Page 1

Universal Motor Pack

MOTORPACK ASSEMBLY INSTRUCTIONS

This publication contains universal motorpack assem-

bly instructions.

Carefully read this publication prior to installation, operation, or maintenance. For information and instructions

on special equipment, contact the Loren Cook Company

in Springfield, Missouri at (417) 869-6474.

Additional Information

For additional safety information, refer to AMCA publication 410-90, Safety Practices for Users and Installers

of Industrial and Commercial Fans. This bulletin can be

obtained from the Loren Cook Company Literature

Department by phoning 417/869-6474, extension 166; by

FAX at 417/832-9431; or by e-mail at info@lorencook.com.

Universal Motorpack Parts List

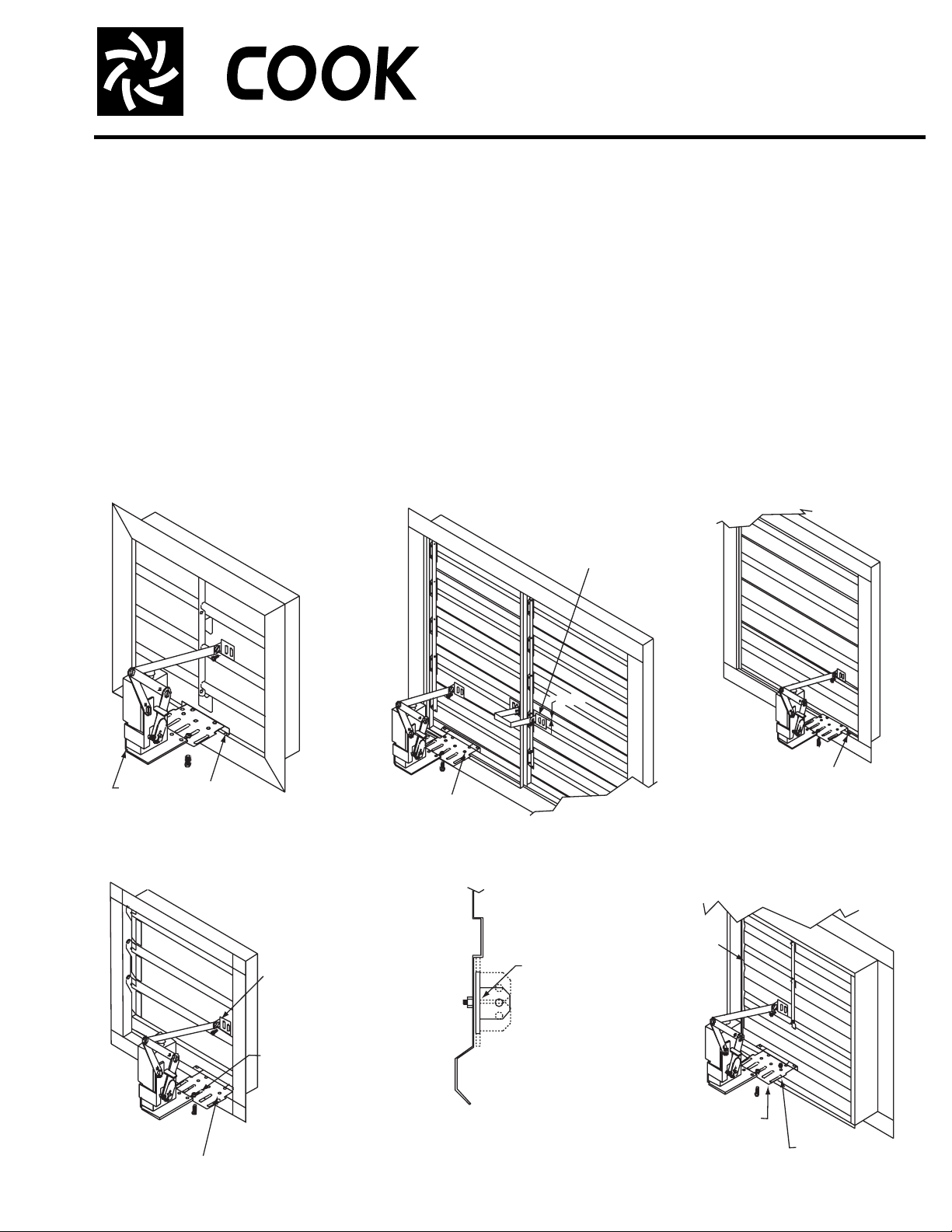

"P" Type Aluminum Shutters

"A" Type Heavy Duty

Aluminum Shutters

Assembly Instructions

Motorpack Assembly

You will need the following tools:

• Magic Marker

• 5/16 Wrench or Socket

• 3/8” Wrench or Socket

• 7/16” Wrench or Socket

• Powerdriver with 1/4” bit

or

Sheet Metal Uni-Bit

"A" Type Aluminum Shutters

Fasten blade bracket as

shown .13" from top of

blade using 10-32 x 3/8"

long Wizz bolts & Nylock nuts.

3rd Blade

2nd Blade

1st Blade

Scaled to

show more

detail

Mount using predrilled

holes & 1/4-20 x 1/2"

Wizz bolts & nuts.

"R" Type Galvanized Shutters Used

Bring arm straight out &

locate blade bracket near

the bottom of the 2nd blade

from the bottom of the

2nd Blade

1st

Blade

Mount using predrilled

holes & 1/420 x 1/2"

Wizz bolts & nuts.

shutter & mark location of

holes on blade. Drill (2) 1/4"

holes in blade & mount blade

bracket to blade using 10-32

Wizz bolts & Nylock nuts.

Fasten the motor mounting

bracket to shutter bracket

using 1/420 x 1/2" Wizz

bolts & nuts, mount near

center of bracket. Do not

tighten yet. After attaching

to blade, pull motor away

from shutter until blades are

shut tightly and then tighten

bolts.

2nd

Blade

Mark & drill 1/4"

holes then mount

using 1/4-20 x 1/2" Wizz bolts & nuts.

1

0.13

When marking hole

locations in blade,

pick a point that

will allow the most

up & down adjustment

of the bracket in the

slot. The adjustment

will prevent the need

to redrill new holes

in cases of binding. If

binding does occur,

loosen nut, adjust

then retighten nut.

Reference "R" type shutter mounting

instructions. Special Note: On this

type of shutter the motor should be

located as far from the shutter as the

mounting slots will allow.

"R" Type MIC Shutters

Center pivot

type shutter

2nd Blade

1st Blade

2nd

1st Blade

Mark & drill 1/4"

holes then mount

using 1/4-20 x 1/2"

Wizz bolts & nuts.

Blade

Mount using predrilled holes &

1/420 x 1/2"

Wizz bolts & nuts.

Page 2

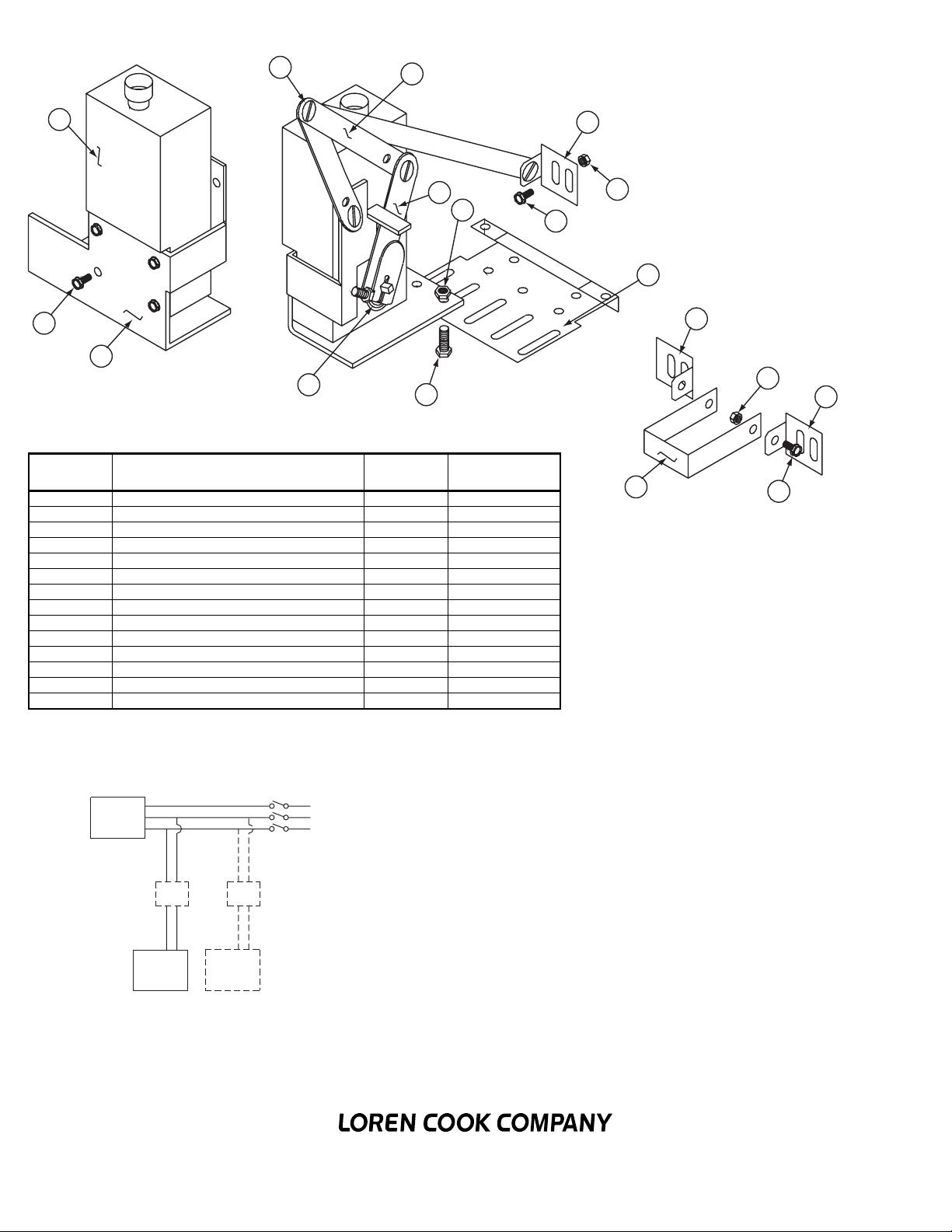

Universal Motorpack Parts List

2

3

1

4

14

13

12

Item

No.

1 Actuator Motor 554196 2 1/4” Long Screw Post & 8—32 Screw (4) 554225 3 Linkage Arm (4) 556764 4 Actuator Motor Arm 556766 5 1/4-20 Wizz Nut (4) 137555 6 Shutter Blade Bracket (3) 556128 556128-B

7 10-32 Nylock Nut (8) 137552 8 10—32 x 3/8” Wizz Bolt (8) 137573 -

9 Shutter Bracket 556121 556121-C

10 Two Panel Bracket 556123 556123-B

11 1/4—20 x 1/2” Wizz Bolt (4) 137578 12 Spring 554095 13 Actuator Motor Mounting Bracket 556126 556126-C

14 8—32 x 5/16” Hex Head Screw (4) 137502 -

* Lock-Tite all screw posts.

Description

Inventory

11

No.

5

Drawing

No.

6

7

8

9

6

7

6

10

8

Typical Damper Motor Schematic

Fan

Motor

Transformer**

Damper

Motor*

Second

Damper

Transformer**

Motor

Corporate Offices: 2015 E. Dale Street Springfield, MO 65803 417.869.6474

L3

L2

L1

For 3 phase, damper motor voltage should be the same between L1 and

L

. For single phase application, disregard L3. *Damper motors may be

2

available in 115, 230 and 460 volt models. The damper motor nameplate

voltage should be verified prior to connection. ** A transformer may be

provided in some installations to correct the damper motor voltage to the

specified voltage.

www.lorencook.com

2

Universal Motorpack Assembly Instructions - March 2005

Loading...

Loading...