Page 1

1

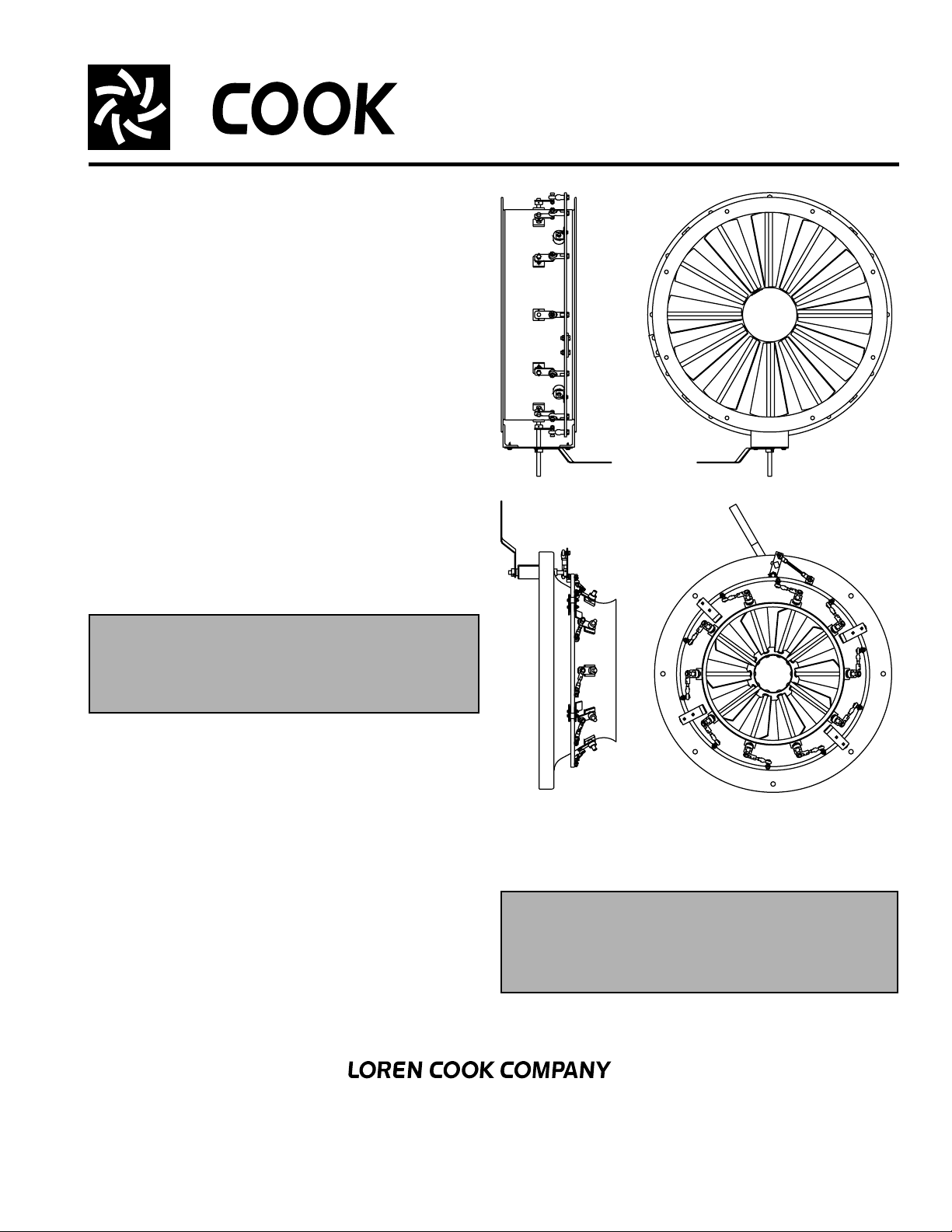

Inlet Vane Damper

INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

This publication contains the installation, operation

and maintenance instructions for standard Inlet Vane

Damper’s on Centrifugal Blower

Carefully read this publication prior to any installation or maintenance procedure.

For additional safety information, refer to AMCA publication 410-96,

Industrial and Commercial Fans.

All of the publications listed above can be obtained from

Loren Cook Company by phoning 417/869-6474, extension

166; by FAX at 417/862-0968; or by e-mail at info@lorencook.com.

For information on special equipment or torque settings,

contact Loren Cook Company Customer Service Department at 417/869-6474.

Receiving and Inspection

Carefully inspect the Inlet Vane Damper for any damage

and shortage immediately upon receipt.

• Turn the blower wheel by hand to ensure it turns freely

and does not bind.

• Inspect dampers for free operation of all moving parts.

• Record on the

age.

WARNING

This unit has rotating parts. Safety precautions

should be exercised at all times during installation,

operation, and maintenance.

ALWAYS disconnect power prior to working on fan.

Safety Practices for Users and Installers of

Delivery Receipt

units.

any visible sign of dam-

External

Nested

Handling

Lift unit by the outside housing or by the blower mounting

brace. Never lift by the linkage.

Storage

If the unit is stored for any length of time prior to installa-

tion, store the unit in its original shipping crate.

Preventive Maintenance

• Check for freedom of operation.

• Check for excessive wear.

• Semi-annually, the linkage should be lubricated with light

weight oil, and inspected for wear. Replace if necessary.

• When equipped with actuator, the manufacturer’s recom-

mended maintenance procedure should be observed.

Check visually to see that the vane position agrees with

the position of the control arm.

2015 E. DALE STREET

SPRINGFIELD, MO 65803-4637

www.lorencook.com

NOTE: Only recommended for non-ducted inlets.

If the unit is a double width fan equipped with variable inlet

vane control, synchronize both inlet vanes so that they are in

the same relative position with respect to the impeller on

both inlets).

WARNING

Un-synchronized inlet vanes cause an unbalanced

flow between inlets, which results in deficient air

performance, unbalanced thrust on the bearings and/

or a surge condition in the fan.

Make certain that as variable inlet vanes close they cause

entering air to spin in the same direction as the impeller.

417.869.6474

Inlet Vane Damper IOM - October 1999

Loading...

Loading...