 6000L

any

CoolMaster 7000F

v2.8.4

CoolMaster 8000I(MH)

any

CoolMaster 9000M

any

CoolMaster G

Supported: a,h

>temp 101 20

OK

Set unit 1-01 temperature to 20ºC

>temp 101 -1

OK

Decrease unit 1-01 temperature by 1ºC

>temp 101 +3

OK

Increase unit 1-01 temperature by 3ºC

>temp 101 20.5

OK

Set unit 1-01 temperature to 20.5ºC

OK

Request Successfully Executed

ERROR:1

Unit with specified UID not found

temp <UID> <XX.xx> support:

EXIT CODE

COMPATIBILITY

4.1.20 temp

SYNOPSIS

Rev 4.08

temp <UID> [±]<TEMPERATURE>

temp <UID> <XX.xx>

Commands Reference

23

DESCRIPTION

Set indoor unit set point temperature.

· In temp <UID> [±]<TEMPERATURE> form:

<TEMPERATURE> parameter must be integer number. Command can work in relative or absolute

manner. If plus '+' or minus '-' sign precede <TEMPERATURE> parameter it's value will be used as

requested delta. It means the set temperature will be increased (+) or decreased (-) by that delta.

Otherwise temperature will be set to the given value.

· In temp <UID> <XX.xx> form:

Temperature parameter can be fractal number with 0.01 precision. In this case preceding +|- are not

supported.

EXAMPLE

EXIT CODE

COMPATIBILITY

www.coolautomation.com

© 2015 Cool Automation LTD

Page 24

CoolMaster PRM

Only CoolMaster 1000D

v 2.6.9

>group 101 102

OK

Group units 1-01 and 1-02. Unit 1-02 will

follow all settings of the 1-01 unit.

>group

101-->101

102-->102

OK

List groups

group delall

Delete all groups

OK

Request Successfully Executed

ERROR:1

Unit with specified UID not found

CoolMaster 1000D

v 2.4.4

CoolMaster 2000S

v 2.4.4

CoolMaster 3000D

v 2.4.4

CoolMaster 4000M

v 2.4.4

CoolMaster 6000L

N.A.

CoolMaster 7000F

N.A.

CoolMaster 8000I(MH)

N.A.

CoolMaster 9000H

N.A.

CoolMaster G

any

Letter

Compatibility

1000D(DK)

4000M(ME)

6000L(LG)

a - Auto Mode

PPP

b - Bypass (Bps) Mode

P

P

x - Heat Exchange (HExc) Mode

PPP

n - Normal Mode

P

4.1.21 group

SYNOPSIS

DESCRIPTION

Without parameters group command will list current groups. With delall parameter command will

delete all groups. In format with two UID's command will group two units. First unit is a master, second

unit will follow all settings of the master unit. Grouping will take effect only after power reset of

CoolMaster.

EXAMPLE

Rev 4.08

group [<UID_MASTER> <UID>] | delall

Commands Reference

24

EXIT CODE

COMPATIBILITY

Before v2.5.6 number of groups is limited to 4. Beginning from v2.5.6 number of groups is limited to 20.

4.1.22 vam

SYNOPSIS

DESCRIPTION

This command controls VAM (Ventilation) HRV unit mode and fan speed.

vam <UID> a|b|x|l|L|h|H|s|A

www.coolautomation.com

© 2015 Cool Automation LTD

Page 25

CoolMaster PRM

l - Low Fan

PPP

L - Low Fan with Fresh-Up

P

h - High Fan

PPP

H - high Fan with Fresh-Up

P

s - Super High Fan

P

P

A - Auto Fan

P

P

>vam 101 a

OK

VAM unit 101 auto mode

>vam 101 L

OK

VAM unit 101 low fan speed with fresh-up

>vam 101 h

OK

VAM unit 101 high fan speed

OK

Request Successfully Executed

ERROR:1

Unit with specified UID not found

CoolMaster 1000D

v 2.4.7

CoolMaster 4000M

v 2.8.4

CoolMaster 6000L

v 2.8.0

On/off control for VAM units is performed with regular on off commands.

EXAMPLE

EXIT CODE

Rev 4.08

Commands Reference

25

COMPATIBILITY

4.1.23 lock

SYNOPSIS

DESCRIPTION

This command controls Locking (Prohibit) of the Wall Controller (Thermostat) operation for unit <UID>.

Following operations can be Locked/UnLocked:

· lock <UID>

Query current Lock settings

· lock <UID> +

Lock ALL

lock <UID>

lock <UID> +

lock <UID> lock <UID> [+|-][o|m|s] ...

o - On/Off

m - Mode change

s - Set Temperature change

n - On (CoolMaster 1000D Only)

· lock <UID> -

UnLock ALL

· lock <UID> <+|-><o|m|t> ...

www.coolautomation.com

© 2015 Cool Automation LTD

Page 26

CoolMaster PRM

>lock 101

+o -m -s

OK

Query Lock settings for unit 101

OnOff Locked

>lock 101 +

OK

Lock ALL for unit 101

>lock 101 OK

UnLock ALL for unit 101

>lock 101 +o -m

OK

Lock On/Off operation and UnLock Mode

change for unit 101

OK

Request Successfully Executed

ERROR:1

Unit with specified UID not found

CoolMaster 2000S

v 2.8.4

CoolMaster 3000T

v 2.8.4

CoolMaster 1000D

v 2.8.8

Letter

4000M(ME)

h - Heating Mode

P

e - ECO Mode

P

w - Hot Water Mode

P

a - Anti-freeze Mode

P

>wh 101 h

OK

set Water Heating unit 101 to Heating

Mode

>wh 101 a

OK

set Water Heating unit 101 to Anti-freeze

Mode

OK

Request Successfully Executed

ERROR:1

Unit with specified UID not found

Lock (+) or UnLock (-) specific operation(s).

EXAMPLE

EXIT CODE

COMPATIBILITY

Rev 4.08

Commands Reference

26

4.1.24 wh

SYNOPSIS

DESCRIPTION

This command controls Water Heating unit mode.

On/off control for Water Heating units is performed with regular on off commands.

EXAMPLE

EXIT CODE

wh <UID> <h|e|w|a>

www.coolautomation.com

© 2015 Cool Automation LTD

Page 27

CoolMaster PRM

CoolMaster 4000M

v 2.8.9

>feed 101 20

OK

Set unit 1-01 ambient temperature to 20ºC

>feed 101 -1

OK

Decrease unit 1-01 ambient temperature by 1ºC

>feed 101 +3

OK

Increase unit 1-01 ambient temperature by 3ºC

>feed 101 20.5

OK

Set unit 1-01 ambient temperature to 20.5ºC

OK

Request Successfully Executed

ERROR:1

Unit with specified UID not found

Only CoolMaster 4000M

v 2.9.0

COMPATIBILITY

4.1.25 feed

SYNOPSIS

DESCRIPTION

Provide indoor unit with ambient temperature measured by external device.

· In feed <UID> [±]<TEMPERATURE> form:

<TEMPERATURE> parameter must be integer number. Command can work in relative or absolute

manner. If plus '+' or minus '-' sign precedes <TEMPERATURE> parameter it's value will be used as

requested delta. It means that ambient temperature will be increased (+) or decreased (-) by that delta.

Otherwise ambient temperature will be set to the given value.

· In feed <UID> <XX.x> form:

Temperature parameter can be fractal number with 0.1 precision. In this case preceding +|- are not

supported.

Rev 4.08

feed <UID> [±]<TEMPERATURE>

feed <UID> <XX.x>

Commands Reference

27

For CoolMaster 4000M feed command is efficient only for Indoor units configured to take ambient

temperature from wall controller and not from internally measured return air temperature.

EXAMPLE

EXIT CODE

COMPATIBILITY

www.coolautomation.com

© 2015 Cool Automation LTD

Page 28

CoolMaster PRM

Step1

Disconnect power supply from the

CoolMaster

Step2

Open CoolMaster top cover

Step3

Open BOOT jumper shown on the

diagram

Step4

Connect power supply to CoolMaster

Rev 4.08

5 Firmware Update

5.1 Entering bootloader mode

The process of updating CoolMatser's firmware is very simple and straightforward. First of all

CoolMaster has be switched into bootloader mode. In order to do so, please connect your PC (Laptop)

to the RS232 port of the CoolMaster. Next open the Hyper Terminal program and run boot command.

This process is described in "User Manual" document. At this point "BOOT" message should appear

on the LCD screen of the CoolMaster. Now it is ready for firmware uploading. Please close Hyper

Terminal program and follow to the next step - Firmware Download.

If for some reason CoolMaster is not responding to boot command or preceding firmware update has

failed and CoolMaster is not functioning at all, follow the next steps in order to enter bootloader mode.

Firmware Update

28

For CoolMaster 7000F firmware update process is described in separate document. For details please contact

CoolAutomation support.

5.2 Firmware Download

Firmware update is supplied as a set of BAT file(s) and firmware image(s). BAT file can be for

example progp-DAIKIN.bat and corresponding image file DAIKIN.INC. Make sure that BAT file and the

image file are located in same directory. In order to start the process, please simply run the BAT file.

After running BAT file, the ComPort selection prompt will appear and the correct port number should be

entered in order to proceed.

www.coolautomation.com

© 2015 Cool Automation LTD

Page 29

CoolMaster PRM

Rev 4.08

Firmware Update

29

CoolMaster will react with running address counter on its LCD screen. The whole process may take

about a few minutes, and it ends with "EOF" and shortly afterwards "READY" messages on the LCD

screen.

5.3 Reboot

After firmware downloading has being finished you need to power reset CoolMaster. If it was entered

bootloader mode with BOOT jumper, please make sure to close BOOT jumper back before power

reset.

www.coolautomation.com

© 2015 Cool Automation LTD

Loading...

Loading...