Page 1

•

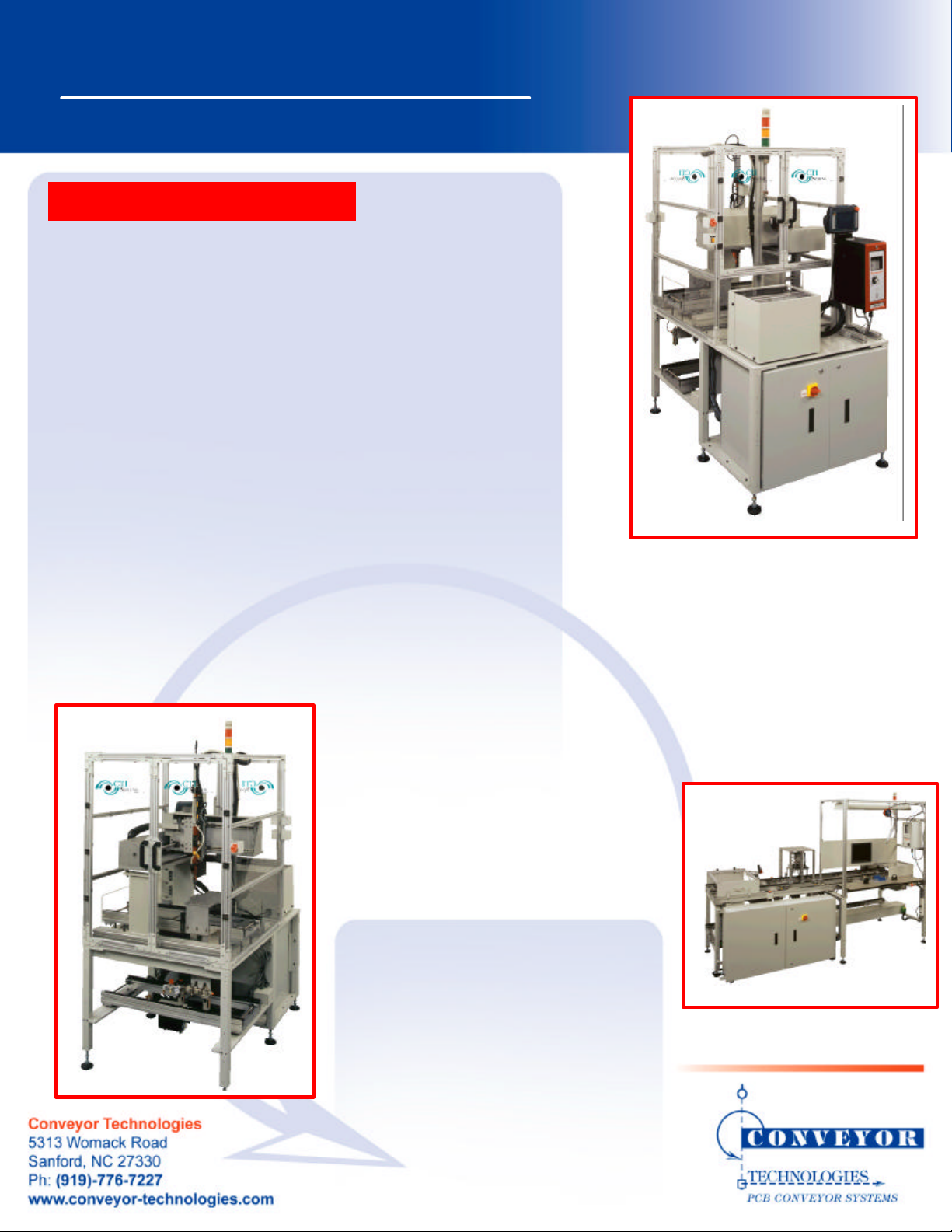

AUTOMATIC SCREW MACHINE

STANDARD FEATURES:

1 Meter X 1.2 Meter Footprint

• CONVEYOR

- 1 Meter Edge Conveyor

- PCB Edge Lift and Clamp

- Precision PCB Board Stop

- Speed Control Slow Down

• GANTRY

- 2 Axis Precision Gantry

- 18 X 20" Platform

- Yaskawa Servo Drives for Each Axis

- THK Slide and Ball Screw Cartesian Gantry Assembly

•SCREW GUN

- Bottom or Top Side Screw Gun Assembly

- Single Spindle Assembly

- Depth Sensor Controls

- Torque Sensor Controls

- Closed Loop Feed Back for Screw Assembly Complete

- 50 MM Z Axis Stroke (On Precision Slide Assembly)

- Screw Feeder Assemblies

- Capable of Changing Torque Automatically

• PRESS PLATE

- Pneumatic Press Plate Assembly

- Interchangeable Tooling Fixtures (Change out in Less than 5 Minutes)

• SOFTWARE

- Programmable Positions

- Recall Programming from Recipe

PN: ASM-1M-1F-3A

Page 2

OPTIONS:

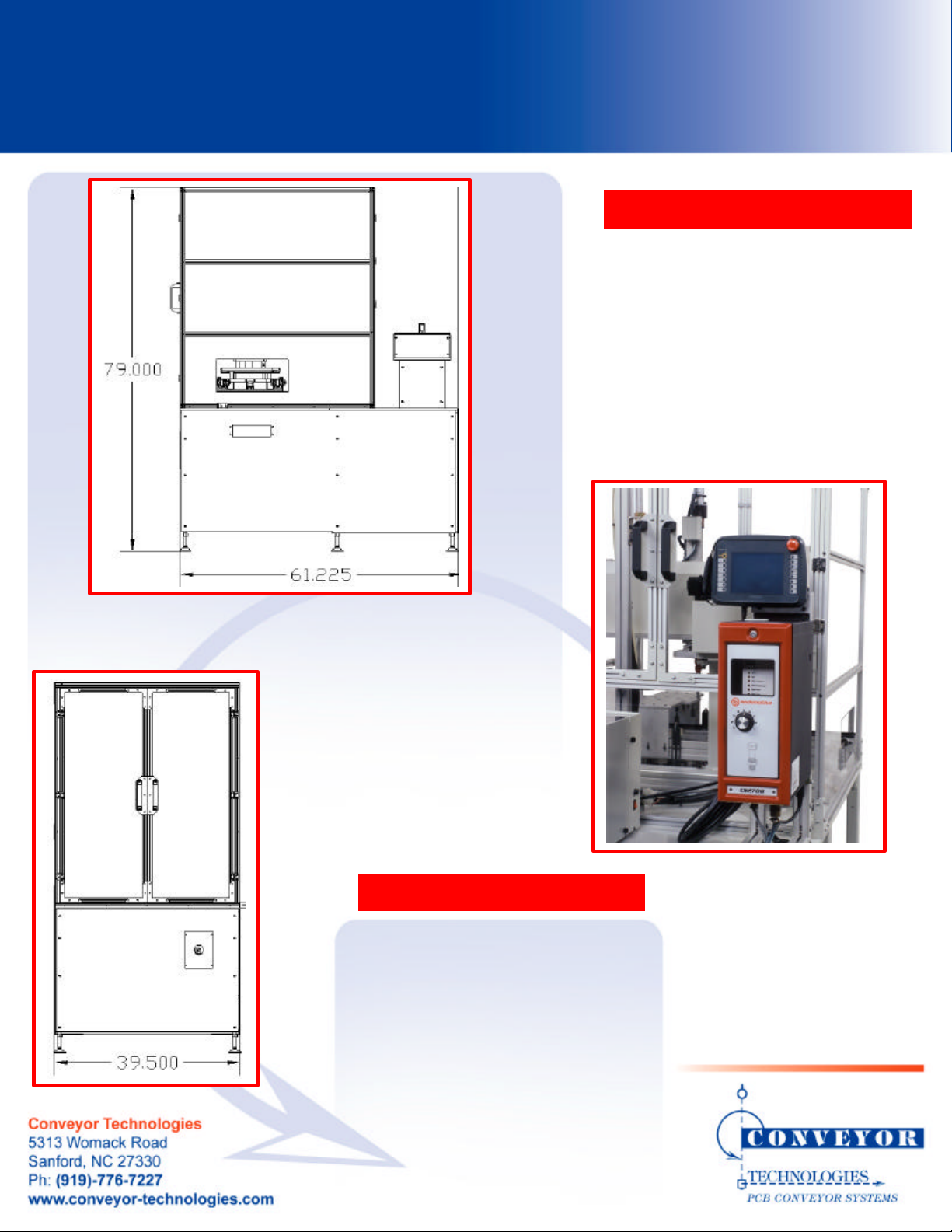

SPECIFICATIONS:

• PCB Size:

................................

.........

Min. 2” X 4”

• Multiple Screw Guns

• Multiple Bowl Feeders

• Manual Assembly Station

• Conveying Media:

- Pallet Timing Belt

- Edge Chain

- Edge Roller

• Light Tower with Alarm

• Automatic Width Adjust

• Remote Control Station

• Depth/Presence Pin Check Station

• PC Controls

• Line Networking

• 2D Barcode Reader

........................................................Max.16” X 18”

• PCB Height:....................................37.5” + - 2”

• Edge Clearance: .......100” from edge of PCB

• Air Requirements:...................2 cfm @ 25 PSI

• Power Requirements:....15 amps @ 220VAC

• PCB Max Weight:.....................................10 lb.

• PCB Min. Thickness:.................................010”

• PCB Max. Thickness:................................180”

• Cycle Times:

- Load/Unload...........................................6 sec.

- Screw Drive ..................................2.3 – 3 sec.

Loading...

Loading...