Page 1

®

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

This publication contains the installation, operation and

maintenance instructions for standard units of the GI/GR:

Gravity Ventilators.

Carefully read this publication and any

supplemental documents prior to any

installation or maintenance procedure.

Loren Cook catalog, Gravity Ventilation, provides addi-

tional information describing the equipment, unit perfor-

mance, available accessories and specication data.

For additional safety information, refer to AMCA Publica-

tion 410-96, Safety Practices for Users and Installers of

Industrial and Commercial Fans.

All of the publications listed above can be obtained from:

• lorencook.com

• info@lorencook.com

• 417-869-6474 ext. 166

For information and instructions on special equipment,

contact Loren Cook Company at 417-869-6474.

Receiving and Inspection

Immediately upon receipt of a GI/GR unit, carefully in-

spect it for damage and shortage.

• Check dampers (if supplied) for free operation of moving parts.

• Record on the Delivery Receipt any visible sign of damage.

Handling

Lift the unit by the lifting lugs (refer to Figure 4).

NOTICE! Never lift by the hood or end panels.

Storage

If the unit is stored for any length of time prior to installation, store it in its original shipping crate and protect it from

dust, debris and the weather.

Installation

Standard Units

Standard units not requiring knock down are shipped

fully assembled and ready for installation.

GI/GR

Gravity Vents

The attachment of roof mounted fans to the roof curb as

well as the attachment of roof curbs to the building structure must exceed the structural requirements based on the

environmental loading derived from the applicable build-

ing code for the site. The local code ofcial may require

variations from the recognized code based on local data.

The licensed engineer of record will be responsible for

prescribing the correct attachment based on construction

materials, code requirements and environmental effects

specic to the installation.

Failure to follow these instructions could result in death or

serious injury.

Knockdown Units

All knocked down units are factory pre-assembled and

then disassembled for shipping. Reassemble by aligning

holes and bolting together. Parts are marked as to allow

for ease of reassembly.

Reassembling the hood is best done from the underneath side. To work on the hood it is recommended to turn

the hood upside down on two wooden four by fours, this

will prevent it from rocking during assembly. Attach the

hood sections together by the overlapping joining seams

(see Figure 5). Make sure the upper sean is overlapping

the lower seam along their entire length. A slight tap with a

rubber mallet or dead blow hammer maybe required. Align

holes and use the provided section rail splice and bolts to

secure the hood section(s) together (see Figure 3).

For units with birdscreen, rst completely assemble the

hood. Then fasten birdscreen securely to the inside of the

section rail, (see Figure 1), using speed screws (A) and

washer (B) stretching the birdscreen (C) as tight as possible. For units with aluminum birdscreen, the washers are

replaced with 1” aluminum strips at the factory. On units

with lters and birdscreen, the bird screen should extend

across the throat, not hindering the lter placement (see

Figure 4).

For units with a two piece mounting channel, insert the

mounting channel splice between the two pieces of the

mounting channel, aligning the holes (see Figure 3). Fasten the three pieces of the mounting channel assembly to

the base using the bolts and nuts provided.

For units with multiple base sections: securely fasten the

base sections through the base section splice brackets

welded to the base sections using the bolts and nuts provided (see Figure 3). To eliminate the possible egress of

water through the base splices, caulking is recommended.

1 B51116-002GI/GR IO&M

Page 2

To attach the base and hood sections: set the assembled hood on the assembled base, aligning the mounting

bracket holes with the holes in the section rails. Units with

support angles require the support angles to be bolted to

the base, using the bolts and nuts provided.

Figure 1

Section RailHood Panel

C

B

A

Throat

Filters

Filters are installed between the base and the hood pan-

els (see Figure 4). The lters should come in two sizes.

One size ts between the end panel and the base. The

other size is mounted between the base and the section

rail. Filter inspection and cleaning intervals can vary from

once a week to twice per year depending on contaminant

present and acceptable pressure drops across the lter.

Under most conditions lters may be cleaned with hot wa-

ter and a mild soap solution (such as dish washing liquid)

or steam. Some caustic cleaners will damage the lter. If

in doubt, please consult the factory for a compatibility list.

High pressure spray washers should be limited to 2,000

PSI operating pressure. Every attempt should be made to

remove the contaminants from the lter in a “backwash”

ow (NOTE: airow arrow on the lter frame). Once the

lter is dry, it may be returned to the appropriate lter racks

in the same orientation (airow direction) as they were re-

moved.

Maintenance

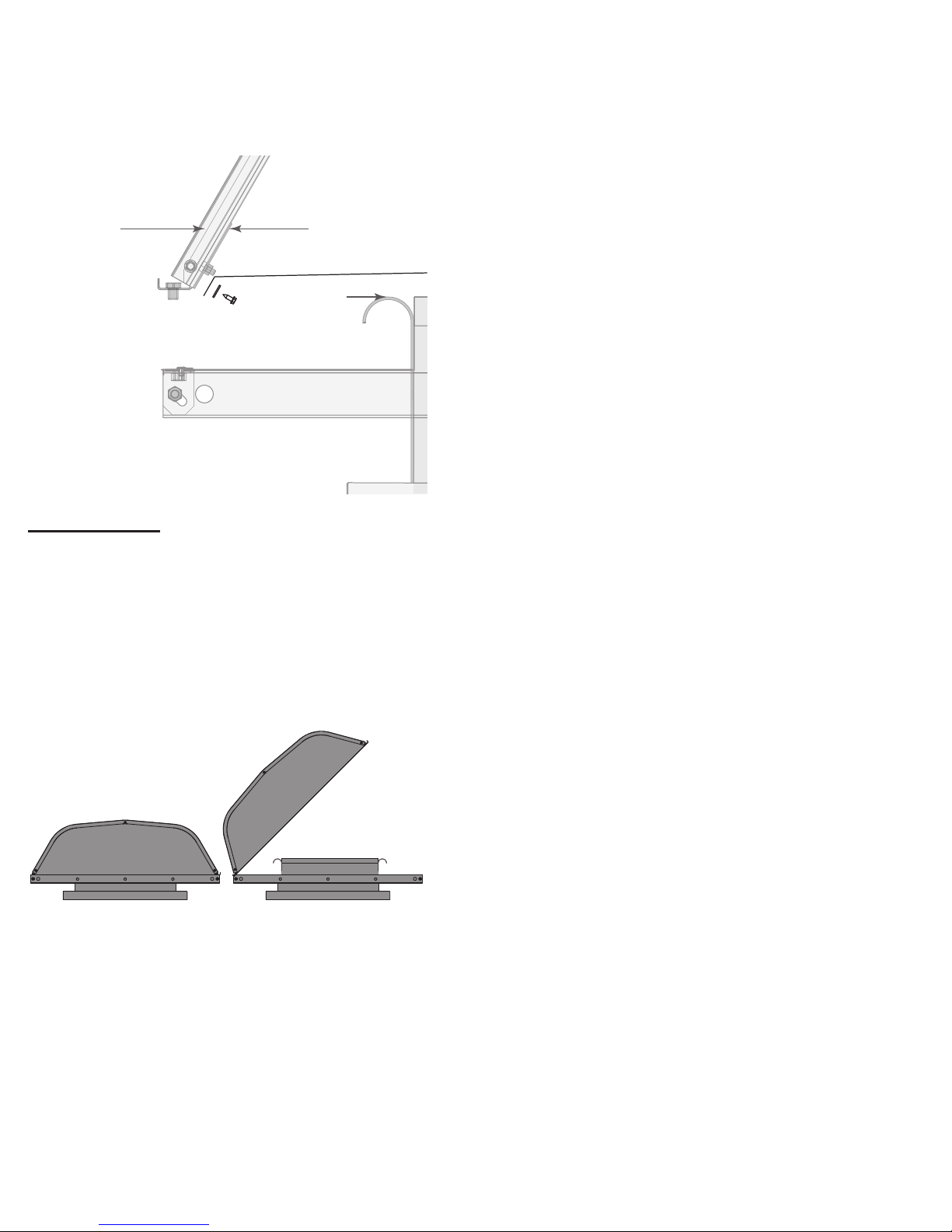

Hood Access

To access the throat of the unit, take the entire hood off

by removing the bolts and attaching the mounting bracket

to the mounting channels (see Figure 4). GR units with

less than a 73” throat length and GI units with less than a

61” throat length can be hinged. Hinging is accomplished

by removing the bolts on one side and loosening the two

bolts (refer to Figure 2) on the other side. Care should be

taken when hinging the hood, especially in high wind conditions.

Figure 2

2GI/GR IO&M B51116-002

Page 3

Section Rail

Mounting Channel Splic

Cross section of the end peice

Cross section of the hood panel

Figure 3

Support Angle

Mounting Channel

Hood Section

Figure 4

e

Hood Panel

End Panel

Base / Throat

Section Rail Splice

Base Splice

Hinged bolt

Lifting lug

Filter retaining clip

Filter

Mounting rail

3 B51116-002GI/GR IO&M

Page 4

Parts List

Part No. Description

1 Hood Panel

2 End Panel

3 Section Rail

4 Mounting Bracket - Left

5 Mounting Bracket - Right

6 Mounting Rail

7 Base / Throat

8 Self-Tapping Screw

9 Wizzbolt

10 Wizznut

A Self Tapping Screw

B Flat Washer

C Birdscreen

See Figure 1,

page 2

Figure 5

1

For replacement hood sections (not individual hood panels)

please indicate which open end extrusion is required: (A) the

top extrusion or (B) the bottom extrusion. For replacement

middle hood sections the extrusion designation is not required.

8

3

9

10

4

10

Standard Assembly

2

9

5

10

7

9

6

8

Limited Warranty

Loren Cook Company warrants that your Loren Cook fan was manufactured free of defects in materials and workmanship, to the extent stated herein.

For a period of ve (5) years after date of shipment, we will replace any parts found to be defective without charge, except for shipping costs which will be

paid by you. This warranty is granted only to the original purchaser placing the fan in service. This warranty is void if the fan or any part thereof has been

altered or modied from its original design or has been abused, misused, damaged or is in worn condition or if the fan has been used other than for the

uses described in the company manual. This warranty does not cover defects resulting from normal wear and tear. To make a warranty claim, notify Loren

Cook Company, General Ofces, 2015 East Dale Street, Springeld, Missouri 65803-4637, explaining in writing, in detail, your complaint and referring

to the specic model and serial numbers of your fan. Upon receipt by Loren Cook Company of your written complaint, you will be notied, within thirty

(30) days of our receipt of your complaint, in writing, as to the manner in which your claim will be handled. If you are entitled to warranty relief, a warranty

adjustment will be completed within sixty (60) business days of the receipt of your written complaint by Loren Cook Company. This warranty gives only

the original purchaser placing the fan in service specically the right. You may have other legal rights which vary from state to state.

Corporate Ofces: 2015 E. Dale St. Springeld, MO 65803

Phone 417-869-6474 | Fax 417-862-3820 | lorencook.com

March 2017

4GI/GR IO&M B51116-002

Loading...

Loading...