Page 1

Rigging and Installation Instructions for Single Piece

and Multiple Piece Energy Recovery Plenums

Due to the custom design and build nature of Loren Cook equipment these

instructions are given as general information and are not model specific.

This discussion is broken down into five separate sections of consideration for setting a

single or multiple piece Energy Recovery Plenum. These five areas are as follows:

Section 1.0: Pre-Lift considerations

Section 2.0: Receiving of the equipment

Section 3.0: Rigging of the equipment

Section 4.0: Assembly of the sections

Section 5.0: Finish work for the Installation

Section 6.0: Installation of Extended Exhaust Porch

Section 7.0: Recommended Tools

Page 2

1.0 Pre-Lift Considerations

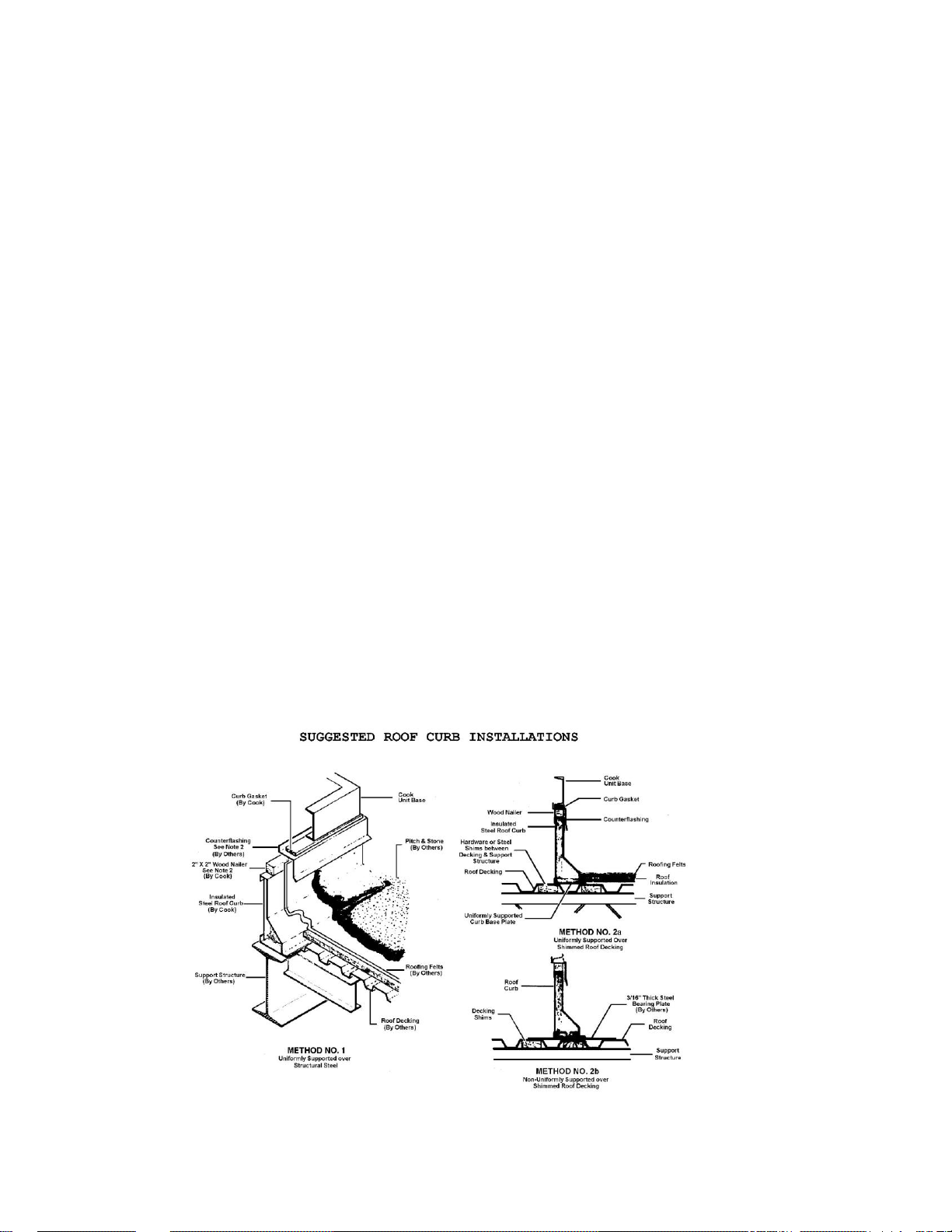

Curbs may be structural steel, formed concrete or formed metal. A Loren Cook supplied formed

metal curb will be shipped, unassembled, to the job-site prior to the shipping of the unit.

Scheduling of the curb will be the responsibility of the contractor. Each part of the curb is

identified with the proper tags and / or markings. Complete assembly instructions are shipped

with and attached to each curb package. Where more than one curb is shipped to one location,

there will be assembly instructions with and attached to each curb package. It is important the

curb be installed level and square and that it is checked for proper length and width. Each curb

is marked with matching serial numbers for each unit. The structural steel, concrete pad or

formed curb to be used should be level and of an even plane. Uneven surfaces at the point of

mating sections will cause considerable alignment problems. It would be beneficial to shoot the

grade with a transit prior to the lift. This will determine the high or low points of the installation

and thus the points to be shimmed as well as the amount of shimming material needed.

The curb installation shows a curb gasket that is mounted between the curb and the unit. When

Loren Cook supplies this gasket, it is not shipped with the curb, but shipped with the completed

unit and is so noted on the unit packing list. It is necessary to check the unit packing list for

location of the section of the unit in which the curb gasket is located. It is necessary to install

the curb gasket before setting the unit on the curb. This is necessary for an air seal between

the unit and the curb and also serves as dampening. However, this should not be used as a

vibration isolator where the prevention of noise and vibration transmission into the building is

critical.

Note: See section under receiving instructions when receiving curbs, inspecting for freight

damage and filing of freight damage claims. Any freight damage is the responsibility of the

receiving contractor and/ or his authorized receiving agent and the delivering carrier.

Page 3

2.0: Receiving of the Equipment

Most equipment delivered is shipped FOB Factory. Once the equipment is loaded on the trailer,

it ownership and responsibility transfers to the purchaser. The equipment is considered

delivered when the bill of lading is signed. Receiving the equipment and all of the “Shipped

Loose” components is the responsibility of the party signing the bill of lading presented by the

trucker. Prior to signing for the equipment, make an inspection of its physical condition and also

take an inventory of the listed “shipped loose” items. Should there be damaged or missing

items, note them on the bill of lading in the presence of the delivering agent of the carrier and

contact the factory immediately. If the decision is made by the contractor or representative

agent to accept the equipment it becomes the responsibility of the accepting party to file the

freight claim with the carrier in accordance with ICC regulations. It will also be the responsibility

of the contractor to ensure the equipment is repaired to the satisfaction of Loren Cook in order

to validate the warranty on the equipment. Proper handling of the equipment is mandatory

during unloading and setting it into position.

Note: If equipment is not set in its permanent position and is stored on the ground or other

unleveled area, proper provisions must be taken for supporting and protecting the

equipment. See section for both short term and long term storage.

Shipped Loose Parts:

1. Check the packing list for the list of shipped loose parts.

2. Packing list will note how many and what type of parts.

3. Packing list will note in what section of the unit and where each “shipped loose part”

is located.

4. All air filters are shipped as loose parts. Small rain hoods will be inside the units.

Large rain hoods will be outside the unit and so noted on packing list.

Storage

2.1.1 Short-Term Storage

Short-term storage is considered six (6) months or less from date shipment. Storage

maintenance during this time period is usually, but not necessarily, limited to the following:

A. Make sure the equipment is received and unloaded and set in position per guidelines listed

under “Rigging”.

B. Make sure all access doors are tightly closed and that all access openings into the unit are

sealed, such as air supply and air return openings, pipe chase openings, fresh air openings,

exhaust air openings, electrical connections openings and other access openings of the

unit’s cabinet that may permit entry of snow, ice, rain water, dust, dirt, mud and other

construction debris, or birds and rodents that may enter the interior of the unit.

C. The unit must also be protected when setting on the ground level to prevent damage to the

exterior of the cabinet by construction vehicles and or personnel.

Page 4

2.1.2 Long-Term Storage

Long-term storage is considered to be any period longer than six (6) months from date of

shipment. If long-term storage is anticipated, contact the Loren Cook sales office at time of

order entry for the proper instruction for long-term storage. It is mandatory that a detailed record

be maintained during this long-term storage period, such as, but not limited to, proper sealing of

the cabinet, rotation of the blowers and bearings and protection of all motors from moisture.

Note: Under certain conditions, it may be necessary to remove the motors from the unit and/or

add heat to the motor. This record must be available to Loren Cook should a failure occur

during the warranty period. There is a time limit of one year from date of shipment that any unit

may be kept in long-term storage. At the end of the one year period, the unit must be in

operation.

Note: Failure to perform the long-term storage requirements and properly log these required

procedures will void the warranty.

3.0 Rigging the Equipment

Decide which section of the equipment that would be most advantageous to set first. You may

need to consult the rigger in this decision. Items to be considered would be the reach of the

pick, configuration of the building and obstructions on the roof. It is important that an

experienced and reliable rigger be selected to handle unloading and final placement of the

equipment. Weight of the unit or of its individual sections is the key consideration. This will

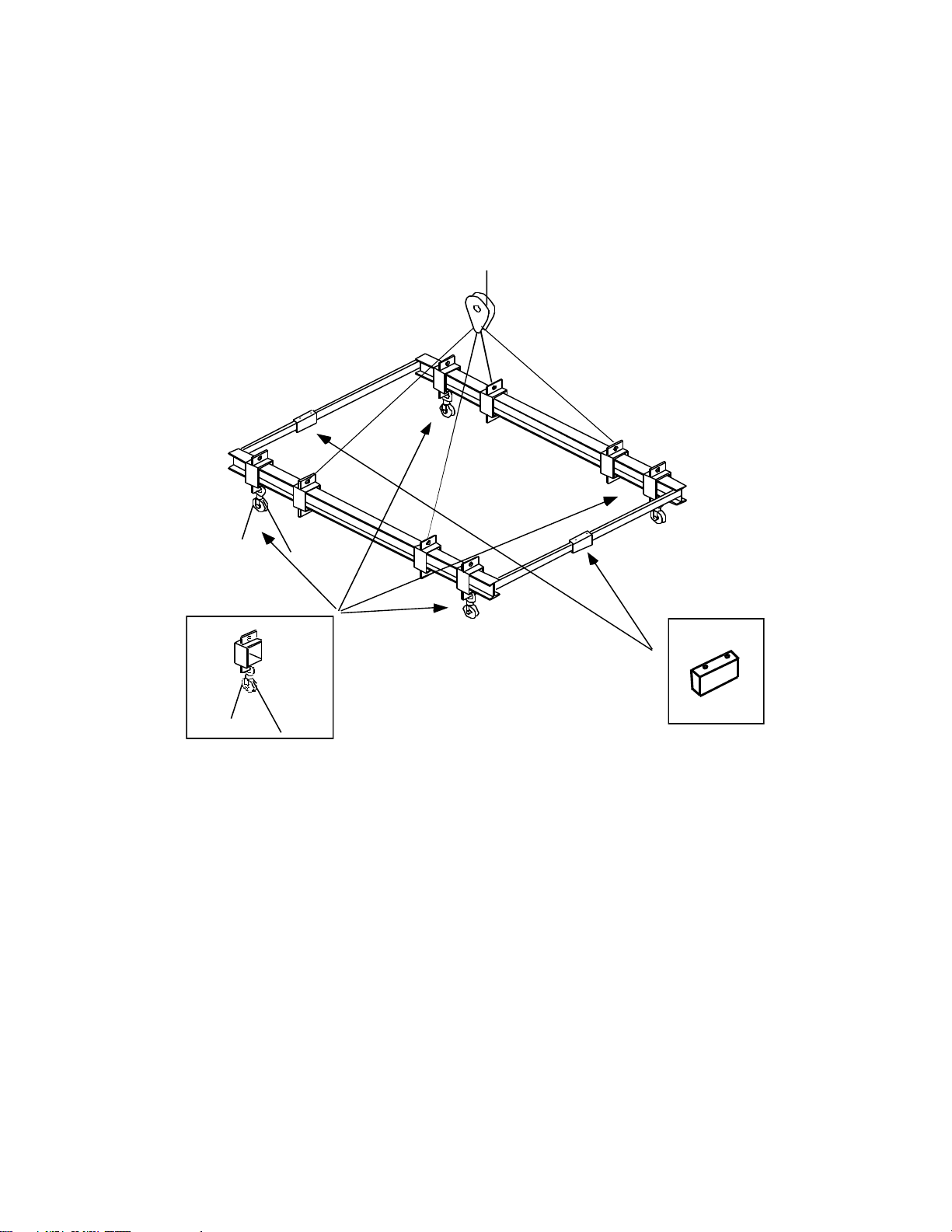

determine the size of the crane needed to execute the lift. The rigger should have spreader

bars capable of spanning both the width and length of the equipment. The rigging should

employ some method that allows self-leveling of the load. All of the cables tied to the

equipment should be reasonable confirmed to have the same stress as the section being lifted.

An imbalance or unleveled lift will damage piping and components installed in the equipment

and will not allow proper alignment of the sections as they are lowered into position.

Page 5

Adjustable pulley for

every two lifting eyes.

Adjustable clamp

for adjusting width

of spreader.

Figure 1 is an example of a rigging and spreader bar unit. This is only an example. Loren

Cook takes no responsibility for the design of the rigging and spreading apparatus. It is critical

that the proper spreader bars and hosting straps be used when rigging the unit. Your rigger

must be advised that the unit contains delicate components and that it is to be handled in an

upright position. Care must be exercised to avoid twisting the structure. The unit must be

rigged to assure a level lift. This will insure each piece will fit together with the least amount of

effort.

Figure 1

Page 6

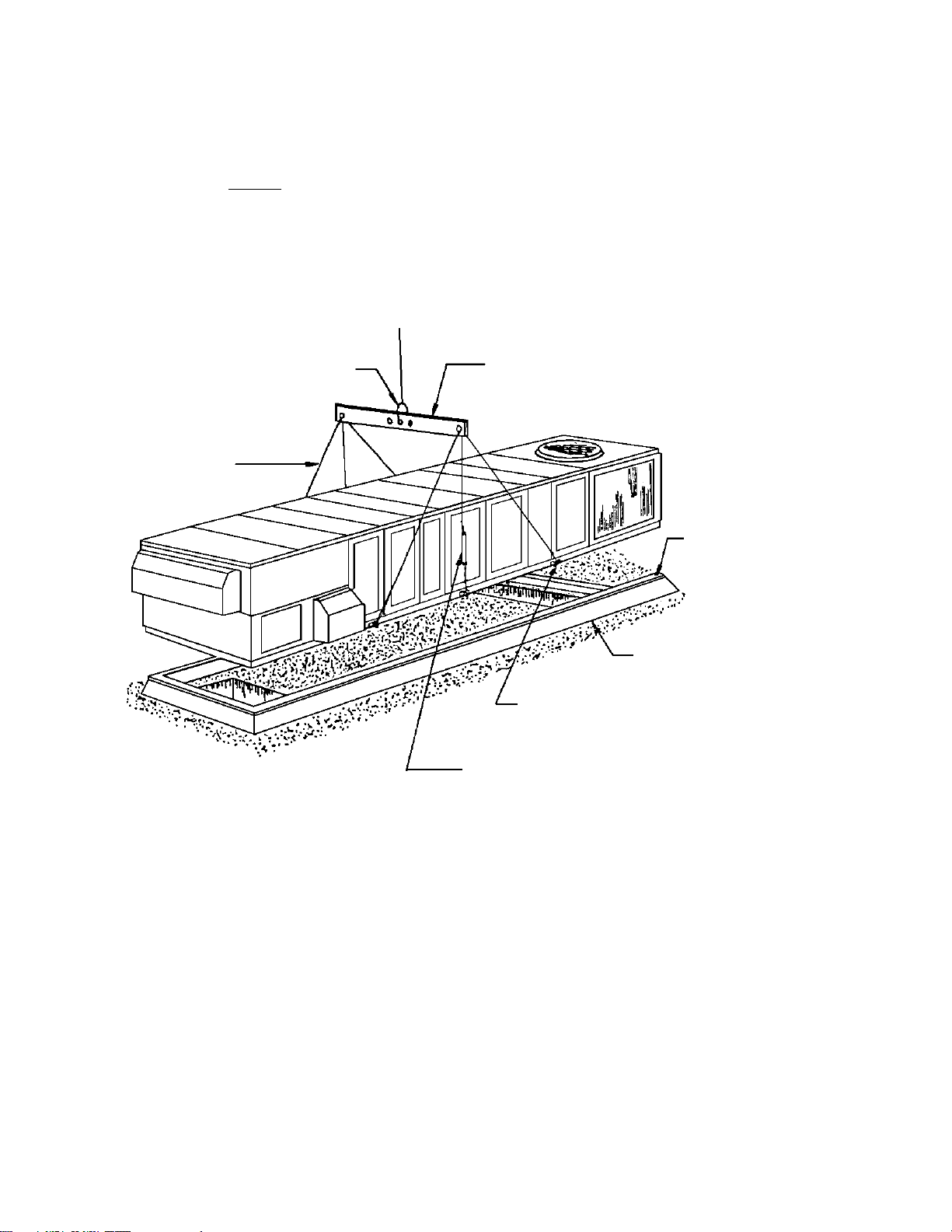

3.1 Rigging a Single Piece Unit

CLEVIS

HOISTING STRAPS

OF EQUAL LENGTH

SPREADER BAR MUST BE

LONG ENOUGH TO HOLD

HOISTING STRAPS AWAY FROM

UNIT TO PREVENT DAMAGE

TO CABINET.

CURB

GASKET

OPTIONAL FACTORY

SUPPLIED CURB

LIFTING LUGS

WHEN MORE THAN TWO LIFTING LUGS ARE SUPPLIED

ON EACH SIDE OF UNIT, AN ADJUSTABLE TURNBUCKLE MUST BE USED ON EACH SIDE TO EVEN

THE HOISTING LOAD ON EACH HOISTING STRAP. THIS

IS MANDATORY TO PREVENT DAMAGE TO THE UNIT.

NOTE: ALL LIFTING LUGS SUPPLIED MUST BE USED

FOR EACH LIFT!

Note: Use all of the lifting points provided on the equipment.

Loren Cook will not be responsible for damages incurred from not using all of the lifting points.

If the equipment is to set on a curb, install the curb gasket to the curb only. Do not apply curb

gasket to the unit’s base frame. The curb gasket is ½’ x 1 ¾” and is supplied with the unit.

Remove all of the sheet metal covers marked “Remove—For Shipping Purpose only” that may

interfere with the installation. When the unit is lifted, check the bottom for truck supports.

These supports will be 2” x 2” tubing screwed to the bottom of the unit to provide support to

units whose width exceeds that of the trailer that it was shipped on. Remove these as the unit is

lifted as they may interfere with the installation.

Page 7

3.2 Rigging a Multiple Section Unit

Note: Use all of the lifting points provided on the equipment.

Loren Cook will not be responsible for damages incurred from not using all of the lifting points.

Remove all of the sheet metal covers marked “Remove—For Shipping Purpose only” that may

interfere with the installation. When the unit is lifted, check the bottom for truck supports.

These supports will be 2” x 2” tubing screwed to the bottom of the unit to provide support to

units whose width exceeds that of the trailer that it was shipped on. Remove these as the unit is

lifted as they may interfere with the installation.

If the equipment is to set on a curb, install the curb gasket to the curb only. Do not apply curb

gasket to the unit’s base frame. Apply the demount gasket to the equipment. Do not double

gasket the sectional abutment. Apply the gasket to the face of only one of the mating sections.

Be sure that gasket is applied to the perimeter of the cabinet and also around the separate air

passages, which may exist on some units (i.e. units with heat reclaim, exhaust air, heat wheels,

multi-zone units, etc.) Demount gasket is 3/8” x 1” and is also supplied with the equipment.

Select the first section to be set and prepare for lifting. Rig into place being careful to place it

square and in line of the curb or support base. Once the first section is in place, secure it to the

supporting structure. When the second and continuing sections are set, they will be drawn to

the previous section. That is why it is necessary to secure the first section before proceeding. It

is critical that each section is rigged as level a possible.

Page 8

4.0 Assembly of the Sections

Apply the 1”x3/8” gasket material to the frame as shown in figure 3. Apply this gasket to only

one section of the two mating sections. Set the equipment as close as possible to the adjacent

sections and the remove the bolt-on lifting lugs if so equipped. There are demount lugs welded

to the base frame of the unit. These connection points are welded at the mating line of each

section. The equipment is supplied with ¾” all-thread, nuts and washers. Slide the all-thread

through the opening in the angles and install the washers and nuts. (Fig 3.2) Do not draw the

sections together at this time. Make sure that all of the bolt points around the upper perimeter

of the frame are aligned about their vertical axis. The crane should be used to get the sections

as close together as possible and at least every other bolt are to be installed and tightened

before unhooking from the crane. Some sections may be heavier than others thus causing

them to set down further. This can be overcome with the crane lifting slightly up on the heavier

section until the Demount bolts are installed. Shimming material may be required to be

installed between the base frame and the supporting member in order to level mating

sections. At this time, draw the sections tightly together using the demount bolts and the ¾”

all-thread. When the crane is unhooked, the two sections will settle together. The sections can

then be drawn together utilizing a chain type come-along if necessary. Do not bring up the next

section until these two sections are tightly together. Continue to bring up each section and

follow above directions until all sections are secured together.

Reference Figures 3.1 thru 3.3 for bolting configurations.

Page 9

Figure 3.2

Page 10

Figure 3.3 Bolting Method Inside Demount – Angles

Figure 3.4 Bolting Method Inside Demount – Flat Plates

Page 11

Figure 3.5 Bolting Method Inside Demount – Four Corner Connection

Page 12

4.1 Water Shedding Components

If the equipment is designed as an outdoor unit it will be supplied with a water shedding

roof installed over the paneled roof. Trim components to complete the seal of

demounted equipment will be shipped loose components. The illustrations of figures 6, 7

and 8 pictorially describe the installation of these components as related to the type of

roof design incorporated into the equipment.

Figure 6 Typical Outdoor Units, Water Shed Panels Parallel

Figure 6 shows the water shedding “Z” trim, Batten End Cap and Batten Strip at the demount

connection for outdoor equipment. The components must be installed in this order.

Page 13

Figure 8 Installing Ridge Cap and Flashing – Center Demounts

Figure 7 Typical Outdoor Units, Water Shed Panels Center Pitched Roof, Water Shed Panels

Perpendicular to Pitch of Roof

Figures 7 and 8 show how a demounted center (or double) pitched roof configuration is

assembled. Note: The water shedding panels are aligned perpendicular to the demount line.

The only parts that need to be assembled in the field are the ridge caps and the tall “L” trim as

indicated in figure 8. Apply sealant to the back side of this trim prior to installation of this trim.

Attach the ridge cap as shown in Figure 8 in the following section.

Page 14

5.0 Finish Work for the Installation

Once the equipment has been set and completely bolted together, the following finish work must

be done to complete the installation:

1. Caulk all demount seams with an RTV silicone clear caulk (not furnished) after the

sections have been secured.

2. Additional RTV silicone caulking should be applied to the interior of the cabinet around

any separate air passages and at the demount joints.

3. Re-caulk if and where caulking has been broken due to rigging or shipment.

4. Check to see that all doors are square. The rigging may sometimes warp the doors out

of alignment. This must be corrected before unit is started. Check all door latches and

re-adjust if necessary to maintain a good tight seal.

5.1 Electrical

Electrical wiring for controls and internal lighting circuits will require splicing where they cross a

demount line on Loren Cook units. A separate numbered terminal strip and conduit is provided

for the control wiring and internal lighting circuits, all wires are numbered to match the terminal

strips. A short piece of flexible conduit is provided on one side and a terminal box housing the

terminal strip is provided on the other side of demount to facilitate assembly.

Note: Loren Cook is not responsible for the demount mandated wiring requirements.

5.2 Refrigerant Line and Piping

All CW, HW and various black iron piping that crosses a demount will be flanged of union

joined. If the pipe is flanged, a flange gasket kit is provided. Check the packing list for the

location of the flange kits.

Note: Loren Cook is not responsible for the demount mandated piping requirement. Loren

Cook is not responsible for quality of workmanship during the pipe reconnection process

or warranty concerns associated with lack of proper piping techniques during this

process.

Page 15

6.0 Installation of Extended Exhaust Porch

The final step in assembly of the equipment is the installation of the extended exhaust.

1. Caulk base tube of porch and base tube of energy recovery coil plenum

2. Pull both sections together with the lifting lugs

3. Apply finish seam of caulk after the unit is bolted tightly together.(See Figure 9)

Assembly Instructions:

1. Apply degaseal 200 adhesive sealant or equal in a z-pattern on both sides of the

demount tubes.

2. Pull unit sections together by lugs and bolt together with supplied hardware.

3. Apply a finish seam of degaseal 2000 adhesive sealant or equal between the exterior

unit panel and the exhaust fan base (as seen in above picture).

Page 16

Page 17

Page 18

7.0 Recommended Tools

The following are recommended tools that the contractor should have on hand for the rigging.

Provisions of these tools are at the discretions of the installing contractor.

1. 6' Pinch Bar (2)

2. 3/4" Drift Pins (2)

3. Chain Come-Alongs (2)

4. 3/4" Box Wrenches (2)

5. 3/4" Socket Wrenches (2)

6. 1 1/8” Box Wrenches (4)

7. Lengths of chain w/ hooks

8. Battery Operated Screwdrivers (4)

9. Assorted Hand Tools (i.e., Hammers, Screw Drivers, Vise Grips)

10. Welder

11. 4” x 4” Shimming Material (Various Gauges)

12. Grease or Silicon Caulk.

Limited Warranty

Loren Cook Company warrants that your Loren Cook fan was manufactured free of defects in materials and workmanship, to the extent stated herein.

For a period of one (1) year after date of shipment, we will replace any parts found to be defective without charge, except for shipping costs which will

be paid by you. This warranty is granted only to the original purchaser placing the fan in service. This warranty is void if the fan or any part thereof has

been altered or modified from its original design or has been abused, misused, damaged or is in worn condition or if the fan has been used other than

for the uses described in the company manual. This warranty does not cover defects resulting from normal wear and tear. To make a warranty claim,

notify Loren Cook Company, General Offices, 2015 East Dale Street, Springfield, Missouri 65803-4637, explaining in writing, in detail, your complaint

and referring to the specific model and serial numbers of your fan. Upon receipt by Loren Cook Company of your written complaint, you will be notified,

within thirty (30) days of our receipt of your complaint, in writing, as to the manner in which your claim will be handled. If you are entitled to warranty

relief, a warranty adjustment will be completed within sixty (60) business days of the receipt of your written complaint by Loren Cook Company. This

warranty gives only the original purchaser placing the fan in service specifically the right. You may have other legal rights which vary from state to

state.

LOREN COOK COMPANY

Corporate Offices: 2015 E. Street Springfield, MO 65803 417.869.6474

WWW.LORENCOOK.COM

ENERGY RECOVERY PLENUM IOM – November 2013

Loading...

Loading...