Installation and

Commissioning Guide

HMI Bypass

Controller

HVAC Drive H300

Part Number: PSD-H300HMIBP-ICG

Issue: 2.0

Contents

Section 1 - Introduction ........................................................................................5

Section 2 - Installation Instructions .....................................................................6

2.1 Receiving ......................................................................................................6

2.2 Nameplate Information ................................................................................6

2.2.1 Labels ...................................................................................................6

2.2.1.1 HMI Bypass Package Label ............................................................6

2.2.1.2 Typical Standard VFD Rating Label ...............................................7

2.3 Part Number Identication ............................................................................8

2.4 Mounting & Clearances .................................................................................9

2.5 Wiring and Precautions ..............................................................................10

2.5.1 General ..............................................................................................10

2.5.2 Input Wiring .......................................................................................10

2.5.3 Output Wiring ....................................................................................11

2.5.4 Control Circuit Wiring .........................................................................12

2.5.4.1 Analog Input ..............................................................................12

2.5.4.2 Digital Inputs .............................................................................12

2.5.4.3 Relay Outputs ............................................................................12

2.5.4.4 Digital Output ............................................................................13

2.5.4.5 Additional HVAC H300 VFD Connections ....................................13

2.5.4.6 Additional SI-I/O Connections ....................................................13

2.5.5 Grounding .........................................................................................14

2.5.6 Customer Connection Terminals .........................................................14

2.5.6.1 Emergency Bypass Operation .....................................................14

2.5.7 Customer Connection Diagram ..........................................................15

2.5.8 HVAC Drive H300 HMI Bypass Schematic ............................................16

2.6 Inspection ..................................................................................................18

Section 3 – Overview of the HMI bypass ..........................................................18

3.1 HMI Bypass Touchscreen Functions .............................................................18

3.1.1 Splash Screen ......................................................................................18

3.1.2 Main Control Screen ...........................................................................19

3.1.3 Drive Status and System Diagnostics...................................................20

3.1.3.1 General Status ............................................................................20

3.1.3.2 Additional Drive Status ....................................................................21

3.1.3.3 Trip Log ............................................................................................21

3.1.3.4 Graphical Trend Viewer ..............................................................22

3.1.3.5 I/O Status ...................................................................................23

3.2 System Settings...........................................................................................23

3.2.1 Motor Map ..........................................................................................24

3.2.3 Advanced VFD Settings .......................................................................26

3.2.4 Skip Frequencies .................................................................................27

3.2.5 Motor Ramp/Limits .............................................................................27

3.2.6 I/O Settings .........................................................................................28

2 HMI Bypass Controller Installation and Commissioning Guide

3.2.7 Auto-Reset Setup ................................................................................28

3.2.8 Remote Control ..................................................................................29

3.2.10 Modbus RTU Conguration ...............................................................30

3.2.10.1 Serial Data Format ....................................................................31

3.2.11 Alarm Response ................................................................................31

3.2.12 Alarm Response - Fireman’s Override ................................................32

3.2.13 Advanced I/O Settings ......................................................................32

3.2.14 PID Setup ..........................................................................................33

3.2.14.1 PID Setup - Sleep/Wake Function ..............................................33

3.2.15 Miscellaneous ...................................................................................34

3.3 Touchscreen HMI Settings ...........................................................................34

3.3.1 Setting the Date and Time ..................................................................35

3.4 Touchscreen LCD HMI Software Update Procedure ......................................36

Section 4 – Startup ...............................................................................................37

4.1 Setup Wizard Process ..................................................................................38

4.2 Setup Wizard - Step-by-Step Instructions ....................................................38

4.3 Checking Motor Rotation ............................................................................42

4.3.1 Check #1: Rotation on VFD power .....................................................42

4.3.2 Check #2: Rotation on Bypass power ..................................................42

4.4 Normal Operation .......................................................................................43

4.4.1 Current System Status ........................................................................43

4.4.2 Starting Operation .............................................................................44

4.4.3 Ending Operation ...............................................................................44

Section 5 - Troubleshooting ................................................................................45

Section 6 - Additional Information ....................................................................47

6.1 Specications - HVAC Drive H300 HMI Bypass .............................................47

6.1.1 Approvals ...........................................................................................47

6.1.2 Design ................................................................................................47

6.1.3 Operating Conditions .........................................................................47

6.1.4 Options ..............................................................................................48

6.2 Maintenance & Inspection ...........................................................................48

6.3 VFD Parameter Access .................................................................................49

6.4 VFD Replacement ........................................................................................49

6.5 HVAC Drive H300 HMI Bypass Parameter Defaults .......................................50

HMI Bypass Controller Installation and Commissioning Guide 3

Safety and Precautions

WARNING

1. Read this manual in its entirety before installing or operating the HMI

bypass package. This manual applies to HMI bypass packages with the

Nidec Control Techniques HVAC Drive H300 variable frequency drive.

2. Do not connect or disconnect wiring, or perform signal checks while the

power supply is turned ON.

3. The internal capacitor of the installed drive may be charged even after the

power supply has been turned OFF. To prevent electrical shock, disconnect

all power before servicing the HMI bypass. Wait at least 10 minutes

after the power supply has been disconnected and all LEDs have been

extinguished.

4. Do not perform a voltage withstand test on the HMI bypass or the

installed drive. This electronic equipment uses semiconductors and is

vulnerable to high voltage. Severe damage to the equipment may occur.

5. The HMI bypass is suitable for use on a circuit capable of delivering not

more than 100,000 RMS symmetrical Amperes, 240 volts maximum (230

Volt class units), 480 Volts maximum (460 Volt Class units), 600 Volts

maximum (575 Volt Class units).

6. Static sensitive printed circuit boards are installed in the HMI bypass

package. Damage may occur due to Electrostatic Discharge (ESD). DO NOT

handle any components without following proper ESD precautions.

Failure to observe these and other precautions highlighted in this manual

will expose the user to high voltages, resulting in equipment damage, serious

injury or death.

The information contained within this document is proprietary to Nidec

Control Techniques and may not be copied, reproduced or transmitted

to other parties without the expressed written consent of Nidec Control

Techniques.

No patent liability is assumed with respect to the use of information

contained herein. Moreover, because Nidec Control Techniques is constantly

improving its high quality products, the information contained in the manual

is subject to change without notice. Every precaution has been taken in

the preparation of the manual. Nevertheless, the manufacturer assumes no

responsibility for errors or omissions. Neither is liability assumed for damages

resulting from the use of the information contained in this publication.

4 HMI Bypass Controller Installation and Commissioning Guide

Section 1 - Introduction

Thank you for purchasing your Nidec Control Techniques HMI bypass

package. This manual provides information concerning the installation,

wiring and general startup procedures for the HVAC Drive H300 line of HMI

bypass packages. The HMI bypass is a complete integrated HVAC control

system which employs the latest Variable Frequency Drive (VFD) technology

and incorporates a dedicated micro-processor based controller for HVAC

applications. The HMI bypass package uses a dedicated LCD touchscreen

Human Machine Interface (HMI) that clearly shows the system operating

status. The HMI bypass is designed for ease of installation and startup.

Please follow this instruction manual’s guidelines for proper installation and

programming of your HMI bypass package.

HVAC Drive H300

LCD touchscreen HMI bypass

Lower enclosure

Disconnect handle

(padlockable)

HMI Bypass Controller Installation and Commissioning Guide 5

Section 2 - Installation Instructions

2.1 Receiving

After unpacking the HMI bypass package:

3 Verify that the part numbers on the package match the numbers on your

purchase order, packing slip or tagging information.

3 Check the unit for physical damage which may have occurred during

shipping. If any part of the package is missing or damaged, notify the

carrier and your Nidec Control Techniques representative immediately.

3 Verify that all internal hardware (i.e. components, screws, etc.) is properly

seated and fastened securely.

2.2 Nameplate Information

The HMI bypass package has two nameplates for identification. The main

label is located on the inside of the enclosure. This nameplate provides

information on the entire package. The second nameplate is located on

the VFD. This nameplate contains information related to the VFD only. The

nameplate information should be recorded and kept in a safe location. This

information is required for any service or repair.

2.2.1 Labels

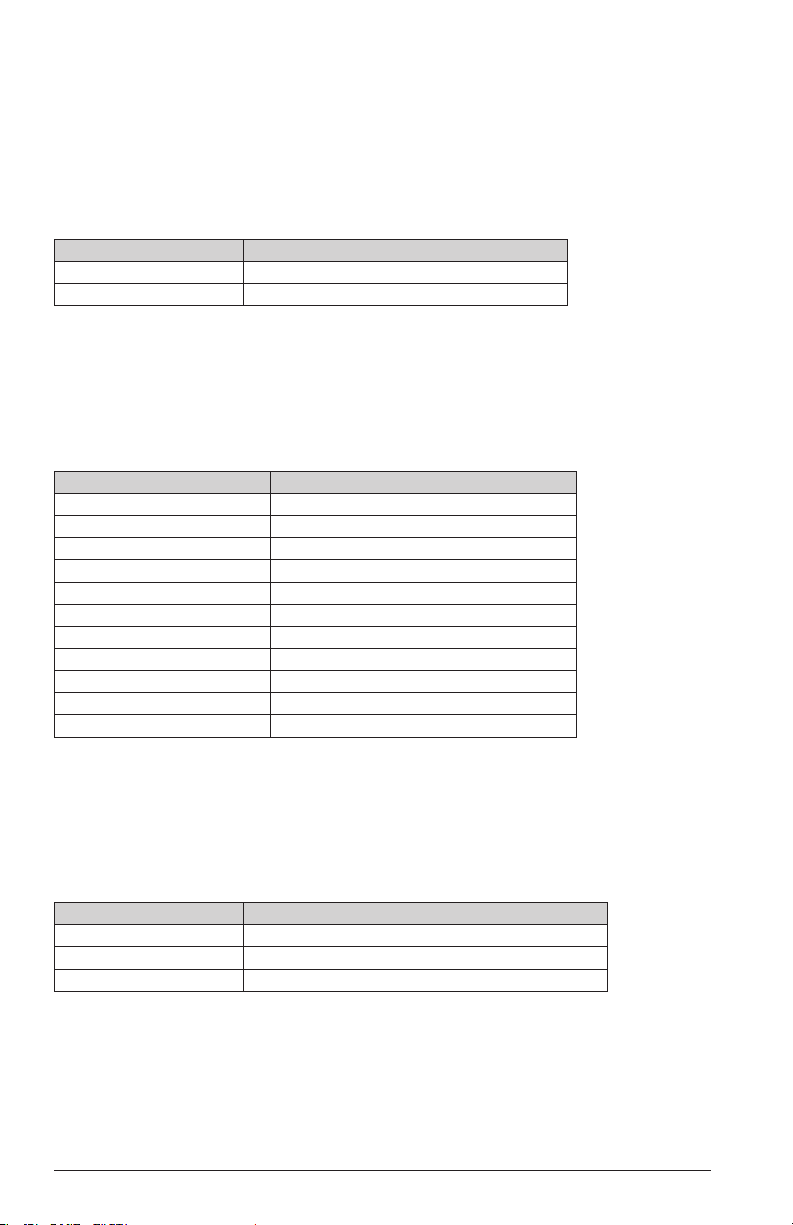

2.2.1.1 HMI Bypass Package Label

6 HMI Bypass Controller Installation and Commissioning Guide

2.2.1.2 Typical Standard VFD Rating Label

* This label is only applicable to VFD size 7 and above.

Refer to the following page Section 2.3 Part Number Identification for further

information relating to the labels.

HMI Bypass Controller Installation and Commissioning Guide 7

2.3 Part Number Identification

Order Code Configurator

HVAC/R Packaged Drives

Packaged HVAC/R Drives from 1 to 600 hp

BASE ORDER CODE POWER & DOOR OPERATOR OPTIONS CONTROL OPTIONS

[Order Code

digit number]

P X XXXX N X X X - X 0 X X X X X 0 - X X X X 0 X X X X X

1 2 3 - 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30

[1] Package Types

G = Pre-Engineered, New Generation

P = Pre-Engineered

S = Seismic*

C = Custom*

*Contact Factory

[2] Voltage Ratings

8 = 208 Vac

2 = 230 Vac

4 = 460 Vac

5 = 575 Vac

[3] - [6] Horsepower Ratings

0001 = 1 HP 0060 = 60 HP

01P5 = 1.5 HP 0075 = 75 HP

0002 = 2 HP 0100 = 100 HP

0003 = 3 HP 0125 = 125 HP

0005 = 5 HP 0150 = 150 HP

0007 = 7.5 HP 0200 = 200 HP

0010 = 10 HP 0250 = 250 HP

0015 = 15 HP 0300 = 300 HP

0020 = 20 HP 0350 = 350 HP

0025 = 25 HP 0400 = 400 HP

0030 = 30 HP 0450 = 450 HP

0040 = 40 HP 0500 = 500 HP

0050 = 50 HP 0600 = 600 HP

[7] Duty Ratings

N = Normal Duty

[8] Enclosure Styles

1 = NEMA 1

2 = NEMA 12

3 = NEMA 3R

4 = NEMA 4X

B = NEMA 1 (Bypass Only)

F = NEMA 1 (Disconnect with Fusing)

[9] Input Power Connections

1 = Circuit Breaker (25 kAIC)

2 = Disconnect Switch with Fusing

3 = Circuit Breaker (65 kAIC)

4 = Circuit Breaker (100 kAIC)

5 = Fused Disconnect (100 kAIC)

Input fuses for drives are included as

standard for all input power options

[10] Products

A = Afnity Active Front End

B = Afnity Drive

2 = Unidrive M200

3 = HVAC Drive H300

X = HVAC Drive H300 AFE

[12] Bypass Options

0 = No Bypass

1 = Electronic 3-Contactor Bypass

2 = Manual Bypass

3 = HMI 2-Contactor Bypass

with VFD Service Swtich

4 = HMI 2-Contactor Bypass

6 = Soft Starter 3-Contactor Bypass

[14] Door-Mounted Keypad/HMI

0 = None

C = LCD Keypad

E = LED Keypad

H = Door-mounted Touchscreen HMI

E = LED Keypad

Unidrive M200 includes LED keypad as standard.

Afnity BA includes LCD keypad as standard.

[15] Input Filtering

0 = None

1 = Input Reactor 3%

2 = Input Reactor 5%

3 = RFI Filter

4 = Input Reactor 3% + RFI Filter

5 = Input Reactor 5% + RFI Filter

6 = Matrix AP Filter

Enclosure size considerations. Addition of one or

multiple ltering options may change the size

and/or style of the enclosure.

Matrix lter - consult factory.

[16] Output Filtering

0 = None

1 = Output Reactor 3%

2 = dV/dt Filter

3 = Sine Filter

4 = Output Reactor 1.5%

[17] Multiple Motors

0 = None Drive Protected

2 = Two Manual Motor Protectors (MMP)

3 = Three Manual Motor Protectors

4 = Four Manual Motor Protectors

5 = Five Manual Motor Protectors

6 = Six Manual Motor Protectors

Cumulative amp ratings of motors must not

exceed the drive rating. Each motor must have its

own overload protection. Multiple Manual Motor

Protectors are of equal size.

[18] Space Heater**

0 = None

2 = 200 W

4 = 400 W

Larger heaters can be chosen for extremely cold

ambient temperatures.

[21] - [23] Option Modules

0 = None

A = SM-APPS-LITE-V2

C = SM-BIPOLAR

D = SM-CANOPEN

E = SM-DEVICENET

H = SM-ETHERCAT

I = SM-ETHERNET

K = SM-I/O-120V

L = SM-I/O-24V

M = SM-I/O-32

N = SM-I/O-LITE

P = SM-I/O-PLUS

Q = SM-I/O-TIMER

R = SM-INTERBUS

S = SM-LON

T = SM-PROFIBUS-DP

V = SM-REGISTER

W = SI-I/O*

Y = AI-485-ADAPTOR*

Z = KI-485-ADAPTOR*

1 = SI-PROFIBUS*

2 = SI-ETHERNET*

3 = SI-DEVICENET*

4 = SI-CANOPEN*

5 = SI-PROFINET-V2*

6 = SI-ETHERCAT*

Unidrive M200 has 1 option

module slot only, Afnity has 2

option module slots, HVAC Drive

H300 has 3 option slots

[24] Phase Loss Monitor

0 = None

1 = Yes

[26] Temperature Controller***

0 = None

1 = Thermocouple

2 = RTD

*SI options used with Unidrive M200 & HVAC Drive H300

**Available with NEMA 3R enclosure only

***Selection of options 26-29 require a cooling tower NEMA 3R enclosure.

NOTE:

For options not included in the Order Code Congurator, please consult

factory for a custom quote.

[27] Basin Heater**

0 = None

1 = 1 kW

2 = 2 kW

3 = 3 kW

4 = 4 kW

5 = 5 kW

6 = 6 kW

7 = 7 kW

8 = 8 kW

9 = 9 kW

A = 10 kW

B = 11 kW

C = 12 kW

D = 13 kW

E = 14 kW

F = 15 kW

G = 16 kW

H = 17 kW

I = 18 kW

J = 19 kW

K = 20 kW

[28] Spray Pump***

0 = None

1 = 1 HP

2 = 2 HP

3 = 3 HP

5 = 5 HP

7 = 7 HP

A = 10 HP

B = 15 HP

[29] De-icer / Sun Shield***

0 = None

1 = De-icer

2 = Sun Shield

3 = De-icer & Sun Shield

[30] Siemens FLN

0 = None

1 = Yes

8 HMI Bypass Controller Installation and Commissioning Guide

2.4 Mounting & Clearances

TOP SIDE-TO-SIDE

Install the HMI bypass package on a vertical surface and allow the following

minimum clearances for normal heat dissipation.

12 in

6 in 12 in 6 in

WARNING

WARNING

Potentially hazardous voltage

can exist within this device. Only fully trained, qualied personnel should

service this equipment.

Pressing the stop button will not remove power from this equipment.

Never service this equipment without rst being sure all power is safely

removed. Hazardous voltage levels may exist for up to 5 minutes after

power is disconnected!

WARNING

WARNING

Potentially hazardous voltage

can exist within this device. Only fully trained, qualied personnel should

service this equipment.

Pressing the stop button will not remove power from this equipment.

Never service this equipment without rst being sure all power is safely

removed. Hazardous voltage levels may exist for up to 5 minutes after

power is disconnected!

Air Flow

Notes:

• Ambient operating temperature; 32 °F to 104 °F (0 °C to 40 °C)

• Install the unit in a dry environment free from oil mist and dust

• Install the unit in a location free from radioactive materials, combustible

materials, harmful gases or liquids

• Do not install the unit in a location susceptible to excessive vibrations

• Do not install in direct sunlight

• During installation, protect the unit from foreign particles such as metal

shavings produced by drilling

• Failure to follow these notes could void the warranty

HMI Bypass Controller Installation and Commissioning Guide 9

2.5 Wiring and Precautions

2.5.1 General

1. DO NOT connect or disconnect wiring or perform signal checks while the

power supply is turned ON.

2. Connect the power supply wiring to the HMI bypass input terminals L1, L2

and L3 on the main circuit disconnect device.

3. Connect the motor wiring to the bypass output terminals T1, T2 and T3 at

the Class 20 Motor O/L or the output reactor if installed.

4. Never touch the output circuit directly or place the output line in contact

with the package enclosure.

5. DO NOT connect power factor correction capacitors on the output circuit.

6. Power supply wiring and motor wiring must be in separate conduits with

separate ground conductors. (DO NOT use conduits as ground).

7. Control wiring must be in conduit separate from both power supply and

motor wiring.

8. Tighten the screws on the main circuit disconnect (if provided) and control

circuit terminals.

9. Observe national and local codes when wiring electrical devices.

Failure to observe these precautions may result in equipment damage or

improper operation and may not be covered under warranty.

2.5.2 Input Wiring

The HMI bypass package may be supplied with several different input device

options. These input options include protective devices as well as non–

protective devices. It is the responsibility of the installing parties to ensure

that requirements for branch circuit protection of the appropriate size and

location are observed. All incoming power is connected to terminals L1, L2,

and L3. The following input options are available.

» Fused disconnect

» Circuit breaker

» Input line reactor

» Input RFI filter

10 HMI Bypass Controller Installation and Commissioning Guide

Connect the main power supply, motor and control wiring using the following

control wiring

Recommended

y

recommended conduit locations. The input phase sequence does not affect

the output phase sequence of the VFD. It will affect bypass sequence and

motor rotation direction.

conduit entrances

WARNING

WARNING

Potentially hazardous voltage

can exist within this device. Only fully trained, qualied personnel should

service this equipment.

Pressing the stop button will not remove power from this equipment.

Never service this equipment without rst being sure all power is safely

removed. Hazardous voltage levels may exist for up to 5 minutes after

power is disconnected!

incoming suppl

motor connection

2.5.3 Output Wiring

The HMI bypass package is always supplied with a Class 20 motor O/L on its

output. However, the unit may be supplied with several different output

options. The following output options are available.

• Single motor O/L (Terminals T1, T2, and T3)

• Dual motor O/L (Terminals (Motor 1 – T1, T2, and T3)

(Motor 2 – T4, T5, and T6))

• Output reactor

Note: All contactors and relays supplied in the HMI bypass package are

suppressed with R/C snubbers. If adding additional inductive loads (i.e.

magnetic contactors, magnetic relays, magnetic valves, solenoids, magnetic

brakes, etc.) in or near the HMI bypass package, use an appropriate surge

suppressor across the coils to limit the transients on the supply lines.

HMI Bypass Controller Installation and Commissioning Guide 11

2.5.4 Control Circuit Wiring

2.5.4.1 Analog Input

A 4 to 20 mA analog input signal is available by connecting to the customer

terminals 5 (+) and 4 (-).

Terminal No. Description

4 0V Common Analog

5 Speed/Frequency Reference

2.5.4.2 Digital Inputs

The HMI bypass combines digital inputs from the HVAC H300 VFD and SI-I/O

option module. As per the following table, the HMI bypass control provides

ten (10) digital inputs.

There are ten (10) digital inputs. (24 Vdc).

Terminal No. Description

1 (3 positions) 0V Common

22 Fireman’s Override

23 Damper Feedback

24 Fire Alarm

25 Customer Reset

27 Auto Run

29 Enable

203 Safety

204 Relay Output Select (223)

207 Remote Bypass Select

208 Remote VFD Select

Terminal 204 is used as an input signal to control terminal 223 relay output

when terminal 223 is set to “T204 24V Input”. All digital inputs are dry

contacts (voltage free).

2.5.4.3 Relay Outputs

There are two (2) form A relay outputs.

Terminal No. Description

221 System Fault

222 0V Common for dry contacts 221 & 223

223 System On or 204 24V Input

When Relay Output Select is set up for “204 24V Input” terminal 223 will be

controlled by the input on terminal 204.

12 HMI Bypass Controller Installation and Commissioning Guide

There is one (1) form C relay output.

Terminal No. Description

71 0V Damper Control Contact Common

74 Damper Control Contact (NO)

2.5.4.4 Digital Output

There is one (1) digital output. (24 Vdc).

Terminal No. Description

202 Auto Mode Selected

2.5.4.5 Additional HVAC H300 VFD Connections

Additional analog inputs and outputs are available by making connections

directly to the HVAC H300 VFD. The following connections are located on the

VFD and not the customer connection terminal block.

VFD Terminal No. Description

4 0V Common Analog Input

6 Analog PID Feedback

VFD Terminal No. Description

7 Speed/Frequency Output

8 Analog Torque Output

9 0V Common Analog Output

For further information see HVAC Drive H300 User Guide.

2.5.4.6 Additional SI-I/O Connections

Additional Analog I/O and Digital I/O can be made by making connections

directly to the SI-I/O module mounted in slot 3 of the HVAC Drive H300. The

following connections are not found on the customer connection terminal

block.

SI-I/O Terminal No. Description

205 Digital Input/Output 4

206 0V Common SI-I/O

209 Analog Input 3/Digital Input 7

210 0V Common SI-I/O

211 Analog Output 1/Digital Input 8

HMI Bypass Controller Installation and Commissioning Guide 13

2.5.5 Grounding

(a) Acceptable (b) Acceptable (c) Not Acceptable

Never ground the HMI bypass package in common with welding machines,

motors or other high current electrical equipment. Run all ground wires in a

separate conduit.

When using several electronic bypass packages side by side, ground as shown

below.

√ √

x

2.5.6 Customer Connection Terminals

All control circuit connections are made through the Customer Connection

terminal block. There are connections between the Customer Terminal block,

the HVAC Drive H300, and the SI-I/O module. These connections are made at

the factory and are for reference only. DO NOT change this wiring as it will

cause the HMI bypass to operate improperly or not at all.

See following page for Customer Connection Terminal diagram.

2.5.6.1 Emergency Bypass Operation

In situations requiring Emergency Bypass operation (i.e. drive removal or +24

Vdc supply failure) bypass contactor can be engaged to run the motor across

the line by moving Jumper (41-100) to (44-EB). Note the thermal overload

protection is protecting the motor.

14 HMI Bypass Controller Installation and Commissioning Guide

2.5.7 Customer Connection Diagram

NOTE: For Emergency Bypass

Operation (i.e. drive removal

or +24 Vdc supply failure) bypass

contactor can be engaged to run

the motor across the line by

moving Jumper (41-100) to (44EB). Note the thermal overload

protection is protecting the motor.

HMI Bypass Controller Installation and Commissioning Guide 15

2.5.8 HVAC Drive H300 HMI Bypass Schematic

16 HMI Bypass Controller Installation and Commissioning Guide

HMI Bypass Controller Installation and Commissioning Guide 17

2.6 Inspection

Once all wiring is complete, verify that:

1. All wiring is installed.

2. Excess screws, metal filings and wire clippings are removed from inside the

unit(s).

3. Screws and fasteners are securely tightened.

4. Exposed wiring has no contact with other wiring or terminals.

Section 3 – Overview of the HMI bypass

All start/stop, safety, fire alarm inputs and VFD analog output are routed to the

inputs of the VFD and IO module via customer terminal connections.

The analog input is factory set to accept a 4–20 mA speed reference signal.

All control wiring must be run in a separate conduit from ANY high voltage or

power wiring. The wiring should also be properly grounded and shielded when

necessary to ensure proper operation.

3.1 HMI Bypass Touchscreen Functions

3.1.1 Splash Screen

Upon initial power-up or any power cycle the LCD touchscreen HMI will

reset to the splash screen. If the HMI Bypass has been setup, operation will

continue in the same state as it was before shutdown/power loss.

4.1.1 Splash Screen

CONTINUE: Navigate to the main control screen.

SETUP WIZARD: Begins the bypass configuration process. Users must enter the

security pin number before changing system settings. See section 4.1 for HMI

bypass commissioning using the setup wizard.

18 HMI Bypass Controller Installation and Commissioning Guide

3.1.2 Main Control Screen

From the main screen, users can control the state of the bypass system and

navigate to system configuration (settings) and status menus.

HAND: Pressing this icon will put the bypass system in Hand Mode. In VFD and

Hand Mode, the system will run at a manually selected frequency and the

bypass contactor will automatically close if BYP (Bypass Mode) is selected and

the VFD output is off.

AUTO: Pressing this icon puts the bypass system in Auto Mode. In Auto Mode,

the system will require the “Auto Run Input” on terminal 27 to be active in

order to run the motor. If VFD Mode is also selected, the system will follow

the analog speed reference on terminal 5 (4-20 mA). If BYP is selected, the

system will run at line frequency, but still requires the “Auto Run Input”

(terminal 27).

STOP: This button will stop the motor and also acts as a reset.

Note: If a Remote Bypass, Remote VFD, or Fireman’s Override command is

present on the digital inputs, the STOP icon will not stop the motor.

VFD: Puts the system in VFD Mode. The output contactor is closed and the

motor is powered by the VFD.

BYP: Puts the system in Bypass Mode. The bypass contactor will close and the

motor will rotate at line frequency.

Note: If you are in Hand|Auto “VFD” Mode and want to switch To Bypass

“BYP” Mode, serlect Bypass Mode “BYP” and then reselect HAND or AUTO.

HMI Bypass Controller Installation and Commissioning Guide 19

3.1.3 Drive Status and System Diagnostics

3.1.3.1 General Status

The drive status screen displays basic VFD information.

Motor RPM: Displays the estimated speed of the motor.

Current Magnitude: The instantaneous drive output current scaled so that it

represents the r.m.s. phase current in Amps under steady-state conditions.

Output Power: Displays the current power output of the VFD.

Output Frequency: Displays the frequency applied to the motor.

Drive Thermal Accumulator: Displays the percentage of the thermal trip level

of the drive.

Motor Thermal Accumulator: Displays the level of the motor overload

accumulator.

Software Version: Displays the current software version of the LCD

touchscreen HMI program.

More: Navigates to an additional Drive Status page.

Trip Log: Navigates to the system fault log.

View Trends: Displays the Graphical Trend Viewer for Motor RPM, Motor Load

%, and Motor Thermal Overload %.

I/O Status: Shows the current status of all digital inputs, outputs and relays.

20 HMI Bypass Controller Installation and Commissioning Guide

3.1.3.2 Additional Drive Status

This screen displays the estimated total running cost of the HMI bypass system

and filter change reminders.

Power Consumption: Displays the current power consumption of the VFD.

Power Cost per kWhr: Defines the cost of energy per kWh in cents.

Total Power Consumption: Displays the accumulated VFD power consumption.

Total Running Cost: Uses the Total Power Consumption and Power Cost per

kWhr to calculate Total Running Cost.

3.1.3.3 Trip Log

The previous 5 system faults are recorded and displayed. For accurate

timestamps, the time must be manually set in the HMI settings menu.

Clear Log: Pressing this button will clear the recorded fault list.

• Motor Overload/PL: Motor thermal overload relay (resettable) or phase

loss monitor (if fitted) is tripped connecting 24V to terminal 26 or VFD

parameter 18.035 is set to 1 via serial communications.

Recommended actions:

» Check Motor

» Check Insulation, phase to phase, and phase to ground

» Check Bearings

» Check Load/transmission

» Check for Phase loss or phase loss monitor (if fitted)

» Reduce Starts per hour

» Check Motor winding configuration (delta or wye)

HMI Bypass Controller Installation and Commissioning Guide 21

If all above checks are good, attempt to reset the overload relay using the

overload reset button.

• Fire Alarm: A 24V input signal on Fire Alarm input (24) is present.

Recommended action:

» If an external fire alarm is not present, verify customer terminal block

wiring.

• Damper Timeout: A 24V input signal on Damper Feedback (23) is present,

Damper Fault Response is “ENABLED,” and Damper Timeout has expired.

Recommended action:

» Check operation of the customer damper and verify customer terminal

block wiring.

• Safety Input: A 24V input signal on Safety input (203) is present

Recommended action:

» If an external Safety input is not present, verify customer terminal block

wiring.

• Watchdog: External VFD trip due to loss of communication between VFD

and HMI.

Recommended action:

» Verify physical Ethernet connection between VFD and LCD touchscreen

HMI. Verify IP address of LCD touchscreen HMI and VFD are on the

same network.

Notes: If the fault cannot be cleared from the LCD touch screen HMI with a

reset it may be required to access the HVAC Drive H300 VFD directly with a

keypad or through Connect VFD configuration software.

For a full explanation of VFD faults, refer to the HVAC Drive H300 VFD User

Guide.

3.1.3.4 Graphical Trend Viewer

Historical view of Motor RPM, Motor Load (0-100%), and Motor Thermal

Overload (0-100%) going back 8 minutes. Use the left and right arrows to

navigate between the graphs.

22 HMI Bypass Controller Installation and Commissioning Guide

3.1.3.5 I/O Status

Displays the status of inputs, outputs, and relays in the system, terminals 22

through 74.

MORE: Navigates to the second I/O status page. The second I/O status page

displays the SI-I/O expansion module I/O, terminals 202 through 223 and

analog input terminals 5 and 6.

3.2 System Settings

From this screen, users can access the configuration menus for the bypass

system.

Default Settings: After confirmation, all system settings will revert to default

values.

Setup Wizard: Begins the commissioning process starting with motor data.

HMI Bypass Controller Installation and Commissioning Guide 23

3.2.1 Motor Map

The HMI Bypass motor data can be found or entered in the Motor Data

screen. The Motor Data screen also allows access to the autotune feature and

Advanced VFD settings. Motor data can usually be found on the nameplate of

the motor.

Rated Frequency: Set to the rated frequency of the motor (nameplate value).

Current: Set to the rated current of the motor (nameplate value).

Speed: Set to the rated speed of the motor (nameplate value).

Voltage: Set to the rated voltage of the motor (nameplate value).

Motor Poles: Set to the number of poles of the motor. If motor poles are set

to “0”, the number of motor poles will be calculated automatically.

Power Factor: Set to the motor power factor (nameplate value). If the power

factor is not known, it can be automatically calculated by performing a

rotating autotune.

Note: If the power factor is calculated using the autotune function the user

will not be able to manually change the value.

Autotune: Navigates to the autotune feature page. autotune is not necessary

to run the motor, but doing so will result in improved performance and

efficiency.

Advanced: Navigates to the advanced motor settings.

24 HMI Bypass Controller Installation and Commissioning Guide

3.2.2 Autotune

WARNING

The VFD is able to perform either a stationary or a rotating autotune. The

motor must be at a standstill before an autotune is enabled. A rotating

autotune should be used whenever possible, so the measured value of power

factor of the motor is used by the drive.

Autotune: is an algorithm that the VFD uses to detect physical characteristics

of the motor in order to improve control and efficiency.

To perform an autotune, first select either STATIONARY or ROTATING

(recommended) and then hit the AUTOTUNE button. The motor must be at a

standstill before an autotune is enabled.

Note: The drive will not perform an autotune if there is an existing fault or if

the STO input is not closed.

Note: A rotating autotune should only be used if the motor is uncoupled. To

clear incorrect values calculated from a coupled rotating autotune perform a

stationary autotune. Performing a stationary autotune will clear the incorrect

values and reset motor rated power factor to factory default (0.85).

A rotating autotune will cause the motor to accelerate up to 40 Hz in the

direction selected regardless of the reference provided. Once complete the

motor will coast to a stop.

HMI Bypass Controller Installation and Commissioning Guide 25

3.2.3 Advanced VFD Settings

The Advanced VFD Settings menu allows access to advanced settings of the

VFD.

Voltage Boost: Defines the level of voltage boost at 0Hz when using a fixed V

to F relationship.

Current Limit: Limits the current when the motor is being accelerated or

decelerated.

Open-Loop Control Mode: Defines the VFD output mode. The default setting

for Open-Loop Control Mode is “Fixed” or V/Hz.

• Ur S: Resistance compensation, stator resistance measured at each start.

• Ur: Resistance compensation with no stator resistance measurement.

• Fixed: (Default) Fixed boost with a linear characteristic. Also known as V/

Hz Boost mode.

• UR Auto: Resistance compensation, stator resistance measured on the first

start.

• Ur I: Resistance compensation, stator resistance measured at power-up.

Also known as Open-Loop Vector mode.

• Square: Fixed boost with square characteristic. Also known as Quadratic

Motor V/Hz mode.

• Current 1P: Single phase current output.

Note: For further information on Open-Loop control modes refer to the HVAC

H300 User Guide.

Reverse Motor Direction: If Reverse Motor Direction is on, the output phase

sequence is reversed so that the phase sequence in W-V-U for positive

frequencies and U-V-W for negative frequencies.

Dynamic V to F: Dynamic V to F is intended for applications where power

loss should be kept to a minimum under low load conditions, but dynamic

performance is not important. The setting is enabled by default.

26 HMI Bypass Controller Installation and Commissioning Guide

3.2.4 Skip Frequencies

The skip reference functions are available to prevent continuous operation

within a specified speed range (i.e., where mechanical resonance may occur).

The HMI Bypass allows up to three (3) speed/frequencies to be skipped.

Skip Reference: Sets the center point of the speed/frequency reference the

VFD should skip.

Band Width: Defines the range which speed/frequency references are

rejected in either direction. The actual reference band is, therefore, twice that

defined in the Band Width, with Skip Reference as the center of the band.

3.2.5 Motor Ramp/Limits

The Motor Ramps/Limits screen allows configuration of speed/frequency limits

as well as acceleration and deceleration values the VFD will use during motor

start and stop.

Max Switching Freq: Defines the maximum switching frequency used by the drive.

If drive will operate at this frequency unless the inverter becomes too hot. Under

these conditions the drive will reduce switching frequency to avoid tripping.

Minimum Frequency: Defines the minimum value for the reference.

Maximum Frequency: Defines the maximum value for the reference.

Generally set to 60 Hz or less.

Accel Time: Defines the rate of acceleration. This is the time to accelerate

from minimum frequency to maximum frequency.

Decel Time: Defines the rate of deceleration. This is the time to decelerate

from maximum frequency to minimum frequency.

HMI Bypass Controller Installation and Commissioning Guide 27

3.2.6 I/O Settings

The I/O Setting screen allows the setup of the system I/O.

Analog Speed Reference Mode: Defines the input mode for analog input

speed/frequency reference (5). The following list provides a brief explanation

of the available settings. For further information see HVAC H300 User Guide.

• 0-20 mA: 0-20 mA

• 20-0 mA: 20-0 mA

• 4-20 mA Trip: 4-20mA trip on current loss

• 20-4 mA Trip: 20-4mA trip on current loss

• 4-20 mA (default): 4-20mA no action on loss

• 20-4 mA: 20-4mA no action on loss

• 0-10 Vdc: 0-10Vdc no action on loss

Scaling: The analog input will be multiplied by a factor between 0.000 to

10.000.

Relay Output Select (T223): Select between “System On” and “T204 24V

Input” The HMI Bypass default is “System ON.”

System ON: Configures relay terminal 223 to close when the HMI Bypass has

power

T204 24V Input: Configures relay terminal 223 to close dependent on the

signal input to terminal 204.

3.2.7 Auto-Reset Setup

This screen defines the VFD behavior when tripped/faulted.

28 HMI Bypass Controller Installation and Commissioning Guide

Auto-Reset Delay: The time interval between reset attempts. The HMI Bypass

default is 5 seconds.

Hold Drive Healthy: If set to “ON,” the fault alarm relay will not close until all

reset attempts have been exhausted.

Note: If Hold Drive Healthy is set to “ON” and if Number of Auto-Reset

Attempts is set to “6” (infinite) the Drive Healthy status will always remain

“Healthy.”

3.2.8 Remote Control

The Remote Control screen defines whether the HMI Bypass is controlled by

the customer terminal block inputs or serial fieldbus communications.

This screen allows you to select either “Local” or “Remote” (Serial/Ethernet

communications) control for each individual input. If Remote is selected, the

bypass system will be controlled by the corresponding bit in the VFD rather

than the digital input. Parameter’s referenced below can only be accessed

directly from the HVAC Drive H300 with a keypad or with Connect VFD

configuration software. For further information on Remote setup see the

HVAC Drive H300 User Guide.

Remote Local

Input Parameter Terminal

Fireman Override* 18.031 22

Damper Feedback 18.032 23

Fire Alarm 18.033 24

Reset 18.034 25

Forward/Reverse** 18.037 -

Motor Overload 18.035 26

Auto Run 18.036 27

*Remote Fireman’s Override is only available if Fireman’s Override VFD mode

is off. Remote control will then initiate a bypass run.

**Foreword/Reverse is a remote parameter only used to reverse a running

motor using configured ramps.

SERIAL COMMS: Navigates to the serial communication configuration screens.

HMI Bypass Controller Installation and Commissioning Guide 29

3.2.9 Serial Communications

This screen allows for the configuration of settings needed for serial

communication.

BAN (Building Automation Network) Protocol: Selects the network protocol.

0 = Modbus RTU

1 = BACnet

2 = Metasys N2 Open

MS/TP Max Master Mac Address: (BACnet use only) this is the highest address

that the bypass system will use when looking for the next master on the

network with which token passing can be achieved. Range 0-127

Communications Timeout Period: The period in seconds that the system will

wait to see a valid communications frame on the network.

NOTE: See HVAC Drive H300 User Guide for further serial communications

setup details.

3.2.10 Modbus RTU Configuration

This screen allows for the configuration of settings needed for serial

communication.

Serial Address: Defines the node address for the serial communications

interface range from 1 to 247.

Note: It is necessary to perform a reset by hitting the “RESET” button on the

previous page for this setting to take effect.

Baud Rate: Defines the baud rate used by the serial communications interface.

30 HMI Bypass Controller Installation and Commissioning Guide

3.2.10.1 Serial Data Format

Defines how the serial data packets are formatted. Stop bits, parity, and

standard/modified address schemes.

3.2.11 Alarm Response

The Alarm Response screen allows for the configuration of the Automatic

Bypass and Damper Fault Response features.

Automatic Bypass: When enabled, the system will automatically go

into Bypass Mode after a fault is detected and after “Auto-Bypass Time”

has elapsed.

Auto-Bypass Time: This is the delay between the VFD fault detection

and closing the bypass contactor.

Damper Fault Response: When enabled, a damper feedback signal will

be required to run the motor. If no signal is detected after the “Damper

Timeout” window has elapsed, a Damper Timeout fault will be triggered.

Damper Timeout: The window of time during which the bypass system will

wait for a damper feedback signal. If this time has elapsed and no damper

feedback is detected, a damper timeout fault is triggered.

Damper Motor On Delay: The time delay between when a motor run signal

is received (VFD or Bypass) and when the motor starts. This time is typically

adjusted to allow for damper operation.

HMI Bypass Controller Installation and Commissioning Guide 31

3.2.12 Alarm Response - Fireman’s Override

This Alarm Response screen allows for the configuration of the Fireman’s

Override feature.

Fireman’s Override: When enabled, a fireman override command will ignore

“Motor Overload” and “Damper Timeout” faults. The system will still wait for

a damper feedback, but if no feedback is detected and a timeout is triggered,

the system will bypass anyway. The system will run to destruction as long as

the override command and safety input (terminal 203) are present.

Note: When disabled, “Motor Overload” and “Damper Timeout” will stop the

motor.

Firemans’s Override (VFD mode): If ON, a Fireman’s Override command will

initiate VFD operatin rater than turning the bypass contactor on.

VFD Override Setpoint: Determines the frequency reference used by the VFD

when in override mode.

Fireman’s Override PID Control: Allows PID control loop to regulate frequency

reference in override mode (ignores VFD Setpoint frequency).

Note: Fireman’s Override (VFD mode) must be ON for Fireman’s Override PID

Control to function (requires analog input to terminal 6 of VFD).

3.2.13 Advanced I/O Settings

The Advanced, I/O Settings screen, allows the setup of the I/O settings needed

for the onboard PID feature

Analog PID Feedback Mode: Defines the input mode for analog input 2 (PID

feedback input) VFD terminal 6.

Sensor Range: Defines the operating range of the feedback sensor. This

information can be found in the documentation provided with your sensor.

32 HMI Bypass Controller Installation and Commissioning Guide

3.2.14 PID Setup

The PID setup screen allows for the configuration of the onboard PID feature.

Control Action: Direct control means that as the PID error increases, the speed

reference also increases. A common application for direct control is a cooling/

heating fan. Reverse control will decrease the speed reference as the PID

error increases. A common application for reverse PID control is a pump with

pressure feedback.

Display Units: Determines the display units for PID setpoint and feedback.

Does not affect PID operation. An example would be “F” or “psi.”Gains:

Determines the gains for the internal PID controller.

3.2.14.1 PID Setup - Sleep/Wake Function

This screen allows the setup of the Sleep/Wake Threshold feature.

The Sleep/Wake function is used to stop the motor if the frequency or

speed reference falls below a specified level so that the system does not run

inefficiently at low speeds.

If the reference is greater than the Sleep/Wake Threshold for longer than

the Wake Delay, then the motor is enabled. If the reference falls below the

(Sleep/Wake Threshold - Sleep Offset) for longer than the Sleep Delay, then

the motor is disabled.

Sleep/Wake Threshold: This is the threshold that the speed reference is

compared against. A value of zero will disable the Sleep/Wake function.

HMI Bypass Controller Installation and Commissioning Guide 33

Wake Delay: Defines the elapsed time before the system restarts the motor if

the wake function is active.

Sleep Delay: Defines the elapsed time before the system stops the motor if

the sleep function is active.

Max Sleep Offset time: Defines the maximum amount of time that the Sleep

Offset function can be active.

3.2.15 Miscellaneous

The miscellaneous screen is used to setup the security pin feature and read/

write HVAC H300 VFD parameters.

Security Pin Protection: Determines whether the security pin is enabled or

disabled. If it is disabled, users will no longer be prompted to enter security

pin when entering system settings. By default, the HMI Bypass will ship with

Security Pin Protection Enabled with a Security Pin of “1111”.

Set Security Pin: Set the security pin to any 4-digit number.

Smartcard Parameter Cloning: With a Control Techniques’ Smartcard in the

VFD Smartcard slot, users can read and write parameter files to the Smartcard

to easily duplicate or backup settings.

3.3 Touchscreen HMI Settings

Select the HMI SETTINGS button to navigate to the Internal HMI menu screen

where you can set/update Date/Time from the default (Central Standard Time

“CT”). HMI Backlight and Ethernet settings can also be accessed from this

screen.

34 HMI Bypass Controller Installation and Commissioning Guide

Note: It is recommended that the HMI SETTINGS menu be accessed for Date/

Time setting and Backlight setting only. Changing any other HMI settings

may prevent the HMI Bypass from operating satisfactorily.

In order to navigate to the HMI Settings menu, click YES.

3.3.1 Setting the Date and Time

LCD Touchscreen HMI XP-Runtime Menu

Press the “Settings” icon to navigate to the HMI Settings menu.

Select DateTime Setting.

HMI Bypass Controller Installation and Commissioning Guide 35

A window will appear with date and time. Set values to current date and

time. Press “OK” when complete.

To return to the HMI Bypass menus press the “Start” icon from the

XP-Runtime menu.

To navigate back to the HMI Bypass menus press the “Start” icon from the

XP-Runtime menu

3.4 Touchscreen LCD HMI Software Update Procedure

To update the LCD touchscreen HMI program from a portable USB drive:

1. Start with a USB drive that has the correctly formatted file and file

directory.

• Drive:\XP_Project\[name]

• The program should be saved as a compiled .xpdz file using the

XP-Builder software.

2. Ensure that USB flash drive has been fitted into the USB host port on the

back of the eXP20 HMI.

3. To access the XP-Runtime menu, hit the “HMI Settings” button in the

system menu and press yes to confirm.

4. Select “Storage Function”

5. Select “Project Download”

36 HMI Bypass Controller Installation and Commissioning Guide

6. Choose the correct file name from the list and hit “OK”

7. Wait while the HMI extracts and installs the new project file.

Section 4 – Startup

This section provides guidance on how to setup an HVAC Drive H300 HMI

Bypass. It is recommended that before the initial HMI Bypass setup process

begins that the HVAC H300 HMI Bypass Installation and Commissioning Guide

is read in its entirety and the steps in Section 2.1 through 2.6 are completed.

It is recommended that initial setup of the HMI Bypass is completed using the

Setup Wizard. The Setup Wizard can be accessed from the Splash Screen upon

system power up or from the System Settings menu.

The Setup Wizard will step you through the basic HMI Bypass setup screens.

HMI Bypass Controller Installation and Commissioning Guide 37

4.1 Setup Wizard Process

The Setup Wizard will step you through the Motor Data, Motor Ramps/Limits,

I/O Settings, Auto-Reset Setup, Remote Control, Alarm Response – Automatic

Bypass, and Alarm Response – Fireman’s Override setup screens. If the PID

Controller is to be used, upon selection, it will step you through the Advanced

I/O Settings, PID Setup, and PID Setup – Sleep/Wake screens.

4.2 Setup Wizard - Step-by-Step Instructions

The following steps provide a basic step-by-step guides for initial setup of the

HMI Bypass.

Step 1 – Start Setup Wizard: Press the Setup Wizard Icon on the Splash Screen

or System Settings screen.

38 HMI Bypass Controller Installation and Commissioning Guide

Step 2 – Motor Data: Enter motor nameplate information in the following

settings.

• Rated Frequency: Motor nameplate value

• Current: Motor nameplate value

• Speed: Motor nameplate value

• Voltage: Motor nameplate value

• Power Factor: Motor nameplate value

Once complete press the “NEXT” icon.

Step 3 – Motor Ramps/Limits: Enter the necessary settings for the application.

Once complete press the “NEXT” icon.

Step 4 – I/O Settings: Verify the Analog Speed Reference mode matches the

HMI Bypass system analog speed/frequency reference type.

Once complete press the “NEXT” icon.

HMI Bypass Controller Installation and Commissioning Guide 39

Step 5 - Auto-Reset Setup:

If Auto-Reset feature is desired, set the number auto-reset attempts and the

delay between attempts when the VFD trips. Setting Hold Drive Healthy to

“ON” will hold the VFD drive health status to “Healthy” until the Auto-Reset

attempts are complete.

Once complete press the “NEXT” icon.

Step 6 – Remote Control:

Select whether the HMI Bypass function is to be controlled by Remote serial

communications or Local customer terminals. By default the HMI Bypass will be

set for Local control via the customer terminals.

Once complete press the “NEXT” icon.

Step 7 – Alarm Response – Automatic Bypass:

If the application requires the HMI Bypass to automatically transfer to Bypass

mode upon VFD trip set Automatic Bypass to “ENABLE”. The HMI Bypass will

transfer to Bypass Mode after the Auto-Bypass time has elapsed.

40 HMI Bypass Controller Installation and Commissioning Guide

If the application requires the HMI Bypass to disable in the case of loss of

Damper Feedback input (terminal 23) and enable the Damper Timeout trip,

then the Damper Fault Response should be set to “ENABLED.” If enabled,

set Damper Timeout for the time between loss of Damper Feedback input

(terminal 23) and when the HMI Bypass initiates a Damper Timeout trip.

Once complete press the “MORE” icon.

Step 8 - Alarm Response - Fireman’s Override:

Set Fireman’s Override (VFD mode) to “ON” if you require the VFD to run at

a fixed frequency when the Fireman’s Override is ENABLED. The fixed speed

setting is adjusted in the SETPOINT window. Setting to “OFF” will result in the

system running in Bypass Mode when the Fireman’s Override is ENABLED

Note: To adjust the setpoint Fireman’s Override (VFD mode) must be “ON.”

Once set, return Fireman’s Override (VFD mode) to “OFF” for normal HMI

Bypass operation.

Set Fireman’s Override PID Control to “ON” if you require the VFD to run

from PID control frequency reference.

Note: This feature requires the PID controller to be setup and ignores VFD

Setpoint frequency.

Once complete press the “NEXT” icon.

Step 9 - PID Controller: The Setup Wizard will prompt the question, “Are you

using the onboard PID controller?”

HMI Bypass Controller Installation and Commissioning Guide 41

If “NO” then setup the HMI Bypass basic setup is complete and the Setup

WARNING

Wizard will return to the System Settings screen.

If “YES” the Setup Wizard will continue to the optional PID setup screen.

Optional Step - Onboard PID Controller: If the Onboard PID Controller will be

used, the Setup Wizard will continue to the Advanced I/O Settings, PID Setup,

and PID Setup – Sleep/Wake screens. For further information regarding the

setup of these screens refer to section 4.2.14.

4.3 Checking Motor Rotation

Before attempting a trial operation of the HMI bypass package, ensure that

the enclosure door is securely closed. Also, ensure all personnel are clear of

the connected load as this operation will energize and rotate the motor.

After applying 3 phase power to the HMI bypass package, ensure that

the HMI is illuminated. If any alarms are present, refer to the trip log and

troubleshooting sections.

There is no standard for the rotational direction of an induction motor based

on the motor lead markings. This, plus the uncertainty of the phase rotation

of the utility power being applied to the HMI bypass package terminals,

requires that the motor rotation direction be checked and be correct in both

VFD and Bypass Modes. Failure to confirm rotation may cause severe damage

to the HMI bypass package, motor or the driven equipment.

4.3.1 Check #1: Rotation on VFD power

Place the VFD package in Hand (local) Mode control by pressing the VFD

and HAND icons on the HMI bypass touchscreen. The VFD icon will turn

blue indicating that the bypass is in VFD Mode and the HAND icon will be

highlighted indicating that the bypass is in local control. Use the up arrow on

the touchscreen HMI to increase the speed reference of the VFD or the down

arrow on to decrease the speed reference of the VFD.

Note the direction of rotation as the motor shaft begins to rotate as

compared to the required rotation direction.

To stop the VFD/Motor, press the STOP icon on the HMI touchscreen.

4.3.2 Check #2: Rotation on Bypass power

NOTE: This operation will start the motor across the line. Place the HMI

bypass in the Bypass Mode by pressing the BYP icon on the HMI bypass LCD

touchscreen. The BYP icon will be highlighted green indicating the HMI

bypass is in Bypass Mode.

42 HMI Bypass Controller Installation and Commissioning Guide

Press the HAND icon on the HMI bypass touchscreen. The HAND icon will

be highlighted indicating the HMI bypass is in local control. This will start

the motor across the line. Check motor rotation.

To stop the motor press STOP on the HMI touchscreen.

Note the direction of rotation as the motor shaft begins to rotate as

compared to the required rotation direction.

Motor Rotation Correction

VFD Correct Correct Incorrect Incorrect

Bypass Correct Incorrect Correct Incorrect

Action No Action Change any

two power

leads at input

disconnect

Change any two leads

at input disconnect, and

change any two leads at

the output of the motor

overload

Change any

two leads

at output of

motor overload

4.4 Normal Operation

There are two (2) buttons used to select the modes of operation available:

1. VFD (VFD Mode) – Energizes the VFD output contactor

2. BYP (Bypass Mode) – Allows bypass operation

Stop (reset) Button

The STOP button section will stop motor operation in either the VFD or

Bypass modes. This button will also reset any faults indicated by the system.

4.4.1 Current System Status

The One-line diagram on the main screen will indicate if the motor is being

run by the VFD or across the line (bypass) by highlighting the active control

in green. The VFD or the BYP icon will highlighted green and the One-line

diagram will indicate the motor status.

HMI Bypass Controller Installation and Commissioning Guide 43

4.4.2 Starting Operation

There are two (2) basic steps required to begin operation.

Step 1 – Select the operation mode by pressing the VFD or BYP (bypass) icon.

You must select one of these modes. For VFD operation, press the VFD icon.

For bypass operation press the BYP (bypass) icon. Upon selection the selected

icon will be highlighted in green.

Step 2 – Select the start mode by pressing either the HAND or AUTO icon.

Upon selection the selected icon will be highlighted. Selecting HAND allows

an immediate start in VFD or Bypass Mode; whichever was selected in step 1.

RUN will not occur until the customer-supplied run contact closes between

terminals 27 and 1 (AUTO RUN INPUT and 24 Vdc). The RUN status indication

will illuminate when the contact closes.

4.4.3 Ending Operation

Press STOP/(reset) icon once – Cancels the start mode of operation.

44 HMI Bypass Controller Installation and Commissioning Guide

Section 5 - Troubleshooting

The HMI will annunciate VFD and system alarms and trips when supply and

control power is applied.

The chart below is intended to assist with troubleshooting a system when the

HMI is not illuminated or no fault is indicated.

Symptom Indications Corrective Actions

Power disconnect is

ON, the HMI display

does not illuminate

when the screen is

tapped

Motor does not

rotate when VFD

mode is selected and

HAND is pressed or

AUTO is pressed and

the Auto-Run input

is ON

HMI is OFF - Check power lights on 24 Vdc power supply

- If power lights on, check 24 Vdc connections

to HMI

- If no power lights, check the 24 Vdc power

supply and control transformer fusing and

connections

HMI Bypass

status

displays

"VFD FAULT

DETECTED"

VFD and

BYP are

not visible

and/or HMI

displayed

"Timeout"

VFD and BYP

are green

and status

displays

"RUN"

- Check Trip log in HMI (see Section 3.1.3.3 for

instructions)

- If no fault is indicated on the HMI connect to

the drive using a plug in keypad or Connect

software and record the trip code. Refer to

the drive manual for further assistance or

download the diagnostic APP from www.

controltechniques.us

- Check that the optional VFD service switch

is ON

- Check the VFD input fusing

- Check Ethernet cable connection between

HMI and VFD SI-ETHERNET module

- Check HMI IP address is 192.168.0.2 (see

Section 3.3 for instructions)

- Check VFD SI-ETHERNET module connection

status lights (see Section 6.4 for instructions)

- Check mechanical motor to load couplings

are intact

- Ensure that motor connections are made

and no VFD to motor disconnects are open

- If VFD contactor is not closed check control

transformer and contactor coil

- Check I/O status screen Terminal 29 STO

status is “ON”

- If Terminal 29 STO status is “OFF,” check OC

[1-C11] auxiliary contactor and connections

HMI Bypass Controller Installation and Commissioning Guide 45

Symptom Indications Corrective Actions

Motor does not

rotate when Bypass

mode is selected and

HAND is pressed or

AUTO is pressed and

the Auto-Run input

is ON

Fuses blow on

power up

Input circuit breaker

trips on power up

Input circuit breaker

trips when a Bypass

run is initiated

- Check mechanical motor to load couplings

are intact

- Ensure that motor connections are made

and no bypass to motor disconnects are open

- Check that the mechanical load is not

binding

- If Bypass contactor is not closed check

control transformer and contactor coil

- Check VFD input wiring

- Replace VFD (see Section 6.4 for instructions)

- Check control transformer

- If fuses are blown see “Fuses blow” on

power up

- Check motor cables

- Check motor direction

- Check motor

46 HMI Bypass Controller Installation and Commissioning Guide

Section 6 - Additional Information

6.1 Specifications - HVAC Drive H300 HMI Bypass

The HMI bypass package features a user-friendly application-specific full-color

live-graphics LCD touch screen HMI (Human Machine Interface) to simplify

operation and provide status indication.

6.1.1 Approvals

• VFD Section – UL508C

» UL Plenum rated

• Bypass Section – UL508A

6.1.2 Design

• 2 contactor bypass with optional VFD service switch

• NEMA 1, NEMA 12, NEMA 3R, and NEMA 4X enclosure options

• LCD Color touch screen HMI

• 32-bit microprocessor

• MODBUS RTU, BACnet, and Metasys N2 communications

• EtherNet/IP and Modbus TCP/IP

• HAND/OFF/AUTO selection icons

• VFD/BYPASS selection icons

• Auto transfer to bypass on VFD fault (selectable)

• Damper Mode (programmable)

• Damper actuator control (5 A @ 125 Vac relay contact)

• Fire Alarm – programmable to:

» Fireman’s Override

» Fireman’s Override VFD Control

• PID controller

• Class 20 motor overload relay

• One (1) analog output:

» 0-10 Vdc, scalable

• Two (2) analog inputs – programmable for:

» 4-20 mA, scalable (default auto speed input)

» 0-10 Vdc, scalable (default onboard PID controller input)

• Speed search function

• 3 skip frequencies

• Digital manual speed control

• Bypass setup wizard

6.1.3 Operating Conditions

• Altitude: to 3,300 ft, higher with derating

HMI Bypass Controller Installation and Commissioning Guide 47

• Ambient operating temp: +32 to +104 °F (0 to +40 ˚C)

WARNING

• Storage temp: -40 to +140 ˚F (-40 to +60 ˚C)

• 95% relative humidity, non-condensing

• Input voltage: +10%, -10%; 208, 230, 460 and 575 Vac

• Protected from exposure to direct sunlight

6.1.4 Options

• Input fused disconnect

• Input circuit breaker

• Input or output reactors

• Multiple motor overloads

• Input RFI filter

6.2 Maintenance & Inspection

This section describes the basic periodic maintenance and inspection

procedures for the electronic bypass.

CAUTION! To prevent electrical shock and damage, disconnect all power

before servicing the electronic bypass package. Then wait at least ten (10)

minutes after the power supply is disconnected and all LEDs are extinguished.

The bypass system will function longer if kept clean, cool and dry, and if all

precautions highlighted in this manual are observed. Periodically inspect

the electronic bypass package as described in the table below to prevent

accidents and to ensure high performance with high reliability.

Component Check Corrective Action

External terminals,

connectors, mounting

screws, etc.

Heat sink Build-up of

Printed Circuit Board

(PCB)

Cooling fan For abnormal

Power components Accumulation

Loose screws

or connectors

dust and dirt

Accumulation

of conductive

dust or oil

noise and

vibration

of dust and

dirt

Secure / tighten

Blow with dry compressed air

(4 to 6kg-cm2 pressure)

Blow with dry compressed air (4 to 6kgcm2 pressure). If dust cannot be removed,

replace the board.

Replace the cooling fan

Blow with dry compressed air

(4 to 6kg-cm2 pressure)

48 HMI Bypass Controller Installation and Commissioning Guide

6.3 VFD Parameter Access

WARNING

The HVAC Drive H300 VFD parameters settings required

for operation in a bypass system are set at the factory.

Adjustments can be made to VFD parameters via the HMI

for all standard applications. If there is a need to access

advanced parameters not accessible via the HMI there are

2 methods available:

1. Remove the HVAC Drive H300 keypad cover and plug in

a keypad, order code HOA-KEYPAD-RTC. For a complete list of parameters go

to www.controltechniques.com

2. Connect a PC to the SI-ETHERNET module

in the drive and use “Connect” software to

access parameters. This software is available

as a no charge download from www.

controltechniques.com

In order to successfully connect to the drive

via the SI-ETHERNET module the PC

Ethernet IP address needs to be set to

192.168.0.xxx where xxx is not = 010 and

the subnet mask needs to be 255.255.255.0.

CAUTION: Changes made to VFD parameters may result in unintended motor

operation and damage to equipment.

6.4 VFD Replacement

If the VFD has to be replaced, it is

recommended that the SI-ETHERNET module

in the existing drive is re-used and fitted to

the replacement drive. If a new SI-ETHERNET

MODULE is needed, order code HMI-BYP-SI-

ETHERNET is pre-configured at the factory

for HVAC Drive H300 HMI Bypass settings. If

a new SI-ETHERNET module is fitted it is necessary to set the IP address of

the module to 192.168.0.010 and the subnet mask to 255.255.255.0. A VFD

keypad or Connect software is required to set the address.

HMI Bypass Controller Installation and Commissioning Guide 49

To configure a drive to HVAC Drive H300 HMI Bypass factory defaults

(examples: replacement VFD or existing VFD that is reset to HVAC Drive H300

defaults), from the System Settings screen select the Default Settings icon.

Select “YES” to restore the HVAC Drive H300 HMI Bypass to system defaults.

Select “NO” to return to the SYSTEM SETTINGS Screen.

Warning: Selecting “YES” will reset the HVAC Drive HMI Bypass to factory

default settings and the Setup Wizard must be completed again.

6.5 HVAC Drive H300 HMI Bypass Parameter Defaults

The following table represents the parameter differences of an HVAC Drive

H300 HMI Bypass and a standalone HVAC Drive H300 parameter defaults.

These do not include user settable HMI Bypass settings.

VFD

Paremeter

01.014 Reference Selector A2 Preset A1 A2

01.021 Preset Reference 1 15.0 Hz 0.0 Hz

01.023 Preset Reference 3 20.0 Hz 0.0 Hz

01.052 Hand/Off/Auto Operating Mode 0 1

01.053 Fire Mode Reference 40.0 Hz 0.0 Hz

02.004 Ramp Mode Std boost Standard

02.008 Standard Ramp Voltage Drive rating Drive rating

02.011 Acceleration Rate 1 20.0 s 10.0 s

02.021 Deceleration Rate 1 20.0 s 10.0 s

04.015 Motor Thermal Time Constant 1 120.0 s 89.0 s

04.016 Thermal Protection Mode 0x0 0x1

04.037 Motor Thermal Time Constant 2 50.0 s 89.0 s

05.007 Rated Current Drive rating Drive rating

05.008 Rated Speed Drive rating Drive rating

Parameter

Description

HMI

Bypass Value

HVAC Drive

H300 Default

50 HMI Bypass Controller Installation and Commissioning Guide

VFD

Paremeter

05.009 Rated Voltage Drive rating Drive rating

05.018 Maximum Switching Frequency 3 kHz 3 kHz

05.027 Enable Slip Compensation Off On

06.015 Drive Enable Off On

06.019 Date/Time Selector Acc Powered Local Keypad

06.043 Control Word Enable On Off

06.048 Supply Loss Detection Level Drive rating Drive rating

06.065 Standard Under Voltage Threshold Drive rating Drive rating

06.066 Low Under Voltage Threshold Drive rating Drive rating

07.010 Analog Input 1 Destination 1.037 1.036

07.014 Analog Input 2 Destination 18.018 1.037

07.022 Analog Output 2 Source 10.001 4.002

07.040 Analog Input 1 Minimum 0.05 % 0.00 %

07.041 Analog Input 2 Minimum 0.05 % 0.00 %

08.021 Digital I/O 01 Source/Destination 1.054 10.002

08.022 Digital I/O 02 Source/Destination 0.000 10.033

08.023 Digital I/O 03 Source/Destination 0.000 6.030

08.024 Digital Input 04 Destination 10.033 1.054

08.025 Digital Input 05 Destination 0.000 1.041

08.027 Relay Output Source 0.000 10.001

08.031 Digital I/O 01 Output Select Off On

08.071 Digital I/O Output Enable Register 1 0xFF7F 0x0000

09.004 Logic Function 1 Source 1 19.031 0.000

09.005 Logic Function 1 Source 1 Invert On Off

09.006 Logic Function 1 Source 2 9.002 0.000

09.007 Logic Function 1 Source 2 Invert On Off

09.008 Logic Function 1 Output Invert On Off

09.009 Logic Function 1 Delay 8.0 s 0.0 s

09.010 Logic Function 1 Destination 10.032 0.000

09.014 Logic Function 2 Source 1 19.031 0.000

09.015 Logic Function 2 Source 1 Invert On Off

09.016 Logic Function 2 Source 2 19.041 0.000

09.017 Logic Function 2 Source 2 Invert On Off

10.030 Braking Resistor Rated Power 0.000 kW 0.050 kW

10.031 Braking Resistor Thermal Time Constant 0.000 s 3.300 s

10.034 Number of Auto reset Attempts None 5

10.035 Auto reset Delay 10.0 s 5.0 s

10.061 Braking Resistor Resistance 22.00 5.0 s

Parameter

Description

HMI

Bypass Value

HVAC Drive

H300 Default

HMI Bypass Controller Installation and Commissioning Guide 51

VFD

Paremeter

10.034 Number Of Auto-reset Attempts None 5

10.035 Auto-reset Delay 10.0 s 5.0 s

10.061 Braking Resistor Resistance 00.00 Ω 75.00 Ω

11.024 Serial Mode 7 1 NP 8 2 NP

11.044 User Security Status All Menus

12.010 Variable Selector 1 Mode Subtract Input 1

12.028 Variable Selector 2 Source 1 18.021 0.000

12.031 Variable Selector 2 Destination 1.053 0.000

14.003 PID1 Reference Source 18.017 0.000

14.004 PID1 Feedback Source 18.018 0.000

14.014 PID1 Output Lower Limit 0.01 % -100.00 %

18.013 Application Menu 1 Read-write Integer 13 2 0

18.017 Application Menu 1 Read-write Integer 17 750 0

18.019 Application Menu 1 Read-write Integer 19 1111 0

18.020 Application Menu 1 Read-write Integer 20 32727 0

18.021 Application Menu 1 Read-write Integer 21 24545 0

18.031 Application Menu 1 Read-write bit 31 On Off

20.001 Application Menu 3 Read-write Integer 1 20839 0

29.010 User Selectable Parameter 1 18.029 0.000

29.011 User Selectable Parameter 2 18.030 0.000

29.012 User Selectable Parameter 3 1.021 0.000

2.02.005 DHCP Enable Off On

2.02.006 IP Address 192.168.0.10 192.168.1.100

2.02.007 Subnet Mask 255.255.0.0 255.255.255.0

2.02.008 Default Gateway 0.0.0.0 192.168.1.254

3.01.011 T2 Digital I/O 1 Mode Digital Output Digital Input

3.01.015 T7 Digital Input 5, Analog Input 1 Mode Digital Input Volt In

3.01.016 T8 Digital Input 6, Analog Input 2 Mode Digital Input Volt In

3.01.017 T9 Digital Input 7, Analog Input 3 Mode Digital Input Volt In

3.01.019 Collective Digital I/O Mode CDIO Mappings CDIO Disabled

3.02.031 Collective Digital Input Destination 0.18.013 0.00.000

3.02.032 Collective Digital Output Source 0.18.022 0.00.000

Parameter

Description

HMI

Bypass Value

HVAC Drive

H300 Default

The HMI IP address can be accessed through the HMI Settings icon and should