Page 1

Drop-In Plancha

Installation Guide

Model Numbers

MPLD362CS-200, MPLD362CS-400,

MPLD362CR-200, MPLD362CR-400

MPLD Installation 13302_A USINTL

Page 2

Drop In Plancha Installation Guidelines

This document will provide guidelines for installing a drop-in Plancha. These

instructions apply to Cooktek model numbers: MPLD362CR-200, MPLD362CS-200,

MPLD362CR-400, and MPLD362CS-400.

The figures on the following pages show the necessary counter cut-outs and

maintenance access clearance. Read and understand thoroughly before attempting

installation.

For technical support, please call +1 (312) 274-9786 x 105.

The Plancha is comprised of a self-contained drop-in cooking module, plus two remote

control units (control knob and mode select button) which are connected via two 36”

(91.4 cm) long cables with push-in connectors. The power cord is hardwired in to the

unit and should be connected to a three phase supply (see spec. sheet for correct

voltage for each model number). The module is held securely in-place by a series of

studs (attached to unit) and nuts (provided). Once it is lowered into the required cutout, a bead of silicone or RTV should be used to completely seal the edge gaps to

prevent build-up of moisture and / or food debris under the rim. The counter should be

capable of supporting unit weight of 160lbs plus any applicable food load while using

the Plancha. The counter should be constructed out of stainless steel or suitably thick

stone so as to support the load.

The space directly in front and below the unit should be kept either open, or feature an

access panel at least 30” (76.2 cm) wide by 8” (20.3 cm) high centered on the unit for

maintenance access.

MPLD Installation 13302_A USINTL

Page 3

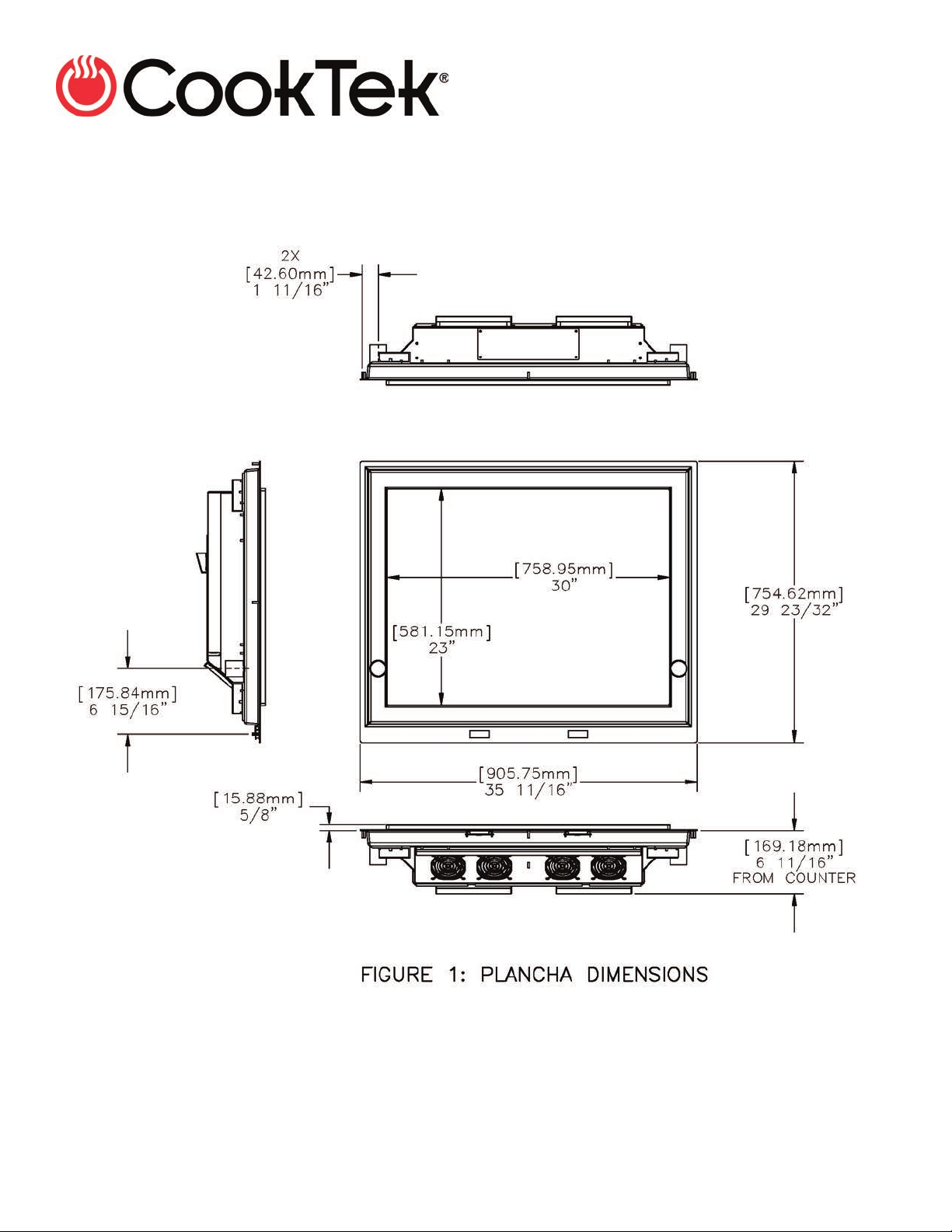

Figure 1 shows the overall general dimensions of the unit.

MPLD Installation 13302_A USINTL

Page 4

Figure 2 shows the required counter cut-out (essentially a large rectangle with two

smaller rectangular notches at the front edge).

MPLD Installation 13302_A USINTL

Page 5

Figure 3 shows the QTY 8 required Ø 5/16” (8 mm) holes for securing the unit to the

counter. The Plancha has #10-32 studs welded to the underside of the unit.

MPLD Installation 13302_A USINTL

Page 6

Figure 4 shows the required space below the bottom of the unit for maintenance. Front

access is also required for maintenance. Maintenance includes swinging the hinged

electronics base-plate away from the unit and disconnecting the control, display, power,

and litz cable. Once the cables are disconnected the base-plate can be removed.

MPLD Installation 13302_A USINTL

Page 7

Figure 5 shows the required cut-out for the grease drawers. Two drawers are installed

on either side of the unit and slide on qty 2 Ø0.375” x 26.75” long rods (included). The

back panel of the cabinet should have qty 2 holes matching those on the front

coincident vertical and horizontal placement. The rods are installed with qty 2 (per rod)

8-32 countersink screws (included). The specific location of the cut-out is shown with

respect to the center of the unit and the top of the counter.

MPLD Installation 13302_A USINTL

Page 8

Figure 6 shows a cut-away view of the grease drawers and installed rods.

MPLD Installation 13302_A USINTL

Page 9

Figure 7 shows the mode button and control knob cut-out. The cut-out is required

below both of the displays on the Plancha unit.

MPLD Installation 13302_A USINTL

Page 10

Figure 8 depicts a typical cross section for a flush mounted unit. An offset is formed

into the counter to allow for the 0.075” thick metal and a bead of silicone caulk to glue

the unit down. A bead of silicon should also fill the gap between the Plancha flange and

the vertical surface of the offset.

DO NOT WELD THE UNIT INTO PLACE AS

THIS CAN DAMAGE THE ELECTRONICS OF

THE UNIT AND WILL VOID THE WARRANTY

MPLD Installation 13302_A USINTL

.

Loading...

Loading...