Page 1

CAC

Air Circulators

INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

This publication contains the installation, operation

and maintenance procedures for standard units of the

CAC - Air Circulator Fans.

• CAC-DF • CAC-WH • CAC-M • CAC-CH • CAC-FH

• CAC-MH • CAC-WX • CAC-WW • CAC-WO • CAC-PO

Carefully read this publication prior to any installation

or maintenance procedure.

Loren Cook catalog, CAC, provides additional information

describing the equipment, fan performance, available accessories and specification data.

For additional safety information, refer to AMCA publication 410-96, Safety Practices for Users and Installers of

Industrial and Commercial Fans.

All of the publications listed above can be obtained from

Loren Cook Company by phoning (417)869-6474, extension

166; by FAX at (417)832-9431; or by e-mail at info@lorencook.com.

For information and instructions on special equipment,

contact Loren Cook Company at (417)869-6474.

Receiving and Inspection

Carefully inspect the fan and accessories for any damage

and shortage immediately upon receipt of the fan.

• Insepect for any damage that may have occurred during

transit.

• Shipping damage claim must be filed with carrier.

• Check all bolts, screws, setscrews, etc. for looseness

that may have occurred during transit. Retighten as

required.

• Record on the Delivery Receipt any visible sign of dam-

age.

Handling

Lift and support Air Circulator fans as per the assembly

instructions (See Page 2). Do not use hooks, clamps, or

forks to lift any of the circulator heads. Do not lift oscillating

head by their connecting arm or gear assembly.

Storage

To maintain good working condition of the fan do not store

outdoors, follow the additional instructions below.

• Periodically rotate the propeller to keep a coating of

grease on all internal bearing parts.

• Periodically inspect the fan to prevent damaging conditions.

• Cover the unit with some type of weather cover to prevent

moisture, corrosion, dirt or dust accumulation.

General Safety Information

To reduce the risk of fire, electric shock, and injury to persons, circulator must be installed with brackets that are

marked on their cartons to indicate the suitability with

model. Other brackets cannot be substituted.

To reduce the risk of fire, electric shock, or injury to

persons, observe the following:

a. Use this unit only in the manner intended by the

manufacturer. If you have questions, contact the

manufacturer.

b. Before servicing or cleaning unit, switch power OFF at

service panel and lock service disconnecting means to

prevent power from being switched on accidentally.

When the service disconnecting means cannot be

locked, securely fasten a prominent warning device,

such as a tag, to the service panel. This is important

with motors equipped with automatic reset thermal

protection. Motor may activate without warning.

c. Installation work and electrical wiring must be done by a

qualified person(s) in accordance with all applicable

codes and standards, including fire-rated construction.

d. When cutting or drilling into wall or ceiling, do not

damage electrical wiring and other hidden utilities.

This unit has rotating parts. Safety precautions should be

exercised at all times during installation, operation, and

maintenance. ALWAYS disconnect power prior to

working on fan. Disconnect switches are recommended.

Place the disconnect switch near the fan in order that the

power can be swiftly cut off in case of an emergency, and

in order that maintenance personnel are provided

complete control of the power source.

CAC-P

Page 2

Motors may be equipped with automatic reset thermal

protection. Motor may activate without warning.

Do not place body parts or objects in circulator, motor

openings, or drives while motor is connected to the

power source.

To reduce the risk of fire, electric shock, or injury to

persons, observe the following: Do not use a three-prong

to two-prong adapter on the power cord. Do not use

circulators with a solid state speed control device. Do not

depend on any switch or thermostat to disconnect power

supply. Always unplug the power cord.

1. Read and follow all instructions, cautionary markings

and make sure power source conforms to requirements

of equipment.

2. Follow all local electrical and safety codes, as well as

the National Electrical Code (NEC) and the

Occupational Safety and Health Act (OSHA) in the United States, including fire rated construction. Ground

motor in accordance with NEC Article 250, (grounding).

3. Avoid extension cords. If used, assure it is UL rated and

of proper type, gauge, and length. Never operate more

than one fan from a single extension cord.

4. Do not kink power cord or allow it to contact oil, grease,

hot surfaces, sharp objects, or chemicals. Replace worn

or damaged cord immediately.

5. Do NOT use general purpose circulators in flammable,

explosive, chemical-laden, or wet or rainy atmospheres.

Use special purpose circulators designed for that

application. Do not attach ductwork to a circulator.

6. In critical applications, use a suitable alarm (air switch,

temperature sensor, etc.) should the circulator

malfunction.

Installation

Installation, troubleshooting, and parts repair to be performed only by qualified personnel.

Where power cord is not provided, connect power to the

motor in accordance with the United States NEC and all

local codes. Motor terminal connection data is provided on

the motor nameplate or on the motor terminal box cover

plate. Use adequate size wire for all branch and feeder

runs.

a. Dock Door Fan (Model CAC-DF): Refer to Page 6, for

correct positioning of parts.

b. Mobile Air Circulators and High Volume, High Velocity

Industrial Fans (Models CAC-M, CAC-WH & CAC-FH):

Locate the fan in the desired location on a stable, level

surface, or on ceiling for ceiling mounted high volume,

high velocity industrial fans. Connect the power cord or

wire unit per all National and Local

Electrical Codes as required.

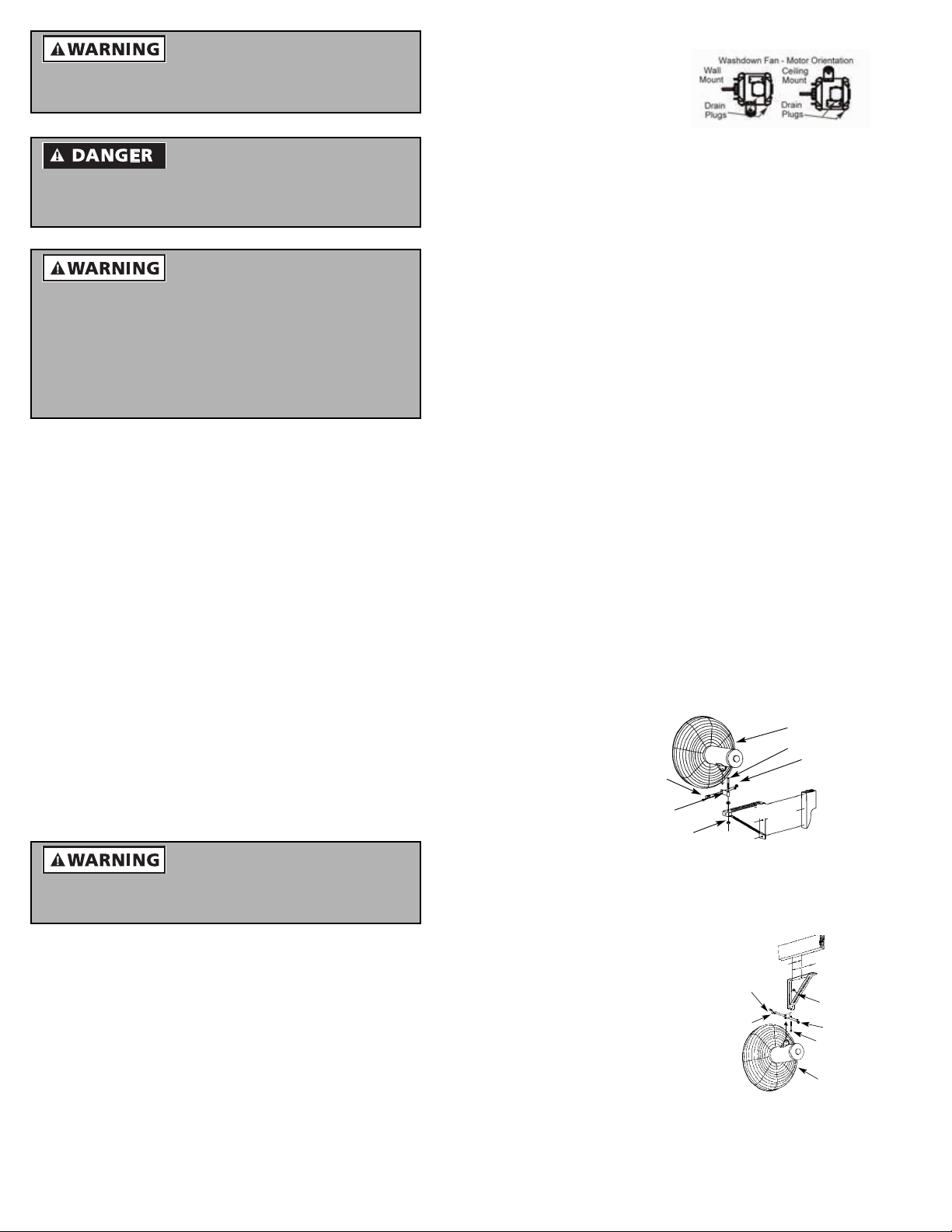

c. Washdown Air Circulators

(CAC-WW): After

mounting motor, remove

drain plugs.

Operation

1. CAC-P, CAC-W, CAC-PO and CAC-WO are operated

by pulling chain: High - Low - Off

2. CAC-M operates by rocker style switch: On - Off

3. CAC-DF operates by two-speed rocker style switch:

Low - Off - High

4. CAC-FH, CAC-WH, CAC-WW and CAC-WX requires

service switch wired by others.

Maintenance

1. Periodically clean propeller, guard, and motor of any

excessive dirt accumulation. Allow unit to cool; motors

can be hot enough to cause injury.

2. Follow motor manufacturer’s instructions for motor

lubrication.

IMPORTANT: When making repairs, use only Loren Cook

authorized repair parts.

Wall/Ceiling Bracket

1. For mounting circulator to wall, post, or ceiling.

Adjustable pivot bracket allows omni-directional air

circulation.

2. Furnished with secondary support cable for use when

circulator is mounted overhead. NOTE: Not

recommended for use with oscillating circulators when

ceiling mounted.

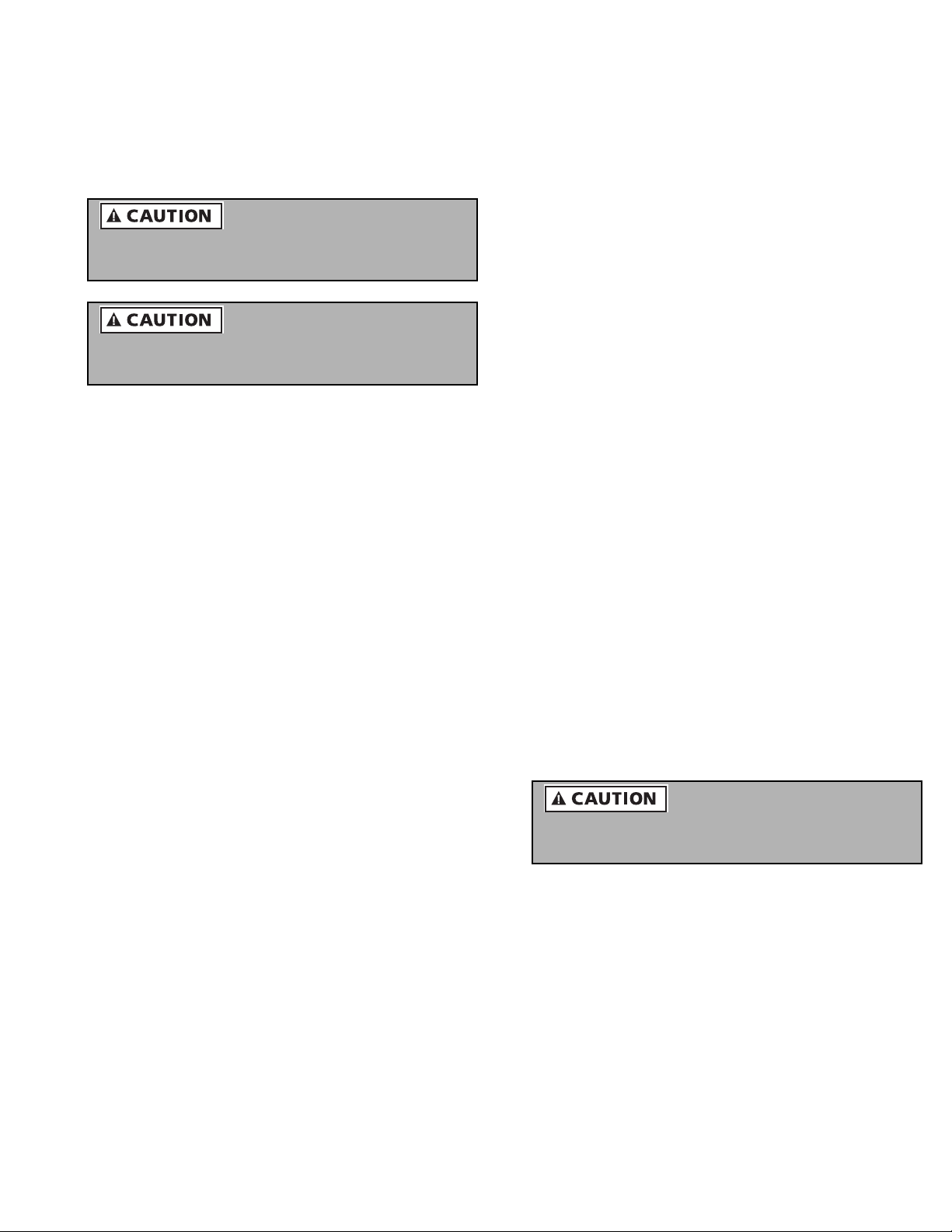

Wall/Ceiling Bracket Assembly Instructions

(Refer to Figures 1 and 2)

1. The wall/ceiling bracket should be assembled with the

swivel bracket as shown in the appropriate illustration.

The bracket has two holes; be sure smaller hole is as

specified in the illustration.

2. Locate the

wall or ceiling

stud nearest

the desired

fan location.

Attach the

bracket to the

stud using (3)

5/16 x 2”lag

screws or

Mounting

Bolts

Swivel Bracket

(Smaller Hole Down)

Mounting Nut

Figure 1 - Wall Mounted Assembly

appropriately sized bolts and nuts if attaching to Ibeams.

NOTE: Always install the

bracket to a minimum of 2 x

4 studding.

3. Position the swivel bracket

in the motor yoke (or along

side the oscillation circular

Swivel Bracket

(Smaller Hole Down)

Mounting

Bolts

cast aluminum support

bracket) and align the pivot

hole with the larger hole in

the swivel bracket.

4. Insert the larger dia. bolt in

Figure 2 - Ceiling

Mounted Assembly

the pivot hole and install

the lock nut finger tight.

5. Insert the smaller dia. bolt in the slot in the motor yoke

2

5-7/16"

10-7/8"

5-7/16"

Circulator

Mounting Bolt

Mounting Nuts

Wall

Stud

10-7/8"

Mounting

Nut

Mounting

Nuts

Mounting

Bolt

Circulator

Page 3

(or support bracket) and smaller hole in the pivot bracket

and install lock nut finger tight.

6. While holding the circulator at the desired angle, tighten

the smaller diameter bolt.

7. Tighten larger bolt to 200-230 in. lbs. and smaller bolt to

150-160 in. lbs., being careful to maintain the desired

position.

8. Plug the power cord into a properly grounded threeprong receptacle.

To avoid personal injury, circulators must be supported

any time angle is adjusted.

Use only as a wall mounting for oscillating units. Do not

use as a ceiling mount.

Pedestal Mount Assembly Instructions

Circulator head comes pre-assembled, ready for installation.

1. Remove the circulator head, base, and column

assembly from the box.

2. Secure the column assembly onto the base using the

four bolts pro-vided. Apply 35-45 in-lbs. of torque.

3. Adjust column to desired height and lock in position by

tightening socket head screw in collar.

IMPORTANT: Do not over-tighten!

4. Place assembled circulator facedown on a flat surface.

5. Tip pedestal assembly over, placing flattened column

end in motor yoke. Align holes and insert larger bolt and

finger-tighten lock nut.

6. Insert smaller bolt through motor adjustment slot and

column end and finger-tighten lock nut.

7. Stand entire unit upright by lifting at the motor end of the

column. Adjust circulator angle to desired position and

tighten larger bolt to 200-230 in. lbs. and smaller bolt

to150-160 in. lbs.

8. Place assembled pedestal and fanon a flat, level

surface. Do not place the cord under the pedestal base.

Locate assembly where cord will not be a tripping

hazard.

9. Insert the plug into a properly grounded three-prong

receptacle. The unit is now ready for operation.

NOTE: Use only the mounting hardware which is provided.

Optional Heavy Duty Floor Pedestal Mountings

(Standard on CAC-PO)

1. Large diameter column adjusts from 3 1/2- 6 ft.

circulator heights.

2. 33” round base is heavy gauge steel for stability and

ease of moving.

Optional Floor Pedestal Assembly Instructions

1. Insert column firmly into tapered cup.

2. Secure column to base by slightly moving the top of the

column by hand while exerting a downward pressure

until column is tight in tapered cup.

3. Insert enclosed screw and washer through the pedestal

base into the pedestal column and tighten to 150in. lbs.

torque securing the assembly.

4. Adjust column to desired height and lock in position by

tightening socket head screw in collar.

IMPORTANT: Do not over tighten!

5. Place assembled circulator face down on a flat surface.

6. Tip pedestal assembly over, placing flattened column

end in motor yoke (or along side cast aluminum support

on oscillating circulators). Align holes and insert larger

bolt and finger tighten lock nut.

7. Insert smaller bolt through motor adjustment slot and

column end and finger tighten lock nut.

8. Stand entire unit upright by lifting at the motor end of the

column. Adjust circulator angle to desired position and

tighten larger bolt to 200-230 in. lbs. and smaller bolt to

150-160 in. lbs.

9. Place assembled pedestal and fan on a flat, level

surface. Do not place the cord under the pedestal base.

Locate assembly where cord will not be a tripping

hazard.

10. Insert the plug into a properly grounded three-prong

receptacle. The unit is now ready for operation.

Optional Open Pedestal Floor Mounting

1. Large diameter column adjusts from 3 1/2- 6 ft. circulator

heights.

2. 38” open base is heavy gauge steel for stability and

designed for ease of area cleaning.

Optional Open Pedestal Assembly Instructions

1. Insert column firmly into base cup.

2. Secure column to base by inserting the enclosed screw

through the base cup hole and tightening to 50-75 in.

lbs.

3. Adjust column to desired height and lock in position by

tightening socket head screw in collar.

NOTE: Refer to Step 5 of the previous section for

assembling the circulator head to the pedestal.

NOTE: Use only the mounting hardware which is

recommended for use on Cook Air Circulators.

Optional Suspension Bracket

1. For mounting circulators from ceiling beams or rafters.

2. Furnished with secondary support cable for use when

circulator is mounted overhead.

Oscillating circulators must not be used with suspension bracket.

Optional I-Beam Mount

1. For mounting circulator from I-beams and columns.

Adjustable bracket allows omni-directional air

circulation.

2. Length can be increased by adding apiece of standard

1-1/2” threaded pipe between the I-beam mount flange

and the yoke adapter.

NOTE: Use only the mounting hardware which is

recommended for use on Cook Air Circulators.

Optional Suspension Bracket

(Refer to Figure 3)

1. The suspension bracket is designed to fit over standard

size 2” lumber and should be hung from any horizontal

member 2 x 3” or larger.

3

Page 4

2. Install a lag screw

through the

mounting hole to

hold the bracket

securely to the

wooden member.

Mounting

Bolts

Beam

Mounting

Nuts

3. Position

suspension

Circulator

bracket in the

motor yoke and

align bolt holes.

4. Insert the larger

Figure 3 - Suspension Bracket

Installation

dia. bolt in the pivot

hole and install the lock nut finger tight.

5. Insert the smaller dia. bolt in the slot in the motor yoke

(or support bracket) and smaller hole in the pivot

bracket and install lock nut finger tight.

6. While holding the circulator at the desired angle, tighten

the smaller dia. bolt.

7. Tighten larger bolt to 200-230 in. lbs. and smaller bolt to

150-160 in. lbs., being careful to maintain desired

position.

8. Plug the power cord into a properly grounded threeprong receptacle.

NOTE: No replacement parts available.

Optional I-Beam Mount Assembly Instructions

(Refer to Figure 4)

1. (Locate the L-shaped

pipe to the desired

location on the I-beam

flange). Install the 5/16 x

2” U-bolts over the pipe

and through the

clamping plate holes.

The flat part of the

clamping plate fits on the

I-beam flange and the

end with the slight bend

goes against the pipe.

Finger tighten the nuts

on the U-bolt.

2. Slide the clamping plate

onto I-beam flange until

Figure 4 - I-Beam Installation

U-bolts contact flange.

3. Tighten nuts on U-bolt so pipe does not move.

4. Screw on the adapter mount as far as it will go to the Lshaped pipe. Rotate adapter mount back to desired

location and tighten set screw in pipe coupling.

5. Install circulator to adapter mount using hardware

provided. Tilt fan to desired angle and tighten larger bolt

to 200-230 in. lbs. and smaller bolt to150-160 in. lbs.

6. Install secondary support cable according to

instructions.

7. Move fan control rocker switch to OFF position and plug

power cord into a properly grounded three-prong

receptacle.

Secondary Support Cable

(For use with CAC-W, CAC-WW and CAC-WX)

To insure proper installation, carefully read and follow

steps 1 thru 6 listed.

Use of this product does not guarantee protection

against injury of persons. Mounting of both the circulator and cable could fall if subject to abuse or neglect or if

improperly installed.

Figures 2 and 3 show typical installations using

suspension and wall/ceiling type brackets.

1. Loop one end of the cable

around the large diameter

wires of both the front and

rear guard.

1 - 2" Tail

Tight Loop

in Cable

(Refer to Figure 5).

2. Attach a cable clamp with

the “U” on the tail side of

the loop leaving a tail of

approximately 1 to 2”.

Tighten clamp nuts to 32

Figure 5 - Cable Clamping

in. pounds and torque

forming a tight loop. Make sure no part of the cable

interferes with the propeller.

3. Attach a second clamp (not shown) 1 to 2” from the first

and tighten to 32 in. pounds torque. A tail of 1 to 2”

must extend past the second clamp.

4. Wrap the other end of

the cable around a

secure building joist,

beam, truss, or other

support near the fan

(Refer to Figures 6 and

7). Take up all excess

slack in the cable. If

the fan is an oscillating

model, leave enough

slack to allow free

Ceiling

Joists

Secondary

Support

Cable

Figure 6 - Suspension Bracket

Support

Bracket

movement through range of motion.

5. Attach the two (2)

remaining cable

clamps as indicated in

step 2. The excess tail

should be trimmed to

extend 1 to 2” past the

second clamp.

6. Check the assembly to

assure the propeller is

free of all obstructions.

Figure 7 - Wall/Ceiling Bracket

Secondary

Support

Cable

Wall/Ceiling

Bracket

NOTE: No replacement

parts available.

Large

Guard

Wires

4

Page 5

Assembly & Installation – (CAC-DF)

IMPORTANT: It is recommended that the wall mount be

assembled and installed prior to mounting fan.

1. Assemble the back

channel, bottom

channel, and arm

assembly with four

bolts (5/16-18 x 2-1/

2" long) and nylon

locknuts (Refer to

Figure 8).

2. Tighten all bolts.

IMPORTANT: Do not

Figure 8 - Mounting Arm

Assembly

over tighten bolts.

Overtightening will cause the channels to collapse.

Mounting Fan/Arm Assemblies

Anchoring hardware and building structure must be

capable of holding 500 pounds per bolt.

1. Layout a rectangular pattern for four (4) bolt anchors

that is 5.0” wide to bolt centers at top and bottom

and10.0” high at both sides of bolt centers.

2. Mount the bracket to

the wall as shown in

Figure 9.

3. Locate two 1/2 x 11/2”

long bolts, two 1/2”

nuts, three 1/2” flat

washers and one

friction washer. These

will be used in step 4

to install the arm

assembly.

4. Insert the arm assembly

into the wall bracket as

shown in Figure 10.

NOTE: Friction washer

goes between the wall

bracket and lower pivot

channel.

5. (Refer to Figure 11)

Insert the steel spacer

tube in the end of the

arm tube as shown.

Line up holes in tube with inside of spacer.

6. Insert the 3/8 x 3” long

carriage bolt through

the hole in the top

center portion of the

fan yoke.

7. Slip one (1) flat washer

onto bolt followed by

the bent “Z” bracket

(silver color).

NOTE: Position the

upward extending leg

toward the front of the fan as shown in Figure 11. Add

another (1) flat washer on top of “Z” bracket.

Figure 9 - Mounting Bracket

Orientation

Figure 10 - Arm Installation

Black "Z"

Bracket

Steel

Spacer Tube

Silver "Z"

Bracket

Carriage

Bolt

Figure 11 - Fan and Light

Attachment

IMPORTANT: Do not assemble without “Z” brackets. The

“Z” brackets are designed to prevent damage to the

cords caused by twisting, which may occur if the

brackets are not present.

8. Attach the fan to wall mount by inserting the carriage

bolt in the hole provided at the end of the square tube.

Add black colored “Z” bracket with leg toward the front

of the light extending downward. Add light. Slip one (1)

flat washer over top, followed by the 3/8-16nylon

locking nut provided.

9. Tighten nut to a snug fit. The pivot should provide

sufficient resistance to hold position while in operation,

but still allow movement for easy positioning.

10. Plug fan and light in as shown. Route the fan cord in a

loop as shown to prevent pinching.

NOTE: The recommended location for the electrical outlet is

directly below the wall mount pivot.

Lamp Installation

1. Screw lamp (300 watt max.) into socket until seated

firmly.

2. For lamp replacement, press spring loaded, black push

button in the back of the shade. This will relieve the

spring tension on the socket and allow for easy removal

of the lamp.

Do not use ordinary A-type light bulbs, or any lamp rated

higher than 300 watts.

CAC-MH Assembly

1. Tilt fan onto its side.

2. Using 2” bolts and nuts, bolt tube to angle, taking care to

align proper holes (See CAC-MH Parts List on Page 8).

Tighten bolts finger-tight. (All hardware will be tightened

fully in step 5).

3. Bolt gussets (See CAC-MH Parts List on Page 8) to

tube/angle assembly, finger-tight.

4. Bolt tube/angle assemblies to sides. Position adjustable

stand against fan stand, matching holes in fan stand to

slots in adjustable stand. Bolt together with 1” bolts and

nuts.

5. Tighten all bolts securely.

6. Assemble casters as shown.

7. Chock wheels. Carefully tilt unit upright.

CAC-WH Assembly Column Installation

1. Locate column for mounting bracket. (NOTE: 6”

minimum, 10” maximum column width).

2. Mount the Column Mounting Bracket to the column

using four 5/8” bolts, grade 5 minimum (not included),

through the Back Plate (See CAC-WH Parts List on

Page 7). NOTE: Bolt length will be determined by the

width of the column. Bolts should be approximately 2”

longer than column depth.

3. Ensure that the centerline of the bracket and the

centerline of the column align with each other and that

the bolts are placed against the column’s surface before

tightening.

5

Page 6

Troubleshooting Chart

Symptom Possible Cause(s) Corrective Action

Fan inoperative

Fan cycles on and off

Unit fails to

oscillate (sweep)

Excessive noise

while operating

Insufficient air flow

1. Blown fuse or open circuit breaker

2. Defective motor or

switch

3. Broken belt

1. Thermal protector

2. Faulty wiring or control

switch

1. Connection arm not

secured

2. Defective gear assembly

1. Defective bearing

2. Loose or damaged propeller

3. Loose, worn, or dirty belt

4. Motor not secure

1. Belt slippage

2. Guard excessively dirty

1. Replace or reset

2. Repair or replace

3. Replace

1. Check for obstructions

to air flow , voltage,

intake air temperature

2. Repair or replace

1. Tighten

2. Replace

1. Replace shaft/bearing

assembly

2. Tighten or replace

3. Adjust, replace, or

clean

4. Tighten motor nuts

1. Replace and/or adjust

tension

2. Clean guards

4. Torque bolt to 85-90 ft-lb.

5. Proceed to unit mounting.

Wall Mounting

1. Locate a solid support structure within the wall.

2. Discard the back plate when wall mounting.

3. Use four 5/8” x 2” lag bolts, grade 5 minimum (not

included), to secure bracket to the wall.

4. Proceed to unit mounting.

Unit Mounting

1. Using 4-1/2” x 1/75” bolts and nuts, attach the high

volume, high velocity industrial circulator to the column/

wall bracket (See CAC-WH Parts List on Page 7).

Tighten the nuts and bolts to 45-50 ft-lb torque.

2. Using the safety cable holes located in the Column

Mounting Bracket and the Back Plate, install the safety

cable (See CAC-WH Parts List). Overlap the cable’s

ends, and tighten the clamps and nuts to 45 ft-lb torque.

The cable should not exceed 1” of slack.

CAC-W / CAC-WO Parts List

3

2

4

1

Part

No.

Description

1 Propeller

2 Front Guard

3 Rear Guard

7

4 Motor Assembly (includes cord & switch)

7 Wall/Ceilling Bracket

CAC-P / CAC-PO Parts List

3

2

1

4

17

CAC-M Parts List

15

15

16

9

8

6

17

1

10

3

6

2

4

12

11

5

14

Part

No.

Description

1 Propeller

2 Front Guard

3 Rear Guard

6

4 Motor Assembly (includes cord & switch)

5 Pedestal Base Assembly

6 Column Assembly

5

Part

No.

Description

1 Housing

2 Motor (w/key)

3 Propeller

4 SPST Switch

5 Cord Assembly

16

13

6 Guard

7 Handle

81/2” Dia. Axle

9 7” Dia. Wheel

7

10 #10-32 Lock Nut

11 Strain Relief

12 1/4-20 x 1/2” HWH Screw

13 Wire Tie

14 1” Crutch Tip

15 Parts Pack

16 1/4-20 x 1/2” Screw

17 1/4-20 Nut

6

Page 7

CAC-WW / CAC-WX Parts List

5

4

2

3

CAC-CH Parts List

14

2

4

Hazardous

Location Mount

4

6A

Part

No.

Description

1 Motor*

2 Propeller

3 Guard Set: Front Guard & Rear Guard

4

1

4 Mounting Hardware Package

5 1/4”-20 x 1” HHC Screw

6A Wall Bracket

7

4

6B

Washdown Mount

6B Wall/Ceiling Bracket (Includes support cable)

7 5/16” x .688” x .065” Flat Washer

*Does not include cord and switch.

Part

No.

Description

1 Propeller

2Guard

3 1/2”-13 x 1.5” Hex Bolt

4 3/8”-24 Nut

3

5 3/8”-24 x 1” Bolt

6 3/8” x 13/16” Washer

7 5/16”-24 x .75” HHC Bolt

12

8

10

11

9

7

1

2

6

5

8 5/16”-24 Nut

9 5/16” x .688” Washer

10 .88” Conduit Bushing

11 Motor *

12 Housing Assembly

13 Split Taper Bushing

14 Bracket Assembly

*Replacement motor does not include cord.

CAC-WH Parts List

Column

1

2

3

7

10

(CAC-CH with wall mount assembly)

13

8

9

4

Part

No.

Description

1 Column Mounting Bracket

2 1/2 “ x 1.75” Flanged Bolt

31/2” Nut

5

6

4 Back Plate

5 Safety Cable

6 Cable Clamp with Nuts

7 5/8” Bolt (Grade 5 min.)

85/8” Nut

9 5/8” Washer

(1.25” OD min. x 0.12” thickness min.)

10 5/8” Split Lock Washer

7

Page 8

8

CAC-FH Parts List

12

3

Part

2

No.

1 Propeller

Description

2 Guard

12

8

10

11

1

2

3 1/2”-13 x 1.5” Hex Bolt

4 3/8”-24 Nut

5 3/8”-24 x 1” Bolt

6 3/8” x 13/16” Washer

7 5/16”-24 x .75” HHC Bolt

8 5/16”-24 Nut

9 5/16” x .688” Washer

10 .88” Conduit Bushing

4

9

7

13

6

5

11 Motor *

12 Housing Assembly / Stand Assembly

13 Split Taper Bushing

*Replacement motor does not include cord.

CAC-MH Parts List

2

8

1

8

6

12

10

11

7

8

9

4

(CAC-FH with stand assembly)

Part

10

11

No.

1 Left Gusset

Description

2 Right Gusset

12

3 Tubing Assembly

4 Angle Assembly

5 Right Side Channel Assembly

7

3

5

6 Left Side Channel Assembly

7 3/8 - 16 x 1.00” Bolt

8 3/8 - 16 x 2.00” Flanged Bolt

9 3/8 - 16 Flanged Nut

10 Cotter Pin

11 5” Dia. Wheel

12 1/2 x 1.4 x .11 Zinc Washer

Limited Warranty

Loren Cook Company warrants that your Loren Cook fan was manufactured free of defects in materials and workmanship, to the extent stated herein. For a period of one (1)

year after date of shipment, we will replace any parts found to be defective without charge, except for shipping costs which will be paid by you. This warranty is granted only to

the original purchaser placing the fan in service. This warranty is void if the fan or any part thereof has been altered or modified from its original design or has been abused,

misused, damaged or is in worn condition or if the fan has been used other than for the uses described in the company manual. This warranty does not cover defects resulting

from normal wear and tear. To make a warranty claim, notify Loren Cook Company, General Offices, 2015 East Dale Street, Springfield, Missouri 65803-4637, explaining in

writing, in detail, your complaint and referring to the specific model and serial numbers of your fan. Upon receipt by Loren Cook Company of your written complaint, you will be

notified, within thirty (30) days of our receipt of your complaint, in writing, as to the manner in which your claim will be handled. If you are entitled to warranty relief, a warranty

adjustment will be completed within sixty (60) business days of the receipt of your written complaint by Loren Cook Company. This warranty gives only the original purchaser

placing the fan in service specifically the right. You may have other legal rights which vary from state to state.

Corporate Offices: 2015 E. Dale Street Springfield, MO 65803 417.869.6474

lorencook.com

8

CAC IOM - July 2004

Loading...

Loading...