Page 1

Gemini

6

s

atte

G

Ceiling and cabinet fans

®

INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

This publication contains the installation, operation and

maintenance procedures for standard units of the Gemini:

Ceiling and Cabinet Fans.

Carefully read this publication and any

supplemental documents prior to any

installation or maintenance procedure.

Loren Cook Company’s Gemini catalog provides

additional information describing the equipment, fan

performance, available accessories and specication

data.

For additional safety information, refer to AMCA

publication 410-96, Safety Practices for Users and

Installers of Industrial and Commercial Fans.

All of the publications listed above can be obtained

from Loren Cook Company by phoning (417) 869-6474,

extension 166; by FAX at (417) 832-9431; or by e-mail at

info@lorencook.com.

For information and instructions on special equipment,

contact Loren Cook Company at (417) 869-6474.

Rotating Parts & Electrical Shock Hazard:

Disconnect electric power before working on unit.

Follow proper lockout / tagout procedures to ensure

the unit cannot be energized while being installed or

serviced.

Receiving and Inspection

Carefully inspect the fan and accessories for any

damage and shortage immediately upon receipt of fan.

• Turn the wheel by hand to ensure it turns freely and

does not bind.

• Inspect dampers (if included) for free operation of

all moving parts.

• Remove mounting brackets from packing insert &

install mounting brackets (Gemini 100 only).

• Remove shipping tape.

• Record on the Delivery Receipt any visible sign of

damage.

Handling

Lift fan by the outside housing (box) or by the blower

mounting brace. Never lift by the shaft or motor.

Storage

If the fan is stored for any length of time prior to

installation, store it in its original shipping crate and

protect it from dust, debris and the weather.

Installation

Motor Installation

All Gemini units are shipped with motors mounted at

the factory.

A disconnect switch should be placed near the fan

in order that the power can be swiftly cut off, in case

of an emergency and in order that maintenance

personnel are provided complete control of the

power source.

Grounding is required. All eld-installed wiring

must be completed by qualied personnel. All eld

installed wiring must comply with National Electric

Code (NFPA 70) and all applicable local codes.

Failure to follow these instructions could result in

death or serious injury.

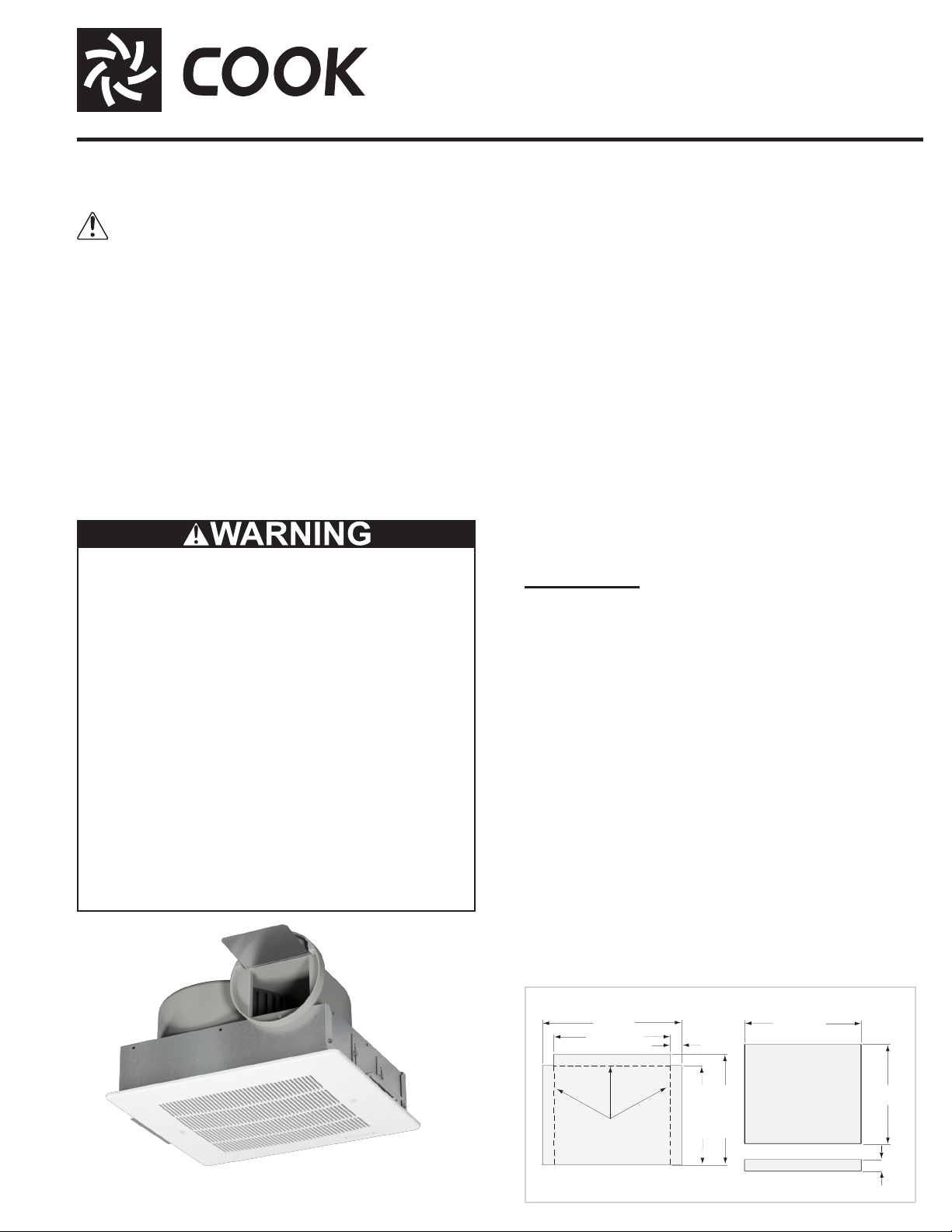

Gemini 100 Inline to Ceiling Conversion

The Gemini 100 series can be converted from inline

to ceiling by ordering the Inline to Ceiling Conversion Kit

from Loren Cook Company (Part Number 797180). The

kit includes all parts required, plus detail instructions on

how to convert the Gemini 100.

Gemini 100 Ceiling to Inline Conversion

The Gemini 100 series can be eld converted from

ceiling to inline by following these steps:

1. Remove and discard the inlet box end plate.

2. Install the inline cover panel with sheet metal

screws as shown on the following page. Ceiling to

Inline Conversion Kit can be ordered from Loren

Cook Company (Part Number 797181), or fabricate

the required part using the following two sketches.

a. Galvanized Steel

16-3/4

13-15/16

Bend up at 90o

18

1-3/8

11-15/16

14-1/16

12

13-5/16

Gemini 100

1-7/1

1

Flat P

rn

(Inches)

Finished View

Page 2

Figure 1

Use foil tape on the joints

Start

Outlet

Inlet

Remove Parts

Inline

Cover

Panel

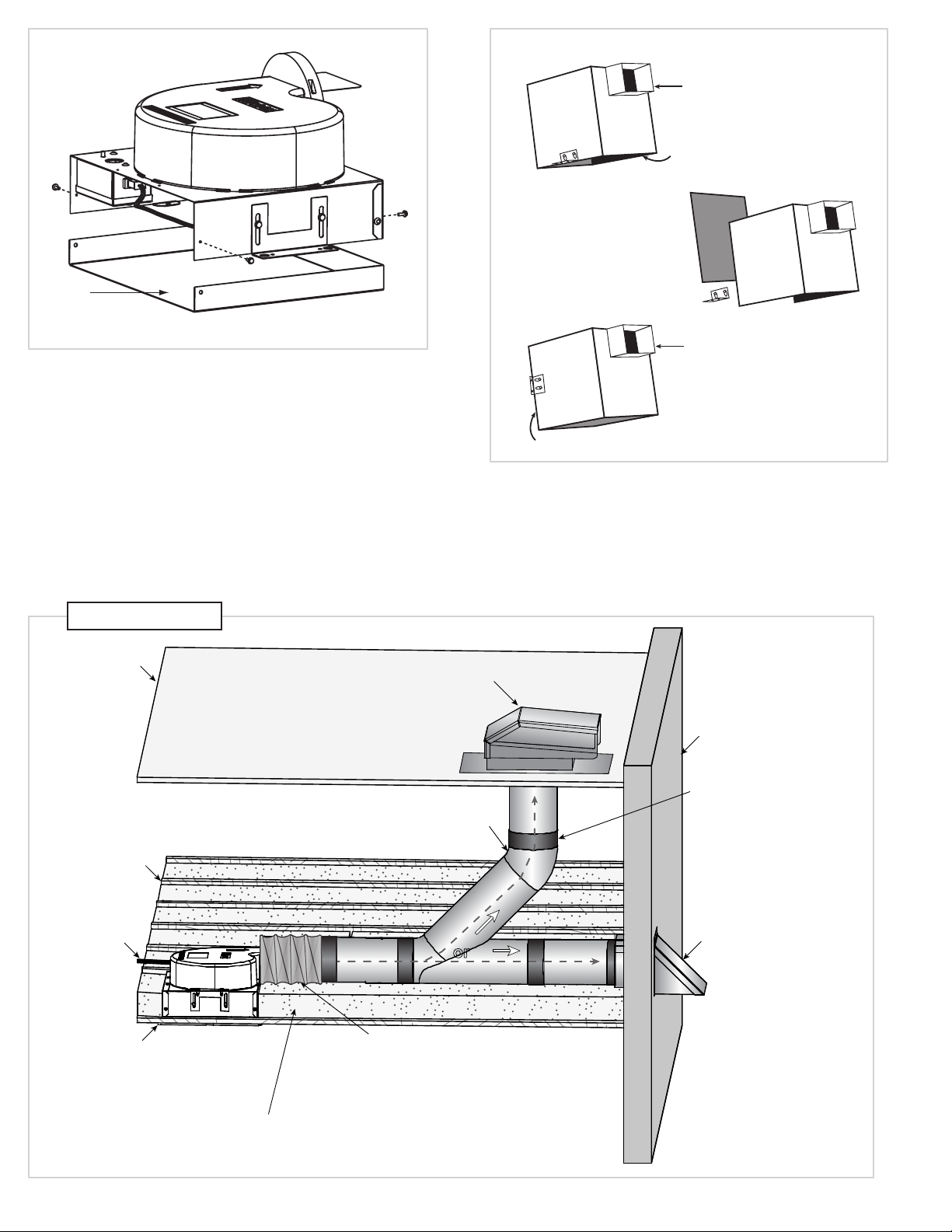

Direction of Discharge (200-900 Series)

Discharge direction can be converted from right angle to

straight line, without a kit, by swapping outer panel and

the inlet/grille: See Figure 1.

1. Remove the side panel, mounting brackets (2) and

grille (if present).

2. Place the side panel where the inlet/grille had

been. Place the mounting brackets on the edge

where the side panel had been. Holes are

prepunched for this procedure.

3. Rotate unit so that the outlet is on top.

Typical Installation

Roof

Roof jack with damper

or roof cap

x2

Replace Parts

Outlet

Inlet

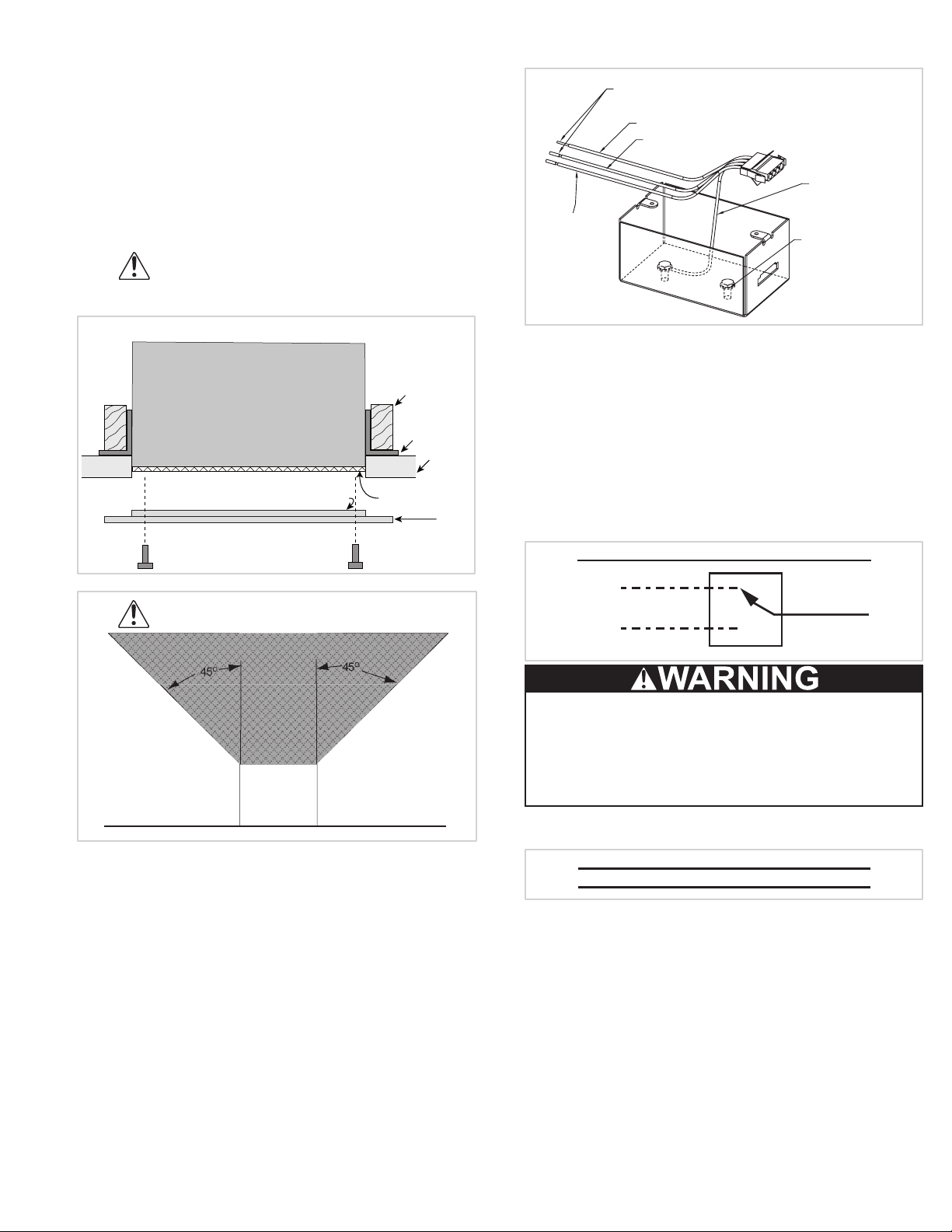

Fan Installation

1. Use the mounting bracket slots to lower the

unit housing by a distance equal to the ceiling

thickness. Refer to gure 2.

2. Raise the unit, as needed to accommodate

accessories and options: If lter present, raise

Exterior

Wall

6” round duct. Insulated duct will help

absorb vibration. Use the shortest runs

Joists

Power

cord

Seal around the

unit with caulk.

Insulation around unit.

Also, cover the fan with insulation.

to ensure a good seal.

possible & long radius elbows.

Wall cap

with damper

or

Short (1’) piece of flexible duct

will absorb vibration & noise.

2

Page 3

unit 3/8”. If lter and deluxe aluminum grille are

Mounting

Filter (optional)

Ceiling

Grille

both present, raise unit 7/8”, due to the 1/2” grate

protrusion on the aluminum grille. If lter is not

present: the grate on the aluminum grille will t inside

of the unit (except sizes 160 & 180). Other grilles have

no protrusion and t ush with the fan.

3. Fasten duct work to the outside of the duct collar

(damper frame) using sheet metal screws and foil

tape. Make sure sheet metal screws are placed

where they do not interfere with damper operation.

4. Fasten the housing to the bottom of the joists

through the holes provided in the mounting bracket.

For Ceiling Radiation Damper Installation

see separate document “Gemini/CRD

Installation Supplement.”

Figure 2

Unit Housing

Joists

Bracket

Grate Protrusion (aluminum grille only)

Wiring Diagrams

Gemini 100 Series:

Cap off wire that is not in use.

Red Wire (Low Speed)

Black Wire (High Speed)

Green Wire

(Ground by COOK)

White Wire

(Common)

For fan power supply connection use 4-wire cable

provided in eld wiring box shown above. Connect eld

ground wire to green ground screw located inside fan

electrical box. Connect one supply line to white wire.

Depending on fan speed requirements connect other

supply line to Red wire for Low Speed or Black wire

for High Speed. Insulate unused Red or Black wire.

Replace electrical box cover. Model 126, 146, 166, 186

are Low Speed. Models 128, 148, 168, 188 are High

Speed.

Gemini 200, 300, 500, 600 and 700 Series:

White Line

Ground Screw for

Field Grounding

Notice! Do not install above or around

cooking equipment (shaded area)

O

45

O

Cooking

Equipment

45

Floor

Wiring Installation

All wiring should be in accordance with local

ordinances and the National Electrical Code, NFPA 70.

Ensure the power supply (voltage, frequency, and current

carrying capacity of wires) is in accordance with the

motor nameplate. Refer to Wiring Diagrams.

Lock out all power sources before unit is wired to power

source.

Follow the wiring diagram in the disconnect switch and

the wiring diagram provided with the motor. Correctly

label the circuit on the main power box and always

identify a closed switch to promote safety (i.e., red tape

over a closed switch).

Note: Insulate Unused Leads. Fan plug box is designed

for single speed operation, using an FSC to vary speed if

required. Do not wire to more than two leads.

Black (High)

Red (Low)

Line

Electrical Shock & Fire Hazard:

Insulate Unused Lead

Failure to follow these instructions could result in

death or serious injury.

Gemini 400 Series:

White Line

Black Line

Wiring continued on the next page.

3

Page 4

Gemini 800 - 900 Series:

2

3

2

3

2

1

3

e

e

e

White Line

Black (High)

Blue (Medium)

Red (Low)

Line

1 PH / 60 HZ / 115 V

LEESON 10.2 AMPS

P1

P2

T3

T2

T4

T5 T5

Line 1

Insulate

Line 2

P1

P2

T3

T2

T4

1 PH / 60 HZ / 208-230 V

LEESON 5.2 AMPS

Insulate

Insulate

Line 1

Line 2

Electrical Shock & Fire Hazard:

Insulate Unused Leads Separately

Failure to follow these instructions could result in

death or serious injury.

Gemini 1000:

1 PH / 60 HZ / 115V

MARATHON 6.0 AMPS

Purple

White

Yellow

Orange

Brown

1 PH / 60 HZ / 115V

MAGNETEK 8.0 AMPS

Black

White

Red

Blue

Orange

T4

P4

T5

P6

T6

P6

T4

T7

T6

T9

T5

T8

Gemini 2000:

1 PH / 60 HZ / 115V

MARATHON 10.8 AMPS

Purple

Brown

Blue

White

Black

Line 1

Line 2

Insulate

Line 1

Line 2

Insulate

3 PH / 60 HZ / 208-230 V

MARATHON 2.2-2.0 AMPS

MAGNETEK 2.2-2.0 AMPS

Insulate

Insulate

Insulate

3 PH / 60 HZ / 460 V

MARATHON 1.0 AMP

MAGNETEK 1.0 AMP

Insulate

Insulate

Insulate

Line 1

Insulate

Line 2

1 PH / 60 HZ / 208-230 V

MARATHON 2.8-3.0 AMPS

Purple

Yellow

Brown

Orange

White

1 PH / 60 HZ / 208-230 V

MAGNETEK 4.1 AMPS

Purple

Yellow

Blue

Orange

White

T1

T7

T2

T8

T3

T9

T1

T2

T3

P4

P5

P6

1 PH / 60 HZ / 208-230 V

MARATHON 6.0-5.4 AMPS

Orange

Brown

Blue

White

Black

Insulate

Insulate

Insulate

Insulate

Insulate

Insulate

Insulate

Insulate

Line 1

Line 2

Line 2

Line 1

Line 1

Line

Line

Line 1

Line

Line

Line 1

Line 2

3 PH / 60 HZ / 208-230 V

MARATHON 4.1-4.2 AMPS

T4

P4

T5

P6

T6

P6

LEESON 3.4 AMPS

Insulate

Insulate

Insulate

T1

T7

T2

T8

T3

T9

Line 1

Line 2

Line 3

3 PH / 60 HZ / 460 V

MARATHON 2.1 AMPS

T4

T7

T6

T9

T5

T8

LEESON 1.7 AMPS

Insulate

Insulate

Insulate

T1

T2

T3

P4

P5

T6

Line

Line

Line

Insulat

Insulat

Insulat

FSC:

Fan

FSC

White

Black

Time Delay Switch:

light

Final Installation Steps

1. Inspect fasteners and setscrews, particularly fan

mounting fasteners, and tighten as required.

2. Inspect for correct amperage and voltage with an

ammeter and voltmeter.

3. Ensure blower is secured to duct work.

4. Ensure all accessories are installed.

5. Inspect wheel-to-inlet clearance. Make sure wheel

does not rub against the inlet.

6. Test the fan to be sure the rotation is the same as

indicated by the arrow marked Rotation.

Grille installation is described after the operation

and inspection sections.

4

Fan

Red

Blue

Switch

White

Black

Page 5

Operation

Pre-Start Checks

1. Lock out all the primary and secondary power

sources.

2. Inspect fasteners and setscrews, particularly those

used for mounting the fan, and tighten if necessary.

3. Inspect motor wiring.

4. Ensure fan and ductwork are clean and free of

debris.

5. Test the fan to ensure the rotation of the wheel is

the same as indicated by the rotation label.

6. Restore power to unit.

Start Up

Before attaching the grille, turn the fan on and inspect

for the following:

• Direction of rotation.

• Excessive vibration.

• Unusual noise.

• Motor noise.

• Improper motor amperage or voltage.

If a problem is discovered, immediately shut off the fan.

Lock out all electrical power and check for the cause of

the trouble — refer to the ‘Troubleshooting’ section.

Inspection

Inspection of the fan should be conducted at the rst

30 minute interval of satisfactory operation. During the

inspection, stop the fan and inspect as per directions

below.

• Inspect bolts, setscrews, and motor mounting bolts.

• Adjust and tighten as necessary.

Grille Installation

Attach the grille by hand-tightening the grille screws.

When the unit is furnished with a lter, place the screws

through the hole in the grille. Install the lter through the

holes provided in the lter frame. See gure 2.

1. Disconnect the motor from electrical supply

2. Remove the mounting bolts on the inlet plate

assembly and remove the motor/wheel assembly

3. Remove the blower wheel with an allen wrench

Electrical Supply

Grill Mount Holes

Gemini 200 - 700 series

To inspect, clean, or repair, refer to the follow diagram

and follow these steps:

1. Remove grille.

2. Remove blower assembly from housing:

1. Disconnect the motor from electrical supply.

2. Remove mounting bolts.

3. Slide discharge ange out of spring clip and

remove motor/blower assembly from box.

3. Remove inlet ring from blower housing.

4. Remove blower wheel with an allen wrench.

Blower Mounting Brace

Mounting Bolts

Junction Box & Cover

Wheel

Maintenance

Establish a schedule for inspecting all parts of the fan.

The frequency of inspection depends on the operating

conditions and location of the fan.

Fans exhausting contaminated air (airborne abrasives)

should be inspected every three months.

Regular inspections are recommended for fans

exhausting non-contaminated air.

It is recommended the following inspections be

conducted twice per year.

• Inspect bolts and setscrews for tightness. Tighten

as necessary.

• Inspect for cleanliness. Clean exterior surfaces

only. Removing dust and grease on motor housing

assures proper motor cooling.

Access

Gemini 100:

To inspect, clean or repair refer to the diagram below

and follow these steps:

1. Remove grille.

2. Remove blower assembly from housing:

Unit

Mounting

Bracket

Adjustment

Wiring

Box

Duct Collar

Bolts

Motor

Damper

Blade

Gemini 800 - 2000 series:

To inspect, clean, or repair, refer to the diagram below

and follow these steps:

1. Remove grille.

2. Remove blower assembly from housing:

5

Page 6

1. Disconnect the motor from the electrical supply.

2. Remove motor plate bolts.

3. Slide motor plate and remove motor/blower

assembly from box.

3. Remove inlet rings from blower housing (both

sides).

4. Mark the wheel and housing to ensure correct

replacement of blower wheels (one is clockwise

and the other is counter-clockwise), then remove

the blower wheels with an allen wrench.

Wheel

Blower Housing

Mo tor Plate

Motor Plat e Bolts

Motor

Inlet Ring

(Ensure proper clearance between wheel and inlet ring)

damper operation.

Excessive Vibration and Noise

1. Damaged or unbalanced wheel.

2. Speed too high.

3. Incorrect direction of rotation. Make sure the fan

rotates in same direction as the arrows on the

motor or belt drive assembly.

4. Motor needs lubrication or replacement.

5. Fan surge.

Overheated Motor

1. Motor improperly wired.

2. Incorrect direction of rotation. Make sure the fan

rotates in same direction as the arrows on the

motor or belt drive assembly.

3. Cooling air diverted or blocked.

4. Improper inlet clearance.

5. Incorrect fan RPMs.

6. Incorrect voltage.

Reassembly

Simply reverse the disassembly instructions. Make sure

the wheel rotates in the same direction as the arrow on

the blower housing. Make sure the wheels do not rub on

the inlet rings. When replacing the motor, make sure the

motor and wheels are properly aligned with the blower

housing.

Notice! Ensure that the blower discharge ange is

secured in slot of the cabinet on Gemini 200 - 700

series.

Motor Bearings

Motor bearings are pre-lubricated and sealed.

Under normal conditions they will not require further

maintenance for a period of ten years.

Motor Services

Should the motor prove defective within a one-year

period, contact your local Loren Cook representative

or your nearest authorized electric motor service

representative

Troubleshooting

Problem and Potential Causes:

Low Capacity or Pressure

1. Incorrect direction of rotation. Make sure the fan

rotates in same direction as the arrows on the

motor or belt drive assembly.

2. Poor fan inlet conditions. There should be a straight

clear duct at the inlet.

3. Improper wheel alignment.

4. Damper held shut by tape.

5. Screw attaching duct work to collar interfering with

6

Page 7

Gemini 100 Parts List

1

2

3

4

5

6

7

8

9

10

Air Flow

11

11

Diagram Part

Number

1 Inlet Box End Plate

(Ceiling only)

2 Housing/Scroll

3 Field Wiring Compartment

4 Motor

5 Tinnerman Clip (Grill) X2

6 Mounting Bracket

7 Backdraft Damper

8 Wheel

9 Motor Mount/Inlet

10 Inlet Box

11 Grille

Part Description

Gemini 200 - 900 Parts List

Diagram Part

Number

1 Backdraft Damper Backdraft Dampers

2 Damper Frame Damper Frame (2)

3 Mounting Bracket

(2)

4 Wheel Wheel (2)

5 Grille (Ceiling and

Wall)

6 Blower Housing Blower Housing (2)

7 Motor Motor

8 Insulation Insulation

9 Cabinet housing Cabinet housing

10 Housing Side

Cover

Size

200 - 700

(2)

Mounting Bracket

(2)

Grille (Ceiling and

Wall)

Housing Side

Cover

Size

800 - 900

1

67

5

2

Air Flow

3

9

8

4

10

7

Page 8

Gemini 1000 - 2000 Parts List

Diagram Part

Number

1 Grille (ceiling and wall)

2 Backdraft Damper (2)

3 Wheel (2)

4 Blower Housing (2)

5 Motor

6 Insulation

7 Mount Brackets (2)

8 Cabinet housing

9 Housing Side Cover

2

Part Description

8

Limited Warranty

Loren Cook Company warrants that your Loren Cook

fan was manufactured free of defects in materials

and workmanship, to the extent stated herein. For

a period of one (1) year after date of shipment, we

will replace any parts found to be defective without

charge, except for shipping costs which will be paid

by you.

This warranty is granted only to the original

purchaser placing the fan in service.

This warranty is void if the fan or any part thereof

has been altered or modied from its original design

or has been abused, misused, damaged or is in

worn condition or if the fan has been used other

than for the uses described in the company manual.

3

This warranty does not cover defects resulting from

normal wear and tear.

9

To make a warranty claim, notify Loren Cook

Company, General Ofces, 2015 East Dale Street,

Springeld, Missouri 65803-4637, explaining in

writing, in detail, your complaint and referring to the

specic model and serial numbers of your fan. Upon

receipt by Loren Cook Company of your written

1

complaint, you will be notied, within thirty (30) days

of our receipt of your complaint, in writing, as to the

4

5

6

manner in which your claim will be handled. If you

are entitled to warranty relief, a warranty adjustment

will be completed within sixty (60) business days of

the receipt of your written complaint by Loren Cook

Company.

This warranty gives only the original purchaser

7

placing the fan in service specically the right. You

may have other legal rights which vary from state to

state.

Corporate Ofces 2015 E. Dale Street Springeld, MO 65803

Phone 417-869-6474 Fax 417-862-3820 lorencook.com

8

Gemini IOM - June 2014

Loading...

Loading...