Page 1

AUTOMATIC SERVO PRESS

TOOLING FIXTURES

ROBOTIC LOAD

VISION INSPECTION

WITH PIN CHECK

TRAY FEEDE

RS

CUSTOMER SATISFACTION…………“Whatever it takes”

PRESS DESCRIPTION

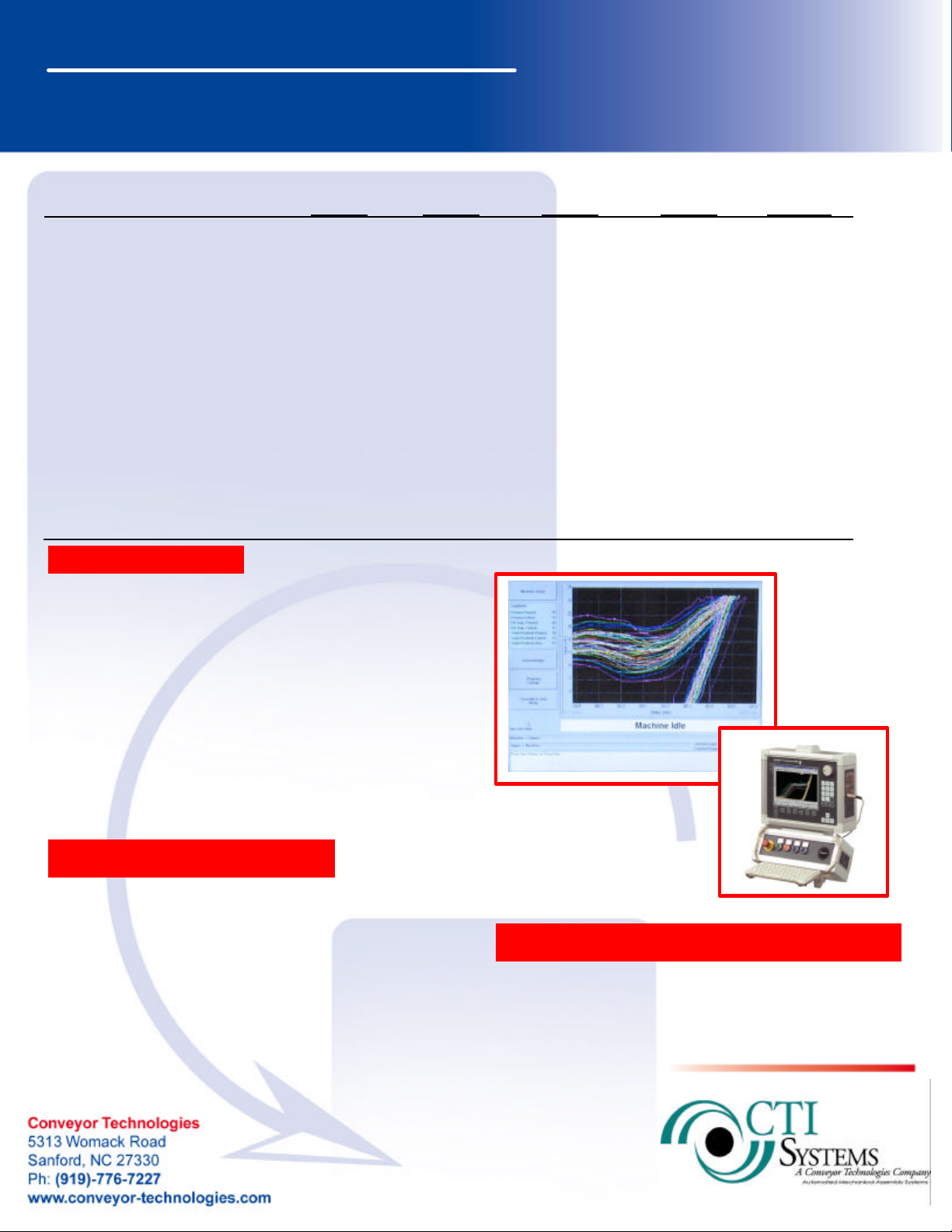

The Servo Automatic Press System allows precise control of the press

operating parameters (Force, Distance and Speed) as a self contained

ergonomic solution.

Both force curve and SPC control graphs are displayed for the current product

being processed.

Data for all products are stored in a database and sent to facility mainframe on

demand.

Product recipes (programs) are entered with Pass/Fail characteristics. At the

end of each cycle the system displays and records pass/fail information.

STANDARD FEATURES

PN: AP-12/110-20/36

- 15 inch touch screen operator interface

- Force and SPC graphs shown of product in-process

- Unlimited storage of product profiles

- Display current production run Quantities

- Process stops with unexpected press force at distance

- Windows based PC software

- Bar code ready

- Programmable hold time

- Automatic product and component loading

Page 2

SA

P(Force)

-

(Window width)

-

(options)

-

(options)

AUTOMATIC SERVO PRESS

CHART NOTES:

SOFTWARE

(TS)

CUSTOMER SATISFACTION…………“Whatever it takes”

Features for 20" window AP12-20 AP32-20 AP55-20 AP80-20 AP110-20

Force KN / Tons 12 / 1.3 32 / 3.6 55 / 6.2 80 / 9 110 / 12.3

Footprint (W" x D” x H") (in) 28x25.5x78 28x25.5x82 28x25.5x84 28x25.5x86 28x25.5x92

Ram Stroke (in) 5.5 5.5 5.5 5.5 5.5

Vertical tooling / Product Area (in) 11.5 11.5 11.5 11.5 11.5

Ram Approach Speed (in/sec) 3 3 3 3 3

Ram Press Speed- Programmable .1-3 in/sec .1-3 in/sec .1-3 in/sec .1-3 in/sec .1-3 in/sec

Drive Type Screw Screw Screw Screw Screw

Accuracy (in) 0.0002 0.0002 0.0002 0.0002 0.0002

Repeatability (in) 0.0001 0.0001 0.0001 0.0001 0.0001

Tooling surface on Ram (W" x D") 6.5x4 9 x 5 9 x 5 10 x 6 10 x 6

Max Product width accepted (in) * 20 20 20 20 20

Throat Depth (behind Ram) (in) 14.5 14.5 14.5 14.5 14.5

Machine Front to Press center (in) 10.5 10.5 10.5 10.5 10.5

Force, Speed, SPC Graphing std std std std std

Safety Light Curtains std std std std std

1) Ram strokes available up to 20 inches

2) Higher Ram Approach speeds Available

3) Tooling Surface should be centered ( 80% of Load ) on

ram

4) Deeper throat depths available

* 24” and 36” Product windows optional

SPECIAL NOTES:

Top & Bottom Press Tooling Set

(TSET) Top & Bottom Tooling set w/ Electrical Pin Check

(PTF) Press-Thru fixture

(HC) Hand crank (x-axis) Top Tooling Position

(PTT) Programmable Position Top Tooling (x-axis)

(FS) Bar Code Scanning - Fixed Location - (2D)

(HS) Hand Held Bar Code Scanner

(MPxx-24) 24" Product Window

(MPxx-36) 36" Product Window

(LT) Light Tower w/ alarm

(TF) Tray Feeders

(RA) Robotic Assist Loading

PART NUMBER CONFIGURATION

MP= Manual Press

SAP= Semi-Automatic Press

AP= Automatic Press

Loading...

Loading...