Control Techniques Reconditioned Unimotor fm Catalog

UNIMOTOR FM

Unimotor fm 230 V | 460 V

ISO 9001

Unimotor fm 230 V / 460 V

Flexible Configuration AC Servo Motors

Flexible Configuration AC Servo Motors

Unimotor fm is a high performance, brushless AC Servo

motor range matched for use with Control Techniques' brand

drives. “FM” stands for “Flexible Motor” and is designed to

accommodate a wide range of applications. The motors are

available in six frame sizes with various mounting arrangements

and motor lengths. Control Techniques' drives and motors are

designed to function as an optimized system. Unimotor fm is the

perfect partner for Unidrive M, Digitax ST and Epsilon EP servo

drives.

Key Features

• Torque range: 12.4 to 1204 lb-in (1.4 to 136.0 Nm)

• Medium inertia design with high inertia option available

• Connector styles include vertical, low profile and

90° rotatable

• Variety of flange possibilities (IEC/NEMA)

• Holding brake option

• IP65 conformance

• Winding to suit 230 V and 460 V

• Speed options include 2000, 3000, 4000 and 6000 rpm

• Multiple feedback options:

• Resolver: Robust for extreme applications and

conditions — lower accuracy, medium resolution

• Incremental encoder: High accuracy, medium resolution

• Absolute: Medium accuracy, medium resolution, single-turn

and multi-turns

• SinCos/Absolute: High accuracy, high resolution, single-turn

and multi-turn

• HIPERFACE (SICK) and EnDat (Heidenhain) protocols

supported

NOW WITH EVEN HIGHER PERFORMANCE!

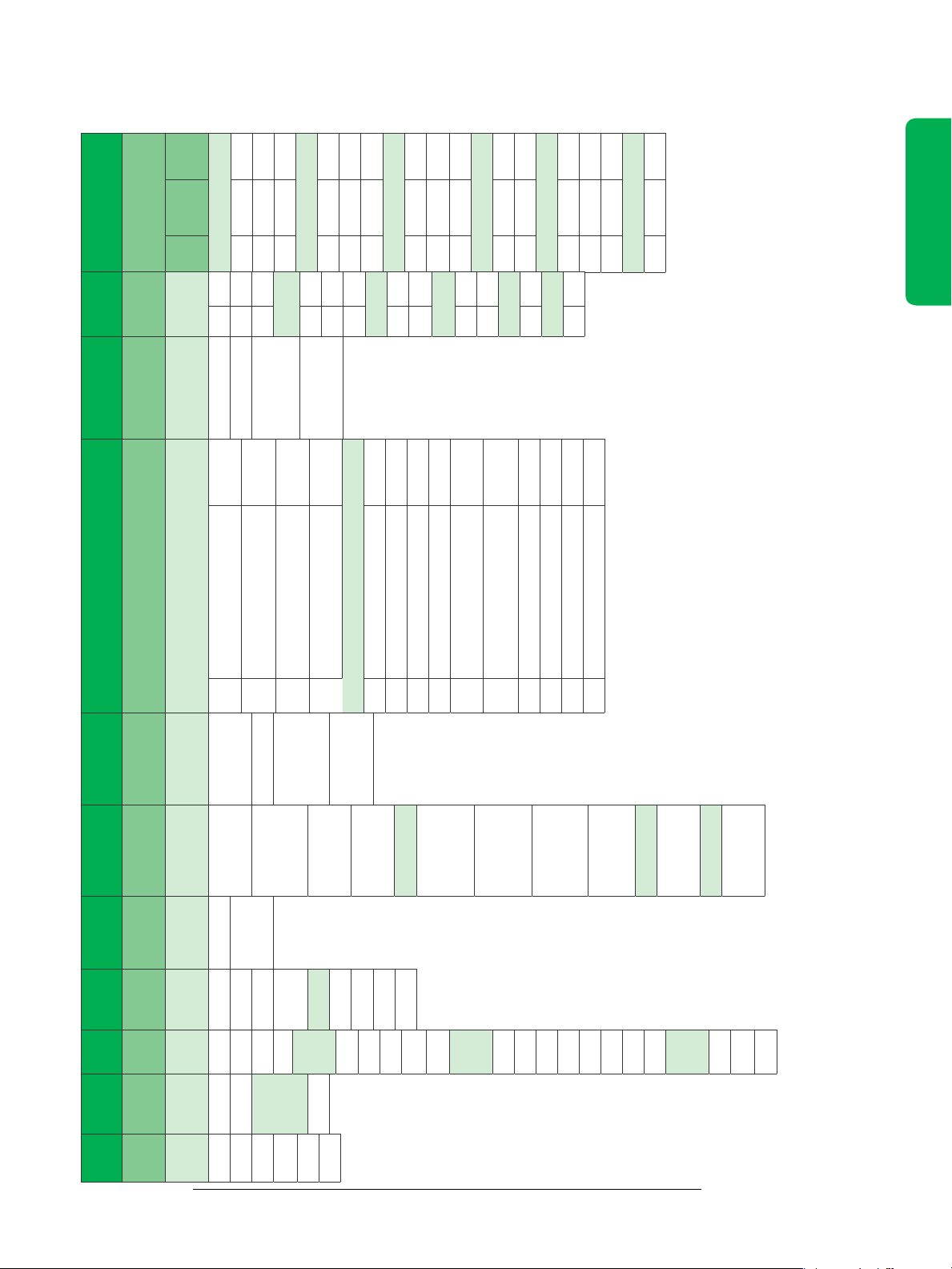

Frame

Size

75

95

115

142

190

250

10 100 1000

Electronic Nameplate Capability

Unimotor fm Torque Range

42

Continuous (lb-in) Peak (lb-in)

82

124

246

142

221

686 2044

1204 3611

425

664

2000 4000

Approvals

4

Certificate No. Q 05176

QUALITY

MANAGEMENT

003

When a Unidrive M, Unidrive SP or Digitax ST servo drive is

connected to a SinCos or absolute encoder, it can recognize and

communicate with the motor to obtain the “electronic nameplate”

data. This motor data can then be used to automatically optimize

the drive settings. This feature simplifies commissioning and

maintenance, ensures consistent performance and saves time.

UNIMOTOR FM

Unimotor fm Order Information

Use the information below to create an order code for a Unimotor fm (top row is an example).

Frame

Length

190

Shaft Diameter

100

A

Inertia +

CA

(mm)

Shaft

Length

075 Frame

(ex. 110=11.0 mm)

BCD

075 Std

075 Frame

Temp sensor

075-250 Frames

A = Standard + PTC

‡

EQI 1331

075-250 Frames

Feedback device

EC = Inductive Absolute

110 23 A

140 30 B-D

190 40

080 Opt

085 Opt

095 Frame

B = High + PTC

C = Standard +

KTY84-130

thermistor**

‡

SEL 52

ECI 1319

Multi-turn EnDat

Single-turn EnDat

= Capacitive Hiperface SinCos

†

FC = Inductive Absolute

VF

095 Frame

140 30 A

100 Std

098 Opt

D = High +

KTY84-130

thermistor**

190 40 B-E

115 Opt

115 Frame

240 50

115 Std

115 Frame

SEK 52

075-250 Frames

Single-turn

Multi-turn

= Capacitive Hiperface SinCos

†

WF

AE = Resolver

CA = Incremental Encoder (Std) 4096 ppr

190 40 A-C

240 50 D, E

130 Opt

142 Frame

FB = Optical Absolute Single-turn EnDat ECN 1313

EB = Optical Absolute Multi-turn EnDat EQN 1325

142 Frame

240 50

240 50 A-E

165 Std

149 Opt

190 Frame

SRS 50

SRM 50

Multi-turn Hiperface

Single-turn Hiperface

SA = Optical SinCos

RA = Optical SinCos

190 Frame

320 58 D, E

215 Std

250 Frame

FF = Inductive Serial Single-turn EnDat ECI 1319**

EF = Inductive Serial Multi-turn EnDat EQI 1331**

320 58 A-H

380 58

320* 80* A-H*

300 Std

GB = Optical Multi-turn EnDat EQN 1337**

HB = Optical Single-turn EnDat ECN 1325**

250 Frame

480 110 D-F

* Add (-SREL) to end of E3/U3

order string for 80 mm length

shafts on 190 mm frames.

A

B

5

30

A

U3

095

Output shaft

type

Connection

Brake

(rpm)

Rated

speed

Stator

length

Motor

voltage

size

Frame

Frames

075-250

Frames

075-142

Frames

075-250

Frames

075-190

075

Frame

Frames

075-190

A = Keyway w/

Full Key installed

B = No Keyway

B = Power and

Signal 90° and

rotatable size 1.0

C = Power 90°

5 = 24 Vdc

0 = No Brake

Parking brake

20 = 2000

30 = 3000

40 = 4000

B

A

C

E3 = 230 V

U3 = 460 V

075

095

115

E* = Keyway w/

Half Key installed

rotatable and

signal vertical

size 1.0

V = Power and

a

60 = 6000

250 Frame

D

095

-142

250

Frame

U3 = 460 V

142

190

F* = Keyway w/

Half and Full Key

included

Signal Vertical

size 1.0

D = Hybrid power

10 = 1000

15 = 1500

B

A

Frames

250

142-190 Frames

and signal 90°

size 1.0**

J = 1.5 size

b

b

20 = 2000

25 = 2500

C*

D*

Power90° and

signal 90°

and rotatable

E = Hybrid power

E*

190

Frame

and signal 90°

size 1.5**

N = Power 90°

rotatable and

B

A

C*

signal vertical

size 1.0

M = Power and

Signal Vertical

F*

E*

D*

115-190 Frames

size 1.0

H = Power

H*

G*

Notes:

*Half key is used to balance shaft. It does not complete shaft radius

Frame

b,c

250

hybrid box and

250

H = Power hybrid

signal vertical

b

b

D

Frame

Bearingless design recommended for light duty applications only

a 6000 rpm not available on all frames sizes

b 250 D and E lengths, rated speed equal and above 2500 rpm are supplied with a terminal box "H" connector options

c 250 F Lengths, rated speed equal and above 2000 rpm are supplied with a terminal box "H" connector options

d use if replacing E2/U2 motors

e “J” connector option available on 142E3 and 142U3 frames, refer to stator lengths marked with an asterisk

**Single cable option

‡

box and signal

vertical (Std)

F

E

f “H” connector option available on some E3 and U3 190 frames, refer to stator lengths marked with an asterisk

5

UNIMOTOR FM

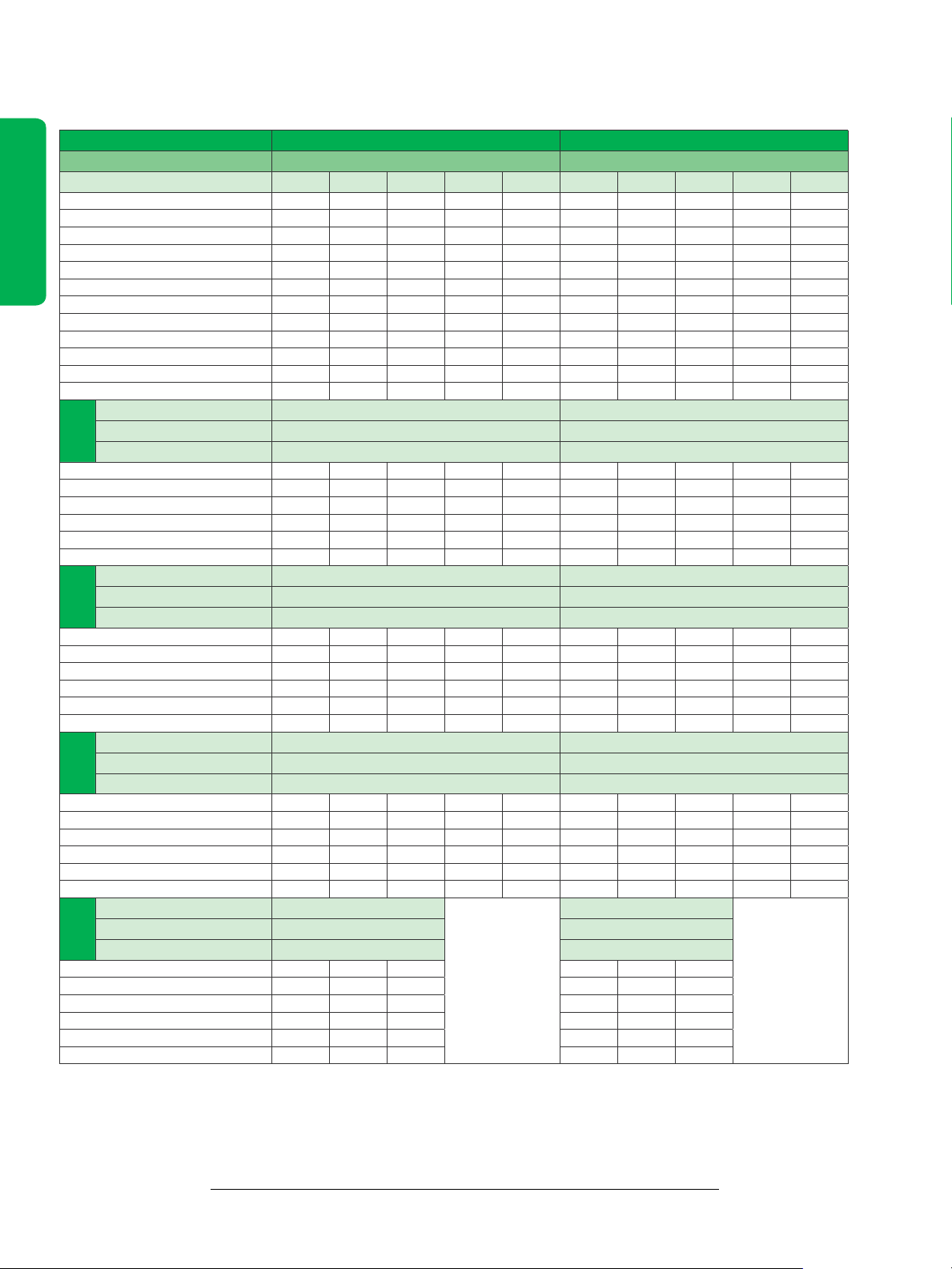

75 mm Frame Ratings

Unimotor fm 75 mm Frame Ratings

Motor Frame Size (mm) 075E3 075U3

Voltage (Vrms) 230 460

Frame Length A B C D A B C D

Continuous Stall Torque (lb-in) 12.4 23.9 32.7 41.6 12.4 23.9 32.7 41.6

Continuous Stall Torque (Nm) 1.4 2.7 3.7 4.7 1.4 2.7 3.7 4.7

Peak Torque (lb-in) 38 71 99 124 38 71 99 124

Peak Torque (Nm) 4.3 8 11.2 14 4.3 8 11.2 14

Standard Inertia (lb-in-sec²) 0.00069 0.00108 0.00142 0.00180 0.00069 0.00108 0.00142 0.00180

Standard Inertia (kgm²) 0.00008 0.00012 0.00016 0.00020 0.00008 0.00012 0.00016 0.00020

High Inertia (lb-in-sec²) 0.00104 0.00142 0.00180 0.00218 0.00104 0.00142 0.00180 0.00218

High Inertia (kgm²) 0.00012 0.00016 0.00020 0.00025 0.00012 0.00016 0.00020 0.00025

Winding Thermal Time Const. (s) 63 58 73 78 63 58 73 78

Motor Weight (lbs) 6.4 8.1 9.9 11.7 6.4 8.1 9.9 11.7

Motor Weight (kg) 2.9 3.7 4.5 5.3 2.9 3.7 4.5 5.3

Number of Poles 6 6 6 6 6 6 6 6

Kt (lb-in/A) = 12.4 21.24

Kt (Nm/A) = 1.4 2.4

2000 rpm

3000 rpm

4000 rpm

6000 rpm

Ke (V/k rpm) = 85.5 147

Rated Torque (lb-in) 11.5 22.1 31.0 39.8 11.5 21.9 31.0 39.5

Rated Torque (Nm) 1.3 2.5 3.5 4.5 1.3 2.5 3.5 4.5

Stall Current (A) 1.0 1.9 2.7 3.3 0.6 1.1 1.6 1.9

Rated Power (kW) 0.72 0.52 0.73 0.93 0.27 0.52 0.73 0.93

R (ph-ph) (Ohms) 48.24 16.32 8.96 6.22 148.5 52.2 27.3 19.97

L (ph-ph) (mH) 87.47 39.77 24.68 19.15 258.7 117.28 74.2 56.97

Kt (lb-in/A) = 8.23 14.16

Kt(Nm/A) = 0.93 1.6

Ke (V/k rpm) = 57.0 98.0

Rated Torque (lb-in) 11.5 20.4 29.2 37.2 11.5 20.3 29.3 37.0

Rated Torque (Nm) 1.3 2.3 3.3 4.2 1.3 2.29 3.3 4.18

Stall Current (A) 1.55 2.85 4.9 5.02 0.90 1.66 2.33 2.92

Rated Power (kW) 0.41 0.72 1.04 1.31 0.41 0.72 1.04 1.31

R (ph-ph) (Ohms) 19.8 6.69 3.71 2.72 62.08 21.07 12.54 7.81

L (ph-ph) (mH) 37.2 16.8 10.69 8.27 114.6 52.65 34.18 23.89

Kt (lb-in/A) = 6.37 10.62

Kt (Nm/A) = 0.72 1.2

Ke (V/k rpm) = 44.0 73.5

Rated Torque (lb-in) 10.6 18.6 24.8 33.6 10.6 18.2 24.7 33.6

Rated Torque (Nm) 1.2 2.1 2.8 3.8 1.2 2.06 2.79 3.8

Stall Current (A) 2.06 3.79 5.31 6.67 1.20 2.21 3.10 3.89

Rated Power (kW) 0.5 0.86 1.17 1.59 0.50 0.86 1.17 1.59

R (ph-ph) (Ohms) 12.44 4.01 2.26 1.53 38.01 12.71 6.49 4.94

L (ph-ph) (mH) 23.35 9.62 6.32 4.63 68.39 30.46 18.28 13.97

Kt (lb-in/A) = 4.16 7.08

Kt (Nm/A) = 0.47 0.8

Ke (V/k rpm) = 28.5 49.0

Rated Torque (lb-in) 9.7 16.8 24.8 30.1 9.6 17.0 24.3 30.1

Rated Torque (Nm) 1.1 1.9 2.8 3.4 1.08 1.92 2.75 3.4

Stall Current (A) 3.06 5.64 7.91 9.94 1.80 3.31 4.65 5.84

Rated Power (kW) 0.68 1.21 1.73 2.14 0.68 1.21 1.73 2.14

R (ph-ph) (Ohms) 5.37 1.81 1.02 0.68 15.48 5.19 2.86 2.12

L (ph-ph) (mH) 9.8 4.42 2.88 2.06 28.66 12.77 8.01 6.33

NOTES:

∆t = 212 ˚F (100 ˚C) winding 104 ˚F (40 ˚C) maximum ambient

All data subject to ±10% tolerance

Stall torque, rated torque and power relate to maximum continuous operation tested in a 68 °F (20 °C) ambient at 12 kHz drive switching frequency

Nidec has an ongoing process of development and reserves the right to change the specification without notice

All other figures relate to a 68 °F (20 °C) motor temperature; maximum intermittent winding temperature is 284 °F (140 °C)

6

UNIMOTOR FM

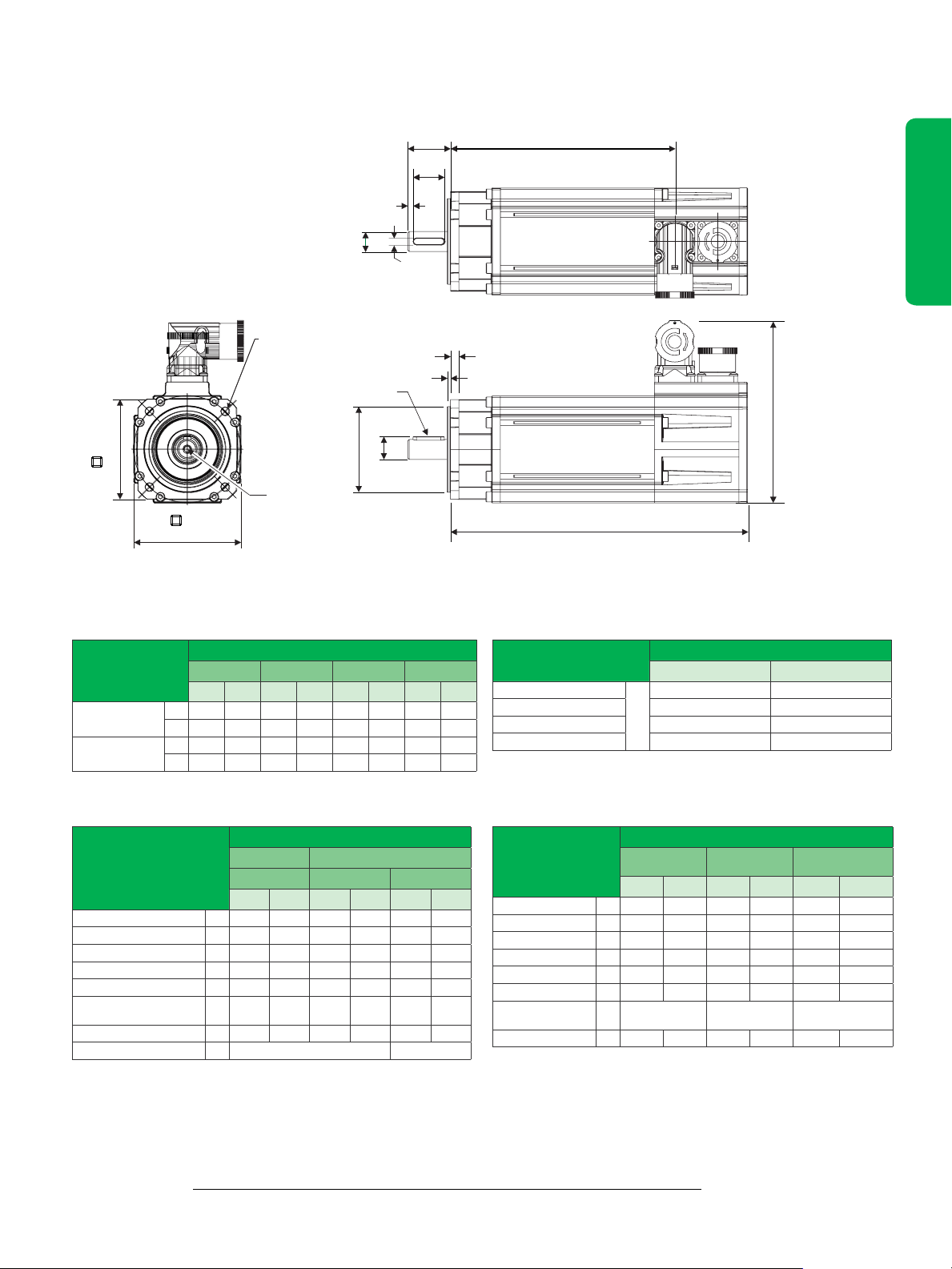

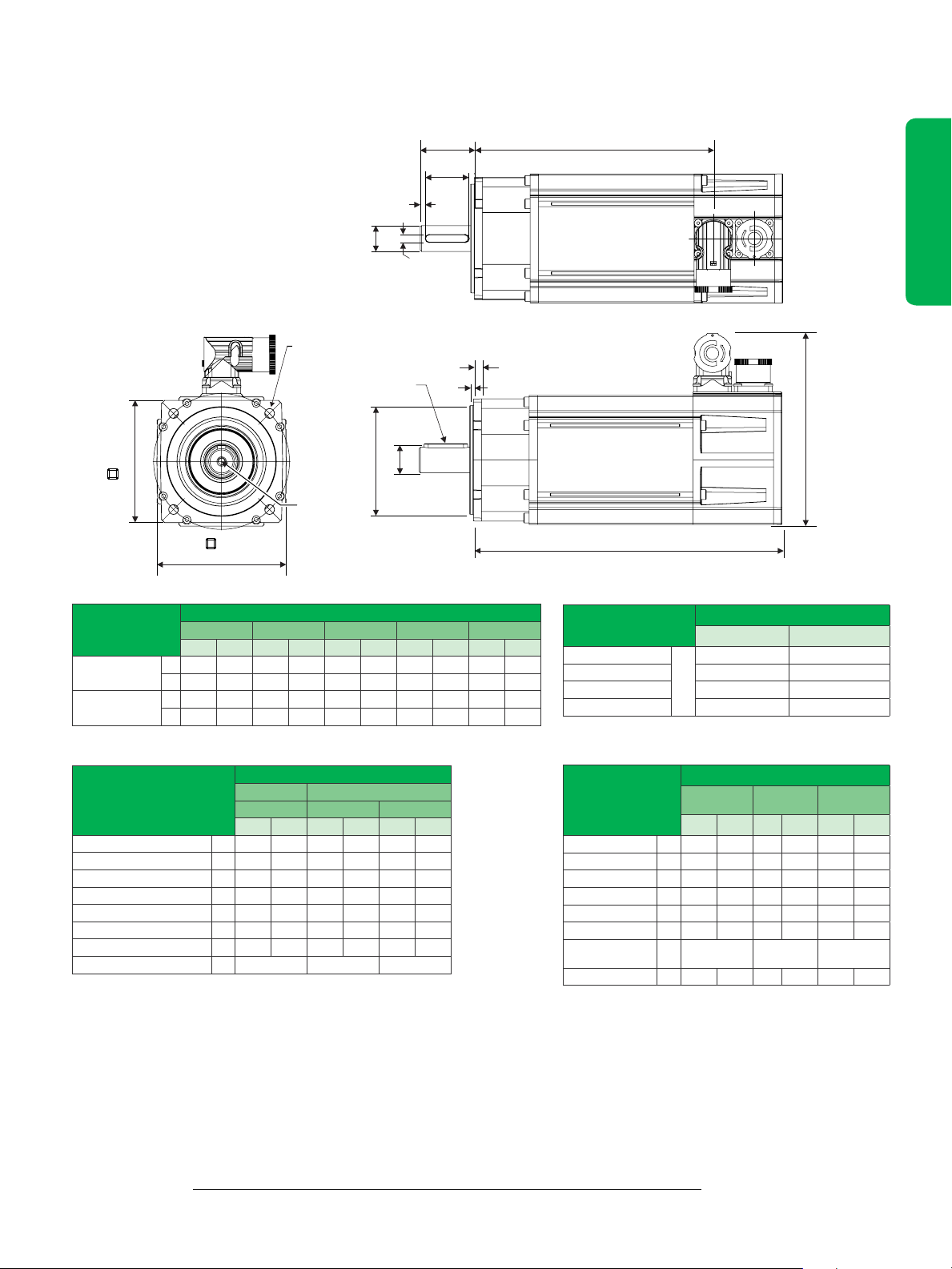

75 mm Frame Dimensions

Unimotor fm 75 mm Frame Dimensions

P

Motor flange

NOTE: Output key dimensions

(E,F,G and H) are applicable

to keyed units only.

90° connectors are standard

T

Motor housing

Ø C (j6)

4 holes Ø R (H14)

equispaced on a

mounting BCD ØS

Optional key

Ø M (j6)

Tapped hole

thread size

I to depth J

D

B

F

G

H (h9)

K Flange

L

E

A

For vertical

connectors,

allow

approximately

N

175.0 mm

clearance for

mating cable

Motor

Dimensions*

Unbraked Length

Braked Length

*PCD 085 motor lengths differ from the above, refer to drawings for complete details

A B C D

(in) (mm) (in) (mm) (in) (mm) (in) (mm)

A 8.20 208.2 9.38 238.2 10.56 268.2 11.74 298.2

B 6.19 157.2 7.37 187.2 8.55 217.2 9.73 247.2

A 9.38 238.2 10.56 268.2 11.74 298.2 12.92 328.2

B 7.37 187.2 8.55 217.2 9.73 247.2 10.91 277.2

BCD Code

Frame Length

Flange

Dimensions

Flange Thickness K 0.23 5.8 0.23 5.8 0.23 5.8

Pilot Thickness L 0.09 2.4 0.09 2.4 0.09 2.4

Pilot Diameter (J6) M 2.36 60.0 2.36 60.0 2.76 70.0

Flange Square P 2.76 70.0 2.76 70.0 3.15 80.0

Mounting Hole Dia. (H14) R 0.23 5.8 0.23 5.8 0.28 7.0

Mounting Hole BCD S

Motor Housing T 2.95 75 2.95 75 2.95 75

Mounting Bolts M5 M6

Standard Optional

075 080 085

(in) (mm) (in) (mm) (in) (mm)

2.6 to

66.7 to

3.0 to

3.0

75.0

3.2

75.0 to

80.0

3.4 85

Connector

Type

“A”

“B” (std) 5.0 126.0

“C” 5.0 126.0

“V” 4.7 118.5

Dimensions for power connectors size 1.0

N

Connector Height

(in) (mm)

4.7 118.5

Shaft Diameter Code

Shaft

Dimensions

Shaft Diameter (J6) C 0.43 11.0 0.55 14.0 0.75 19.0

Shaft Length D

Key Height E

Key Length F

Key-to-Shaft End G

Key Width (H9) H 0.16 4.0 0.20 5.0 0.24 6.0

Tapped Hole

thread Size

Tapped Hole Depth J

1

±0.45 mm, 2To IEC 72-1, 3±0.25 mm, 4±1.1 mm, 5±0.4 mm

11.0 mm

Frame A

(in) (mm) (in) (mm) (in) (mm)

1

0.91 23.0 1.18 30.0 1.57 40.0

2

0.49 12.5 0.63 16.0 0.85 21.5

3

0.55 14.0 0.98 25.0 1.26 32.0

4

0.14 3.6 0.06 1.5 0.14 3.6

I M4 x 0.7 M5 x 0.8 M6 x 1.0

5

0.43 11.0 0.53 13.5 0.67 17.0

14.0 mm

Frames B-D

19.0 mm

Opt

7

UNIMOTOR FM

95 mm Frame Ratings

Unimotor fm 95 mm Frame Ratings

Motor Frame Size (mm) 095E3 095U3

Voltage (Vrms) 230 460

Frame Length A B C D E A B C D E

Continuous Stall Torque (lb-in) 22.1 39.8 55.8 69.9 82.3 21.7 39.8 55.8 69.9 81.9

Continuous Stall Torque (Nm) 2.5 4.5 6.3 7.9 9.3 2.5 4.5 6.3 7.9 9.3

Peak Torque (lb-in) 65 119 167 210 246 65 119 167 210 246

Peak Torque (Nm) 7.4 13.5 18.9 23.7 27.8 7.4 13.5 18.9 23.7 27.8

Standard Inertia (lb-in-sec²) 0.00128 0.00230 0.00329 0.00427 0.00531 0.00128 0.00230 0.00329 0.00427 0.00531

Standard Inertia (kgm²) 0.00015 0.00026 0.00037 0.00048 0.00060 0.00015 0.00026 0.00037 0.00048 0.00060

High Inertia Option (lb-in-sec²) 0.00116 0.00398 0.00496 0.00593 0.00690 0.00116 0.00398 0.00496 0.00593 0.00690

High Inertia Option (kgm²) 0.00013 0.00045 0.00056 0.00067 0.00078 0.00013 0.00045 0.00056 0.00067 0.00078

Winding Thermal Time Const. (s) 84 82 73 90 108 84 82 90 108 112

Motor Weight (lbs) 10.1 12.8 15.4 18 20.7 10.1 12.8 15.4 18 20.7

Motor Weight (kg) 4.6 5.8 7 8.2 9.4 4.6 5.8 7 8.2 9.4

Number of Poles 6 6 6 6 6 6 6 6 6 6

Kt (lb-in/A) = 12.4 21.2

Kt (Nm/A) = 1.4 2.4

2000 rpm

3000 rpm

4000 rpm

6000 rpm

Ke (V/k rpm) = 85.5 147.0

Rated Torque (lb-in) 21.2 38.1 52.2 64.6 75.2 21.2 38.1 52.2 64.6 75.2

Rated Torque (Nm) 2.4 4.3 5.9 7.3 8.5 2.4 4.3 5.9 7.3 8.5

Stall Current (A) 1.8 3.2 4.5 5.6 6.6 1.0 1.9 2.6 3.3 3.9

Rated Power (kW) 0.51 0.9 1.23 1.53 1.77 0.51 0.9 1.23 1.53 1.77

R (ph-ph) (Ohms) 20.69 6.78 3.79 2.42 1.92 64.08 20.88 10.46 7.46 5.09

L (ph-ph) (mH) 57.78 26.1 16.36 11.83 9.75 173.4 78.16 47.02 35.44 27.18

Kt (lb-in/A) = 8.23 14.2

Kt (Nm/A) = 0.93 1.60

Ke (V/k rpm) = 57.0 98.0

Rated Torque (lb-in) 20.6 36.3 49.6 61.1 72.1 20.4 36.3 49.6 61.1 72.6

Rated Torque (Nm) 2.33 4.1 5.6 6.9 8.15 2.3 4.1 5.6 6.9 8.2

Stall Current (A) 2.63 4.84 6.77 8.49 9.95 1.5 2.8 3.9 4.9 5.8

Rated Power (kW) 0.73 1.29 1.76 2.17 2.56 0.73 1.29 1.76 2.17 2.56

R (ph-ph) (Ohms) 9.62 2.99 1.64 1.07 0.86 26.7 8.63 4.67 3.16 2.27

L (ph-ph) (mH) 26.29 11.47 7.15 5.16 4.35 76.65 33.71 21.09 15.95 12.06

Kt (lb-in/A) = 6.2 10.6

Kt (Nm/A) = 0.72 1.2

Ke (V/k rpm) = 42.75 73.5

Rated Torque (lb-in) 20.4 33.6 46.9 56.6 65.5 20.4 33.6 46.9 56.6 65.5

Rated Torque (Nm) 2.3 3.8 5.3 6.4 7.4 2.3 3.8 5.3 6.4 7.4

Stall Current (A) 3.5 6.43 9.0 11.29 13.21 2.0 3.8 5.3 6.6 7.7

Rated Power (kW) 0.94 1.59 2.2 2.68 3.1 0.94 1.59 2.2 2.68 3.1

R (ph-ph) (Ohms) 5.26 1.76 1.04 0.74 0.48 16.14 5.22 2.61 1.81 1.4

L (ph-ph) (mH) 14.94 6.67 4.52 3.53 2.44 44.25 19.54 11.75 8.86 7.25

Kt (lb-in/A) = 4.2 7.1

Kt (Nm/A) = 0.47 0.8

Ke (V/k rpm) = 28.5 49.0

Rated Torque (lb-in) 17.5 28.3 37.2 17.7 28.3 37.2

Rated Torque (Nm) 1.98 3.2 4.2 2.0

ent (A) 5.21 9.57 13.4 3.1 5.6 7.9

Stall Curr

Rated Power (kW) 1.24 2.01 2.64 1.24 2.01 2.64

R (ph-ph) (Ohms) 2.33 0.73 0.46 6.59 2.13 1.22

L (ph-ph) (mH) 6.57 2.77 2.07 18.62 8.24 5.44

3.2 4.2

NOTES:

∆t = 212 ˚F (100 ˚C) winding 104 ˚F (40 ˚C) maximum ambient

All data subject to ±10% tolerance

Stall torque, rated torque and power relate to maximum continuous operation tested in a 68 °F (20 °C) ambient at 12 kHz drive switching frequency

Nidec has an ongoing process of development and reserves the right to change the specification without notice

All other figures relate to a 68 °F (20 °C) motor temperature; maximum intermittent winding temperature is 284 °F (140 °C)

8

UNIMOTOR FM

95 mm Frame Dimensions

Unimotor fm 95 mm Frame Dimensions

P

Motor flange

T

Motor housing

NOTE: Output key dimensions

(E,F,G and H) are applicable

to keyed units only.

90° connectors are standard

Ø C (j6)

4 holes Ø R (H14)

equispaced on a

mounting BCD ØS

Optional key

Ø M (j6)

E

Tapped hole

thread size

I to depth J

G

H (h9)

D

B

F

K Flange

L

A

For vertical

connectors,

allow

approximately

N

175.0 mm

clearance for

mating cable

Motor

Dimensions

Unbraked Length

Braked Length

BCD 098 and 115 motor lengths differ from the above, refer to draw for motor details

A B C D E

(in) (mm) (in) (mm) (in) (mm) (in) (mm) (in) (mm)

A 8.93 226.9 10.11 256.9 11.3 286.9 12.48 316.9 13.66 346.9

B 6.93 175.9 8.11 205.9 9.29 235.9 10.47 265.9 11.65 295.9

A 10.11 256.9 11.3 286.9 12.48 316.9 13.66 346.9 14.84 376.9

B 8.11 205.9 9.29 235.9 10.47 265.9 11.65 295.9 12.83 325.9

Frame Length

BCD Code

Flange

Dimensions

Flange Thickness K 0.23 5.9 0.268 6.8 0.268 6.8

Pilot Thickness L 0.11 2.8 0.11 2.8 0.11 2.8

Pilot Diameter (J6) M 3.15 80.0 2.87 73.0 3.74 95.0

Flange Square P 3.54 90.0 3.54 90.0 4.13 105.0

Mounting Hole Dia. (H14) R 0.28 7.0 0.28 7.0 0.29 10.0

Mounting Hole BCD S 3.94 100.0 3.88 98.43 4.53 115.0

Motor Housing T 3.74 95.0 3.74 95.0 3.74 95.0

Mounting Bolts M6 M6 M8

†

NEMA 34 flange option; shaft diameters differ from typical NEMA 34 flange

Standard Optional

100

(in) (mm) (in) (mm) (in) (mm)

098

†

115

Connector

Type

“A”

“B” (std) 5.47 139.0

“C” 5.47 139.0

“V” 5.18 131.5

Dimensions for power connectors size 1.0

N

Connector Height

(in) (mm)

5.18 131.5

Shaft Diameter Code

Shaft

Dimensions

Shaft Dia. (J6) C 0.55 14.0 0.75 19.0 0.866 22.0

Shaft Length D

Key Height E

Key Length F

Key-to-Shaft End G

Key Width (H9) H 0.20 5.0 0.24 6.0 0.245 6.0

Tapped Hole

thread Size

Tapped Hole Depth J

1

±0.45 mm, 2To IEC 72-1, 3±0.25 mm, 4±1.1 mm, 5±0.4 mm

14.0 mm

Frame A

(in) (mm) (in) (mm) (in) (mm)

1

1.18 30.0 1.57 40.0 1.97 50.0

2

0.63 16.0 0.85 21.5 1.0 24.5

3

0.98 25.0 1.26 32.0 1.63 40.0

4

0.06 1.5 0.14 3.6 0.188 4.6

I M5 x 0.8 M6 x 1.0 M8 x 1.25

5

0.53 13.5 0.67 17.0 0.816 20.0

19.0 mm

Frames B-E

22.0 mm

Opt.

9

Loading...

Loading...