Control User Guide

Unidrive M200/M201

Variable Speed AC drive for induction

motors

Part Number: 0478-0351-03

Issue: 3

Original Instructions

For the purposes of compliance with the EU Machinery Directive 2006/42/EC, the English version of this manual is the Original Instructions. Manuals

in other languages are Translations of the Original Instructions.

Documentation

Manuals are available to download from the following locations: http://www.drive-setup.com/ctdownloads

The information contained in this manual is believed to be correct at the time of printing and does not form part of any contract. The manufacturer

reserves the right to change the specification of the product and its performance, and the contents of the manual, without notice.

Warranty and Liability

In no event and under no circumstances shall the manufacturer be liable for damages and failures due to misuse, abuse, improper installation, or

abnormal conditions of temperature, dust, or corrosion, or failures due to operation outside the published ratings. The manufacturer is not liable for

consequential and incidental damages. Contact the supplier of the drive for full details of the warranty terms.

Environmental policy

Control Techniques Ltd operates an Environmental Management System (EMS) that conforms to the International Standard ISO 14001.

Further information on our Environmental Policy can be found at: http://www.drive-setup.com/environment

Restriction of Hazardous Substances (RoHS)

The products covered by this manual comply with European and International regulations on the Restriction of Hazardous Substances including EU

directive 2011/65/EU and the Chinese Administrative Measures for Restriction of Hazardous Substances in Electrical and Electronic Products.

Disposal and Recycling (WEEE)

When electronic products reach the end of their useful life, they must not be disposed of along with domestic waste but should be recycled

by a specialist recycler of electronic equipment. Control Techniques products are designed to be easily dismantled into their major

component parts for efficient recycling. The majority of materials used in the product are suitable for recycling.

Product packaging is of good quality and can be re-used. Large products are packed in wooden crates. Smaller products are packaged

in strong cardboard cartons which have a high recycled fibre content. Cartons can be re-used and recycled. Polythene, used in protective

film and bags for wrapping the product, can be recycled. When preparing to recycle or dispose of any product or packaging, please

observe local legislation and best practice.

REACH legislation

EC Regulation 1907/2006 on the Registration, Evaluation, Authorisation and restriction of Chemicals (REACH) requires the supplier of an article to

inform the recipient if it contains more than a specified proportion of any substance which is considered by the European Chemicals Agency (ECHA)

to be a Substance of Very High Concern (SVHC) and is therefore listed by them as a candidate for compulsory authorisation.

Further information on our compliance with REACH can be found at: http://www.drive-setup.com/reach

Registered Office

Nidec Control Techniques Ltd

The Gro

Newtown

Powys

SY16 3BE

UK

Registered in England and Wales. Company Reg. No. 01236886.

Copyright

The contents of this publication are believed to be correct at the time of printing. In the interests of a commitment to a policy of continuous development

and improvement, the manufacturer reserves the right to change the specification of the product or its performance, or the contents of the guide, without

notice.

All rights reserved. No parts of this guide may be reproduced or transmitted in any form or by any means, electrical or mechanical including

photocopying, recording or by an information storage or retrieval system, without permission in writing from the publisher.

Copyright © January 2018 Nidec Control Techniques Ltd

How to use this guide

NOTE

1 Safety information

2 Product information

3 Mechanical installation

4 Electrical installation

5 Getting started

6 Basic parameters

7 Running the motor

8 Optimization

9 NV media card operation

11 Advanced parameters

10 Onboard PLC

12 Diagnostics

13 UL listing information

This guide is intended to be used in conjunction with the appropriate Power Installation Guide. The Power Installation

Guide gives information necessary to physically install the drive. This guide gives information on drive configuration,

operation and optimization.

There are specific safety warnings throughout this guide, located in the relevant sections. In addition, Chapter 1 Safety

information contains general safety information. It is essential that the warnings are observed and the information

considered when working with or designing a system using the drive.

This map of the user guide helps to find the right sections for the task you wish to complete, but for specific information,

refer to Contents on page 4 :

Contents

1 Safety information .................................7

1.1 Warnings, Cautions and Notes .............................7

1.2 Important safety information. Hazards. Competence

of designers and installers ....................................7

1.3 Responsibility ........................................................7

1.4 Compliance with regulations .................................7

1.5 Electrical hazards ..................................................7

1.6 Stored electrical charge ........................................7

1.7 Mechanical hazards ..............................................7

1.8 Access to equipment .............................................7

1.9 Environmental limits ..............................................7

1.10 Hazardous environments ......................................7

1.11 Motor .....................................................................8

1.12 Mechanical brake control ......................................8

1.13 Adjusting parameters ............................................8

1.14 Electromagnetic compatibility (EMC) ....................8

2 Product information ..............................9

2.1 Introduction ...........................................................9

2.2 Model number .......................................................9

2.3 Ratings ................................................................10

2.4 Operating modes .................................................11

2.5 Keypad and display .............................................11

2.6 Nameplate description ........................................12

2.7 Options ................................................................13

3 Mechanical installation .......................15

3.1 Installing / removing options ................................15

3.2 Real time clock battery replacement ...................18

4 Electrical installation ...........................19

4.1 24 Vdc supply ......................................................19

4.2 Communication connections ...............................19

4.3 Control connections ............................................20

5 Getting started .....................................23

5.1 Understanding the display ...................................23

5.2 Keypad operation ................................................23

5.3 Menu structure ....................................................25

5.4 Menu 0 ................................................................25

5.5 Advanced menus ................................................26

5.6 Changing the operating mode .............................26

5.7 Saving parameters ..............................................26

5.8 Restoring parameter defaults ..............................27

5.9 Parameter access level and security ..................27

5.10 Displaying parameters with non-default

values only ..........................................................27

5.11 Displaying destination parameters only ..............28

5.12 Communications .................................................28

6 Basic parameters .................................29

6.1 Menu 0: Basic parameters ..................................29

6.2 Parameter descriptions .......................................34

6.3 Control terminal configurations and wiring ..........35

7 Running the motor .............................. 41

7.1 Quick start connections ...................................... 41

7.2 Changing the operating mode ............................ 41

7.3 Quick start commissioning / start-up .................. 46

8 Optimization ........................................ 48

8.1 Motor map parameters ....................................... 48

8.2 Maximum motor rated current ............................ 54

8.3 Current limits ...................................................... 54

8.4 Motor thermal protection .................................... 54

8.5 Switching frequency ........................................... 55

8.6 CT Modbus RTU specification ........................... 56

9 NV Media Card .................................... 61

9.1 Introduction ........................................................ 61

9.2 SD card support ................................................. 61

9.3 NV Media Card parameters ............................... 64

9.4 NV Media Card trips ........................................... 64

9.5 Data block header information ........................... 64

10 Onboard PLC ....................................... 65

10.1 Onboard PLC and Machine Control Studio ........ 65

10.2 Benefits .............................................................. 65

10.3 Features ............................................................. 65

10.4 Onboard PLC parameters .................................. 66

10.5 Onboard PLC trips ............................................. 66

11 Advanced parameters ........................ 67

11.1 Parameter ranges and Variable minimum/

maximums: ......................................................... 70

11.2 Menu 1: Frequency reference ............................ 78

11.3 Menu 2: Ramps .................................................. 82

11.4 Menu 3: Frequency control ................................ 85

11.5 Menu 4: Torque and current control ................... 90

11.6 Menu 5: Motor control ........................................ 93

11.7 Menu 6: Sequencer and clock ............................ 98

11.8 Menu 7: Analog I/O .......................................... 101

11.9 Menu 8: Digital I/O ........................................... 104

11.10 Menu 9: Programmable logic, motorized

pot, binary sum and timers ............................... 108

11.11 Menu 10: Status and trips ................................ 112

11.12 Menu 11: General drive set-up ......................... 114

11.13 Menu 12: Threshold detectors, variable

selectors and brake control function ................ 115

11.14 Menu 14: User PID controller ........................... 120

11.15 Menu 15: Option module set-up ....................... 123

11.16 Menu 18: Application menu 1 ........................... 124

11.17 Menu 20: Application menu 2 ........................... 125

11.18 Menu 21: Second motor parameters ................ 126

11.19 Menu 22: Additional Menu 0 set-up ................. 127

11.20 Menu 24: Option Module Application ............... 128

4 Unidrive M200 / M201 Control User Guide

Issue Number: 3

12 Diagnostics ........................................129

12.1 Status modes (Keypad and LED status) ...........129

12.2 Trip indications ..................................................129

12.3 Identifying a trip / trip source .............................129

12.4 Trips, Sub-trip numbers ....................................130

12.5 Internal / Hardware trips ....................................150

12.6 Alarm indications ...............................................150

12.7 Status indications ..............................................151

12.8 Displaying the trip history ..................................151

12.9 Behaviour of the drive when tripped .................152

13 UL Listing ...........................................153

13.1 UL file reference ................................................153

13.2 Option modules, kits and accessories ..............153

13.3 Enclosure ratings ..............................................153

13.4 Mounting ...........................................................153

13.5 Environment ......................................................153

13.6 Electrical Installation .........................................153

13.7 Motor overload protection and thermal

memory retention ..............................................153

13.8 External Class 2 supply ....................................153

13.9 Modular Drive Systems .....................................153

13.10 Requirement for Transient Surge Suppression .154

Unidri ve M200 / M201 Control User Guide 5

Issue Number: 3

EU Declaration of Conformity

Nidec Control Techniques Ltd,

The Gro,

Newtown,

Powys,

UK.

SY16 3BE.

This declaration is issued under the sole responsibility of the manufacturer. The object of the declaration is in conformity with the relevant Union

harmonization legislation. The declaration applies to the variable speed drive products shown below:

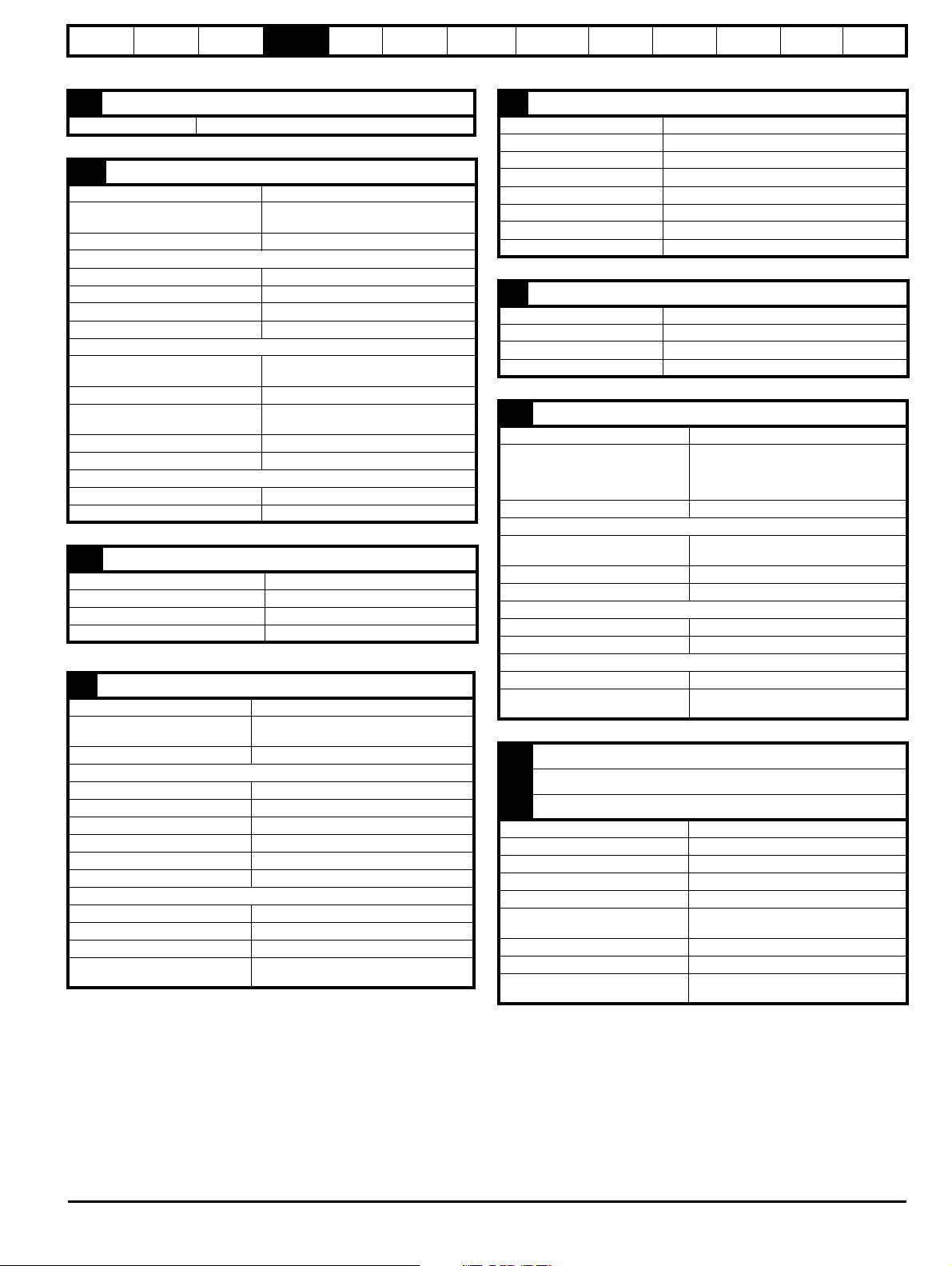

Model number Interpretation Nomenclature aaaa - bbc ddddde

aaaa Basic series

bb Frame size 01, 02, 03, 04, 05, 06, 07, 08, 09, 10, 11

c Voltage rating 1 = 100 V, 2 = 200 V, 4 = 400 V, 5 = 575 V, 6 = 690 V

ddddd Current rating Example 01000 = 100 A

e Drive format

The model number may be followed by additional characters that do not affect the ratings.

The variable speed drive products listed above have been designed and manufactured in accordance with the following European harmonized

standards:

M100, M101, M200, M201, M300, M400, M600, M700, M701, M702, M708, M709, M751, M753, M754,

F300, H300, E200, E300, HS30, HS70, HS71, HS72, M000, RECT

A = 6P Rectifier + Inverter (internal choke), D = Inverter, E = 6P Rectifier + Inverter (external choke),

T = 12P Rectifier + Inverter (external choke)

EN 61800-5-1:2007 Adjustable speed electrical power drive systems - Part 5-1: Safety requirements - Electrical, thermal and energy

EN 61800-3: 2004+A1:2012 Adjustable speed electrical power drive systems - Part 3: EMC requirements and specific test methods

EN 61000-6-2:2005 Electromagnetic compatibility (EMC) - Part 6-2: Generic standards - Immunity for industrial environments

EN 61000-6-4: 2007+ A1:2011

EN 61000-3-2:2014

EN 61000-3-3:2013

EN 61000-3-2:2014 Applicable where input current < 16 A. No limits apply for professional equipment where input power ≥1 kW.

These products comply with the Restriction of Hazardous Substances Directive (2011/65/EU), the Low Voltage Directive (2014/35/EU) and the

Electromagnetic Compatibility Directive (2014/30/EU).

G Williams

Vice President, Technology

Date: 6th September 2017

These electronic drive products are intended to be used with appropriate motors, controllers, electrical protection components and other

equipment to form complete end products or systems. Compliance with safety and EMC regulations depends upon installing and

configuring drives correctly, including using the specified input filters.

The drives must be installed only by professional installers who are familiar with requirements for safety and EMC. Refer to the Product

Documentation. An EMC data sheet is available giving detailed information. The assembler is responsible for ensuring that the end product

or system complies with all the relevant laws in the country where it is to be used.

Electromagnetic compatibility (EMC) - Part 6-4: Generic standards - Emission standard for industrial

environments

Electromagnetic compatibility (EMC) - Part 3-2: Limits for harmonic current emissions (equipment input current

16 A per phase)

Electromagnetic compatibility (EMC) - Part 3-3: Limitation of voltage changes, voltage fluctuations and flicker in

public, low voltage supply systems, for equipment with rated current 16 A per phase and not subject to

conditional connection

6 Unidrive M200 / M201 Control User Guide

Issue Number: 3

Safety

WARNING

CAUTION

NOTE

information

Product

information

Mechanical

installation

Electrical

installation

Getting

started

Basic

parameters

Running the

motor

Optimization

NV Media

Card

Onboard

PLC

Advanced

parameters

Diagnostics UL Listing

1 Safety information

1.1 Warnings, Cautions and Notes

A Warning contains information which is essential for

avoiding a safety hazard.

A Caution contains information which is necessary for

avoiding a risk of damage to the product or other equipment.

A Note contains information which helps to ensure correct operation of

the product.

1.2 Important safety information. Hazards.

This guide applies to products which control electric motors either

directly (drives) or indirectly (controllers, option modules and other

auxiliary equipment and accessories). In all cases the hazards

associated with powerful electrical drives are present, and all safety

information relating to drives and associated equipment must be

observed.

Specific warnings are given at the relevant places in this guide.

Drives and controllers are intended as components for professional

incorporation into complete systems. If installed incorrectly they may

present a safety hazard. The drive uses high voltages and currents,

carries a high level of stored electrical energy, and is used to control

equipment which can cause injury. Close attention is required to the

electrical installation and the system design to avoid hazards either in

normal operation or in the event of equipment malfunction. System

design, installation, commissioning/start-up and maintenance must be

carried out by personnel who have the necessary training and

competence. They must read this safety information and this guide

carefully.

1.3 Responsibility

It is the responsibility of the installer to ensure that the equipment is

installed correctly with regard to all instructions given in this guide. They

must give due consideration to the safety of the complete system, so as

to avoid the risk of injury both in normal operation and in the event of a

fault or of reasonably foreseeable misuse.

The manufacturer accepts no liability for any consequences resulting

from inappropriate, negligent or incorrect installation of the equipment.

1.4 Compliance with regulations

The installer is responsible for complying with all relevant regulations,

such as national wiring regulations, accident prevention regulations and

electromagnetic compatibility (EMC) regulations. Particular attention

must be given to the cross-sectional areas of conductors, the selection

of fuses or other protection, and protective ground (earth) connections.

This guide contains instructions for achieving compliance with specific

EMC standards.

All machinery to be supplied within the European Union in which this

product is used must comply with the following directives:

2006/42/EC Safety of machinery.

2014/30/EU: Electromagnetic Compatibility.

Competence of designers and

installers

1.5 Electrical hazards

The voltages used in the drive can cause severe electrical shock and/or

burns, and could be lethal. Extreme care is necessary at all times when

working with or adjacent to the drive. Hazardous voltage may be present

in any of the following locations:

• AC and DC supply cables and connections

• Output cables and connections

• Many internal parts of the drive, and external option units

Unless otherwise indicated, control terminals are single insulated and

must not be touched.

The supply must be disconnected by an approved electrical isolation

device before gaining access to the electrical connections.

The STOP and Safe Torque Off functions of the drive do not isolate

dangerous voltages from the output of the drive or from any external

option unit.

The drive must be installed in accordance with the instructions given in

this guide. Failure to observe the instructions could result in a fire

hazard.

1.6 Stored electrical charge

The drive contains capacitors that remain charged to a potentially lethal

voltage after the AC supply has been disconnected. If the drive has been

energized, the AC supply must be isolated at least ten minutes before

work may continue.

1.7 Mechanical hazards

Careful consideration must be given to the functions of the drive or

controller which might result in a hazard, either through their intended

behaviour or through incorrect operation due to a fault. In any application

where a malfunction of the drive or its control system could lead to or

allow damage, loss or injury, a risk analysis must be carried out, and

where necessary, further measures taken to reduce the risk - for

example, an over-speed protection device in case of failure of the speed

control, or a fail-safe mechanical brake in case of loss of motor braking.

With the sole exception of the Safe Torque Off function, none of the

drive functions must be used to ensure safety of personnel, i.e.

they must not be used for safety-related functions.

The Safe Torque Off function may be used in a safety-related

application. The system designer is responsible for ensuring that the

complete system is safe and designed correctly according to the

relevant safety standards.

The design of safety-related control systems must only be done by

personnel with the required training and experience. The Safe Torque

Off function will only ensure the safety of a machine if it is correctly

incorporated into a complete safety system. The system must be subject

to a risk assessment to confirm that the residual risk of an unsafe event

is at an acceptable level for the application.

1.8 Access to equipment

Access must be restricted to authorized personnel only. Safety

regulations which apply at the place of use must be complied with.

1.9 Environmental limits

Instructions in this guide regarding transport, storage, installation and

use of the equipment must be complied with, including the specified

environmental limits. This includes temperature, humidity,

contamination, shock and vibration. Drives must not be subjected to

excessive physical force.

1.10 Hazardous environments

The equipment must not be installed in a hazardous environment (i.e. a

potentially explosive environment).

Unidrive M200 / M201 Control User Guide 7

Issue Number: 3

Safety

information

Product

information

Mechanical

installation

Electrical

installation

Getting

started

Basic

parameters

Running the

1.11 Motor

The safety of the motor under variable speed conditions must be

ensured.

To avoid the risk of physical injury, do not exceed the maximum specified

speed of the motor.

Low speeds may cause the motor to overheat because the cooling fan

becomes less effective, causing a fire hazard. The motor should be

installed with a protection thermistor. If necessary, an electric forced vent

fan should be used.

The values of the motor parameters set in the drive affect the protection

of the motor. The default values in the drive must not be relied upon. It is

essential that the correct value is entered in the Motor Rated Current

parameter.

1.12 Mechanical brake control

Any brake control functions are provided to allow well co-ordinated

operation of an external brake with the drive. While both hardware and

software are designed to high standards of quality and robustness, they

are not intended for use as safety functions, i.e. where a fault or failure

would result in a risk of injury. In any application where the incorrect

operation of the brake release mechanism could result in injury,

independent protection devices of proven integrity must also be

incorporated.

1.13 Adjusting parameters

Some parameters have a profound effect on the operation of the drive.

They must not be altered without careful consideration of the impact on

the controlled system. Measures must be taken to prevent unwanted

changes due to error or tampering.

motor

Optimization

NV Media

Card

Onboard

PLC

Advanced

parameters

Diagnostics UL Listing

1.14 Electromagnetic compatibility (EMC)

Installation instructions for a range of EMC environments are provided in

the relevant Power Installation Guide. If the installation is poorly

designed or other equipment does not comply with suitable standards for

EMC, the product might cause or suffer from disturbance due to

electromagnetic interaction with other equipment. It is the responsibility

of the installer to ensure that the equipment or system into which the

product is incorporated complies with the relevant EMC legislation in the

place of use.

8 Unidrive M200 / M201 Control User Guide

Issue Number: 3

Safety

Optional Build

Identification Label

Derivative Electrical Specifications

M200 - 03 4 00073

Unidrive M200/201

Product Line

Frame Size

:

Current Rating:

Heavy Duty current rating x 10

Drive Format:

A - AC in AC out

Customer Code

01

A B 1 00

Customer Code:

00 = 50 Hz

01 = 60 Hz

Reserved:

Conformal Coating:

0 = Standard

IP / NEMA Rating:

1 = IP20 / NEMA 1

Brake Transistor:

B = Brake

Cooling:

A = Air

Reserved

01

A

Documentation

1

Documentation:

Voltage Rating:

2 - 200 V (200 - 240

- 400 V (380 - 480

- 575 V (500 - 575

- 690 V (500 - 690

± 10 %)

4

1 - 100 V (100 - 120 10 %)±

±±10 %)

5

6 10 %)

± 10 %)

0 - Supplied separately

1 - English

2 - French

3 - Italian

4 - German

5 - Spanish

N = No

E - AC in AC out (without internal choke)

information

Product

information

Mechanical

installation

Electrical

installation

Getting

started

Basic

parameters

Running the

motor

Optimization

NV Media

Card

Onboard

PLC

Advanced

parameters

Diagnostics UL Listing

2 Product information

2.1 Introduction

Open loop AC drive

Unidrive M200 and Unidrive M201 deliver maximum machine performance with open loop vector and sensorless induction motor control, for dynamic

and efficient machine operation.

Features

• Flexible machine integration through communications

• NV Media Card for parameter copying and data storage

• 24 Vdc backup supply (optional)

• EIA 485 serial communications interface (optional)

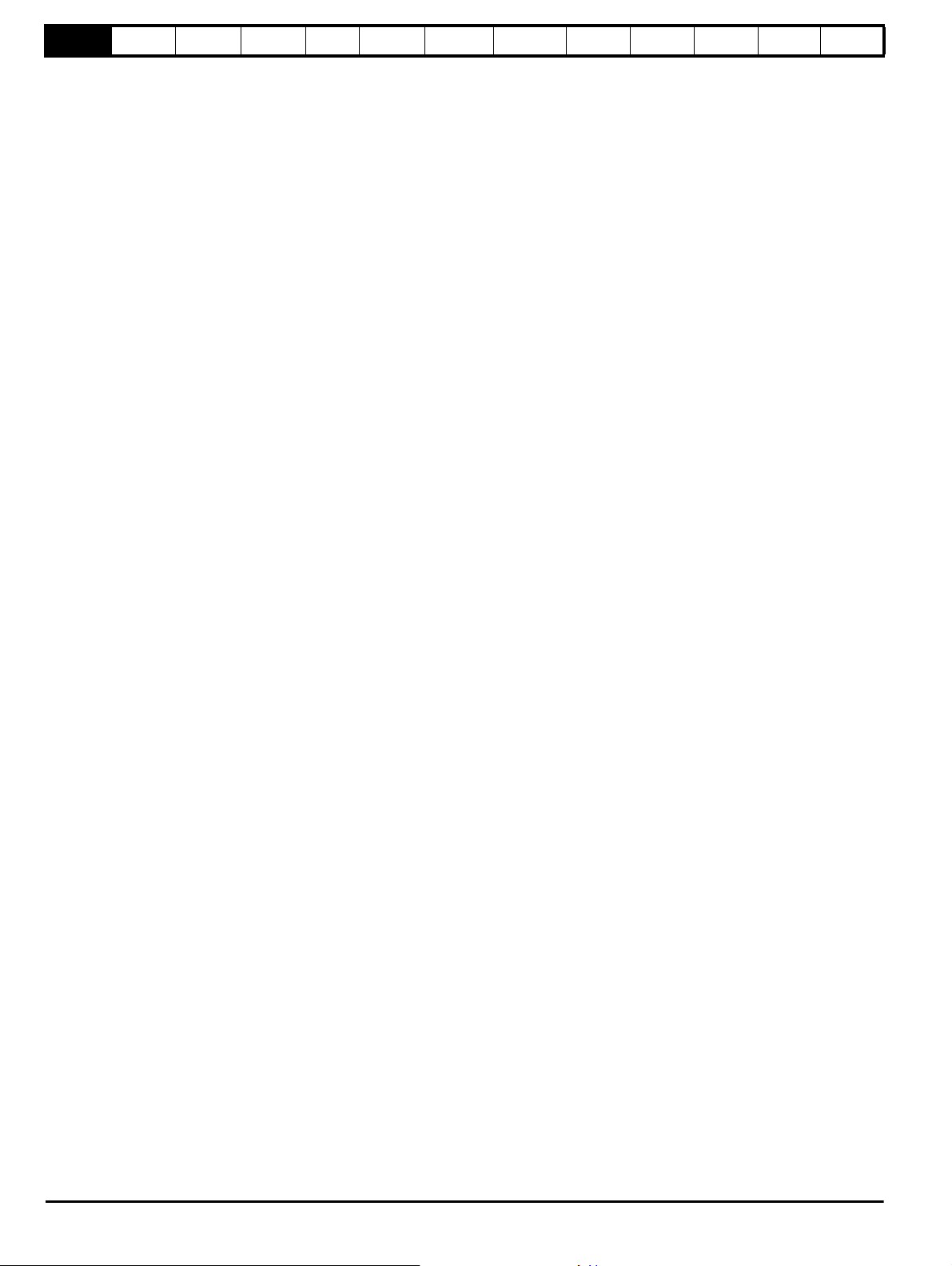

2.2 Model number

The way in which the model numbers for the Unidrive M range are formed is illustrated below:

Figure 2-1 Model number

Unidrive M200 / M201 Control User Guide 9

Issue Number: 3

Safety

Available output

current

Overload limit -

Heavy Duty

Maximum

continuous

current (above

50% base

speed) -

Normal Duty

Maximum

continuous

current -

Heavy Duty

Motor rated

current set

in the drive

Heavy Duty

- with high

overload capability

Normal Duty

Overload limit -

Normal Duty

NOTE

NOTE

Motor total

current (Pr 04.001)

as a percentage

of motor rated

current

Motor speed as a

percentage of base speed

100%

Max. permissible

continuous

current

100%

I t protection operates in this region

2

70%

50%15%

Pr = 0

Pr = 1

04.025

04.025

Motor total

current (Pr 04.001)

as a percentage

of motor rated

current

Motor speed as a

percentage of base speed

100%

Max. permissible

continuous

current

100%

I t protection operates in this region

2

70%

50%

Pr = 0

Pr = 1

04.025

04.025

information

Product

information

Mechanical

installation

Electrical

installation

Getting

started

Basic

parameters

Running the

motor

Optimization

2.3 Ratings

The size 1 to 4 drive is Heavy Duty rated only.

The size 5 to 9 drive is dual rated.

The setting of the motor rated current determines which rating applies Heavy Duty or Normal Duty.

The two ratings are compatible with motors designed to IEC60034.

The graph aside illustrates the difference between Normal Duty and

Heavy Duty with respect to continuous current rating and short term

overload limits.

Normal Duty Heavy Duty (default)

For applications which use Self ventilated (TENV/TEFC) induction

motors and require a low overload capability, and full torque at low

speeds is not required (e.g. fans, pumps).

Self ventilated (TENV/TEFC) induction motors require increased

protection against overload due to the reduced cooling effect of the fan

at low speed. To provide the correct level of protection the I

2

t software

operates at a level which is speed dependent. This is illustrated in the

graph below.

The speed at which the low speed protection takes effect can be

changed by the setting of Low Speed Thermal Protection Mode

(04.025). The protection starts when the motor speed is below 15 % of

base speed when Pr 04.025 = 0 (default) and below 50 % when

Pr 04.025 = 1.

Operation of motor I2t protection

Motor I2t protection is fixed as shown below and is compatible with:

• Self ventilated (TENV/TEFC) induction motors

For constant torque applications or applications which require a high

overload capability, or full torque is required at low speeds (e.g. winders,

hoists).

The thermal protection is set to protect force ventilated induction motors

by default.

N

If the application uses a self ventilated (TENV/TEFC) induction motor

and increased thermal protection is required for speeds below 50 %

base speed, then this can be enabled by setting Low Speed Thermal

Protection Mode (04.025) = 1.

Motor I2t protection defaults to be compatible with:

• Forced ventilation induction motors

NV Media

Card

Advanced

parameters

Diagnostics UL Listing

10 Unidrive M200 / M201 Control User Guide

Issue Number: 3

Safety

10

7

8

6

5

4

9

1

2

3

1

3

2

5

V A Hz rpm %

1

4

information

Product

information

Mechanical

installation

Electrical

installation

Getting

started

Basic

parameters

Running the

motor

Optimization

NV Media

Card

Onboard

PLC

Advanced

parameters

Diagnostics UL Listing

2.4 Operating modes

The drive is designed to operate in any of the following modes:

1. Open loop mode

Open loop vector mode

Fixed V/F mode (V/Hz)

Square V/F mode (V/Hz)

2. RFC - A

Without position feedback sensor

2.4.1 Open loop mode

The drive applies power to the motor at frequencies varied by the user. The motor speed is a result of the output frequency of the drive and slip due

to the mechanical load. The drive can improve the speed control of the motor by applying slip compensation. The performance at low speed depends

on whether V/F mode or open loop vector mode is selected.

Open loop vector mode

The voltage applied to the motor is directly proportional to the frequency except at low speed where the drive uses motor parameters to apply the

correct voltage to keep the flux constant under varying load conditions.

Typically 100 % torque is available down to 1 Hz for a 50 Hz motor.

Fixed V/F mode

The voltage applied to the motor is directly proportional to the frequency except at low speed where a voltage boost is provided which is set by the

user. This mode can be used for multi-motor applications.

Typically 100 % torque is available down to 4 Hz for a 50 Hz motor.

Square V/F mode

The voltage applied to the motor is directly proportional to the square of the frequency except at low speed where a voltage boost is provided which is

set by the user. This mode can be used for running fan or pump applications with quadratic load characteristics or for multi-motor applications. This

mode is not suitable for applications requiring a high starting torque.

2.4.2 RFC-A mode

Rotor Flux Control for Asynchronous (induction) motors (RFC-A) encompasses closed loop vector control without a position feedback device

Rotor flux control provides closed loop control without the need for position feedback by using current, voltages and key motor parameters to estimate

the motor speed. It can eliminate instability traditionally associated with open loop control for example when operating large motors with light loads at

low frequencies.

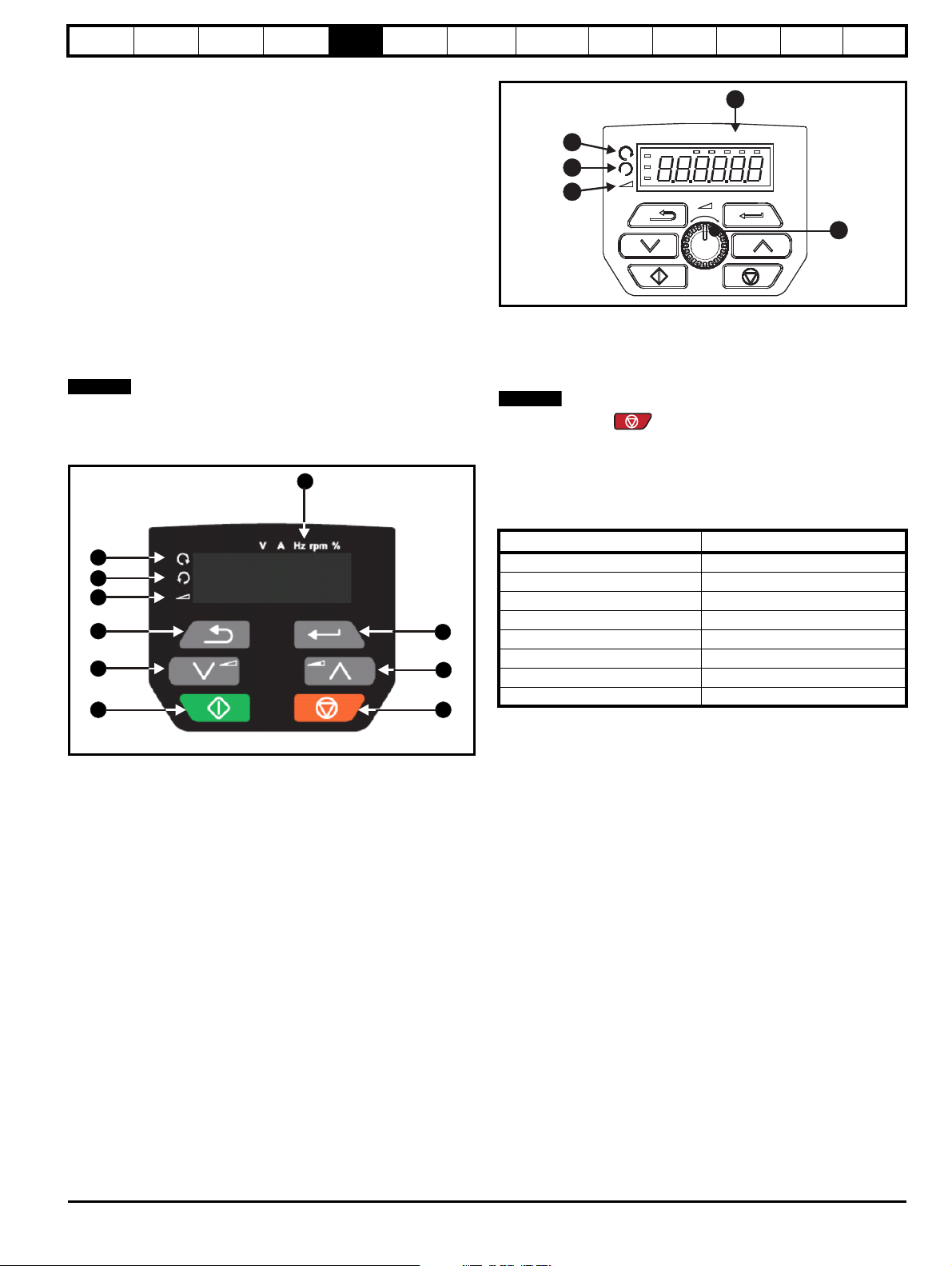

2.5 Keypad and display

The keypad and display provide information to the user regarding the operating status of the drive and trip codes, and provide the means for changing

parameters, stopping and starting the drive, and the ability to perform a drive reset.

Figure 2-2 Unidrive M200 keypad detail Figure 2-3 Unidrive M201 keypad detail

1. Escape button

2. Down button

3. Start button (green)

4. Stop / Reset button (red)

5. Up button

6. Enter button

7. Run forward indicator

8. Run reverse indicator

9. Keypad reference indicator

10. Unit indicators

1. Run forward indicator

2. Unit indicators

3. Speed reference potentiometer

4. Keypad reference indicator

5. Run reverse indicator

Unidri ve M2 00 / M 201 C ontr ol User Gui de 11

Issue Number: 3

Safety

Model number

Refer to

User Guide

Date code

Input

voltage

Power rating

M200-022 00042 A

200-240V 0.75kW

1714

Model

number

Input voltage

Output

voltage

Serial

number

Input

frequency

Power

rating

Date code

No. of phases &

Typical input current

Heavy duty

output current

Approvals

M200-022 0042 A

7.5A

Patents: www.ctpatents.info

Manuals: www.ctmanuals.info

0-550Hz

Output

frequency

1714

8000001001

Key to approvals

CE approval Europe

C Tick approval Australia

UL / cUL approval

USA &

Canada

RoHS compliant Europe

Functional safety

USA &

Canada

EurAsian Conformity EurAsia

R

NOTE

information

Product

information

Mechanical

installation

Electrical

installation

2.6 Nameplate description

Figure 2-4 Typical drive rating labels for size 2

Getting

started

Basic

parameters

Running the

motor

Optimization

NV Media

Card

Advanced

parameters

Diagnostics UL Listing

Refer to Figure 2-1 Model number on page 9 for further information relating to the labels.

Date code format

The date code is four numbers. The first two numbers indicate the year and the remaining numbers indicate the week of the year in which the drive

was built. This new format started in 2017.

Example:

A date code of 1710 would correspond to week 10 of year 2017.

12 Unidrive M200 / M201 Control User Guide

Issue Number: 3

Safety

1

2

4

5

3

information

Product

information

Mechanical

installation

Electrical

installation

2.7 Options

Figure 2-5 Options available with the drive

Getting

started

Basic

parameters

Running the

motor

Optimization

NV Media

Card

Onboard

PLC

Advanced

parameters

Diagnostics UL Listing

1. AI-485 adaptor

2. Option module (SI)

3. CT USB comms cable

4. Remote mountable LCD keypad

5. AI-Backup adaptor module

Unidri ve M2 00 / M 201 C ontr ol User Gui de 13

Issue Number: 3

Safety

information

Product

information

Mechanical

installation

Electrical

installation

Getting

started

Basic

parameters

Running the

motor

Optimization

NV Media

Card

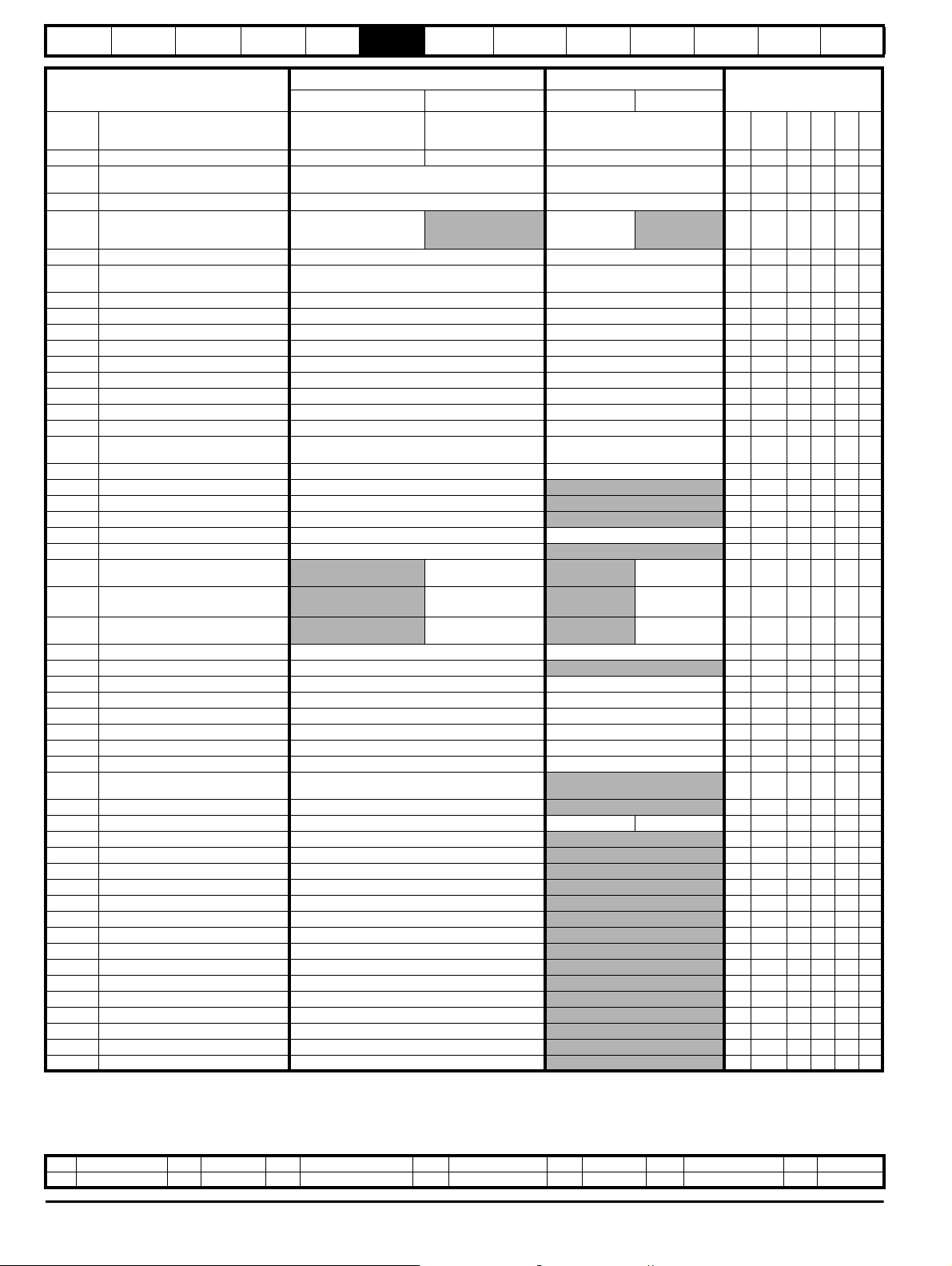

Table 2-1 System Integration Option module identification

Type Option module Color Name Further details

Advanced

parameters

Diagnostics UL Listing

Fieldbus

Automation

(I/O expansion)

Purple SI-PROFIBUS

Medium

Grey

SI-DeviceNet

Light Grey SI-CANopen

Yellow

Green

SI-PROFINET V2

Beige SI-Ethernet

Brown Red SI-EtherCAT

Orange SI-I/O

Profibus option

PROFIBUS adaptor for communications with the drive

DeviceNet option

DeviceNet adaptor for communications with the drive

CANopen option

CANopen adaptor for communications with the drive

PROFINET V2 option

PROFINET V2 adapter for communications with the drive

External Ethernet module that supports EtherNet/IP, Modbus

TCP/IP and RTMoE. The module can be used to provide global

connectivity and integration with IT network technologies, such as

wireless networking

EtherCAT option

EtherCAT adapter for communications with the drive

Extended I/O

Increases the I/O capability by adding the following combinations:

• Digital I/O

• Digital Inputs

• Analog Inputs (differential or single ended)

• Relays

Table 2-2 Adaptor Interface (AI) option module identification

Type Option module Name Further details

EIA-485 serial communications option

AI-485 adaptor

Provides a EIA-485 serial communications interface via an

RJ45 connector or alternative screw terminals.

Communications

AI-485 24V adaptor

EIA 485 serial communications option

Provides a EIA-485 serial communications interface via an

RJ45 connector or alternative screw terminals. It also provides a

24 V Backup supply input.

AI-Backup adaptor

Backup

AI-Smart adaptor

+24 V Backup and SD card interface

Provides a +24 V Backup supply input and SD card interface.

+24 V Backup and SD card interface

Supplied with 4 GB SD Card for parameter copying and an input

for 24 V Backup.

Table 2-3 Keypad identification

Type Keypad Name Further Details

Remote-Keypad

Remote LCD keypad option

Remote Keypad with a LCD display

Keypad

Remote-Keypad RTC

Remote LCD keypad option

Remote Keypad with a LCD display and real time clock

14 Unidrive M200 / M201 Control User Guide

Issue Number: 3

Safety

CAUTION

3

2

1

NOTE

1

2

information

Product

information

Mechanical

installation

Electrical

installation

Getting

started

Basic

parameters

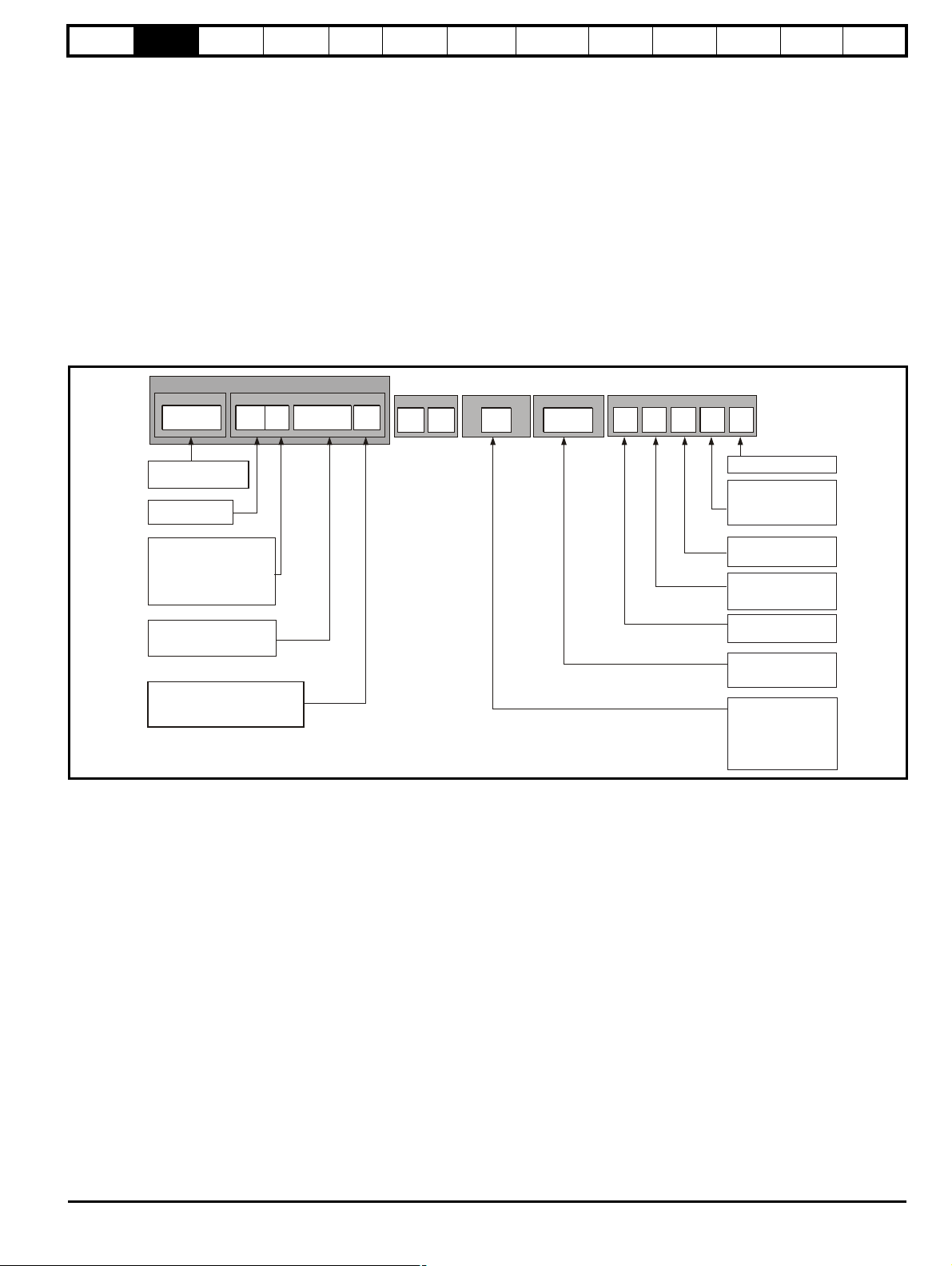

3 Mechanical installation

3.1 Installing / removing options

Power down the drive before installing / removing the SI option module. Failure to do so may result in damage to the product.

Figure 3-1 Installation of an SI option module (size 2 to 4)

Running the

motor

Optimization

NV Media

Card

Onboard

PLC

Advanced

parameters

Diagnostics UL Listing

Installing the option module

• With the option module tilted slightly backwards, align and locate the two holes in the rear of the option module onto the two tabs (1) on the drive.

• Press the option module onto the drive as shown in (2) until the connector mates with the drive, ensuring that the tab (3) retains the option module

in place.

Check that the option module is securely located on the drive. Always ensure that the terminal cover is always replaced before use as this ensures

that the option module is firmly secured.

Figure 3-2 Removing the SI-Option module (size 2 to 4)

• Press down on the tab (1) to release the option module from the drive housing as shown.

• Tilt the option module slightly towards you and pull away from the drive housing (2).

Unidrive M200 / M201 Control User Guide 15

Issue Number: 3

Safety

A

1

2

1

2

3

A

information

Product

information

Mechanical

installation

Electrical

installation

Getting

started

Basic

parameters

Running the

motor

Optimization

NV Media

Card

Figure 3-3 Installation of an SI option module (size 5 to 9)

• Move the option module in the direction shown (1).

• Align and insert the option module tab into the slot provided (2), This is shown in the detailed view (A).

• Press down on the option module until it clicks in place.

Figure 3-4 Removal of an SI option module (size 5 to 9)

Onboard

PLC

Advanced

parameters

Diagnostics UL Listing

• To release the option module from the drive housing, press down on the tab (1) as shown in detailed view (A).

• Tilt the option module towards you as shown in (2).

• Remove the option module by lifting away from the drive as shown in (3).

16 Unidrive M200 / M201 Control User Guide

Issue Number: 3

Safety

1

3

2

information

Product

information

Mechanical

installation

Electrical

installation

Getting

started

Basic

parameters

Running the

motor

Optimization

NV Media

Card

Onboard

PLC

Advanced

parameters

Diagnostics UL Listing

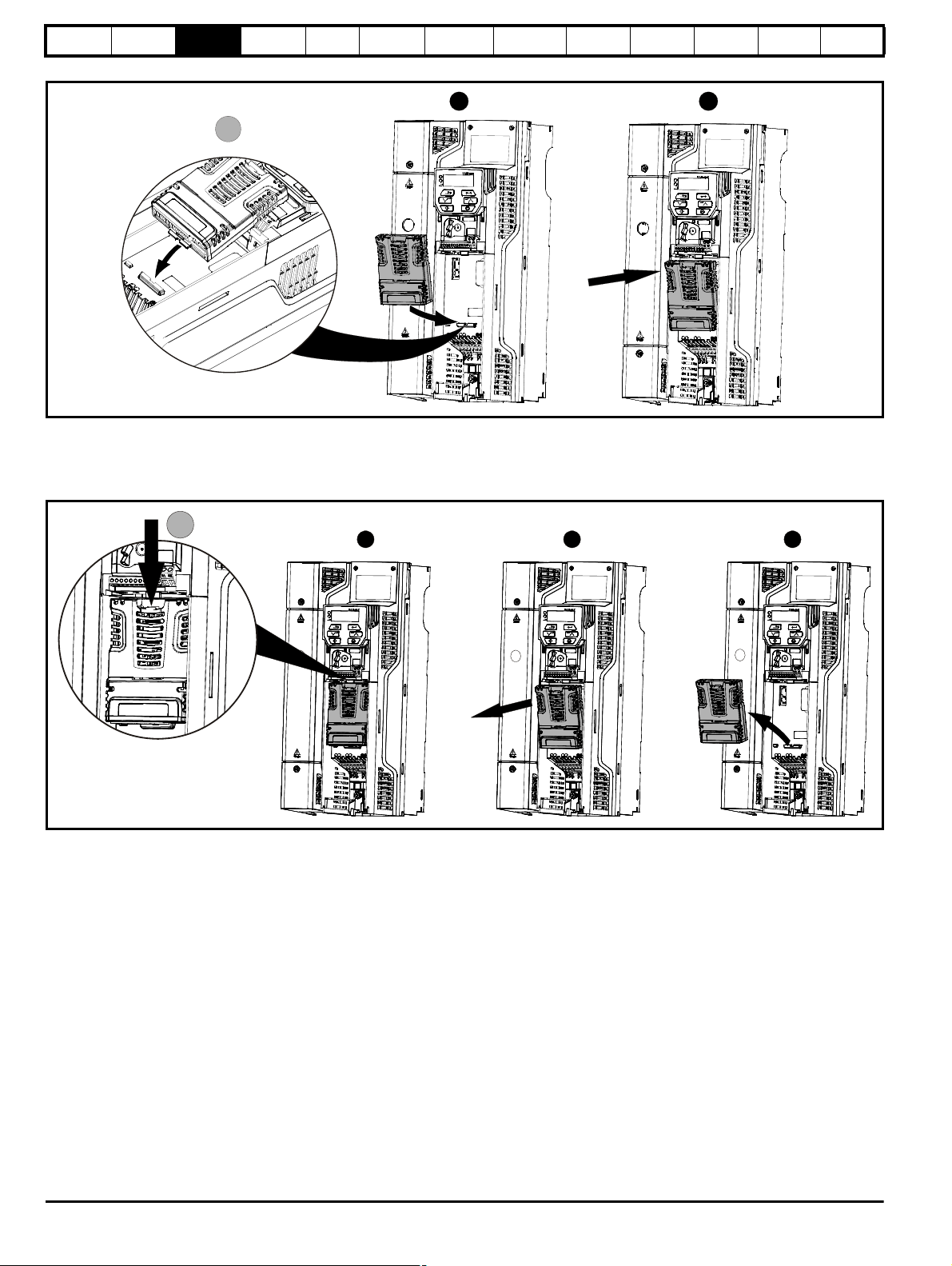

Figure 3-5 Installing the AI-485 / AI-Backup Adaptor to the drive (AI-485 Adaptor shown)

• Identify the two plastic fingers on the underside of the AI-485 / AI-Backup Adaptor (1) - then insert the two fingers into the corresponding slots in

the spring-loaded sliding cover on the top of the drive.

• Hold the adaptor firmly and push the spring loaded protective cover towards the back of the drive to expose the connector block (2) below.

• Press the adaptor downwards (3) until the adaptor connector locates into the drive connection below.

Figure 3-6 Removal of the AI-485 / AI-Backup Adaptor adaptor (AI-485 Adaptor shown)

• To remove the AI-485 / AI-Backup Adaptor, pull it up away from the drive in the direction shown (1)

Unidrive M200 / M201 Control User Guide 17

Issue Number: 3

Safety

NOTE

information

Product

information

Mechanical

installation

Electrical

installation

Getting

started

Basic

parameters

Running the

motor

Optimization

NV Media

Card

Onboard

PLC

Advanced

parameters

Diagnostics UL Listing

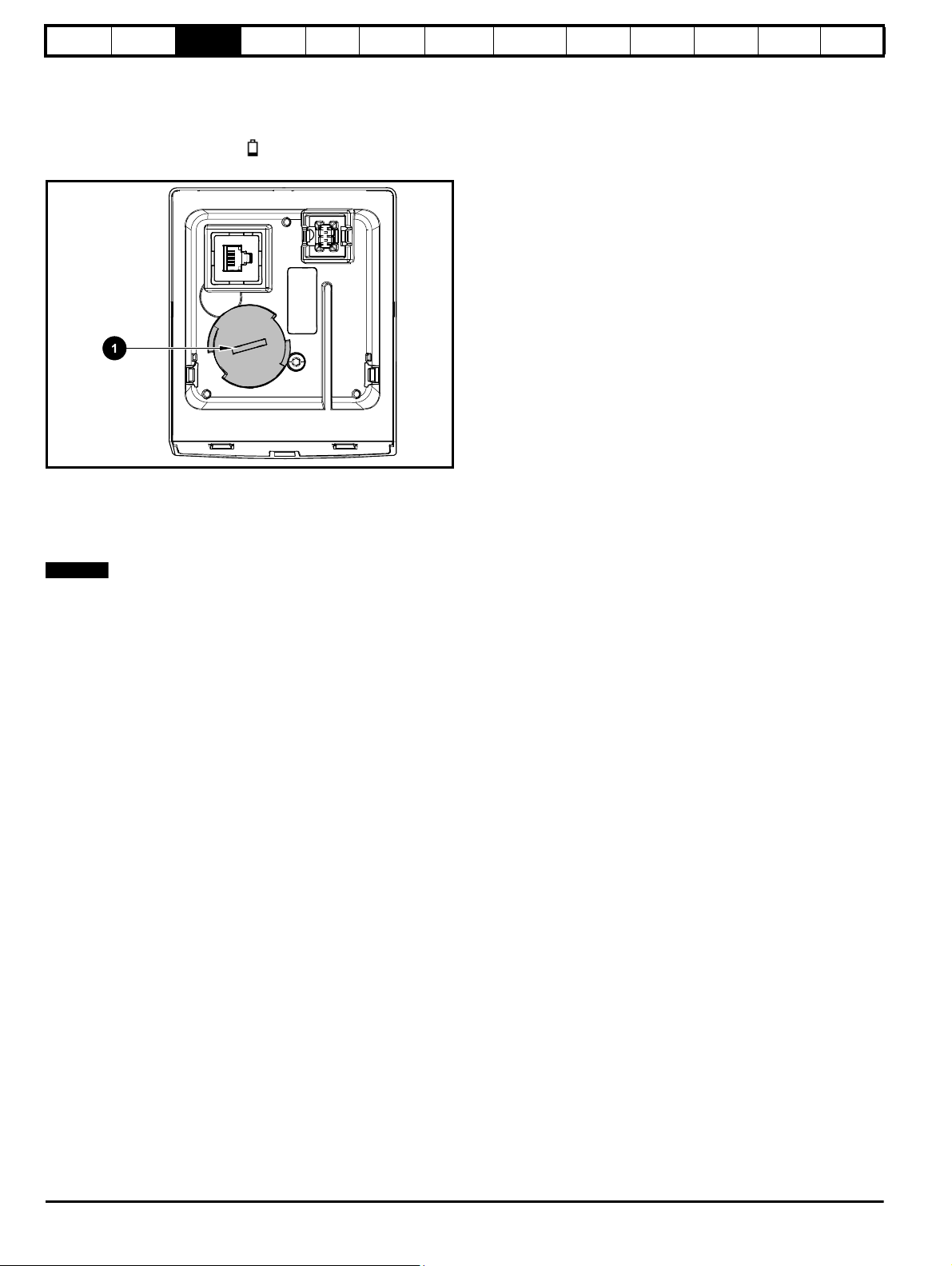

3.2 Real time clock battery replacement

Those keypads which have the real time clock feature contain a battery to ensure the clock works when the drive is powered down. The battery has a

long life time but if the battery needs to be replaced or removed, follow the instructions below.

Low battery voltage is indicated by

low battery symbol on the keypad display.

Figure 3-7 Remote Keypad RTC (rear view)

Figure 3-7 above illustrates the rear view of the Remote Keypad RTC.

1. To remove the battery cover insert a flat head screwdriver into the slot as shown (1), push and turn anti-clockwise until the battery cover is

released.

2. Replace the battery (the battery type is: CR2032).

3. Reverse point 1 above to replace battery cover.

Ensure the battery is disposed of correctly.

18 Unidrive M200 / M201 Control User Guide

Issue Number: 3

Safety

NOTE

8

1

123456

NOTE

NOTE

information

Product

information

Mechanical

installation

Electrical

installation

Getting

started

Basic

parameters

Running the

motor

Optimization

NV Media

Card

Onboard

PLC

Advanced

parameters

Diagnostics UL Listing

4 Electrical installation

4.1 24 Vdc supply

The 24 Vdc supply connected to the +24 V supply terminals on the AIBackup adaptor provides the following functions:

• It can be used as a back-up power supply to keep the control circuits

of the drive powered up when the line power supply is removed. This

allows any fieldbus modules or serial communications to continue to

operate. If the line power supply is re-applied, then the normal

operation can carry on after the drive automatically re-initializes the

power board parameters.

• It can be used to clone or load parameters in order to pre-configure

drives when the line power supply is not available. The keypad can

be used to setup parameters if required. However, the drive will be in

the Under Voltage state unless the line power supply is enabled,

therefore diagnostics may not be possible. (Power down save

parameters are not saved when using the 24 V back-up power

supply input).

The working voltage range of the 24 V back-up power supply is as

follows:

0 V (connected internally to 0V common - Control

0 V

terminal 1)

+ 24 V + 24 V Backup supply input

Nominal operating voltage 24.0 Vdc

Minimum continuous operating voltage 19.2 V

Maximum continuous operating voltage 30.0 V

Minimum start up voltage 12.0 V

Minimum power supply requirement at 24 V 20 W

Maximum power supply continuous current 3 A

Recommended fuse 1 A, 50 Vdc

Minimum and maximum voltage values include ripple and noise. Ripple

and noise values must not exceed 5 %.

Figure 4-1 Location of the 24 Vdc power supply connection on the

AI-Backup adaptor

4.2 Communication connections

Installing an AI-485 Adaptor provides the drive with a 2 wire EIA-485

serial communications interface. This enables the drive set-up, operation

and monitoring to be carried out with a PC or controller as required.

Figure 4-2 Location of the AI-485 Adaptor option

4.2.1 EIA 485 serial communications

The drive only supports Modbus RTU protocol. See Table 4-1 for the

connection details.

Standard Ethernet cables must not be used when connecting drives on

a EIA 485 network as they do not have the correct twisted pairs for the

pinout of the serial comms port.

Table 4-1 Serial communication port pin-outs (RJ45)

Minimum number of connections are 2, 3, 7 and shield.

Table 4-2 Serial communication port pin-outs (screw terminal

Pin Function

1 120 Ω Termination resistor

2RX TX

30 V

4 +24 V (100 mA) output

5 Not connected

6 TX enable

7RX\ TX\

8 RX\ TX\ (if termination resistors are required, link to pin 1)

block)

Pin Function

10 V

2 RX\ TX\ (if termination resistor required, link to pin 4)

3RX TX

4 120 Ω Termination resistor

5 TX Enable

6 +24 V (100 mA) output

N

The connections on the RJ45 connector and terminal block are in

parallel.

The 24 Vdc Backup supply can be used on all frame sizes.

Unidri ve M2 00 / M 201 C ontr ol User Gui de 19

Issue Number: 3

Safety

WARNING

WARNING

WARNING

CAUTION

NOTE

1

14

41

42

12

13

At zero frequency

Frequency

Run forward

Run reverse

Analog input 1/

input 2 select

41

42

Relay

(over-voltage

category II)

Drive OK

Analog

frequency

reference 1

Analog

frequency

reference 2

1

4

5

7

9

10

11

2

0V common

Drive enable

+10 V

+24 V

Analog input 1 select

Analog input 2 select

14

information

Product

information

Mechanical

installation

Electrical

installation

Getting

started

Basic

parameters

4.2.2 Isolation of the EIA 485 serial communication

port

The serial communication port is single insulated and meets the

requirements for ELV.

When using the communications port with a personal

computer or centralised controller e.g. PLC, an isolation

device must be included with a rated voltage at least equal

to the drive supply voltage. Ensure that the correct fuses are

installed at the drive input, and that the drive is connected to

the correct supply voltage.

If a serial communications converter other than the CT

Comms cable is used to connect to other circuits classified

as Safety Extra Low Voltage (SELV) (e.g. to a personal

computer), then a safety isolating barrier must be included to

maintain the SELV classification.

An isolated serial communications lead has been designed to connect

the drive to IT equipment (such as laptop computers), and is available

from the supplier of the drive. See below for details:

Table 4-3 Isolated serial comms lead details

Part number Description

4500-0096 CT USB Comms cable

The “isolated serial communications” lead has reinforced insulation as

defined in IEC60950 for altitudes up to 3,000 m.

4.3 Control connections

4.3.1 General

Table 4-4 The control connections consist of:

Function Qty

Single ended analog

input

Control parameters

available

Mode, offset, invert, scaling,

2

destination

Analog output 1 Source, mode, scaling, 7

Digital input 5 Destination, invert

Digital input / output 1

Frequency input 1

PWM or frequency

output

Motor thermistor input 1

Relay 1 Source, invert 41, 42

Drive enable 1 11

+10 V User output 1 4

+24 V User output 1 9

0V common 1 1

Input / output mode select,

destination / source, invert

Maximum reference, input

limit, scaling, destination

Source, scaling, maximum

1

output frequency, mode

Mode, type, trip threshold,

reset threshold

Key:

Destination parameter:

Source parameter:

Mode parameter:

Indicates the parameter which is being controlled

by the terminal / function

Indicates the parameter being output by the

terminal

Analog - indicates the mode of operation of the

terminal, i.e. voltage 0-10 V, current 4-20 mA etc.

Digital - indicates the mode of operation of the

terminal, (the Drive Enable terminal is fixed in

positive logic).

All analog terminal functions can be programmed in menu 7.

All digital terminal functions (including the relay) can be programmed in

menu 8.

Ter mina l

number

2, 5

5, 11, 12,

13, 14

10

14

10

14

Running the

motor

Optimization

NV Media

Card

Onboard

PLC

Advanced

parameters

Diagnostics UL Listing

The control circuits are isolated from the power circuits in the

drive by basic insulation (single insulation) only. The installer

must ensure that the external control circuits are insulated

from human contact by at least one layer of insulation

(supplementary insulation) rated for use at the AC supply

voltage.

If the control circuits are to be connected to other circuits

classified as Safety Extra Low Voltage (SELV) (e.g. to a

personal computer), an additional isolating barrier must be

included in order to maintain the SELV classification.

If any of the digital inputs (including the drive enable input)

are connected in parallel with an inductive load (i.e.

contactor or motor brake) then suitable suppression (i.e.

diode or varistor) should be used on the coil of the load. If no

suppression is used then over voltage spikes can cause

damage to the digital inputs and outputs on the drive.

N

Any signal cables which are carried inside the motor cable (i.e. motor

thermistor, motor brake) will pick up large pulse currents via the cable

capacitance. The shield of these signal cables must be connected to

ground close to the point of exit of the motor cable, to avoid this noise

current spreading through the control system.

Figure 4-3 Default terminal functions

20 Unidrive M200 / M201 Control User Guide

Issue Number: 3

Safety

information

Product

information

Mechanical

installation

Electrical

installation

Getting

started

Basic

parameters

4.3.2 Control terminal specification

1 0V common

Function Common connection for all external devices

2 Analog input 1

Default function Frequency reference

Type of input

Mode controlled by… Pr 07.007

Operating in voltage mode (default)

Full scale voltage range 0 V to +10 V ±3 %

Maximum offset ±30 mV

Absolute maximum voltage range -18 V to +30 V relative to 0 V

Input resistance 100 k

Operating in current mode

Current ranges

Maximum offset 250 µA

Absolute maximum voltage (reverse

bias)

Absolute maximum current 25 mA

Equivalent input resistance 165

Common to all modes

Resolution 11 bits

Sample rate 4 ms

4 +10 V user output

Default function Supply for external analog devices

Nominal voltage 10.2 V

Voltage tolerance ±3 %

Maximum output current 5 mA

5 Analog input 2

Default function Frequency reference

Type of input

Mode controlled by.... Pr 07.011

Operating in voltage mode (default)

Full scale voltage range 0 V to +10 V ±3 %

Maximum offset ±30 mV

Absolute maximum voltage range -18 V to +30 V relative to 0 V

Input resistance 100 k

Resolution 11 bits

Sample rate 4 ms

Operating in digital mode

Absolute maximum voltage range -18 V to +30 V relative to 0 V

Impedance 6.8 k

Input threshold 10 V ±0.8 V (IEC 61131-2)

Sample rate

Unipolar single-ended analog voltage or

unipolar current

0 to 20 mA ±5 %, 20 to 0 mA ±5 %,

4 to 20 mA ±5 %, 20 to 4 mA ±5 %

-18 V to +30 V relative to 0 V

Unipolar single-ended analog voltage or

positive logic only digital input

1 ms when routed to destinations Pr 06.035

or Pr 06.036, otherwise 4 ms.

Running the

motor

Optimization

NV Media

Card

Onboard

PLC

Advanced

parameters

Diagnostics UL Listing

7 Analog output 1

Default function Frequency output

Type of output Unipolar single-ended analog voltage

Voltage range +10 V

Maximum offset 15 mV

Load resistance 2 k

Protection Short circuit relative to 0 V

Resolution 0.1 %

Sample rate 4 ms

9 +24 V user output

Default function Supply for external digital devices

Voltage tolerance ±20 %

Maximum output current 100 mA

Protection Current limit and trip

10 Digital I/O 1

Default function AT ZERO FREQUENCY output

Positive logic digital input, positive logic

Type

Input / output mode controlled by … Pr 08.031

Operating as in input

Absolute maximum applied voltage

range

Impedance 6.8 k

Input threshold 10 V ±0.8 V (IEC 61131-2)

Operating as an output

Nominal maximum output current 50 mA

Maximum output current 100 mA (total including +24 Vout)

Common to all modes

Voltage range 0 V to +24 V

Sample rate

voltage source output.

PWM or frequency output modes can be

selected.

-8 V to +30 V relative to 0 V

1 ms when routed to destinations

Pr 06.035 or Pr 06.036, otherwise 4 ms

11 Digital Input 2

12 Digital Input 3

13 Digital Input 4

Terminal 11 default function DRIVE ENABLE input

Terminal 12 default function RUN FORWARD input

Terminal 13 default function RUN REVERSE input

Type Positive logic only digital inputs

Voltage range 0 V to +24 V

Absolute maximum applied voltage

range

Impedance 6.8 k

Input threshold 10 V ±0.8 V (IEC 61131-2)

Sample rate

-18 V to +30 V relative to 0 V

1 ms when routed to destinations

Pr 06.035 or Pr 06.036, otherwise 4 ms.

Unidri ve M2 00 / M 201 C ontr ol User Gui de 21

Issue Number: 3

Safety

WARNING

information

Product

information

Mechanical

installation

Electrical

installation

Getting

started

Basic

parameters

Running the

14 Digital Input 5

Terminal 14 default function Analog INPUT 1 / INPUT 2 select

Positive logic only digital input. Frequency

Type

Voltage range 0 V to +24 V

Absolute maximum applied

voltage range

Impedance 6.8 k

Input threshold 10 V ±0.8 V (IEC 61131-2)

Sample rate

41

Relay contacts

42

Default function Drive OK indicator

Contact voltage rating 240 Vac, Installation over-voltage category II

Contact maximum current rating

Contact minimum recommended

rating

Contact type Normally open

Default contact condition Closed when power applied and drive OK

Update rate 1 ms

input or motor thermistor input (bias for

DIN44081 ptc, KTY84, PT1000, PT2000

and other types) mode can be selected.

-18 V to +30 V relative to 0 V

1 ms when routed to destinations Pr 06.035

or Pr 06.036, otherwise 4 ms.

2 A AC 240 V

4 A DC 30 V resistive load

0.5 A DC 30 V inductive load (L/R = 40 ms)

12 V 100 mA

motor

Optimization

NV Media

Card

Onboard

PLC

Advanced

parameters

Diagnostics UL Listing

To prevent the risk of a fire hazard in the event of a fault, a

fuse or other over-current protection must be installed in the

relay circuit.

22 Unidrive M200 / M201 Control User Guide

Issue Number: 3

Safety

NOTE

10

7

8

6

5

4

9

1

2

3

1

3

2

5

V A Hz rpm %

1

4

NOTE

information

Product

information

Mechanical

installation

Electrical

installation

Getting

started

Basic

parameters

Running the

5 Getting started

This chapter introduces the user interfaces, menu structure and security

levels of the drive.

5.1 Understanding the display

5.1.1 Keypad

The keypad display consists of a 6 digit LED display. The display shows

the drive status or the menu and parameter number currently being

edited.

The option module Unidrive menu (S.mm.ppp) is only displayed if the

option module is installed. Where S signifies the option module slot

number and the mm.ppp signifies the menu and parameter number of

the option module’s internal menus and parameter.

The display also includes LED indicators showing units and status as

shown in Figure 5-1. When the drive is powered up, the display will show

the power up parameter defined by Parameter Displayed At Power-Up

(11.022).

The values in the Status Mode Parameters (Pr 22 and Pr 23) shown on

the display when the drive is running, can be toggled by using the

escape button.

Figure 5-1 Unidrive M200 keypad detail

motor

Optimization

NV Media

Card

Onboard

PLC

Advanced

parameters

Diagnostics UL Listing

Figure 5-2 Unidrive M201 keypad detail

1. Run forward indicator

2. Unit indicators

3. Speed reference potentiometer

4. Keypad reference indicator

5. Run reverse indicator

The red stop button is also used to reset the drive.

The parameter value is correctly displayed on the keypad display as

shown in Table 5-1.

On the Unidrive M201, the speed reference potentiometer is used to

adjust the keypad reference.

Table 5-1 Keypad display formats

Display formats Value

Standard 100.99

Date 31.12.11 or 12.31.11

Time 12.34.56

Character ABCDEF

Binary 5

IP Address 192.168 88.1*

MAC Address 01.02.03 04.05.06*

Version number 01.23.45

*Alternate display

1. Escape button

2. Down button

3. Start button (green)

4. Stop / Reset button (red)

5. Up button

6. Enter button

7. Run forward indicator

8. Run reverse indicator

9. Keypad reference indicator

10. Unit indicators

5.2 Keypad operation

5.2.1 Control buttons

The keypad consists of:

• Up and down button - Used to navigate the parameter structure and

change parameter values.

• Enter button - Used to change between parameter edit and view

mode as well as entering data. This button can also be used to

select between slot menu and parameter display.

• Escape button - Used to exit from parameter edit or view mode. In

parameter edit mode, if parameter values are edited and the escape

button pressed, the parameter value will be restored to the value it

had on entry to edit mode.

• Start button - Used to provide a 'Run' command if keypad mode is

selected.

• Stop / Reset button - Used to reset the drive. In keypad mode can be

used for 'Stop'.

Unidri ve M2 00 / M 201 C ontr ol User Gui de 23

Issue Number: 3

Safety

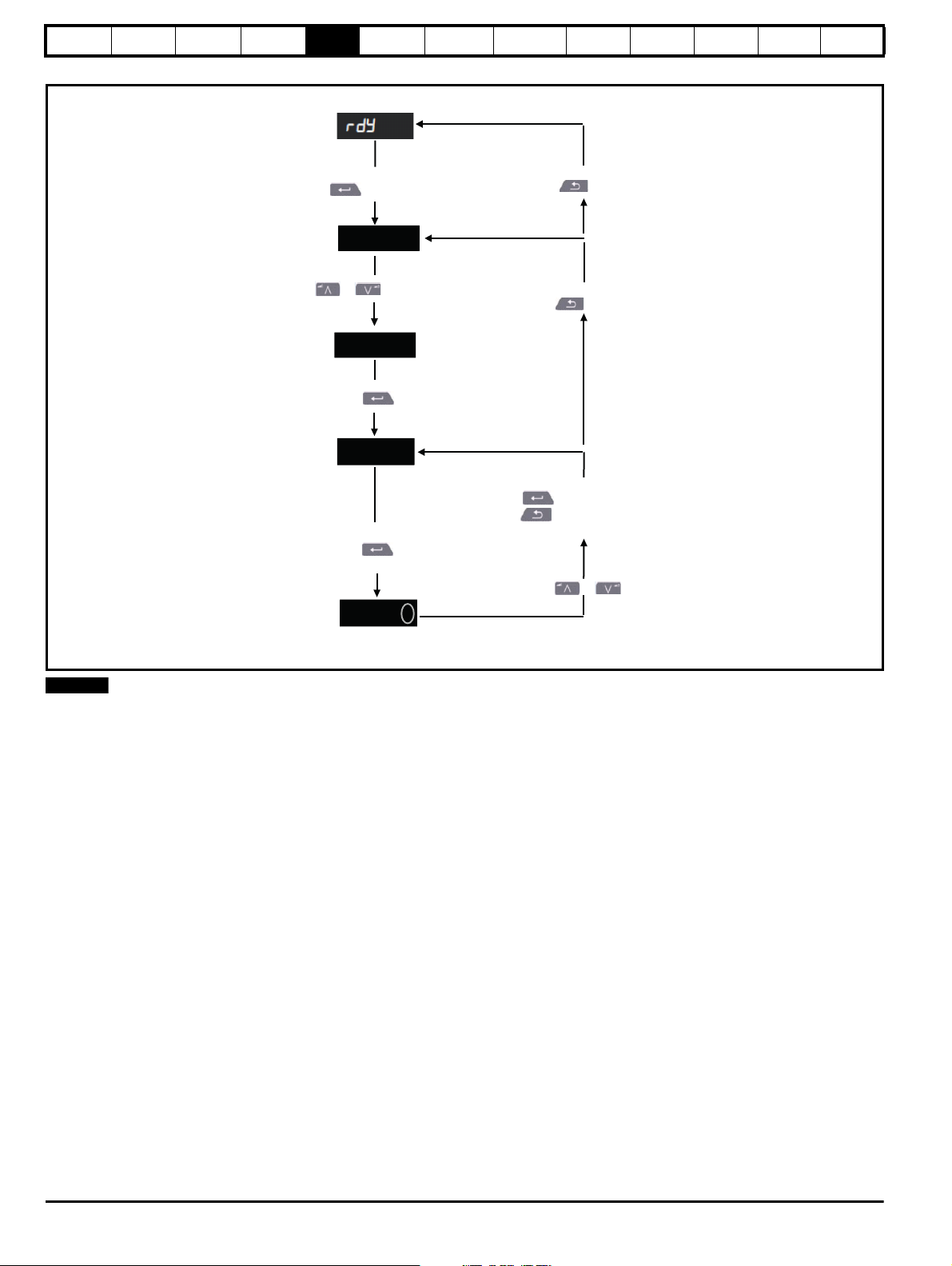

To return to Status Mode,

press button

To return to Parameter View Mode,

press button

Press or to select parameter

Status

Mode

To enter Parameter View Mode,

press button

Parameter

View Mode

Pr 10

Pr 01

0.00

0.00

To view parameter value

press button

To enter Edit Mode,

press button

0.00

Edit Mode (edited digit flashes)

Holding or increases or decreases value

Parameter

Value View

To return to Parameter Value View

press button to keep the new value

press

button to ignore new value and

return the parameter to the pre-edited value

NOTE

information

Product

information

Mechanical

installation

Figure 5-3 Display modes

Electrical

installation

Getting

started

Basic

parameters

Running the

motor

Optimization

NV Media

Card

Onboard

PLC

Advanced

parameters

Diagnostics UL Listing

The up and down buttons can only be used to move between menus if Pr 10 has been set to show 'ALL'. Refer to section 5.9 Parameter access level

and security on page 27.

24 Unidrive M200 / M201 Control User Guide

Issue Number: 3

Safety

3 4

1 2

WARNING

NOTE

NOTE

Menu 0

04

05

06

Menu 2

02.021

Menu 11

11.034

Menu 5

05.007

10.0

AV

4.1

AV

4.1

10.0

information

Product

information

Mechanical

installation

Electrical

installation

Getting

started

Basic

parameters

Running the

motor

Optimization

NV Media

Card

Onboard

PLC

Advanced

parameters

Diagnostics UL Listing

Figure 5-4 Mode examples

1 Parameter view mode: Read write or Read only

2 Status mode: Drive OK status

If the drive is ok and the parameters are not being edited or viewed, the

display will show one of the following:

inh', 'rdy' or status mode parameter value.

3 Status mode: Trip status

When the drive is in trip condition, the display will indicate that the drive

has tripped and the display will show the trip code. For further

information regarding trip codes, refer to section 12.4 Trips, Sub-trip

numbers on page 130.

4 Status mode: Alarm status

During an 'alarm' condition the display flashes between the drive status

parameter value and the alarm.

5.3 Menu structure

The drive parameter structure consists of menus and parameters.

The drive initially powers up so that only Menu 0 can be viewed. The up

and down arrow buttons are used to navigate between parameters and

once Pr 10 has been set to 'All' the up and down buttons are used to

navigate between menus.

For further information refer to section 5.9 Parameter access level and

security on page 27.

The menus and parameters rollover in both directions i.e. if the last

parameter is displayed, a further press will cause the display to rollover

and show the first parameter.

When changing between menus, the drive remembers which parameter

was last viewed in a particular menu and thus displays that parameter.

5.4 Menu 0

Menu 0 is used to bring together various commonly used parameters for

basic easy set up of the drive. The parameters displayed in Menu 0 can

be configured in Menu 22.

Appropriate parameters are copied from the advanced menus into Menu

0 and thus exist in both locations.

For further information, refer to Chapter 6 Basic parameters on page 29.

Figure 5-5 Menu 0 copying

Do not change parameter values without careful

consideration; incorrect values may cause damage or a

safety hazard.

When changing the values of parameters, make a note of the new

values in case they need to be entered again.

New parameter values must be saved to ensure that the new values

apply after the drive has been power cycled. Refer to section 5.7 Saving

parameters on page 26.

Unidri ve M2 00 / M 201 C ontr ol User Gui de 25

Issue Number: 3

Safety

NOTE

information

Product

information

Mechanical

installation

Electrical

installation

Getting

started

Basic

parameters

Running the

motor

Optimization

NV Media

Card

Onboard

PLC

Advanced

parameters

Diagnostics UL Listing

5.5 Advanced menus

The advanced menus consist of groups or parameters appropriate to a

specific function or feature of the drive. Menus 0 to 24 can be viewed on

the Keypad.

The option module menu (1.mm.ppp) is only displayed if the option

module is installed. Where 1 signifies the option module slot number and

the mm.ppp signifies the menu and parameter number of the option

module’s internal menus and parameters.

Table 5-2 Advanced menu descriptions

Menu Description

Commonly used basic set up parameters for quick / easy

0

programming

1 Frequency reference

2Ramps

3 Frequency control

4 Torque and current control

5 Motor control

6 Sequencer and clock

7 Analog I/O

8 Digital I/O

9 Programmable logic, motorized pot, binary sum, timers

10 Status and trips

11 Drive set-up and identification, serial communications

12 Threshold detectors and variable selectors

14 User PID controller

15 Option module slot 1 set-up menu

18 General option module application menu 1

20 General option module application menu 2

21 Second motor parameters

22 Menu 0 set-up

24 Option module slot 1 application menu

Slot 1 Slot 1 option menus*

* Only displayed when the option module is installed.

5.5.1 Display messages

The following tables indicate the various possible mnemonics which can

be displayed by the drive and their meaning.

Table 5-3 Status indications

Drive

String Description

The drive is inhibited and cannot be run.

The Drive Enable signal is not applied to

inh

the drive enable terminal or Pr 06.015 is

set to 0. The other conditions that can

prevent the drive from enabling are shown

as bits in Enable Conditions (06.010)

The drive is ready to run. The drive enable

rdy

is active, but the drive inverter is not active

because the final drive run is not active

Stop The drive is stopped / holding zero speed. Enabled

S.Loss Supply loss condition has been detected Enabled

dc inj The drive is applying dc injection braking Enabled

The drive has tripped and no longer

Er

controlling the motor. The trip code

appears on the display.

UV

The drive is in the under voltage state

either in low voltage or high voltage mode.

HEAt The motor pre-heat function is active. Enabled

output

stage

Disabled

Disabled

Disabled

Disabled

5.5.2 Alarm indications

An alarm is an indication given on the display by alternating the alarm

string with the drive status string on the display. Alarms strings are not

displayed when a parameter is being edited.

Table 5-4 Alarm indications

Alarm string Description

Brake resistor overload. Braking Resistor Thermal

br.res

Accumulator (10.039) in the drive has reached

75.0 % of the value at which the drive will trip.

Motor Protection Accumulator (04.019) in the drive

OV.Ld

has reached 75.0 % of the value at which the drive

will trip and the load on the drive is >100 %.

Drive over temperature. Percentage Of Drive

d.OV.Ld

Thermal Trip Level (07.036) in the drive is greater

than 90 %.

tuning

LS

The autotune procedure has been initialized and an

autotune in progress.

Limit switch active. Indicates that a limit switch is

active and that is causing the motor to be stopped.

Opt.AI Option slot alarm.

Lo.AC Low voltage mode. See Low AC Alarm (10.107).

I.AC.Lt

24.LoSt

Current limit active. See Current Limit Active

(10.009).

24 V backup not present. See 24V Alarm Loss

Enable (11.098).

5.6 Changing the operating mode

Procedure

Use the following procedure only if a different operating mode is

required:

1. Ensure the drive is not enabled, i.e. drive is in inhibit or under

voltage state.

2. Change the setting of Pr 79 as follows:

Pr 79 setting Operating mode

1 Open-loop

2RFC-A

The figures in the second column apply when serial communications are

used.

When the operating mode is changed, a parameter save is carried out.

3. Either:

Press the red reset button

Carry out a drive reset through serial communications by setting Pr

10.038 to 100.

5.7 Saving parameters

When changing a parameter in Menu 0, the new value is saved when

pressing the Enter button to return to parameter view mode

from parameter edit mode.

If parameters have been changed in the advanced menus, then the

change will not be saved automatically. A save function must be carried

out.

Procedure

1. Select ‘Save' in Pr 00 or Pr mm.000 (alternatively enter a value of

1001 in Pr 00 or Pr mm.000)

2. Either:

• Press the red reset button

• Carry out a drive reset through serial communications by setting

Pr 10.038 to 100

26 Unidrive M200 / M201 Control User Guide

Issue Number: 3

Safety

information

Product

information

Mechanical

installation

Electrical

installation

Getting

started

Basic

parameters

Running the

motor

Optimization

NV Media

Card

Onboard

PLC

Advanced

parameters

Diagnostics UL Listing

5.8 Restoring parameter defaults

Restoring parameter defaults by this method saves the default values in

the drives memory. User security status (Pr 10) and User security code

(Pr 25) are not affected by this procedure).

Procedure

1. Ensure the drive is not enabled, i.e. drive is in inhibit or under

voltage state.

2. Select 'Def.50’ or 'Def.60' in Pr 00 or Pr mm.000. (alternatively, enter

1233 (50 Hz settings) or 1244 (60 Hz settings) in Pr 00 or

Pr mm.000).

3. Either:

• Press the red reset button

• Carry out a drive reset through serial communications by setting

Pr 10.038 to 100

5.9 Parameter access level and security

The parameter access level determines whether the user has access to

Menu 0 only or to all the advanced menus (Menus 1 to 24) in addition to

Menu 0.

The User Security determines whether the access to the user is read

only or read write.

Both the User Security and Parameter Access Level can operate

independently of each other as shown in Table 5-5.

Table 5-5 Parameter access level and security

User

security

status

Access

level

Menu 0 status

(Pr 10)

0 LEVEL.1 RW Not visible

1 LEVEL.2 RW Not visible

2ALL RW RW

3 StAtUS RW Not visible

4 no.Acc RW Not visible

The default settings of the drive are Parameter Access Level LEVEL.1

and user Security Open i.e. read / write access to Menu 0 with the

advanced menus not visible.

Advanced menu

status

5.9.1 User Security Level / Access Level

The drive provides a number of different levels of security that can be set

by the user via User Security Status (Pr 10); these are shown in the table

below.

User Security

Status

Description

(Pr 10)

LEVEL.1 (0) Access to first 10 parameters in Menu 0 only.

LEVEL.2 (1) Access to all parameters in Menu 0.

ALL (2) Access to all menus.

StAtU S (3)

The keypad remains in status mode and only first 10

parameters in Menu 0 can be viewed or edited.

The keypad remains in status mode and only first 10

no.Acc (4)

parameters in Menu 0 can be viewed or edited. Drive

parameters cannot be accessed via a comms

interface.

5.9.2 Changing the User Security Level /Access Level

The security level is determined by the setting of Pr 10 or Pr 11.044. The

Security Level can be changed through the keypad even if the User

Security Code has been set.

5.9.3 User Security Code

The User Security Code, when set, prevents write access to any of the

parameters in any menu.

Setting User Security Code

Enter a value between 1 and 9999 in Pr 25 and press the

button; the security code has now been set to this value. In order to

activate the security, the Security level must be set to desired level in

Pr 10. When the drive is reset, the security code will have been activated

and the drive returns to LEVEL.1. The value of Pr 25 will return to 0 in

order to hide the security code.