Control User Guide

Unidrive M600

Part Number: 0478-0337-02

Issue: 2

Original Instructions

For the purposes of compliance with the EU Machinery Directive 2006/42/EC, the English version of this manual is the Original Instructions. Manuals

in other languages are Translations of the Original Instructions.

Documentation

Manuals are available to download from the following locations: http://www.drive-setup.com/ctdownloads

The information contained in this manual is believed to be correct at the time of printing and does not form part of any contract. The manufacturer

reserves the right to change the specification of the product and its performance, and the contents of the manual, without notice.

Warranty and Liability

In no event and under no circumstances shall the manufacturer be liable for damages and failures due to misuse, abuse, improper installation, or

abnormal conditions of temperature, dust, or corrosion, or failures due to operation outside the published ratings. The manufacturer is not liable for

consequential and incidental damages. Contact the supplier of the dive for full details of the warranty terms.

Environmental policy

Control Techniques Ltd operates an Environmental Management System (EMS) that conforms to the International Standard ISO 14001.

Further information on our Environmental Policy can be found at: http://www.drive-setup.com/environment

Restriction of Hazardous Substances (RoHS)

The products covered by this manual comply with European and International regulations on the Restriction of Hazardous Substances including EU

directive 2011/65/EU and the Chinese Administrative Measures for Restriction of Hazardous Substances in Electrical and Electronic Products.

Disposal and Recycling (WEEE)

When electronic products reach the end of their useful life, they must not be disposed of along with domestic waste but should be recycled

by a specialist recycler of electronic equipment. Control Techniques products are designed to be easily dismantled into their major

component parts for efficient recycling. The majority of materials used in the product are suitable for recycling.

Product packaging is of good quality and can be re-used. Large products are packed in wooden crates. Smaller products are packaged

in strong cardboard cartons which have a high recycled fibre content. Cartons can be re-used and recycled. Polythene, used in protective

film and bags for wrapping the product, can be recycled. When preparing to recycle or dispose of any product or packaging, please

observe local legislation and best practice.

REACH legislation

EC Regulation 1907/2006 on the Registration, Evaluation, Authorisation and restriction of Chemicals (REACH) requires the supplier of an article to

inform the recipient if it contains more than a specified proportion of any substance which is considered by the European Chemicals Agency (ECHA)

to be a Substance of Very High Concern (SVHC) and is therefore listed by them as a candidate for compulsory authorisation.

Further information on our compliance with REACH can be found at: http://www.drive-setup.com/reach

Registered Office

Nidec Control Techniques Ltd

The Gro

Newtown

Powys

SY16 3BE

UK

Registered in England and Wales. Company Reg. No. 01236886.

Copyright

The contents of this publication are believed to be correct at the time of printing. In the interests of a commitment to a policy of continuous development

and improvement, the manufacturer reserves the right to change the specification of the product or its performance, or the contents of the guide, without

notice.

All rights reserved. No parts of this guide may be reproduced or transmitted in any form or by any means, electrical or mechanical including

photocopying, recording or by an information storage or retrieval system, without permission in writing from the publisher.

Copyright © December 2017 Nidec Control Techniques Ltd

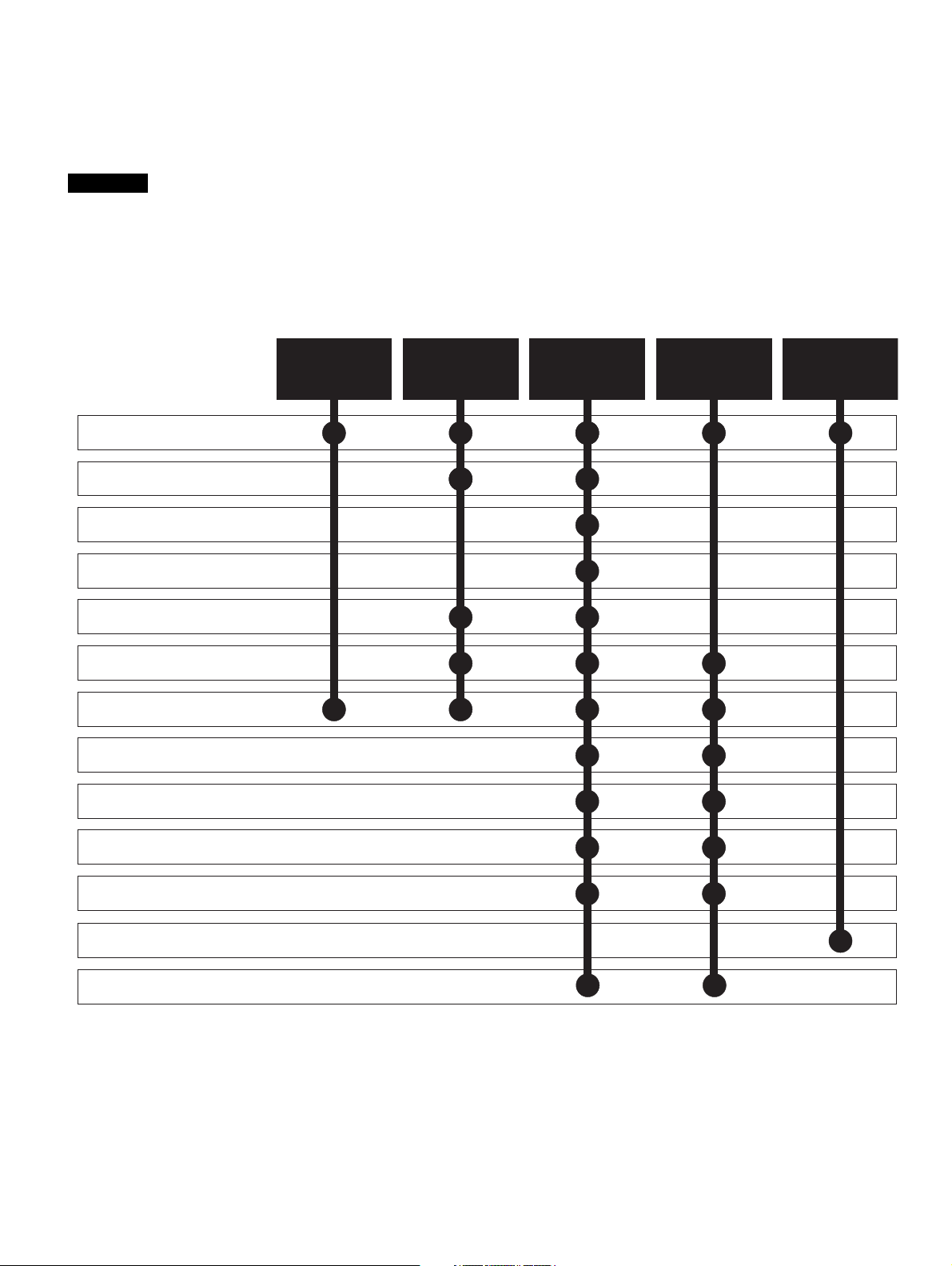

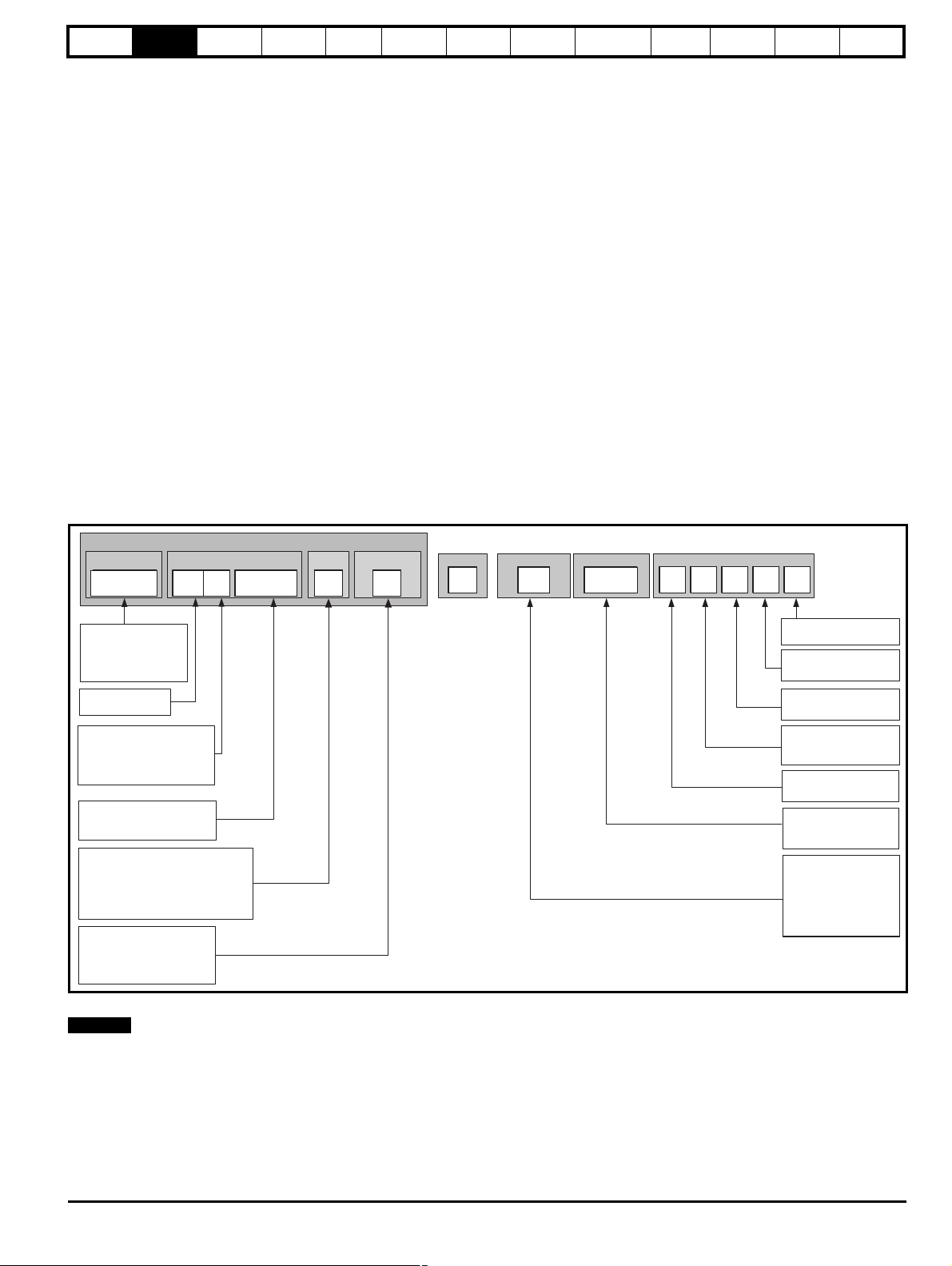

How to use this guide

NOTE

Quick Start /

bench testing

Quick Start /

bench

testing

Familiarisation

System designSystem design

Programming

and

commissioning

Programming

and

commissioning

Troubleshooting

1 Safety information

2 Product information

3 Mechanical installation

4 Electrical installation

5 Getting started

6 Basic parameters

7 Running the motor

8 Optimization

9 NV media card operation

11 Advanced parameters

12 Diagnostics

13 UL listing information

10 Onboard PLC

This guide is intended to be used in conjunction with the appropriate Power Installation Guide. The Power Installation

Guide gives information necessary to physically install the drive. This guide gives information on drive configuration,

operation and optimization.

There are specific safety warnings throughout this guide, located in the relevant sections. In addition, Chapter 1 Safety

information contains general safety information. It is essential that the warnings are observed and the information

considered when working with or designing a system using the drive.

This map of the user guide helps to find the right sections for the task you wish to complete, but for specific information,

refer to :

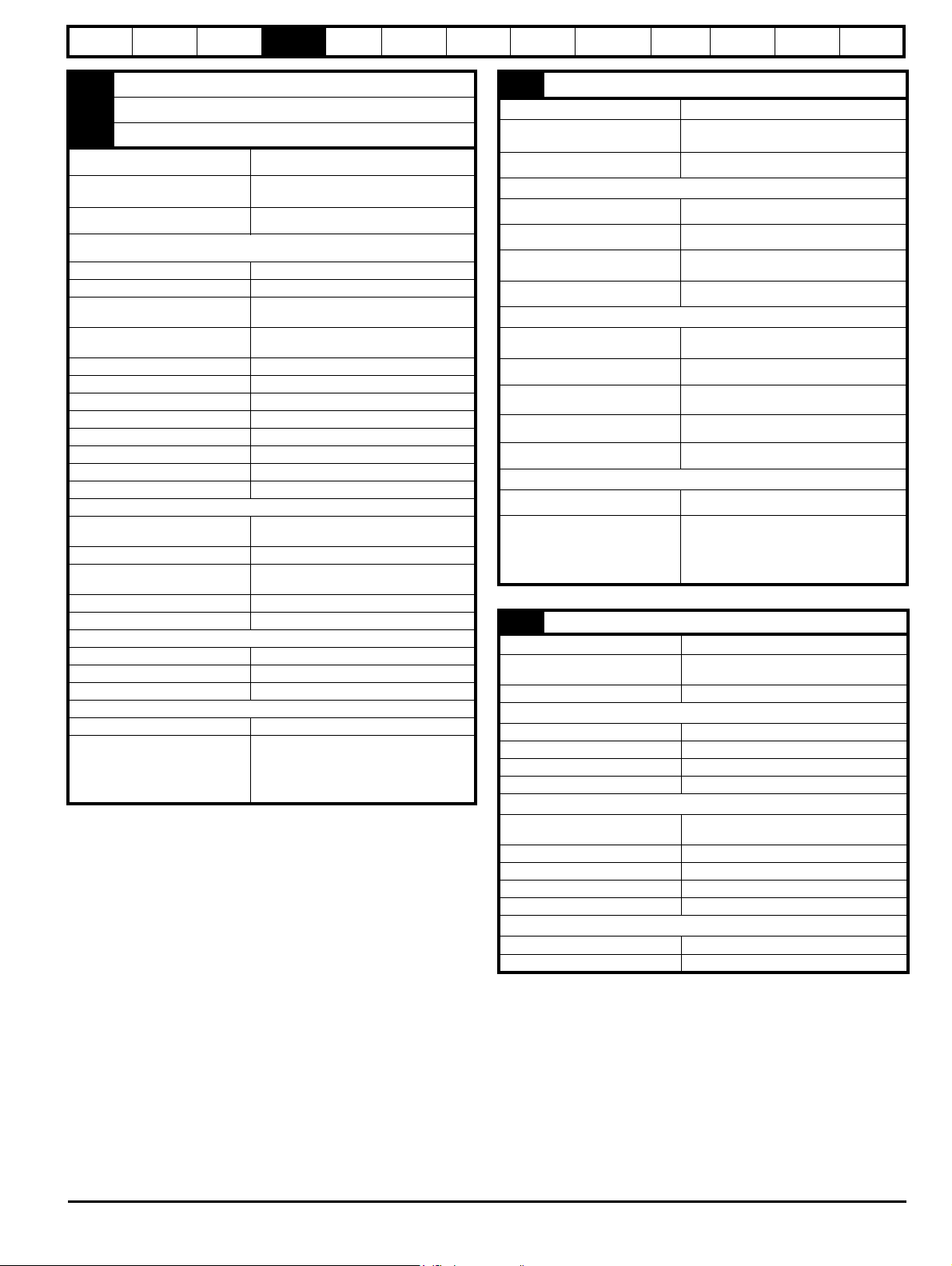

Contents

1 Safety information .................................9

1.1 Warnings, Cautions and Notes .............................9

1.2 Important safety information. Hazards.

Competence of designers and installers ...............9

1.3 Responsibility ........................................................9

1.4 Compliance with regulations .................................9

1.5 Electrical hazards ..................................................9

1.6 Stored electrical charge ........................................9

1.7 Mechanical hazards ..............................................9

1.8 Access to equipment .............................................9

1.9 Environmental limits ..............................................9

1.10 Hazardous environments ......................................9

1.11 Motor ...................................................................10

1.12 Mechanical brake control ....................................10

1.13 Adjusting parameters ..........................................10

1.14 Electromagnetic compatibility (EMC) ..................10

2 Product information ............................11

2.1 Introduction .........................................................11

2.2 Drive firmware version ........................................11

2.3 Model number .....................................................11

2.4 Ratings ................................................................12

2.5 Operating modes .................................................13

2.6 Nameplate description ........................................14

2.7 Options ................................................................15

2.8 Drive features ......................................................17

3 Mechanical installation .......................18

3.1 Installing / removing option modules and

keypads ...............................................................18

4 Electrical installation ...........................21

4.1 24 Vdc supply ......................................................21

4.2 Communication connections ...............................22

4.3 Control connections ............................................23

4.4 Safe Torque Off (STO) ........................................28

6 Running the motor .............................. 59

6.1 Quick start connections ...................................... 59

6.2 Changing the operating mode ............................ 59

6.3 Quick start commissioning / start-up .................. 64

6.4 Quick start commissioning / start-up using

Unidrive M Connect (V02.00.00.00 onwards) .... 72

6.5 Diagnostics ......................................................... 76

7 Optimization ........................................ 77

7.1 Motor map parameters ....................................... 77

7.2 Maximum motor rated current ............................ 89

7.3 Current limits ...................................................... 89

7.4 Motor thermal protection .................................... 89

7.5 Switching frequency ........................................... 90

7.6 High speed operation ......................................... 90

7.7 CT Modbus RTU specification ........................... 92

8 NV Media Card Operation .................. 99

8.1 Introduction ........................................................ 99

8.2 NV Media Card support ...................................... 99

8.3 Transferring data .............................................. 100

8.4 Data block header information ......................... 101

8.5 NV Media Card parameters ............................. 102

8.6 NV Media Card trips ......................................... 103

9 Onboard PLC ..................................... 104

9.1 Onboard PLC and Machine Control Studio ...... 104

9.2 Benefits ............................................................ 104

9.3 Features ........................................................... 104

9.4 Onboard PLC parameters ................................ 105

9.5 Onboard PLC trips ........................................... 105

5 Getting started .....................................30

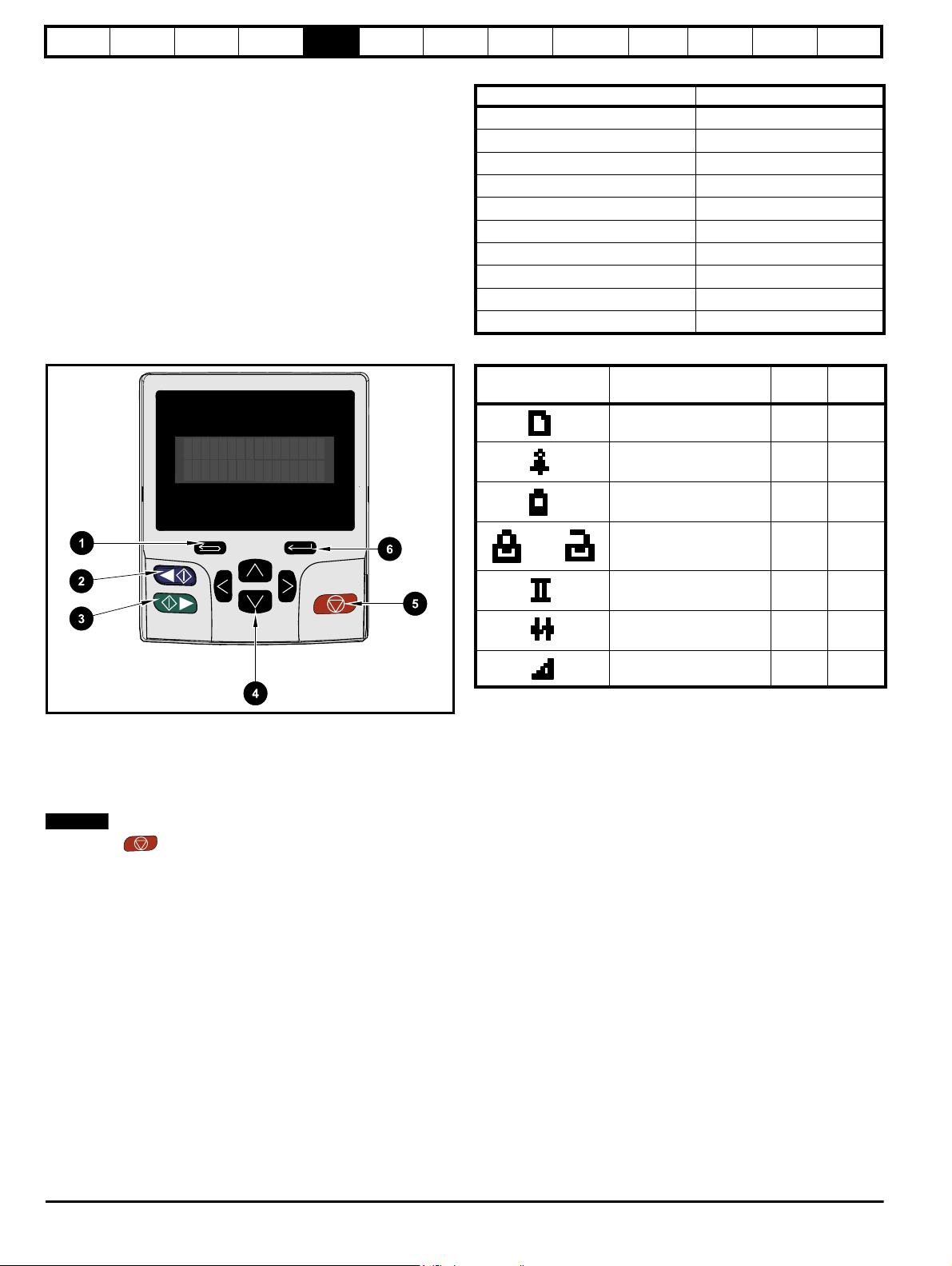

5.1 Understanding the display ...................................30

5.2 Keypad operation ................................................30

5.3 Menu structure ....................................................32

5.4 Menu 0 ................................................................33

5.5 Advanced menus ................................................33

5.6 Changing the operating mode .............................35

5.7 Saving parameters ..............................................35

5.8 Restoring parameter defaults ..............................36

5.9 Parameter access level and security ..................36

5.10 Displaying parameters with non-default

values only ..........................................................37

5.11 Displaying destination parameters only ..............37

5.12 Communications .................................................37

6 Basic parameters .................................38

6.1 Menu 0: Basic parameters ..................................39

6.2 Parameter descriptions .......................................44

6.3 Full descriptions ..................................................46

4 Unidrive M600 Control User Guide

Issue Number: 2

10 Advanced parameters .......................106

10.1 Parameter ranges and Variable minimum/

maximums: ........................................................109

10.2 Menu 1: Frequency / speed reference ..............120

10.3 Menu 2: Ramps .................................................124

10.4 Menu 3: Speed feedback and speed control ....127

10.5 Menu 4: Torque and current control ..................131

10.6 Menu 5: Motor control .......................................135

10.7 Menu 6: Sequencer and clock ..........................140

10.8 Menu 7: Analog I/O ...........................................144

10.9 Menu 8: Digital I/O ............................................148

10.10 Menu 9: Programmable logic, motorized

pot, binary sum and timers ................................152

10.11 Menu 10: Status and trips .................................158

10.12 Menu 11: General drive set-up .........................160

10.13 Menu 12: Threshold detectors, variable

selectors and brake control function .................162

10.14 Menu 13: Standard motion controller ................170

10.15 Menu 14: User PID controller ............................174

10.16 Menus 15, 16 and 17: Option module set-up ....177

10.17 Menu 18: Application menu 1 ...........................178

10.18 Menu 19: Application menu 2 ...........................178

10.19 Menu 20: Application menu 3 ...........................178

10.20 Menu 21: Second motor parameters ................179

10.21 Menu 22: Additional Menu 0 set-up ..................181

11 Diagnostics ........................................183

11.1 Status modes (Keypad and LED status) ...........183

11.2 Trip indications ..................................................183

11.3 Identifying a trip / trip source .............................184

11.4 Trips, Sub-trip numbers ....................................185

11.5 Internal / Hardware trips ....................................211

11.6 Alarm indications ...............................................211

11.7 Status indications ..............................................211

11.8 Programming error indications ..........................212

11.9 Displaying the trip history ..................................212

11.10 Behavior of the drive when tripped ...................212

12 UL Information ...................................213

12.1 UL file reference ................................................213

12.2 Option modules, kits and accessories ..............213

12.3 Enclosure ratings ..............................................213

12.4 Mounting ...........................................................213

12.5 Environment ......................................................213

12.6 Electrical Installation .........................................213

12.7 Motor overload protection and thermal

memory retention ..............................................214

12.8 Electrical supply ................................................214

12.9 External Class 2 supply ....................................214

12.10 Requirement for Transient Surge Suppression .214

12.11 Group Installation and Modular Drive Systems .214

12.12 cUL requirements for 575 V frame size 7 and 8 214

Unidrive M600 Control User Guide 5

Issue Number: 2

EU Declaration of Conformity

Nidec Control Techniques Ltd

The Gro

Newtown

Powys

UK

SY16 3BE

This declaration is issued under the sole responsibility of the manufacturer. The object of the declaration is in conformity with the relevant European

Union harmonization legislation. The declaration applies to the variable speed drive products shown below:

Model number Interpretation Nomenclature aaaa - bbc ddddde

aaaa Basic series

bb Frame size 01, 02, 03, 04, 05, 06, 07, 08, 09, 10, 11

c Voltage rating 1 = 100 V, 2 = 200 V, 4 = 400 V, 5 = 575 V, 6 = 690 V

ddddd Current rating Example 01000 = 100 A

e Drive format

The model number may be followed by additional characters that do not affect the ratings.

The variable speed drive products listed above have been designed and manufactured in accordance with the following European harmonized

standards:

M100, M101, M200, M201, M300, M400, M600, M700, M701, M702, M708, M709, M751, M753, M754,

F300, H300, E200, E300, HS30, HS70, HS71, HS72, M000, RECT

A = 6P Rectifier + Inverter (internal choke), D = Inverter, E = 6P Rectifier + Inverter (external choke),

T = 12P Rectifier + Inverter (external choke)

EN 61800-5-1:2007 Adjustable speed electrical power drive systems - Part 5-1: Safety requirements - Electrical, thermal and energy

EN 61800-3: 2004+A1:2012 Adjustable speed electrical power drive systems - Part 3: EMC requirements and specific test methods

EN 61000-6-2:2005 Electromagnetic compatibility (EMC) - Part 6-2: Generic standards - Immunity for industrial environments

EN 61000-6-4: 2007+ A1:2011

EN 61000-3-2:2014

EN 61000-3-3:2013

EN 61000-3-2:2014 Applicable where input current < 16 A. No limits apply for professional equipment where input power ≥1 kW.

These products comply with the Restriction of Hazardous Substances Directive (2011/65/EU), the Low Voltage Directive (2014/35/EU) and the

Electromagnetic Compatibility Directive (2014/30/EU).

G Williams

Vice President, Technology

Date: 6th September 2017

These electronic drive products are intended to be used with appropriate motors, controllers, electrical protection components and other

equipment to form complete end products or systems. Compliance with safety and EMC regulations depends upon installing and

configuring drives correctly, including using the specified input filters.

The drives must be installed only by professional installers who are familiar with requirements for safety and EMC. Refer to the Product

Documentation. An EMC data sheet is available giving detailed information. The assembler is responsible for ensuring that the end product

or system complies with all the relevant laws in the country where it is to be used.

Electromagnetic compatibility (EMC) - Part 6-4: Generic standards - Emission standard for industrial

environments

Electromagnetic compatibility (EMC) - Part 3-2: Limits for harmonic current emissions (equipment input current

≤16 A per phase)

Electromagnetic compatibility (EMC) - Part 3-3: Limitation of voltage changes, voltage fluctuations and flicker in

public, low voltage supply systems, for equipment with rated current ≤16 A per phase and not subject to

conditional connection

6 Unidrive M600 Control User Guide

Issue Number: 2

EU Declaration of Conformity (including 2006 Machinery Directive)

Nidec Control Techniques Ltd

The Gro

Newtown

Powys

UK

SY16 3BE

This declaration is issued under the sole responsibility of the manufacturer. The object of the declaration is in conformity with the relevant Union

harmonization legislation. The declaration applies to the variable speed drive products shown below:

Model No. Interpretation Nomenclature aaaa - bbc ddddde

aaaa Basic series

bb Frame size 01, 02, 03, 04, 05, 06, 07, 08, 09, 10, 11

c Voltage rating 1 = 100 V, 2 = 200 V, 4 = 400 V, 5 = 575 V, 6 = 690 V

ddddd Current rating Example 01000 = 100 A

e Drive format

The model number may be followed by additional characters that do not affect the ratings.

This declaration relates to these products when used as a safety component of a machine. Only the Safe Torque Off function may be used

for a safety function of a machine. None of the other functions of the drive may be used to carry out a safety function.

These products fulfil all the relevant provisions of the Machinery Directive 2006/42/EC and the Electromagnetic Compatibility Directive (2014/30/EU).

EC type examination has been carried out by the following notified body:

TUV Rheinland Industrie Service GmbH

Am Grauen Stein

D-51105 Köln

Germany

M600, M700, M701, M702, M708, M709, M751, M753, M754, F300, H300, E200, E300, HS70, HS71, HS72,

M000, RECT

A = 6P Rectifier + Inverter (internal choke), D = Inverter, E = 6P Rectifier + Inverter (external choke),

T = 12P Rectifier + Inverter (external choke)

The harmonized standards used are shown below:

EC type-examination certificate numbers:

01/205/5270.02/17 dated 2017-08-28

Notified body identification number: 0035

EN 61800-5-1:2016 Adjustable speed electrical power drive systems - Part 5-2: Safety requirements - Functional

EN 61800-5-1:2016 (in

extracts)

EN 61800-3: 2004+A1:2012 Adjustable speed electrical power drive systems - Part 3: EMC requirements and specific test methods

EN ISO 13849-1:2015 Safety of Machinery, Safety-related parts of control systems, General principles for design

EN 62061:2005 + AC:2010

+ A1:2013 + A2:2015

IEC 61508 Parts 1 - 7:2010 Functional safety of electrical/ electronic/programmable electronic safety-related systems

Person authorised to complete the technical file:

P Knight

Conformity Engineer

Newtown, Powys, UK

Adjustable speed electrical power drive systems - Part 5-1: Safety requirements - Electrical, thermal and energy

Safety of machinery, Functional safety of safety related electrical, electronic and programmable electronic control

systems

Unidrive M600 Control User Guide 7

Issue Number: 2

DoC authorised by:

G. Williams

Vice President, Technology

Date: 6th September 2017

Place: Newtown, Powys, UK

IMPORTANT NOTICE

These electronic drive products are intended to be used with appropriate motors, controllers, electrical protection components and other

equipment to form complete end products or systems. It is the responsibility of the installer to ensure that the design of the complete

machine, including its safety-related control system, is carried out in accordance with the requirements of the Machinery Directive and any

other relevant legislation. The use of a safety-related drive in itself does not ensure the safety of the machine. Compliance with safety and

EMC regulations depends upon installing and configuring drives correctly, including using the specified input filters. The drive must be

installed only by professional installers who are familiar with requirements for safety and EMC. The assembler is responsible for ensuring

that the end product or system complies with all relevant laws in the country where it is to be used. For more information regarding Safe

Torque Off, refer to the Product Documentation.

8 Unidrive M600 Control User Guide

Issue Number: 2

Safety

WARNING

CAUTION

NOTE

information

Product

information

Mechanical

installation

Electrical

installation

Getting

started

Basic

parameters

Running the

motor

Optimization

NV Media Card

Operation

Onboard

PLC

Advanced

parameters

Diagnostics

UL

Information

1 Safety information

1.1 Warnings, Cautions and Notes

A Warning contains information which is essential for

avoiding a safety hazard.

A Caution contains information which is necessary for

avoiding a risk of damage to the product or other equipment.

A Note contains information which helps to ensure correct operation of

the product.

1.2 Important safety information. Hazards.

This guide applies to products which control electric motors either

directly (drives) or indirectly (controllers, option modules and other

auxiliary equipment and accessories). In all cases the hazards

associated with powerful electrical drives are present, and all safety

information relating to drives and associated equipment must be

observed.

Specific warnings are given at the relevant places in this guide.

Drives and controllers are intended as components for professional

incorporation into complete systems. If installed incorrectly they may

present a safety hazard. The drive uses high voltages and currents,

carries a high level of stored electrical energy, and is used to control

equipment which can cause injury. Close attention is required to the

electrical installation and the system design to avoid hazards either in

normal operation or in the event of equipment malfunction. System

design, installation, commissioning/start-up and maintenance must be

carried out by personnel who have the necessary training and

competence. They must read this safety information and this guide

carefully.

1.3 Responsibility

It is the responsibility of the installer to ensure that the equipment is

installed correctly with regard to all instructions given in this guide. They

must give due consideration to the safety of the complete system, so as

to avoid the risk of injury both in normal operation and in the event of a

fault or of reasonably foreseeable misuse.

The manufacturer accepts no liability for any consequences resulting

from inappropriate, negligent or incorrect installation of the equipment.

1.4 Compliance with regulations

The installer is responsible for complying with all relevant regulations,

such as national wiring regulations, accident prevention regulations and

electromagnetic compatibility (EMC) regulations. Particular attention

must be given to the cross-sectional areas of conductors, the selection

of fuses or other protection, and protective ground (earth) connections.

This guide contains instructions for achieving compliance with specific

EMC standards.

All machinery to be supplied within the European Union in which this

product is used must comply with the following directives:

2006/42/EC Safety of machinery.

2014/30/EU: Electromagnetic Compatibility.

Competence of designers and

installers

1.5 Electrical hazards

The voltages used in the drive can cause severe electrical shock and/or

burns, and could be lethal. Extreme care is necessary at all times when

working with or adjacent to the drive. Hazardous voltage may be present

in any of the following locations:

• AC and DC supply cables and connections

• Output cables and connections

• Many internal parts of the drive, and external option units

Unless otherwise indicated, control terminals are single insulated and

must not be touched.

The supply must be disconnected by an approved electrical isolation

device before gaining access to the electrical connections.

The STOP and Safe Torque Off functions of the drive do not isolate

dangerous voltages from the output of the drive or from any external

option unit.

The drive must be installed in accordance with the instructions given in

this guide. Failure to observe the instructions could result in a fire

hazard.

1.6 Stored electrical charge

The drive contains capacitors that remain charged to a potentially lethal

voltage after the AC supply has been disconnected. If the drive has been

energized, the AC supply must be isolated at least ten minutes before

work may continue.

1.7 Mechanical hazards

Careful consideration must be given to the functions of the drive or

controller which might result in a hazard, either through their intended

behaviour or through incorrect operation due to a fault. In any application

where a malfunction of the drive or its control system could lead to or

allow damage, loss or injury, a risk analysis must be carried out, and

where necessary, further measures taken to reduce the risk - for

example, an over-speed protection device in case of failure of the speed

control, or a fail-safe mechanical brake in case of loss of motor braking.

With the sole exception of the Safe Torque Off function, none of the

drive functions must be used to ensure safety of personnel, i.e.

they must not be used for safety-related functions.

The Safe Torque Off function may be used in a safety-related

application. The system designer is responsible for ensuring that the

complete system is safe and designed correctly according to the

relevant safety standards.

The design of safety-related control systems must only be done by

personnel with the required training and experience. The Safe Torque

Off function will only ensure the safety of a machine if it is correctly

incorporated into a complete safety system. The system must be subject

to a risk assessment to confirm that the residual risk of an unsafe event

is at an acceptable level for the application.

1.8 Access to equipment

Access must be restricted to authorized personnel only. Safety

regulations which apply at the place of use must be complied with.

1.9 Environmental limits

Instructions in this guide regarding transport, storage, installation and

use of the equipment must be complied with, including the specified

environmental limits. This includes temperature, humidity,

contamination, shock and vibration. Drives must not be subjected to

excessive physical force.

1.10 Hazardous environments

The equipment must not be installed in a hazardous environment (i.e. a

potentially explosive environment).

Unidrive M600 Control User Guide 9

Issue Number: 2

Safety

information

Product

information

Mechanical

installation

Electrical

installation

Getting

started

Basic

parameters

Running the

1.11 Motor

The safety of the motor under variable speed conditions must be

ensured.

To avoid the risk of physical injury, do not exceed the maximum specified

speed of the motor.

Low speeds may cause the motor to overheat because the cooling fan

becomes less effective, causing a fire hazard. The motor should be

installed with a protection thermistor. If necessary, an electric forced vent

fan should be used.

The values of the motor parameters set in the drive affect the protection

of the motor. The default values in the drive must not be relied upon. It is

essential that the correct value is entered in the Motor Rated Current

parameter.

1.12 Mechanical brake control

Any brake control functions are provided to allow well co-ordinated

operation of an external brake with the drive. While both hardware and

software are designed to high standards of quality and robustness, they

are not intended for use as safety functions, i.e. where a fault or failure

would result in a risk of injury. In any application where the incorrect

operation of the brake release mechanism could result in injury,

independent protection devices of proven integrity must also be

incorporated.

1.13 Adjusting parameters

Some parameters have a profound effect on the operation of the drive.

They must not be altered without careful consideration of the impact on

the controlled system. Measures must be taken to prevent unwanted

changes due to error or tampering.

motor

Optimization

NV Media Card

Operation

Onboard

PLC

Advanced

parameters

Diagnostics

UL

Information

1.14 Electromagnetic compatibility (EMC)

Installation instructions for a range of EMC environments are provided in

the relevant Power Installation Guide. If the installation is poorly

designed or other equipment does not comply with suitable standards for

EMC, the product might cause or suffer from disturbance due to

electromagnetic interaction with other equipment. It is the responsibility

of the installer to ensure that the equipment or system into which the

product is incorporated complies with the relevant EMC legislation in the

place of use.

10 Unidrive M600 Control User Guide

Issue Number: 2

Safety

Identification Label

Electrical Specifications

Derivative

Unidrive M600

Product Line

Frame Size:

Voltage Rating :

Current Rating:

Heavy Duty current rating x10

Power Format:

Reserved

0

Optional Build

Customer Code

01

A B 1 00

Customer Code:

00 = 50 Hz

01 = 60 Hz

Reserved:

Conformal Coating:

0=Standard

IP / NEMA Rating:

1=IP20 / NEMA 1

Brake Transistor:

B=Brake

Cooling:

A=Air

Documentation

1

Documentation:

0 - Supplied separately

1 - English

2 - French

3 - Italian

4 - German

5 - Spanish

2 - 200 V (200 - 240

- 400 V (380 - 480

- 575 V (500 - 575

- 690 V (500 - 690

± 10 %)

4 ±

±

±

10 %)

510 %)

610 %)

Power

Format

M600 - 03 4 00078 A

Configuration*

1

A - AC inAC out (with internal choke)

D - DC in AC out (Inverter)

C - AC in DC out (Rectifier)

E - AC in AC out (without internal choke)

Configuration:

1 - Standard

U - No Control

M - Master

F - Follower

T - AC in AC out (12P rectifier plus inverter)

N = No brake

NOTE

information

Product

information

Mechanical

installation

Electrical

installation

Getting

started

Basic

parameters

Running the

motor

Optimization

NV Media Card

Operation

Onboard

PLC

Advanced

parameters

Diagnostics

UL

Information

2 Product information

2.1 Introduction

Universal AC and servo drive

Unidrive M600 delivers maximum machine performance with sensorless induction and sensorless permanent magnet motor control, for dynamic and

efficient machine operation. An optional encoder port can be used for precise closed loop velocity applications and digital lock / frequency following.

Features

• Universal high performance drive for induction and sensorless permanent magnet motors.

• Onboard IEC 61131-3 programmable automation

• NV Media Card for parameter copying and data storage

• EIA 485 serial communications interface

• Single channel Safe Torque Off (STO) input

Optional features

• Select up to three option modules

2.2 Drive firmware version

This product is supplied with the latest firmware version. If this drive is to be connected to an existing system or machine, all drive firmware versions

should be verified to confirm the same functionality as drives of the same model already present. This may also apply to drives returned from an

Nidec Industrial Automation Service Centre or Repair Centre. If there is any doubt please contact the supplier of the product.

The firmware version of the drive can be checked by looking at Pr 00.050 {11.029}.

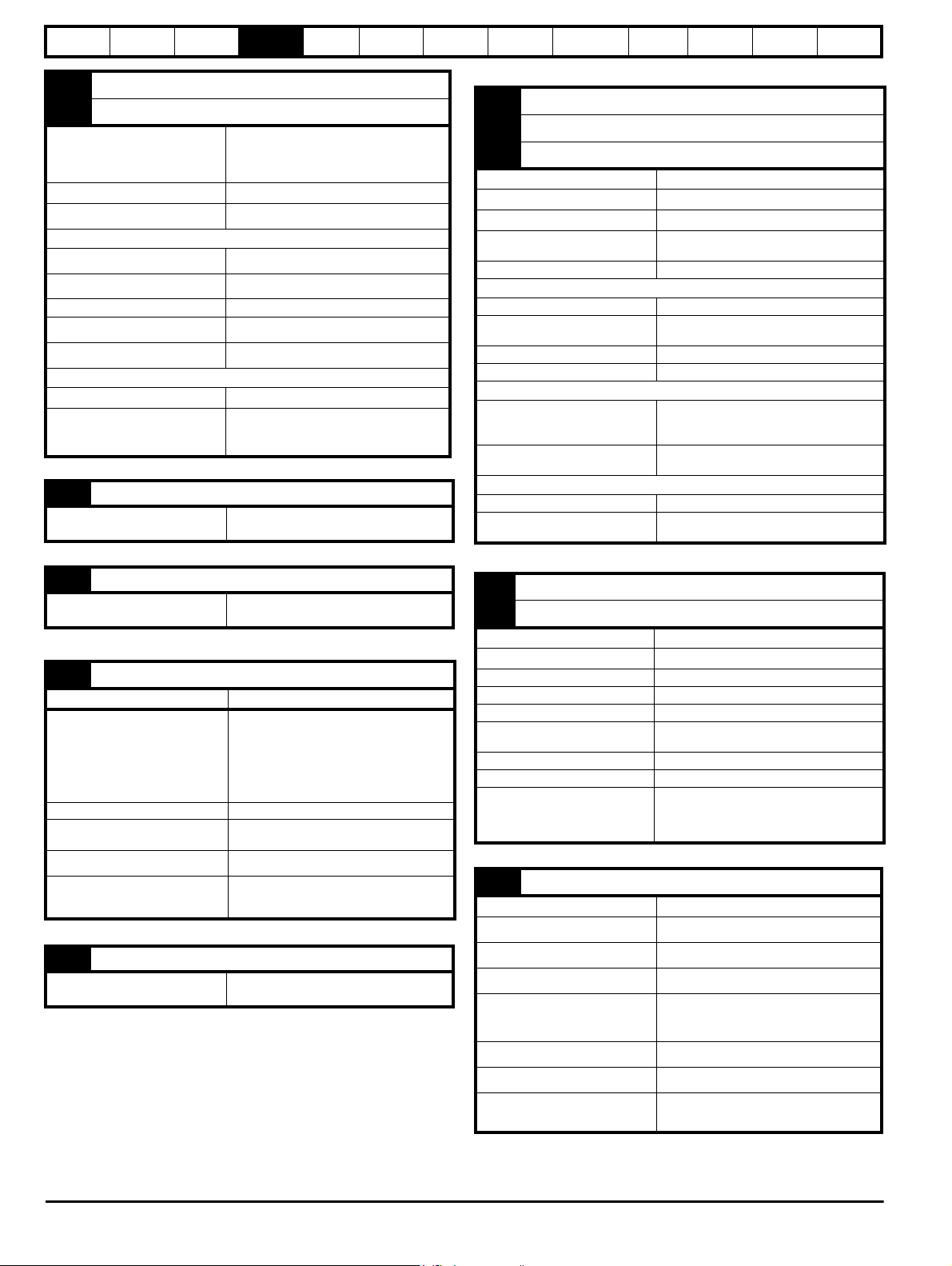

2.3 Model number

The way in which the model numbers for the Unidrive M600 range are formed is illustrated below:

Figure 2-1 Model number

* Only shown on Frame 9 to 11 identification label.

For simplicity, a Frame 9 drive with no internal choke (i.e. model 09xxxxxxE) is referred to as a Frame 9E and a Frame 9 drive with an internal choke

(i.e. model 09xxxxxxA) is referred to as a Frame 9A. Any reference to Frame 9 is applicable to both sizes 9E and 9A.

Unidri ve M600 Control User Guide 11

Issue Number: 2

Safety

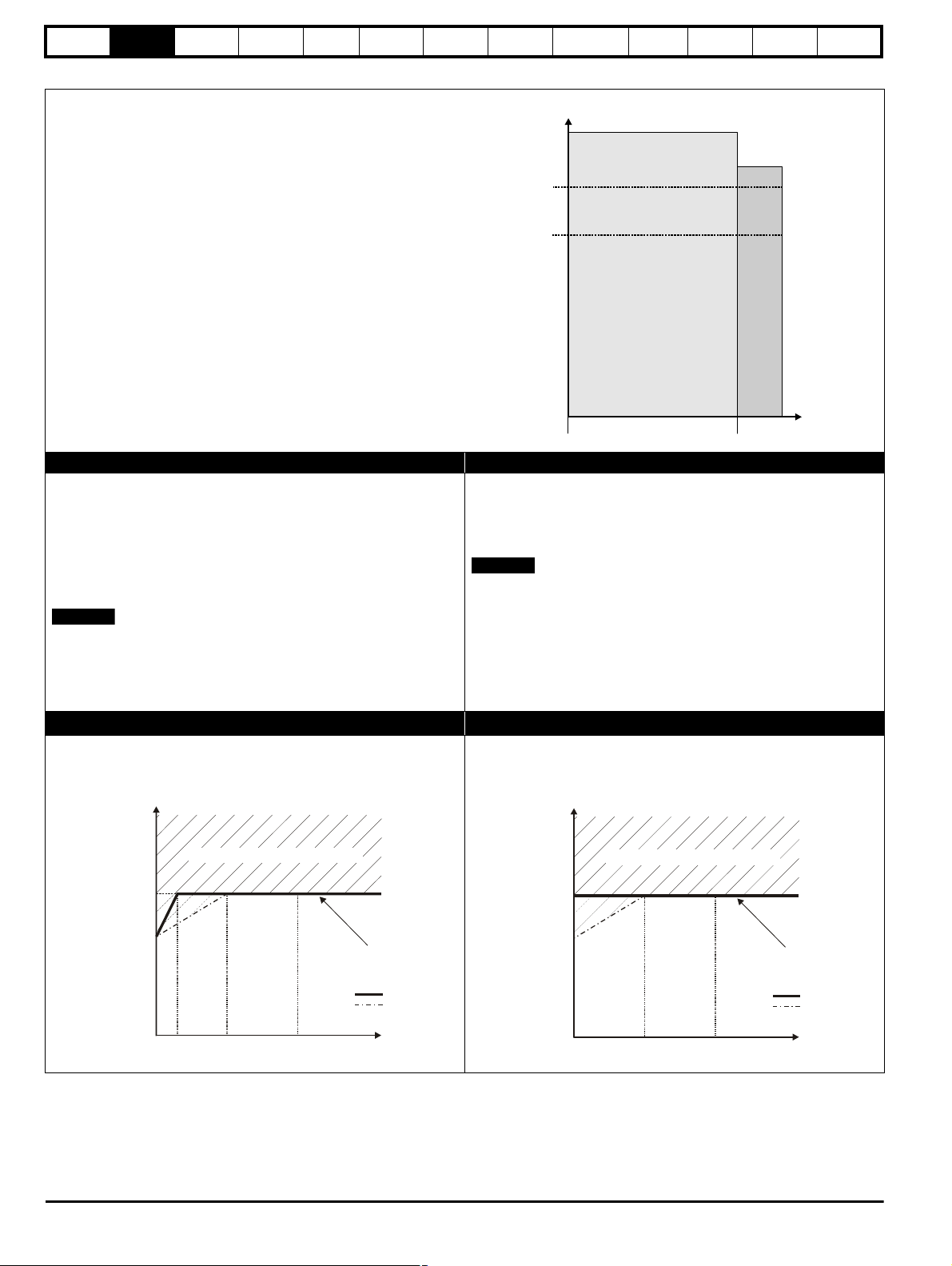

Available output

current

Overload limit -

Heavy Duty

Maximum

continuous

current (above

50% base

speed) -

Normal Duty

Maximum

continuous

current -

Heavy Duty

Motor rated

current set

in the drive

Heavy Duty

- with high

overload capability

Normal Duty

Overload limit -

Normal Duty

NOTE

NOTE

Motor total

current (Pr 04.001)

as a percentage

of motor rated

current

Motor speed as a

percentage of base speed

100%

Max. permissible

continuous

current

100%

I t protection operates in this region

2

70%

50%15%

Pr = 0

Pr = 1

04.025

04.025

Motor total

current (Pr 04.001)

as a percentage

of motor rated

current

Motor speed as a

percentage of base speed

100%

Max. permissible

continuous

current

100%

I t protection operates in this region

2

70%

50%

Pr = 0

Pr = 1

04.025

04.025

information

Product

information

Mechanical

installation

Electrical

installation

Getting

started

Basic

parameters

Running the

motor

Optimization

NV Media Card

Operation

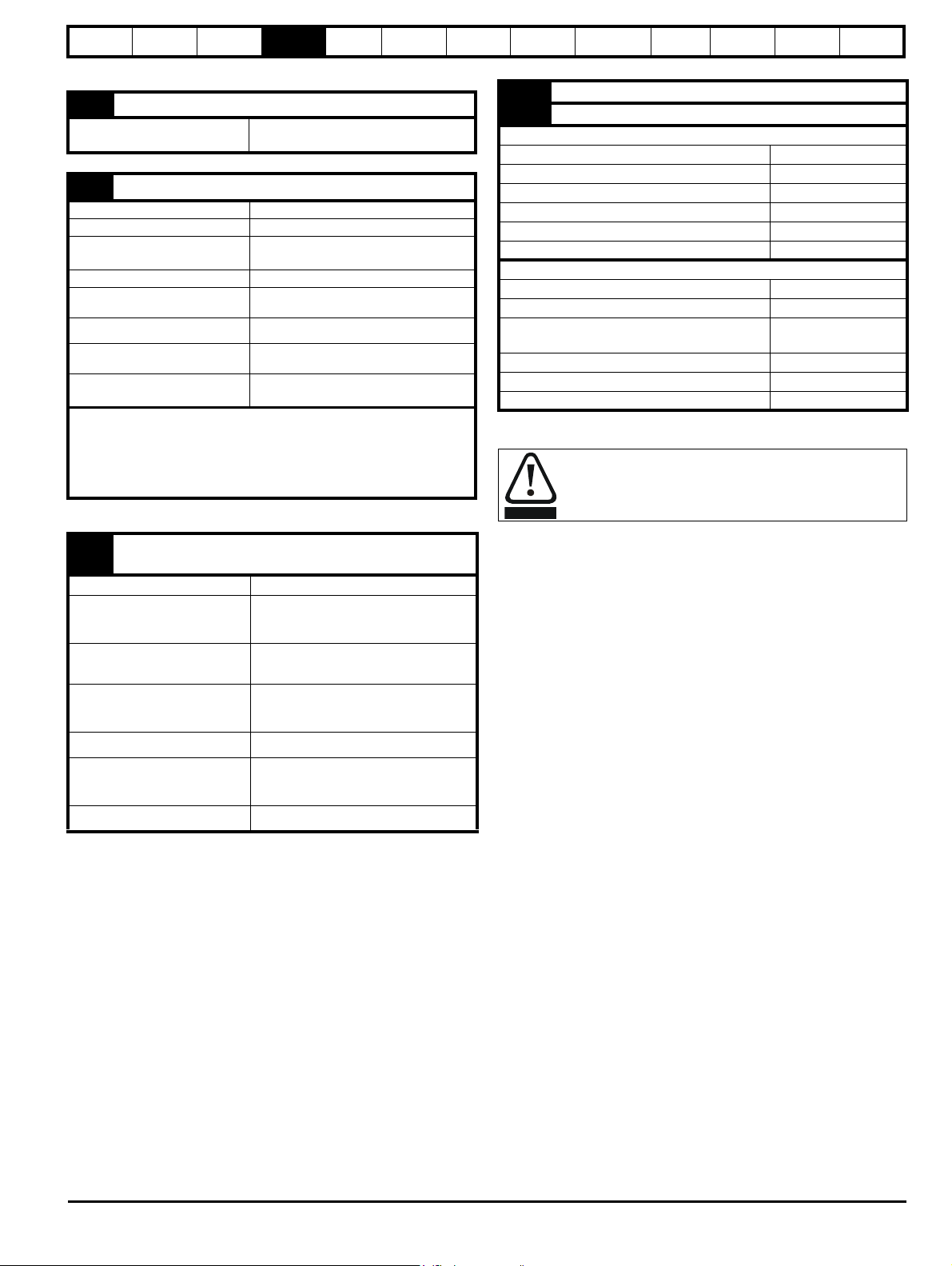

2.4 Ratings

The drive is dual rated.

The setting of the motor rated current determines which rating applies Heavy Duty or Normal Duty.

The two ratings are compatible with motors designed to IEC60034.

The graph aside illustrates the difference between Normal Duty and

Heavy Duty with respect to continuous current rating and short term

overload limits.

Normal Duty Heavy Duty (default)

For applications which use Self ventilated (TENV/TEFC) induction

motors and require a low overload capability, and full torque at low

speeds is not required (e.g. fans, pumps).

Self ventilated (TENV/TEFC) induction motors require increased

protection against overload due to the reduced cooling effect of the fan

at low speed. To provide the correct level of protection the I

2

t software

operates at a level which is speed dependent. This is illustrated in the

graph below.

The speed at which the low speed protection takes effect can be

changed by the setting of Low Speed Thermal Protection Mode

(04.025). The protection starts when the motor speed is below 15 % of

base speed when Pr 04.025 = 0 (default) and below 50 % when

Pr 04.025 = 1.

Operation of motor I2t protection

Motor I2t protection is fixed as shown below and is compatible with:

• Self ventilated (TENV/TEFC) induction motors

For constant torque applications or applications which require a high

overload capability, or full torque is required at low speeds (e.g. winders,

hoists).

The thermal protection is set to protect force ventilated induction motors

and permanent magnet servo motors by default.

N

If the application uses a self ventilated (TENV/TEFC) induction motor

and increased thermal protection is required for speeds below 50 %

base speed, then this can be enabled by setting Low Speed Thermal

Protection Mode (04.025) = 1.

Motor I2t protection defaults to be compatible with:

• Forced ventilation induction motors

• Permanent magnet servo motors

Onboard

PLC

Advanced

parameters

Diagnostics

UL

Information

.

12 Unidrive M600 Control User Guide

Issue Number: 2

Safety

information

Product

information

Mechanical

installation

Electrical

installation

Getting

started

Basic

parameters

Running the

motor

Optimization

NV Media Card

Operation

Onboard

PLC

Advanced

parameters

Diagnostics

UL

Information

2.5 Operating modes

The drive is designed to operate in any of the following modes:

Open loop mode

Open loop vector mode

Fixed V/F mode (V/Hz)

Quadratic V/F mode (V/Hz)

RFC - A

With position feedback sensor (requires optional SI-Encoder module)

Without position feedback sensor (Sensorless)

RFC - S

Without position feedback sensor (Sensorless)

Regen mode

2.5.1 Open loop mode

The drive applies power to the motor at frequencies varied by the user. The motor speed is a result of the output frequency of the drive and slip due

to the mechanical load. The drive can improve the speed control of the motor by applying slip compensation. The performance at low speed depends

on whether V/F mode or open loop vector mode is selected.

Open loop vector mode

The voltage applied to the motor is directly proportional to the frequency except at low speed where the drive uses motor parameters to apply the

correct voltage to keep the flux constant under varying load conditions.

Typically 100 % torque is available down to 1 Hz for a 50 Hz motor.

Fixed V/F mode

The voltage applied to the motor is directly proportional to the frequency except at low speed where a voltage boost is provided which is set by the

user. This mode can be used for multi-motor applications.

Typically 100 % torque is available down to 4 Hz for a 50 Hz motor.

Quadratic V/F mode

The voltage applied to the motor is directly proportional to the square of the frequency except at low speed where a voltage boost is provided which is

set by the user. This mode can be used for running fan or pump applications with quadratic load characteristics or for multi-motor applications. This

mode is not suitable for applications requiring a high starting torque.

2.5.2 RFC-A mode

Rotor Flux Control for Asynchronous (induction) motors (RFC-A) encompasses closed loop vector control with and without a position feedback

device.

With position feedback (requires optional SI-Encoder module)

For use with induction motors with a feedback device installed. The drive directly controls the speed of the motor using the feedback device to ensure

the rotor speed is exactly as demanded. Motor flux is accurately controlled at all times to provide full torque all the way down to zero speed.

Without position feedback (Sensorless)

Sensorless mode provides closed loop control without the need for position feedback by using current, voltages and key operating motor parameters

to estimate the motor speed. It can eliminate instability traditionally associated with open loop control such as operating large motors with light loads

at low frequencies.

2.5.3 RFC- S

Rotor Flux Control for Synchronous (permanent magnet brushless) motors (RFC-S) provides closed loop control without a position feedback device.

Without position feedback

For use with permanent magnet brushless motors without a feedback device installed.

Flux control is not required because the motor is self excited by the permanent magnets which form part of the rotor.

Full torque is available all the way down to zero speed, with salient motors.

2.5.4 Regen mode

For use as a regenerative front end for four quadrant operation.

Regen operation allows bi-directional power flow to and from the AC supply. This provides far greater efficiency levels in applications which would

otherwise dissipate large amounts of energy in the form of heat in a braking resistor.

The harmonic content of the input current is negligible due to the sinusoidal nature of the waveform when compared to a conventional bridge rectifier

or SCR/thyristor front end.

Unidri ve M600 Control User Guide 13

Issue Number: 2

Safety

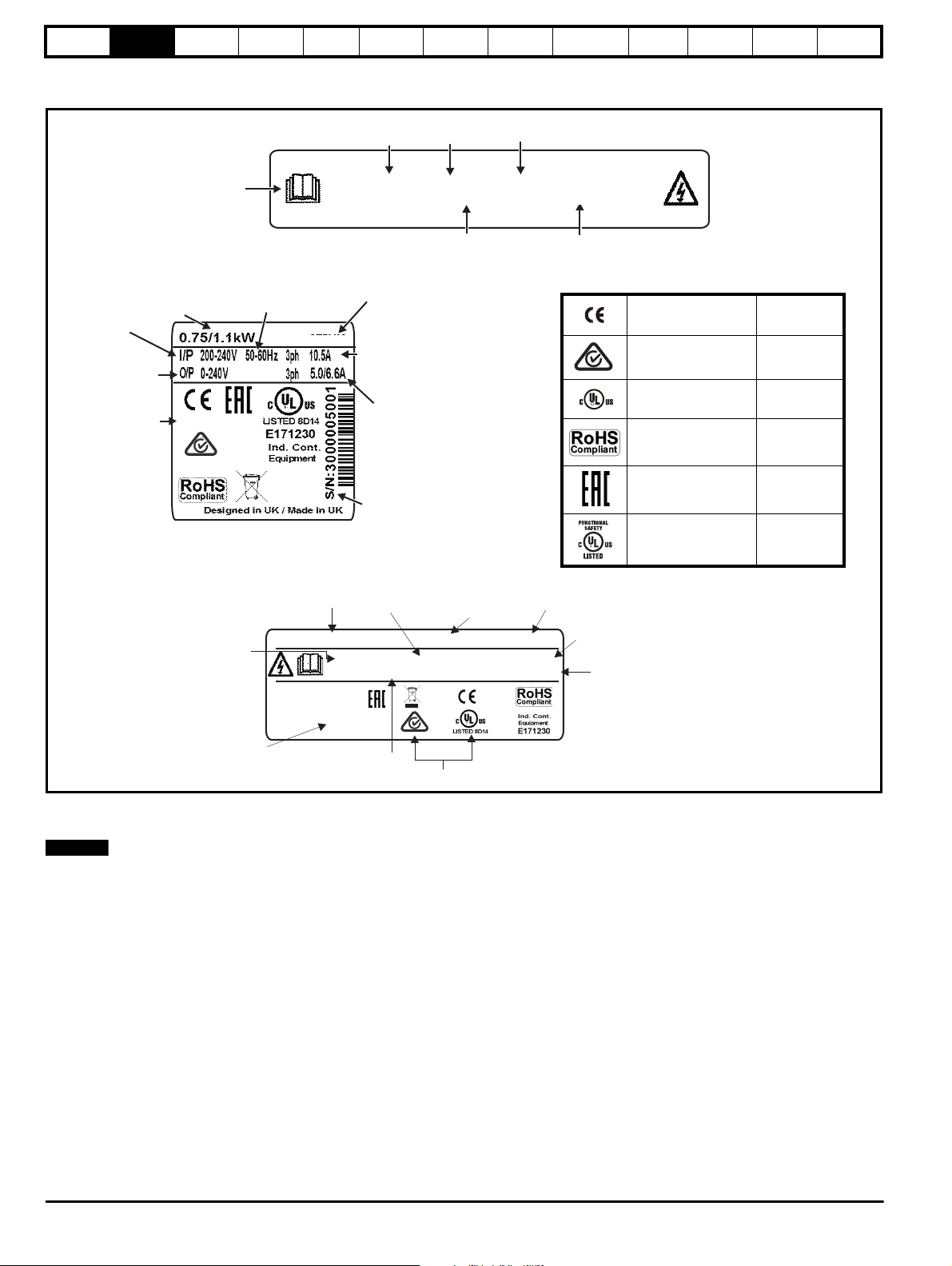

Refer to

User Guide

Model

Frame

size

Voltage

Heavy Duty

current rating

Drive format

M600-032 00050 A

Approvals

Output

voltage

Heavy Duty /

Normal Duty

power rating

Date code

Serial

number

Input

frequency

No.of phases &

Typical input current for

Normal Duty rating

Heavy Duty /

Normal Duty rating

output current

1710

M600-074-00660-A30/37kW 1710

I/P 380-480V 50-60Hz 3ph 74A

O/P 0-480V 3ph 66/79A

Designed in UK

Made in U.K.

Serial No: 3000005001

No. of Input phase &

Input current

No. of Output phase

&

Output current

Heavy Duty/

Normal Duty Rating

Model

Input

frequency

Heavy Duty /

Normal Duty

power rating

Date code

Approvals

Serial number

Input

voltage

Output

voltage

Large label*

Key to approvals

CE approval Europe

RCM - Regulatory

Compliance Mark

Australia

UL / cUL approval

USA &

Canada

RoHS compliant Europe

Eurasian conformity Eurasia

Functional safety

USA &

Canada

R

NOTE

information

Product

information

Mechanical

installation

Electrical

installation

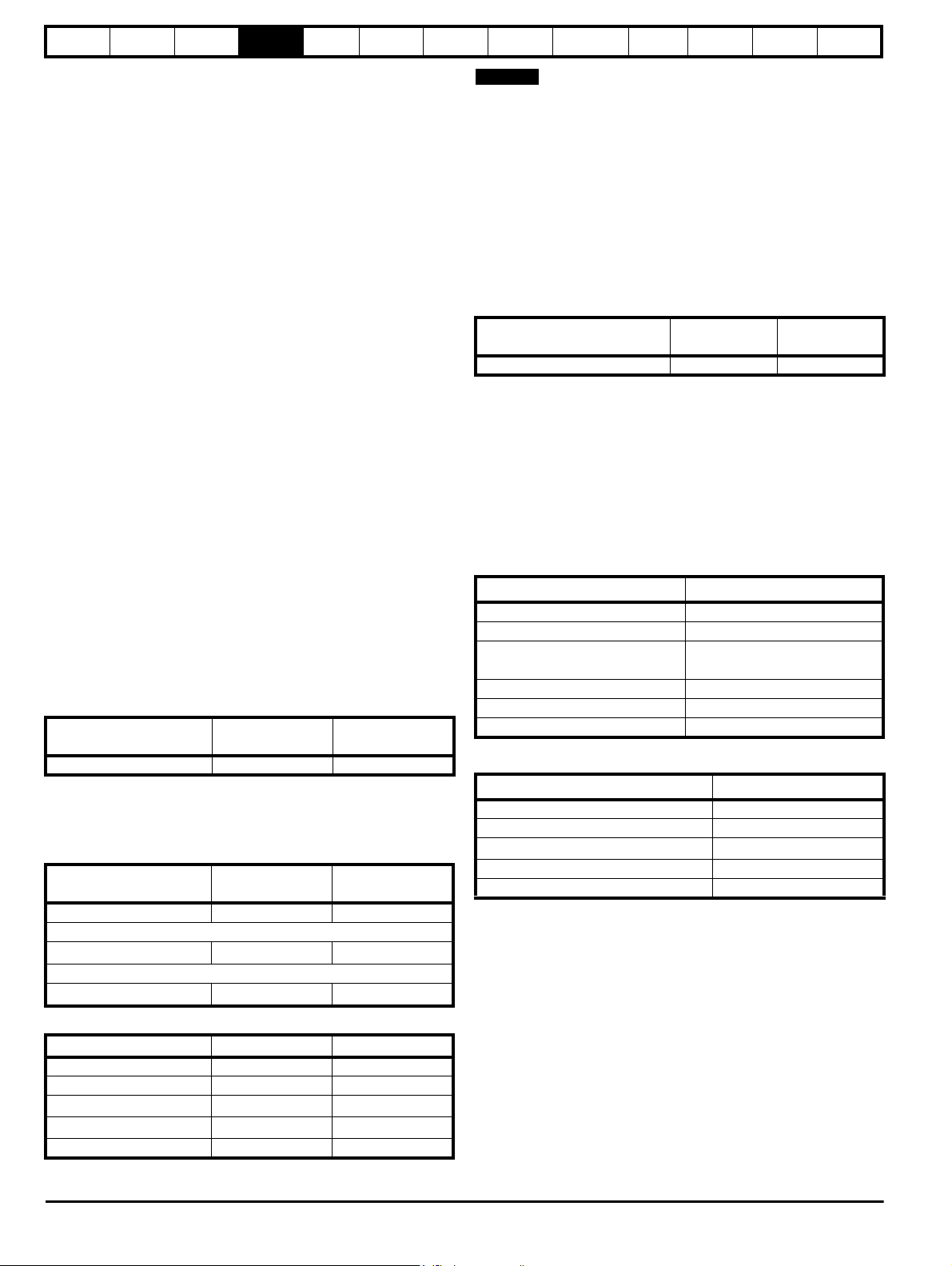

2.6 Nameplate description

Figure 2-2 Typical drive rating labels

Getting

started

Basic

parameters

Running the

motor

Optimization

NV Media Card

Operation

Onboard

PLC

Advanced

parameters

Diagnostics

UL

Information

* This label is only applicable to Size 7 and above.

Refer to Figure 2-1 Model number on page 11 for further information relating to the labels.

Date code format

The date code is four numbers. The first two numbers indicate the year and the remaining numbers indicate the week of the year in which the drive

was built.

Example:

A date code of 1710 would correspond to week 10 of year 2017.

14 Unidrive M600 Control User Guide

Issue Number: 2

Safety

8

WARN ING

information

Product

information

Mechanical

installation

Electrical

installation

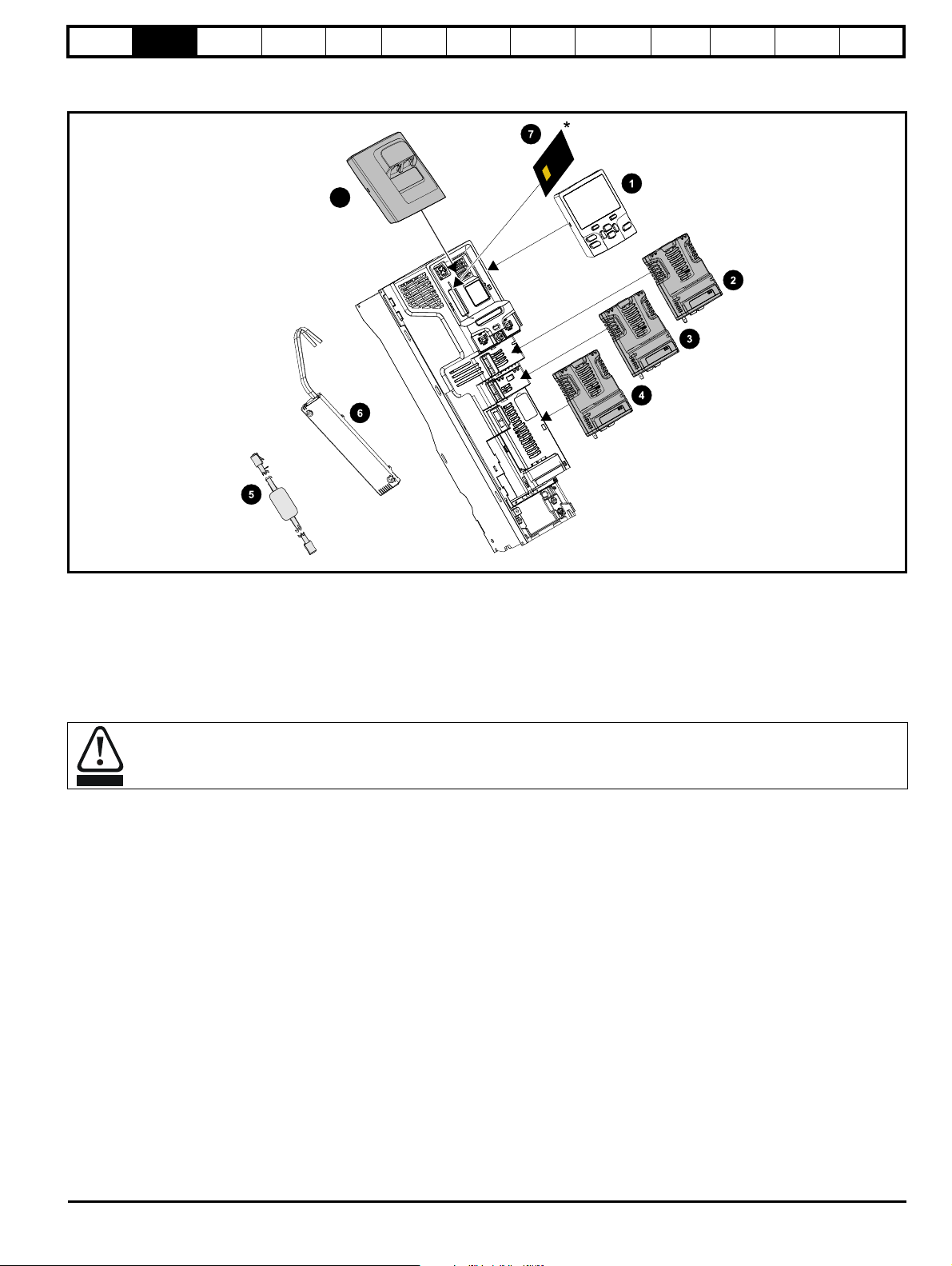

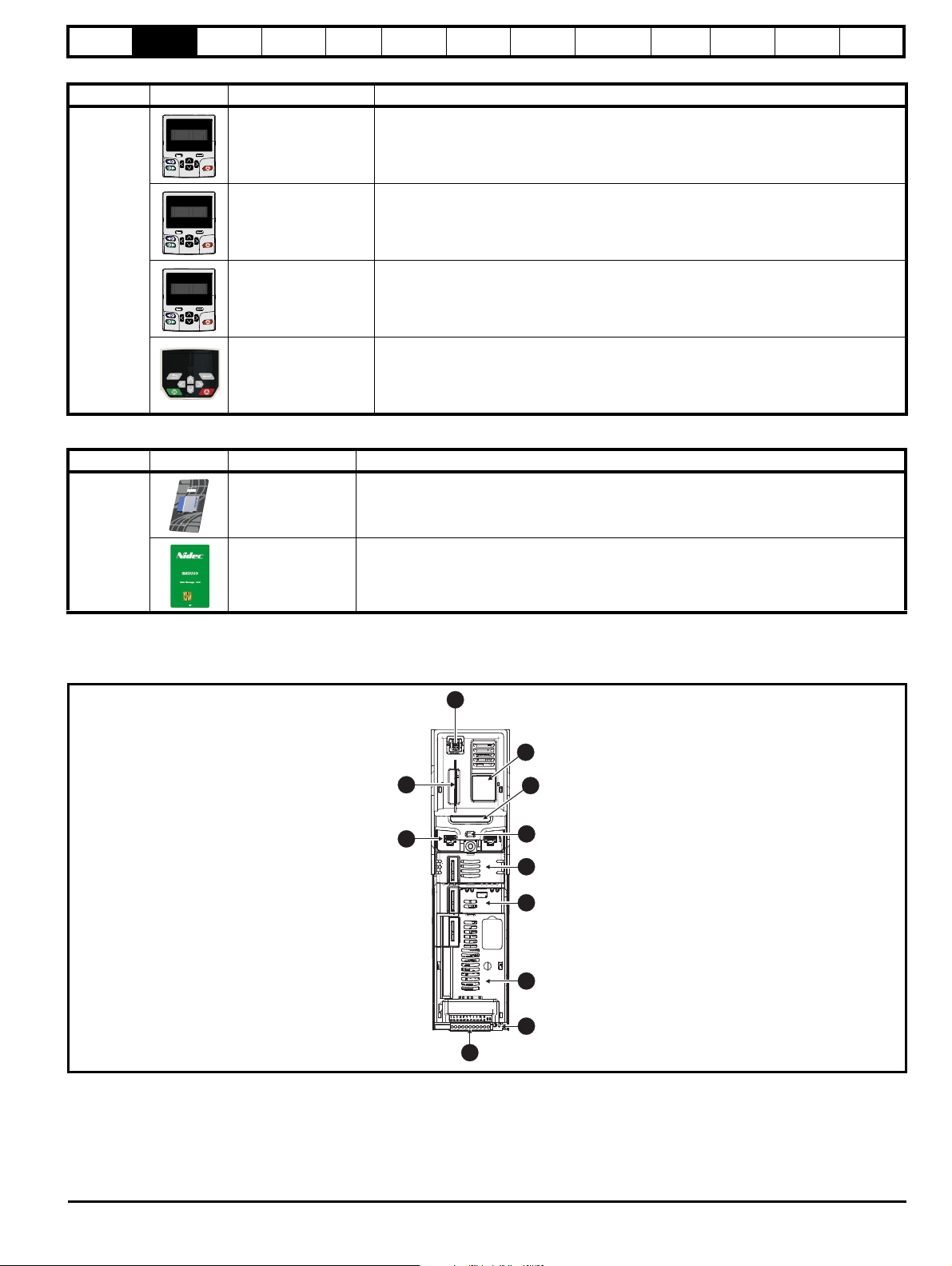

2.7 Options

Figure 2-3 Options available with the drive

Getting

started

Basic

parameters

Running the

motor

Optimization

NV Media Card

Operation

Onboard

PLC

Advanced

parameters

Diagnostics

UL

Information

1. Keypad

2. Option module slot 1

3. Option module slot 2

4. Option module slot 3

5. CT USB Comms cable

6. Internal braking resistor

7. NV media card (* For further information refer to chapter 8 NV Media Card Operation on page 99).

8. KI-485 comms adaptor

Be aware of possible live terminals when inserting or removing the NV media card.

Unidri ve M600 Control User Guide 15

Issue Number: 2

Safety

information

Product

information

Mechanical

installation

Electrical

installation

Getting

started

Basic

parameters

Running the

motor

Optimization

NV Media Card

Operation

Onboard

PLC

Advanced

parameters

Diagnostics

UL

Information

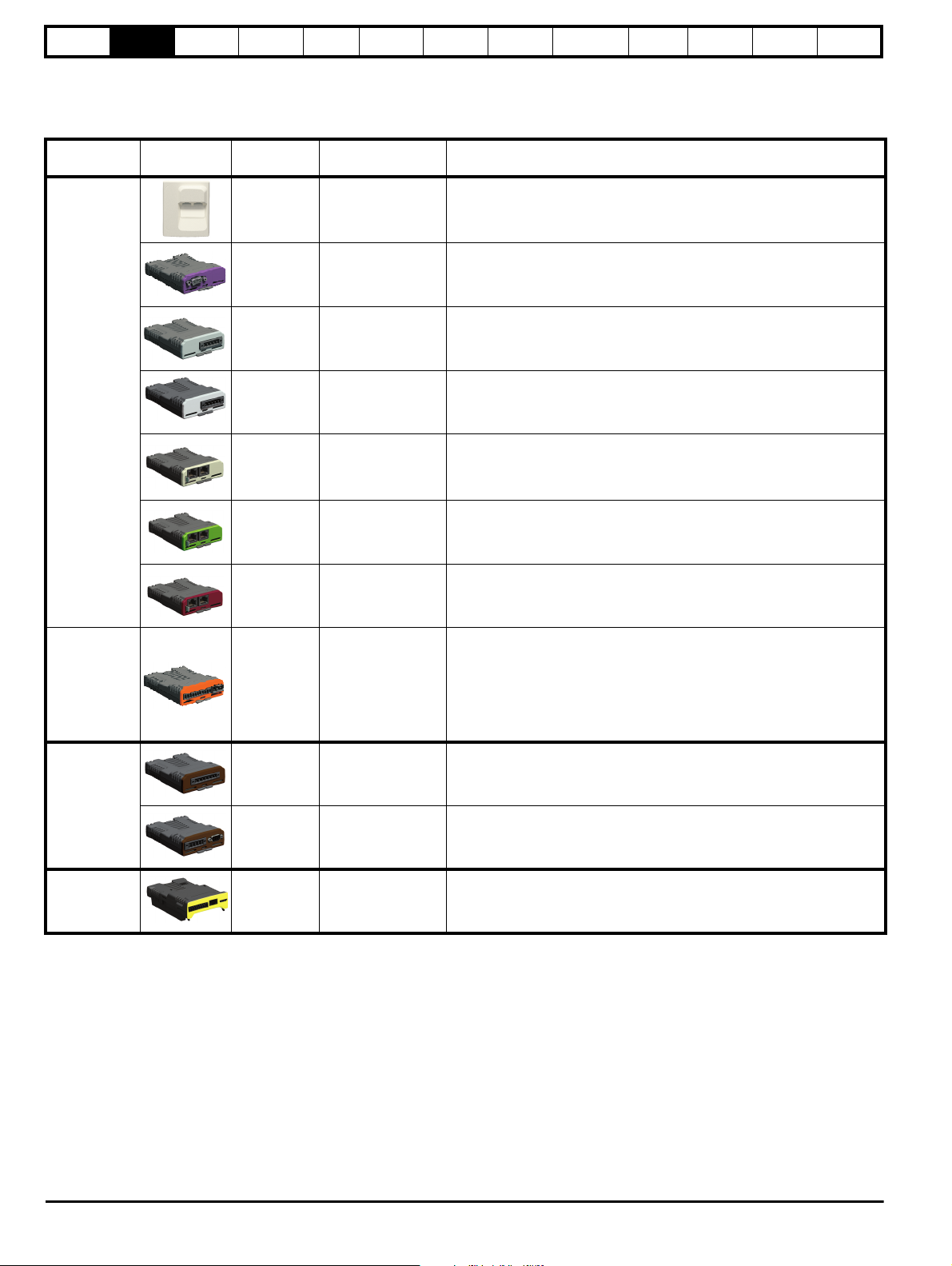

All standard option modules are color-coded in order to make identification easy. All modules have an identification label on top of the module.

Standard option modules can be installed to any of the available option slots on the drive. The following tables shows the color-code key and gives

further details on their function.

Table 2-1 Option module identification

Typ e

Option

module

Color Name Further Details

EIA 485 Comms Adaptor

N/A KI-485 Adaptor

EIA 485 Comms adaptor provides EIA 485 communication interface. This

adaptor supports 115 k Baud, node addresses between 1 to 16 and 8 1 NP M

serial mode.

Fieldbus

Automation

(I/O expansion)

Purple SI-PROFIBUS

Medium Grey SI-DeviceNet

Light Grey SI-CANopen

Beige SI-Ethernet

Yellow Green SI-PROFINET V2

Brown Red SI-EtherCAT

Orange SI-I/O

PROFIBUS option

PROFIBUS adapter for communications with the drive

DeviceNet option

DeviceNet adapter for communications with the drive

CANopen option

CANopen adapter for communications with the drive

External Ethernet module that supports EtherNet/IP, Modbus TCP/IP and

RTMoE. The module can be used to provide high speed drive access, global

connectivity and integration with IT network technologies, such as wireless

networking

PROFINET V2 option

PROFINET V2 adapter for communications with the drive

Note: PROFINET V2 replaces PROFINET RT.

EtherCAT option

EtherCAT adapter for communications with the drive

Extended I/O

Increases the I/O capability by adding the following combinations:

• Digital I/O

• Digital Inputs

• Analog Inputs (differential or single ended)

• Analog Output

• Relays

Light Brown SI-Encoder

Incremental encoder input interface module. Provides Closed loop Rotor

Flux Control for induction motors (RFC-A) on M600.

Feedback

Dark Brown SI-Universal Encoder

Safety Yellow SI-Safety

Additional combined encoder input and output interface supporting

Incremental, SinCos, HIPERFACE, EnDAT and SSI encoders.

Safety module that provides an intelligent, programmable solution to meet

the IEC 61800-5-2 functional safety standard

16 Unidrive M600 Control User Guide

Issue Number: 2

Safety

1

2

3

4

5

6

7

8

9

10

11

information

Product

information

Mechanical

installation

Electrical

installation

Getting

started

Basic

parameters

Running the

motor

Optimization

NV Media Card

Operation

Table 2-2 Keypad identification

Type Keypad Name Further Details

Onboard

PLC

Advanced

parameters

Diagnostics

UL

Information

KI-Keypad

LCD keypad option

Keypad with an LCD display

KI-Keypad RTC LCD keypad option

Keypad with an LCD display and real time clock

Keypad

Remote-Keypad RTC

Remote-Keypad

Remote LCD keypad option

Remote Keypad with an LCD display and real time clock

Remote LCD keypad option

Remote Keypad with an LCD display.

Table 2-3 Additional options

Type Option Name Further Details

SD Card Adaptor

SD Card Adaptor

Allows the drive to use an SD card for drive back-up

Back-up

SMARTCARD

SMARTCARD

Used for parameter back-up with the drive

2.8 Drive features

Figure 2-4 Features of the drive control section

Key

1. Keypad connection

4. Status LED 5. Option module slot 1 6. Option module slot 2

7. Option module slot 3 8. Relay connections 9. Control connections

10. Communications port 11. NV media card slot

2. Rating label 3. Identification label

Unidri ve M600 Control User Guide 17

Issue Number: 2

Safety

CAUTION

NOTE

information

Product

information

Mechanical

installation

Electrical

installation

Getting

started

Basic

parameters

Running the

motor

Optimization

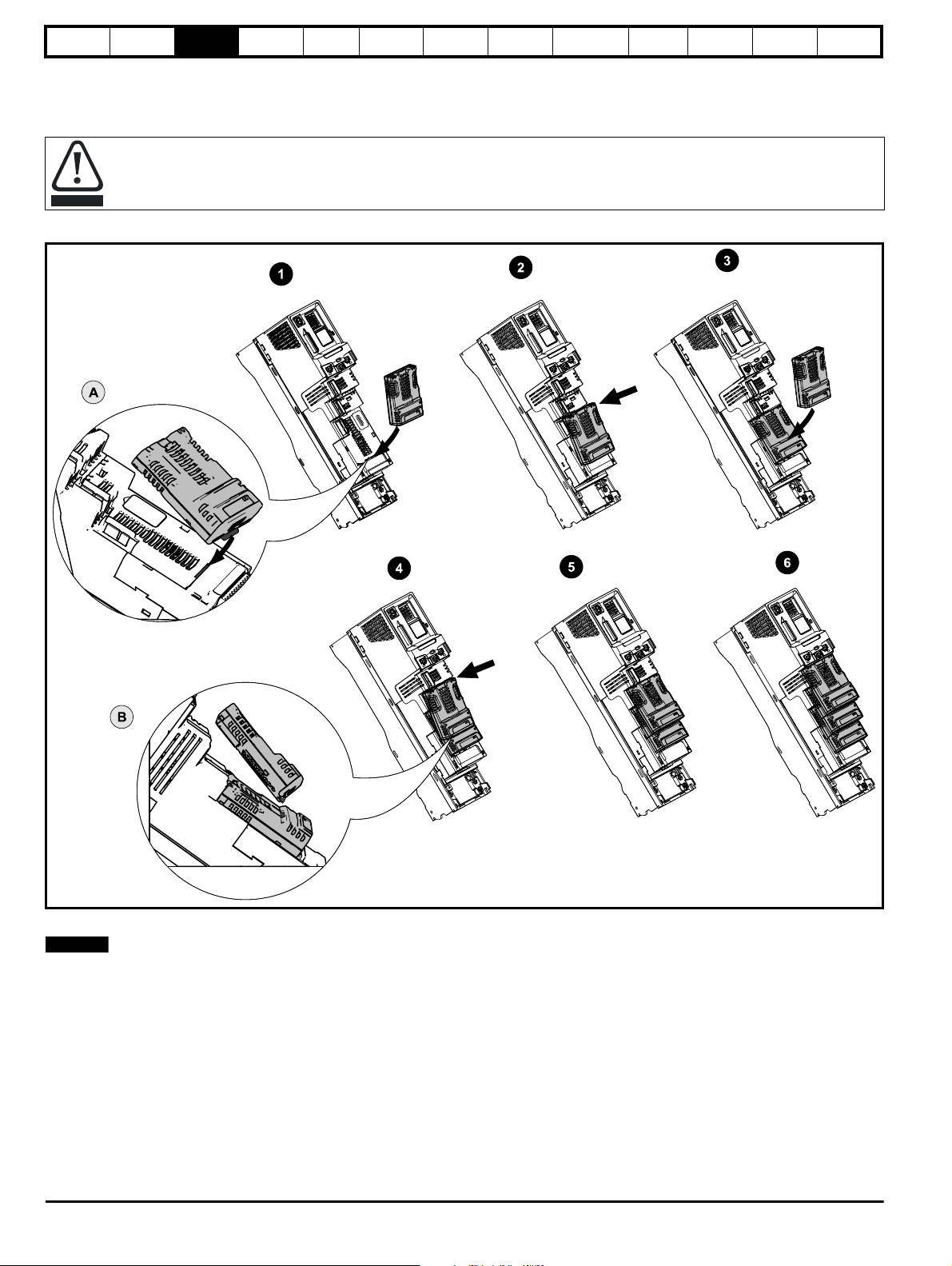

3 Mechanical installation

3.1 Installing / removing option modules and keypads

Power down the drive before installing / removing the option module. Failure to do so may result in damage to the product.

Figure 3-1 Installation of an option module

NV Media Card

Operation

Onboard

PLC

Advanced

parameters

Diagnostics

UL

Information

Installing the first option module

Option module slots must be used in the following order: slot 3, slot 2 and slot 1 (refer to Figure 2-3 Options available with the drive on page 15 for

slot numbers).

• Move the option module in direction shown (1).

• Align and insert the option module tab in to the slot provided (2), this is highlighted in the detailed view (A).

• Press down on the option module until it clicks into place.

Installing the second option module

• Move the option module in direction shown (3).

• Align and insert the option module tab in to the slot provided on the already installed option module (4), this is highlighted in the detailed view (B).

• Press down on the option module until it clicks into place. Image (5) shows two option modules fully installed.

Installing the third option module

• Repeat the above process.

The drive has the facility for all three option module slots to be used at the same time, image (6) shows the three option modules installed.

18 Unidrive M600 Control User Guide

Issue Number: 2

Safety

NOTE

information

Product

information

Mechanical

installation

Electrical

installation

Getting

started

Basic

parameters

Running the

motor

Optimization

NV Media Card

Operation

Onboard

PLC

Advanced

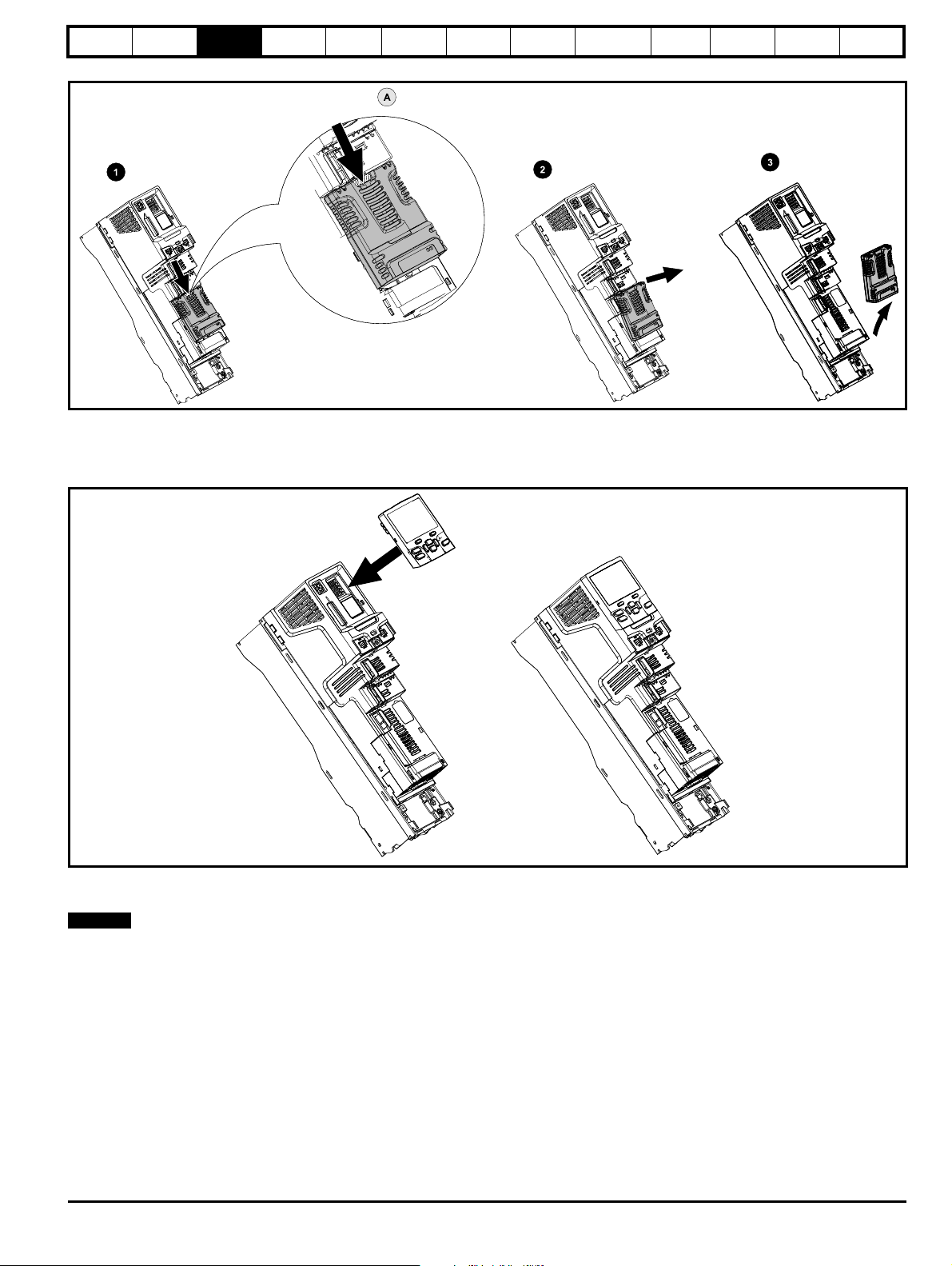

parameters

Figure 3-2 Removal of an option module

• Press down on the tab (1) to release the option module from the drive housing, the tab is highlighted in the detailed view (A).

• Tilt the option module towards you as shown (2).

• Totally remove the option module in direction shown (3).

Figure 3-3 Installation and removal of the KI-Keypad

Diagnostics

UL

Information

To install, align the keypad and press gently in the direction shown until it clicks into position.

To remove, reverse the installation instructions.

N

The keypad can be installed / removed while the drive is powered up and running a motor, providing that the drive is not operating in keypad mode.

Unidrive M600 Control User Guide 19

Issue Number: 2

Safety

NOTE

information

Product

information

Mechanical

installation

Electrical

installation

Getting

started

Basic

parameters

Running the

motor

Optimization

NV Media Card

Operation

Onboard

PLC

Advanced

parameters

Diagnostics

UL

Information

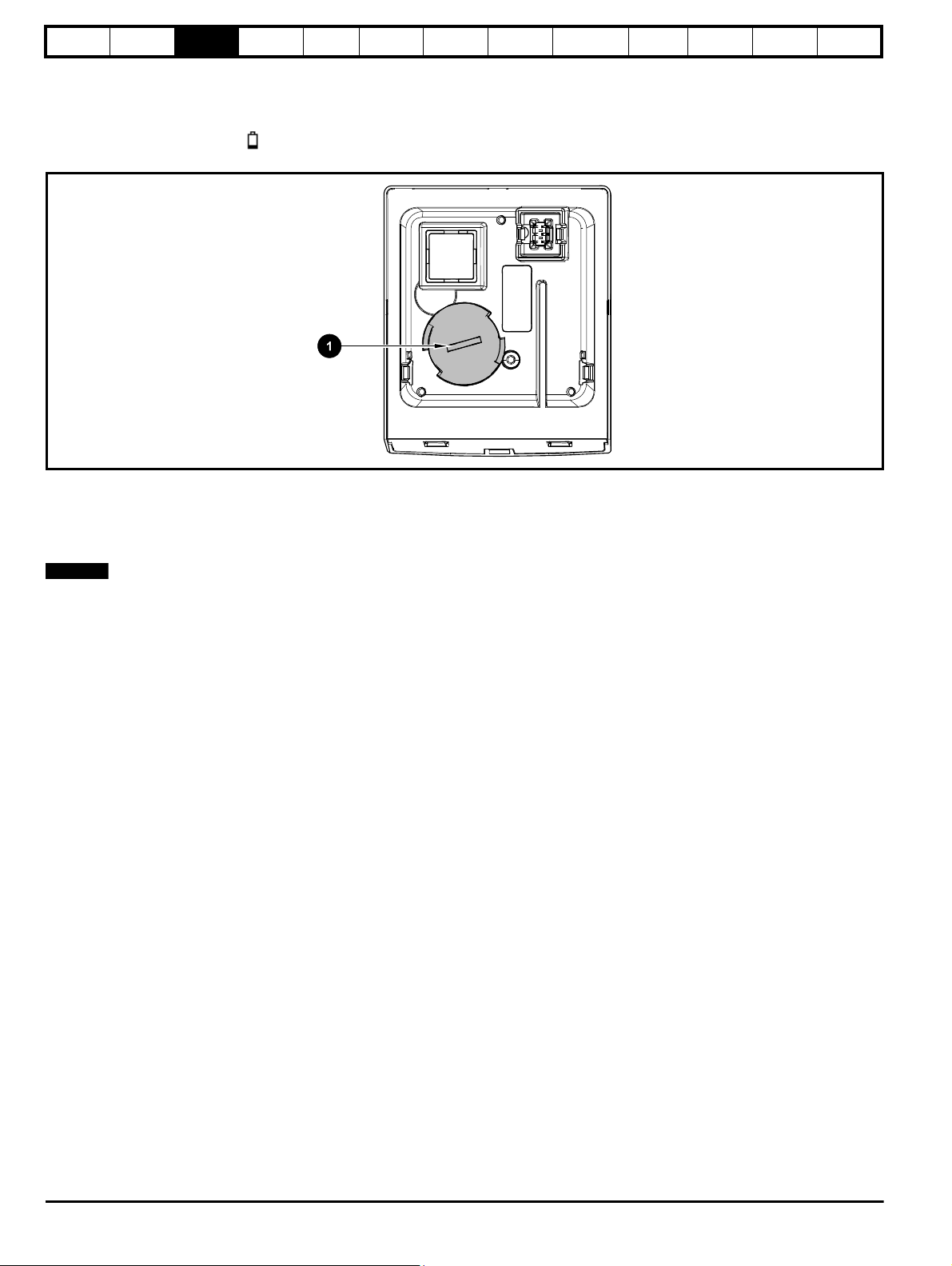

3.1.1 Real time clock battery replacement

Those keypads which have the real time clock feature contain a battery to ensure the clock works when the drive is powered down. The battery has a

long life time but if the battery needs to be replaced or removed, follow the instructions below.

Low battery voltage is indicated by

low battery symbol on the keypad display.

Figure 3-4 KI-Keypad RTC (rear view)

Figure 3-4 above illustrates the rear view of the KI-Keypad RTC.

1. To remove the battery cover insert a flat head screwdriver into the slot as shown (1), push and turn anti-clockwise until the battery cover is

released.

2. Replace the battery (the battery type is: CR2032).

3. Reverse point 1 above to replace battery cover.

Ensure the battery is disposed of correctly.

20 Unidrive M600 Control User Guide

Issue Number: 2

Safety

NOTE

515251

52

51 5251

52

51 5251

52

information

Product

information

Mechanical

installation

Electrical

installation

Getting

started

Basic

parameters

Running the

motor

Optimization

NV Media Card

Operation

Onboard

PLC

Advanced

parameters

Diagnostics

UL

Information

4 Electrical installation

4.1 24 Vdc supply

The 24 Vdc supply connected to control terminals 1 & 2 provides the

following functions:

• It can be used to supplement the drive's own internal 24 V supply

when multiple option modules are being used and the current drawn

by these module is greater than the drive can supply.

• It can be used as a back-up power supply to keep the control circuits

of the drive powered up when the line power supply is removed. This

allows any fieldbus modules, application modules, encoders or serial

communications to continue to operate.

• It can be used to commission the drive when the line power supply is

not available, as the display operates correctly. However, the drive

will be in the Under voltage state unless either line power supply or

low voltage DC operation is enabled, therefore diagnostics may not

be possible. (Power down save parameters are not saved when

using the 24 V back-up power supply input).

• If the DC bus voltage is too low to run the main SMPS in the drive,

then the 24 V supply can be used to supply all the low voltage power

requirements of the drive. Low Under Voltage Threshold Select

(06.067) must also be enabled for this to happen.

On size 6 and larger, the power 24 Vdc supply (terminals 51, 52) must

be connected to enable the 24 Vdc supply to be used as a backup

supply, when the line power supply is removed. If the power 24 Vdc

supply is not connected none of the above mentioned functions can be

used, "Waiting For Power System" will be displayed on the keypad and

no drive operations are possible. The location of the power 24 Vdc can

be identified from Figure 4-1 Location of the 24 Vdc power supply

connection on size 6 on page 21.

Table 4-1 24 Vdc Supply connections

The working voltage range of the control 24 V power supply is as

follows:

Nominal operating voltage 24.0 Vdc

Minimum continuous operating voltage 19.2 V

Maximum continuous operating voltage 28.0 V

Minimum start up voltage 21.6 V

Maximum power supply requirement at 24 V 40 W

Recommended fuse 3 A, 50 Vdc

Minimum and maximum voltage values include ripple and noise. Ripple

and noise values must not exceed 5 %.

Function Sizes 3-5 Sizes 6-11

Supplement the drive’s

internal supply

Back-up supply for the

control circuit

Terminal

1, 2

Terminal

1, 2

1 0V common

2 +24 Vdc

Terminal

1, 2

Terminal

1, 2

51, 52

The working range of the 24 V power supply is as follows:

51 0V common

52 +24 Vdc

Size 6

Nominal operating voltage 24.0 Vdc

Minimum continuous operating voltage 18.6 Vdc

Maximum continuous operating voltage 28.0 Vdc

Minimum startup voltage 18.4 Vdc

Maximum power supply requirement 40 W

Recommended fuse 4 A @ 50 Vdc

Size 7 to 11

Nominal operating voltage 24.0 Vdc

Minimum continuous operating voltage 19.2 Vdc

Maximum continuous operating voltage

30 Vdc (IEC),

26 Vdc (UL)

Minimum startup voltage 21.6 Vdc

Maximum power supply requirement 60 W

Recommended fuse 4 A @ 50 Vdc

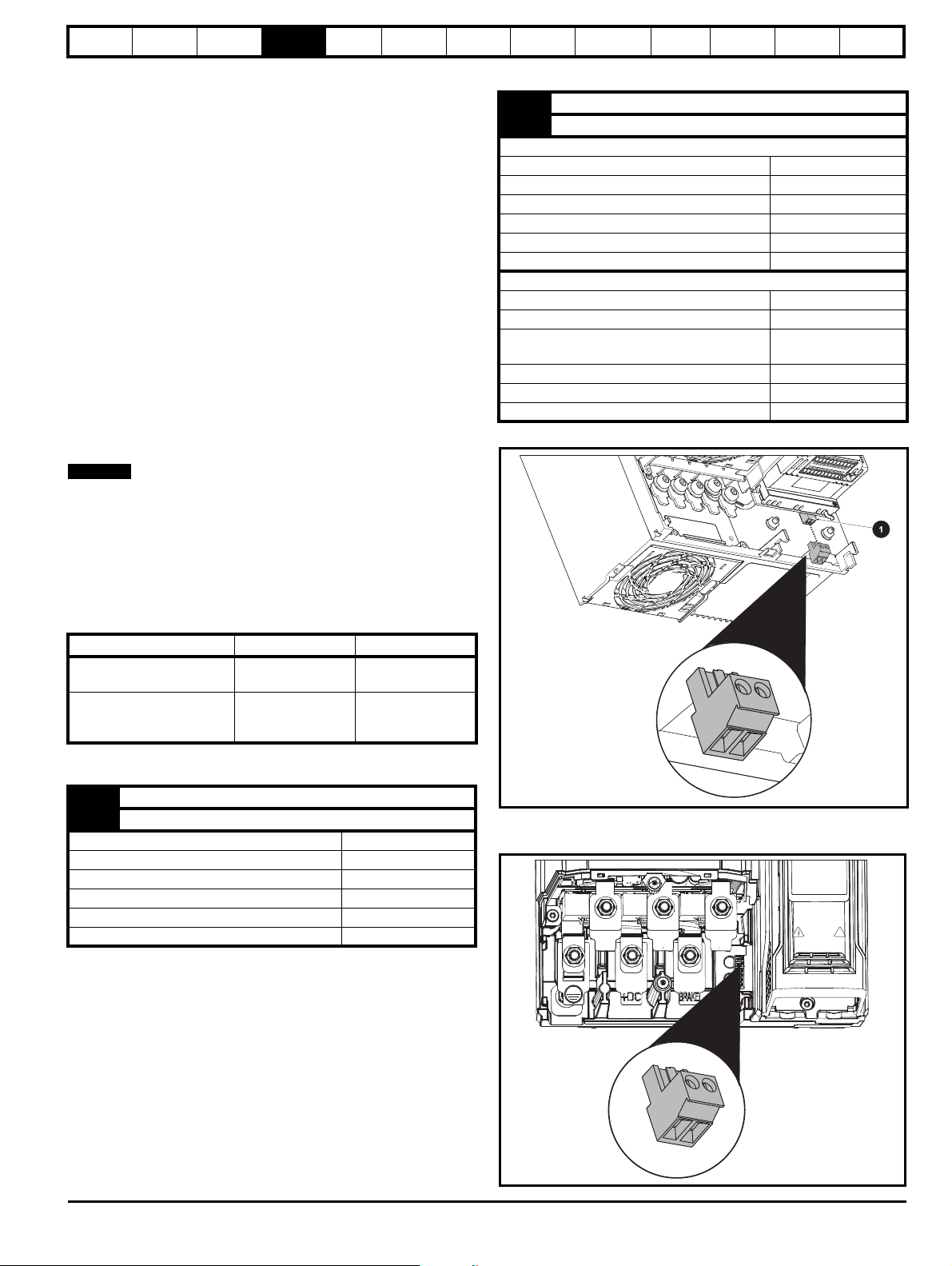

Figure 4-1 Location of the 24 Vdc power supply connection on size 6

1. 24 Vdc power supply connection

Figure 4-2 Location of the 24 Vdc power supply connection on size 7

Unidrive M600 Control User Guide 21

Issue Number: 2

Safety

51 5251

52

1 1

8

8

NOTE

CAUTION

WARNING

information

Product

information

Mechanical

installation

Electrical

installation

Getting

started

Basic

parameters

Running the

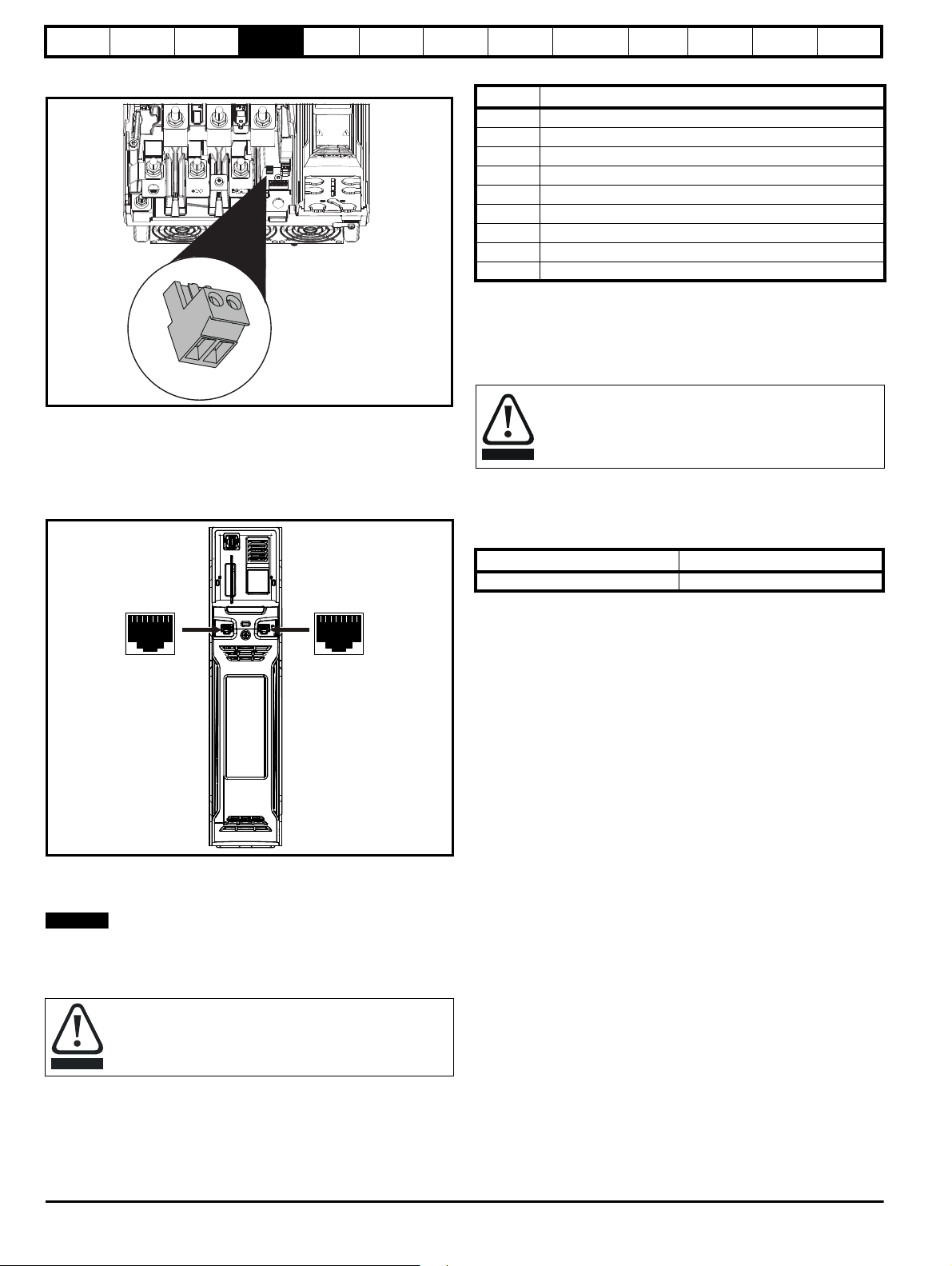

Figure 4-3 Location of the 24 Vdc power supply connection on size 8

to 11

4.2 Communication connections

The drive offers a 2 wire EIA 485 interface. This enables the drive setup, operation and monitoring to be carried out with a PC or controller if

required.

Figure 4-4 Location of the comms connectors

motor

Optimization

NV Media Card

Operation

Onboard

PLC

Advanced

parameters

Diagnostics

Table 4-2 Serial communication port pin-outs

Pin Function

1 120 Ω Termination resistor

2RX TX

3 Isolated 0 V

4 +24 V (100 mA)

5 Isolated 0 V

6 TX enable

7RX\ TX\

8 RX\ TX\ (if termination resistors are required, link to pin 1)

Shell Isolated 0 V

Minimum number of connections are 2, 3, 7 and shield.

4.2.1 Isolation of the EIA 485 serial communications port

The serial PC communications port is double insulated and meets the

requirements for SELV in EN 50178:1998.

In order to meet the requirements for SELV in IEC60950 (IT

equipment) it is necessary for the control computer to be

grounded. Alternatively, when a lap-top or similar device is

used which has no provision for grounding, an isolation

device must be incorporated in the communications lead.

An isolated serial communications lead has been designed to connect

the drive to IT equipment (such as laptop computers), and is available

from the supplier of the drive. See below for details:

Table 4-3 Isolated serial comms lead details

Part number Description

4500-0096 CT USB Comms cable

The “isolated serial communications” lead has reinforced insulation as

defined in IEC60950 for altitudes up to 3,000 m.

4.2.2 Communication networks and cabling

Any isolated signal circuit has the capability to become live through

accidental contact with other conductors; as such they should always be

double-insulated from live parts. The routing of network and signal wires

should be done so as to avoid close proximity to mains voltage cabling.

UL

Information

The EIA 485 interface provides two parallel RJ45 connectors, these are

provided allowing easy daisy chaining. The drive only supports Modbus

RTU protocol. See Table 4-2 for the connection details.

Standard Ethernet cables are not recommended for use when

connecting drives on a EIA 485 network as they do not have the correct

twisted pairs for the pinout of the serial comms port.

If an Ethernet network adaptor is inadvertently connected to

a Unidrive M600 drive, a low impedance load across the EIA

485 24V is applied. If this is connected for a significant period

of time, it can introduce the potential risk of damage.

22 Unidrive M600 Control User Guide

Issue Number: 2

Safety

WARNING

WARNING

CAUTION

CAUTION

NOTE

NOTE

NOTE

NOTE

Analog Input 1+

Analog Input 3

0V

Analog Input 1-

5

8

11

6

information

Product

information

Mechanical

installation

Electrical

installation

Getting

started

Basic

parameters

Running the

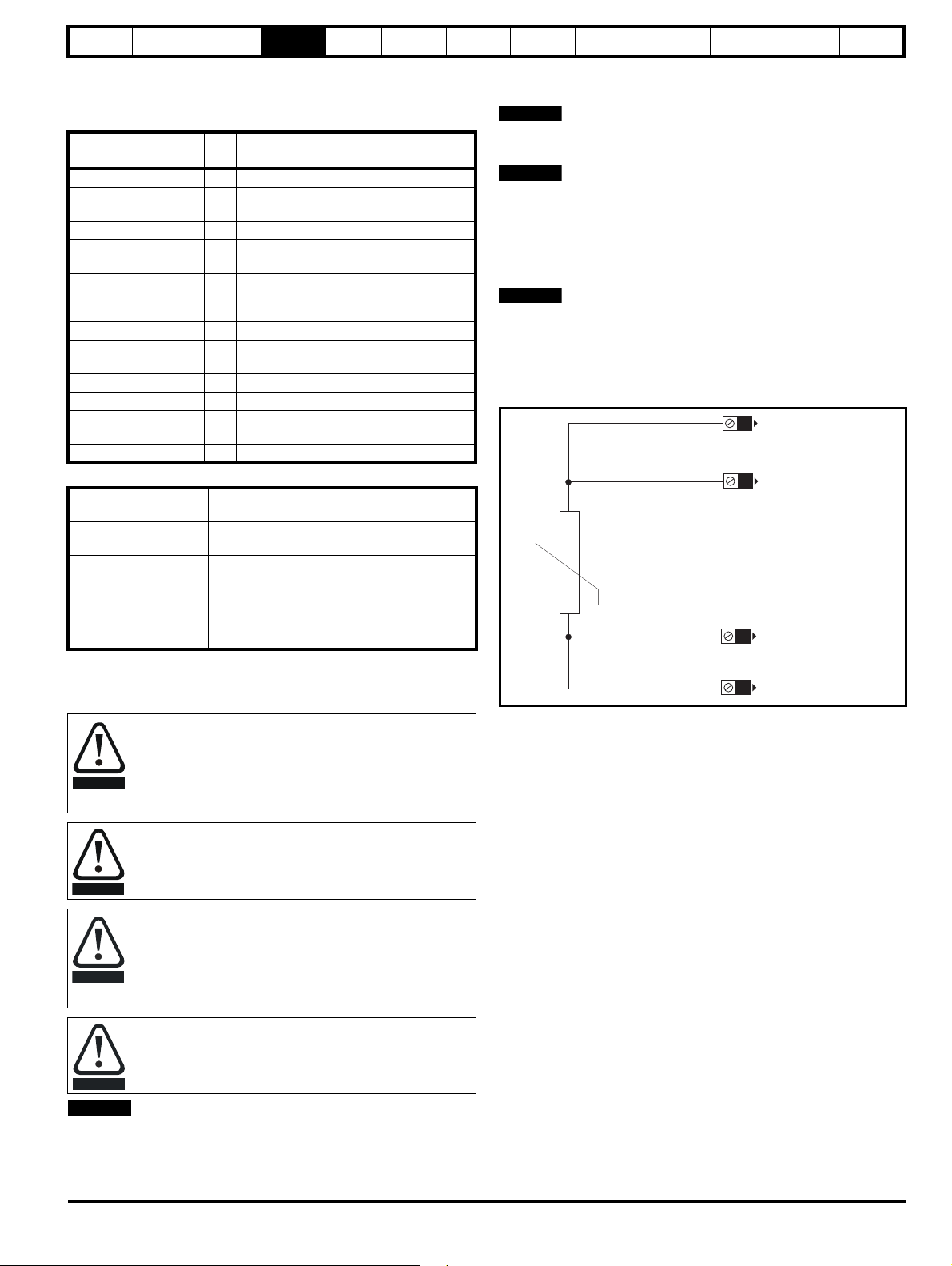

4.3 Control connections

4.3.1 General

Table 4-4 The control connections consist of:

Function Qty

Control parameters

available

Differential analog input 1 Mode, offset, invert, scaling 5, 6

Single ended analog

input

Mode, offset, invert, scaling,

2

destination

Analog output 2 Source, scaling, 9, 10

Digital input 3

Destination, invert, logic

select

Input / output mode select,

Digital input / output 3

destination / source, invert,

logic select

Relay 1 Source, invert 41, 42

Drive enable (Safe

Tor q u e O ff )

131

+10 V User output 1 4

+24 V User output 1 Source, invert 22

0V common 6

+24V External input 1 Destination, invert 2

Key:

Destination parameter:

Source parameter:

Indicates the parameter which is being controlled

by the terminal / function

Indicates the parameter being output by the

terminal

Analog - indicates the mode of operation of the

terminal, i.e. voltage 0-10 V, current 4-20 mA etc.

Mode parameter:

Digital - indicates the mode of operation of the

terminal, i.e. positive / negative logic (the Drive

Enable terminal is fixed in positive logic), open

collector.

All analog terminal functions can be programmed in menu 7.

All digital terminal functions (including the relay) can be programmed in

menu 8.

The control circuits are isolated from the power circuits in the

drive by basic insulation (single insulation) only. The installer

must ensure that the external control circuits are insulated

from human contact by at least one layer of insulation

(supplementary insulation) rated for use at the AC supply

voltage.

Ter mina l

number

7, 8

27, 28, 29

24, 25, 26

1, 3, 11, 21,

23, 30

motor

Optimization

NV Media Card

Operation

Onboard

PLC

Advanced

parameters

Diagnostics

ground close to the point of exit of the motor cable, to avoid this noise

current spreading through the control system.

N

The Safe Torque Off drive enable terminal is a positive logic input only. It

is not affected by the setting of Input Logic Polarity (08.029).

N

The common 0 V from analog signals should, wherever possible, not be

connected to the same 0 V terminal as the common 0 V from digital

signals. Terminals 3 and 11 should be used for connecting the 0V

common of analog signals and terminals 21, 23 and 30 for digital

signals. This is to prevent small voltage drops in the terminal

connections causing inaccuracies in the analog signals.

N

A two wire motor thermistor can be connected to analog input 3 by

connecting the thermistor between terminal 8 and any 0 V common

terminal. It is also possible to connect a 4-wire thermistor to analog input

3 as shown below. Pr 07.015 and Pr 07.046 need to be set-up for the

thermistor type required.

Figure 4-5 Connection of 4-wire thermistor

UL

Information

If the control circuits are to be connected to other circuits

classified as Safety Extra Low Voltage (SELV) (e.g. to a

personal computer), an additional isolating barrier must be

included in order to maintain the SELV classification.

If any of the digital inputs (including the drive enable input)

are connected in parallel with an inductive load (i.e.

contactor or motor brake) then suitable suppression (i.e.

diode or varistor) should be used on the coil of the load. If no

suppression is used then over voltage spikes can cause

damage to the digital inputs and outputs on the drive.

Ensure the logic sense is correct for the control circuit to be

used. Incorrect logic sense could cause the motor to be

started unexpectedly.

Positive logic is the default state for the drive.

N

Any signal cables which are carried inside the motor cable (i.e. motor

thermistor, motor brake) will pick up large pulse currents via the cable

capacitance. The shield of these signal cables must be connected to

Unidrive M600 Control User Guide 23

Issue Number: 2

Safety

1

11

Polarized

connectors

21 31

41

42

0V common**

External 24V supply

0V common**

Analog frequency/speed

reference 1

Connections for

single-ended input

signal

Connections for

differential input signal

0V common**

0V common**

0V common**

Analog input 2

Analog input 1

0V common**

1

2

5

6

3

5

6

3

21

22

23

24

25

26

27

28

29

30

31

41

42

At zero speed

Reset

Run forward

Run reverse

Analog input 1/

input 2 select

Jog forward select

SAFE TORQUE OFF /

Drive enable*

Relay

(Over voltage

category II)

Drive OK

Speed / frequency

0V common**

Analog

frequency/speed

reference 2

4

7

11

9

10

8

Torque (active

current)

Analog input 3

information

Product

information

Mechanical

installation

Electrical

installation

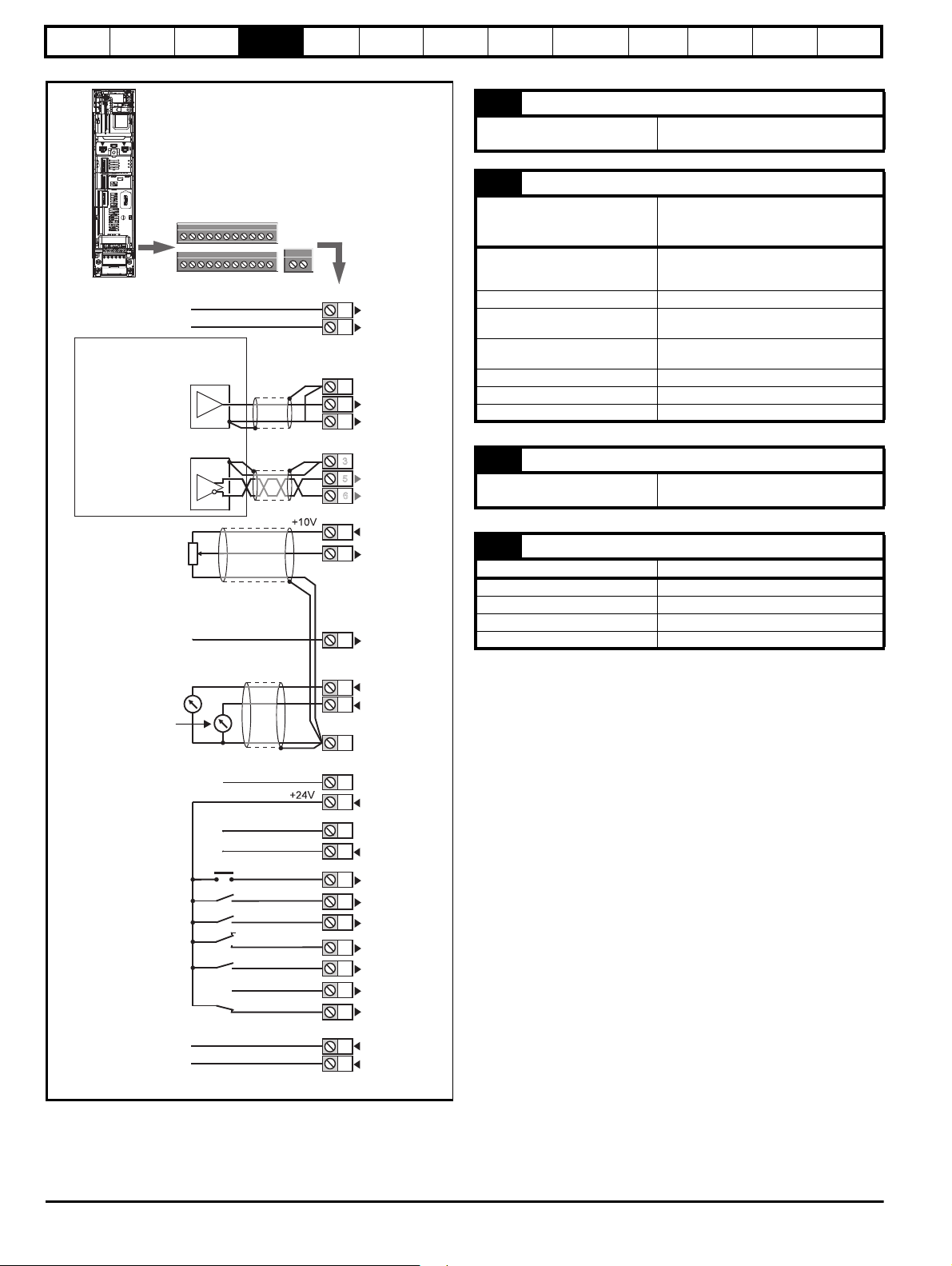

Figure 4-6 Default terminal functions

Getting

started

Basic

parameters

Running the

motor

Optimization

NV Media Card

Operation

Onboard

PLC

4.3.2 Control terminal specification

1 0V common

Function

2 +24V external input

Function

Programmability

Nominal voltage +24.0 Vdc

Minimum continuous operating

voltage

Maximum continuous operating

voltage

Minimum start-up voltage 21.6 Vdc

Recommended power supply 40 W 24 Vdc nominal

Recommended fuse 3 A, 50 Vdc

Advanced

parameters

Diagnostics

UL

Information

Common connection for all external

devices

To supply the control circuit

without providing a supply to the

power stage

Can be switched on or off to act as a digital

input by setting the source Pr 08.063 and

input invert Pr 08.053

+19.2 Vdc

+28.0 Vdc

3 0V common

Function

Common connection for all external

devices

4 +10V user output

Function Supply for external analog devices

Voltage 10.2 V nominal

Voltage tolerance ±1 %

Nominal output current 10 mA

*The Safe Torque Off / Drive enable terminal is a positive logic input only.

** 0V common is connected to ground internally in size 9 to 11 modular

drives.

Protection Current limit and trip @ 30 mA

24 Unidrive M600 Control User Guide

Issue Number: 2

Safety

information

Product

information

Mechanical

installation

Electrical

installation

Getting

started

Basic

parameters

Running the

motor

Optimization

NV Media Card

Operation

Onboard

PLC

Advanced

parameters

Diagnostics

UL

Information

4 Precision reference Analog input 1

5 Non-inverting input

6 Inverting input

Default function Frequency/speed reference

Type of input

Mode controlled by: Pr 07.007

Operating in Voltage mode

Full scale voltage range ±10 V ±2 %

Maximum offset ±10 mV

Absolute maximum

voltage range

Working common mode voltage

range

Input resistance ≥100 kΩ

Monotonic Yes (including 0 V)

Dead band None (including 0 V)

Jumps None (including 0 V)

Maximum offset 20 mV

Maximum non linearity 0.3% of input

Maximum gain asymmetry 0.5 %

Input filter bandwidth single pole ~3 kHz

Operating in current mode

Current ranges

Maximum offset 250 μA

Absolute maximum voltage

(reverse biased)

Equivalent input resistance ≤300 Ω

Absolute maximum current ±30 mA

Operating in thermistor input mode (in conjunction with analog input 3)

Internal pull-up voltage 2.5 V

Trip threshold resistance User defined in Pr 07.048

Short-circuit detection resistance 50 Ω ± 40 %

Common to all modes

Resolution 12 bits (11 bits plus sign)

Sample / update period

Bipolar differential analog voltage or

current, thermistor input

±36 V relative to 0 V

±13 V relative to 0 V

0 to 20 mA ±5 %, 20 to 0 mA ±5 %,

4 to 20 mA ±5 %, 20 to 4 mA ±5 %

±36 V relative to 0 V

250 µs with destinations Pr 01.036,

Pr 01.037, Pr 03.022 or Pr 04.008 in RFC-A

and RFC-S modes. 4 ms for open loop

mode and all other destinations in RFC-A or

RFC-S modes.

7 Analog input 2

Default function Frequency / speed reference

Type of input

Mode controlled by... Pr 07.011

Bipolar single-ended analog voltage or

unipolar current

Operating in voltage mode

Full scale voltage range ±10 V ±2 %

Maximum offset ±10 mV

Absolute maximum voltage range ±36 V relative to 0 V

Input resistance

≥100 k Ω

Operating in current mode

Current ranges

Maximum offset 250 μA

Absolute maximum voltage

(reverse bias)

Absolute maximum current ±30 mA

Equivalent input resistance ≤ 300 Ω

0 to 20 mA ±5 %, 20 to 0 mA ±5 %,

4 to 20 mA ±5 %, 20 to 4 mA ±5 %

±36 V relative to 0V

Common to all modes

Resolution 12 bits (11 bits plus sign)

250 µs with destinations Pr 01.036,

Sample / update

Analog input 3

8

Pr 01.037 or Pr 03.022, Pr 04.008 in RFC-A

or RFC-S. 4ms for open loop mode and all

other destinations in RFC-A or RFC-S

mode.

Default function Voltage input

Type of input

Mode controlled by... Pr 07.015

Bipolar single-ended analog voltage, or

thermistor input

Operating in Voltage mode (default)

Voltage range ±10 V ±2 %

Maximum offset ±10 mV

Absolute maximum voltage range ±36 V relative to 0 V

Input resistance ≥100 k Ω

Operating in thermistor input mode

Supported thermistor types

Internal pull-up voltage 2.5 V

Trip threshold resistance User defined in Pr 07.048

Reset resistance User defined in Pr 07.048

Short-circuit detection resistance 50 Ω ± 40 %

Din 44082, KTY 84, PT100, PT 1000,

PT 2000, 2.0mA

Common to all modes

Resolution 12 bits (11 bits plus sign)

Sample / update period 4 ms

Unidrive M600 Control User Guide 25

Issue Number: 2

Safety

information

Product

information

Mechanical

installation

Electrical

installation

Getting

started

Basic

parameters

9 Analog output 1

10 Analog output 2

OL> Motor FREQUENCY output

Terminal 9 default function

signal

RFC> SPEED output signal

Terminal 10 default function Motor active current

Type of output Bipolar single-ended analog voltage

Operating in Voltage mode (default)

Voltage range ±10 V ±5 %

Maximum offset ±120 mV

Maximum output current ±20 mA

Load resistance ≥1 k Ω

Protection 20 mA max. Short circuit protection

Common to all modes

Resolution 10-bit

Sample / update period

250 µs (output will only change at update

the rate of the source parameter if slower)

11 0V common

Function

Common connection for all external

devices

Running the

motor

Optimization

NV Media Card

Operation

Onboard

PLC

Advanced

parameters

Diagnostics

UL

Information

24 Digital I/O 1

Digital I/O 2

25

26 Digital I/O 3

Terminal 24 default function AT ZERO SPEED output

Terminal 25 default function DRIVE RESET input

Terminal 26 default function RUN FORWARD input

Type

Input / output mode controlled by... Pr 08.031, Pr 08.032 and Pr 08.033

Positive or negative logic digital inputs,

positive logic voltage source outputs

Operating as an input

Logic mode controlled by... Pr 08.029

Absolute maximum applied

voltage range

Impedance >2 mA @15 V (IEC 61131-2, type 1, 6.6 k Ω)

Input thresholds 10 V ±0.8 V (IEC 61131-2, type 1)

-3 V to +30 V

Operating as an output

100 mA (DIO1 & 2 combined)

Nominal maximum output current

Maximum output current

100 mA (DIO3 & 24 V User Output

Combined)

100 mA

200 mA (total including all Digital I/O)

Common to all modes

Voltage range 0 V to +24 V

Sample / Update period

2 ms (output will only change at the update

rate of the source parameter)

21 0V common

Function

Common connection for all external

devices

22 +24 V user output (selectable)

Terminal 22 default function +24 V user output

Can be switched on or off to act as a fourth

Programmability

Nominal output current 100 mA combined with DIO3

Maximum output current

Protection Current limit and trip

Sample / update period

digital output (positive logic only) by setting

the source Pr 08.028 and source invert

Pr 08.018

100 mA

200 mA (total including all Digital I/O)

2 ms when configured as an output (output

will only change at the update rate of the

source parameter if slower)

23 0V common

Function

Common connection for all external

devices

Digital Input 4

27

28 Digital Input 5

Terminal 27 default function

Terminal 28 default function

Type Negative or positive logic digital inputs

Logic mode controlled by... Pr 08.029

Voltage range 0 V to +24 V

Absolute maximum applied

voltage range

Impedance >2 mA @15 V (IEC 61131-2, type 1, 6.6 k Ω)

Input thresholds 10 V ±0.8 V (IEC 61131-2, type 1)

Sample / Update period

RUN REVERSE input

Analog INPUT 1 / INPUT 2 select

-3 V to +30 V

250 µs when configured as an input with

destinations Pr 06.035 or Pr 06.036. 600 µs

when configured as an input with destination

Pr 06.029. 2 ms in all other cases.

29 Digital Input 6

Terminal 29 default function JOG SELECT input

Type Negative or positive logic digital inputs

Logic mode controlled by... Pr 08.029

Voltage range 0 V to +24 V

Absolute maximum applied

voltage range

-3 V to +30 V

Impedance

Input thresholds 10 V ±0.8 V (IEC 61131-2, type 1)

Sample / Update period

>2 mA @15 V (IEC 61131-2,

250 µs when configured as an input with

destinations Pr 06.035 or Pr 06.036.

2 ms in all other cases.

type 1, 6.6 k Ω)

26 Unidrive M600 Control User Guide

Issue Number: 2

Safety

WARNING

information

Product