COOK Lo-Pro User Manual

Lo-Pro

Low Profile Centrifugal Exhaust Fans

INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

This publication contains the installation, operation and

maintenance procedures for standard units of the “Lo-Pro”

(LPD & LPB) Low Profile Centrifugal Exhaust Fans.

Carefully read this publication and any supplemental documents prior to any installation or

maintenance procedure.

Loren Cook Company LC catalog provides additional

information describing the equipment, fan performance,

available accessories, and specification data.

For additional safety information, refer to AMCA

publication 410-96, Safety Practices for Users and

Installers of Industrial and Commercial Fans.

All of the publications listed above can be obtained from

Loren Cook Company by phoning (417)869-6474,

extension 166; by FAX at (417)832-9431; or by e-mail at

info@lorencook.com.

For information and instructions on special equipment,

contact Loren Cook Company at (417)869-6474.

Receiving and Inspection

Carefully inspect the fan and accessories for any damage and shortage immediately upon receipt of the fan.

• Turn the wheel by hand to ensure it turns freely and

does not bind.

• Check dampers (if included) for free operation of all

moving parts.

• Record on the Delivery Receipt any visible sign of

damage.

Handling

Lift the fan by the base or by the shipping carton.

NOTICE! Never lift by the shaft, motor or housing.

Rotating Parts & Electrical Shock Hazard:

Disconnect electric power before working on unit.

Follow proper lockout / tagout procedures to ensure

the unit cannot be energized while being installed or

serviced.

A disconnect switch should be placed near the fan in

order that the power can be swiftly cut off, in case of

an emergency and in order that maintenance

personnel are provided complete control of the power

source.

Grounding is required. All field-installed wiring must

be completed by qualified personnel. All fieldinstalled wiring must comply with National Electric

Code (NFPA 70) and all applicable local codes.

Failure to follow these instructions could result in

death or serious injury.

Storage

If the fan is stored for any length of time prior to installation, store it in its original shipping crate and protect it from

dust, debris and the weather.

Installation

The attachment of roof mounted fans to the roof curb

as well as the attachment of roof curbs to the building

structure must exceed the structural requirements

based on the environmental loading derived from the

applicable building code for the site. The local code

official may require variations from the recognized

code based on local data. The licensed engineer of

record will be responsible for prescribing the correct

attachment based on construction materials, code

requirements and environmental effects specific to

the installation.

Failure to follow these instructions could result in

death or serious injury.

To prevent damage to the fan during shipping, motors 5

HP and larger, and extremely heavy motors (cast iron or

severe duty) are shipped loose and must be field mounted

by bolting the motor on the motor mounting plate in the

existing mounting slots.

Damper Installation

If your fan is supplied with dampers, follow the directions

below. If your fan does not include dampers, proceed to

Belt and Pulley Installation.

a. Place the damper inside the curb. Ensure the damper

will open freely for the correct direction of the airflow.

b. Secure to curb at the damper shelf.

c. Drill a hole in the curb shelf for conduit needed for

motor wiring.

d. Operate the dampers manually to ensure the baldes

move freely.

e. Install ventilator over curb.

Lo-Pro

Conduit Nipple

Diverter

Terminator Lid

Sealing Nut

Terminator

Terminator

Terminator

Roof Top Installation Shown

Figure 4

Wall Installation

1 foot

1/4 inch

a. Position unit so that hinge on topcap is facing down.

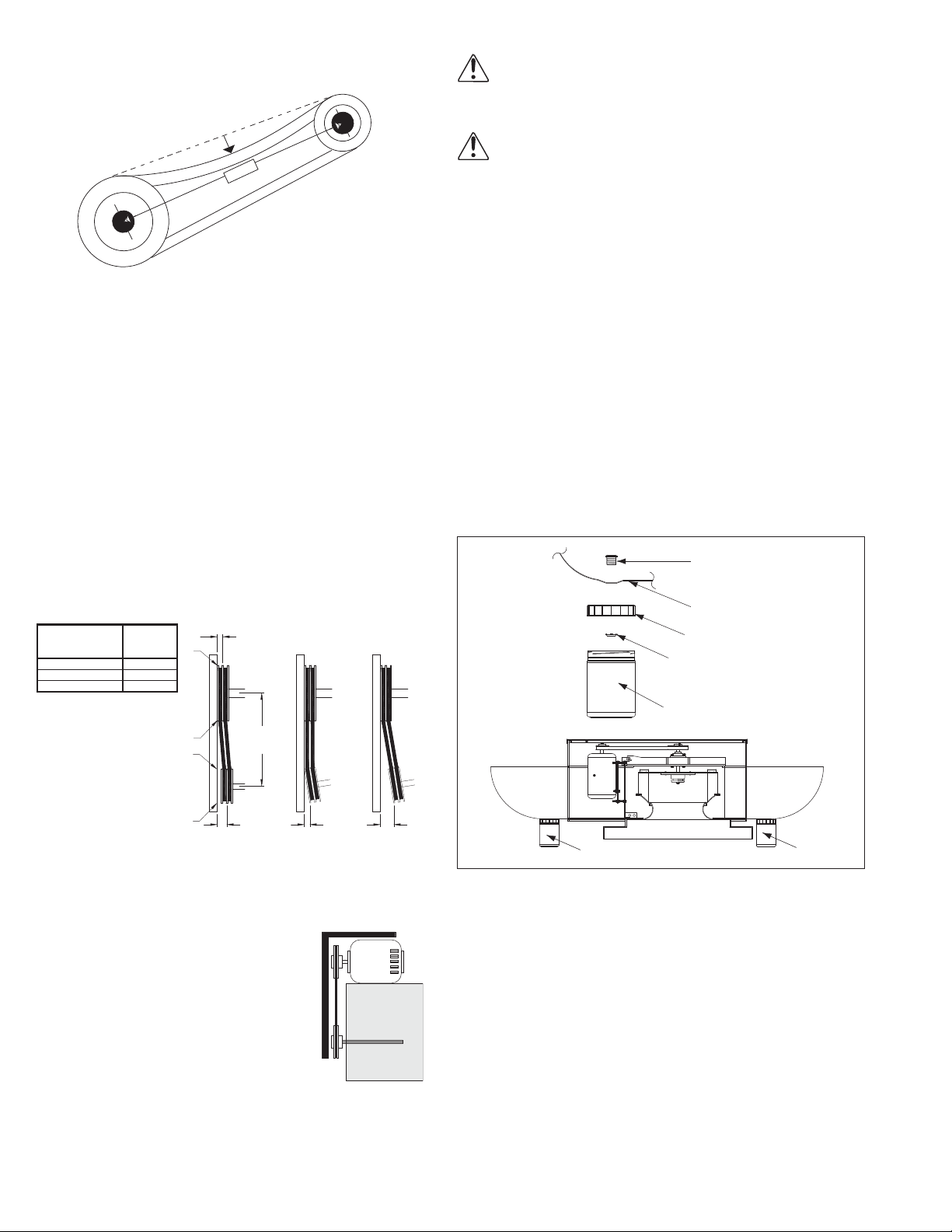

Belt and Pulley Installation

Figure 1

Belt tension is determined by the sound of the belts when

the fan is first started. The belts will produce a loud squeal,

which dissipates after the fan is operating at full capacity . If

belt tension is too tight or too loose, lost efficiency and

damage can occur.

Do not change the pulley pitch diameter to change tension. The change will result in a different fan speed. )

a. Loosen the motor plate adjustment nuts on motor

base and move motor plate in order that the belts can

easily slip into the grooves on the pulleys. Never pry,

roll, or force the belts over the rim of the pulley.

b. Adjust the motor plate until proper tension is reached.

For proper tension, a deflection of approximately 1/4”

per foot of center distance should be obtained by

firmly pressing the belt. Refer to Figure 1.

c. Lock the motor plate adjustment nuts in place.

d. Ensure pulleys are properly aligned. Refer to Figure 2.

Tolerance

Center Distance

Up thru 12” 1/16”

12” up through 48 1/8”

Over 48” 1/4”

Figure 2

Maximum

Gap

OFFSET ANGULAR OFFSET/ANGULAR

A

W

X

Y

CENTER

DISTANCE

(CD)

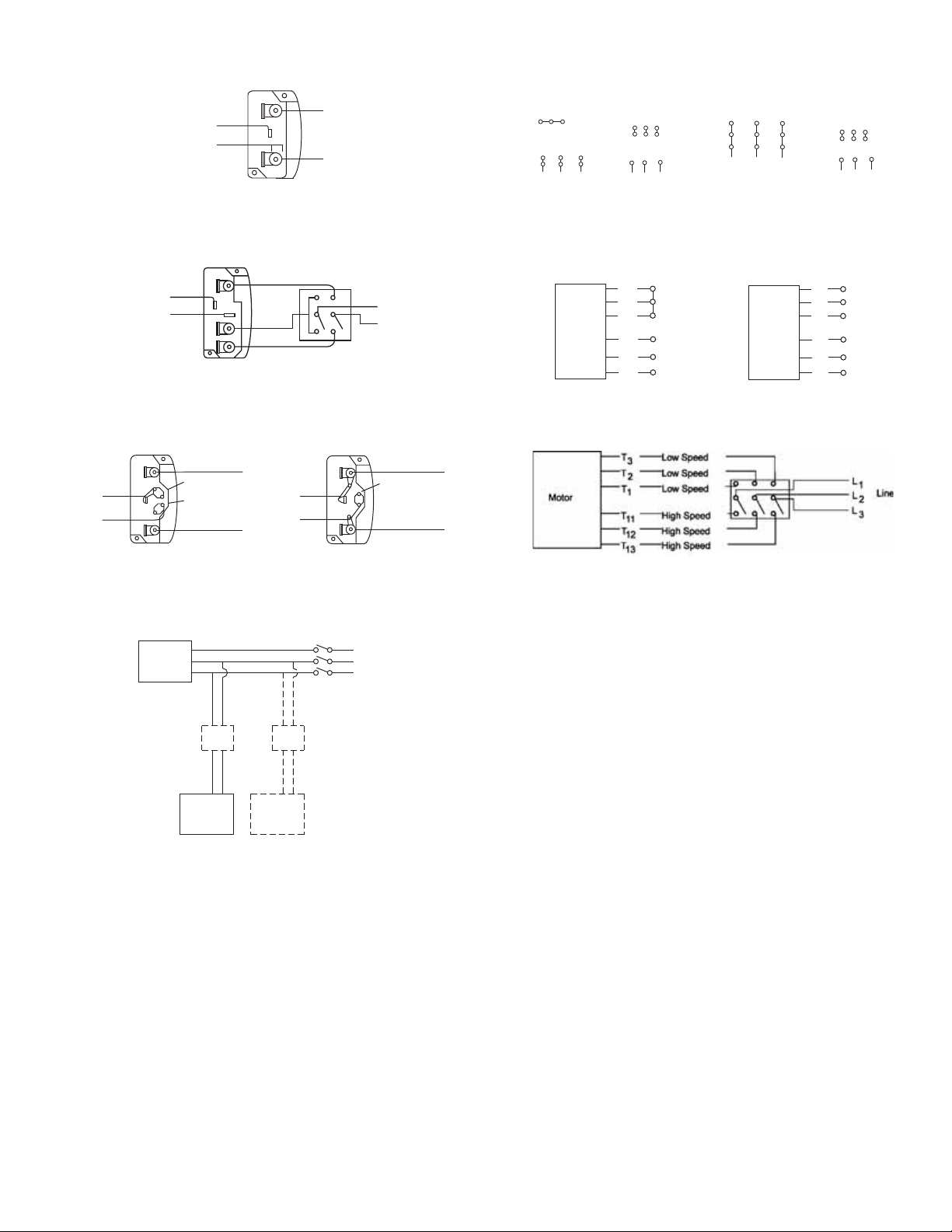

Wiring Installation

All wiring should be in accordance with local

ordinances and the National Electrical Code,

NFPA 70. Ensure the power supply (voltage, frequency, and current carrying capacity of wires)

is in accordance with the motor nameplate.

Refer to the Wiring Diagrams, next page.

Leave enough slack in the wiring to allow for motor movement when adjusting belt tension. Some fractional motors

have to be removed in order to make the connection with

the terminal box at the end of the motor.

NOTICE! Follow the wiring diagram in the disconnect

switch and the wiring diagram provided with the motor.

Correctly label the circuit on the main power box and

always identify a closed switch to promote safety (i.e.,

red tape over a closed switch).

Optional Diverter

a. Position diverter so that air flow is directed up.

b. Seal between diverter flange and unit side panel with

RTV 400 silicone. (RTV Silicone is NOT supplied.)

c. Use screws provided to secure diverter to unit.

Optional Grease Terminator Installation

a. Attach hardware to drain hole in the diverter.

See Figure 4.

b. Screw new canister into lid.

Roof Top Installation Shown

Conduit Nipple

Diverter

Terminator Lid

Sealing Nut

Terminator

Z

B

Pulley Alignment

Pulley alignment is adjusted by loosening the motor pulley

setscrew and by moving the motor pulley on the motor shaft.

Figure 2 indicates where to measure

GAP

GAP

the allowable gap for the drive alignment

tolerance. All contact points (indicated by

WXYZ) are to have a cap less than the

tolerance shown in the table. When the

pulleys are not the same width, the allowable gap must be adjusted by half of the

difference in width. Figure 3 illustrates

using a carpenter’s square to adjust the

position of the motor pulley until the belt

Figure 3

is parallel to the longer leg of the square.

Terminator

Figure 4

Terminator

Final Installation Steps

a. Inspect fasteners and setscrews, particularly fan

mounting and bearing fasteners, and tighten according

to the recommended torque shown in the table on

page 4, Recommended Torque for Setscrews/Bolts.

b. Inspect for correct amperage and voltage with an

ammeter and voltmeter.

c. Ensure all accessories are installed.

d. Check wheel-to-inlet clearance on power roof fans.

e. Test the fan to be sure the rotation is the same as indi-

cated by the arrow marked ‘Rotation’.

NOTICE! Do not allow the fan to run in the wrong

direction. This will overheat the motor and cause serious damage. For 3-phase motors, if the fan is running

2

Wiring Diagrams

Single Speed, Single Phase Motor

Ground A

L

T-1

T-4

Ground B

When ground is required, attach to ground A or B with no. 6 thread forming

1

Line

L

2

Wiring Diagrams

3 Phase, 9 Lead Motor

Y-Connection

Low Voltage

208/230 Volts

4

5

6

3

1

9

728

L2L

L

1

To reverse, interchange any 2 line leads.

3

High Voltage

460 Volts

456

789

3

12

L2L

L

1

208/230 Volts

3

3 Phase, 9 Lead Motor

Delta-Connection

Low Voltage

8

7

4

6

2

1

L

1

screw. To reverse, interchange T-1 and T-4.

2 Speed, 2 Winding, Single Phase Motor 2 Speed, 1 Winding, 3 Phase Motor

Ground A

High Speed

T-1

T-4

L

1

Line

L

2

Low Speed

Ground B

When ground required, attach to ground A or B with No. 6 thread forming

screw. To reverse, interchange T-1 and T-4 leads.

Motor

To reverse, interchange any 2 line leads. Motors require magnetic control.

High Speed

1

Together

2

3

L

4

1

L

5

6

L

Motor

2

Line

3

Single Speed, Single Phase, Dual Voltage 2 Speed, 2 Winding, 3 Phase

Ground A

L

T-5

J-10

Link A

Link B

Low Voltage

Ground B

Line

L

1

T-5

J-10

2

Ground B

When ground required, attach to ground A or B with No. 6 thread forming

screw. To reverse, interchange T-5 and J-10 leads.

Ground A

Link A & B

L

Line

L

1

2

To reverse: High Speed-interchange leads T11 and T12.

Low Speed-interchange leads T1 and T2. Both Speeds-interchange any 2

line leads.

Typical Damper Motor Schematic

9

5

3

L

3L2

Low Speed

1

2

3

4

5

6

High Voltage

460 Volts

789

456

3

12

L1L

L

3

2

L

1

L

2

Line

L

3

Open

Fan

Motor

Transformer**

Damper

Motor*

Second

Damper

Motor

L3

L2

L1

Transformer**

For 3 phase, damper motor voltage should be the same between L1 and

L2. For single phase application, disregard L3. *Damper motors may be

available in 115, 230 and 460 volt models. The damper motor nameplate

voltage should be verified prior to connection. **A transfomer may be provided in some installations to correct the damper motor voltage to the

specified voltage.

3

Loading...

Loading...