Control Techniques Reconditioned Unimotor hd, Unimotor fm, NT Series, XV Series Sales Brochure

Servo Motors

Unimotor hd, Unimotor fm, NT Series and XV Series

0.9 - 1,204 lb-in (0.11 - 136 Nm)

230 V | 460 V

Contents

Introduction: A Servo Motor for Every Application .... 1

Selecting the Right Motor for the Right Drive ........................... 3

Electronic Nameplates ............................................................... 3

UNIMOTOR FM 230 V | 460 V

Flexible Configuration AC Servo Motors ......................... 4

75 mm Frame Ratings .............................................................. 6

75 mm Frame Dimensions ....................................................... 7

95 mm Frame Ratings .............................................................. 8

95 mm Frame Dimensions ....................................................... 9

115 mm Frame Ratings .......................................................... 10

115 mm Frame Dimensions ................................................... 11

142 mm Frame Ratings .......................................................... 12

142 mm Frame Dimensions ................................................... 13

190 mm Frame Ratings – 230 V .............................................. 14

190 mm Frame Ratings – 460 V ............................................. 15

190 mm Frame Dimensions – 230 V and 460 V ...................... 16

250 mm Frame Ratings .......................................................... 18

250 mm Frame Dimensions ................................................... 19

Unimotor fm E3/U3 Power Connector Size Reference Tables ... 20

Selection Considerations ........................................................ 21

UNIMOTOR HD 230 V | 460 V

Compact, Powerful High Dynamic AC Servo Motors 24

Order Information ................................................................... 25

55 mm Frame Ratings and Dimensions .................................. 26

67 mm Frame Ratings and Dimensions .................................. 27

89 mm Frame Ratings and Dimensions .................................. 28

115 mm Frame Ratings and Dimensions ................................ 29

142 mm Frame Ratings and Dimensions ................................ 30

190 mm Frame Ratings and Dimensions ................................ 31

Selection Considerations ........................................................ 32

NT MOTOR 230 V

Compact NEMA or Metric Flange AC Servo Motors .. 36

2-inch Frame Ratings and Dimensions .................................... 37

3-inch Frame Ratings and Dimensions .................................... 38

Flying Lead and Connector Details ......................................... 39

Flying Lead and Connector Details ......................................... 40

Selection Considerations ........................................................ 41

XV MOTOR 230 V

Economical Metric AC Servo Motor ................................ 44

40 mm Frame Ratings and Dimensions .................................. 45

60/80 mm Frame Ratings and Dimensions ............................. 46

130 mm Frame Ratings and Dimensions ................................ 47

Selection Considerations ........................................................ 48

CABLES

Unimotor hd, Unimotor fm .................................................... 51

Unimotor hd, Unimotor fm, NT (-ExNS) .................................. 52

Unimotor hd, Unimotor fm, NT (-ExNS) .................................. 53

Unimotor hd, Unimotor fm .................................................... 54

NT Motors to Drives ............................................................... 57

XV Motors to Drives ............................................................... 59

FAN KITS

Unimotor hd, Unimotor fm .................................................... 60

Certificate No. EMS 54446

ISO 30610

ENVIROMENTAL

MANAGEMENT

003

Certificate No. Q 05176

ISO 9001

QUALITY

MANAGEMENT

003

Introduction: A Servo Motor for Every Application

A Servo Motor for Every Application

Reliability and Innovation

Control Techniques designs its products using a proven

development process that prioritizes innovation and reliability.

This process has resulted in Nidec's market-leading reputation for

performance and quality.

Control Techniques offers a wide range of reliable servo motors

designed to meet specific application requirements. When

matched to a Control Techniques' brand servo drive product

(Unidrive M, Digitax ST, Epsilon EP or MDS servo drive), the

resulting drive/motor combination provides an optimized system

in terms of ratings, performance, cost and ease of use.

Today, businesses of all sizes are searching for partners who

understand the unique demands of today’s global economy.

Time and again they turn to Control Techniques. With our

world-class brands, broad industry experience and extensive

global presence, Control Techniques is uniquely positioned to

deliver cost-effective solutions for the ever-changing industrial

manufacturing market.

Performance Advantage

Unimotor fm

Designed for flexible configuration for use in a wide range of

applications. A high inertia option is available.

• Voltage Rating: 230 V/460 V

• Continuous Torque: 10.6 to 1,204 lb-in (1.2 to 136 Nm)

• Feedback Choices: Resolver, incremental and absolute

encoder with multiple connector options

• Frame Sizes (with NEMA flange options): 75, 95, 115,

142 ,190 and 250 mm

• Ratings: IP65, UL, CE and RoHS

Unimotor hd

Compact low-inertia servo motor for high-dynamic applications

• Voltage Rating: 230 V/460 V

• Continuous Torque: 6.4 to 752 lb-in (0.72 to 85.0 Nm)

• Feedback Choices: Resolver, encoder and absolute encoder

• Frame Sizes: 55, 67, 89, 115, 142 and 190 mm

• Ratings: IP65, UL, CE and RoHS

NT Series

Compact NEMA or metric flange motors

• Voltage Rating: 230 V

• Continuous Torque: 7.5 to 56 lb-in (0.85 to 6.3 Nm)

• Feedback Choices: Incremental encoder

• Flying Lead Option

• Frame Sizes: English (NEMA 23 or 34) or Metric (IEC-72-1)

• Ratings: IP65, UL and RoHS

XV Series

Economical metric motors

• Voltage Rating: 230 V

• Continuous Torque: 0.9 to 101 lb-in (0.11 to 11.5 Nm)

• Frame Sizes: 40, 60, 80 and 130 mm

• Ratings: IP55 and IP65, UL, CE and RoHS

Shaft seals standard on Unimotor hd, Unimotor fm

and NT series motors

1

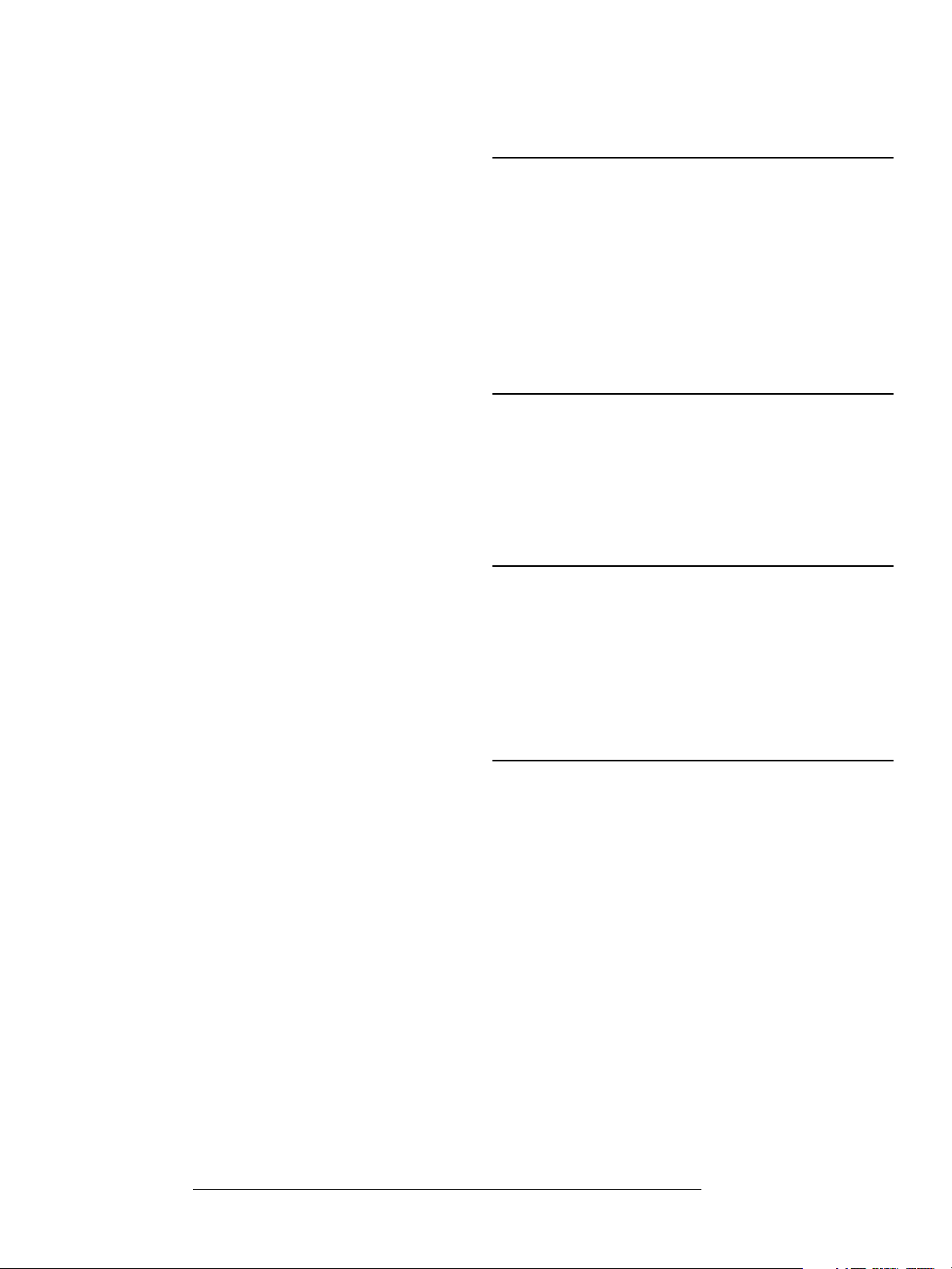

A Wide Range of Rugged and Reliable Servo Motors

Servo Motor Unimotor fm Unimotor hd NT Series XV Series

Product Matrix

Motor Family

Drive Voltage 230 V / 460 V 230 V / 460 V 230 V 230 V

Continuous Stall Torque

Flange IEC (NEMA option) IEC IEC, NEMA Metric

Frame

Inertia Med. (high inertia option) Low Low Low, medium

Peak Torque

Base Speeds Up to 6000 rpm Up to 6000 rpm Up to 5000 rpm Up to 5000 rpm

Brake Options 24 Vdc Holding Brake

Connector Options

Feedback Options

Ingress Protection IP65 IP65 IP65, IP67, IP68 IP55, IP65

Approvals CE, UL, RoHS CE, UL, RoHS UL, RoHS CE, UL, RoHS

Shaft Seals

Circular style frame-mounted

SinCos single- and multi-turn,

SinCos single and multi-turn,

Page 4 Page 21 Page 31 Page 36

Up to 1204 lb-in

(136 Nm)

75, 95, 115, 142,

190, 250 mm

Up to 3611 lb-in

(408 Nm)

90° and rotatable; optional

90° fixed, vertical, or mixed

Incremental encoders,

resolver, HIPERFACE

and EnDat

®

(SICK)

Up to 752 lb-in

(85.0 Nm)

55, 67, 89, 115, 142, 190 mm 2, 3 in 40, 60, 80, 130 mm

Up to 2257 lb-in

(255.0 Nm)

Circular style frame mounted

90° and rotatable

Incremental encoders,

SinCos single- and multi-turn,

SinCos single and multi-turn,

resolver, HIPERFACE® (SICK)

and EnDat

Up to 56 lb-in

(6.3 Nm)

Up to 144 lb-in

(16.2 Nm)

MS or circular style

frame mounted, MS style

on 40-in lead, flying leads, drive

connector terminated leads (20

ft max.)

Incremental

2048 line count

Up to 101 lb-in

(11.4 Nm)

Up to 301 lb-in (34 Nm)

AMP Mat-n-Loc on 1-ft. lead

(40 to 80 mm); MS style

frame-mounted (130 mm)

Incremental

2048 line count

Why Motion Customers Choose Nidec's Motion Control Solutions...

• A full line of servo motors up to 1200 lb-in

• Single-source motion control lowers total system costs

• Complimentary software offers the ultimate programming

capability and greatly reduces programming time

• Multiple fieldbus options including EtherCAT, EtherNet/IP,

Modbus TCP/IP and more

• High-speed, peer-to-peer communications

• 8 feedback types supported as standard

• Integrated programs eliminate need for PLC

• Drive and Automation Center support

• Zero-space internal EMI and dynamic braking resistor options

• AC drives with closed-loop vector control and sensorless

rotor control

2

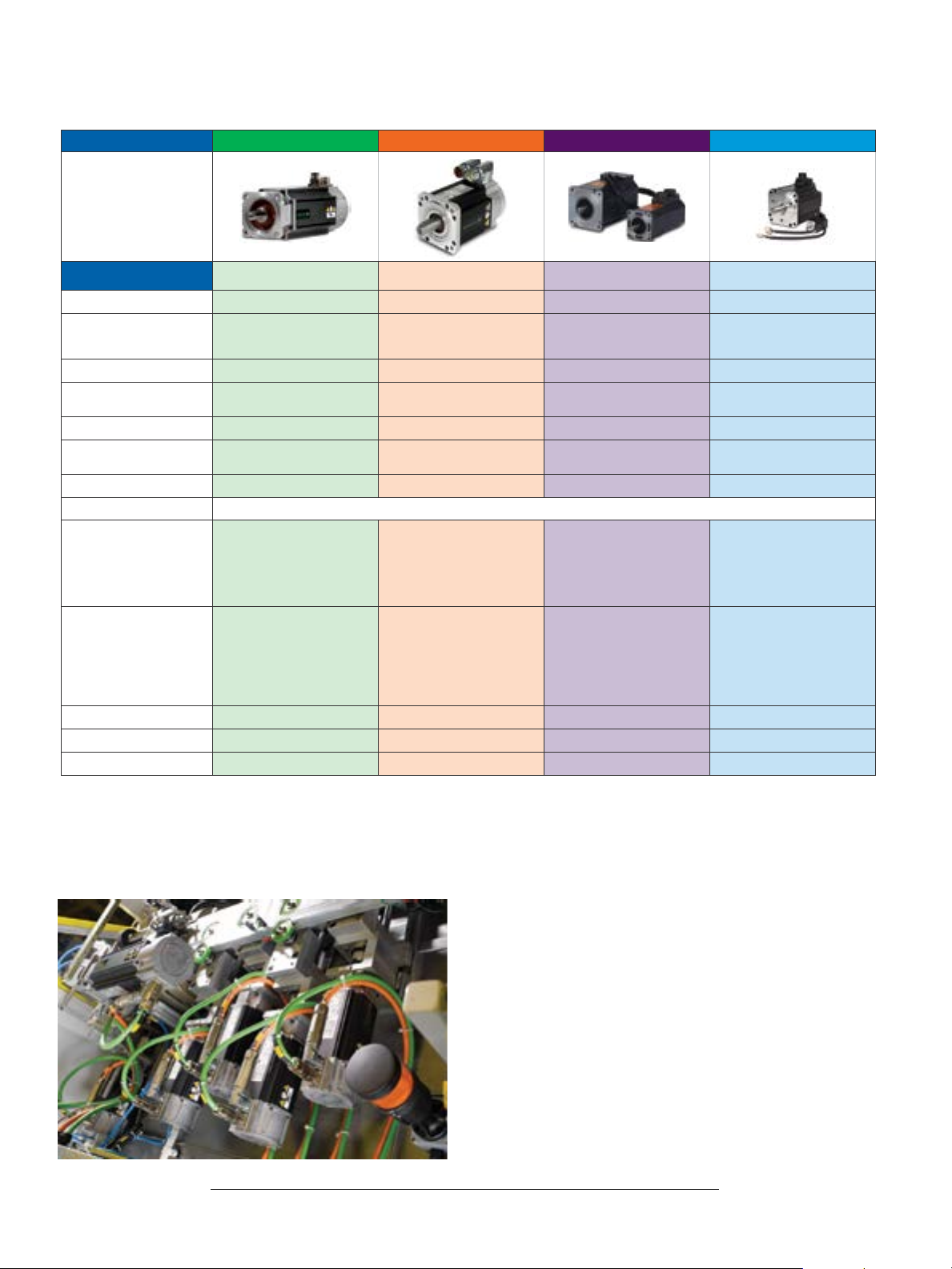

Selecting the Right Motor for the Right Drive

2020

7

7.5

Electronic Nameplates

Selecting the Right Motor for the Right Drive

Control Techniques' drive and motor combinations provide an

optimized system in terms of ratings, performance, cost and

ease-of-use. You can manually select the system components

using the following steps, or download the SERVOSoft

®

sizing

software which includes our Control Techniques' servo drive and

motor data.

1. Determine the application’s continuous and peak torque

requirements at various motor shaft speeds, then refer to

motor data tables and the visual reference overview to help

determine which motor family will be most appropriate for

the application.

2. Once the motor family is selected, use this brochure to select

a specific motor model that delivers the required torque and

speed. Make note of the continuous and peak current (Amps)

requirements of the selected motor.

3. Check the specification tables in the Control Techniques'

individual drive brochures for Digitax ST, Epsilon EP, Unidrive

M or MDS servo drives to select the drive model that delivers

adequate continuous and peak torque for the selected motor.

4. Refer to the Servo Motor Cables section of this brochure to

select the motor power and feedback cables for the selected

motor and drive.

5. Confirm that the ratio of rotor inertia to load inertia is <10:1

load inertia/rotor inertia <10

Note: A gear reducer will reduce the load inertia based on

the following equation:

Reflected load inertia = load inertia/gear ratio

2

Note: When specifying a motor system, be sure to consider

such options as user-interfaces (HMI), braking resistors and

other options and accessories that will enhance the system’s

performance and value.

Example

using the NT motor family and Digitax ST servo drive family

Step 1: The application requires 12 lb-in continuous torque.

Frame

Size

NT-207

NT-212

NT-320

110 100

Continuous Stall (lb-in) Peak (lb-in)

NT Torque Range

7.5 18

12.5 37.5

20 56

22.5

59

Step 2: The Servo Motors brochure lists the NT-212 motor

with 2.7 A stall current.

Motor Frame Size 2 in

Voltage 230 Vrms

Model NT-207 NT-212

Continuous Stall Torque (lb-in) 7.5 12.5

Continuous Stall Torque (Nm) 0.85 1.4

Standard Inertia (lb-in-sec²) 0.000094 0.000164

Standard Inertia (kgm2) 0.0000106 0.0000185

Peak Torque (lb-in) 22.5 37.5

Peak Torque (Nm) 2.54 4.24

Maximum Cogging (lb-in) 0.094 0.12

Maximum Cogging (Nm) 0.011 0.014

Motor Weight (lbs) 3 4

Motor Weight (kg) 1.36 1.81

Rated Speed 5000 rpm Kt (lb-in/A) = 5.12 5.08

Kt (Nm/A) = 0.58 0.57

Ke (V/k rpm) = 35 34.7

Rated Torque (lb-in) 7.50 12.50

Rated Torque (Nm) 0.85 1.4

Stall Current (A) 1.7 2.7

Rated Power (kW) 0.432 0.740

R (ph-ph) (Ohms) 11.1 4.56

L (ph-ph) (mH) 39.1 18.9

Electronic Nameplates

Some motors fitted with high-resolution SinCos or absolute

encoders are pre-loaded with the motor “electronic nameplate”

data during the manufacturing process. This data can be

read by most Control Techniques' brand servo drives and

used to automatically optimize the drive settings. This feature

simplifies commissioning and maintenance, ensures consistent

performance and saves time.

For comprehensive information on Control Techniques' motor and drive solutions, refer to our website.

Step 3: Select the Digitax ST drive with adequate current rating.

Ratings — Digitax ST

Drive Model

Number

DST1201 200-230 3Ø 1.7 5.1

DST1202 200-230 3Ø 3.8 11.4

DST1203 200-230 3Ø 5.4 16.2

DST1204 200-230 3Ø 7.6 22.8

DST1401 380-480 3Ø 1.5 4.5

Drive switching frequency at 6 kHz for rated performance

*Peak current is duty cycle limited

** Derate continuous current above 6 kHz drive switching frequency

Voltage / Ø

Output Current*

Cont. A Peak A

3

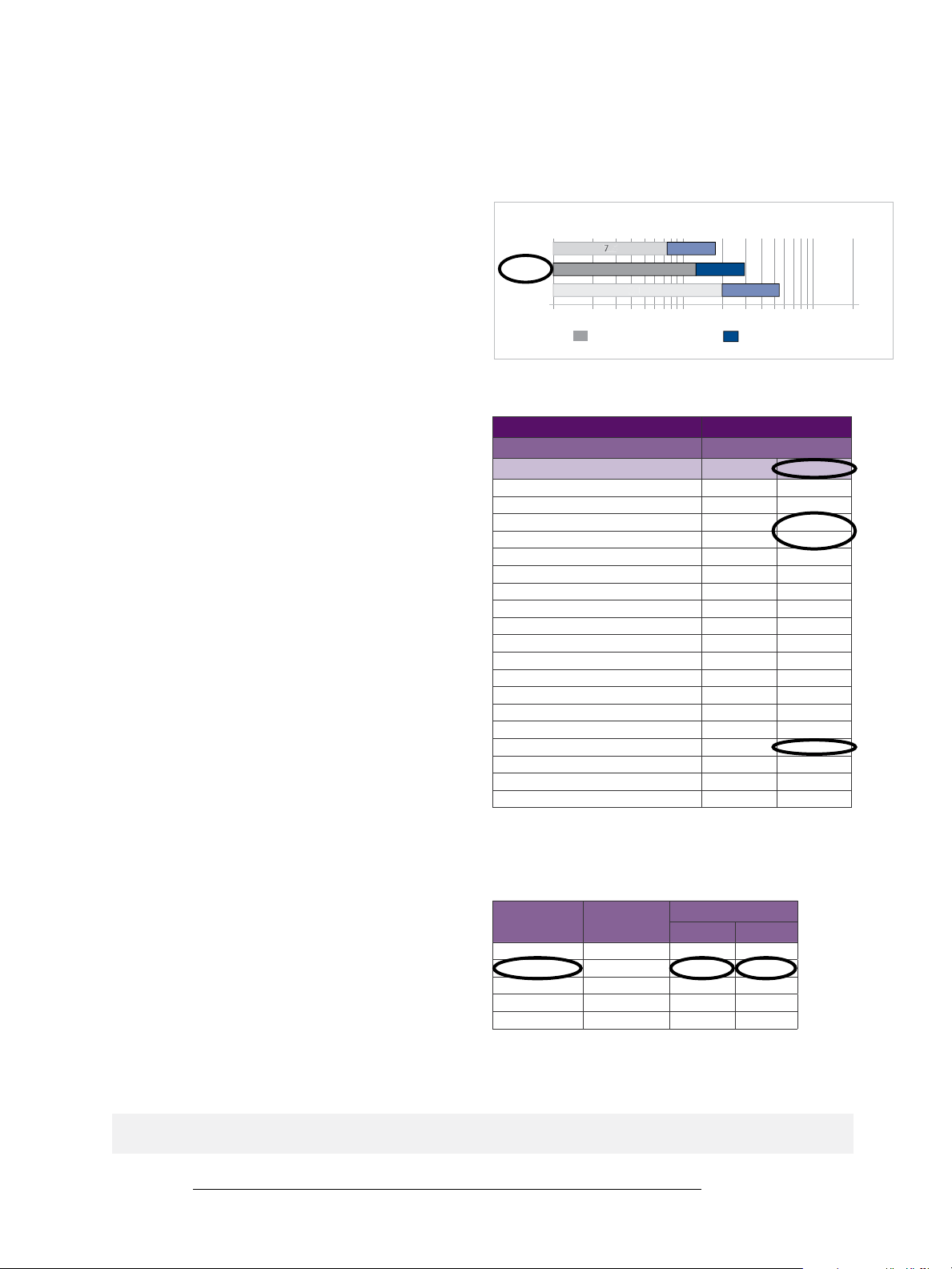

UNIMOTOR FM

Unimotor fm 230 V | 460 V

ISO 9001

Unimotor fm 230 V / 460 V

Flexible Configuration AC Servo Motors

Flexible Configuration AC Servo Motors

Unimotor fm is a high performance, brushless AC Servo

motor range matched for use with Control Techniques' brand

drives. “FM” stands for “Flexible Motor” and is designed to

accommodate a wide range of applications. The motors are

available in six frame sizes with various mounting arrangements

and motor lengths. Control Techniques' drives and motors are

designed to function as an optimized system. Unimotor fm is the

perfect partner for Unidrive M, Digitax ST and Epsilon EP servo

drives.

Key Features

• Torque range: 12.4 to 1204 lb-in (1.4 to 136.0 Nm)

• Medium inertia design with high inertia option available

• Connector styles include vertical, low profile and

90° rotatable

• Variety of flange possibilities (IEC/NEMA)

• Holding brake option

• IP65 conformance

• Winding to suit 230 V and 460 V

• Speed options include 2000, 3000, 4000 and 6000 rpm

• Multiple feedback options:

• Resolver: Robust for extreme applications and

conditions — lower accuracy, medium resolution

• Incremental encoder: High accuracy, medium resolution

• Absolute: Medium accuracy, medium resolution, single-turn

and multi-turns

• SinCos/Absolute: High accuracy, high resolution, single-turn

and multi-turn

• HIPERFACE (SICK) and EnDat (Heidenhain) protocols

supported

NOW WITH EVEN HIGHER PERFORMANCE!

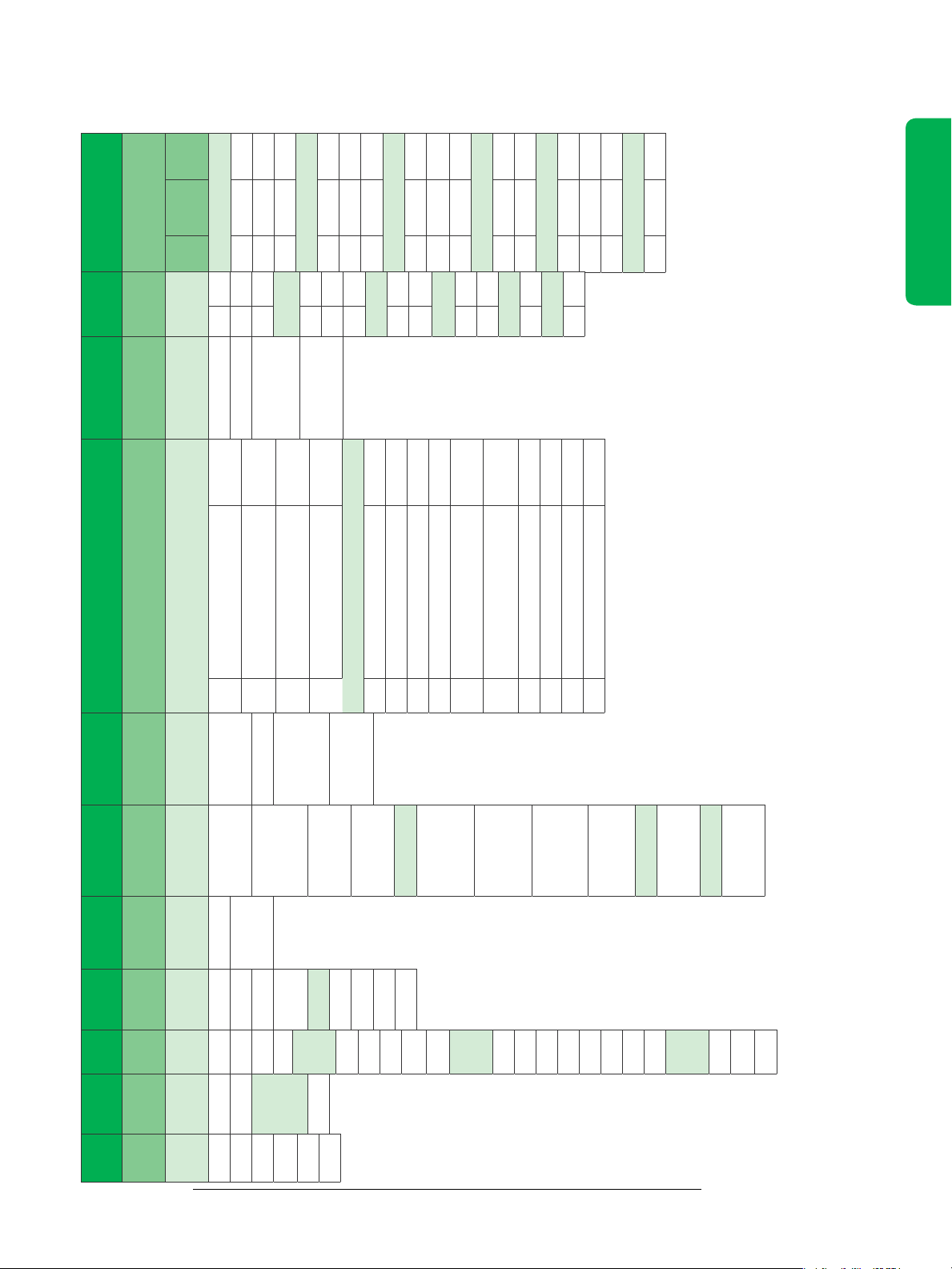

Frame

Size

75

95

115

142

190

250

10 100 1000

Electronic Nameplate Capability

Unimotor fm Torque Range

42

Continuous (lb-in) Peak (lb-in)

82

124

246

142

221

686 2044

1204 3611

425

664

2000 4000

Approvals

4

Certificate No. Q 05176

QUALITY

MANAGEMENT

003

When a Unidrive M, Unidrive SP or Digitax ST servo drive is

connected to a SinCos or absolute encoder, it can recognize and

communicate with the motor to obtain the “electronic nameplate”

data. This motor data can then be used to automatically optimize

the drive settings. This feature simplifies commissioning and

maintenance, ensures consistent performance and saves time.

UNIMOTOR FM

Unimotor fm Order Information

Use the information below to create an order code for a Unimotor fm (top row is an example).

Frame

Length

190

Shaft Diameter

100

A

Inertia +

CA

(mm)

Shaft

Length

075 Frame

(ex. 110=11.0 mm)

BCD

075 Std

075 Frame

Temp sensor

075-250 Frames

A = Standard + PTC

‡

EQI 1331

075-250 Frames

Feedback device

EC = Inductive Absolute

110 23 A

140 30 B-D

190 40

080 Opt

085 Opt

095 Frame

B = High + PTC

C = Standard +

KTY84-130

thermistor**

‡

SEL 52

ECI 1319

Multi-turn EnDat

Single-turn EnDat

= Capacitive Hiperface SinCos

†

FC = Inductive Absolute

VF

095 Frame

140 30 A

100 Std

098 Opt

D = High +

KTY84-130

thermistor**

190 40 B-E

115 Opt

115 Frame

240 50

115 Std

115 Frame

SEK 52

075-250 Frames

Single-turn

Multi-turn

= Capacitive Hiperface SinCos

†

WF

AE = Resolver

CA = Incremental Encoder (Std) 4096 ppr

190 40 A-C

240 50 D, E

130 Opt

142 Frame

FB = Optical Absolute Single-turn EnDat ECN 1313

EB = Optical Absolute Multi-turn EnDat EQN 1325

142 Frame

240 50

240 50 A-E

165 Std

149 Opt

190 Frame

SRS 50

SRM 50

Multi-turn Hiperface

Single-turn Hiperface

SA = Optical SinCos

RA = Optical SinCos

190 Frame

320 58 D, E

215 Std

250 Frame

FF = Inductive Serial Single-turn EnDat ECI 1319**

EF = Inductive Serial Multi-turn EnDat EQI 1331**

320 58 A-H

380 58

320* 80* A-H*

300 Std

GB = Optical Multi-turn EnDat EQN 1337**

HB = Optical Single-turn EnDat ECN 1325**

250 Frame

480 110 D-F

* Add (-SREL) to end of E3/U3

order string for 80 mm length

shafts on 190 mm frames.

A

B

5

30

A

U3

095

Output shaft

type

Connection

Brake

(rpm)

Rated

speed

Stator

length

Motor

voltage

size

Frame

Frames

075-250

Frames

075-142

Frames

075-250

Frames

075-190

075

Frame

Frames

075-190

A = Keyway w/

Full Key installed

B = No Keyway

B = Power and

Signal 90° and

rotatable size 1.0

C = Power 90°

5 = 24 Vdc

0 = No Brake

Parking brake

20 = 2000

30 = 3000

40 = 4000

B

A

C

E3 = 230 V

U3 = 460 V

075

095

115

E* = Keyway w/

Half Key installed

rotatable and

signal vertical

size 1.0

V = Power and

a

60 = 6000

250 Frame

D

095

-142

250

Frame

U3 = 460 V

142

190

F* = Keyway w/

Half and Full Key

included

Signal Vertical

size 1.0

D = Hybrid power

10 = 1000

15 = 1500

B

A

Frames

250

142-190 Frames

and signal 90°

size 1.0**

J = 1.5 size

b

b

20 = 2000

25 = 2500

C*

D*

Power90° and

signal 90°

and rotatable

E = Hybrid power

E*

190

Frame

and signal 90°

size 1.5**

N = Power 90°

rotatable and

B

A

C*

signal vertical

size 1.0

M = Power and

Signal Vertical

F*

E*

D*

115-190 Frames

size 1.0

H = Power

H*

G*

Notes:

*Half key is used to balance shaft. It does not complete shaft radius

Frame

b,c

250

hybrid box and

250

H = Power hybrid

signal vertical

b

b

D

Frame

Bearingless design recommended for light duty applications only

a 6000 rpm not available on all frames sizes

b 250 D and E lengths, rated speed equal and above 2500 rpm are supplied with a terminal box "H" connector options

c 250 F Lengths, rated speed equal and above 2000 rpm are supplied with a terminal box "H" connector options

d use if replacing E2/U2 motors

e “J” connector option available on 142E3 and 142U3 frames, refer to stator lengths marked with an asterisk

**Single cable option

‡

box and signal

vertical (Std)

F

E

f “H” connector option available on some E3 and U3 190 frames, refer to stator lengths marked with an asterisk

5

UNIMOTOR FM

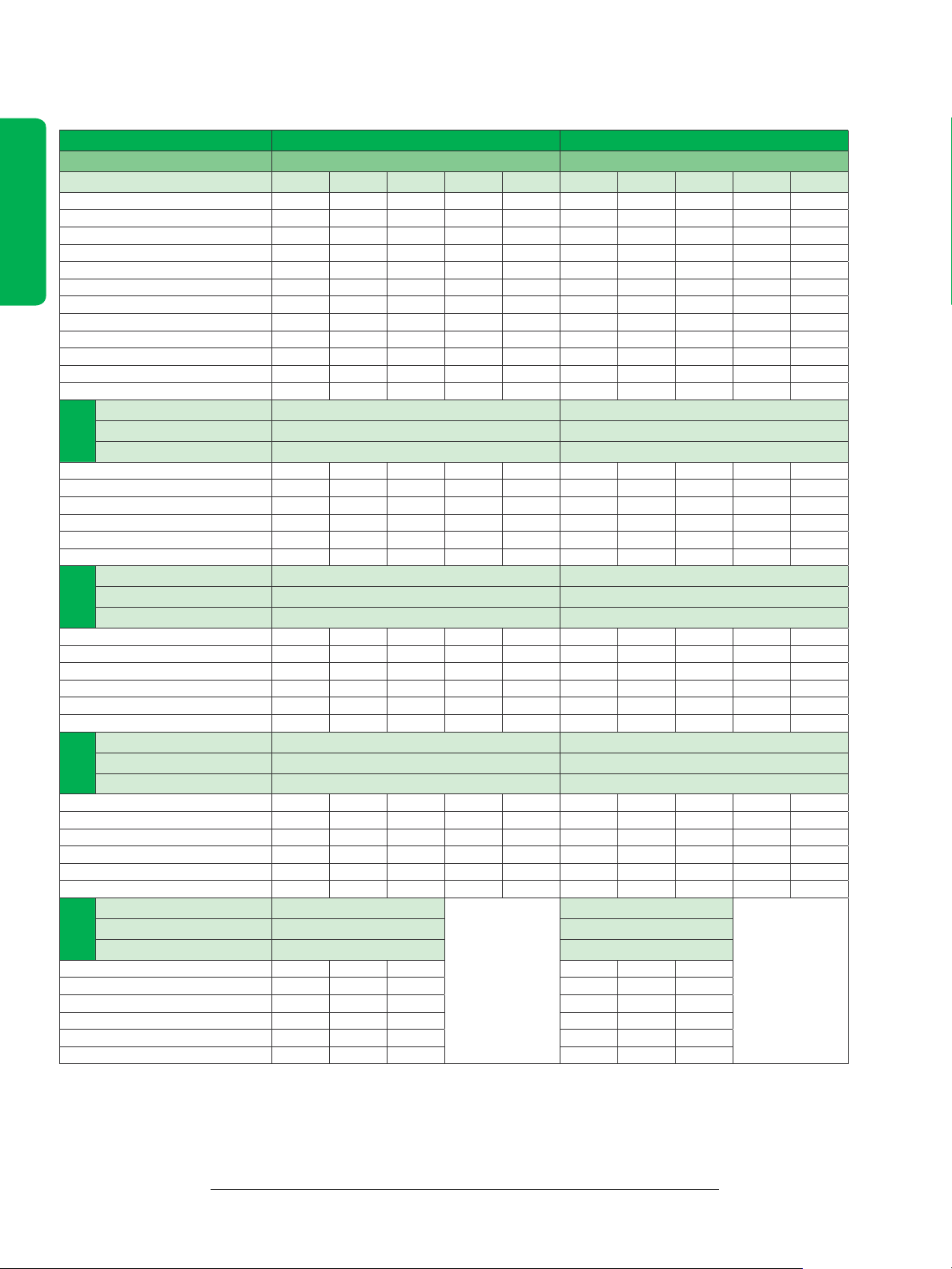

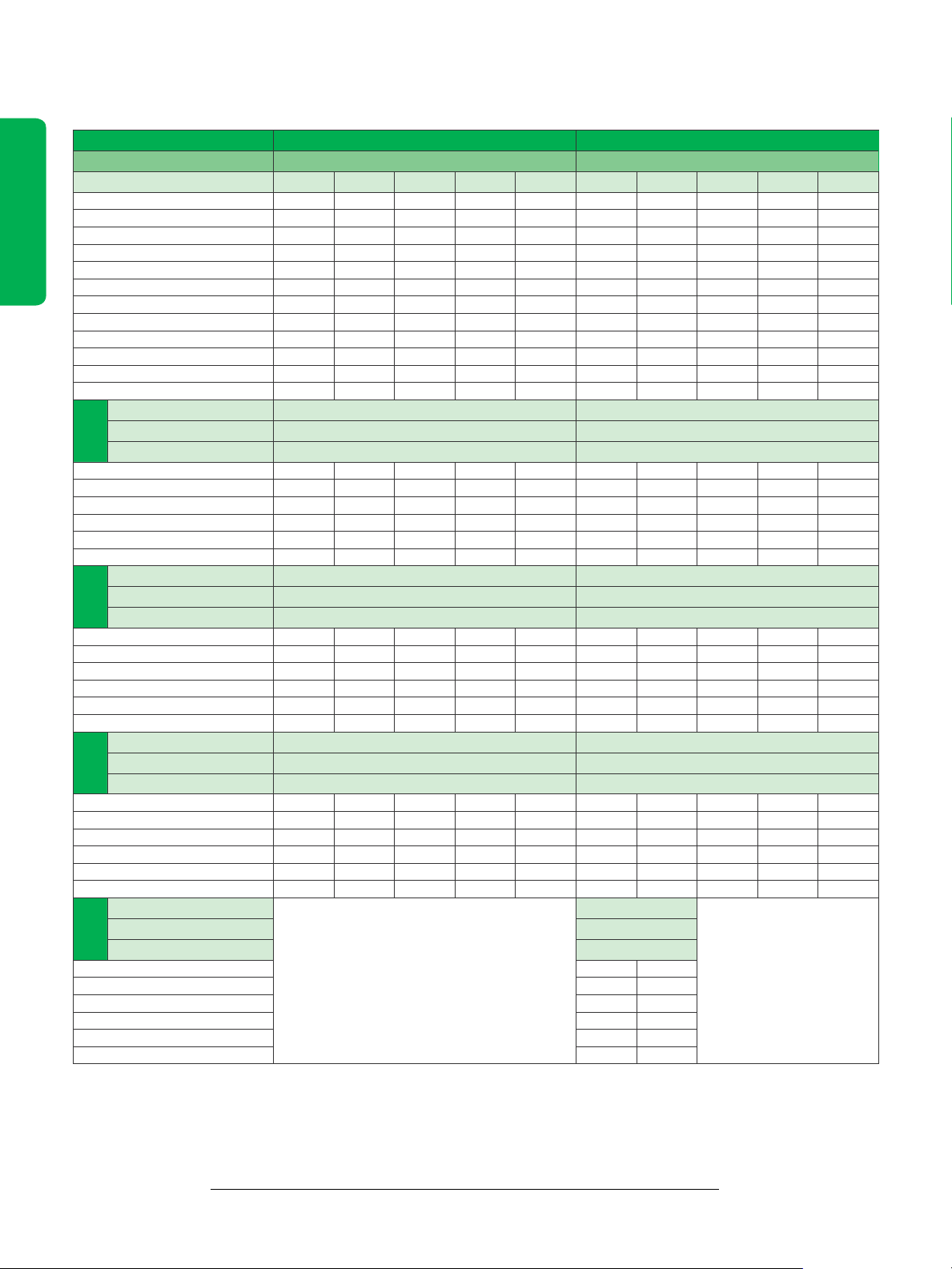

75 mm Frame Ratings

Unimotor fm 75 mm Frame Ratings

Motor Frame Size (mm) 075E3 075U3

Voltage (Vrms) 230 460

Frame Length A B C D A B C D

Continuous Stall Torque (lb-in) 12.4 23.9 32.7 41.6 12.4 23.9 32.7 41.6

Continuous Stall Torque (Nm) 1.4 2.7 3.7 4.7 1.4 2.7 3.7 4.7

Peak Torque (lb-in) 38 71 99 124 38 71 99 124

Peak Torque (Nm) 4.3 8 11.2 14 4.3 8 11.2 14

Standard Inertia (lb-in-sec²) 0.00069 0.00108 0.00142 0.00180 0.00069 0.00108 0.00142 0.00180

Standard Inertia (kgm²) 0.00008 0.00012 0.00016 0.00020 0.00008 0.00012 0.00016 0.00020

High Inertia (lb-in-sec²) 0.00104 0.00142 0.00180 0.00218 0.00104 0.00142 0.00180 0.00218

High Inertia (kgm²) 0.00012 0.00016 0.00020 0.00025 0.00012 0.00016 0.00020 0.00025

Winding Thermal Time Const. (s) 63 58 73 78 63 58 73 78

Motor Weight (lbs) 6.4 8.1 9.9 11.7 6.4 8.1 9.9 11.7

Motor Weight (kg) 2.9 3.7 4.5 5.3 2.9 3.7 4.5 5.3

Number of Poles 6 6 6 6 6 6 6 6

Kt (lb-in/A) = 12.4 21.24

Kt (Nm/A) = 1.4 2.4

2000 rpm

3000 rpm

4000 rpm

6000 rpm

Ke (V/k rpm) = 85.5 147

Rated Torque (lb-in) 11.5 22.1 31.0 39.8 11.5 21.9 31.0 39.5

Rated Torque (Nm) 1.3 2.5 3.5 4.5 1.3 2.5 3.5 4.5

Stall Current (A) 1.0 1.9 2.7 3.3 0.6 1.1 1.6 1.9

Rated Power (kW) 0.72 0.52 0.73 0.93 0.27 0.52 0.73 0.93

R (ph-ph) (Ohms) 48.24 16.32 8.96 6.22 148.5 52.2 27.3 19.97

L (ph-ph) (mH) 87.47 39.77 24.68 19.15 258.7 117.28 74.2 56.97

Kt (lb-in/A) = 8.23 14.16

Kt(Nm/A) = 0.93 1.6

Ke (V/k rpm) = 57.0 98.0

Rated Torque (lb-in) 11.5 20.4 29.2 37.2 11.5 20.3 29.3 37.0

Rated Torque (Nm) 1.3 2.3 3.3 4.2 1.3 2.29 3.3 4.18

Stall Current (A) 1.55 2.85 4.9 5.02 0.90 1.66 2.33 2.92

Rated Power (kW) 0.41 0.72 1.04 1.31 0.41 0.72 1.04 1.31

R (ph-ph) (Ohms) 19.8 6.69 3.71 2.72 62.08 21.07 12.54 7.81

L (ph-ph) (mH) 37.2 16.8 10.69 8.27 114.6 52.65 34.18 23.89

Kt (lb-in/A) = 6.37 10.62

Kt (Nm/A) = 0.72 1.2

Ke (V/k rpm) = 44.0 73.5

Rated Torque (lb-in) 10.6 18.6 24.8 33.6 10.6 18.2 24.7 33.6

Rated Torque (Nm) 1.2 2.1 2.8 3.8 1.2 2.06 2.79 3.8

Stall Current (A) 2.06 3.79 5.31 6.67 1.20 2.21 3.10 3.89

Rated Power (kW) 0.5 0.86 1.17 1.59 0.50 0.86 1.17 1.59

R (ph-ph) (Ohms) 12.44 4.01 2.26 1.53 38.01 12.71 6.49 4.94

L (ph-ph) (mH) 23.35 9.62 6.32 4.63 68.39 30.46 18.28 13.97

Kt (lb-in/A) = 4.16 7.08

Kt (Nm/A) = 0.47 0.8

Ke (V/k rpm) = 28.5 49.0

Rated Torque (lb-in) 9.7 16.8 24.8 30.1 9.6 17.0 24.3 30.1

Rated Torque (Nm) 1.1 1.9 2.8 3.4 1.08 1.92 2.75 3.4

Stall Current (A) 3.06 5.64 7.91 9.94 1.80 3.31 4.65 5.84

Rated Power (kW) 0.68 1.21 1.73 2.14 0.68 1.21 1.73 2.14

R (ph-ph) (Ohms) 5.37 1.81 1.02 0.68 15.48 5.19 2.86 2.12

L (ph-ph) (mH) 9.8 4.42 2.88 2.06 28.66 12.77 8.01 6.33

NOTES:

∆t = 212 ˚F (100 ˚C) winding 104 ˚F (40 ˚C) maximum ambient

All data subject to ±10% tolerance

Stall torque, rated torque and power relate to maximum continuous operation tested in a 68 °F (20 °C) ambient at 12 kHz drive switching frequency

Nidec has an ongoing process of development and reserves the right to change the specification without notice

All other figures relate to a 68 °F (20 °C) motor temperature; maximum intermittent winding temperature is 284 °F (140 °C)

6

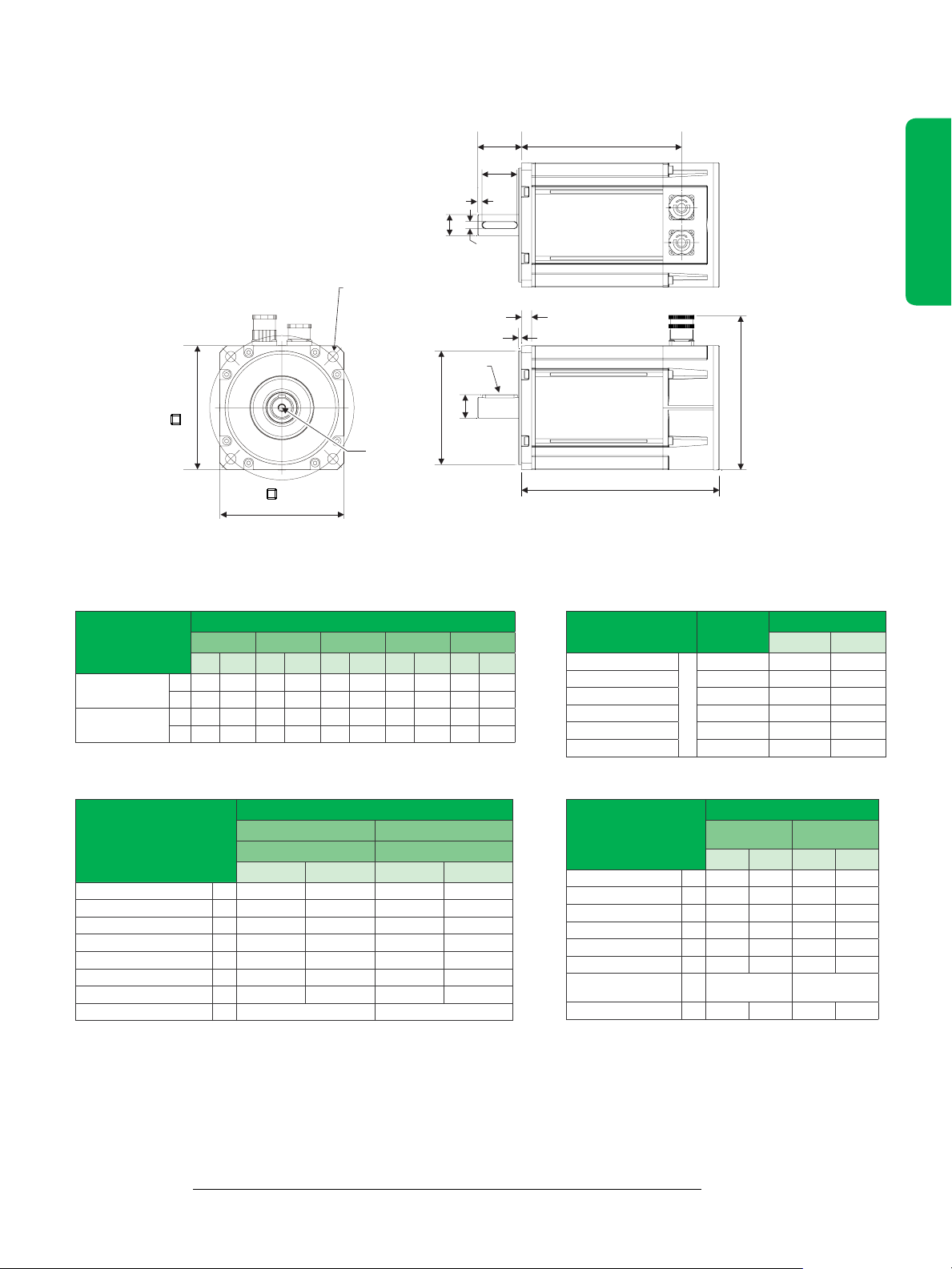

UNIMOTOR FM

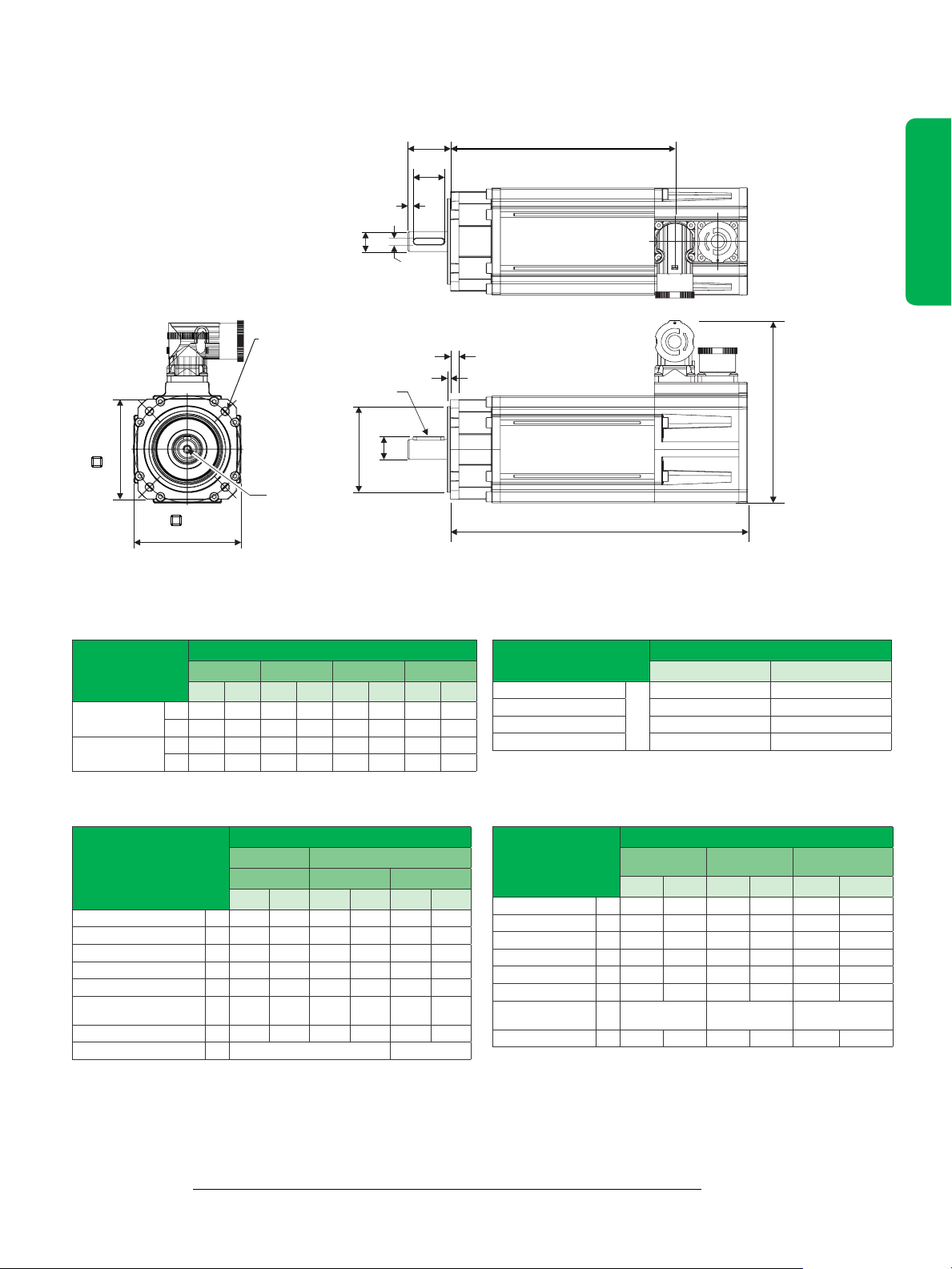

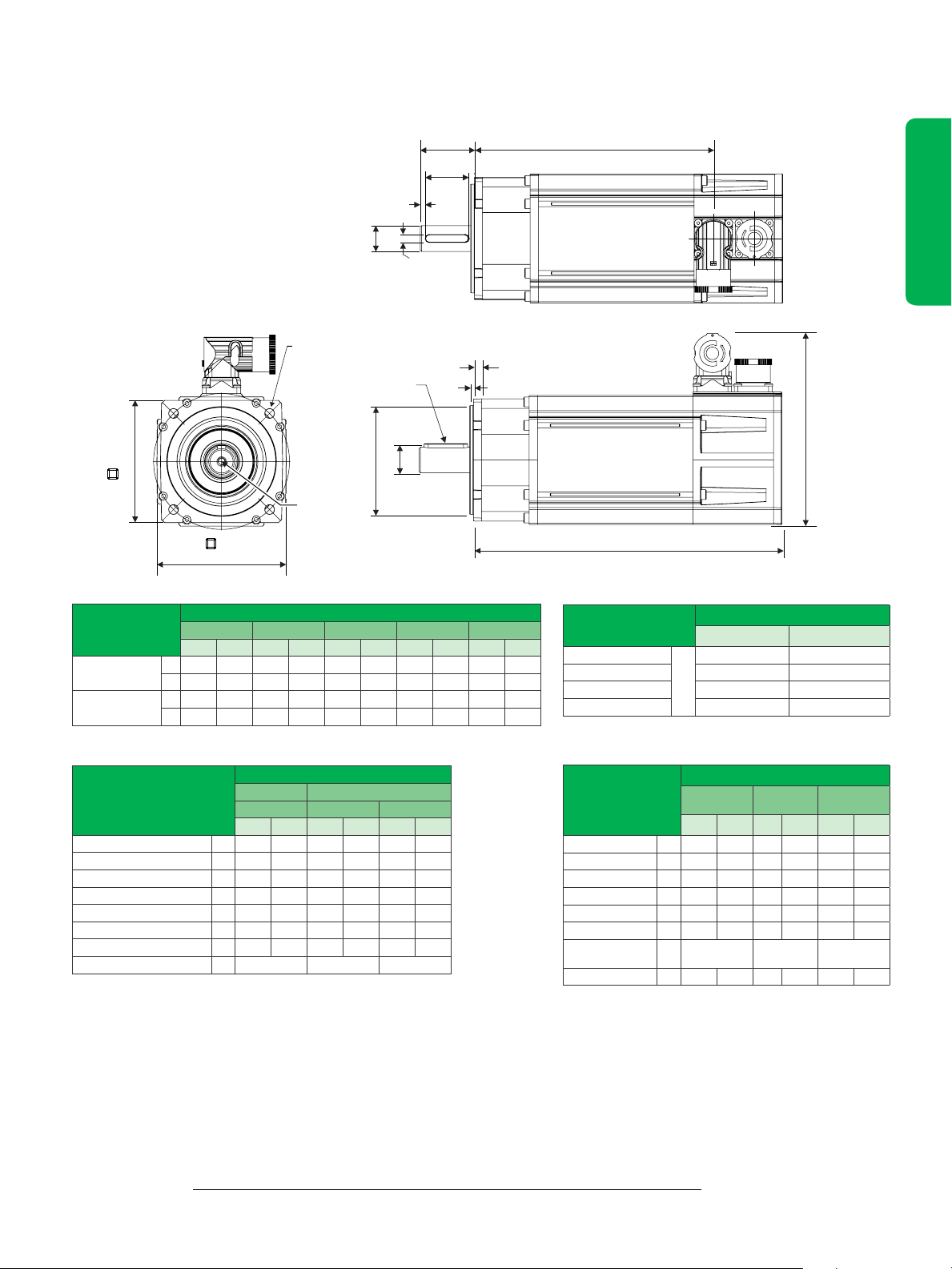

75 mm Frame Dimensions

Unimotor fm 75 mm Frame Dimensions

P

Motor flange

NOTE: Output key dimensions

(E,F,G and H) are applicable

to keyed units only.

90° connectors are standard

T

Motor housing

Ø C (j6)

4 holes Ø R (H14)

equispaced on a

mounting BCD ØS

Optional key

Ø M (j6)

Tapped hole

thread size

I to depth J

D

B

F

G

H (h9)

K Flange

L

E

A

For vertical

connectors,

allow

approximately

N

175.0 mm

clearance for

mating cable

Motor

Dimensions*

Unbraked Length

Braked Length

*PCD 085 motor lengths differ from the above, refer to drawings for complete details

A B C D

(in) (mm) (in) (mm) (in) (mm) (in) (mm)

A 8.20 208.2 9.38 238.2 10.56 268.2 11.74 298.2

B 6.19 157.2 7.37 187.2 8.55 217.2 9.73 247.2

A 9.38 238.2 10.56 268.2 11.74 298.2 12.92 328.2

B 7.37 187.2 8.55 217.2 9.73 247.2 10.91 277.2

BCD Code

Frame Length

Flange

Dimensions

Flange Thickness K 0.23 5.8 0.23 5.8 0.23 5.8

Pilot Thickness L 0.09 2.4 0.09 2.4 0.09 2.4

Pilot Diameter (J6) M 2.36 60.0 2.36 60.0 2.76 70.0

Flange Square P 2.76 70.0 2.76 70.0 3.15 80.0

Mounting Hole Dia. (H14) R 0.23 5.8 0.23 5.8 0.28 7.0

Mounting Hole BCD S

Motor Housing T 2.95 75 2.95 75 2.95 75

Mounting Bolts M5 M6

Standard Optional

075 080 085

(in) (mm) (in) (mm) (in) (mm)

2.6 to

66.7 to

3.0 to

3.0

75.0

3.2

75.0 to

80.0

3.4 85

Connector

Type

“A”

“B” (std) 5.0 126.0

“C” 5.0 126.0

“V” 4.7 118.5

Dimensions for power connectors size 1.0

N

Connector Height

(in) (mm)

4.7 118.5

Shaft Diameter Code

Shaft

Dimensions

Shaft Diameter (J6) C 0.43 11.0 0.55 14.0 0.75 19.0

Shaft Length D

Key Height E

Key Length F

Key-to-Shaft End G

Key Width (H9) H 0.16 4.0 0.20 5.0 0.24 6.0

Tapped Hole

thread Size

Tapped Hole Depth J

1

±0.45 mm, 2To IEC 72-1, 3±0.25 mm, 4±1.1 mm, 5±0.4 mm

11.0 mm

Frame A

(in) (mm) (in) (mm) (in) (mm)

1

0.91 23.0 1.18 30.0 1.57 40.0

2

0.49 12.5 0.63 16.0 0.85 21.5

3

0.55 14.0 0.98 25.0 1.26 32.0

4

0.14 3.6 0.06 1.5 0.14 3.6

I M4 x 0.7 M5 x 0.8 M6 x 1.0

5

0.43 11.0 0.53 13.5 0.67 17.0

14.0 mm

Frames B-D

19.0 mm

Opt

7

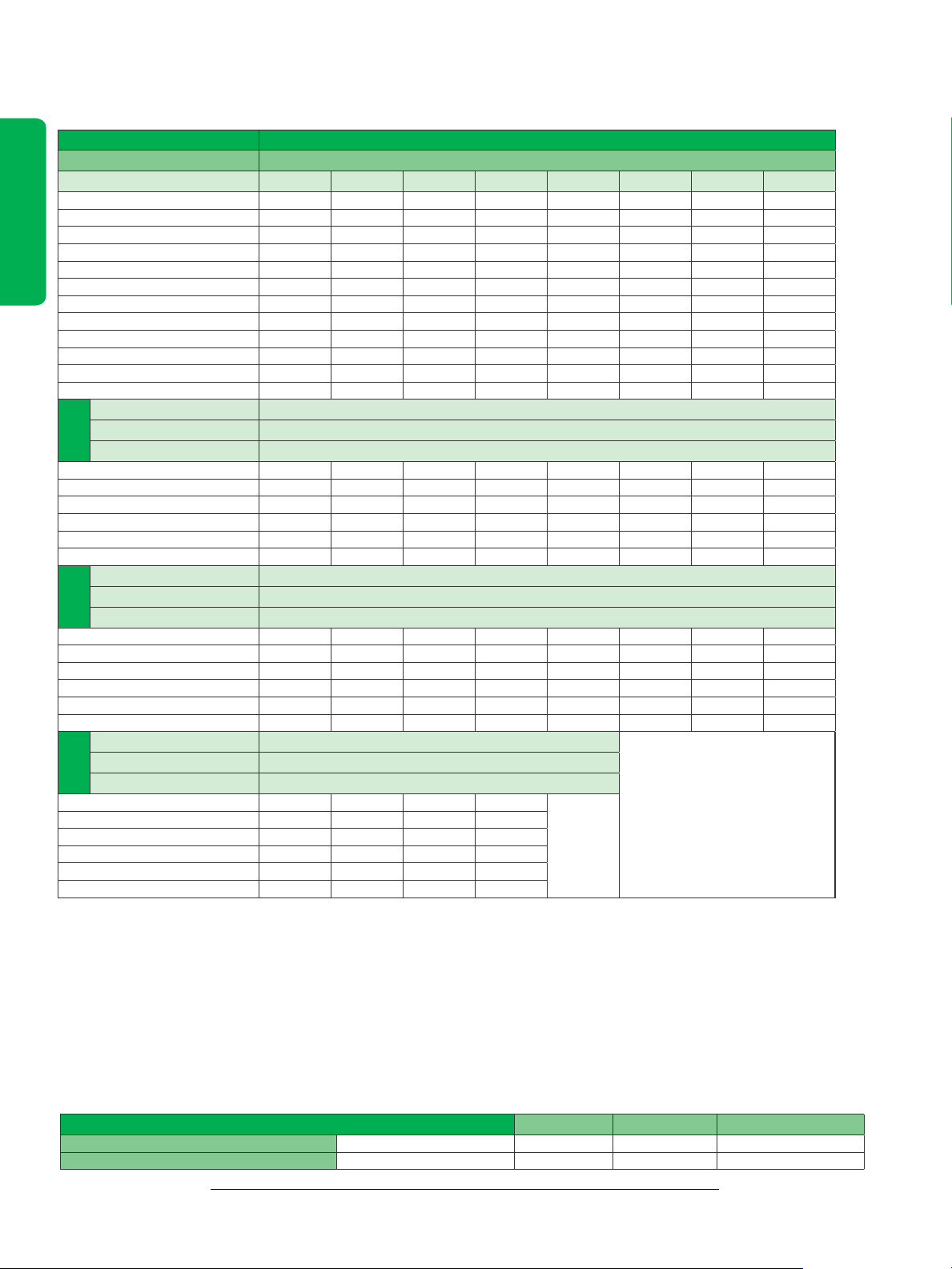

UNIMOTOR FM

95 mm Frame Ratings

Unimotor fm 95 mm Frame Ratings

Motor Frame Size (mm) 095E3 095U3

Voltage (Vrms) 230 460

Frame Length A B C D E A B C D E

Continuous Stall Torque (lb-in) 22.1 39.8 55.8 69.9 82.3 21.7 39.8 55.8 69.9 81.9

Continuous Stall Torque (Nm) 2.5 4.5 6.3 7.9 9.3 2.5 4.5 6.3 7.9 9.3

Peak Torque (lb-in) 65 119 167 210 246 65 119 167 210 246

Peak Torque (Nm) 7.4 13.5 18.9 23.7 27.8 7.4 13.5 18.9 23.7 27.8

Standard Inertia (lb-in-sec²) 0.00128 0.00230 0.00329 0.00427 0.00531 0.00128 0.00230 0.00329 0.00427 0.00531

Standard Inertia (kgm²) 0.00015 0.00026 0.00037 0.00048 0.00060 0.00015 0.00026 0.00037 0.00048 0.00060

High Inertia Option (lb-in-sec²) 0.00116 0.00398 0.00496 0.00593 0.00690 0.00116 0.00398 0.00496 0.00593 0.00690

High Inertia Option (kgm²) 0.00013 0.00045 0.00056 0.00067 0.00078 0.00013 0.00045 0.00056 0.00067 0.00078

Winding Thermal Time Const. (s) 84 82 73 90 108 84 82 90 108 112

Motor Weight (lbs) 10.1 12.8 15.4 18 20.7 10.1 12.8 15.4 18 20.7

Motor Weight (kg) 4.6 5.8 7 8.2 9.4 4.6 5.8 7 8.2 9.4

Number of Poles 6 6 6 6 6 6 6 6 6 6

Kt (lb-in/A) = 12.4 21.2

Kt (Nm/A) = 1.4 2.4

2000 rpm

3000 rpm

4000 rpm

6000 rpm

Ke (V/k rpm) = 85.5 147.0

Rated Torque (lb-in) 21.2 38.1 52.2 64.6 75.2 21.2 38.1 52.2 64.6 75.2

Rated Torque (Nm) 2.4 4.3 5.9 7.3 8.5 2.4 4.3 5.9 7.3 8.5

Stall Current (A) 1.8 3.2 4.5 5.6 6.6 1.0 1.9 2.6 3.3 3.9

Rated Power (kW) 0.51 0.9 1.23 1.53 1.77 0.51 0.9 1.23 1.53 1.77

R (ph-ph) (Ohms) 20.69 6.78 3.79 2.42 1.92 64.08 20.88 10.46 7.46 5.09

L (ph-ph) (mH) 57.78 26.1 16.36 11.83 9.75 173.4 78.16 47.02 35.44 27.18

Kt (lb-in/A) = 8.23 14.2

Kt (Nm/A) = 0.93 1.60

Ke (V/k rpm) = 57.0 98.0

Rated Torque (lb-in) 20.6 36.3 49.6 61.1 72.1 20.4 36.3 49.6 61.1 72.6

Rated Torque (Nm) 2.33 4.1 5.6 6.9 8.15 2.3 4.1 5.6 6.9 8.2

Stall Current (A) 2.63 4.84 6.77 8.49 9.95 1.5 2.8 3.9 4.9 5.8

Rated Power (kW) 0.73 1.29 1.76 2.17 2.56 0.73 1.29 1.76 2.17 2.56

R (ph-ph) (Ohms) 9.62 2.99 1.64 1.07 0.86 26.7 8.63 4.67 3.16 2.27

L (ph-ph) (mH) 26.29 11.47 7.15 5.16 4.35 76.65 33.71 21.09 15.95 12.06

Kt (lb-in/A) = 6.2 10.6

Kt (Nm/A) = 0.72 1.2

Ke (V/k rpm) = 42.75 73.5

Rated Torque (lb-in) 20.4 33.6 46.9 56.6 65.5 20.4 33.6 46.9 56.6 65.5

Rated Torque (Nm) 2.3 3.8 5.3 6.4 7.4 2.3 3.8 5.3 6.4 7.4

Stall Current (A) 3.5 6.43 9.0 11.29 13.21 2.0 3.8 5.3 6.6 7.7

Rated Power (kW) 0.94 1.59 2.2 2.68 3.1 0.94 1.59 2.2 2.68 3.1

R (ph-ph) (Ohms) 5.26 1.76 1.04 0.74 0.48 16.14 5.22 2.61 1.81 1.4

L (ph-ph) (mH) 14.94 6.67 4.52 3.53 2.44 44.25 19.54 11.75 8.86 7.25

Kt (lb-in/A) = 4.2 7.1

Kt (Nm/A) = 0.47 0.8

Ke (V/k rpm) = 28.5 49.0

Rated Torque (lb-in) 17.5 28.3 37.2 17.7 28.3 37.2

Rated Torque (Nm) 1.98 3.2 4.2 2.0

Stall Current (A) 5.21 9.57 13.4 3.1 5.6 7.9

Rated Power (kW) 1.24 2.01 2.64 1.24 2.01 2.64

R (ph-ph) (Ohms) 2.33 0.73 0.46 6.59 2.13 1.22

L (ph-ph) (mH) 6.57 2.77 2.07 18.62 8.24 5.44

3.2 4.2

NOTES:

∆t = 212 ˚F (100 ˚C) winding 104 ˚F (40 ˚C) maximum ambient

All data subject to ±10% tolerance

Stall torque, rated torque and power relate to maximum continuous operation tested in a 68 °F (20 °C) ambient at 12 kHz drive switching frequency

Nidec has an ongoing process of development and reserves the right to change the specification without notice

All other figures relate to a 68 °F (20 °C) motor temperature; maximum intermittent winding temperature is 284 °F (140 °C)

8

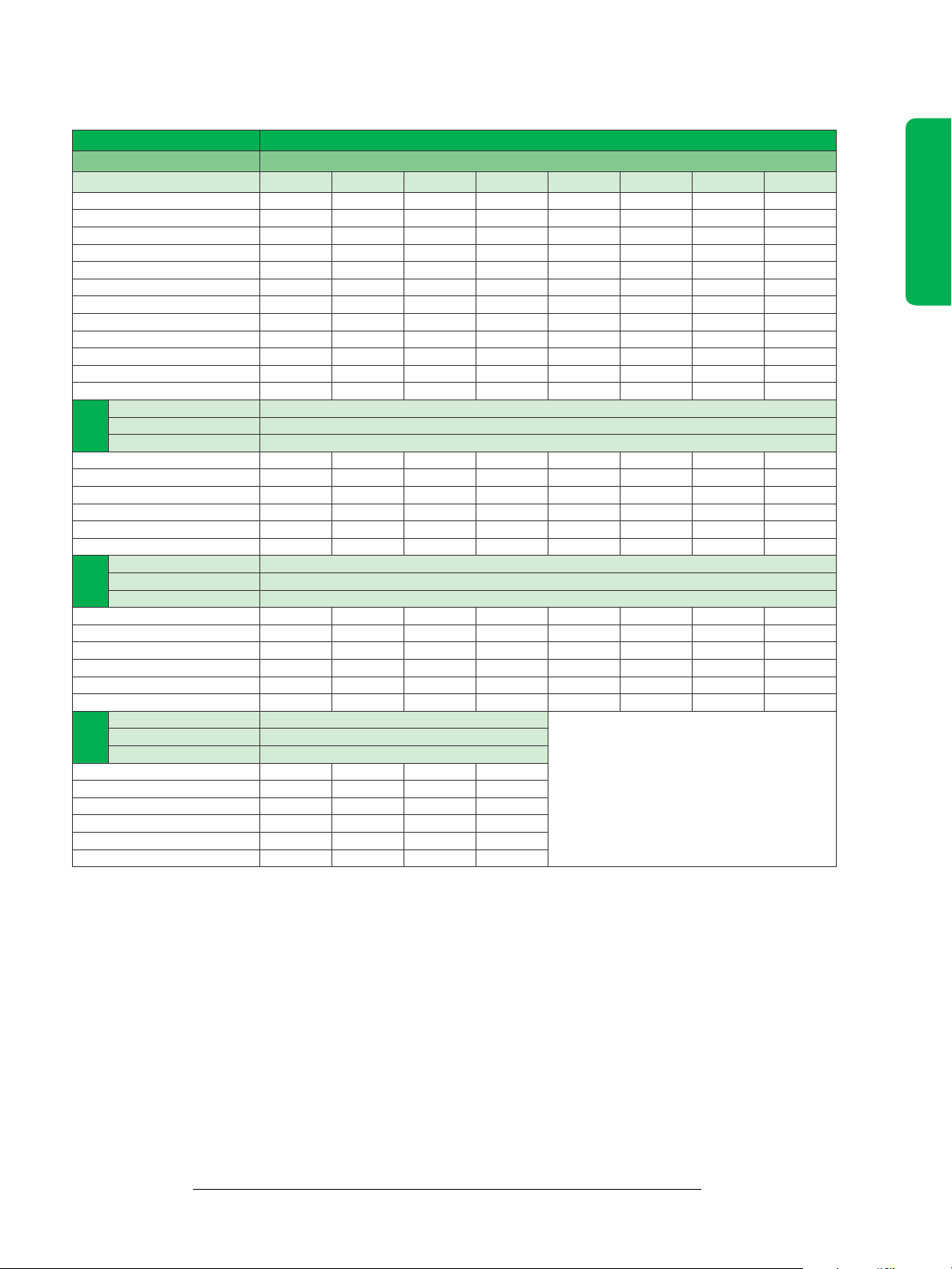

UNIMOTOR FM

95 mm Frame Dimensions

Unimotor fm 95 mm Frame Dimensions

P

Motor flange

T

Motor housing

NOTE: Output key dimensions

(E,F,G and H) are applicable

to keyed units only.

90° connectors are standard

Ø C (j6)

4 holes Ø R (H14)

equispaced on a

mounting BCD ØS

Optional key

Ø M (j6)

E

Tapped hole

thread size

I to depth J

G

H (h9)

D

B

F

K Flange

L

A

For vertical

connectors,

allow

approximately

N

175.0 mm

clearance for

mating cable

Motor

Dimensions

Unbraked Length

Braked Length

A B C D E

(in) (mm) (in) (mm) (in) (mm) (in) (mm) (in) (mm)

A 8.93 226.9 10.11 256.9 11.3 286.9 12.48 316.9 13.66 346.9

B 6.93 175.9 8.11 205.9 9.29 235.9 10.47 265.9 11.65 295.9

A 10.11 256.9 11.3 286.9 12.48 316.9 13.66 346.9 14.84 376.9

B 8.11 205.9 9.29 235.9 10.47 265.9 11.65 295.9 12.83 325.9

Frame Length

BCD 098 and 115 motor lengths differ from the above, refer to draw for motor details

BCD Code

Flange

Dimensions

Flange Thickness K 0.23 5.9 0.268 6.8 0.268 6.8

Pilot Thickness L 0.11 2.8 0.11 2.8 0.11 2.8

Pilot Diameter (J6) M 3.15 80.0 2.87 73.0 3.74 95.0

Flange Square P 3.54 90.0 3.54 90.0 4.13 105.0

Mounting Hole Dia. (H14) R 0.28 7.0 0.28 7.0 0.29 10.0

Mounting Hole BCD S 3.94 100.0 3.88 98.43 4.53 115.0

Motor Housing T 3.74 95.0 3.74 95.0 3.74 95.0

Mounting Bolts M6 M6 M8

†

NEMA 34 flange option; shaft diameters differ from typical NEMA 34 flange

Standard Optional

100

(in) (mm) (in) (mm) (in) (mm)

098

†

115

Connector

Type

“A”

“B” (std) 5.47 139.0

“C” 5.47 139.0

“V” 5.18 131.5

Dimensions for power connectors size 1.0

N

Connector Height

(in) (mm)

5.18 131.5

Shaft Diameter Code

Shaft

Dimensions

Shaft Dia. (J6) C 0.55 14.0 0.75 19.0 0.866 22.0

Shaft Length D

Key Height E

Key Length F

Key-to-Shaft End G

Key Width (H9) H 0.20 5.0 0.24 6.0 0.245 6.0

Tapped Hole

thread Size

Tapped Hole Depth J

1

±0.45 mm, 2To IEC 72-1, 3±0.25 mm, 4±1.1 mm, 5±0.4 mm

14.0 mm

Frame A

(in) (mm) (in) (mm) (in) (mm)

1

1.18 30.0 1.57 40.0 1.97 50.0

2

0.63 16.0 0.85 21.5 1.0 24.5

3

0.98 25.0 1.26 32.0 1.63 40.0

4

0.06 1.5 0.14 3.6 0.188 4.6

I M5 x 0.8 M6 x 1.0 M8 x 1.25

5

0.53 13.5 0.67 17.0 0.816 20.0

19.0 mm

Frames B-E

22.0 mm

Opt.

9

UNIMOTOR FM

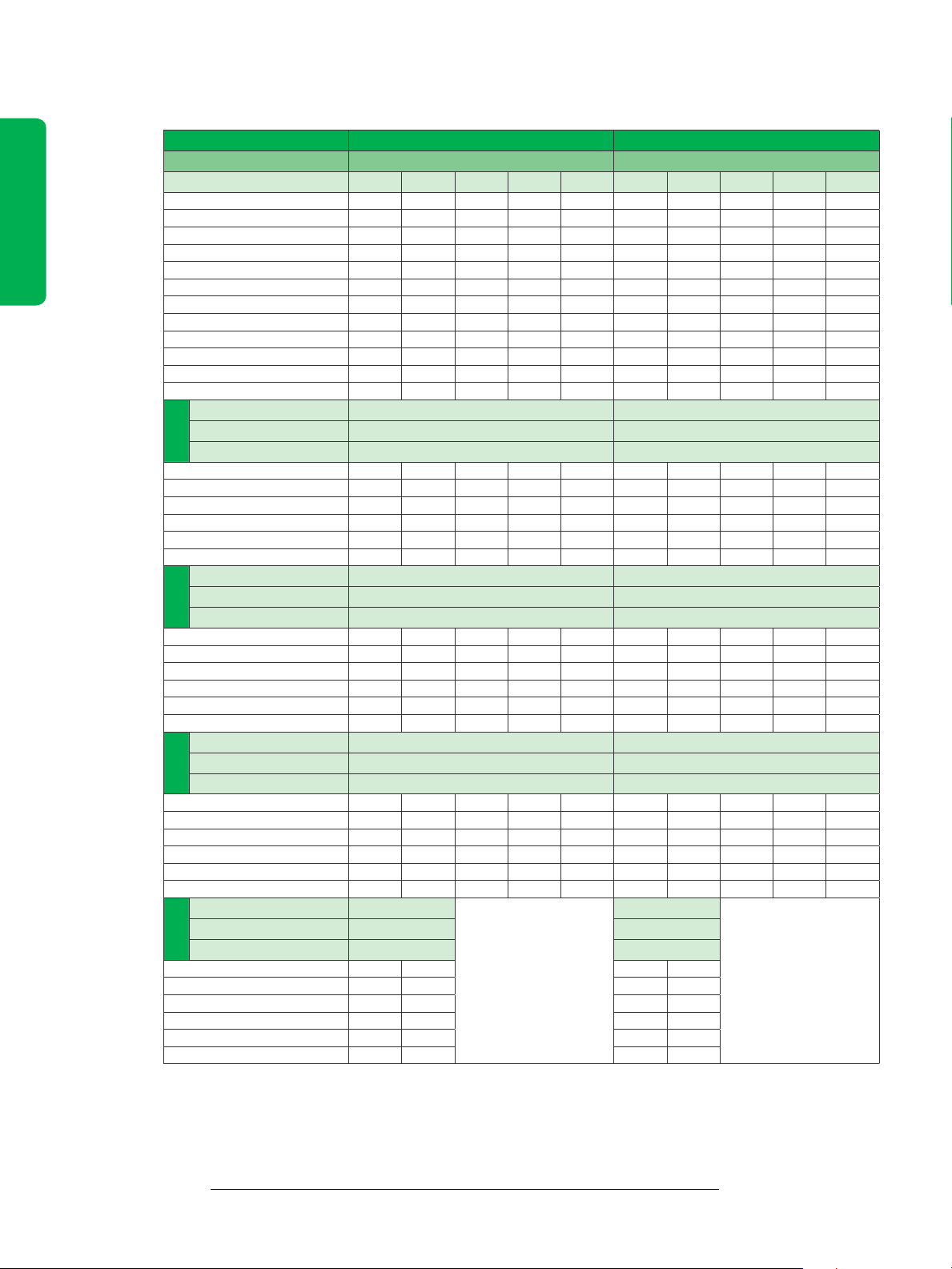

115 mm Frame Ratings

Unimotor fm 115 mm Frame Ratings

Motor Frame Size (mm) 115E3 115U3

Voltage (Vrms) 230 460

Frame Length A B C D* E* A B C D E

Continuous Stall Torque (lb-in) 35 65 96 121 142 35 65 96 121 142

Continuous Stall Torque (Nm) 3.9 7.4 10.8 13.7 16.0 3.9 7.4 10.8 13.7 16.0

Peak Torque (lb-in) 104 196 287 363 425 104 196 287 363 425

Peak Torque (Nm) 11.7 22.2 32.4 41 48 11.7 22.2 32.4 41 48

Standard Inertia (lb-in-sec²) 0.00478 0.00682 0.00885 0.01106 0.0131 0.00478 0.00682 0.00885 0.01106 0.0131

Standard Inertia (kgm²) 0.00054 0.00077 0.001 0.00125 0.00148 0.00054 0.00077 0.001 0.00125 0.00148

High Inertia Option (lb-in-sec²) 0.00885 0.01089 0.01301 0.01513 0.01717 0.00885 0.01089 0.01301 0.01513 0.01717

High Inertia Option (kgm²) 0.001 0.00123 0.00147 0.00171 0.00194 0.001 0.00123 0.00147 0.00171 0.00194

Winding Thermal Time Const. (s) 103 109 116 127 141 103 109 116 127 141

Motor Weight (lbs) 15.2 19.4 23.5 27.7 31.9 15.2 19.4 23.5 27.7 31.9

Motor Weight (kg) 6.9 8.8 10.7 12.6 14.5 6.9 8.8 10.7 12.6 14.5

Number of Poles 6 6 6 6 6 6 6 6 6 6

Kt (lb-in/A) = 12.4 21.2

Kt (Nm/A) = 1.4 2.4

2000 rpm

3000 rpm

4000 rpm

6000 rpm

Ke (V/k rpm) = 85.5 147.0

Rated Torque (lb-in) 32.7 64.6 89.4 105.3 124.8 32.7 64.6 89.4 105.3 124.8

Rated Torque (Nm) 3.7 7.3 10.1 11.9 14.1 3.7 7.3 10.1 11.9 14.1

Stall Current (A) 2.8 5.3 7.7 9.8 11.4 1.6 3.1 4.5 5.7 6.7

Rated Power (kW) 0.77 1.53 2.12 2.49 2.95 0.77 1.53 2.12 2.49 2.95

R (ph-ph) (Ohms) 10.65 3.43 1.82 1.81 1.34 32.92 10.68 5.25 3.7 2.75

L (ph-ph) (mH) 55.83 19.43 12.31 9.5 7.68 139.43 59.51 35.9 27.63 21.87

Kt (lb-in/A) = 8.23 14.2

Kt (Nm/A) = 0.93 1.6

Ke (V/k rpm) = 57.00 98.0

Rated Torque (lb-in) 31.0 59.3 84.1 99.1 112.4* 31.0 59.3 84.1 99.1 112.4

Rated Torque (Nm) 3.5 6.7 9.5 11.2 12.7 3.5 6.7 9.5 11.2 12.7

Stall Current (A) 4.19 7.96 11.61 14.68 17.2 2.4 4.6 6.8 8.5 10.0

Rated Power (kW) 1.1 2.1 2.98 3.52 3.99 1.1 2.1 2.98 3.52 3.99

R (ph-ph) (Ohms) 4.91 1.52 0.81 0.57 0.43 14.74 4.37 2.3 1.53 1.23

L (ph-ph) (mH) 20.26 8.63 5.47 4.35 3.41 57.29 25.19 15.57 11.6 9.89

Kt (lb-in/A) = 6.2 10.6

Kt (Nm/A) = 0.7 1.2

Ke (V/k rpm) = 42.75 73.5

Rated Torque (lb-in) 26.6 51.3 66.4 73.5* 77.9* 26.6 51.3 66.4 73.5 77.9

Rated Torque (Nm) 3.0 5.8 7.5 8.3 8.8 3.0 5.8 7.5 8.3 8.8

Stall Current (A) 5.57 10.57 15.43 19.5 22.9 3.3 6.2 9.0 11.4 13.3

Rated Power (kW) 1.26 2.43 3.12 3.46 3.69 1.26 2.43 3.12 3.46 3.69

R (ph-ph) (Ohms) 3.05 0.93 0.49 0.3 0.27 8.49 2.61 1.31 0.84 0.66

L (ph-ph) (mH) 12.44 5.13 3.34 2.25 2.18 33.79 14.87 8.98 6.27 5.35

Kt (lb-in/A) = 4.2 7.1

Kt (Nm/A) = 0.47 0.8

Ke (V/k rpm) = 28.5 49.0

Rated Torque (lb-in) 23.9 44.3 23.9 44.3

Rated Torque (Nm) 2.7 5.0 2.7 5.0

Stall Current (A) 8.3 15.74

Rated Power (kW) 1.7 3.14 1.7 3.14

R (ph-ph) (Ohms) 1.5 0.41 3.48 1.09

L (ph-ph) (mH) 6.08 2.34 14.31 6.3

4.9 9.3

NOTES:

*Ratings shown require connector option "H" terminal box.

∆t = 212 ˚F (100 ˚C) winding 104 ˚F (40 ˚C) maximum ambient

All data subject to ±10% tolerance

Stall torque, rated torque and power relate to maximum continuous operation tested in a 68 °F (20 °C) ambient at 12 kHz drive switching frequency

Nidec has an ongoing process of development and reserves the right to change the specification without notice

All other figures relate to a 68 °F (20 °C) motor temperature; maximum intermittent winding temperature is 284 °F (140 °C)

10

UNIMOTOR FM

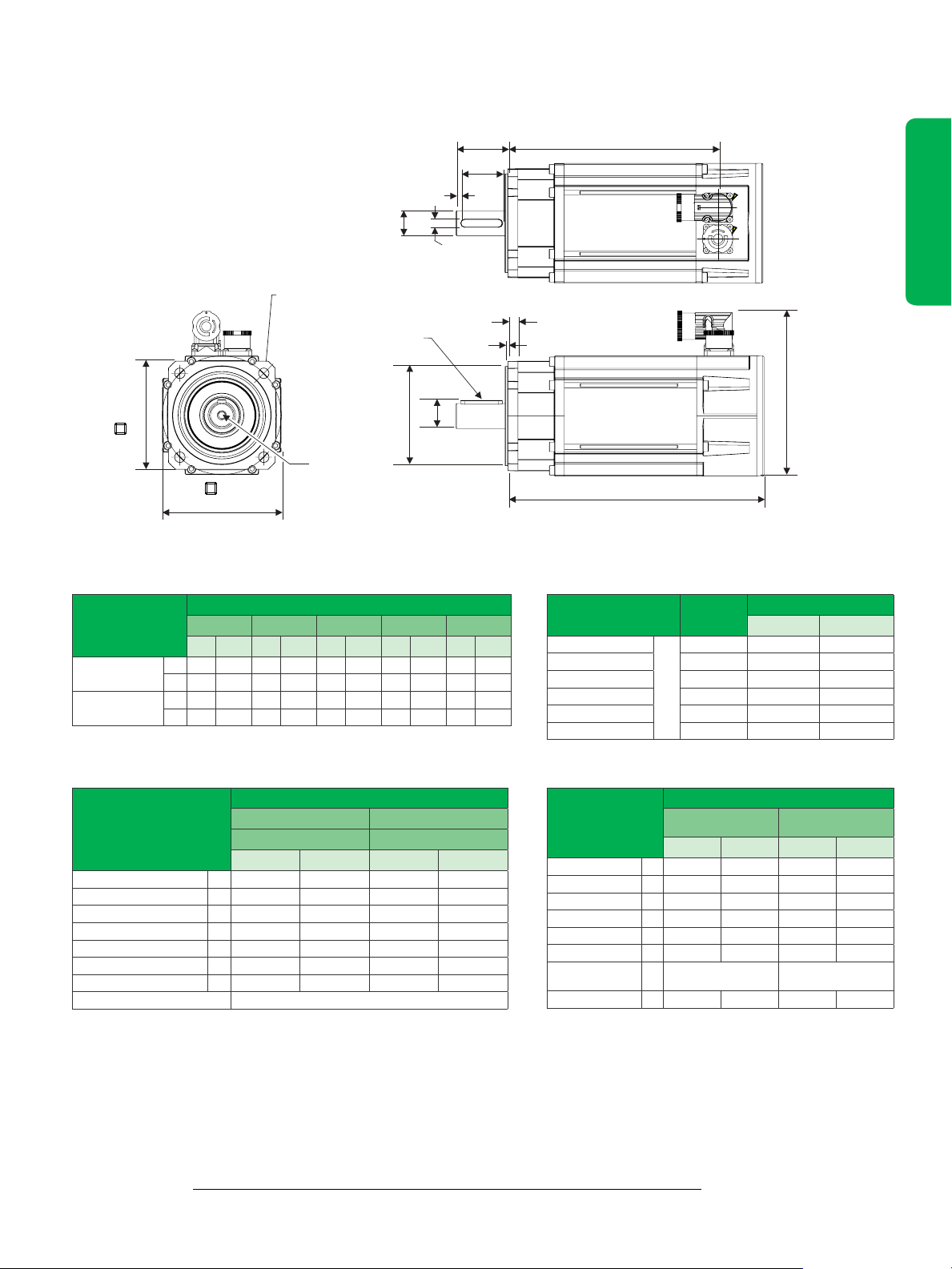

115 mm Frame Dimensions

Unimotor fm 115 mm Frame Dimensions

P

Motor flange

NOTE: Output key dimensions

(E,F,G and H) are applicable

to keyed units only.

90° connectors are standard

T

Motor housing

Ø C (j6/k6)

4 holes Ø R (H14)

equispaced on a

mounting BCD ØS

Optional key

Ø M (j6)

Tapped hole

thread size

I to depth J

E

G

H (h9)

D

B

F

K Flange

L

A

For vertical

connectors,

allow

approximately

N

175.0 mm

clearance for

mating cable

Motor

Dimensions

Unbraked Length

Braked Length

A B C D E

(in) (mm) (in) (mm) (in) (mm) (in) (mm) (in) (mm)

9.71 246.6 10.89 276.6 12.07 306.6 13.25 336.6 14.43 366.6

A

7.63 193.8 8.81 223.8 9.99 253.8 11.17 283.8 12.35 313.8

B

10.89 276.6 12.07 306.6 13.25 336.6 14.43 366.6 15.61 396.6

A

8.81 223.8 9.99 253.8 11.17 283.8 12.35 313.8 13.54 343.8

B

BCD 130 motor lengths differ from the above, refer to draw for motor details

BCD Code

Frame Length

Flange

Dimensions

Flange Thickness K 0.39 10.1 0.52 13.2

Pilot Thickness L 0.11 2.8 0.11 2.8

Pilot Diameter (J6) M 3.74 95 4.33 110

Flange Square P 4.13 105 5.12 130

Mounting Hole Dia. (H14) R 0.39 10 0.39 10

Mounting Hole BCD S 4.53 115 5.12 130

Motor Housing T 4.53 115 4.53 115

Mounting Bolts M8

Standard Optional

115 130

(in) (mm) (in) (mm)

Connector

Type

“A”

“B” (std) 1.0 6.16 156.5

“C” 1.0 6.16 156.5

“V” 1.0 5.87 149.0

"J" 1.5 7.38 187.5

"M" 1.5 6.59 167.5

Connector

Size

1.0 5.87 149.0

N

Connector Height

(in) (mm)

Shaft Diameter Code

Shaft

Dimensions

Shaft Diameter (J6) C 0.75 19.0 0.94 24.0

Shaft Length D

Key Height E

Key Length F

Key-to-Shaft End G

Key Width (H9) H 0.24 6.0 0.31 8.0

Tapped Hole

Thread Size

Tapped Hole Depth J

1

±0.45 mm, 2To IEC 72-1, 3±0.25 mm, 4±1.1 mm, 5±0.4 mm

19.0 mm

Frame A-C

(in) (mm) (in) (mm)

1

1.57 40.0 1.97 50.0

2

0.85 21.5 1.06 27.0

3

1.26 32.0 1.57 40.0

4

0.14 3.6 0.18 4.6

I M6 x 1.0 M8 x 1.25

5

0.67 17.0 0.79 20.0

24.0 mm

Frame D-E

11

UNIMOTOR FM

142 mm Frame Ratings

Unimotor fm 142 mm Frame Ratings

Motor Frame Size (mm) 142E3 142U3

Voltage (Vrms) 230 460

Frame Length A B C* D* E* A B C D E*

Continuous Stall Torque (lb-in) 55.0 97.0 139.0 181.0 221.0 55.0 97.0 139.0 181.0 221.0

Continuous Stall Torque (Nm) 6.2 11.0 15.7 20.5 25.0 6.2 11.0 15.7 20.5 25.0

Peak Torque (lb-in) 165.0 292.0 417.0 544.0 664.0 165.0 292.0 417.0 544.0 664.0

Peak Torque (Nm) 18.6 33.0 47.1 61.5 75.0 18.6 33.0 47.1 61.5 75.0

Standard Inertia (lb-in-sec²) 0.00903 0.01496 0.0208 0.02673 0.03266 0.00903 0.01496 0.0208 0.02673 0.03266

Standard Inertia (kgm²) 0.00102 0.00169 0.00235 0.00302 0.00369 0.00102 0.00169 0.00235 0.00302 0.00369

High Inertia Option (lb-in-sec²) 0.02053 0.02638 0.03231 0.03815 0.04408 0.02053 0.02638 0.03231 0.03815 0.04408

High Inertia Option (kgm²) 0.00232 0.00298 0.00365 0.00431 0.00498 0.00232 0.00298 0.00365 0.00431 0.00498

Winding Thermal Time Const. (s) 145 148 188 206 249 145 148 188 206 249

Motor Weight (lbs) 18.3 25.1 31.9 38.7 45.5 18.3 25.1 31.9 38.7 45.5

Motor Weight (kg) 8.3 11.4 14.5 17.6 20.7 8.3 11.4 14.5 17.6 20.7

Number of Poles 6 6 6 6 6 6 6 6 6 6

Kt (lb-in/A) = 12.4 21.2

Kt (Nm/A) = 1.4 2.4

2000 rpm

3000 rpm

4000 rpm

6000 rpm

Ke (V/k rpm) = 85.5 147.0

Rated Torque (lb-in) 52.2 92.0 130.1 163.7 190.3* 52.2 92.0 130.1 163.7 190.3

Rated Torque (Nm) 5.9 10.4 14.7 18.5 21.5 5.9 10.4 14.7 18.5 21.5

Stall Current (A) 4.4 7.9 11.2 14.6 17.9 2.6 4.6 6.5 8.5 10.4

Rated Power (kW) 1.23 2.18 3.08 3.87 4.49 1.23 2.18 3.08 3.87 4.49

R (ph-ph) (Ohms) 5.56 1.54 0.80 0.51 0.40 14.64 4.71 2.38 1.60 1.11

L (ph-ph) (mH) 35.43 14.25 8.99 6.35 5.25 98.76 42.15 26.32 19.46 15.08

Kt (lb-in/A) = 8.23 14.2

Kt (Nm/A) = 0.93 1.6

Ke (V/k rpm) = 57.0 98.0

Rated Torque (lb-in) 48.7 84.1 113.3 141.6* 161.1* 48.7 84.1 113.3 141.6 161.1

Rated Torque (Nm) 5.5 9.5 12.8 16.0 18.2 5.5 9.5 12.8 16.0 18.2

Stall Current (A) 6.67 11.83 16.88 22.04 26.88 3.9 6.9 9.8 12.8 15.6

Rated Power (kW) 1.73 2.98 4.02 5.03 5.70 1.73 2.98 4.02 5.03 5.7

R (ph-ph) (Ohms) 2.25 0.68 0.35 0.23 0.16 6.2 2.12 1.08 0.70 0.50

L (ph-ph) (mH) 14.68 6.33 3.89 3.66 2.23 42.97 19.11 12.06 8.91 6.7

Kt (lb-in/A) = 6.2 10.6

Kt (Nm/A) = 0.7 1.2

Ke (V/k rpm) = 42.75 73.5

Rated Torque (lb-in) 36.3 71.7 90.3* 108.0* 123.9* 36.3 71.7 90.3 108* 123.9*

Rated Torque (Nm) 4.1 8.1 10.2 12.2 14.0 4.1 8.1 10.2 12.2 14.0

Stall Current (A) 8.86 15.71 22.43 29.3 35.7 5.2 9.2 13.1 17.1 20.8

Rated Power (kW) 1.72 3.37 4.27 5.11 5.86 1.72 3.37 4.27 5.11 5.86

R (ph-ph) (Ohms) 1.29 0.38 0.23 0.13 0.09 3.64 1.18 0.61 0.41 0.29

L (ph-ph) (mH) 8.39 3.44 2.49 1.99 1.2 24.44 10.54 6.78 5.06 3.97

Kt (lb-in/A) = 0.7

Kt (Nm/A) = 0.8

Ke (V/k rpm) = 49.0

Rated Torque (lb-in) 28.3 46.0

Rated Torque (Nm) 3.2 5.2

Stall Current (A) 7.8 13.8

Rated Power (kW) 2.01 3.27

R (ph-ph) (Ohms) 1.63 0.53

L (ph-ph) (mH)

11.08 4.78

NOTES:

*Ratings shown require connector option "J" size 1.5 power connector.

∆t = 212 ˚F (100 ˚C) winding 104 ˚F (40 ˚C) maximum ambient

All data subject to ±10% tolerance

Stall torque, rated torque and power relate to maximum continuous operation tested in a 68 °F (20 °C) ambient at 12 kHz drive switching frequency

Nidec has an ongoing process of development and reserves the right to change the specification without notice

All other figures relate to a 68 °F (20 °C) motor temperature; maximum intermittent winding temperature is 284 °F (140 °C)

12

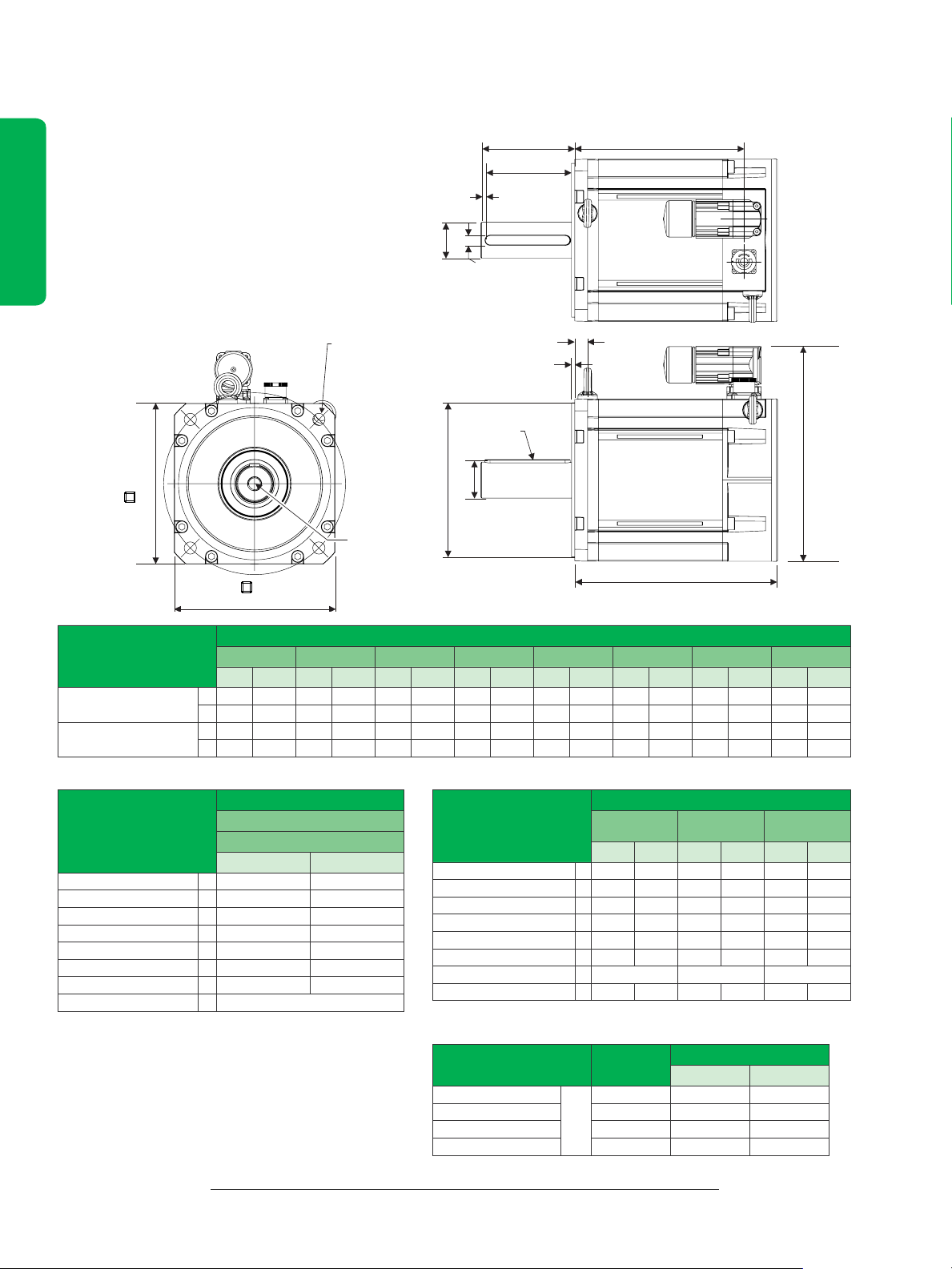

UNIMOTOR FM

142 mm Frame Dimensions

Unimotor fm 142 mm Frame Dimensions

P

Motor flange

NOTE: Output key dimensions

(E,F,G and H) are applicable

to keyed units only.

90° connectors are standard

T

Motor housing

Ø C (j6/k6)

4 holes Ø R (H14)

equispaced on a

mounting BCD ØS

Ø M (j6)

Tapped hole

thread size

I to depth J

G

Optional

key

E

D

F

H (h9)

L

K Flange

B

For vertical

connectors,

allow

approximately

N

175.0 mm

clearance for

mating cable

A

Frame Length

Motor Dimensions

Unbraked Length

Braked Length

BCD 149 motor lengths differ from the above, refer to draw for motor details

A B C D E

(in) (mm) (in) (mm) (in) (mm) (in) (mm) (in) (mm)

7.59 192.8 8.77 222.8 9.95 252.8 11.13 282.8 12.31 312.8

A

6.22 158 7.4 188 8.58 218 9.76 248 10.94 278

B

9.95 252.8 11.13 282.8 12.31 312.8 13.5 342.8 14.68 372.8

A

8.58 218 9.76 248 10.94 278 12.13 308 13.31 338

B

BCD Code

Flange Dimensions

Flange Thickness K 0.55 14.0 0.45 11.5

Pilot Thickness L 0.13 3.4 0.13 3.4

Pilot Diameter (J6) M 5.12 130 4.5 114.3

Flange Square P 5.59 142 5.51 140

Mounting Hole Dia. (H14) R 0.47 12.0 0.47 12.0

Mounting Hole BCD S 6.5 165 5.88 149.23

Motor Housing T 5.59 142 5.59 142

Mounting Bolts M10 M10

†

NEMA 56 flange option; shaft diameter 0.945 in (24 mm)

Standard Optional

165

(in) (mm) (in) (mm)

149

†

Connector Type

“A”

“B” (std) 1.0 7.22 183.5

“C” 1.0 7.22 183.5

“V” 1.0 6.93 176.0

"J" 1.5 204.5 8.05

"M" 1.5 184.5 7.26

Connector

Size

1.0 6.93 176.0

N

Connector Height

(in) (mm)

Shaft Diameter Code

Shaft Dimensions

Shaft Diameter (J6) C 0.94 24.0 1.26 32.0

Shaft Length D

Key Height E

Key Length F

Key-to-Shaft End G

Key Width (H9) H 0.31 8.0 0.39 10.0

Tapped Hole

Thread Size

Tapped Hole Depth J

1

±0.45 mm, 2To IEC 72-1, 3±0.25 mm, 4±1.1 mm, 5±0.4 mm

24.0 mm

Frame A-E

(in) (mm) (in) (mm)

1

1.97 50.0 2.28 58.0

2

1.06 27.0 1.38 35.0

3

1.57 40.0 1.97 50.0

4

0.18 4.6 0.18 4.6

I M8 x 1.25 M12 x 1.75

5

0.79 20.0 1.14 29.0

32.0 mm

Opt.

13

UNIMOTOR FM

190 mm Frame Ratings – 230 V

Unimotor fm 230 V 190 mm Frame Ratings

Motor Frame Size (mm) 190E3

Voltage (Vrms) 230

Frame Length A B C D E F* G* H*

Continuous Stall Torque (lb-in) 100.0 199.1 296.5 393.9 477.9 557.6 628.4 681.5

Continuous Stall Torque (Nm) 11.3 22.5 33.5 44.5 54.0 63.0 71.0 77.0

Peak Torque (lb-in) 299.2 597.4 889.5 1181.6 1433.8 1672.8 1885.2 2044.5

Peak Torque (Nm) 33.8 67.5 100.5 133.5 162.0 189.0 213.0 231.0

Standard Inertia (lb-in-sec²) 0.0277 0.04408 0.06045 0.07682 0.0932 0.10957 0.12595 0.14232

Standard Inertia (kgm²) 0.00313 0.00498 0.00683 0.00868 0.01053 0.01238 0.01423 0.01608

High Inertia Option (lb-in-sec²) 0.06178 0.07815 0.09453 0.11090 0.12727 0.14365 0.16002 0.1764

High Inertia Option (kgm²) 0.00698 0.00883 0.01068 0.01253 0.01438 0.01623 0.01808 0.01993

Winding Thermal Time Const. (s) 194 214 215 216 251 285 425 564

Motor Weight (lbs) 31.68 42.24 52.8 63.36 73.92 84.48 95.04 105.6

Motor Weight (kg) 14.4 19.2 24 28.8 33.6 38.4 43.2 48

Number of Poles 8 8 8 8 8 8 8 8

Kt (lb-in/A) = 12.39

Kt (Nm/A) = 1.4

2000 rpm

3000 rpm

4000 rpm

Ke (V/k rpm) = 85.5

Rated Torque (lb-in) 95.6 182.3 260.2 335.4 392.1 447.0* 477.9* 495.6*

Rated Torque (Nm) 10.8 20.6 29.4 37.9 44.3 50.5 54.0 56.0

Stall Current (A) 8 16.1 23.9 31.8 38.6 45 50.7 55

Rated Power (kW) 2.26 4.31 6.15 7.94 9.28 10.58 11.31 11.73

R (ph-ph) (Ohms) 1.8 0.5 0.25 0.19 0.13 0.1 0.08 0.054

L (ph-ph) (mH) 17.34 7.77 4.66 3.26 3.02 2.65 2.12 1.55

Kt (lb-in/A) = 8.23

Kt (Nm/A) = 0.93

Ke (V/k rpm) = 57.0

Rated Torque (lb-in) 91.2 171.7 234.5 293.8* 302.7* 311.5* 320.4* 327.5*

Rated Torque (Nm) 10.3 19.4 26.5 33.2 34.2 35.2 36.2 37.0

Stall Current (A) 12.1 24.19 36.92 47.85 58.06 67.74 76.34 82.8

Rated Power (kW) 3.24 6.09 8.33 10.43 10.74 11.06 11.37 11.62

R (ph-ph) (Ohms) 0.83 0.256 132 0.09 0.07 0.05 0.05 0.03

L (ph-ph) (mH) 7.94 3.87 2.46 1.81 1.55 1.17 1.36 0.86

Kt (lb-in/A) = 6.20

Kt (Nm/A) = 0.7

Ke (V/k rpm) = 42.8

Rated Torque (lb-in) 72.6 161.1 203.6* 256.7*

Rated Torque (Nm) 8.2 18.2 23 29

Stall Current (A) 16.07 32.14 47.86 63.57

Rated Power (kW) 3.43 7.62 9.63 12.15

R (ph-ph) (Ohms) 0.46 0.14 0.07 0.06

L (ph-ph) (mH) 4.34 2.18 1.39 1.26

NOTES:

* Ratings shown require connector option "H"

∆t = 212 ˚F (100 ˚C) winding 104 ˚F (40 ˚C) maximum ambient

All data subject to ±10% tolerance

Stall torque, rated torque and power relate to maximum continuous operation tested in a 68 °F (20 °C) ambient at 12 kHz drive switching frequency

Nidec has an ongoing process of development and reserves the right to change the specification without notice

All other figures relate to a 68 °F (20 °C) motor temperature; maximum intermittent winding temperature is 284 °F (140 °C)

†

Order Code Information for 230/460 V 190 mm Frame

The Unimotor E3/U3 190 frame models are now supplied with an 58 mm long output shaft. If replacing an existing Unimotor fm

190 E2/U2 model which has a standard 80 mm long output shaft add the suffix -SREL to the order code.

80mm long output shaft order code example:

Unimotor fm E3/U3 190U3D300BACAA215320 58 mm 32 mm New standard offering

Unimotor fm E2/U2 (replacement) 190U3D300JACAA215320-SREL 80 mm 32 mm Previous standard offering

shaft length shaft diameter notes

14

UNIMOTOR FM

190 mm Frame Ratings – 460 V

Unimotor fm 460 V 190 mm Frame Ratings

Motor Frame Size (mm) 190U3

Voltage (Vrms) 460

Frame Length A B C D E F G* H*

Continuous Stall Torque (lb-in) 100 199.1 296.5 393.8 477.9 557.6 628.4 681.5

Continuous Stall Torque (Nm) 11.3 22.5 33.5 44.5 54 63 71 77

Peak Torque (lb-in) 299.1 597.4 889.4 1181.5 1433.7 1672.7 1885.1 2044.4

Peak Torque (Nm) 33.8 67.5 100.5 133.5 162 189 213 231

Standard Inertia (lb-in-sec²) 0.0277 0.04408 0.06045 0.07682 0.0932 0.10957 0.12595 0.14232

Standard Inertia (kgm²) 0.00313 0.00498 0.00683 0.00868 0.01053 0.01238 0.01423 0.01608

High Inertia Option (lb-in-sec²) 0.06178 0.07815 0.09453 0.1109 0.12727 0.14365 0.16002 0.1764

High Inertia Option (kgm²) 0.00698 0.00883 0.01068 0.01253 0.01438 0.01623 0.01808 0.01993

Winding Thermal Time Const. (s) 194 214 215 216 251 285 425 564

Motor Weight (lbs) 37.4 48 58.5 69.1 79.6 90.2 100.8 111.3

Motor Weight (kg) 17 21.8 26.6 31.4 36.2 41 45.8 50.6

Number of Poles 8 8 8 8 8 8 8 8

Kt (lb-in/A) = 21.24

rpm

2000

rpm

3000

rpm

4000

Kt (Nm/A) = 2.4

Ke (V/k rpm) = 147.0

Rated Torque (lb-in) 95.6 182.3 260.2 335.4 392.1 446.9 477.9 495.6

Rated Torque (Nm) 10.8 20.6 29.4 37.9 44.3 50.5 54.0 56.0

Stall Current (A) 4.7 9.4 14.0 18.5 22.5 26.3 29.6 32.1

Rated Power (kW) 2.26 4.31 6.15 7.94 9.28 10.58 11.31 11.73

R (ph-ph) (Ohms) 6.15 1.54 0.83 0.5 0.37 0.28 0.26 0.23

L (ph-ph) (mH) 52.9 23.55 15.0 8.81 8.68 7.36 6.89 6.3

Kt (lb-in/A) = 14.2

Kt (Nm/A) = 1.6

Ke (V/k rpm) = 98.0

Rated Torque (lb-in) 91.2 171.7 234.5 293.8 302.7 311.5 320.4* 327.5*

Rated Torque (Nm) 10.3 19.4 26.5 33.2 34.2 35.2 36.2 37.0

Stall Current (A) 7.0 14.1 20.9 27.8 33.8 39.4 44.4 48.1

Rated Power (kW) 3.24 6.09 8.33 10.43 10.74 11.06 11.37 11.62

R (ph-ph) (Ohms) 2.73 0.7 0.41 0.22 0.17 0.14 0.15 0.08

L (ph-ph) (mH) 23.5 10.47 7.35 4.89 3.86 3.6 3.06 2.42

Kt (lb-in/A) = 10.6

Kt (Nm/A) = 1.2

Ke (V/k rpm) = 73.5

Rated Torque (lb-in) 72.6 161.1 203.6 256.7

Rated Torque (Nm) 8.2 18.2 23.0 29.0

Stall Current (A) 9.4 18.8 27.9 37.1

Rated Power (kW) 3.43 7.62 9.63 12.15

R (ph-ph) (Ohms) 1.35 0.38 0.21 0.14

L (ph-ph) (mH) 13.56 6.05 3.86 2.45

NOTES:

* Ratings shown require connector option "H"

∆t = 212 ˚F (100 ˚C) winding 104 ˚F (40 ˚C) maximum ambient

All data subject to ±10% tolerance

Stall torque, rated torque and power relate to maximum continuous operation tested in a 68 °F (20 °C) ambient at 12 kHz drive switching frequency\

Nidec has an ongoing process of development and reserves the right to change the specification without notice

All other figures relate to a 68 °F (20 °C) motor temperature; maximum intermittent winding temperature is 284 °F (140 °C)

15

UNIMOTOR FM

190 mm Frame Dimensions – 230 V and 460 V

Unimotor fm 230 V and 460 V 190 mm Frame Dimensions

P

Motor flange

NOTE: Output key dimensions

(E,F,G and H) are applicable

to keyed units only.

90° connectors are standard

T

Motor housing

Ø C (k6)

4 holes Ø R (H14)

equispaced on a

mounting BCD ØS

Ø M (j6)

Tapped hole

thread size

I to depth J

G

H (h9)

Optional

E

key

D

B

F

K Flange

L

For vertical

connectors,

allow

approximately

N

300.0 mm

clearance for

mating cable

A

Motor

Dimensions

Unbraked Length

Braked Length

A 7.85 199.4 9.03 229.4 10.21 259.4 11.39 289.4 12.57 319.4 13.76 349.4 14.94 379.4 16.12 409.4

B 6.68 169.6 7.86 199.6 9.04 229.6 10.22 259.6 11.4 289.6 12.58 319.6 13.76 349.6 14.94 379.6

A 11.39 289.4 12.57 319.4 13.76 349.4 14.94 379.4 16.12 409.4 17.3 439.4 18.48 469.4 19.66 499.4

B 10.22 259.6 11.4 289.6 12.58 319.6 13.76 349.6 14.94 379.6 16.13 409.6 17.31 439.6 18.49 469.6

A B C D E F G H

(in) (mm) (in) (mm) (in) (mm) (in) (mm) (in) (mm) (in) (mm) (in) (mm) (in) (mm)

BCD Code

Flange

Dimensions

Flange Thickness K 0.73 18.5

Pilot Thickness L 0.15 3.9

Pilot Diameter (J6) M 7.09 180.0

Flange Square P 7.48 190.0

Mounting Hole Dia. (H14) R .057 14.5

Mounting Hole BCD S 8.46 215.0

Motor Housing T 7.48 190.0

Mounting Bolts M12

Standard

215

(in) (mm)

Frame Length

Shaft Diameter Code

Shaft

Dimensions

Shaft Diameter (J6) C 1.26 32 1.26 32 1.5 38

Shaft Length D

Key Height E

Key Length F

Key-to-Shaft End G

Key Width (H9) H 0.39 10 0.39 10 0.39 10

Tapped Hole Thread Size I M12 x 1.75 M12 x 1.75 M12 x 1.75

Tapped Hole Depth J

1

±0.45 mm, 2To IEC 72-1, 3±0.25 mm, 4±1.1 mm, 5±0.4 mm

Connector

Type

“A”

“J” 1.5 9.94 252.5

“N” 1.5 9.94 252.5

“M” 1.5 9.13 232.0

32.0 mm

Frames A-H

(in) (mm) (in) (mm) (in) (mm)

1

2.28 58 3.15 80 2.28 58

2

1.61 41 1.61 41 1.61 41

3

2.76 7.0 2.76 70 2.76 70

4

0.18 4.6 0.18 4.6 0.18 4.6

5

1.14 29 1.14 29 1.14 29

Connector

Size

1.5 9.65 245.0

N

32.0 mm

Frame A-H Opt.

Connector Height

(in) (mm)

38.0 mm

Opt.

16

17

Loading...

Loading...