Page 1

Page 2

CONVEX

Computer

Corporation

3000 Waterview

Parkway

P.O.

Box

833851

Richardson,

TX

75083-3851

United States

of

America

(214)497-4000

Page 3

CONVEX

Elite

3

Disc

Drive

Service Guide

Order

No. DHW-261

First Edition

April 1993

CONVEX Press

Richardson, Texas

United States of America

Page 4

CONVEX

Elite 3 Disc

Drive

Service

Guide

Order

No.

DHW-261

Copyright©

1993

CONVEX Computer Corporation

All rights reserved.

This document is copyrighted. This document

may

not,

in

whole

or

part, be copied, duplicated, reproduced, translated,

electronically stored,

or

reduced to machine readable form

without prior written consent from

CONVEX

Computer

Corporation.

Although the material contained herein has been carefully

reviewed, CONVEX Computer Corporation does

not

warrant

it to

be free of errors or omissions. CONVEX reserves the right to

make

corrections, updates, revisions

or

changes to the information

contained herein. CONVEX does

not

warrant the material

described herein to

be free of patent infringement.

UNLESS

PROVIDED

OTHERWISE

IN

WRITING

WITH

CONVEX

COMPUTER

CORPORATION

(CONVEX),

THE

PROGRAM

DESCRIBED

HEREIN

IS

PROVIDED

AS

IS

WITHOUT

WARRANTY

OF

ANY

KIND,

EITHER

EXPRESSED

OR

IMPLIED,

INCLUDING,

BUT

NOT

LIMITED

TO

THE

IMPLIED

WARRANTIES

OF

MERCHANTABILITY

AND

FITNESS

FOR A PARTICULAR

PURPOSE.

SOME

STATES

DO

NOT

ALLOW

THE

EXCLUSION

OF

IMPLIED

WARRANTIES.

THE

ABOVE

EXCLUSION

MAY

NOT

BE

APPLICABLE

TO

ALL

PURCHASERS

BECAUSE

WARRANTY

RIGHTS

CAN

VARY

FROM

STATE

TO

STATE.

IN

NO

EVENT

WILL

CONVEX

BE

LIABLE

TO

ANYONE

FOR

SPECIAL,

COLLATERAL,

INCIDENTAL

OR

CONSEQUENTIAL

DAMAGES,

INCLUDING

ANY

LOST

PROFl'IS

OR

LOST

SAVINGS,

ARISING

OUT

OF

THE

USE

OR

INABILITY

TO

USE

THIS

PROGRAM.

CONVEX

WILL

NOT

BE

LIABLE

EVEN

IF

IT

HAS

BEEN

NOTIFIED

OF

THE

POSSIBILITY

OF

SUCH

DAMAGE

BY

THE

PURCHASER

OR

ANY

THIRD

PARTY.

CONVEX and the CONVEX logo ("C") are registered trademarks of CONVEX

Computer

Corporation.

UNIX

is a registered trademark of UNIX System Laboratories, Inc.

Seagate, Seagate Technology,

and

the Seagate logo are registered trademarks

of

Seagate

Technology, Inc.

Computer Products/Power Conversion America

is a registered

trademark

of

Computer

Products, Inc.

()

This book is recyclable excluding cover

and

binding.

Printed in the United States of America

Page 5

Revision

information

for

CONVEX

Elite 3 Disc

Drive

Service

Guide

Edition Document No. Description

First

081-010230-000 Released April

1993.

Page 6

Contents

l'r4tfCIC:ft

••••••••••••••••••••••••••••••••••••••••••••••••••••••••

lci

Purpose and audience ................................................................ xi

Using this guide .......................................................................... xi

Notational conventions .............................................................. xi

Notes

and

cautions .................................................................... xii

Associated documents .............................................................. xii

Ordering documents ................................................................. xii

Technical assistance .................................................................. xiii

FCC notice .................................................................................. xiii

Electrostatic discharge protection .......................................... xiii

1

Description

and specifications ............... 1

Drive specifications ..................................................................... 1

de power requirements ......................................................... 3

Front panel indicators and switches ................................... 4

Control board jumpers .......................................................... 6

I/0

board jumpers ................................................................. 8

Power supply specifications ....................................................... 9

Elite 3 chassis ...............................................................................

11

2 Unpacking and

installation

...................

13

Unpacking and inspection ....................................................... 13

Inspection .............................................................................. 13

Unpacking .............................................................................

13

Damage claims .....................................................................

14

Preparations .......................................................................... 14

Installing power strip

and

disc tray ..................................

14

Installation ..................................................................................

14

Installing the Elite 3 chassis ................................................ 16

Connecting a single drive ................................................... 17

Connecting multiple disc drives ........................................

20

Physical configuration ......................................................... 22

3 Integration and

testing

..........................

27

Software integration .................................................................. 27

General integration procedure ........................................... 27

Contents v

Page 7

I ioconfig file ..........................................................................

28

I

etc/

disktab .......................................................................... 30

Testing the Elite 3 disc drive

with

idcfmt

............................

31

Verifying format ...................................................................

31

Formatting a drive ...............................................................

32

4 Maintenance

and

IPB

............................

33

Troubleshooting ..........................................................................

33

Elite 3 disc drive error codes ...............................................

33

Fault symptom code

(FSC)

..................................................

35

Sector errors ..........................................................................

44

FSC

codes reported

during

autoconf

............................. 45

WM

messages ..................................................................... 45

Determining disc usage ....................................................... 46

Removal

and

replacement procedures ................................... 48

Elite 3 chassis ........................................................................ 48

Disc drive ............................................................................... 48

Power supply ........................................................................ 49

Operator panel ...................................................................... 49

Fan assembly .........................................................................

50

Air filter .................................................................................

51

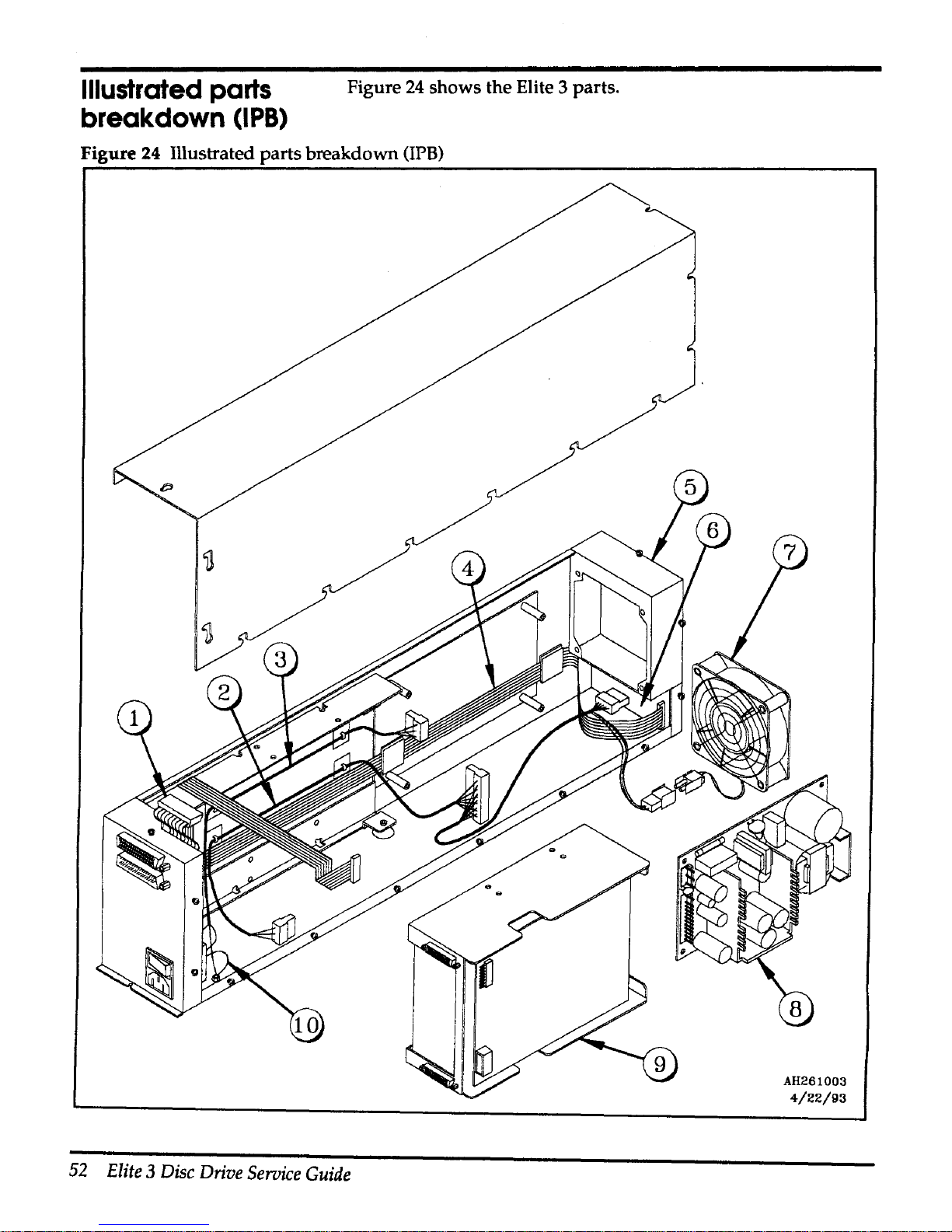

Illustrated parts breakdown

(IPB)

...........................................

52

A idcfmt ( 1

D)

man

page

..........................

55

vi

Elite 3 Disc

Drive

Service

Guide

Page 8

Figures

Figure 1

Figure2

Figure 3

Figure4

Figures

Figure6

Figure 7

Figures

Figure9

Figure 10

Figure

11

Figure

12

Figure

13

Figure

14

Figure

15

Figure 16

Figure 17

Figure

18

Figure

19

Figure20

Figure21

Figure22

Figure23

Figure24

Front panel ...................................................................... 4

Control board jumper location..................................... 6

J/O

board jumper locations .......................................... 8

Power

supply

component location ............................ 10

Elite 3 chassis ............. ...................................... .............

12

Additional power strip location.................................

15

Elite 3 disc tray.............................................................. 16

Connecting a single drive............................................ 17

JDC bulkhead

port

assignments for C3200/C3400.

18

JDC

bulkhead port assignments for C3800 ...............

19

Connecting multiple drives........................................

21

JDC

maximum drive configuration...........................

23

Expansion cabinet drive locations for 32 drives......

24

Expansion cabinet drive locations for 16 drives......

25

/ioconfig example 1 .....................................................

29

/ioconfig example 2 .....................................................

29

Example I

etc/

disktab ................................................. 30

WM

device failure message ...................................... 45

WM

completion message .......................................... 46

Determining disc usage

with

df

I

grep..................

46

Determining disc usage from

/etc/fstab

.................. 47

Elite 3 operator panel cable routing...........................

50

Air filter access..............................................................

51

Illustrated parts breakdown (IPB) .............................

52

Figures

vii

Page 9

Tables

Table 1

Table2

Table3

Table4

Tables

Table6

Table 7

Table8

Table9

Table

10

Table

11

Table

12

Table

13

Drive specifications ......... ........................ ........................ 1

Elite 3 disc drive de

power

requirements..................... 3

Elite 3 front panel indicators

and

switches .................. 5

Control board jumper block

J12

pin

assignments ....... 7

1/0

board jumper block

pin

assignments .................... 8

Power supply characteristics ...............

..

........................ 9

Power supply voltage specifications...........................

10

Power supply

pin

chart ..................................................

11

I

etc/

disktab description ............

..

................................

30

Elite 3 disc drive error codes........................................

34

FSC

field descriptions

..

....................................... ..........

35

FSC

descriptions ............................ ....... .................... .....

36

IPB

parts list ....................................................................

53

Tables

ix

Page 10

Preface

Purpose

and

audience

Notational

conventions

The CONVEX

Elite 3 Disc

Drive

Service

Guide

provides a general

overview of the Seagate Elite 3 disc drive and related equipment.

This guide describes how

to:

• Install the Elite 3 disc drive

and

related equipment

• Integrate the Elite 3 disc drive into the CONVEX operating

system

(ConvexOS)

This document is intended for:

• CONVEX customer support engineers

and

CONVEX

manufacturing personnel

• CONVEX customers who install

and

maintain their

own

Elite 3 disc drives and related equipment

This section discusses notational conventions used

in

this book.

Bold

mono

space

In command examples, text shown

in

bold

monospace

identifies user

input

that

must

be typed exactly as shown.

Mono

space

Italic

In paragraph text,

monospace

identifies:

• Command names

• System calls

• Data structures

and

types

In command examples,

monospace

identifies command output, including error

messages.

In command syntax diagrams, text

shown

in

monospace

must

be

typed exactly as

shown.

In paragraph text,

italic

identifies:

Preface

xi

Page 11

Notes

and

cautions

Note

Caution

Associated

documents

Ordering

documents

•

New

and

important terms

• Titles of documents

In command syntax diagrams,

italic

identifies variables

that

must

be

supplied

by

the user.

This document presents notes

and

cautions in the following

formats:

A Note highlights supplemental information.

A Caution

highlights Information necessary to

avoid

damage

to

the system.

For more information

on

the ConvexOS operating system,

you

can order the following books from CONVEX

Computer

Corporation:

•

ConvexOS

Primer

(DSW-133). This book introduces

new

users to the ConvexOS operating system.

•

ConvexOS

Programmer's

Reference

(DSW-332). This book is

the standard reference for the

ConvexOS operating system.

•

Managing

ConvexOS

Operations

Guide

(DSW-031). This book

is the standard reference for system operation.

•

Managing

ConvexOS

Configuration

Guide

(DSW-030). This

book describes the management of system resources.

To

order the current edition of this

or

any

other

CONVEX

document, send requests to:

CONVEX Computer Corporation

Customer Service

P.O.

Box

833851

Richardson

TX

75083-3851

USA

Please

include the order number (DSW

or

DHW number)

or

the

exact title of the document.

xii

Elite 3 Disc

Drive

Service

Guide

Page 12

Technical

assistance

FCC

notice

Electrostatic

discharge

protection

Caution

If

you

have questions that are

not

answered

in

this book, contact

the CONVEX Technical Assistance Center (TAC)

at

the

following locations:

• Within the continental U.S., call 1 (800) 952-0379.

•

From Canada, call 1(800)345-2384.

• From all other locations, contact the local CONVEX office.

You

may

also use the

contact

utility to report

any

problems

with

ConvexOS

or

its associated documentation. For more

information, refer to the contact(l)

man

page

in

ConvexOS

Man

Pages

for

Users,

or

the appendix ''Reporting problems"

in

the

ConvexOS

·Primer

or

Managing

ConvexOS:

Operations

Guide.

This equipment generates, uses

and

can

radiate radio frequency

energy.

If

the equipment is not installed

and

used

in

strict

accordance with the instruction manual,

it

may

cause

interference to radio communications.

This equipment has been tested

and

found to comply

with

limits

for a Class A digital device,

pursuant

to

Part

15

of

the

FCC Rules.

These limits are designed to provide reasonable protection

against harmful interference

when

equipment

is

operated

in

a

commercial environment.

When this equipment is operated in a residential area, it is likely

to cause interference. In this case, the interference

must

be

corrected at the operator's expense.

Do not connect external equipment to the utility outlets

in

CONVEX equipment cabinets. Unauthorized connection voids

all agencies' emissions certification.

The Elite 3

and

related assemblies are sensitive to static

electricity. Although some devices such as metal-oxide

semiconductors are extremely sensitive, all semiconductors, as

well as some resistors

and

capacitors,

may

be

damaged

or

degraded

by

exposure to static electricity.

Electrostatic damage to electronic devices

may

be caused

by

the

direct discharge of a charged conductor

or

by

exposure to the

static fields surrounding charged objects.

To

avoid

electrostaHc

damage,

service

personnel

must

observe

the

following

precautions

when

servicing

equipment:

Preface

xiii

Page 13

xiv

Elite 3 Disc

Drive

Service

Guide

• Ground yourself to the peripheral cabinet

or a grounded

service area whenever working

on

the Elite 3

or

related

assemblies, or whenever electronics will

be

exposed.

Connect yourself to ground with a wrist strap. Connection

may be made to any grounded metal assembly

in

the

peripheral cabinet. Remember that you

and

the electronic

devices must both be grounded to avoid potentially

damaging static discharges.

• Tum off power before removing

or

installing

power

cords.

• Shut down ConvexOS before cabling drives to the IDC

bulkhead.

•

Do

not remove any circuit boards from the drive.

• Never use an ohmmeter

on

any Elite 3 c.ircuit board.

Page 14

Description

and

specifications

1

Drive

specifications

Table 1 Drive specifications

Characteristics

Size

Interface

Capacity (bytes)

This chapter discusses the features, front panel functions,

and

electromechanical

and

physical specifications of

the

CONVEX

Elite 3 disc drive (CONVEX model DKD-505). The Elite 3 disc

drive

and

related hardware are designed to

be

used

with

the

CONVEX Integrated Disc Channel (IDC).

Table 1 contains the basic specifications for the Elite 3 disc drive.

Conditions

Specifications

Width

146

mm

(5.75

in.)

Height

83

mm

(3.25

in.)

Length

218

mm

(8.6

in.)

Weight

4.1

kg

(9.0

lb)

IPI-2E

(intelligent peripheral

interface)

Unformatted 3.1512019 Gbytes

Chapter 1 Description

and

specifications

1

Page 15

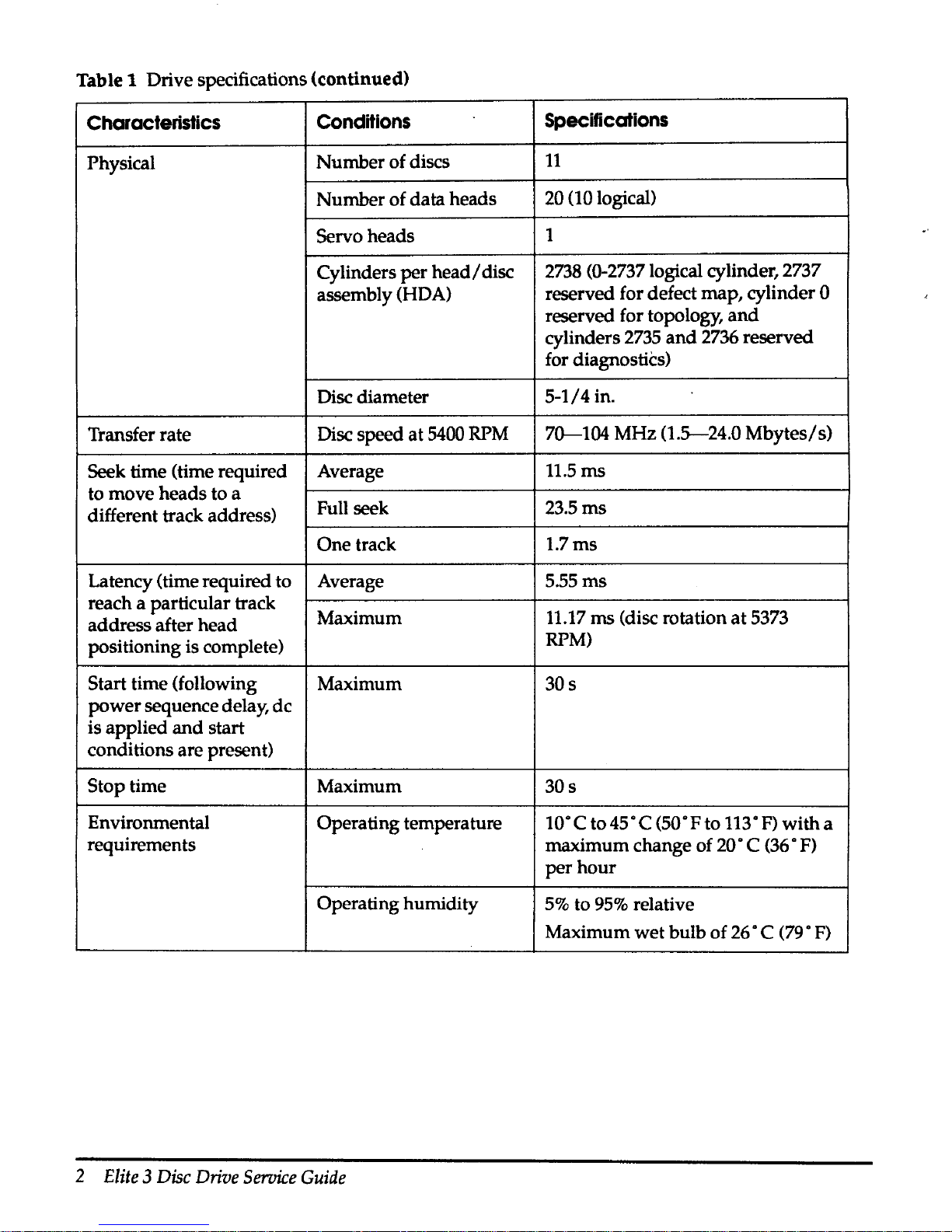

Table 1 Drive specifications (continued)

Characteristics

Conditions

Specifications

Physical

Number

of discs

11

Number

of data heads

20 (10 logical)

Servo heads

1

Cylinders

per

head/

disc

2738

(0-2737 logical cylinder, 2737

assembly (HOA)

reserved for defect map, cylinder

0

reserved for topology,

and

cylinders

2735

and

2736 reserved

for diagnostics)

Disc diameter

5-1/4

in.

Transfer rate Disc speed

at

5400 RPM

70---104

MHz

(1.5-24.0

Mbytes/s)

Seek time (time required Average

11.5ms

to move heads to a

different track address)

Full seek

23.5ms

One

track

1.7ms

Latency (time required to

Average

5.55ms

reach a particular track

Maximum

11.17

ms

(disc rotation

at

5373

address after head

positioning is complete)

RPM)

Start time (following

Maximum

30s

power

sequence delay,

de

is

applied

and

start

conditions are present)

Stop time Maximum

30s

Environmental

Operating temperature

10·c

to45°C

(50"Fto 113"F)

with

a

requirements

maximum change of

20"

C (36 • F)

per

hour

Operating humidity

5%

to

95%

relative

Maximum

wet

bulb

of

26 • C (79 •

F)

2

Elite

3

Disc

Drive

Service

Guide

Page 16

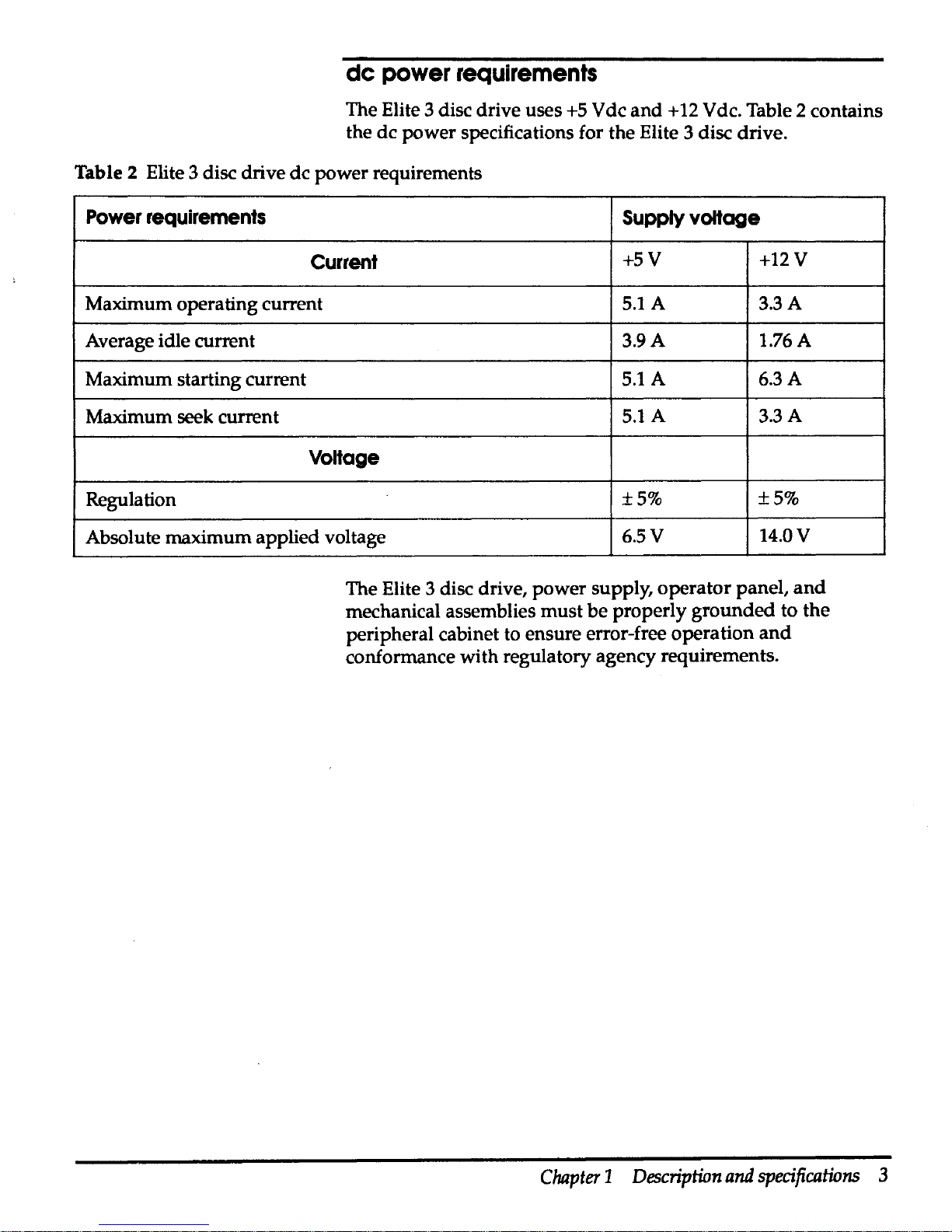

de

power

requirements

The Elite 3 disc drive uses

+5 V de

and + 12

V de. Table 2 contains

the

de

power specifications for the Elite 3 disc drive.

Table 2 Elite 3 disc drive de power requirements

Power

requirements

Supply

voltage

Current

+5V

+12V

Maximum

operating current

5.lA

3.3A

Average idle current

3.9A

1.76A

Maximum starting current

5.lA

6.3A

Maximum seek current

5.lA

3.3A

VoHage

Regulation

±5%

±5%

Absolute maximum applied voltage

6.5V

14.0V

The Elite 3 disc drive, power supply, operator panel,

and

mechanical assemblies

must

be

properly

grounded

to

the

peripheral cabinet to ensure error-free operation

and

conformance with regulatory agency requirements.

Chapter 1 Description

and

specifications

3

Page 17

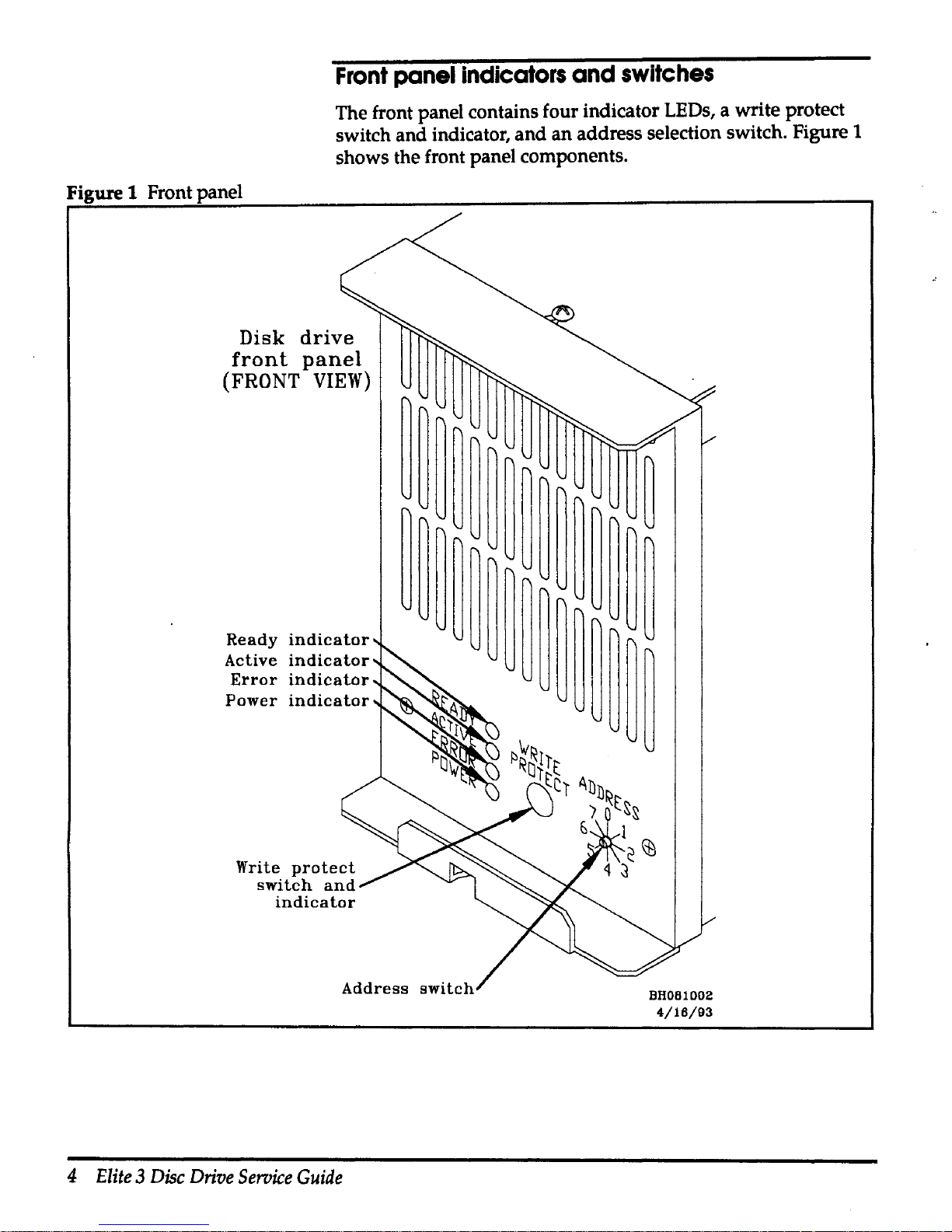

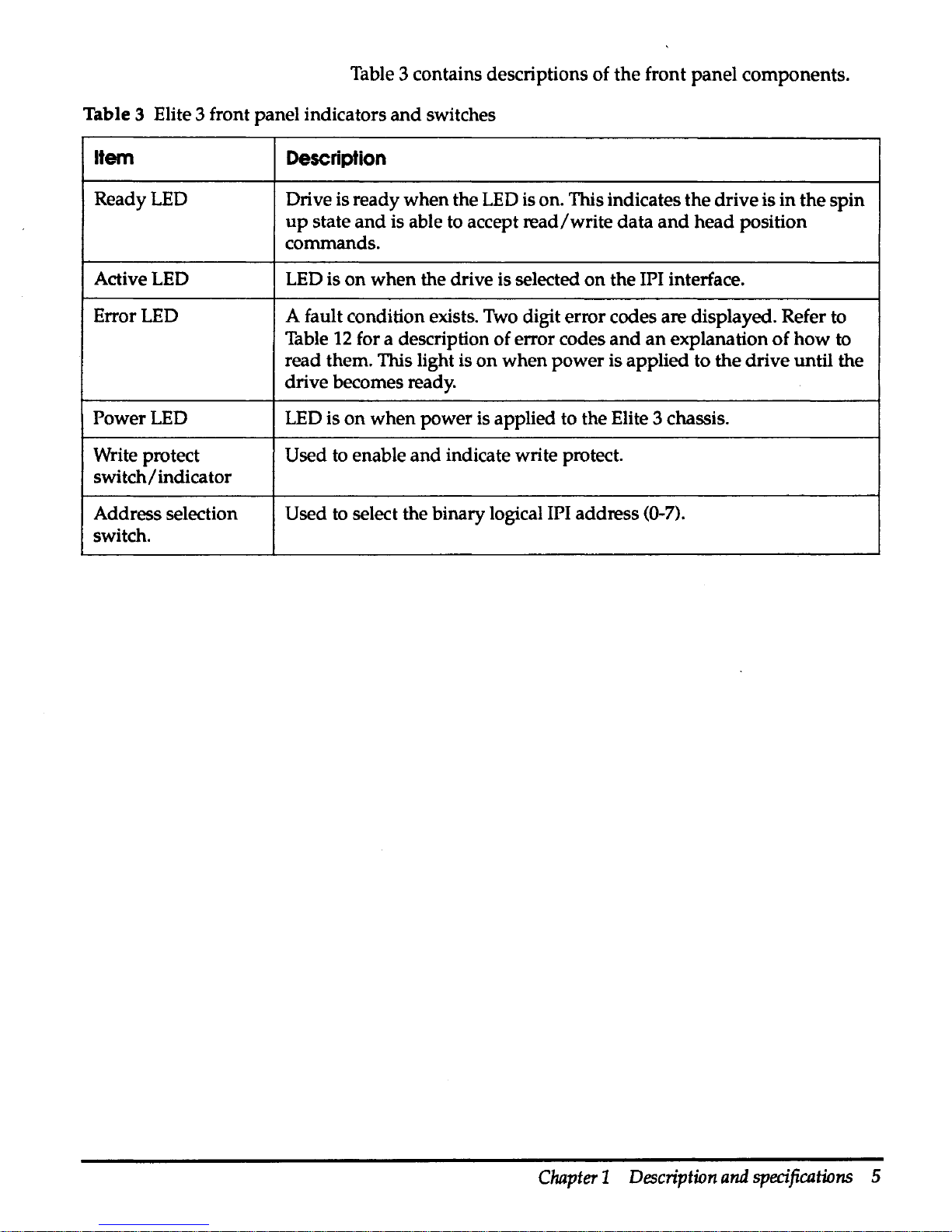

Front

panel

indicators

and

switches

The front panel contains four indicator LEDs, a write protect

switch and indicator,

and

an

address selection switch. Figure 1

shows the front panel components.

Figure

1 Front panel

Disk

drive

front

panel

(FRONT

VIEW}

Ready

indicator

Active

indicator

Error

indicator

Power

indicator

Address

switch

4

Elite 3 Disc

Drive

Service

Guide

BHOB1002

4/16/93

Page 18

Table 3 contains descriptions of

the

front panel components.

Table 3 Elite 3 front panel indicators

and

switches

Item

Description

Ready LED

Drive is ready when the

LED

is on. This indicates the drive is

in

the spin

up

state

and

is able to accept

read/write

data

and

head

position

commands.

Active LED

LED

is

on

when the drive is selected

on

the IPI interface.

Error LED

A fault condition exists.

Two

digit error codes are displayed. Refer to

Table

12

for a description of error codes

and

an

explanation

of

how

to

read them. This light is

on

when

power

is applied to the drive until the

drive becomes ready.

Power LED LED is

on

when

power is applied to the Elite 3 chassis.

Write protect

Used to enable

and

indicate write protect.

switch/

indicator

Address selection

Used to select the binary logical IPI address (0-7).

switch.

Chapter 1 Description

and

specifications

5

Page 19

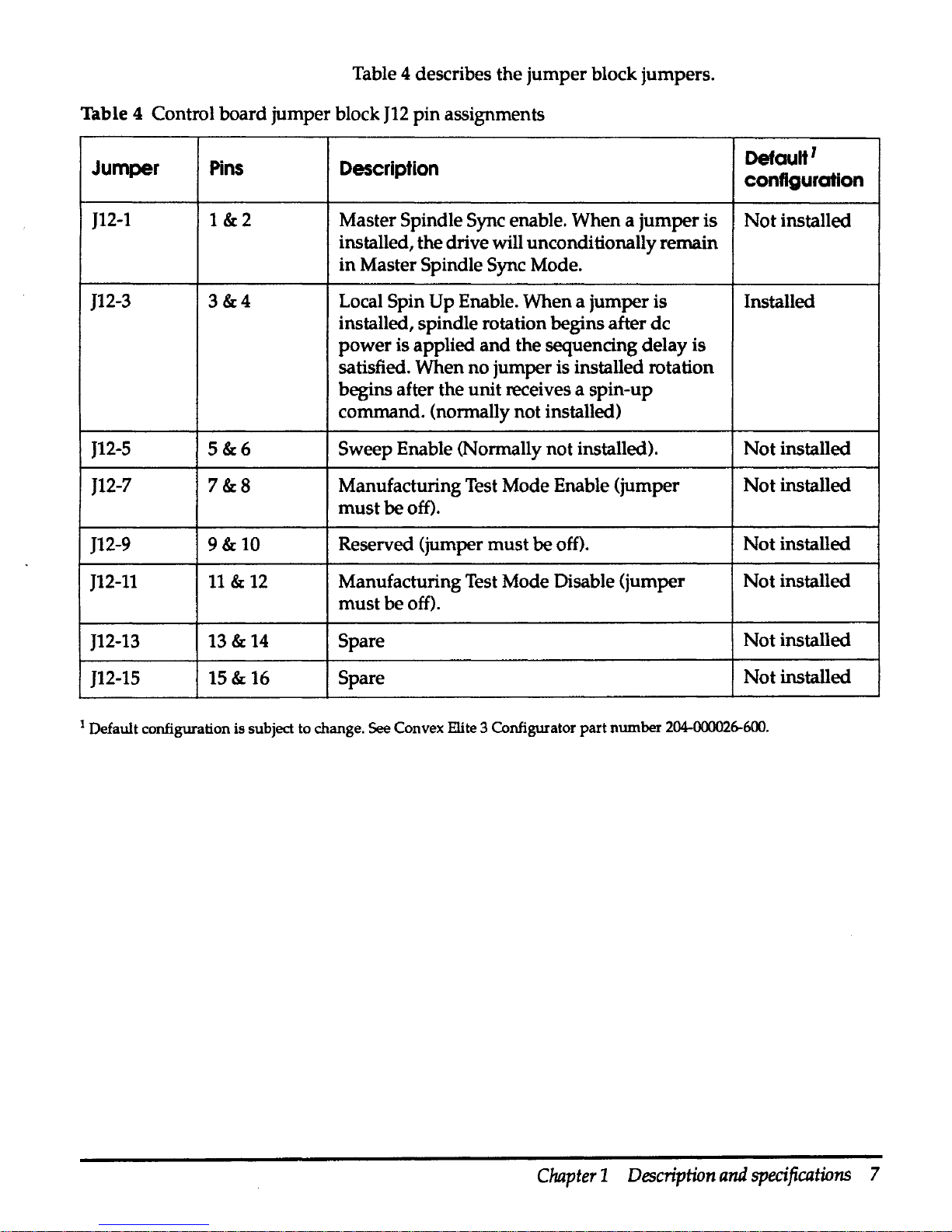

Control

board

jumpers

The disc control board is located

on

the

top

of the disc enclosure.

Jumpers

J9,

Jll,

J16-J19,

and

JSO

are reserved for manufacturing

use only.

J12

controls drive configuration. Figure 2

shows

the

location of the control board jumpers.

Figure 2 Control board jumper location

~JlO

J5

J20

J15

J12

J16

J17

~

rn

J50

c=::::J

J9

rn

J23~

J11A

~

rn

rn

1111111111

J48

JllB

J19

rn

J18

~

AH261011

4/22/93

Jumper block

J12

is a vertical header located

on

the control

board. Drive configuration is controlled

by

installing

configuration jumpers between adjacent pins.

6

Elite 3 Disc

Drive

Service

Guide

Page 20

Table 4 describes the

jumper

block jumpers.

Table 4 Control board jumper block

J12

pin

assignments

Jumper

Pins

Description

Defautt

1

configuration

J12-1

1&2

Master Spindle Sync enable. When a

jumper

is

Not

installed

installed, the drive will unconditionally remain

in

Master Spindle Sync Mode.

J12-3

3&4

Local Spin

Up

Enable. When a jumper is Installed

installed, spindle rotation begins after

de

power

is applied

and

the sequencing delay is

satisfied. When no jumper is installed rotation

begins after the unit receives a spin-up

command. (normally not installed)

J12-5

5&6

Sweep Enable (Normally not installed).

Not

installed

J12-7

7&8

Manufacturing Test Mode Enable (jumper

Not

installed

must

be off).

J12-9

9&10

Reserved (jumper

must

be off).

Not

installed

J12-11

11 & 12

Manufacturing Test Mode Disable (jumper

Not

installed

must

be off).

J12-13

13&

14

Spare

Not

installed

J12-15

15&

16

Spare

Not

installed

1

Default configuration is subject

to

change. See Convex Elite 3 Configurator

part

number

204-000026-600.

Chapter 1 Description

and

specifications

7

Page 21

1/0 board

Jumpers

The

I/0

board has 4 jumper blocks (Wl,W2,W3

and

W4) for

configuring the drive.

Table 5

1/0

board jumper block

pin

assignments

Block Jumper

Pins

Description

Default'

configuration

Wl

Wl-1

1&3

Enable position calibrate

on

seek

Not

installed

Wl

Wl-2

2&4

Enable short

RPS

Not

installed

W2

W2-1

1&3

Disable

read/write

diagnostics

Installed

W2

W2-2

2&4

Reserved

Not

installed

W3

W3-1

1&3

Microcode configuration bit 2

Not

installed

W3

W3-2

2&4

Microcode configuration bit 3 Installed

W4

W4-1

1&3

Microcode configuration bit 0

Not

installed

W4

W4-2

2&4

Microcode configuration bit 1

Not

installed

1

Default configuration

is

subject

to

change. See Convex Elite 3 Configurator part number

204-000<Y26-600.

Figure 3 shows the relative location of the

I/0

board

jumpers.

Figure 3

I/

0 board jumper locations

J031

8

Elite 3 Disc

Drive

Seroice

Guide

J20

W2

W4

I I

DO

OJ

\

\,

Wl

J032

AH261012

4/5/93

Page 22

Power

supply

specifications

Computer Products Power Conversion America manufactures

the

NFS110-7602P power supply used

with

the Elite 3 disc drive.

Universal input voltage allows the

supply

to be powered

in

any

country without changing jumpers

or

switch settings.

Table 6 contains the power supply characteristics

and

Table 7

contains the power supply voltage specifications.

Table 6 Power supply characteristics

Parameter

Condition

Limits

Input voltage

85

Vac

to

264

Vac

Input frequency range

47

Hz

to 440

Hz

Input surge current Cold start

110

Vac

17 A maximum

Cold start

220

Vac

34Amaximum

Output voltage adjustability

+5.1

v

±3%

Over voltage protection threshold

+5.1

V output

6.25

v ±

0.75

v

Total output power@

50°

C ambient Convection cooled

0Wto80W

temperature

Peak

(60

s)

now

Operational environment

Operational altitude

10,000 feet

Nonoperational

40,000 feet

altitude

Operational

o·c

to

+5o·c

temperature

Nonoperational

-40°C to

+ss·c

temperature

Relative humidity

5%

to95%

Weight

1.55

lb

(0.70

kg)

Chapter 1 Description

and

specifications

9

Page 23

Table 7 Power supply voltage specifications

Output vottage

+5.1

v

+24V

+12V

-12V

Minimum current

OA

OA

OA

OA

Maximum current@

80

W

BA

3.5A

4.5 A

O.SA

Peak

current

20A

4.SA

9A

1.5A

Ripple p-p@ 50 MHz 50mV 240mV

120mV

120mV

Total regulation

±2%

+10/-5% ±3%

±3%

Figure 4 shows the component locations for the

power

supply.

Figure 4 Power supply component location

Pin

1

Jl

Pin

1

J2

5 A,

250

Vac

Fl

0

D

D

D

D

D

0

D

D

D

D

D

10

Elite 3 Disc

Drive

Seroice

Guide

11

Voltage

adjust

Tl

C6

0

0

AH261009

5/5/93

Page 24

Table 8 contains the

power

supply

connector pinout.

Table 8 Power supply pin chart

Connector

Location

Pin

number

Signal

Molex

099-50-3051

Jl

with second

and

fourth pins removed

Jl

Jl

Molex

09-50-3131

J2

J2

J2

J2

J2

J2

J2

J2

J2

J2

J2

J2

J2

Elite 3 chassis

Pin 1

acground

Pin2

ac neutral

Pin3

achot

Pin 1

+5.1

v

Pin2

+5.1

v

Pin3

+5.1

v

Pin4

Return

Pin5

Return

Pin6

Return

Pin 7 Return

Pin8

+12V

Pin 9 +12V

Pin 10

PFD

Pin

11

-12V

Pin

12

Removed for key

Pin

13

-24

v

The Elite 3 chassis, shown

in

Figure

5,

contains the Elite 3 disc

drive,

power

supply, fan assembly, operator panel, air filter,

interface cables,

and

power plug.

Chapter 1 Description

and

specifications

11

Page 25

Figure 5 Elite 3 chassis

12

Elite 3 Disc

Drive

Seroice

Guide

AH261013

4-/8/93

Page 26

Unpacking and

installation

2

Unpacking

and

inspection

Step 1

Step2

Step3

This chapter describes unpacking

and

inspection, identifies

major components of the Elite 3 disc drive

and

mechanical

package,

and

provides installation procedures.

This section gives general guidelines for unpacking

and

inspecting the Elite 3 disc drive

and

related assemblies.

Inspection

All shipping containers are designed to protect their

components

under

normal shipping conditions. Carefully

inspect each carton for signs of shipping damage as it is

unpacked.

If

damage is found after visual inspection, document

the damage with photographs

and

contact the transport carrier

immediately.

Unpacking

The customer's bill of materials lists all equipment shipped from

CONVEX.

It

should be used as a checklist to ensure that all

equipment has arrived.

Use the following procedure to unpack

the shipping container:

Remove each item from its shipping container.

Inspect each item for any signs of shipping

damage

as it is

unpacked.

If

equipment damage is found, document the damage,

and

proceed to the next section.

Save all packing material until after operational checkout of the

equipment. This enables equipment to

be returned safely to

CONVEX if required.

Chapter 2 Unpacking

and

installation

13

Page 27

Installation

Damage

claims

If the equipment is damaged, a damage claim form

must

be

completed. Damage claims should

be

completed

by

the

customer and given to the shipping representative. Claim forms

are normally obtained from the shipping representative.This

section describes the installation

of

the Elite 3 disc drive

in a high

performance peripheral cabinet (HPPC).

This section discusses the preparations for

and

installation of the

Elite 3 disc drive.

·

Preparations

Observe the electrostatic discharge procedures described

in

the

"Electrostatic discharge protection" section

on

page xiii, to

prevent damage

to

the drive

during

installation.

Installing

power

strip

and

disc

tray

An

additional power strip

must

be

added

to the

EXP-105

cabinet

to support the maximum number of Elite 3 disc drives. A

maximum of

24

drives may be installed.

The additional power strip is attached to the rear RETMA rail

centered between the existing power strips. Figure 6 shows the

location of the additional power strip.

14

Elite 3 Disc

Drive

Service

Guide

Page 28

Figure 6 Additional power strip location

Additional

power

strip

AH261004

4/16/93

Chapter 2 Unpacking

and

installation

15

Page 29

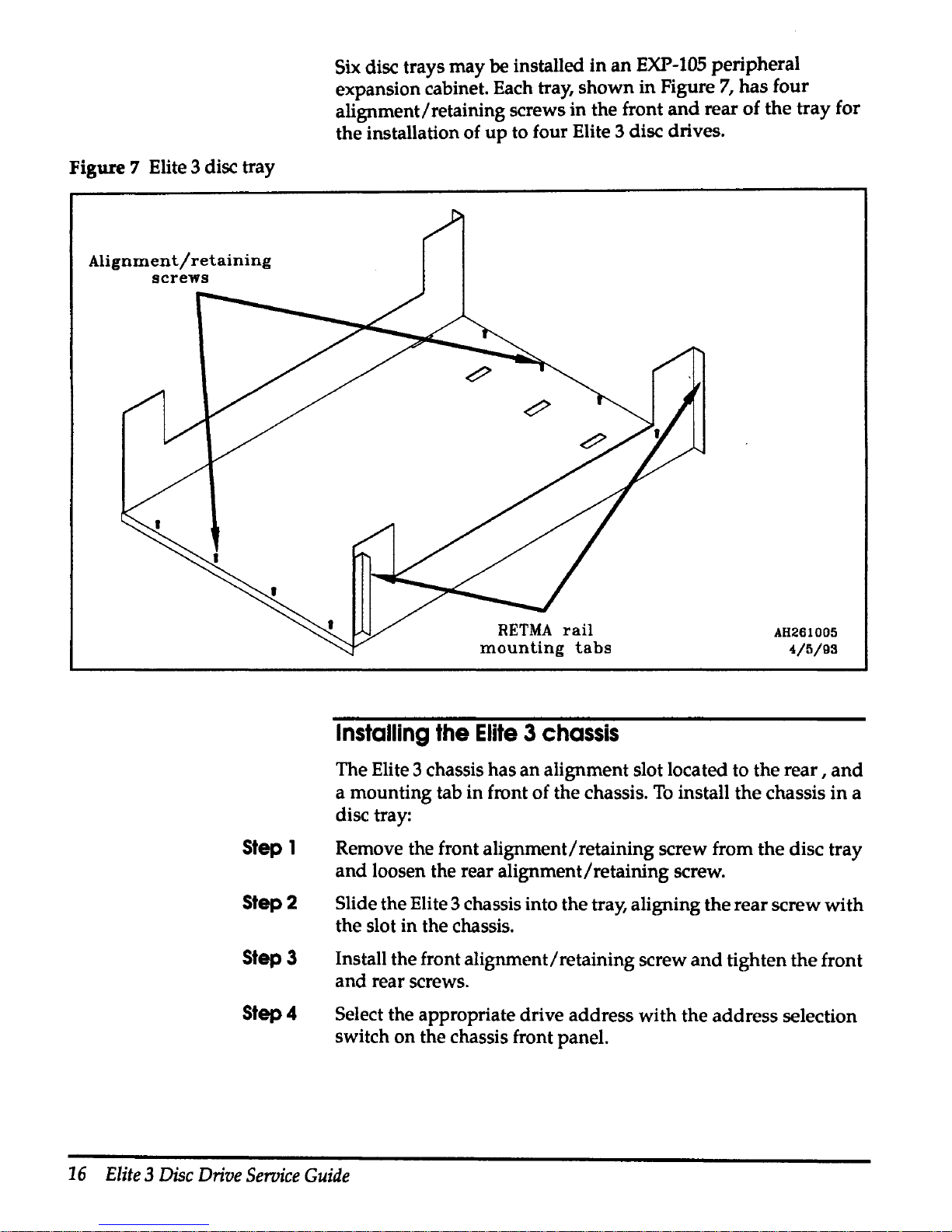

Figure 7 Elite 3 disc tray

Alignment/retaining

screws

Step 1

Step2

Step3

Step4

Six disc trays may be installed

in

an

EXP-105

peripheral

expansion cabinet. Each tray, shown in Figure

7,

has four

alignment/retaining screws in the front

and

rear of the tray for

the installation of

up

to four Elite 3 disc drives.

Installing

the

Elite 3 chassis

AH261005

4/5/93

The Elite 3 chassis has an alignment slot located to the

rear,

and

a mounting tab in front of the chassis.

To

install the chassis

in

a

disc tray:

Remove the front alignment/retaining screw from the disc tray

and

loosen the rear alignment/retaining screw.

Slide the Elite 3 chassis into the tray, aligning the rear screw with

the slot in the chassis.

Install the front alignment/retaining screw

and

tighten the front

and rear screws.

Select the appropriate drive address with the address selection

switch on the chassis front panel.

16

Elite

3

Disc

Drive

Seroice

Guide

Page 30

Caution

Step 1

Step 2

Step3

Connecting a single drive

Each Elite 3 disc chassis

has

3 connectors

at

the rear

of

the

assembly;

an

ac connector,

an

IPI

input

connector,

and

an

IPI

output

connector.

As root, use the

/etc/ebutdown

command

to

halt

ConvexOS

before connecHng a disc

to

the IDC. Failure

to

do

so

may

cause a

system crash

and

loss of data.

To

connect a single drive to

an

JDC:

Install the Elite 3 chassis

in

the peripheral cabinet.

Ensure the ac

power

switch

at

the

rear

of

the

Elite 3 chassis

is

in

the OFF position.

Attach the IPI cable to the

mate connector

on

the

rear

of

the

Elite

3 chassis.

Figure 8 Connecting a single drive

To

IDC

port

AH261008

4/5/93

Chapter 2 Unpacking

and

installation

17

Page 31

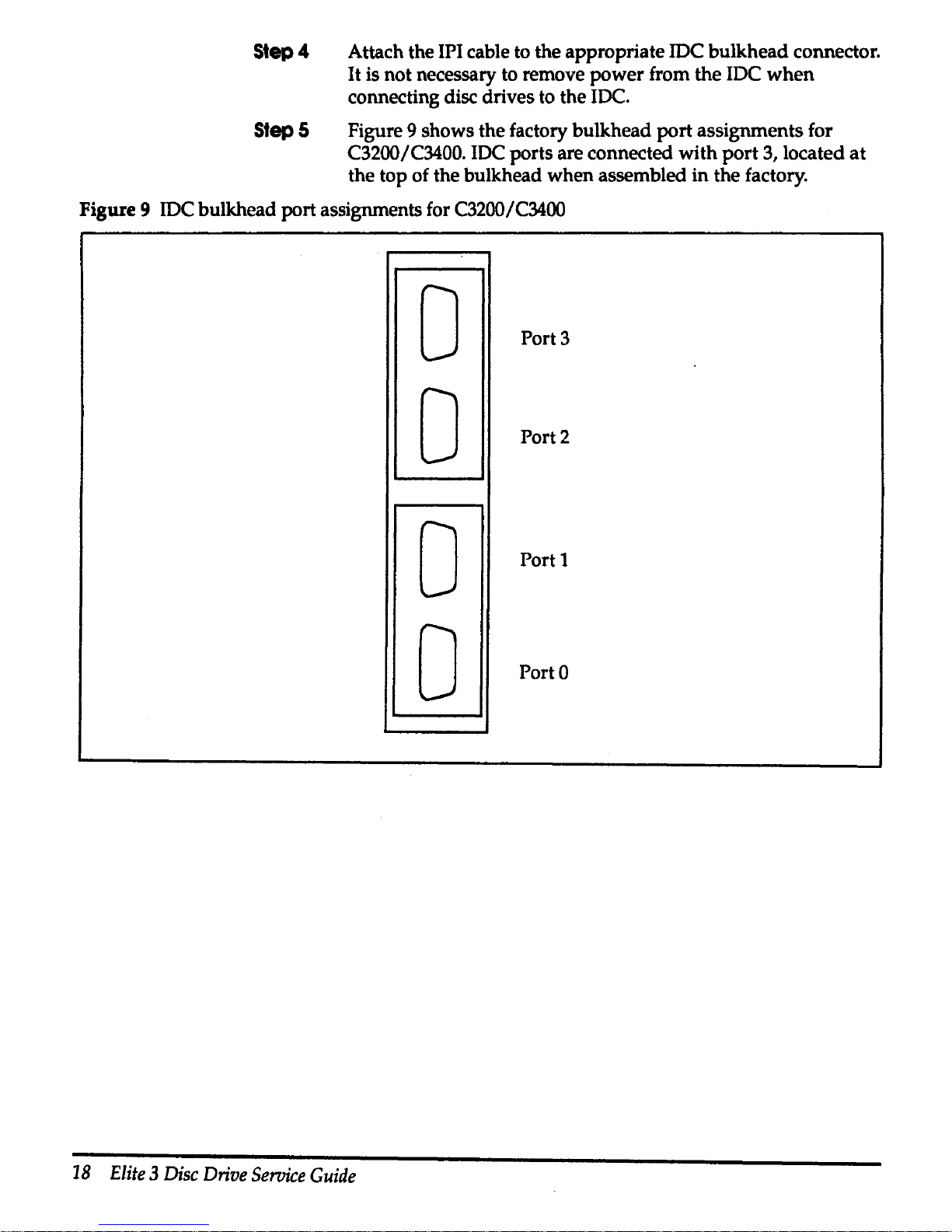

Step4

Attach the IPI cable to the appropriate JDC bulkhead connector.

It

is not necessary to remove power from the IDC

when

connecting disc drives to the IDC.

Step 5 Figure 9 shows the factory bulkhead

port

assignments for

C3200/C3400. IDC ports are connected with

port

3, located

at

the top of the bulkhead when assembled in the factory.

Figure 9 IDC bulkhead port assignments for C3200/C3400

0

Port3

0

Port2

0

Port 1

0

Porto

18

Elite 3 Disc

Drive

Seroice

Guide

Page 32

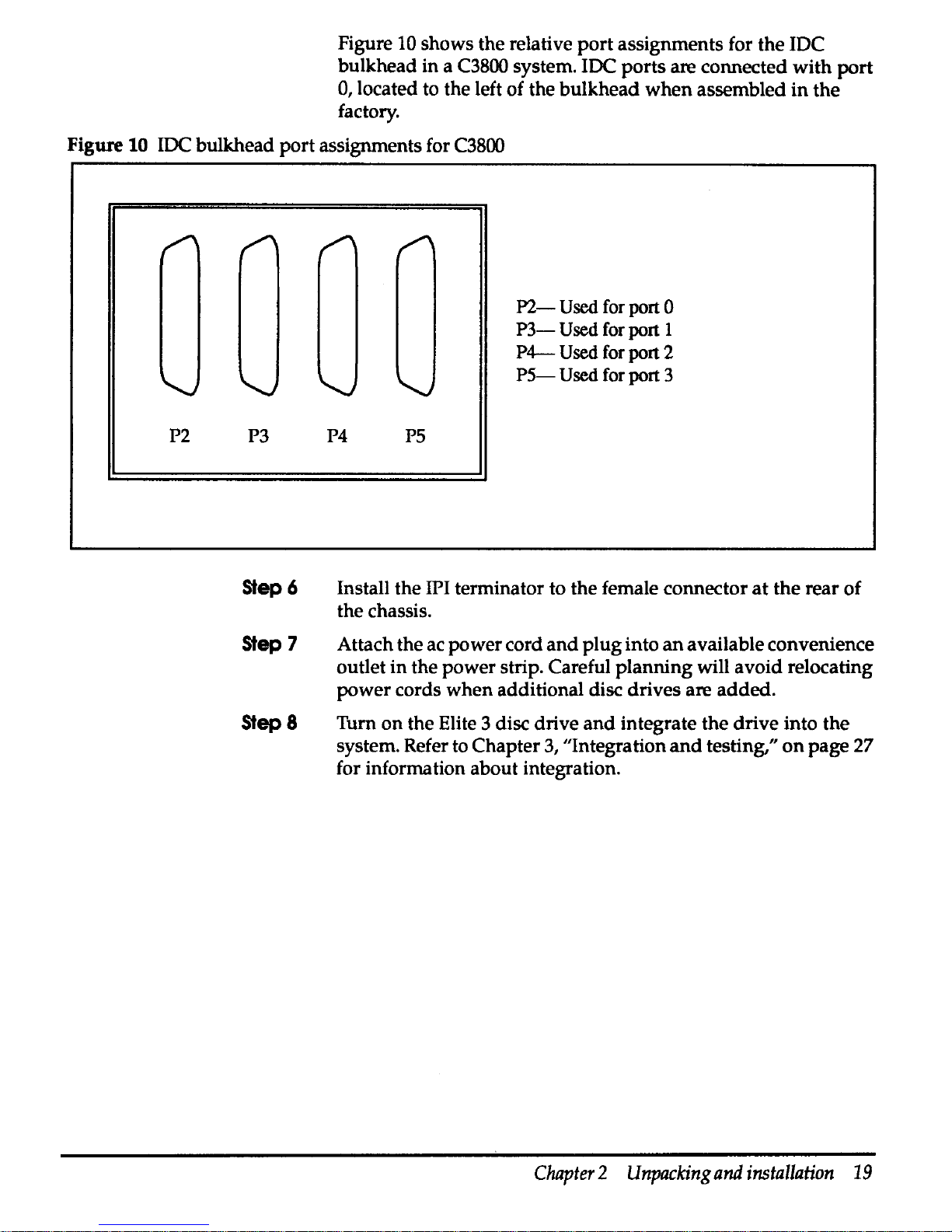

Figure 10

shows

the

relative

port

assignments

for

the

IDC

bulkhead

in

a C3800 system. IDC

ports

are

connected

with

port

0, located to the left

of

the

bulkhead

when

assembled

in

the

factory.

Figure 10 IDC

bulkhead

port

assignments for C3800

P2 P3

Step6

Step7

Step 8

P4

PS

P2-

Used

for port 0

P3-

Used

for port I

P4-

Used

for port 2

PS-

Used

for port 3

Install

the

IPI terminator to

the

female

connector

at

the

rear

of

the

chassis.

Attach

the

ac

power

cord

and

plug

into

an

available

convenience

outlet

in

the

power

strip. Careful

planning

will

avoid

relocating

power

cords

when

additional disc

drives

are

added.

Turn

on

the

Elite 3 disc

drive

and

integrate

the

drive

into

the

system. Refer to

Chapter

3, ''Integration

and

testing,"

on

page 27

for information

about

integration.

Chapter 2 Unpacking

and

installation

19

Page 33

Caution

Step 1

Step2

Step3

Step4

Step5

Step6

Connecting multiple disc drives

Each port

on

an

IDC can

support

up

to eight disc drives. These

may

be

any combination of DKD-501, DKD-502, DKD-503,

DKD-504, or DKD-505 disc drives.

As root, use the

/ate/shutdown

command

to

halt ConvexOS

before connecting a disc to the

IDC.

Failure

to

do

so

may

cause

a system crash and

loss

of data.

To

install multiple disc drives

on

an

IDC:

Install the Elite 3 chassis in the peripheral cabinet.

Ensure the ac power switches

at

the rear of the chassis are

in

the

off position.

Repeat Step 3 through Step 6 for each IDC

port

containing disc

drives. Refer to Figure

11

on

the following page.

Attach the

IPI cable to the IDC bulkhead port.

Attach the

IPI cable to the male connector

at

the rear of

the

first

Elite 3 disc drive in the daisy chain.

Install IPI daisy chain cables between additional drives

in

the

daisy chain.

Install the terminator

plug

on

the last drive in

the

daisy chain.

20

Elite 3 Disc

Drive

Service

Guide

Page 34

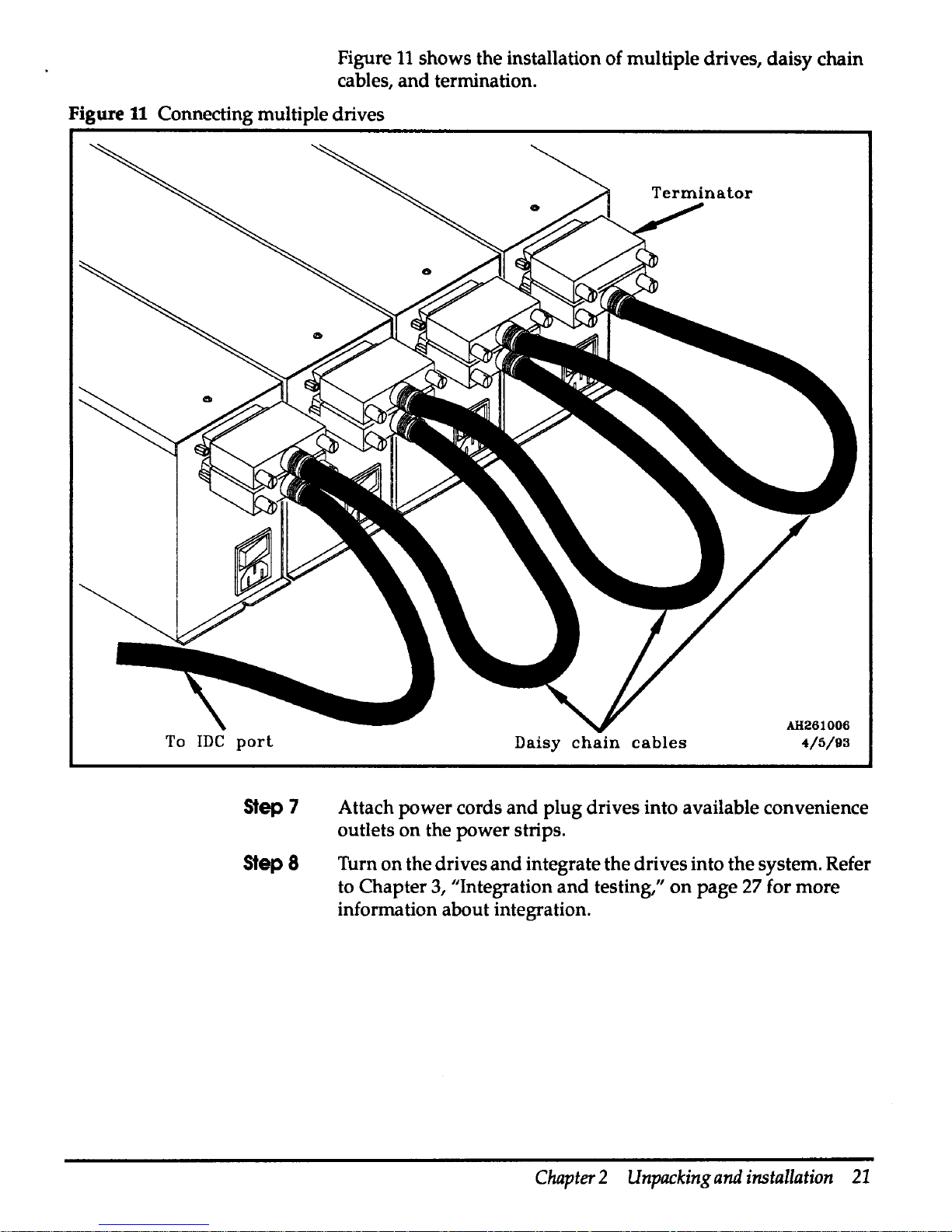

Figure

11

shows the installation of multiple drives, daisy chain

cables, and termination.

Figure

11

Connecting multiple drives

To

JDC

port

Step

7

Step8

Daisy

chain

cables

AH261006

4/5/93

Attach power cords

and

plug drives into available convenience

outlets on the power strips.

Turn on the drives

and

integrate the drives into the system. Refer

to Chapter

3,

"Integration

and

testing,"

on

page 27 for more

information about integration.

Chapter 2 Unpacking

and

installation

21

Page 35

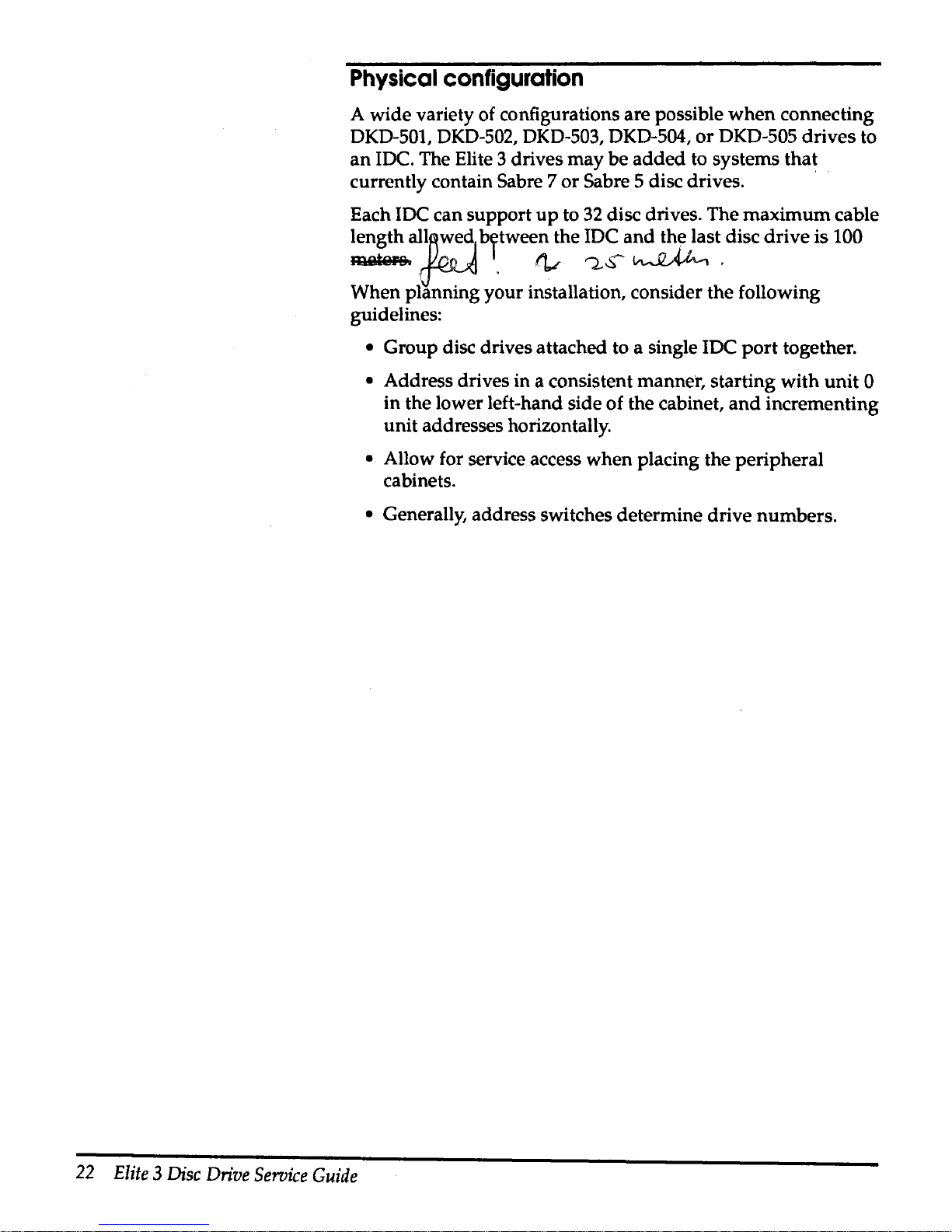

Physical

configuration

A wide variety of configurations are possible

when

connecting

DKD-501, DKD-502, DKD-503,

DKD-504,

or

DKD-505

drives

to

an

IDC. The Elite 3 drives

may

be

added

to systems

that

currently contain Sabre 7

or

Sabre 5 disc drives. · ·

Each IDC can support

up

to

32

disc drives. The

maximum

cable

length

alln~edJ

between the IDC

and

the last disc

drive

is 100

'Ute.~

1.

~

'"2-S-

~

.

When planning your installation, consider the following

guidelines:

22

Elite 3 Disc

Drive

Service

Guide

• Group disc drives attached to a single IDC

port

together.

• Address drives in a consistent manner, starting

with

unit

0

in

the lower left-hand side

of

the cabinet,

and

incrementing

unit addresses horizontally.

• Allow for service access

when

placing the peripheral

cabinets.

• Generally, address switches determine drive numbers.

Page 36

Figure

12

shows the connection of

32

disc drives to

an

IDC.

Figure

U

IDC

maximum drive configuration

IPI

port

r::J. I I I

11

11

i 1

I

I I I

I

3

1~ve11m:ve11~vell

4

vel

drive

drive drive drive

4

5

6 7

IPI

port

T~

..

11~~11~~11~~11

~

..

11~~11~

..

11

~ve

I

2

IPI

port

r-1

I I I I I I I I I I I I I I

1

drive drive

drive drive drive

drive

drive drive

0

1 2

3

4

5

6 7

IPI

r-1

I

port

'TI'a

I I

1

0

drive

BJ

drive I drive I drive drive

drive

I

~

..

I

0

2 3 4 5

6

-

IDC

Chapter 2 Unpacking

and

installation

23

Page 37

A single peripheral expansion cabinet can contain a

maximum

of

24

Elite 3 disc drives. When connecting disc drives to

an

IDC,

disc drives attached to a single

port should

be

grouped

in

horizontal rows to allow the use of the single hot spare cable.

Figure

13

shows the relative locations of 32 Elite 3 disc drives

when

installed in 2 peripheral expansion cabinets.

Figure 13 Expansion cabinet drive locations for

32

drives

I

IPI

port2

drive4

IPI

port2

driveO

IPI

port 1

drive4

IPI

port 1

driveO

IPI-

portO

drive4

IPI

portO

driveO

I

First peripheral

expansion cabinet

Fan assembly

IPI IPI

port2

port2

drives

drive 6

IPI

IPI

port2

port2

drive 1 drive 2

IPI

IPI

portl

portl

drives

drive 6

IPI

IPI

portl

port 1

drive 1 drive2

IPI IPI

portO

portO

drive S drive6

IPI

IPI

portO portO

drive 1 drive 2

PDU

24

Elite 3 Disc

Drive

Service

Guide

11

IPI

port2

drive 7

IPI

port2

drive3

IPI

port 1

drive 7

IPI

port 1

drive 3

IPI

IPI

portO

port3

drive 7 drive4

IPI

IPI

portO

port3

drive 3

drive

0

I

I

Second peripheral

expansion cabinet

Fan assembly

IPI

IPI

port3 port3

drives

drive 6

IPI

IPI

port3 port3

drive 1 drive 2

PDU

I

IPI

port3

drive 7

IPI

port3

drive3

I

Page 38

Although it is possible for

an

IDC to

support

32

Elite 3 disc

drives, a typical configuration

may attach 16 Elite 3 disc drives

toanIDC.

Figure

14

shows

the

relative locations of 16 Elite 3 disc

drives

installed

in

a single peripheral expansion cabinet.

Figure 14 Expansion cabinet drive locations for 16 drives

Fan assembly

IPI

IPI

IPI IPI

port3

port3

port3 port3

driveO drive 1 drive2

drive3

IPI

IPI

IPI IPI

port2

port2

port2

port2

driveO

drive 1 drive2 drive3

IPI

IPI

IPI

IPI

portl

portl

port 1

portl

driveO drive 1 drive 2

drive3

IPI

IPI IPI

IPI

portO

portO portO

portO

driveO

drive 1 drive2

drive3

I

POU

I

Chapter 2 Unpacking

and

installation

25

Page 39

Integration

and

testing

3

Software

integration

Note

Step

1

Step2

Step3

Step4

Steps

Step6

Step

7

Step8

Step

9

Step

10

Step

11

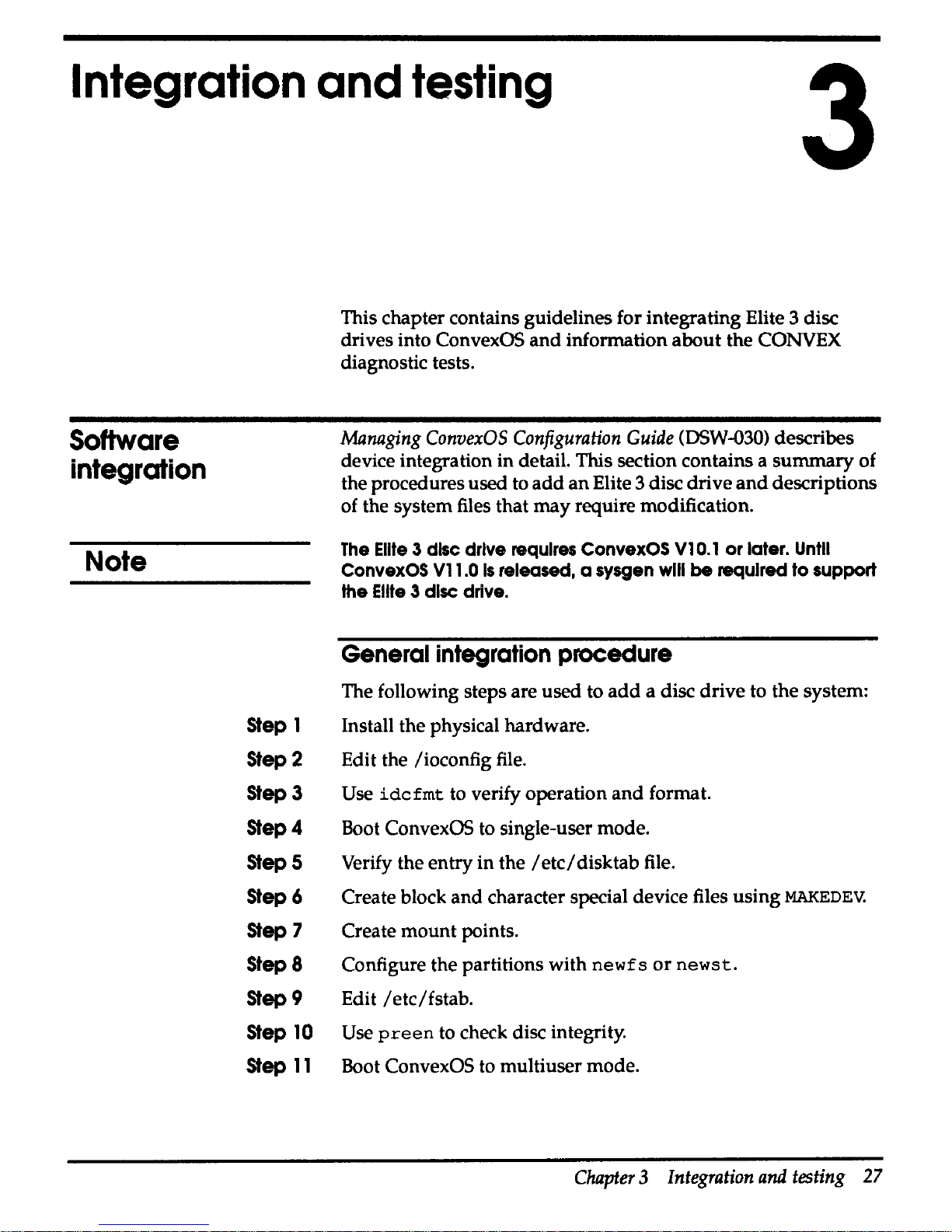

This chapter contains guidelines for integrating Elite 3 disc

drives into

ConvexOS

and

information about the CONVEX

diagnostic tests.

Managing

ConvexOS

Configuration

Guide

(DSW-030) describes

device integration in detail. This section contains a summary of

the procedures used to

add

an Elite 3 disc drive

and

descriptions

of the system files that may require modification.

The

Elite 3 disc

drive

requires

ConvexOS

Vl

0.1

or

later.

Untll

ConvexOS

Vl

1.0

Is

released, a

sysgen

will

be

required

to

support

the

Ellte 3 disc

drive.

General

integration

procedure

The following steps are used to

add

a disc drive to the system:

Install the physical hardware.

Edit the /ioconfig

file.

Use

idcfmt

to verify operation

and

format.

Boot

ConvexOS to single-user mode.

Verify the entry in the

/etc/disktab

file.

Create block and character special device files using

MAKEDEV.

Create mount points.

Configure the partitions with

newfs

or

newst.

Edit /etc/fstab.

Use

preen

to check disc integrity.

Boot

ConvexOS to multiuser mode.

Chapter 3 Integration

and

testing

27

Page 40

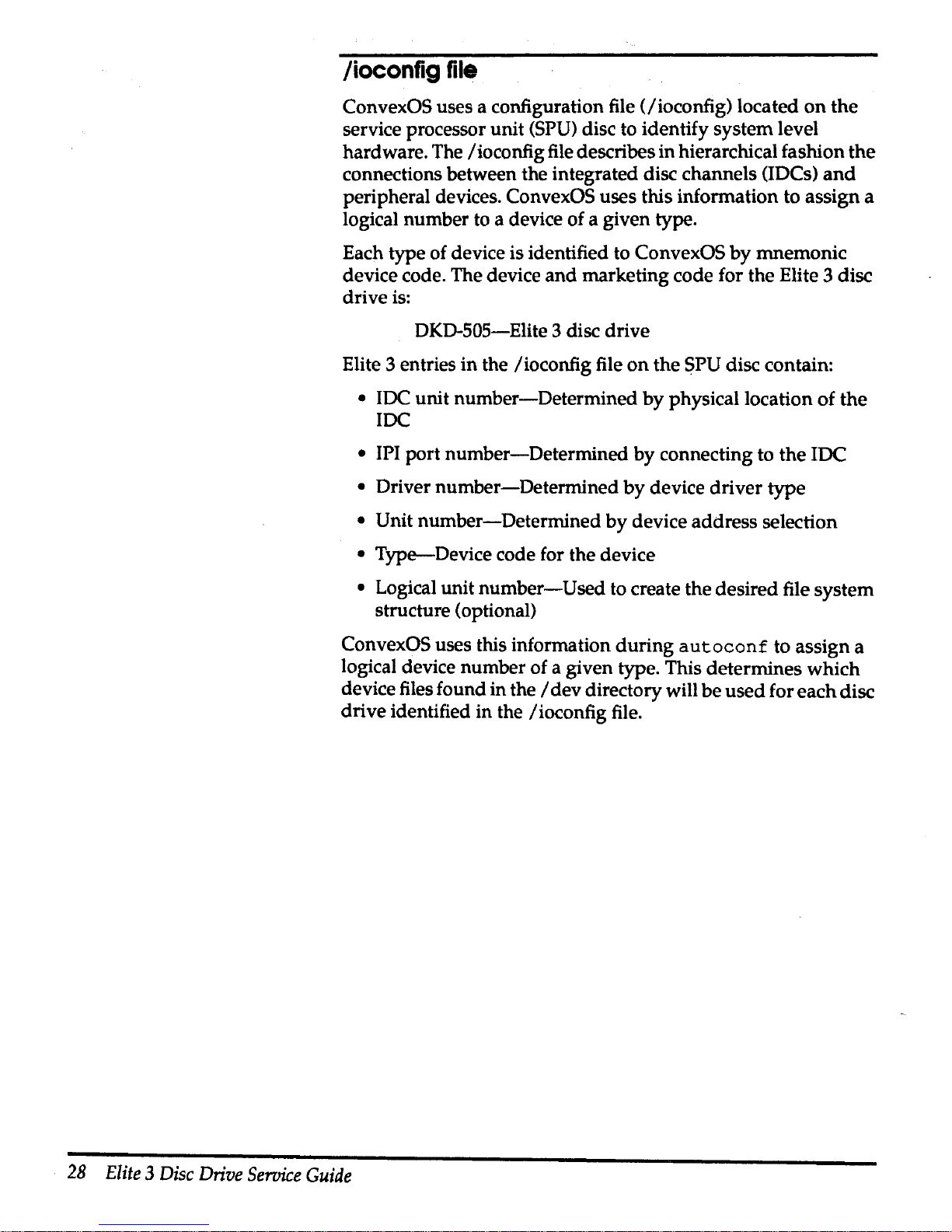

/ioconfig

file

ConvexOS

uses

a configuration file

(/ioconfig)

located

on

the

service processor

unit

(SPU) disc to

identify

system

level

hardware.

The

/ioconfig

file describes

in

hierarchical

fashion

the

connections

between

the

integrated

disc

channels

(IDCs)

and

peripheral

devices. ConvexOS

uses

this

information

to

assign

a

logical

number

to a device

of a given

type.

Each

type

of

device is identified to ConvexOS

by

mnemonic

device

code. The device

and

marketing

code

for

the

Elite 3

disc

drive

is:

DKD-505-Elite

3 disc

drive

Elite 3 entries

in

the

/ioconfig

file

on

the

!:)PU

disc

contain:

• IDC

unit

number-Determined

by

physical

location

of

the

IOC

• IPI

port

number-Determined

by

connecting

to

the

JDC

•

Driver

number-Determined

by

device

driver

type

•

Unit

number-Determined

by

device

address

selection

•

Type-Device

code

for

the

device

• Logical

unit

number-Used

to create

the

desired

file

system

structure

(optional)

ConvexOS

uses

this information

during

autoconf

to

assign

a

logical device

number

of a given

type. This

determines

which

device files

found

in

the I dev

directory

will

be

used

for

each

disc

drive

identified

in

the

/ioconfig

file.

28

Elite 3 Disc

Drive

Seroice

Guide

Page 41

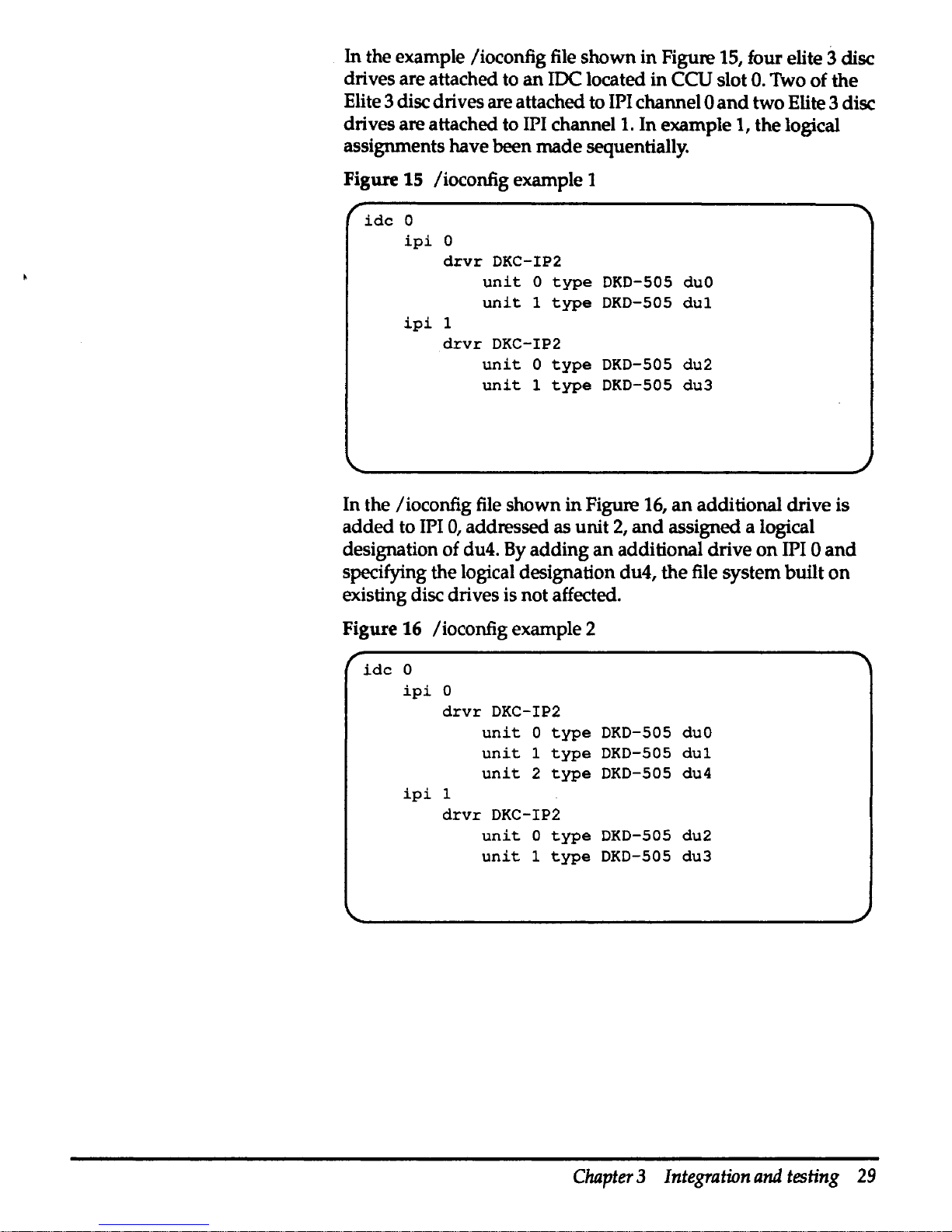

In

the example /ioconfig file

shown

in

Figure 15, four elite 3 disc

drives are attached to

an

JDC

located

in

CCU slot

0.

Two of the

Elite 3 disc drives are attached to

IPI channel 0

and

two Elite 3 disc

drives are attached to

IPI channel 1. In example 1, the logical

assignments have been

made

sequentially.

Figure

15 /ioconfig example 1

idc

0

ipi

0

drvr

DKC-IP2

ipi

1

unit

o

type

DKD-505

duO

unit

1

type

DKD-505

dul

drvr

DKC-IP2

unit

0

type

DKD-505

du2

unit

1

type

DKD-505

du3

In the /ioconfig file shown

in

Figure 16,

an

additional drive is

added

to IPI

0,

addressed as unit

2,

and

assigned a logical

designation of du4. By

adding

an

additional drive

on

IPI 0

and

specifying the logical designation du4, the file system built

on

existing disc drives is not affected.

Figure 16 /ioconfig example 2

idc

0

ipi

0

drvr

DKC-IP2

ipi

1

unit

0

type

DKD-505

duo

unit

1

type

DKD-505

dul

unit

2

type

DKD-505 du4

drvr

DKC-IP2

unit

O

type

DKD-505

du2

unit

1

type

DKD-505

du3

Chapter 3 Integration

and

testing

29

Page 42

/etc/disktab

The I

etc/

disktab file describes disc types, disc geometry, file

system partition sizes,and default block

and

fragment sizes. Do

not

change

/etc/disktab

if

an

entry for the Elite 3 disc

drive

exists.

Figure

17

contains the

/etc/disktab

entry for

an

Elite 3 disc

drive.

Figure

17

Example

/etc/disktab

rdkd-SOSIDKD-5051Elite3-2HPISeagate

ST43200K 3.0SGB

IPI-2

disk:\

:ty=winchester:spilS:set2048:nst53:nttlO:nct2734:rmt5400\

:pat70180:bat16384:fat2048:\

:pbt280555:bbl16384:fbi2048:\

:pct1402490:bct65536:fci8192:\

:pdf70540:bdt32768:fdt4096:\

:pei420320:bet16384:fet2048:\

:pfl140285:bfi16384iffi2048:\

:pgi631145:bgi16384:fgi2048:\

:phi420610:bhi16384:fht2048:

Table 9 shows

/etc/disktab

types

and

descriptions.

Table 9 /etc/disktabdescription

Name

Type/description

ty

Type of disc

se

Number of bytes

per

sector

sp

Number of spare sectors

per

cylinder

ns Number of sectors

per

track

nt

Number of tracks

per

cylinder

nc Number

of

cylinders

per

disc

rm

Disc speed (revolutions

per

minute)

p[a-h]

Partition sizes (sectors)

b[a-h]

Partition block sizes (bytes)

f[a-h]

Partition fragment sizes (bytes)

30

Elite 3 Disc

Drive

Service

Guide

Page 43

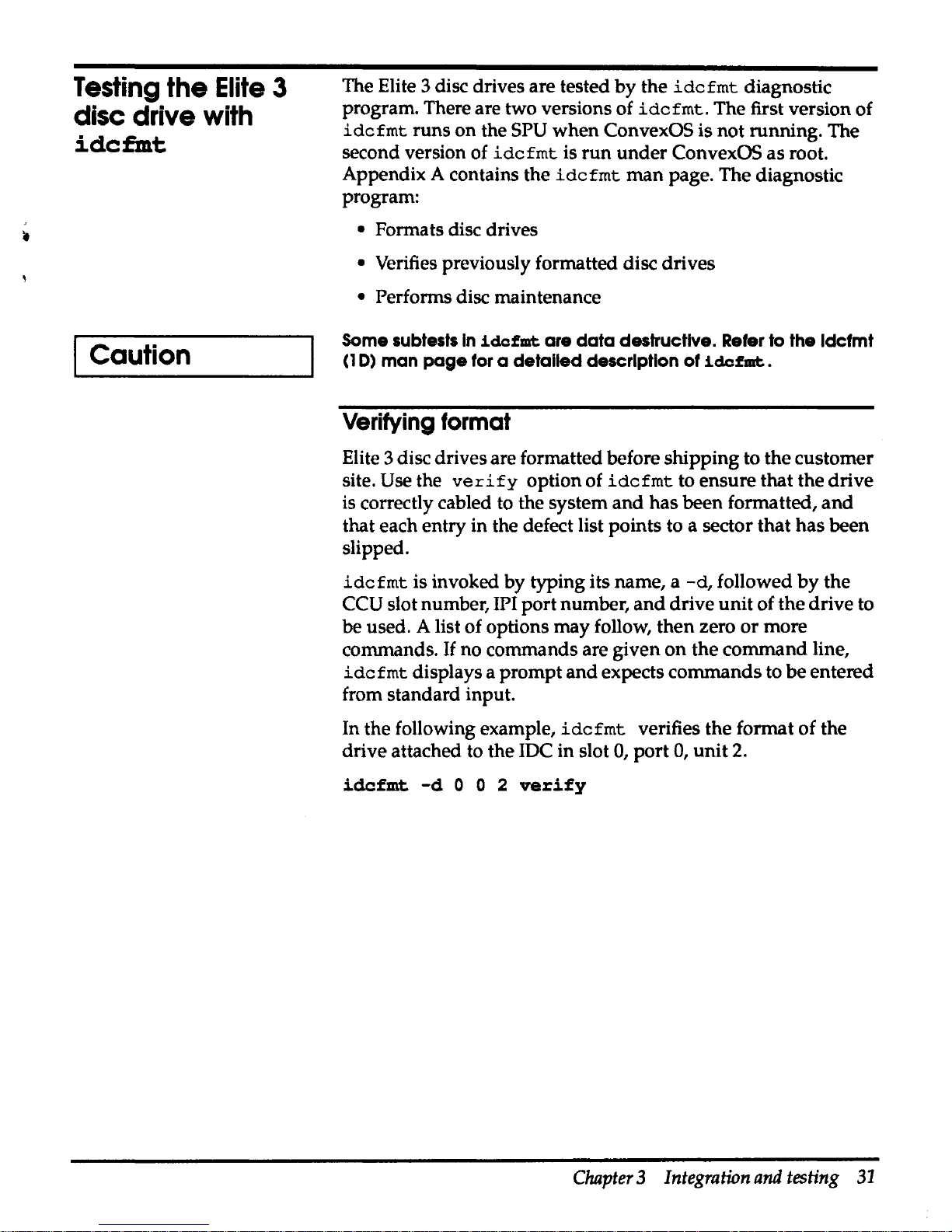

Testing

the

Elite 3

disc drive with

idcfmt

Caution

The Elite 3 disc drives are tested

by

the

idcfmt

diagnostic

program. There are two versions of

idcfmt.

The first version of

idcfmt

runs

on

the SPU

when

ConvexOS is not running. The

second version of

idcfmt

is

run

under

ConvexOS

as

root.

Appendix A contains the

idcfmt

man

page. The diagnostic

program:

• Formats disc drives

• Verifies previously formatted disc drives

• Performs disc maintenance

Some subtests

In

idcfmt

are

data

destructive. Refer to the

ldcfmt

(10) man

page

for a

detailed

description

of

idcfmt.

Verifying format

Elite 3 disc drives are formatted before shipping to the customer

site.

Use the

verify

option of

idcfmt

to ensure that the

drive

is correctly cabled to the system

and

has been formatted,

and

that each entry in the defect list points to a sector that has been

slipped.

idcfmt

is invoked by typing its name, a

-d,

followed

by

the

CCU slot number, IPI port number,

and

drive

unit

of the drive to

be used. A list of options may follow, then zero

or

more

commands.

If

no commands are given

on

the command line,

idcfmt

displays a prompt

and

expects commands to be entered

from standard input.

In the following example,

idcfmt

verifies the format

of

the

drive attached to the IDC in slot

0,

port

0,

unit

2.

idcfmt

-d

0 0 2

verify

Chapter 3 Integration

and

testing

31

Page 44

Caution

No

write operations occur

when

idcfmt

is

used

with

the

verify

option.

To

verify that the drive is formatted:

• Read one copy of all the data

on

the topology cylinder. Verify

that the checksums

and

magic numbers are correct.

• Read the remaining copies of the topology

data

and

verify

that they match the data from the first step.

• Read all logical blocks

on

the disc

and

verify that there

are

'

no header CRC

or

data ECC errors.

If

any

errors are found,

they are listed.

,

•

Read all the sector headers from the disc

and

verify that

there is a one to one correspondence of entries

in

the

defect

list with sectors that are slipped.

• Verify that each entry in the defect list points to a slipped

sector.

Formatting

a drive

The

format

command option is used

with

idcfmt

to format a

drive that has never been formatted.

If

a partial format is found,

the format resumes

at

the appropriate point,

with

the

manufacturers

and

grown defect lists that were

in

effect

when

the format was interrupted.

If

the drive has no valid format

on

it, then the program reads the manufacturers defect

data

from

the drive.

Under most circumstances a format is not required

in

the field.

Using

the

fo:mat

opHon

of

the

idcfmt

command

will destroy

any

existing flies on the disc drive.

In the following example,

idcfmt

formats

an

Elite 3 disc

drive

attached to the

JDC

in

slot

0,

port 0

and

addressed as

unit

2:

idcfmt

-d

0 0 2

fonnat

32

Elite 3 Disc

Drive

Service

Guide

Page 45

'

'

Maintenance and

IPB

4

Troubleshooting

This chapter contains maintenance precautions, removal

and

replacement procedures,

and

an

illustrated

parts

breakdown

(IPB).

This section contains information for interpreting

the

hardware

errors originating from the disc

drive

and

indicated

through

the

error light message codes. Information

about

the

fault

symptom

codes

(F'SC)

associated

with

the

disc

subsystem

is

also provided.

Elite 3 disc

drive

error

codes

The Elite 3 disc drive generates message codes for certain

circumstances

and

presents these codes to the JlO connector. This

connector is used to

drive

the error light

on

the

front panel.

Message codes consist

of

two digits

composed

of

the

numbers

1-9. The message code starts

with a long

pause

followed

by

short

pulses for the first digit, a short pause,

and

then

more

short

pulses for the second digit. The code

can

be

determined

by

counting the short pulses

that

represent the

two

digits.

In addition to being presented to

the

error

indicator on.the front

panel, FSCs associated with the

drive

messages

are

recorded

in

the

/mnt/errlog

file

on

the

SPU disc.

Chapter 4 Maintenance

and

IPB

33

Page 46

Table

10

contains descriptions of the error codes

generated

by

the Elite 3 disc drive.

Table

10

Elite 3 disc drive error codes

Error

Description

Corrective

action

code

11

Invalid micro code

ID-Switch

settings are

Check jumper installation

on

disc

incorrect

control board

21

Illegal

condition-Master

terminate

indicated,

but

the hardware did not indicate

the sending of

90

ending status

22

External RAM failure

23

Unexpected vectored

interrupt/trap

occurred

24

CSAW failure detect in power

up

Cycle power; if failure continues,

initialization

replace disc drive

25

Buffer memory failure detected in power

up

31

BIPIP IPC failure during power

up

32

BIPIP

SFC

failure

during

power

up

33

BIPIP

BUF

failure

during

power

up

34

BIPIP

VIB

failure

during

power

up

35

VIC failure

during

power

up

36

BIPIP

ECC

failure

during

power

up

34

Elite 3 Disc

Drive

Service

Guide

Page 47

Fault

symptom

code

CFSC)

Fault symptom code (FSC) is a standardized

method

for

reporting error conditions

on

the

CONVEX JDC

and

attached

JPJ

disc products.

The

FSC

is a hexadecimal code printed to the console

and

errlog

upon

detection of

an

error condition. The format

of

the

FSC is:

FSC

OxNNNN

idc

N

port

N

unit

N

cyl

OxNNN

trk

OxNNN

sec

OxNNN

p N

cnt

N

Table

11

contains a description of

the

FSC

fields.

Table

11

FSC

field descriptions

FSCfield

Description

FSCOxNNNN Hexadecimal representation of the fault symptom code.

idc

The

JDC

channel number that reported the error.

port The port

on

the

JDC

that reported the error.

unit The address of the drive that reported the error.

cylOxNNN

The hexadecimal cylinder number associated with the reported error.

This field is always reported even if the error

was

not a

data

or

seek

error.

trkOxNNN The hexadecimal track number associated

with

the reported error. This

field is always reported even

if

the error

was

not a

data

or

seek error.

secOxNNN

The hexadecimal sector number associated with the reported error. This

field is always reported even if the error

was

not a

data

or

seek error.

p

The partition number in which the error occurred. Partition 1 is a, 2 is b,

3 is c,

and

so on.

cnt

The number of times the operation was retried. Error threshold is

11.

If

the cnt field is less than

11

the retry succeeded.

Chapter 4 Maintenance

and

IPB

35

Page 48

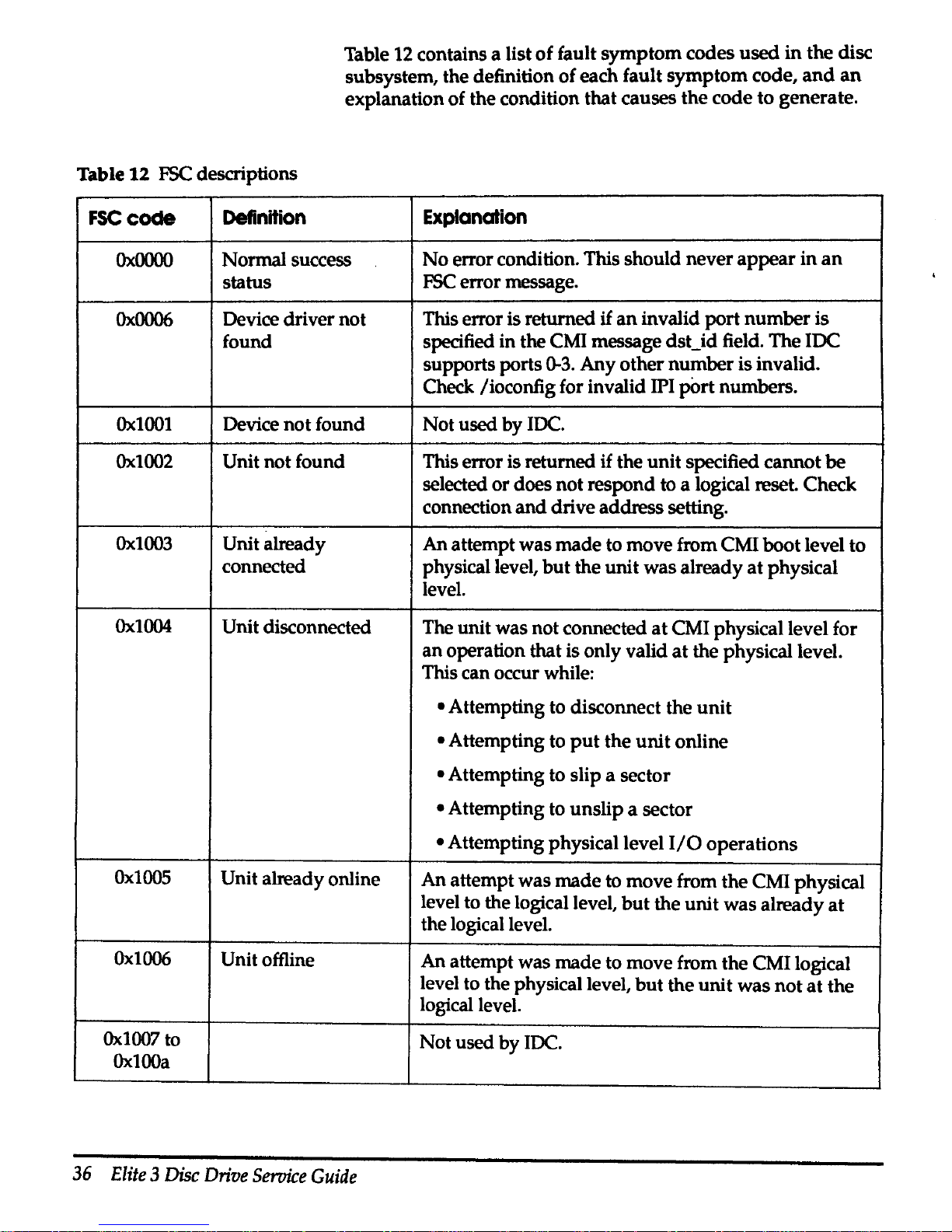

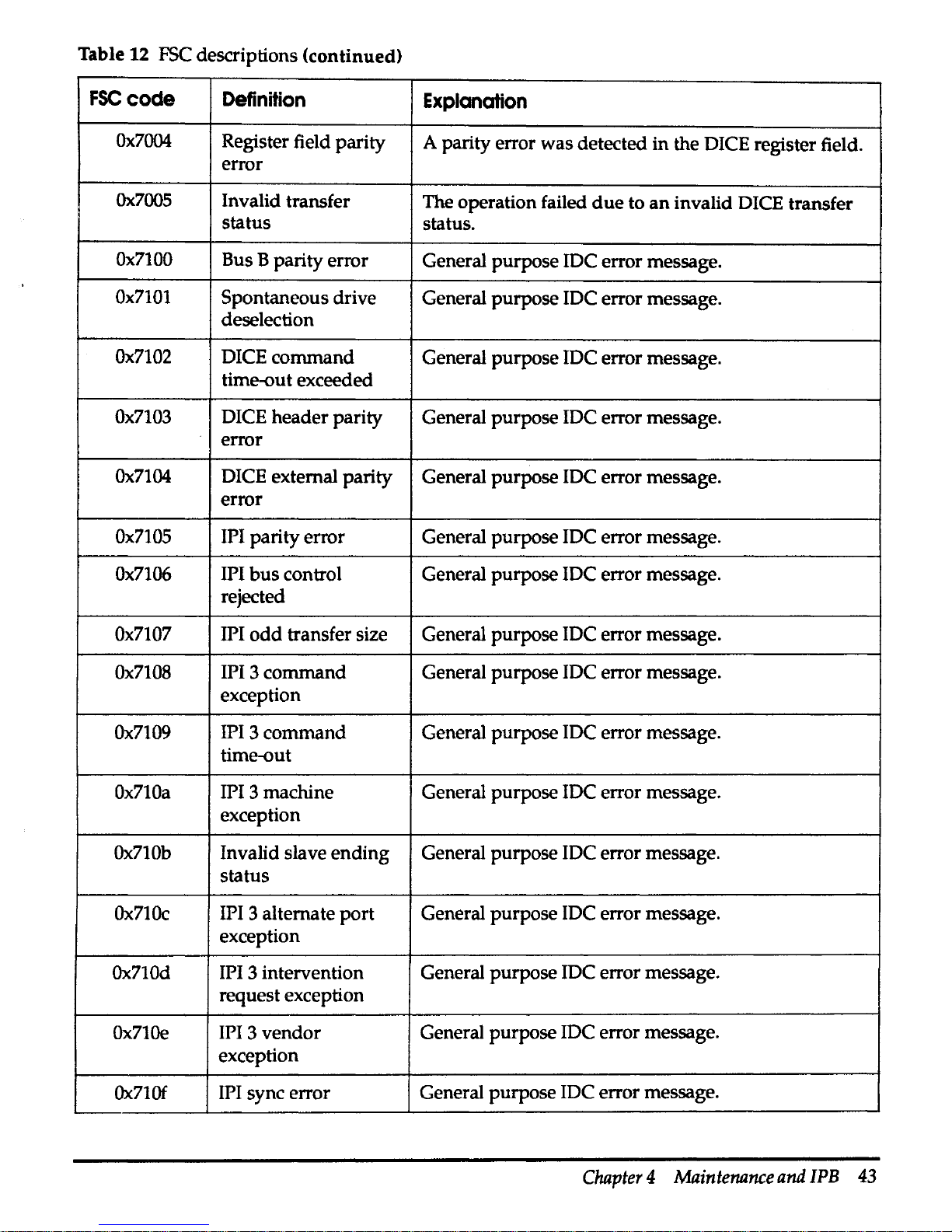

Table 12 contains a list

of

fault

symptom

codes

used

in

the disc

subsystem, the definition

of

each fault

symptom

code,

and

an

explanation of the condition

that

causes

the

code

to

generate.

Table

12

FSC descriptions

FSCcode

Definition

Explanation

Ox.0000

Normal success

No

error condition. This

should

never

appear

in

an

status

FSC

error message.

Ox0006

Device driver

not

This error is returned

if

an

invalid

port

number

is

found

specified in the CMI message dst_id field.

The

IDC

supports ports

0-3.

Any

other

number

is invalid.

Check /ioconfig for invalid IPI

p0rt

numbers.

Ox.1001

Device

not

found

Not

used

by

IDC.

Ox.1002

Unit

not

found This error is returned if the

unit

specified

cannot

be

selected

or

does

not

respond to a logical reset. Check

connection

and

drive

address

setting.

Ox.1003

Unit already

An

attempt

was

made

to move from CMI

boot

level

to

connected

physical level,

but

the

unit

was

already

at

physical

level.

Ox.1004

Unit disconnected

The

unit

was not connected

at

CMI physical level for

an

operation that is only valid

at

the physical level.

This can occur while:

•Attempting

to disconnect the

unit

• Attempting to

put

the

unit

online

• Attempting to slip a sector

•Attempting

to

unslip

a sector

•Attempting

physical level

I/0

operations

Ox.1005

Unit already online

An

attempt

was

made

to

move

from

the

CMI physical

level to the logical level,

but

the

unit

was

already

at

the logical level.

Ox1006

Unit offline

An

attempt was

made

to move from

the

CMI logical

level to the physical level,

but

the

unit

was

not

at

the

logical level.

Ox1007

to

Not

used

by

IDC.

OxlOOa

36

Elite 3 Disc

Drive

Service

Guide

Page 49

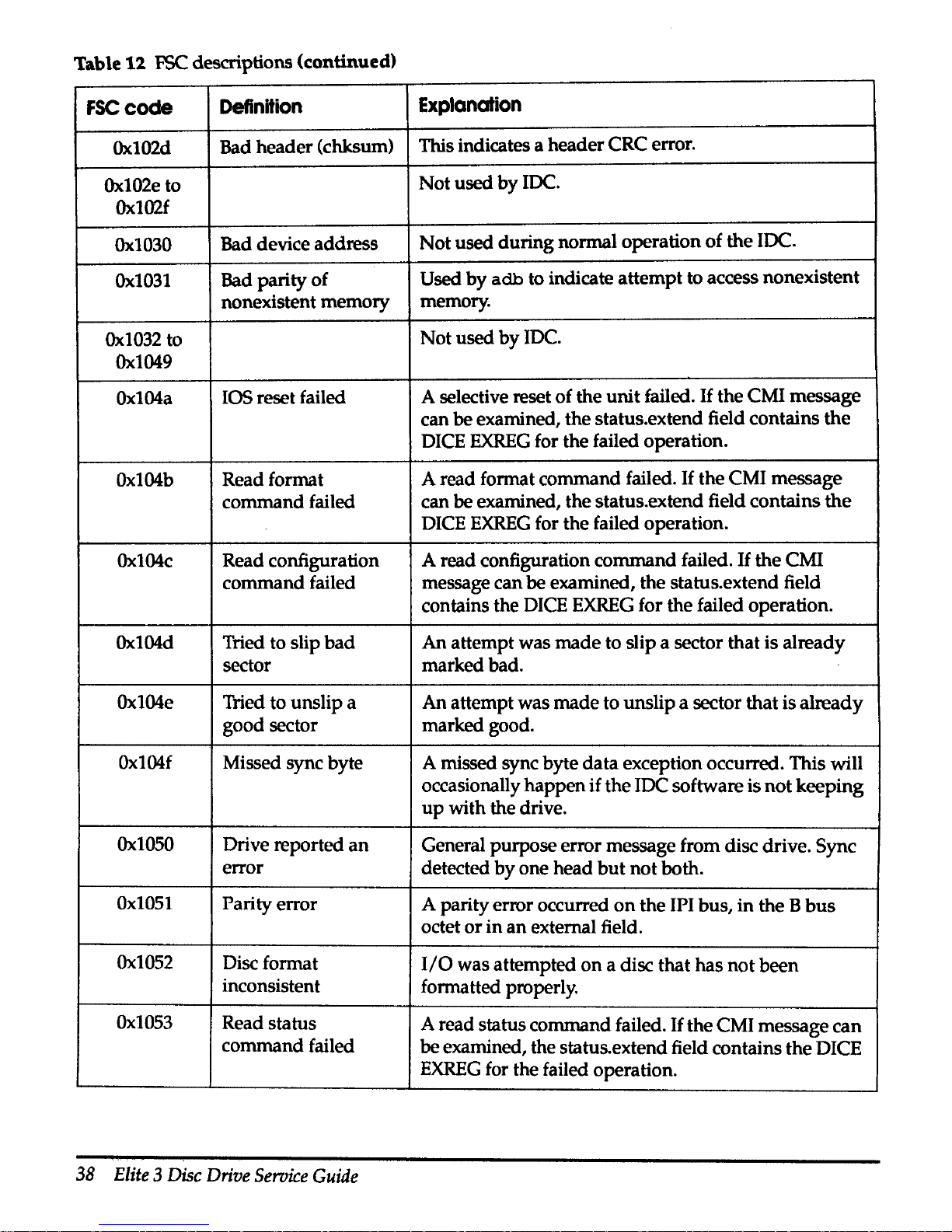

Table 12 FSC descriptions (continued)

FSCcode

Definition

Explanation

OxlOOb

Function time-out

The IDC timed

out

on

a read

or

write operation,

or

an

exceeded

expected attention from a

unit

did

not

arrive

prior

to

time-out.

OxlOOd

Function aborted

by

If

the IDC receives a DEBUG_FLIMBS message, all

CCU

pending operations

on

the specified device are

aborted

and

the error is posted.

OxlOOf

Invalid CMI function

An

invalid CMI function code

was

passed to the IDC.

code

Oxl012 to

Not

used

by

IDC.

Oxl015

Ox1016

CMI revision

An

invalid CMI revision level

was

passed

in

the CMI

unsupported

by

CCU device class field. For

the

IDC, the revision level

must

be

zero.

Ox1017

Defective CMI

The CMI message

was

defective.

message (badparms)

Oxl019 to

Not

used

by

IDC.

Ox

I Ole

OxlOlf Controller not The unit was not initialized

and

an

attempt

was

made

initialized

to connect, disconnect, set geometry, transition offline,

transition online, slip a sector,

unslip

a sector,

perform

physical

or

logical

1/0,

perform

long read

or

write,

or

read the configuration.

Ox1020to

Not

used

by

IDC.

Ox1027

Ox1028

Memory allocation This code is never printed

in

an

FSC error message.

It

(memalloc)

failed

is

used

with adb88 to indicate the breakpoint table is

full.

Ox1029

Not

used

by

IDC.

Ox102a

Unit not ready

The error is returned if the

drive

status cannot

be

read

or

if the device cannot

be

selected after reset.

Ox102b

Could

not seek to A seek error occurred.

required location

Ox102c

Recoverable IDC

An

ECC error occurred

and

the

data

was corrected.

ECCerror

Chapter 4 Maintenance

and

IPB

37

Page 50

Table

12

FSC descriptions (continued)

FSCcocle

Definition

Explanation

Ox102d

Bad header (chksum)

This indicates a header CRC error.

Ox102e

to

Not

used

by

IDC.

Ox102f

Ox1030

Bad device address

Not

used during normal operation

of

the

IDC.

Ox1031

Bad parity

of

Used

by

adb

to indicate attempt to access nonexistent

nonexistent memory

memory.

Ox1032

to

Not

used

by

IDC.

Ox1049

Ox104a

IOS reset failed

A selective reset of the

unit

failed.

If

the CMI message

can

be examined, the status.extend field contains

the

DICE

EXREG

for the failed operation.

Ox104b

Readformat

A read format command failed.

If

the CMI message

command failed

can

be examined, the status.extend field contains

the

DICE

EXREG

for the failed operation.

Ox104c

Read configuration

A read configuration command failed.

If

the

CMI

command failed

message can

be

examined, the status.extend field

contains the DICE

EXREG

for the failed operation.

Ox104d

Tried to slip

bad

An attempt was

made

to slip a sector

that

is already

sector marked bad.

Ox104e

Tried to unslip a An attempt was

made

to unslip a sector

that

is

already

good sector marked good.

Ox104f

Missed sync byte A missed sync byte

data

exception occurred. This will

occasionally

happen

if

the IDC software is

not

keeping

up

with the drive.

Ox1050

Drive reported

an

General purpose error message from disc drive. Sync

error

detected

by

one head

but

not

both.

Ox1051

Parity error

A parity error occurred

on

the IPI bus,

in

the B

bus

octet

or

in

an

external field.

Ox1052

Disc format

1/0

was attempted

on

a disc that has

not

been

inconsistent

formatted properly.

Ox1053

Read status

A read status command failed.

If

the CMI message can

command failed

be examined, the status.extend field contains

the

DICE

EXREG

for the failed operation.

38

Elite 3 Disc

Drive

Seroice

Guide

Page 51

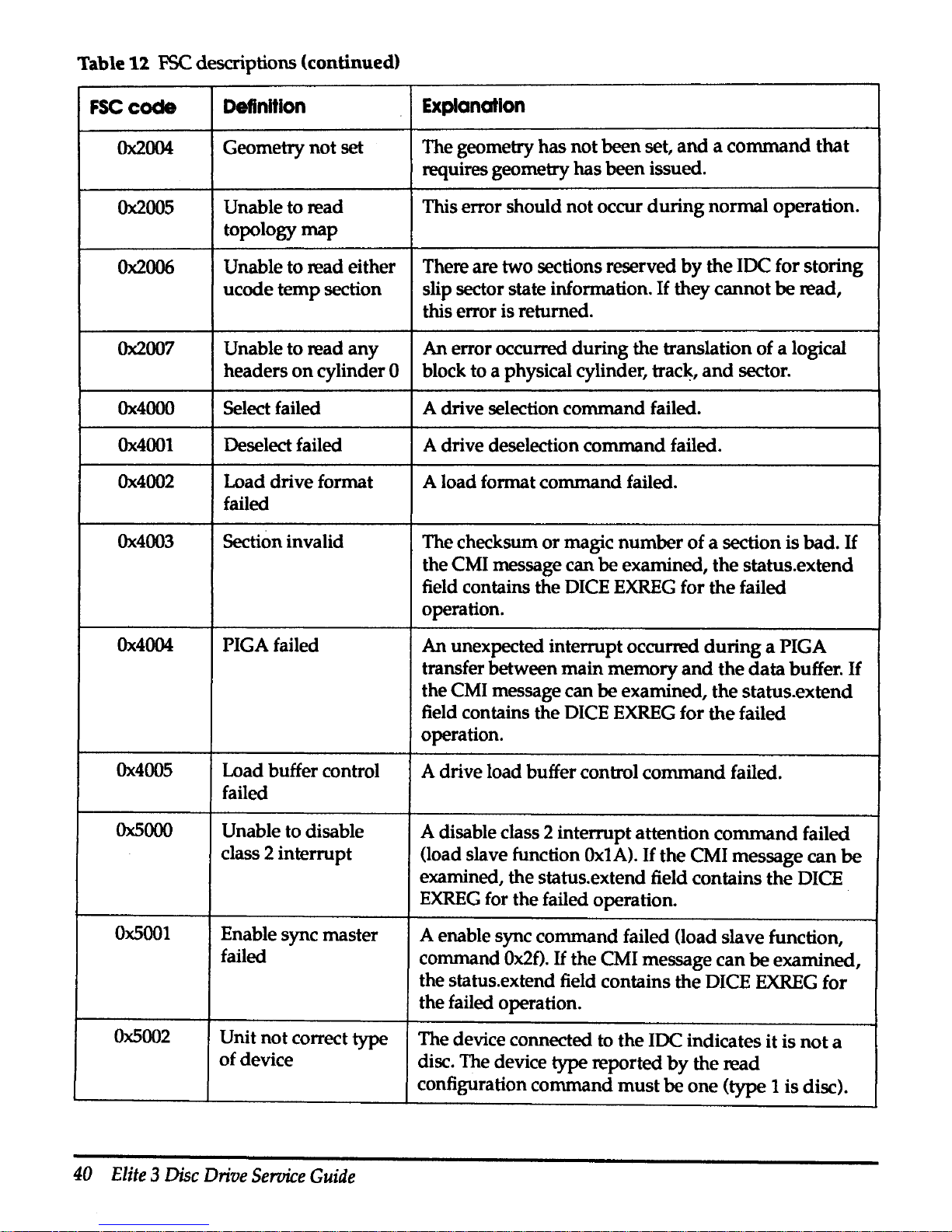

Table

12

FSC

descriptions (continued)

FSCcode

Definition

Explanation

Ox1054

Recalibrate command

A drive recalibration command failed (load slave

failed

function, command

Ox28).

Ox1055to

Not

used

by

IOC.

Ox1057

Ox1058

Header

parity error

A parity error occurred

in

the header field.

Ox1059

Header

miscompare

The header

on

the disc

did

not match the

header

error

expected

by

the software. This will occasionally

happen if the

IOC software is

not

keeping

up

with

the

disc.

If

this error code is reported frequently, there

may be a disc hardware problem.

Ox1060

Drive verify header

This can be a data error

or

a true miscompare.

miscompare

Ox1061

Busy doing

General purpose error message from disc drive.

something else

Ox1062

Out

of spare General purpose error message from disc drive.

cylinders

Ox1063

Usually a warning, General purpose error message from disc drive.

not fatal

Ox1066

Read specification A drive read disc specification values

command

command failed.

Ox1067

Read buffer control A read buffer control command failed.

command failed

Ox1068

Read formatter A read slave formatter parameters command failed.

parameters failed

Ox1069

Recoverable drive The drive reported

it

detected

and

corrected a

data

ECC error error

on

the given sector.

Ox106a

Drive sent wrong

The drive sent a different sector

than

the

one

the IOC

sector

expected. The expected location of the missed sector is

printed

and

stored

in

the status.extend field of the

CMI message. This becomes a fatal error after

11

retries.

Ox106b

Drive buffer

The drive data buffer is temporarily unavailable. This

over

/underflow

becomes a fatal error after

11

retries.

Chapter 4 Maintenance

and

!PB

39

Page 52

Table

1l

FSC

descriptions (continued)

FSC

code

Definition

Explanation

Ox2004

Geometry not set

The geometry

has

not been set,

and a command

that

requires geometry

has

been issued.

Ox2005

Unable to read

This error should not occur

during

normal operation.

topology

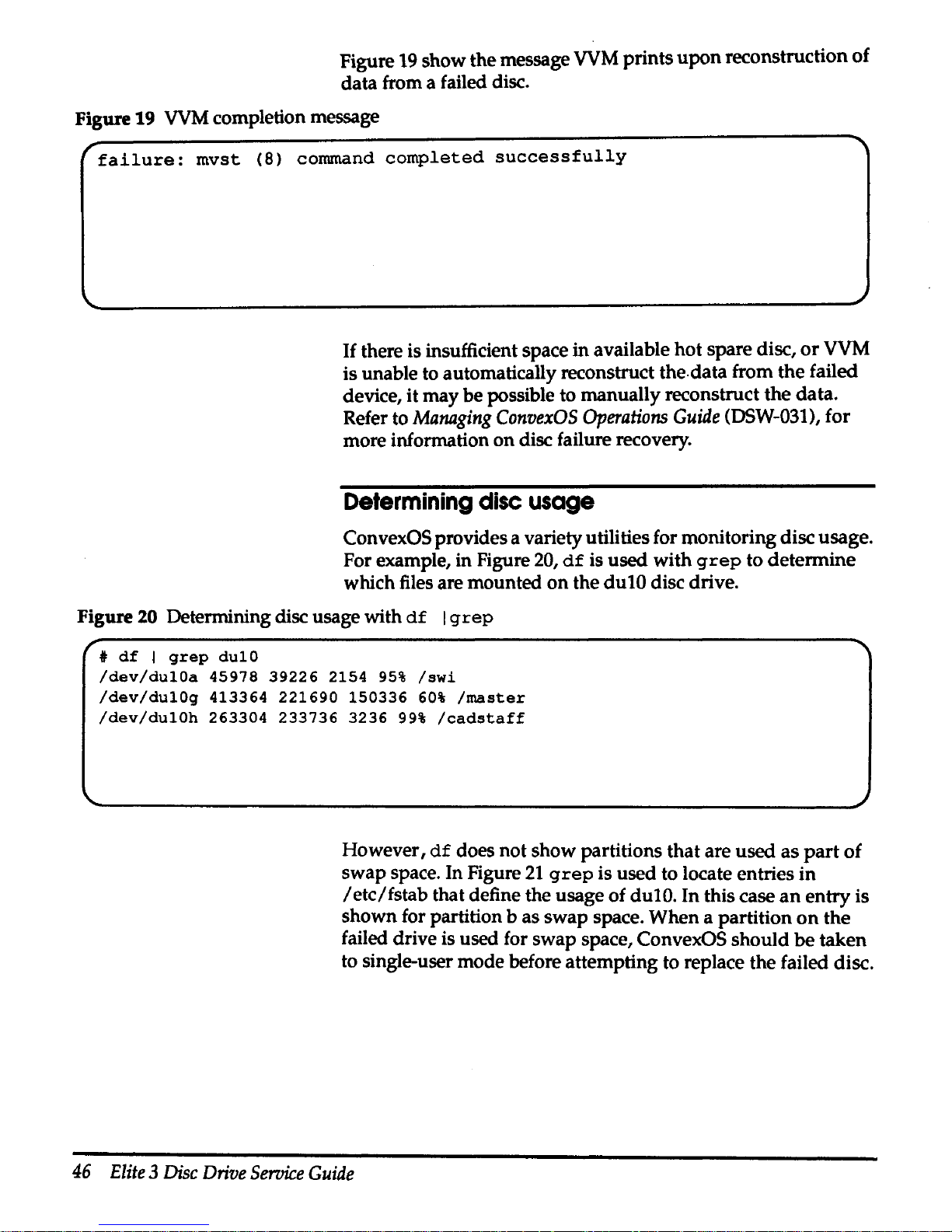

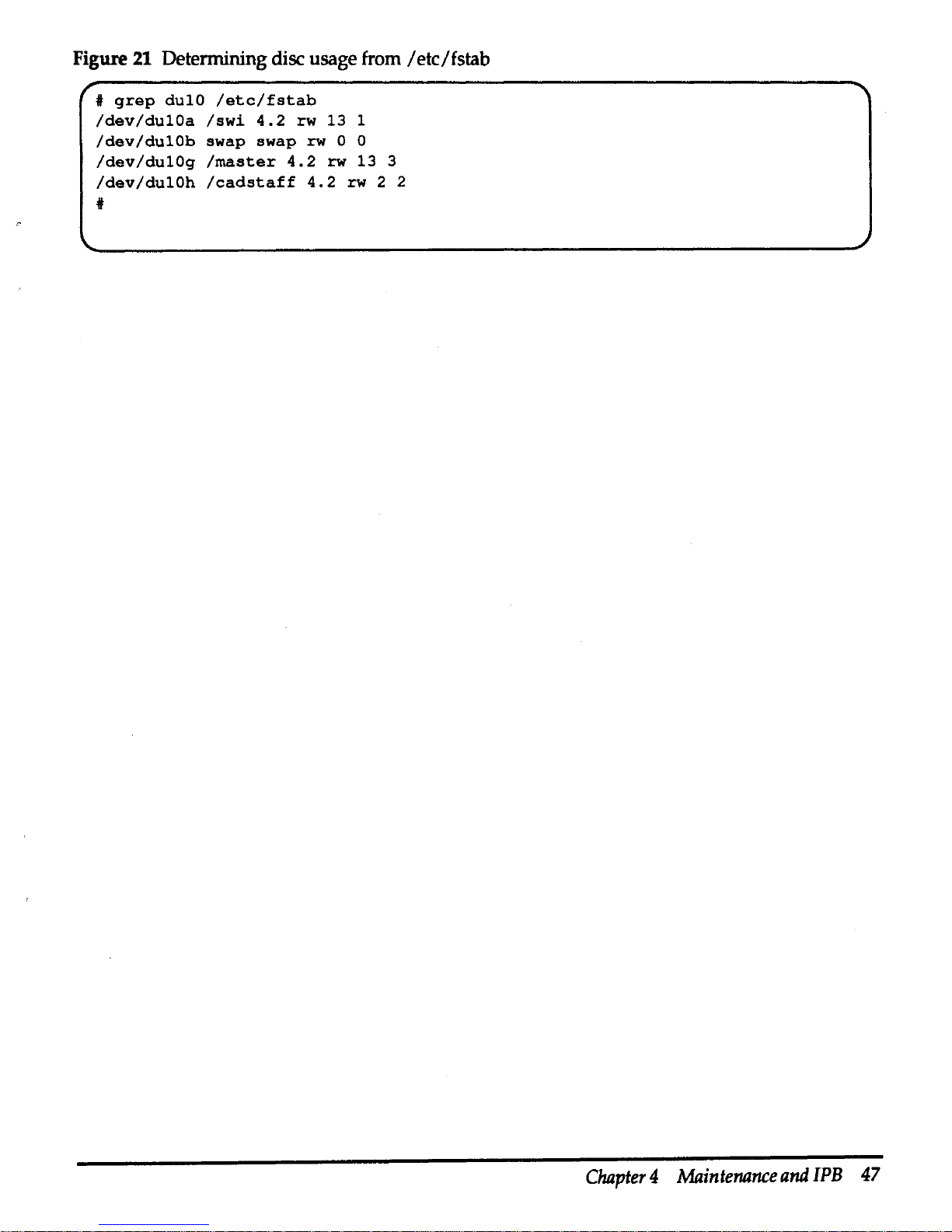

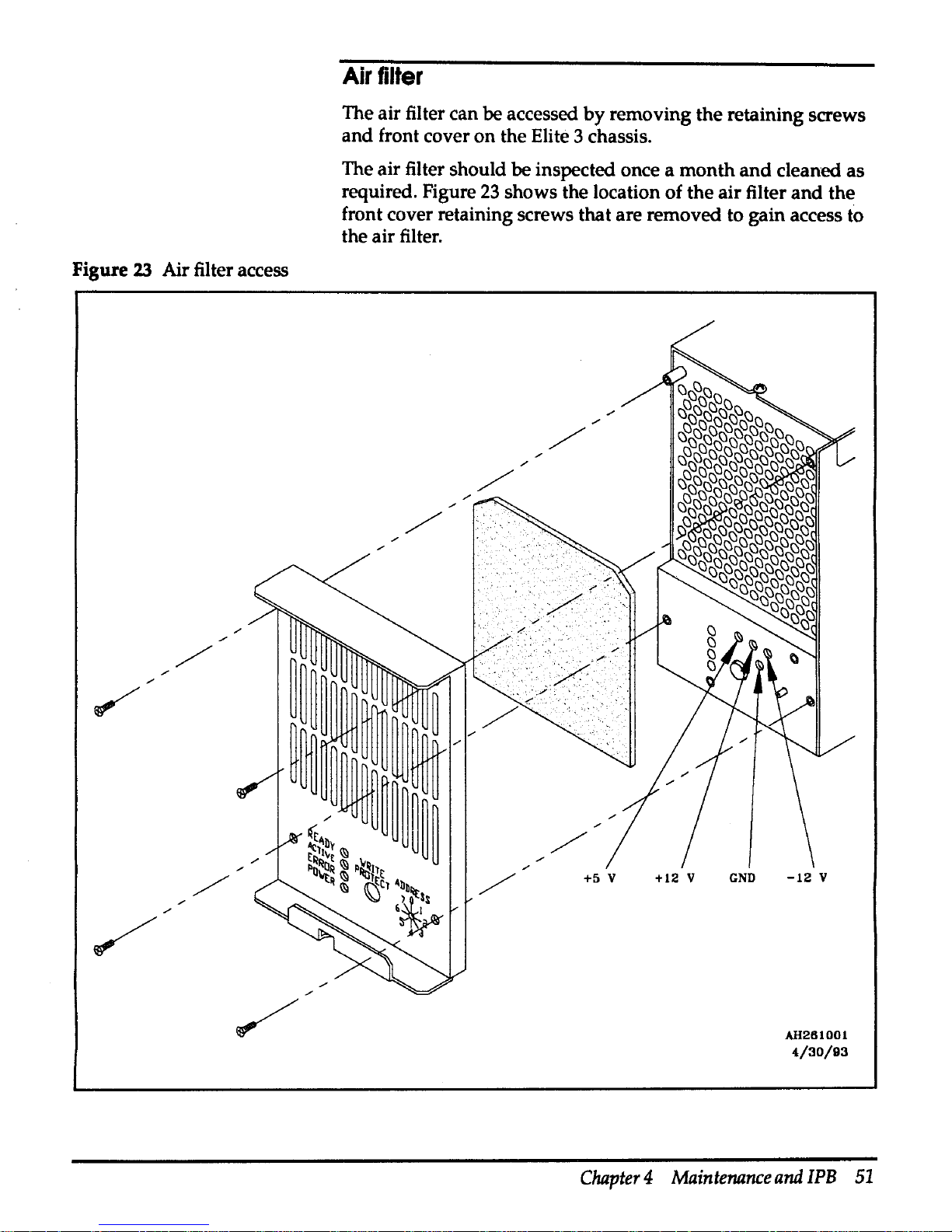

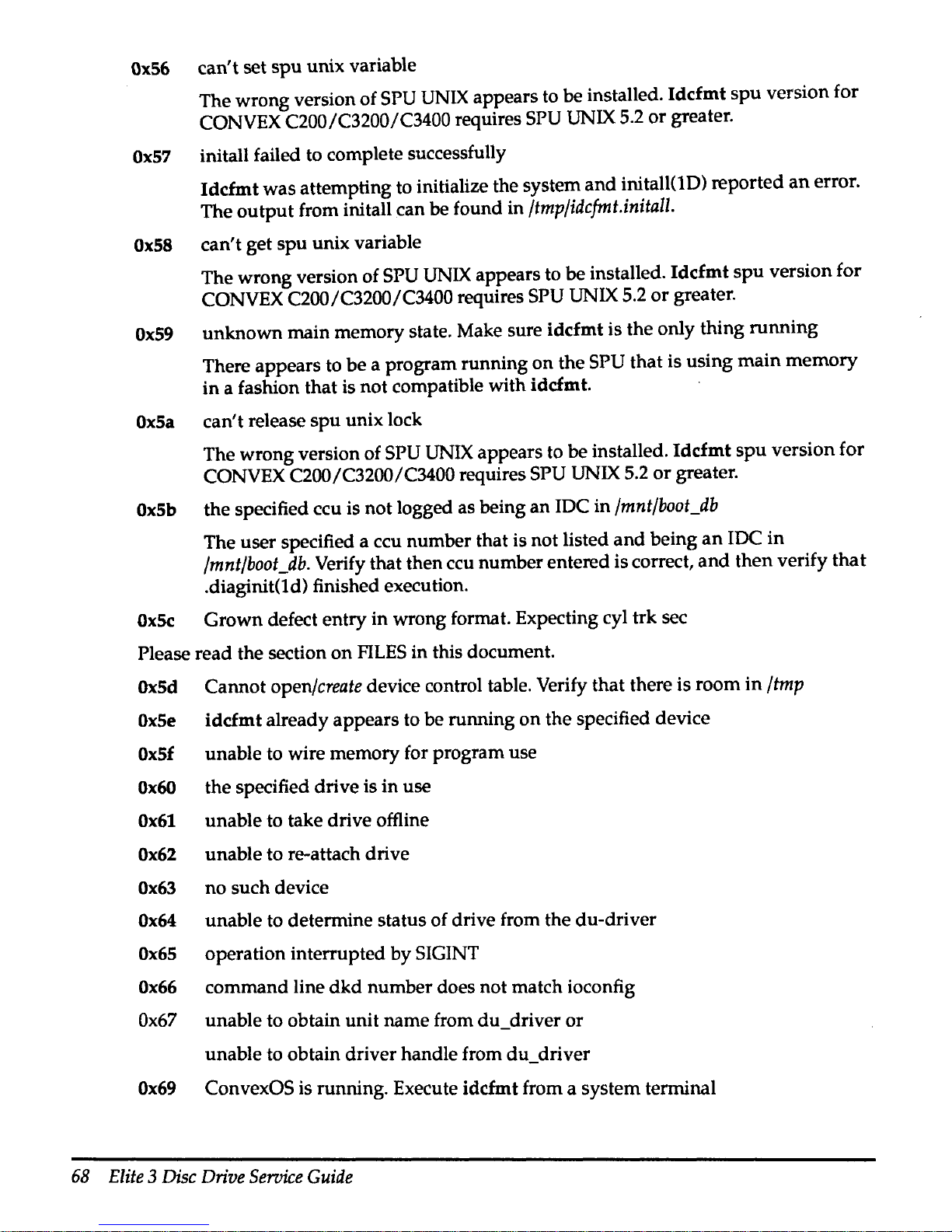

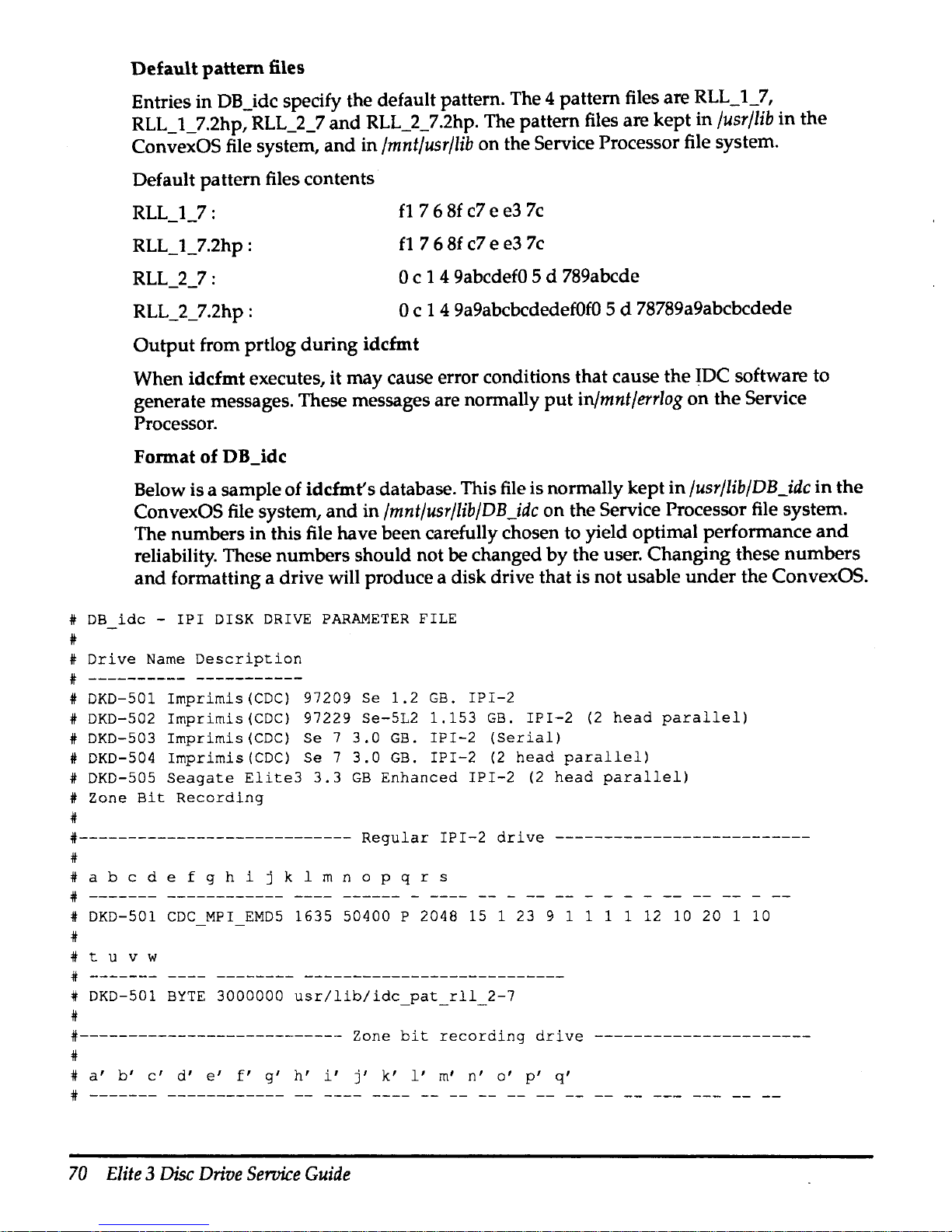

map