Page 1

1

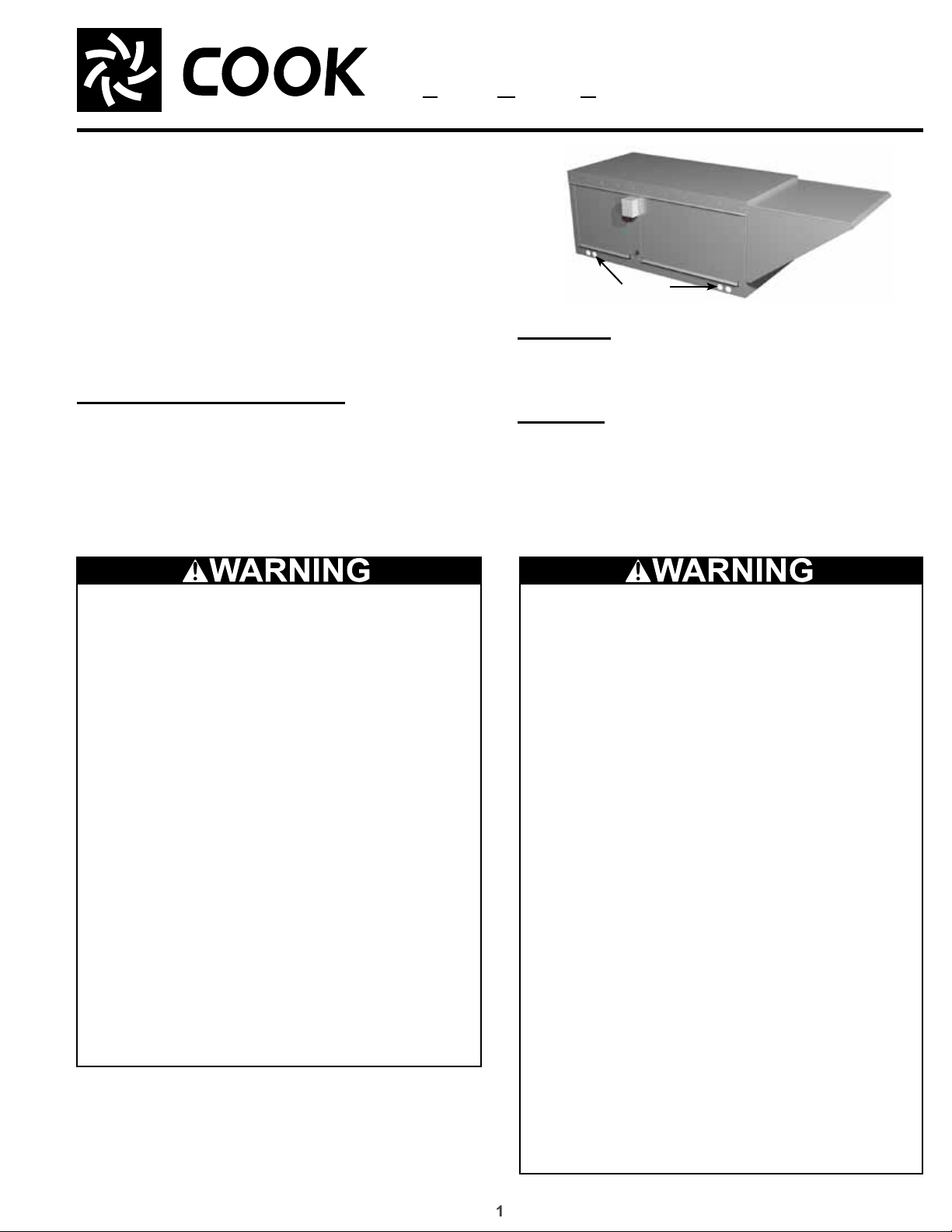

Heated Makeup Direct: A Direct Fire Make-Up Air Unit

®

This installation manual provides information for

installing and conguring the Loren Cook Company HMD.

Models: HMD-2400, HMD-3400, HMD-4100.

For information and instructions on special equipment,

contact Loren Cook Company.

For additional safety information, refer to AMCA

publication 410-96, Safety Practices for Users and

Installers of Industrial and Commercial Fans. This

document and all Cook publications may be obtained from

Cook by phoning (417) 869-6474, extension 166; by FAX

at (417) 832-9431; or by e-mail at info@LorenCook.com.

All Cook publications are available on LorenCook.com.

Installation, Operation, And Maintenance Manual

Receiving and Inspection

Carefully inspect the unit and accessories for any

damage and shortage immediately upon receipt of the unit.

• Turn the blower by hand to ensure it turns freely and

does not bind.

• Record on the Delivery Receipt any visible sign of

damage.

HMD

Lifting

holes

Handling

Lift unit fans by the lifting holes or by the shipping

container. Never lift by the housing.

Storage

If the fan is stored for any length of time prior to

installation, store it in its original shipping crate and protect

it from dust, debris and the weather.

Rotate the wheel several revolutions every three to ve

days to keep a coating of grease on all internal bearing

parts.

WARNING: Improper installation,

adjustment, alteration, service or

maintenance can cause property damage,

injury or death. Read the installation,

operating and maintenance instructions

thoroughly before installing or servicing this

equipment.

FOR YOUR SAFETY

If you smell gas:

1. Open windows.

2. Don’t touch electrical switches.

3. Extinguish any open ame.

4. Immediately call your gas supplier.

FOR YOUR SAFETY

The use and storage of gasoline or other

ammable vapors and liquids in open

containers in the vicinity of this appliance is

hazardous.

Fire Or Explosion Hazard

Installation and service must be performed

by a qualied installer, service agency or

gas supplier.

Intake Air

If HMD unit is used for make-up air for any

type of fuel burning equipment, HMD unit

must NOT be primary source of intake air.

Consult fuel burning equipment manufacture

for requirements and recommendations.

Environmental Hazards

Other considerations may be required if high

winds or seismic activity are present. If more

information is needed, contact a licensed

professional engineer before moving

forward.

Improper installation, adjustment, alteration,

service or maintenance can cause serious

injury, death or property damage. Carefully

read this publication and any supplemental

documents prior to any installation or

maintenance procedure.

Page 2

2

Installation

Rotating Parts & Electrical Shock Hazard

Improper installation and handling can

result in electric shock, possible injury due

to coming in contact with moving parts, as

well as other potential hazards.

Disconnect electric power before working

on unit.

Follow proper lockout / tagout procedures to

ensure the unit cannot be energized while

being installed or serviced.

A disconnect switch should be placed

near the fan in order that the power can

be swiftly cut off, in case of an emergency

and in order that maintenance personnel

are provided complete control of the power

source.

Verify that the power source is compatible

with the equipment. Grounding for the motor

is required. All eld-installed wiring must

be completed by qualied personnel. All

eld installed wiring must comply with local

electrical and safety codes, National Electric

Code(NEC), the National Fire Protection

Agency (NFPA 70), and Canadian Electric

Code (CEC) – when in Canada.

Clearance to Combustible / Service Clearances

The minimum distance required between the heater and

adjacent combustible surfaces is 42 inches (1066.8 mm),

on the controls side of the unit, to ensure the adjacent

surface’s temperature does not exceed 90 degrees above

the ambient temperature.

For specic dimensions, refer to the submittal drawing

for the specic fan type.

Installation of the heater (1) in airplane

hangars must be done in accordance with

the Standard for Aircraft Hangars, ANSI/NFPA

409, and (2) public garages must be done in

accordance with the Standard for Parking

Structures, ANSI/NFPA 88A, or the Standard

for Repair Garages, ANSI/NFPA 88B, and with

CAN/CSA B149.1 Natural Cas and Propane

Installation Codes.

NOTICE! Adequate building relief shall be provided

so as to not over pressurize the building when the

heating system is operating at its rated capacity. It

should be noted that this can be accomplished by

taking into account, through standard engineering

methods, the structure’s designed inltration rate;

by providing properly sized relief openings; or by

interlocking a powered exhaust system; or by a

combination of these methods.

NOTICE! All indoor and outdoor units require

that the air to the heater is ducted directly from

the outdoors. Recirculation of room air is not

permitted.

NOTICE! The heater inlet shall be located in

accordance with the applicable building code

provisions for ventilation air.

Do not allow the power cable to kink

or come in contact with oil, grease, hot

surfaces, or chemicals. Replace cord

immediately if damaged.

Never open blower access doors while the

fan is running.

Failure to follow these instructions could

result in death, serious injury or property

damage.

NOTICE! Field constructed intake accessories

should be properly designed to minimize the entry

of snow and rain.

NOTICE! If in doubt regarding the application, consult

the heater manufacturer.

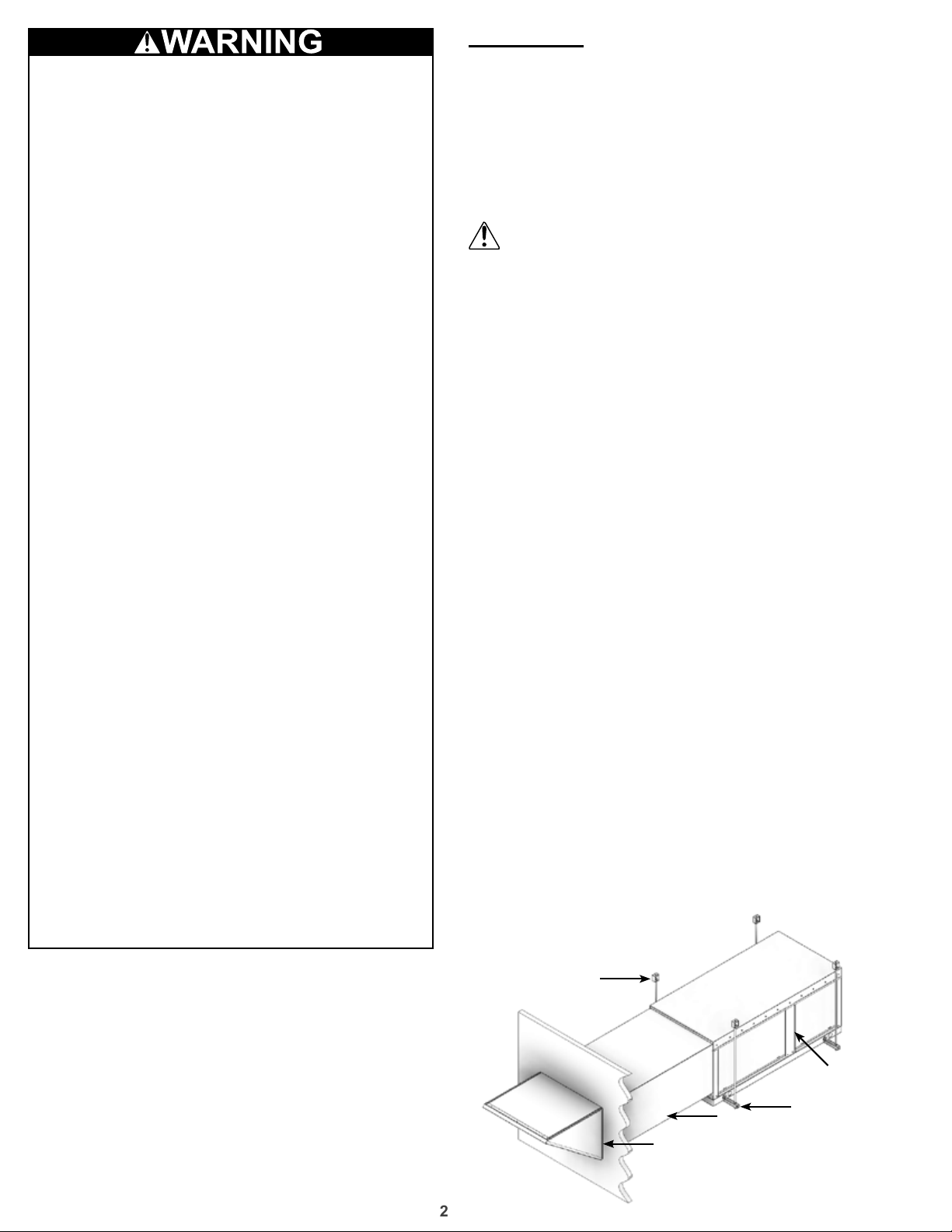

Indoor Hanging Arrangement

1. Install threaded hangers from ceiling supports.

When locating hangers, allow enough room to open

access panel(s). Two nuts must be used on the end

Hanging Mount Example

Hangers

Wiring Entry

Unit

Duct

Sealant

Supports

Page 3

3

of each threaded hanger. Ceiling supports are not

supplied.

2. Using sheet metal screws, attach the weatherhood/

thru-wall / lter section to the damper / burner

section. The ange on the weatherhood / thru-wall

/ lter section should overlap the ange on the

damper / burner section.

3. Raise the unit into place

4. Using two nuts per hanger, fasten the unit supports

to the hangers under the unit. Appropriate unit

supports, such as the optional hanging bracket kit

or c-channel and angle iron (not included) should be

used.

5. Attach ductwork to unit using self-tapping screws

NOTICE! In order to prevent the unit from swinging

and to provide a safe environment for service and

maintenance, additional measures may be needed to

secure the unit.

Good duct practices should be followed for

all ductwork. Ductwork should be installed

in accordance with SMACNA and AMCA

guidelines, NFPA 96 and any local codes.

NOTICE! When a duct work system is attached to

the inlet of the heater purge the volume of the duct

system with at least four air changes prior to an

ignition attempt.

6. Apply sealant around the perimeter of the

weatherhood to prevent water penetration and drafts

into the building.

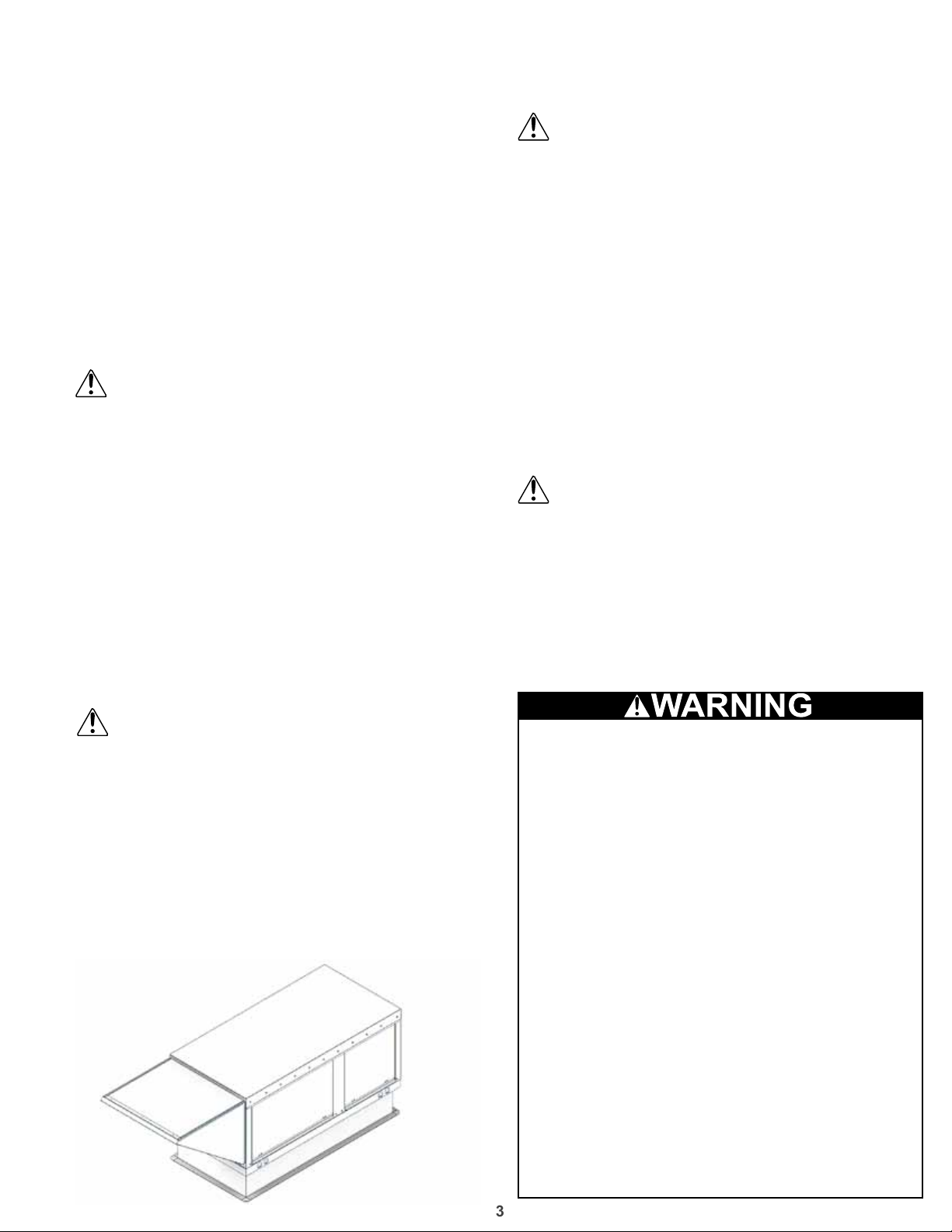

Curb Arrangement

1. Position curb on the roof. Verify that unit supports

are level, shim if necessary.

2. Attach curb to roof, ash in place

3. Attach ductwork to unit using self-tapping screws

Good duct practices should be followed for

all ductwork. Ductwork should be installed

in accordance with SMACNA and AMCA

guidelines, NFPA 96 and any local codes.

4. Apply an appropriate sealant around the perimeter

of the curb and duct adapter(s) to isolate fan

vibration and prevent water penetration

5. Use the 4 lifting lugs to lift and place unit on the

curb. A crane with a spreader bars is required.

6. NOTICE! Do not include a wood nailer. Use self-

tapping sheet metal screws to fasten the unit to the

curb support.

7. The weatherhood can now be assembled and

Curb Mount Example

attached to the unit.

8. Using an appropriate sealant, seal the seam

between the weatherhood and the unit.

Wiring

All wiring should be done in accordance with

the latest edition of the National Electric Code

ANSI / NFPA 70 and any local codes that may

apply. In Canada, wiring should be done in

accordance with the Canadian Electrical Code.

NOTICE! The equipment must be properly

grounded. Any wiring running through the unit in

the airstream must be protected by metal conduit,

metal clad cable or raceways.

NOTICE! If any of the original wire as supplied with

the heater must be replaced, it must be replaced

with type TW1 600v wire or its equivalent.

NOTICE! Field-wiring having a temperature rating

of at least 105ºC shall be used and supply circuit

wiring shall have a minimum size of 14 AWG.

NOTICE! High voltage electrical input is needed for

this equipment.

An electric disconnect switch having adequate

ampacity (see marking on the heater for

voltage and ampacity), if not provided as part

of the heater, shall be installed in accordance

with Article 430 of the National Electrical Code,

ANSI/NFPA 70.

1. The unit’s nameplate states the voltage and the

unit’s MCA. The main power lines to the unit should

be sized accordingly. The nameplate is located on

the outside of the unit on the control panel side.

2. Install eld electrical wires through the provided

Custom work

Any wiring deviations may result in personal

injury or property damage. Manufacturer

is not responsible for any damage to, or

failure of the unit caused by incorrect nal

wiring.

Manufacturer’s standard control voltage is

120 VAC. Control wire resistance should not

exceed 0.75 ohms (approximately 285 feet

total length for 14 gauge wire; 455 feet total

length for 12 gauge wire). If the resistance

exceeds 0.75 ohms, an industrial-style

plug-in relay should be wired in place of

the remote switch. The relay must be rated

for at least 5 amps and have a 120 VAC

coil. Failure to comply with these guidelines

may cause motor starters to chatter or not

pull in, resulting in contactor failures and/or

motor failures.

Page 4

4

holes.

Ground A

3 Phase, 9 Lead Motor

3 Phase, 9 Lead Motor

3. Connect the main power lines to the disconnect

switch and main grounding lug(s). Torque eld

connections to 20 in.-lbs.

4. Wire the optional convenience outlet. The

convenience outlet requires a separate 115V power

supply circuit. The circuit must include short circuit

protection which may need to be supplied by others.

Single Phase

When ground is required, attach

to ground A or B with no. 6

thread forming screw. To reverse,

T-1

T-4

interchange T-1 and T-4

Ground B

Three Phase

A complete wiring diagram is attached on

the inside of the control center door(s). It is

also available in the HMD Wiring Diagram

Supplement.

Y-Connection

Low Voltage

208/230 Volts

4

5

6

1

728

3

9

L2L

L

3

1

High Voltage

460 Volts

456

789

12

L2L

L

1

Delta-Connection

Low Voltage

208/230 Volts

7

6

1

3

L

1

3

High Voltage

9

8

5

4

3

2

L

L

3

2

12

Gas

All gas piping must be installed in accordance

with local codes, or in the absence of local

codes, in accordance with the National Fuel

Gas Code, ANSI 2223.1/NFPA 54, or the

CAN/CSA B149.1 Natural Cas and Propane

Installation Code.

Do not connect the unit to gas types other than

what is specied and do not connect the unit to gas

pressures that are outside of the pressure range

shown on the label.

When connecting the gas supply, the length

of the run must be considered in determining

the pipe size to avoid excessive pressure drop.

Refer to a Gas Engineer’s Handbook for gas

pipe capacities.

Refer to the heater rating plate for determining

the minimum gas supply pressure for obtaining

the maximum gas capacity for which this heater

is specied.

1. Determine the supply gas requirements by looking

at the unit’s nameplate on the outside of the unit on

the control center side.

2. When the supply gas pressure exceeds the maximum

gas pressure shown on the nameplate, an additional

regulator (by others) is required to reduce the

pressure. The regulator must have a listed leak

limiting device or it must be vented to the outdoors.

The regulator located inside the unit is used to adjust

the unit’s maximum output temperature.

460 Volts

789

456

3

L

L

1

2

3. If an optional vent line is located between the safety

shutoff valves it must be piped to the outdoors.

Reference the National Fuel Gas Code for

additional vent line requirements.

4. Test the system for leaks.

Operation

L

1

Line

L

2

Follow the pre start-up list before

proceeding. Follow the procedure in the

exact order that it is presented.

Failure to do so could result in serious injury

or death and damage to equipment.

Pre Start-Up:

General

1. Get: voltage & amperage meter, thermometer, micro

amp meter, u-tube manometer & tachometer.

2. Perform a gas leak check during heater start-up, to

verify the gas tightness of the heater’s components

L

3

and piping under normal operating conditions.

3. Disconnect and lock-out all power and gas.

Blower

1. Check the housing, blower, and ductwork for any

foreign objects before running the blower.

2. Rotate the fan wheel by hand and make sure no

parts are rubbing. Check the V-belt drive for proper

alignment and tension (a guide for proper belt tension

and alignment is provided in the Belt Maintenance

section).

3. Check fasteners, set screws and locking collars on

the fan, bearings, drive, motor base, and accessories

for tightness.

4. Compare the supplied voltage, hertz, and phase with

the unit and motor’s nameplate information.

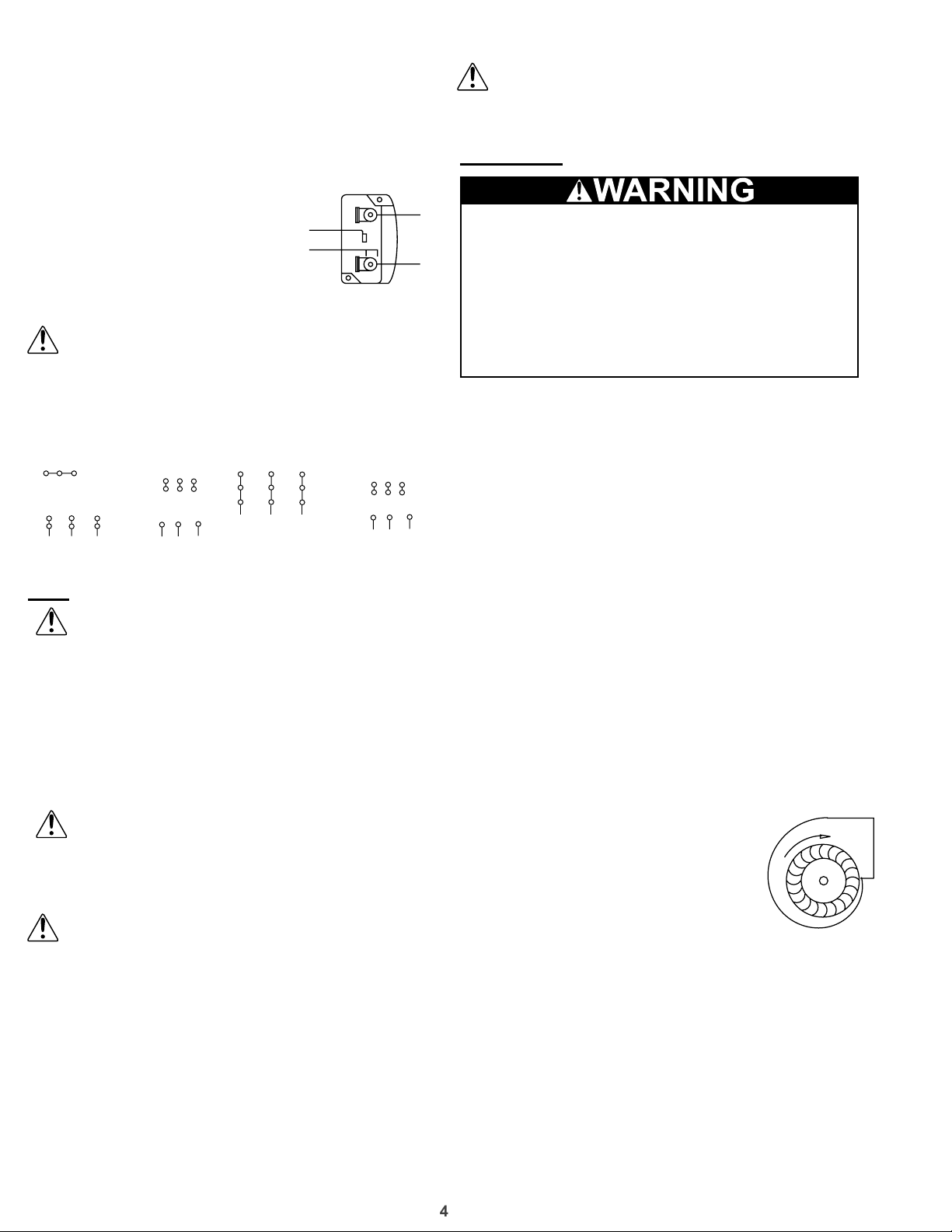

5. Open the blower access door and run

the blower momentarily to determine

the rotation. Arrows are placed on the

blower scroll to indicate the proper

direction.

NOTICE! If the blower is rotating in

the wrong direction, the unit will move

some air, but will not perform as designed. Be sure

to perform a visual inspection to guarantee the

correct blower rotation.

• To reverse the rotation on three phase units,

disconnect and lock-out the power, then interchange

any two power leads.

• To reverse the rotation on single phase units,

disconnect and lock-out the power, then rewire the

motor per the motor manufacturer’s instructions.

6. Check for unusual noise, vibration or overheating

of the bearings. Reference the Troubleshooting

section for corrective actions. Excessive vibration

Pre Start-Up

Page 5

5

may be experienced during the initial start-up. Left

unchecked, it can cause a multitude of problems

including structural and/or component failure.

Generally, fan vibration and noise is transmitted

to other parts of the building by the ductwork. To

minimize this undesirable effect, the use of heavy

canvas duct connectors is recommended.

7. Measure the motor’s voltage, amps and RPM.

Compare to the specications. Motor amps can be

reduced by lowering the motor RPM or increasing

system static pressure. Additional starters and

overloads may be provided in the make-up air

control center for optional exhaust blowers. Any

additional overloads must be checked for proper

voltage and amps.

8. Measure the unit’s air volume (cfm) and compare

it with its rated air volume. If the measured air

volume is wrong, adjust the fan’s RPM by changing/

adjusting the drive. The most accurate way to

measure the air volume is by using a Pitot traverse

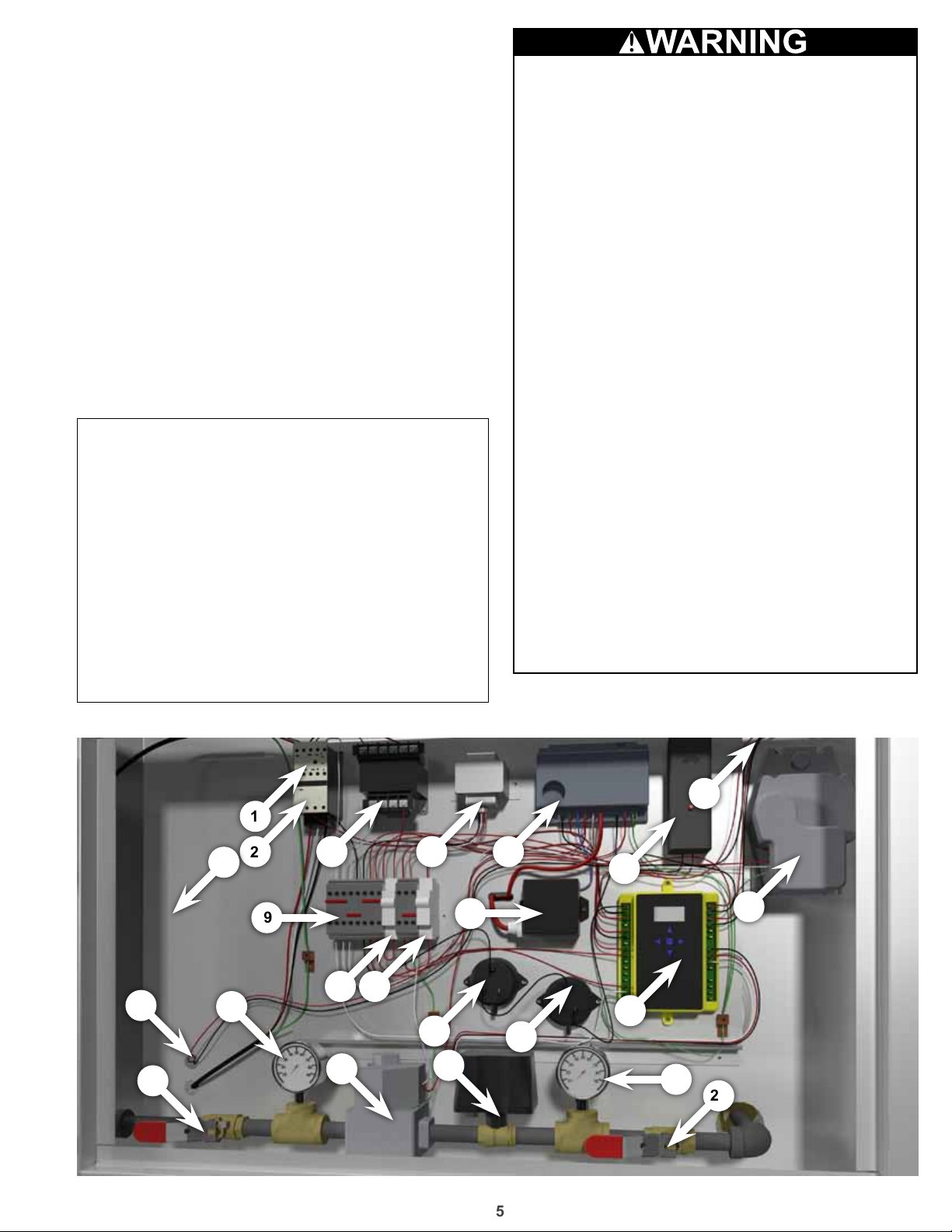

Control Panel Parts

1. Contactor

2. Overload

3. Three phase

transformer #A

4. 120 - 24v

transformer #B

5. Ignition control

6. High Temp Overload

7. Mild weather thermostat

to damper

8. Damper motor

9. Terminal blocks

10. Circuit breaker

11. Override switch

12. 120v spark ignitor

13. Pressure sensing probe

(high)

14. Pressure sensing probe

(low)

15. Temperature controller

16. Thermostat to blower

17. Safety Shut off valve

18. Pressure gauge

19. Gas valve

20. Modulating gas valve

21. Pressure gauge

22. Safety Shut off valve

23. Optional V.F.D. here

Testing Inspection

All components of this or any other gasred heating unit must be leak tested prior

to placing the unit into operation. The

factory piping has been checked for leaks

but should be rechecked due to shipping &

installation issues. The eld-installed shutoff

valve should also be checked.

A soap & water solution should be used to

perform this test.

Never test for gas leaks with a ame.

When leak testing pressures that are less

than or equal to 14 in. wc (3.5 kPa), rst

close the eld-installed shutoff valve to

isolate the unit from gas supply line.

When leak testing presures that are more

than 14 in. wc (3.5 kPa), close the eld-

installed shutoff valve, disconnect the

furnace & gas train from the gas supply line

& plug the supply line before testing.

All piping should be clean & free of any

foreign matter, which may damage the

values, regulators or burner.

Control Panel

16

17

1

2 3 4 5

23

9

10 11

18

13

19

20

12

7

6

8

15

14

21

22

Page 6

6

method downstream of the blower. Changing the air

volume can signicantly increase the motor’s amps.

If the air volume is changed, the motor’s amps must

be checked to prevent overloading the motor. To

ensure accuracy, the dampers are to be open when

measuring the air volume.

9. Adjust the settings on the optional components.

See the Control Center Layout in the Reference

section for location of optional components.

• Heating Inlet Air Sensor

Typical setting: 60-70ºF

• Building Freeze Protection

Typical setting: 45ºF

• Dirty Filter Gauge

Typical setting: Settings vary greatly for each unit.

Gas

1. Check the supply gas pressure and compare it with

the unit’s nameplate pressure requirements. Adjust

the supply regulator as needed until the supply gas

pressure is within the specied range (see below).

The nameplate is located on the outside of the unit

on the control panel side.

2. Check the settings on the optional high and low

gas pressure switches. The high pressure setting is

typically 8 inches wc (2 kPa) and the low pressure

is setting is typically 3 inches wc (0.7 kPa). The

switches are set at the factory and should not need

adjustment. Adjust the setting only if needed. The

purpose of the high and low gas pressure switches

is to automatically shut down the burner if the inlet

gas pressure is too low for the burner to safely

light, or if the manifold pressure is too high for the

burner to operate properly. Proper air velocity over

the burner is critical on direct red gas units. If the

air velocity is not within the unit specications, the

unit will not operate efciently, may have sporadic

shutdowns, and may produce excessive carbon

monoxide (CO) or other gases.

3. With all access panels in place, the fan running

and discharging 70ºF (21ºC) air, connect a U-Tube

manometer to the outer sensing probes and

measure the static pressure across the burner.

The proper static pressure should be (check CFM /

Static Pressure chart on page 8). If needed, evenly

adjust the bafes, keeping the burner centered in

the opening until the required pressure is obtained.

The pressure drop was set at the factory and may

not need adjustment. When required pressure is

obtained, be sure to reconnect the outer sensing

probes. This process may need to be repeated until

the proper pressure is achieved. This adjustment

will change the air quantity delivered by the unit

and therefore the air quantity delivered should be

rechecked. Refer to the Blower Start-Up section.

• To increase static pressure decrease the opening.

• To decrease static pressure increase the opening.

4. Monitor the unit’s actual temperature rise by placing

a thermocouple in the unit’s inlet and a second in

the discharge, three duct diameters downstream

of the burner. Send the unit to maximum ame

by changing the rotation of the motor pack from

left to right. Use a screw driver on top of modular

gas valve. While monitoring the unit’s temperature

rise, set the maximum ring rate by adjusting the

regulator until the designed temperature rise is

achieved. After setting the maximum ring rate,

reconnect the wire to the amplier. Do not set the

burner maximum ring rate based on gas pressure.

It should be set based on the unit’s designed

temperature rise shown on the label. Setting the

maximum ring rate during mild weather conditions

may cause the high limit to trip out during extreme

conditions requiring manual resetting. Gas trains

are equipped with a combined regulator valve.

Clockwise rotation increases the temperature

rise; counterclockwise rotation decreases the

temperature rise. The minimum setting for the

maximum ring rate may be higher than required.

This is acceptable, the burner will modulate as

needed. To convert from Natural Gas to LP or vice

versa follow the instructions associated with the

high re gas valve.

5. Set the operating temperature.

Maintenance - All year

V-Belt Drives

NOTICE! Do not pry belts on or off

the sheave. Loosen belt tension

until belts can be removed by

simply lifting the belts off the

sheaves. When replacing

V-belts on multiple groove

drives, all belts should

be changed to provide

uniform drive loading.

Do not install new belts

on worn sheaves. If the

sheaves have grooves

worn in them, they must be replaced before new

belts are installed.

Tolerance

Center Distance Maximum Gap

Up thru 12” 1/16”

12” up through 48 1/8”

Over 48” 1/4”

1/4 inch

1 foot

Page 7

7

NOTICE! Premature or frequent belt failures can

be caused by improper belt tension, or misaligned

sheaves. Abnormally high belt tension or drive

misalignment will cause excessive bearing loads

and may result in failure of the fan and/or motor

bearings. Abnormally low belt tension will cause

squealing on start-up, excessive belt utter,

slippage, and overheated sheaves.

1. V-belt drives must be checked on a regular basis for

wear, tension, alignment, and dirt accumulation.

2. Check the tension by measuring the deection in the

belt as shown here.

3. Check the alignment by using a straight edge across

both sheaves. The drawings below show where to

measure the allowable gap for the drive alignment

tolerance. All contact points (indicated by WXYZ)

are to have a gap less than the tolerance shown in

the table. When the pulleys are not the same width,

the allowable gap must be adjusted by half of the

difference in width.

Snow Accumulation

Clear snow away from roof mounted units. Keep the

snow clear of the intake and access doors.

Motors

Motor maintenance is generally limited to cleaning and

lubrication (where applicable). Cleaning should be limited

to exterior surfaces only. Removing dust and grease build-

up on the motor assures proper motor cooling.

Motors supplied with grease ttings should be greased

in accordance with the manufacturer’s recommendations.

Greasing motors is only intended when ttings are

provided. Many motors are permanently lubricated,

requiring no additional lubrication.

NOTICE! Do not allow water or solvents to enter

the motor or bearings. Motors and bearings should

never be sprayed with steam, water or solvents.

Relubrication Intervals

NEMA Frame Size

Service

Conditions

Up to and

including 184T

1800

RPM

and

less

Over

1800

RPM

213T-365T 404T and larger

1800

RPM

and

less

Over

1800

RPM

1800

RPM

and

less

Over

1800

RPM

size. The instructions provided in this manual and those

provided by the bearing manufacturer will minimize any

bearing problems.

Lubricate bearings prior to periods of extended

shutdowns or storage and rotate shaft monthly to aid in

corrosion prevention. If the fan is stored more than three

months, purge the bearings with new grease prior to start-

up.

Motors are provided with a polyurea mineral oil NGLI #2

grease. All additions to the motor bearings are to be with

a compatible grease such as Exxon Mobil Polyrex EM and

Chevron SRI.

The above intervals should be reduced to half for vertical

shaft installations.

Relubrication Intervals

RPM Temp °F Greasing Interval

Up to 1000

1000 to 3000

Over 3000

Any Speed < -30 Consult Factory

Any Speed > 200 1 week

-30 to 120 6 months

120 to 200 2 months

-30 to 120 3 months

120 to 200 1 month

-30 to 120 1 month

120 to 200 2 weeks

Filter

Filter maintenance is generally limited to cleaning and

replacement.

If aluminum mesh lters are installed, they can be

washed in warm soapy water.

An adhesive spray can be added to aluminum mesh

lters to increase their efciency.

If disposable lters are installed, they can be checked

by holding up to a light source. If light cannot pass through

the lter, it should be replaced.

When reinstalling lters, be sure to install them with the

airow in the correct direction. An airow direction arrow is

located on the side of the lters.

Replacement lters should be from the same

manufacturer and the same size as the original lters

provided with the unit.

Maintenance - Beginning of season

Start-Up

3 yrs.

Standard

1 yr.

Severe

6

months

3

months

2 yrs.

1 yr.

6

months

3

months6 months1 months

1 yr.

3

months

Wheels

Wheels require little attention when moving clean air.

Occasionally oil and dust may accumulate on the wheel

causing imbalance. When this occurs the wheel and

housing should be cleaned to assure proper operation.

Bearings

The bearings are carefully selected to match the

maximum load and operating conditions of the specic fan

Repeat the Blower Start-Up Step #5 and Direct Gas

Start-Up Steps #1, #2 and #3. This will ensure that the gas

and air are set properly before the heating season begins

and should lead to trouble free operation all winter.

High Limit

The high limit switch may have tripped over the summer;

it should be checked and reset if necessary.

Burner

Inspect the burner for accumulation of scales on both the

upstream and downstream sides of the mixing plates. Any

scaling or foreign material should be removed with a wire

brush.

Visually check that all holes in the mixing plates are

clear. If any burner ports are plugged (even partially), clear

them with a piece of wire or another appropriate tool.

Page 8

8

Do not enlarge burner ports when clearing a blockage,

performance could be affected.

Replace or tighten any loose or missing fasteners on

the mixing plates. Always use zinc plated or stainless

steel fasteners.

Inspect and clean the ame and spark rod. Occasional

replacement of the ame rod and spark rod may be

necessary to ensure optimum unit performance.

Flame rods can last many years, but because of

thermal expansion of the porcelain, ame rods can fail

over time.

Gas Train

The gas connections, joints and valves should be

checked annually for tightness. Apply a soap and water

solution to all piping; watch for bubbling which indicates a

leak. Other leak testing methods can be used.

CFM / Static Pressure chart

Model # Low CFM Low SP High CFM High SP

2400 680 0.05 2400 0.94

3400 2000 0.2 3400 1

4100 3000 0.35 4100 1.1

Parts

To replace parts, contact a COOK representative.

Page 9

9

Blower does not operateTroubleshooting

Is the proper power

supply at the main

disconnect?

Yes

Is there 120 VAC

between terminals X2 &

X1 on transformer #A?

Yes

Is there 120 VAC between

terminal block #2 &

circuit breaker terminal 2?

No

No

No

1. Compare the supplied voltage, hertz, and phase with the motor’s

nameplate information.

2. Make sure disconnect switch is on.

Replace 480-120v transformer #A

1. Make sure supply switch is on.

Yes

Is there 120 VAC

between terminal blocks

1 & 5?

Yes

Is there 120 VAC

between across A1 &

A2 on supply contactor?

Yes

1. Replace fan belt, if broken.

2. Repair or replace motor or capacitor if needed.

3. Repair motor fuse if needed.

4. Repair or replace one or more of the motor

wiring legs, if needed.

No

No

1. Correct supply fan overload if tripped. Check for proper voltage, amps

and RPMs.

2. Check optional exhaust fan interlocks

1. Install the optional damper limit switch, if not installed. If holding, wait

for actuator to fully open or adjust the limit switch.

2. Repair or replace fan relay if not energizing. Check for loose

connection.

At this time the supply contactor

should pull in, passing power to the

supply motor & blower should start.

Refer to the control panel parts list when troubleshooting.

Page 10

10

Troubleshooting

Motor overamps

Is the air volume too

high?

No

Is the static pressure

lower than rated?

No

Is the blower rotating in

the wrong direction? If

the blower is rotating in

the wrong direction, the

unit will move some air,

but will not perform as

designed.

Yes

Yes

Yes

Adjust drive &

increase external

pressure. as needed.

Adjust drive to

reduce rpm as

needed.

To reverse the rotation on three phase units, disconnect and lock-out the

power, then interchange any two power leads.

To reverse the rotation on single phase units, disconnect and lock-out the

power, then rewire the motor per the motor manufacturer’s instructions.

Measure the unit’s air volume

(cfm) and compare it with its

rated air volume. If the measured

air volume is wrong, adjust the

fan’s RPM by changing/adjusting

the drive. The most accurate

way to measure the air volume

is by using a Pitot traverse

method downstream of the

blower. Changing the air volume

can signicantly increase the

motor’s amps. If the air volume

is changed, the motor’s amps

must be checked to prevent

overloading the motor. To ensure

accuracy, the dampers are to be

open when measuring the air

volume.

No

Is the motor voltage

correct?

Yes

Is the motor horse

power too low?

No

Shorted winding on the

motor?

No

Yes

Yes

Compare the supplied voltage, hertz, and phase with the unit and

motor’s nameplate information. Correct as needed.

Replace motor.

Consult factory.

No

Refer to the control panel parts list when troubleshooting.

Page 11

11

Troubleshooting Insufcient airow

Are the dampers not

fully open? This may

take several minutes.

No

Are the system static

losses too high?

No

Is the blower speed too

low?

No

Yes

Yes

Yes

Adjust dampers or replace damper/actuator as needed.

Reduce loss by improving ductwork.

Measure the unit’s air volume (cfm)

and compare it with its rated air

volume. If the measured air volume

is wrong, adjust the fan’s RPM by

changing/adjusting the drive. The

most accurate way to measure

Adjust the drives as needed.

the air volume is by using a Pitot

traverse method downstream of the

blower. Changing the air volume

can signicantly increase the

motor’s amps. If the air volume is

changed, the motor’s amps must

be checked to prevent overloading

the motor. To ensure accuracy,

the dampers are to be open when

measuring the air volume.

Are the lters dirty or

clogged?

No

Are there leaks in the

ductwork?

No

Is the belt slipping?

No

Yes

Yes

Yes

Replace / clean the lters as needed.

Repair ductwork.

1. Replace or tighten as needed.

2. Install automatic belt tensioner if possible.

Refer to the control panel parts list when troubleshooting.

Consult factory.

Page 12

12

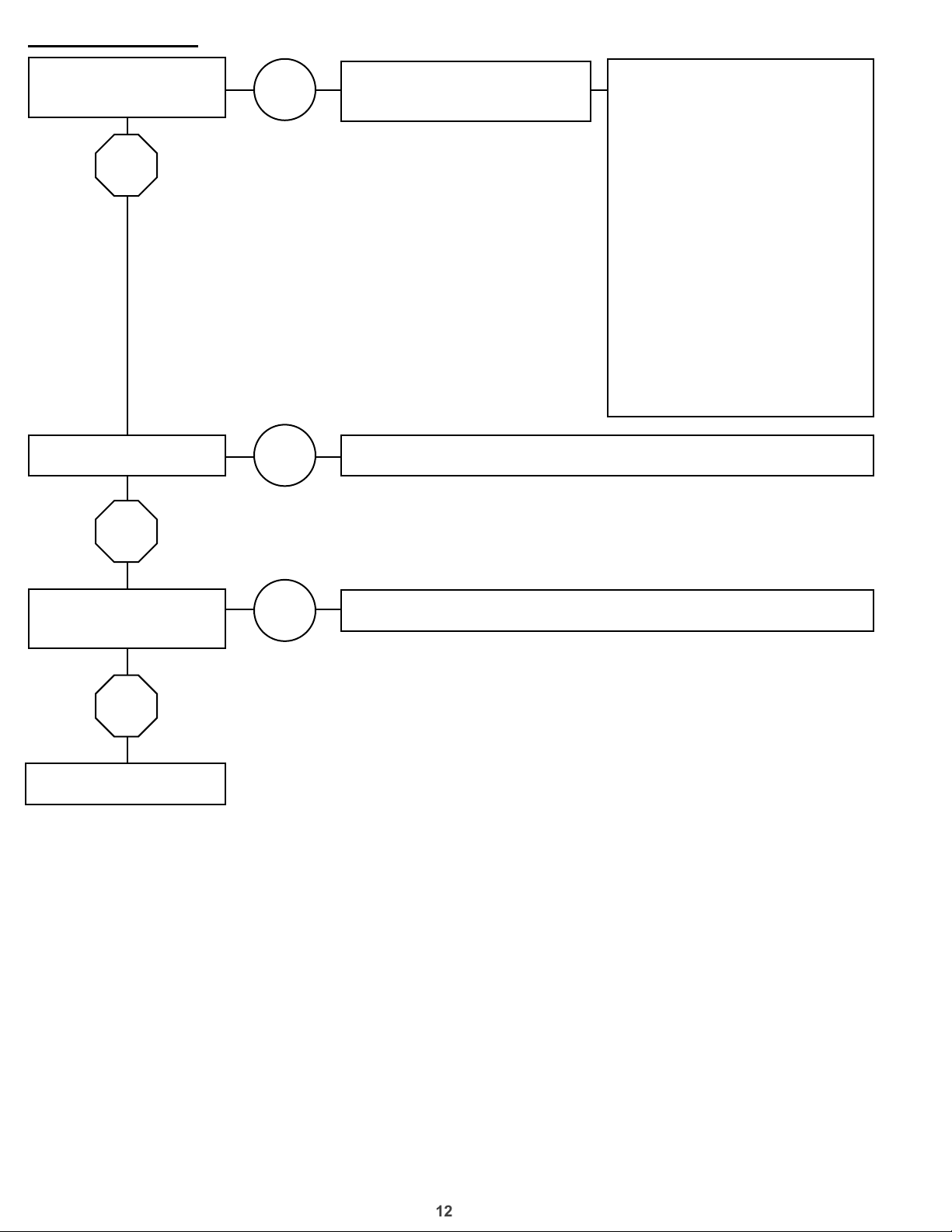

Troubleshooting

Too much airow

Is the blower speed too

high?

No

Are the lters missing?

Yes

Yes

Adjust drive & decrease

external pressure. as needed.

Install lters.

Measure the unit’s air volume

(cfm) and compare it with its

rated air volume. If the measured

air volume is wrong, adjust the

fan’s RPM by changing/adjusting

the drive. The most accurate

way to measure the air volume

is by using a Pitot traverse

method downstream of the

blower. Changing the air volume

can signicantly increase the

motor’s amps. If the air volume

is changed, the motor’s amps

must be checked to prevent

overloading the motor. To ensure

accuracy, the dampers are to be

open when measuring the air

volume.

No

Is there insufcient

external pressure?

No

Consult factory.

Yes

Increase external static pressure.

Refer to the control panel parts list when troubleshooting.

Page 13

13

Troubleshooting

Excessive noise or vibration

Is the belt loose or

damaged?

No

Are the sheave aligned?

Yes

Is the wheel

unbalanced?

No

Yes

No

Yes

1. Replace or tighten as needed.

2. Install automatic belt tensioner if possible.

Align sheaves.

Clean or replace the wheel.

Are the lters dirty /

clogged?

No

Are the bearings worn or

do they need lubrication?

No

At this time the noise or vibration

should be at acceptable levels

Yes

Yes

Clean or replace lters as needed.

Lubricate or replace bearings as needed.

Refer to the control panel parts list when troubleshooting.

Page 14

14

Troubleshooting

Heater does not attempt to light. Heater attempts to light, but no ame

Is there 120 VAC between

terminal block #2 &

circuit breaker terminal 2?

Yes

Is there 24 VAC

between terminal blocks

9 & 10?

Yes

Is there 120 VAC between

terminal block #10 & high

temp limit switch #2?

No

1. Make sure supply switch is on.

Replace 24 VAC transformer.#b

No

Correct / replace high temp overload switch.

No

Yes

Is there continuity

between terminal block

#4 & low pressure switch

normal open?

Yes

Consult factory

No

1. With all access panels in place, the fan running and discharging 700F

(210C) air, connect a U-Tube manometer to the outer sensing probes

(see below) and measure the stac pressure across the burner. The

proper stac pressure should be (check CFM / Static Pressure chart

on page 8). If needed, evenly adjust the baes, keeping the burner

centered in the opening unl the required pressure is obtained. The

pressure drop was set at the factory and may not need adjustment.

When required pressure is obtained, be sure to reconnect the outer

sensing probes. This process may need to be repeated unl the proper

pressure is achieved. This adjustment will change the air quanty

delivered by the unit and therefore the air quanty delivered should be

rechecked. Refer to the Blower Start-Up secon.

2. To increase the stac pressure decrease the opening.

3. To decrease the stac pressure increase the opening.

Refer to the control panel parts list when troubleshooting.

Page 15

15

Troubleshooting

Is the inlet gas pressure

between the min and

max?

Yes

Attempts to light, with visible spark, but no ame

Check the supply gas pressure and compare it with the unit’s nameplate

pressure requirements. Adjust the supply regulator as needed until

No

the supply gas pressure is within the specied range (see below). The

nameplate is located on the outside of the unit on the control panel side.

Is there air in the gas

line?

No

Is the pressure drop

across the burner

correct? (check chart

on page 8)

Yes

Is there still not a proper

spark?

Yes

No

No

Purge the air.

With all access panels in place, the fan running and discharging 70ºF

(21ºC) air, connect a U-Tube manometer to the outer sensing probes

(see below) and measure the static pressure across the burner. The

proper static pressure should be (check CFM / Static Pressure chart

on page 8). If needed, evenly adjust the bafes, keeping the burner

centered in the opening until the required pressure is obtained. The

pressure drop was set at the factory and may not need adjustment.

When required pressure is obtained, be sure to reconnect the outer

sensing probes. This process may need to be repeated until the proper

pressure is achieved. This adjustment will change the air quantity

delivered by the unit and therefore the air quantity delivered should be

rechecked. Refer to the Blower Start-Up section.

To increase the static pressure decrease the opening.

To decrease the static pressure increase the opening.

The wires may be switched. Uncross the spark wires.

Make sure the spark gap is .062 in.

Replace spark the plug.

Yes

Consult factory

Refer to the control panel parts list when troubleshooting.

Page 16

16

Warranty

Loren Cook Company warrants that your Loren

Cook fan was manufactured free of defects in

materials and workmanship, to the extent stated

herein. For a period of one (1) year after date of

shipment, we will replace any parts found to be

defective without charge, except for shipping costs

which will be paid by you.

This warranty is granted only to the original

purchaser placing the fan in service.

This warranty is void if the fan or any part thereof

has been altered or modied from its original design

or has been abused, misused, damaged or is in

worn condition or if the fan has been used other

than for the uses described in the company manual.

This warranty does not cover defects resulting from

normal wear and tear.

To make a warranty claim, notify Loren Cook

Company, General Ofces, 2015 East Dale Street,

Springeld, Missouri 65803-4637, explaining in

writing, in detail, your complaint and referring to the

specic model and serial numbers of your fan. Upon

receipt by Loren Cook Company of your written

complaint, you will be notied, within thirty (30) days

of our receipt of your complaint, in writing, as to the

manner in which your claim will be handled. If you

are entitled to warranty relief, a warranty adjustment

will be completed within sixty (60) business days of

the receipt of your written complaint by Loren Cook

Company.

This warranty gives only the original purchaser

placing the fan in service specically the right. You

may have other legal rights which vary from state to

state.

For fans provided with motors, the motor

manufacturer warrants motors for a designated

period stated in the manufacturer’s warranty.

Warranty periods vary from manufacturer to

manufacturer. Should motors furnished by

Loren Cook Company prove defective during the

designated period, they should be returned to the

nearest authorized motor service station. Loren

Cook Company will not be responsible for any

removal or installation costs.

Service Contacts

Dealer

Installation

Contractor:

Service

Contractor:

Date of Installation:

Name:

Address:

Phone:

Name:

Address:

Phone:

Name:

Address:

Phone:

Corporate Ofces 2015 E. Dale Street Springeld, MO 65803

Phone 417-869-6474 Fax 417-862-3820 lorencook.com

HMD IOM Manual - Feb 2013

Loading...

Loading...