Page 1

Unimotor

hd

230 V I

460

V

Compact, Powerful High Dynamic

AC

Servo

Designed for maximum

brushless

compact,

torque

high

Unimotor hd

absolute

nameplate"

can

be

read by

used

to

simplifies commissioning

performance

Motors

torque

density,

AC

Servo

motor

series provides an exceptionally

low inertia solution for applications

during rapid acceleration and deceleration profiles.

motors

encoders

data

automatically optimize

and

fitted with high resolution SinCos

are

pre-loaded with

during

the

manufacturing process. This

most

Control Techniques' brand servo drives

the

and

maintenance, ensures consistent

saves time.

the

Unimotor

that

require very

the

motor

"electronic

drive settings. This feature

hd

or

data

and

Unimotor

clll1P

The Unimotor

Digitax

maximum dynamic performance.

Key Features

• Torque range:

• High torque-to-inertia ratio for high-dynamic performance

Compact

•

• Optional holding brake

• IP65 conformance

•

Segmented

• World class performance

• Winding

Speeds

•

• Large shafts

• Multiple feedback options:

- Incremental encoder: High accuracy, medium resolution

- Absolute: Medium accuracy,

and

- SinCos/absolute: High accuracy, high resolution,

single-turn

-

HIPERFACE

supported

- Resolver: Robust for

lower accuracy, medium resolution

hd

torque

profile

ST

Servo drives providing

6.4

to

752 lb-in (0.72

and powerful

stator

design

to

suit

230

V and

include

multi-turn

2000,

3000,

to

increase torsional rigidity

and

multi-turn

(SICK)

and

extreme

is

closely matched

up

to

300%

to

85.0

460

V

4000

and

6000

medium

EnDat (Heidenhain) protocols

applications

to

peak

overload for

Nm)

rpm

resolution, single-turn

and

conditions;

Unimotor

Frame

Si

ze

ss

67

89

11

S

1

42

190

-

hd

motors

Unimotor

Contln

uous(lb-ln) -

(shown

10

with a Digitax

ST

Servo

hd Torque Range

100

Pea

k(lb-ln)

drive).

1000

Approvals

24

FM30610

RoHS

Compliant

All

Unimotor

connections

easier

cable

installation.

hd

motors

that

rotate

routing

feature

for

and

Page 2

Unimotor

hd

230 V I

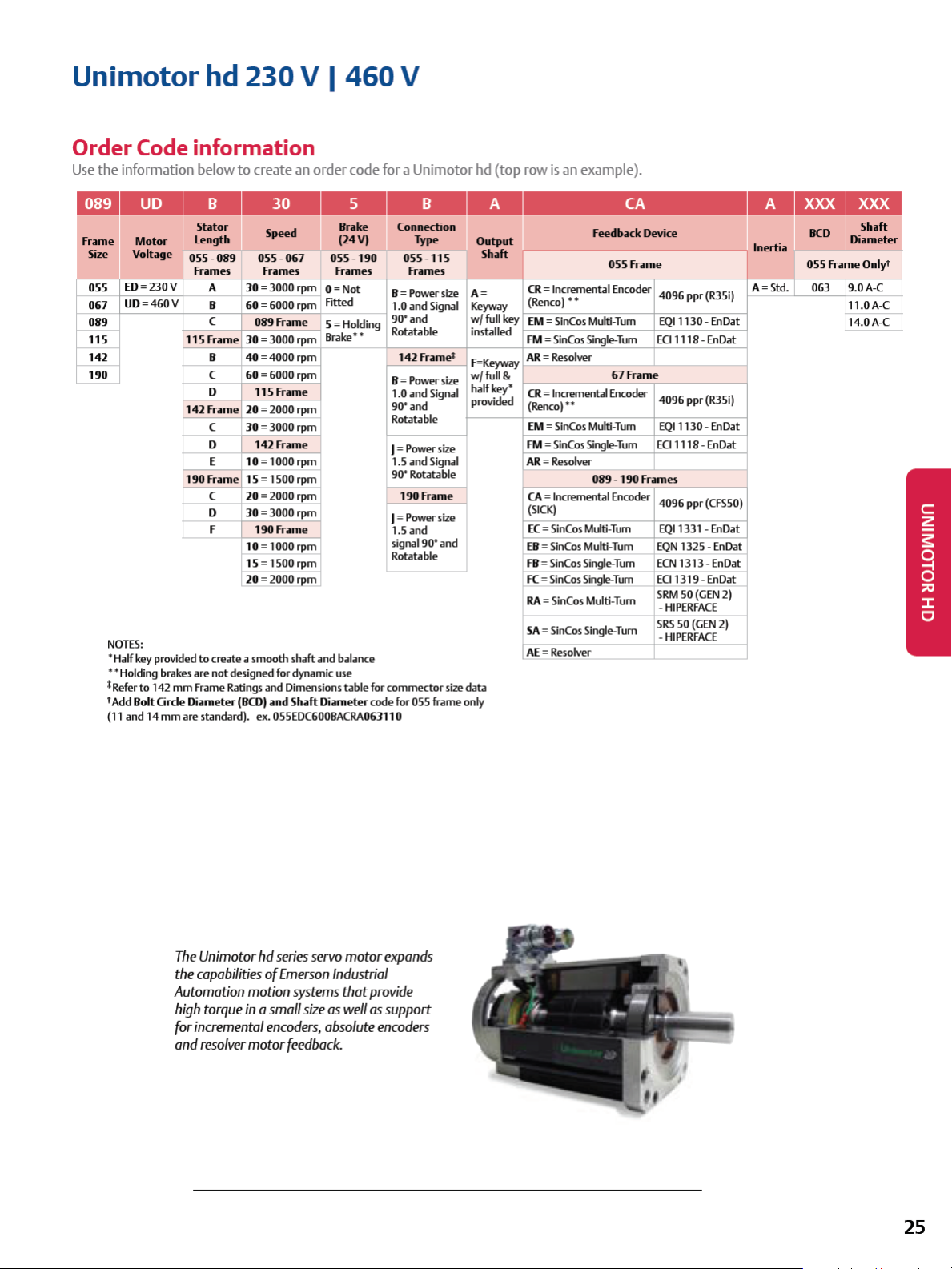

Order Code information

Use

the

information below

to

create

an

order

460

code

for a

V

Uni

motor

hd

(top

row

is

an

example).

l!ID

■

•I•

■

-----

Stator

Frame

>-->-->---

>---

Motor

Siz

e Voltage

ID=

055

UD=4

06

7

089

115

142

190

NOTES:

*Halfke

*

*Holding

!Refer to 142 mm Frame

T

Add

Bolt

(11

and 14 mm are standard). ex.

Length

055-089 055-067 055-190 055-115

Frames Frames Frames Frames

230V

60V

115

142

190

yp

rovided

brakes are not designed

Grde

Diameter

Speed

A

30=

3000 rpm

60=

B

C

Frame

B

C

D

Frame

C

D

E

Frame

C

D

F

to

create a smooth shaft and balance

6000 rpm

089Frame

30=

3000 rpm

40=

4000rpm

60=

6000 rpm

115

Frame

20=

2000 rpm

30=

3000 rpm

142

Frame

10=

1000 rpm

15

= 1500 rpm

20=

2000 rpm

30=

3000 rpm

190

Frame

10=

1000 rpm

15

= 1500 rpm

20=

2000 rpm

Ratings

for

and Dimensions table for commector size data

(BCD)

and Shaft Diameter code

055EDC600BACRA

Brake Connection

(MV)

0=Not

Fitted

5

=

Brake

dynamic use

Holding

..

063110

Ty

pe

B = Power size

1.0 and

90' and w/full

Rotatable installed

142 Framel

B = Power size

1.0 and

90' and

Rotatable

Signal

Signal

Output

Shaft

A =

Keyway

F=

Keyway

w/full&

half key•

provided

I = Power size

Signal

1.5 and

90' Rotatable

190 Frame

I = Power size

1.5 and

90'

signal

Rotatable

and

for

055 frame only

CR= Incremental Encoder

(Renco)

..

key

EM=

SinCos

Multi-Tum

FM = SinCos

AR=

CR=

(Renco)

EM=

FM=

AR= Resolver

CA=

(SICK)

EC=

EB=

FB

FC = SinCos

RA=

SA=

AE

Single-Tum

Resolver

Incremental

..

SinCos

Multi-Tum

SinCos

Single-Tum ECI 1118-EnDat

Incremental Encoder

SinCos Muti-Tum

SinCos

Multi-Tum

=

SinCos

Single-Tum

Sinqle-Tum ECI 1319-EnDat

SinCos

Multi-Tum

SinCos

Single-Tum

= Resolver

Feedback Device

055Frame

4096 ppr

EQI

EO

67Frame

Encoder

089 -190

4096 ppr

EQI

Fram

es

4096 ppr

EQI

EQN

ECN

SRM

-HIPERFACE

SRS

-HIPERFACE

(R35i)

1130 -

EnDat

1118-EnDat

(R35i)

1130 -

EnDat

(CFS50)

1331 -EnDat

1325 -

EnDat

1313 -

EnDat

50

(GEN

2)

50

(GEN

2)

11114\111.'i!N

Inertia

A = Std. I 063

BCD

055 Frame

1

Shaft

Diameter

OnlyT

9.0A-C

11.0A-C

14.0A-C

The

Unimotor

the

capabilities

hd

of

series

servo

Emerson

motor

Industrial

Automation motion systems that

high

torque

in

a small

size

as

well

for

incremental

and

resolver

encoders,

motor

absolute

feedback.

expands

provide

as

support

encoders

25

Page 3

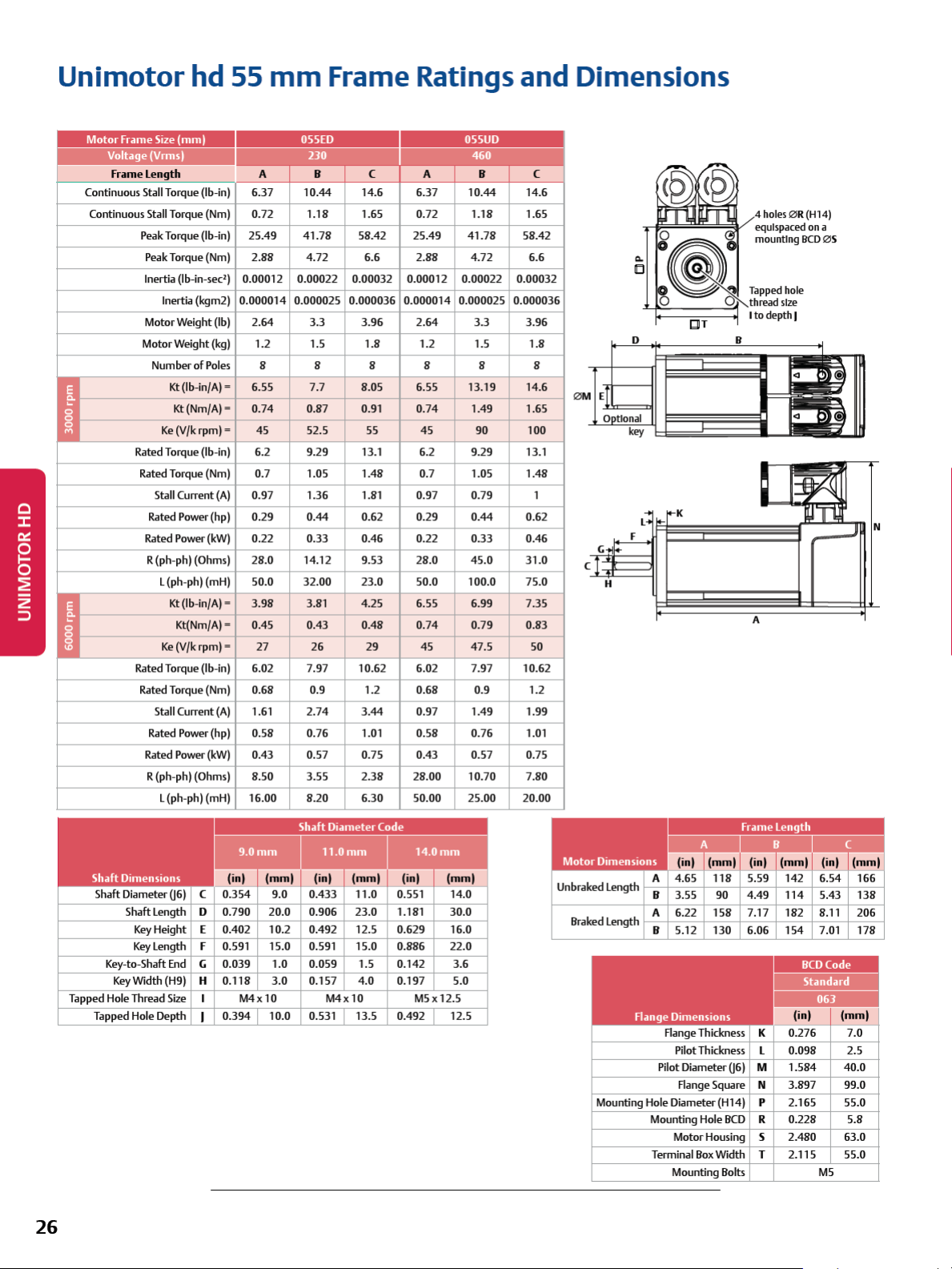

Unimotor

Motor

Frame Size

Voltage (Vrms I

Fr

ame l ength A B C A B

Continuous Stall Torque (lb-in)

Continuous Stall Torque (Nm) 0.72

Peak Torque (lb-in)

Motor Weight (kg) 1.2 1.5

n

~

Iii

Rated Torque (lb-in)

Rated Torque (Nm) 0.7 1.05 1.48 0.7 1.05

n

~

a

Rated Torque (lb-in)

Rated Torque (Nm) 0.68 0.9

hd

(mml

Peak Torque (Nm) 2.88 4.72 6.6 2.88 4.72

Inertia (lb-in-sec') 0.00012 0.00022 0.00032 0.00012 0.00022

Inertia (kgm2) 0.000014 0.000025 0.000036 0.000014 0.000025

Motor Weight (lb)

of

Number

Kt(lb-in/A) = 6.55 7.7 8.05 6.55

Kt(Nm/A) = 0.74 0.87

Ke

(V/k

rpm)=

Stall Current

Rated Power (hp) 0.29 0.44 0.62 0.29 0.44

Rated Power (kW)

R (ph-ph) (Ohms)

l (ph-phl (mH) 50.0

Kt(lb-in/A) =

Kt(Nm/A) = 0.45 0.43 0.48

Ke

(V/k

rpm)=

Stall Current

Rated Power (hp) 0.58 0.76 1.01 0.58 0.76

Rated Power (kW)

R (ph-ph) (Ohms)

l (ph-ph) (mH)

55

mm

6.37 10.44 14.6 6.37

25.49 41.78 58.42 25.49

2.64

Poles 8 8 8 8 8

45

6.2 9.29 13.1 6.2 9.29

(A)

0.97 1.36 1.81 0.97 0.79

0.22 0.33 0.46 0.22 0.33

28.0 14.12 9.53 28.0

3.98

27 26 29

6.02 7.97 10.62 6.02 7.97

(A)

1.61

0.43 0.57 0.75 0.43 0.57

8.50

16.00

Frame Ratings and Dimensions

OSSEO

1.18

3.3

52.5 55

32.00

3.81 4.25

2.74

3.55

8.20

1.65 0.72

3.96

0.91 0.74

23.0 50.0 100.0

3.44

2.38 28.00 10.70

6.30 50.00 25.00

1.8

1.2

2.64

1.2 1.5

45

6.55 6.99

0.74

45

0.68 0.9

0.97

,

10.44

1.18

41.78

3.3

13.19

1.49

45.0

0.79

47.5

1.49

90

'I

C

14.6

1.65

58.42

6.6

0.00032

0.000036

3.96

1.8

8

14.6

1.65

100

13.1

1.48

1

0.62

0.46

31.0

75.0

7.35

0.83

50

10.62

1.2

1.99

1.01

0.75

7.80

20.00

4 holes

0R

hole

depth I

(H14)

BCD

0S

equispaced on a

mounting

~}

I

Tapped

i...i

-.::..--

-~-

--'~"'

thread size

I

[JIT

D

K

H

to

B

A

Shaft

Shaft Diameter

Key-to-Shaft End

Tapped Hole Thread Size

Tapped Hole Depth

26

9.0mm

Dimensions

06)

C

0 0.790 20.0 0.906 23.0 1.181

Key

Height E 0.402 10.2 0.492 12.5

Key

length

F 0.591 15.0 0.591 15.0

c;

0.039 1.0 0.059 1.5

Key

Width (H9)

H 0.118

3.0

M4x10 M4x10

0.394 10.0 0.531 13.5

Shaft

Diameter

11.0mm 14.0mm

0.157 4.0

Code

0.629

0.886

0.142

0.197

0.492

30.0

16.0

22.0

M5x12.5

12.5

3.6

5.0

Unbraked

Braked

Mounting Hole Diameter(H14)

B

A 6.22

length

B 5.12 130 6.06 154 7.01

Mounting Hole

Terminal

A

length

3.55

90

158

Range Thickness

Pilot Thickness

Pilot Diameter 06)

Range Square

BCD

Motor Housing

Box

Width

Mounting

Bolts

4.49

114

5.43

7.17 182 8.11

K 0.276

l 0.098

M 1.584

N

3.897

p

2.165

R 0.228

s 2.480

T 2.115

MS

138

206

178

7.0

2.5

40.0

99.0

55.0

5.8

63.0

55.0

Page 4

Unimotor

hd

67

mm

Frame Ratings and Dimensions

Motor

Frame Size

Voltage

Fram

Continuous Stall Torque (lb-in) 12.8 22.6

Continuous Stall Torque (Nm)

Peak Torque (lb-in)

.

-

-

Iii

Rated Torque (lb-in)

Rated Torque (Nm)

.

!:'

>;

-

,i,

Rated Torque (lb-in)

Rated Torque (Nm)

NOTES:

•

.6.t=

212 'F (100 '

tolerance

• Stall torque, rated torque and power relate

'F (20 '

CJ

• Maximum intermittent winding

ambient

(mml

(Vrmsl

e length A B C A B C

Peak Torque (Nm)

Inertia (lb-in-sec')

Inertia (kgm') 0.000030 0.000053 0.000075 0.000030 0.000053 0.000075

Motor Weight (lb)

Motor Weight (kg)

Number

Kt

(lb-in/A)= 8.23 7.08

Kt(Nm/A) = 0.93 0.80

Ke

(V/k

Stall Current

Rated Power (hp)

Rated Power

R (ph-ph) (Ohms)

L (ph-ph) (mH)

Kt

(lb-in/A)= 4.16 7.08

Kt(Nm/A) = 0.47 0.80

Ke (V/k

Stall Current

Rated Power (hp)

Rated Power

R (ph-ph) (Ohms)

L (ph-ph) (mH)

CJ

winding 104 'F (40 '

above

0.00027 0.00047 0.00066 0.00027 0.00047 0.00066

of

Poles

rpm)=

(A)

(kW)

14.92

45.43 17.40 12.70

rpm)=

(A)

(kW)

11.06 4.35

12

kHz drive switching frequency

temperature

067ED

1.45 2.55

38.5

4.35 7.65 11.10 4.35 7.65 11.10

4.40 5.72 7.04 4.41 5.73 7.05

2.00 2.60

10

12.4 21.7

1.40 2.45

1.56

0.59 1.03 1.48 0.59 1.03 1.48

0.44 0.77 1.10 0.44 0.77 1

11.5 19.5 11.5 19.5 27.4

1.30 2.20

3.12

1.10 1.85

0.82 1.38 0.82 1.38 1.95

3.86

67.7 98.2

57.0

2.74

4.88

28.5

5.48

1.22 11.69

CJ

maximum ambient;

to

32.7

3.70

3.20

10

31.0

3.50

3.98 1.81 1.59 2.31

3.33

maximum continuous operation

is

284

'F

(140

12.8

1.45 2.55

38.5

2.00 2.60

10

10

49.0

12.4

1.40

11.69 15.20 10.70

35.18

1.30

1.81

1.10

35.18

all

data

subject

'

CJ

I ,

• , I

22.5 32.7

3.70

67.7 98.2

3.20

10

21.7

2.45

54.20 40.80

49.0

2.20

3.19

1.85 2.61

3.79

13.60 10.20

to

tested

14.16

1.60

98.0

..

/-10%

in

10

31.0

3.50

3.10

4.63

2.68

a

68

.10

OP

0

~)).

~Tapped

OT thread

Shaft Diameter C 0.551

Shaft Length

Key

Height E 0.629

Key

Length F

Key-to-Shaft

Key

Width

Tapped Hole Thread Size

Tapped Hole Depth

4 holes

equispaced on a

mounting

I

I to depth I

D 1.181

End

G 0.142

H 0.197

0R

(Hl

4}

BCD

0S

hole

size

0.964

M5x0.8

0.53 13.5

14.0

30.0

16.0

25.0

3.6

5.0

Unbraked Length

Braked Length

A 5.62 142.7 6.80 172.7 7.98 202.7

B 4.28 108.8 5.46 138.8 6.65 168.8

A 7.00 177.7 8.18 207.7 9.37 237.7

B 5.66 143.8 6.84 173.8

8.02

203.8

Flange Thickness

Pilot Thickness

Pilot Diameter

Overall Height

Flange Square

Mounting Hole Diameter

Mounting Hole

Motor Housing

Mounting Bolts

BCD

K 0.295 7.5

L

0.098

M 2.362 60.0

N 4.389 111.5

p

2.755 70.0

R

0.228

2.5

5.8

s 2.953 75.0

T 2.637 67.0

MS

27

Page 5

Unimotor

Motor

Frame Size

Voltage (Vrms)

Fr~me

Continuous Stall Torque (lb-in)

Continuous Stall Torque (Nm)

lenqth

Peak Torque (lb-in)

Peak Torque (Nm)

Inertia (lb-in-sec')

Motor Weight (lb)

Motor Weight (kg)

Number

II

El

Ke

-

Rated Torque (lb-in)

Rated Torque (Nm)

Stall Current

Rated Power (hp)

Rated Power

R (ph-ph) (Ohms)

L (ph-ph) (mH)

~

lg

~

Ke

Rated Torque (lb-in)

Rated Torque (Nm)

Stall Current

Rated Power (hp)

Rated Power

R (ph-ph) (Ohms)

L (ph-ph) (mH)

II

II

D

NOTES:

•

.6.t=

212 'F (100 '

.,.

/-10% tolerance

• Stall torque, rated torque and power relate

tested

• Maximum

Ke

Rated Torque (lb-in)

Rated Torque (Nm)

Stall Current

Rated Power (hp)

Rated Power

R (ph-ph) (Ohms)

L (ph-ph) (mH)

in a

68

'F (20 '

intermittent

hd

89

(mm)

A B C A B C

28.3 48.7 70.8 28.3 48.7

3.20

85.0 146.0 212.4

9.60 16.50 24.00 9.60 16.50 24.00

0.00077 0.00142 0.00207 0.00077 0.00142 0.00207

Inertia (kgm')

Kt

(lb-in/A)=

Kt(Nm/A) = 0.93

(V/k

Kt

(lb-in/A)= 6.2

Kt(Nm/A) = 0.70

(V/k

Kt

(lb-in/A)= 4.2

Kt(Nm/A) = 0.47 0.80

(V/k

CJ

winding 104 'F (40 '

CJ

of

Poles

rpm)=

(A)

(kW)

rpm)=

(A)

(kW)

rpm)=

(A)

(kW)

ambient

winding

0.000087 0.000161

6.8 9.2 11.7

3.30

10

26.6 42.9 61.1 26.6

3.0

3.44

1.26 2.04 2.91 1.26 2.04 2.91

0.94 1.52 2.17 0.94 1.52 2.17

3.28

21.55 11.84 7.09 65.17 38.36 21.72

25.7 40.3 56.2 25.7

2.90 4.55 6.35 2.90 4.55 6.35

4.57 7.86 11.43 2. 67 4.58 6.67

1.62 2.56 3.57 1.62 2.56

1.21 1.91 2.66 1.21 1.91 2.66

2.04

13.20 5.97

23.5

2.65

6.88 11.83 17.20 4.00 6.88 10.00

2.24

1.67 2.39

0.98 0.39 0.23 2.52 1.27 0.83

6.24 2.96 1.89 16.29 9.59 6.66

above 12 kHz drive switching frequency

temperature

mm

089ED 089UD

Frame Ratings and Dimensions

~

5.50 8.00

0.000234

4.40 5.50

10

8.2

57.0 98.0

4.85 6.

5.91 8.60 2.00

1.57 0.89 10.10 5.05

42.8

0.79 0.

4.38

28.5 49.0

33.6

3.80

3.21 4.21

CJ

maximum ambient;

to

44.3 23.5

5.00 2.65

3.14

maximum continuous operation

is

284

'F (140 '

3.20

85.0

0.000087 0.000161 0.000234

6.8

3.30

10

10 10

90

3.00

54

6.16 2.47 1.75

39.78

2.24

1.67 2.39

all

data

subject

CJ

• Motor length increases

0.512

in

feedback options

SA

and

RA;

decreases 0.394 in (10 mm)

for feedback option

5.50

146.0 212.4

9.2 11.7

4.40 5.50

14.2

1.60

42

.9 61.1

4.85 6.90

3.44

10.6

1.20

73

.5

40

.3 56.2

18.8 14.03

7.1

33.6

3.80

3.21 4.21

to

(13 mm) for

FB, EB,

motor

length

AE

70.8

8.00

10

5.00

2.68

3.57

44.3

5.00

3.14

CA,

0 (

0 M

Mounting Hole

Tapped

Tapped

4

holes

0R

(

equispaced

mounting

on

BCD

H14)

-~

C

~,,.,~h"'

, , l todepthl

7

D B

F

G

H

Optiona

l

key

IJ'------ll

Braked Length

, . I

Flange Thickness

Pilot Thickness l 0.087 2.2

Pilot Diameter

Overall Height N 5.140 130.5

Range

Square

Mounting Hole

Diameter

BCD

Motor Housing

Mounting Bolts

Shaft Diameter C 0.750

Shaft

Length

Key Hei

ght

Key

length F 1.260

Key-to-Shaft

Hole

End

KeyW

ldth

Thread Size

Ho

le Depth

ild)T

147.8 7.00 177.8 8.16

110.5 5.53 140.5 6.71

187.9

150.6 7.11 180.6

(in) (

K 0.406 10.3

M

p

R 0.276 7.0

s

T

D 1.575

E 0.850 21.5

G 0.146

H 0.236 6.0

3.150

3.583

3.940

3.504

(in)

0.670

thread

8.58

M6

M6x 1.0

size

217.9 9.76

a

0 S

8.29

mm

80.0

91.0

100.0

89.0

(mm)

19.0

40.0

32.0

3.7

17.0

207.8

170.5

247.9

210.6

)

28

Page 6

Unimotor

Motor

Frame Size

Voltage (Vrmsl

Fram

Continuous Stall Torque (lb-in)

Continuous Stall Torque (Nm) 10.20 14.60

e lenoth

Peak Torque (lb-in)

Peak Torque (Nm)

Inertia (lb-in-sec')

Motor Weight (lb)

Motor Weight (kg) 7.20

Number

~

;

~

~

Ke (V/k

Rated Torque (lb-in)

Rated Torque (Nm)

Stall Current

Rated Power (hp) 2.41

Rated Power (kW)

R (ph-ph) (Ohms)

L (ph-ph) (mH)

;

Ke (V/k

-

Rated Torque

Rated Torque (Nm) 7.70 10.50 7.70 10.50 13.60

Stall Current

Rated Power (hp) 3.25 4.43

Rated Power (kW)

R (ph-ph) (Ohms)

L (ph-ph) (mH)

hd

115

(mml

B C D B C D

90.3 129.2 166.4 90.3 129.2 166.4

270.8

30.60

0.00390

Inertia (kgm') 0.000441 0.000639 0.000838 0.000441 0.000639 0.000838

of

Poles

Kt

(lb-in/A)=

Kt(Nm/A) =

rpm)=

(A)

Kt

(lb-in/A)=

Kt(Nm/A) = 0.93

rpm)=

(I

b-in)

(A)

0.00566 0.00742 0.00391 0.00566 0.00742

15.87 19.62 23.6 15.87 19.62 23.6

10

76.1 105.3 138.1 76.1 105.3 138.1

8.60

7.29 10.43 13.43 4.25 6.08 7.83

1.80 2.49

1.40 0.77 0.61 4.41 2.41

12.84

8.2

57.0 98.0

68.2 92.9 68.2 92.9 120.4

10.97 15.70 6.38 9.13 11.75

2.42

0.58 0.39 1.83 1.21

5.40 4.01 16.93 12.72 8.65

mm

115ED 115UD

Frame Ratings and Dimensions

~

18.80 10.20 14.60 18.80

387.6

43.80 56.40

8.90 10.70 7.20 8.90 10.70

12.4

1.40 2.40

85.5

11.90 15.60

3.34

7.87 6.62 40.59 24.69 19.45

3.30

10

499.1 270.8

30.60

10

4.

3.27

38

10

8.60

2.41

1.80 2.49

3.25

2.42

387.6

43.80 56.40

21.2

147.0

11.90 15.60

3.34

14.2

1.60

4.43 5.73

3.30

499.1

10 10

4.

3.27

1.80

4.27

0.78

38

...

IEI

G

0 (

H

Optlou

lkey

\

0 M

11----ll

IC]T

4 h

oles

0 R(H14I

equlsp.1ced

on

depth

BCD

ze

I

.1

0 5

N

mounting

T•pped hole

thre.1d si

Ito

B

NOTES:

•

.6.t=

212 'F (100 '

.,./-10%

• Stall torque, rated torque and power relate

tested

• Maximum

tolerance

in a

68

intermittent

CJ

winding 104 'F (40 '

'F (20 '

CJ

ambient

winding

CJ

above 12 kHz drive switching frequency

temperature

maximum ambient;

to

maximum continuous operation

is

284

all

data

'F (140 '

CJ

•Motor length increases

0.512

in (13

feedback options FB,

SA

and

RA;

decreases

for feedback option AE

0.394

subject

mm)

motor

to

for

EB, CA,

length

in

(10 mm)

!Jraked Length

Flange Thickness

Pilot Thickness

Pilot Diameter

Overall Height

Flange Square

Mounting Hole Diameter

Mounting Hole

Motor Housing

Mounting !Jolts

Key

Tapped Hole Thread

Tapped

IJCD

I

Shaft Diameter

Length

Shaft

Key

Height

Key

length

-to-Shaft

End

KeyWldth

Size

Ho

le Depth

193.8

154.0

230.9

191.1

(

in)

K

L 0.106

M 4.33

N 6.16

p

R

0.519

4.57

0.394

s 5.12

T 4.53

(

in)

C 0.945

D 1.97

E 1.06

F 1.57

c;

H 0.315

0.209

0.79

8.81

7.24

10.27

8.70

M8x

223.8 9.

184.0 8.43

260.9 11.45

221.1

(

110.0

156.5

116.0

130.0

115.0

M8

(

1.25

99

9.89

mml

13.2

2.7

10.0

mml

24.0

50.0

27.0

40.0

5.3

8.0

20.0

253.8

214.0

290.9

251.1

29

Page 7

Unimotor

Motor

Frame Size

Voltage (Vrms I

Fr

ame Length C D

Continuous Stall Torque (lb-in) 221.3 278.8

Continuous StallTorque(Nm) 25.0 31.5

Peak Torque (lb-in) 662.9 836.4

Peak Torque (Nm) 74.9 94.5

Inertia (lb-in-sec')

Inertia (kgm') .0017 .00221

Motor Weight (lb) 25.4 33.1

Motor Weight (kg) 11.5 15.0

Number

Ke

Rated Torque (lb-in) 206.2 256.7

Rated Torque (Nm) 23.3 29.0

Stall Current

Rated Power(hp) 3.27 4.08

Rated Power

R (ph-ph) (Ohms) 1.36 0.94

L(ph-ph)(mH) 21.34 15.17

Power Connector

Ke

Rated Torque (lb-in)

Rated Torque (Nm)

Stall Current

Rated Power (hp)

Rated Power

R (ph-ph) (Ohms)

L (ph-ph) (mH)

Power Connector

Ke

Rated Torque (lb-in) 189.4 227.5

Rated Torque (Nm) 21.4 25.7

Stall Current

Rated Power (hp) 6.01 7.21

Rated Power

R (ph-ph) (Ohms)

L (ph-ph) (mH)

Power Connector

Ke

Rated Torque (lb-in) 162.8 184.9

Rated Torque (Nm) 18.4 20.9

Stall Current

Rated Power (hp) 7.75 8.81

Rated Power

R (ph-ph) (Ohms)

L (ph-ph) (mH)

Power Connector

' These frames use Order Code Connection

hd

142

(mml

.01

of

Poles 10 10

Kt

(lb-in/A)=

Kt(Nm/A)= 2.8

(V/k

rpm)=

(A)

(kW)

Size

Kt

(lb-in/A)=

Kt(Nm/A)=

(V/k

rpm)=

(A)

(kW)

Size

Kt

(lb-in/A)=

Kt(Nm/A)= 1.4

(V/k

rpm)= 85.5

(A)

(kW)

Size

Kt

(lb-in/A)= 8.23

Kt(Nm/A)= 0.93

(V/k

rpm)= 57.0

(A)

(kW)

Size

142EO

505 .01956

24.78

171.0

8.9 11.2

2.44 3.04

12.39

17.8 22.5

4.48 5.38

0.34 0.24

5.33 3.79

26.9 33.9

5.78 6.57

0.12 0.10

1.90 1.57

1.5•

Type

1.0

1.5•

mm

336.3

38.0

1008.9

114.0

.02407

.00272

40.8

18.5

305.4

34.5

13.6

4.84

3.61

0.72

12.3

261.9

29.6

27.1

8.31

6.2

0.18

3.07

option"]'.

Frame Ratings and Dimensions

•

,I

E

10

C D E

221.3 278.8 336.3

25.0 31.5 38.0

662.9 836.4 1008.9

74.9 94.5 114.0

.01505 .01956 .02407

.0017 .00221 .00272

25.4 33.1 40.8

11.5 15.0 18.5

10 10 10

28.32

3.2

196.0

197.4 238.9 280.6

22.3 27.0 31.7

7.8 9.8 11.9

4.69 5.63 6.71

3.5 4.2 5.0

1.36 0.94 0.72

21.34 15.17 12.3

1.0

21.24

2.4

147.0

189.4 227.5 261.9

21.4 25.7 29.6

10.4 13.1 15.8

6.01 7.21 8.31

4.48 5.38 6.2

0.79 0.62 0.49

12 .15 9.66 8.34

1.0

14.16

1.6

98.0

162.8 184.9 203.6

18.4 20.9 23.0

15.6 19.7 23.8

7.75 8.81 9.70

5.78 6.57 7.23

0.34 0.24 0.18

5.33 3.79 3.07

1.0

1.5•

0C

Optional

key

0 M

Pilot Thickness

Pilot Diameter

Overall Height

Flange Square

Mounting

Mounting Hole

Tapped Hole Thread Size

Tapped Hole Depth

Key-to

Hole

Key

Key

-Shaft

Key

Dia.

BCD

Height

Length

End

Width

L

M

N

p

R

s

T

D

E

F

c;

H

217.0 9.72 247.0 10.91 277.0

182.5 8.37 212.5 9.55 242.5

248.0 10.94 278.0 12.13 308.0

(in) (mm)

0.551 14.00

0.134 3.40

5.120 130.0

4.1/8.1'

5.591 142.0

0.472 12.0

6.500 165.0

5.591 142.0

(int (mm)

1.260 32.0

2.283 58.0

1.380 35.0

1.970 50.0

0.118

0.394 10.0

1.142 29.0

4 holes 0 R (Hl 4)

equispaced on a

mounting

Tapped hole

thread size

I

to

N

12.30 312.5 13.48 342.5

M10

M12x1.75

PCD

depth

J

Optional

lifting

aid205.0mm

(±

1)

104/205'

3.0

0S

30

Page 8

Unimotor

Motor

Frame

Size

(mml

Voltage (Vrmsl

Fr

ame Length C D

Continuous Stall Torque (lb-in)

Continuous Stall Torque (Nm)

Peak Torque (lb-in) 1380.7 1646.2

Peak Torque (Nm) 156.0 186.0

Inertia (lb-in-sec')

Inertia (kgm')

Motor Weight (lb)

Motor Weight (kg) 23.5 28.6

of

Number

Kt

.

-

-

-

.

-

-

.

-

-

-

NOTES:

•

6t=

212

'F

,..

/-10% tolerance

• Stall torque, rated

tested

in a 68

• Maximum

(lb-in/A)=

Kt(Nm/

Ke

(V/k

rpm)=

Rated Torque (lb-in)

Rated Torque (Nm)

Stall Current

Rated Power (hp)

Rated Power (kW)

R (ph-ph) (Ohms)

L (ph-ph) (mH)

Kt

(lb-in/A)=

Kt(Nm/

Ke

(V/k

rpm)=

Rated Torque (lb-in)

Rated Torque (Nm)

Stall Current

Rated Power (hp)

Rated Power (kW)

R (ph-ph) (Ohms)

L (ph-ph) (mH)

Kt

(lb-in/A)= 12.39

Kt(Nm/

Ke

(V/k

rpm)=

Rated Torque (lb-in) 376.2

Rated Torque (Nm)

Stall Current

Rated Power (hp)

Rated Power (kW)

R (ph-ph) (Ohms)

L (ph-ph) (mH)

(100 'C)

winding

torque

'F {20 '

C)

intennittentwinding

hd

Poles

A)

=

(A)

A)

=

(A)

A) = 1.4

(A)

104

and

power relate

ambient

190

460.2

52.0

.04833 .06275

.00546 .00709

51.8

10 10

433.7

49.0

18.6

6.88 7.

5.13 5.92

0.47

12.3

85.5

42.5

37.1

11.9

8.9

0.12

3.07

'F (40 '

above

temperature

mm

190ED

548.7

62.0

66.1

24.78

2.8

171.0

500.1

56.5

22.1

94

0.4

10.4

C)

maximum ambient;

to

maximum continuous operation

12

kHz drive switching frequency

F C

752.3

85.0

2256.9 1380.7

255.0 156.0

.09161

.0103

85.5

38.8

10 10

685.9

77.5

30.4

10.89

8.12

0.23

6.79

is

284 'F(140 'C)

Frame Ratings and Dimensions

'I

I

• ' I

D

F

460.2

548.7

752.3

52.0

62.0

85.0

1646.2

2256.9

186.0

255.0

.04833

.06275

.09161

.00546

.00709

.0103

51.8

66.1

85.5

408.9

21.24

-

-

-

376.2

-

-

-

-

-

-

23.5

46.2

16.3

9.74

7.26

0.47

12.3

2.4

147

42.5

21.7

11.9

8.9

0.34

8.2

all

data

28.6

10

28.32

3.2

196.0

462.0

52.2

19.4

11.00

8.2

0.4

10.4

subjectto

38.6

10

606.3

68.5

26.6

14.43

10.76

0.23

6.79

0C

0M

E

B'raked Length

, . I

Flange Thickness K

Pilot Thickness

Pilot Diameter M

Overall Height N

Flange Square

Mounting Hole Diameter R

Mounting Hole

Motor Housing T

Mounting

Shaft Diameter C

Key-to-Shaft End

Tapped Hole Thread Size

Tapped Hole Depth

B'CD

B'olts

I

Shaft Length D

Key

Height E

Key

Length F

Key

Width H

G

L

p

s

12.56

11.40

220.6

191.1

319.1

289.6

(inl

0.728

0.154

7.090

9.940

7.490

0.571

8.465

7.480

(inl

1.500

3.150

1.614

2.760

0.181

0.394

1.142

4

holes0R(H14)

equispaced

mounting

Tapped hole

thread

size

todepth

I

N

9.87 250.6

8.70

221.1

13.74

349.1 16.11

12.58

319.6

M12

M12xl.75

PCD

J

12.23

14.94

(mml

180.0

252.5

190.3

215.0

190.0

(mml

on

9.89

18.5

3.9

14.5

38.0

80.0

41.0

70.0

4.6

10.0

29.0

a

05

310.6

251.1

409.1

379.6

31

Page 9

Unimotor

hd Selection Considerations

Feedback Options

Feedback Device

Order Code Feedback Type

AR

CR

EM

(Multi-Tum)

FM

(Single-Turn)

Resolver'

Incremental encoder

In

ductive

Absolute encoder

EnDat'

Encoder

Supply Voltage

7Vrms

Excitation 5 kHz

5Vdc

5Vdc

SinCos

Cycles or

Incremental

Pulses per

Revolution

055-067 Motors

4096

16

Resolution

Available

Position

16384

2.62 x 105 (18 bits)

to

loop

Me

Hig

Feedback Accuracy

low

.,.

- 600 arc second

Medium

.,.

-150 arc second

Medium

-t-

/-480

arc second

AE

CA

EC(Multi-Turn)

FC

(Single-

Tum)

RA

(Multi-Tum)

SA(Single-Turn)

EB

(Multi-Tum)

FB

(Single-Turn)

NOTES:

'Resolution value shown when used with the

'Resolution value shown when used with the

SC

Hiper,

depending on the encoder-multi-tum devices

Motor

Motor

Selection

Derating

Resolver'

Incremental encoder

In

ductive

Absolute encoder

Optical

SinCos

encoder'

HIPERFACE

Optical

Absolute encoder

EnDat'

EnDat'

Unidrive

Unidrive

Adverse operating conditions require

6Vrms

Excitation 6 kHz

5Vdc

7 - 10Vdc

7 -12Vdc

3.6- 14

M resolver input or

M,

Unidrive

have

that

the

motor

Vdc

SM

SP

or Digitax

4096 (12 bit) resolution

performance be derated. These conditions include ambient

temperature

drive switching frequency

above 104

°F

(40

°C),

motor

or

a drive oversized for

mounting position,

the

motor.

4096

32

1024

2048

-Resolver Option

ST

Medium

when the encoder type

Drive Switching Frequency

Most drive current ratings are reduced

frequencies. See individual drive manuals for details.

See

for guidance only).

Medium

16384 ( 14 bit)

absolute position

524288 (19 bits)

Very

high

1.04x10'(20 bits)

Very

high

2.08x10' (21 bits)

Module

(Unidrive

is

set

the

table below for

SP

and Digitax

to

either

.,.

- 720 arc second

High

-t-

/-60 arc second

f------~_

For

SinCos

For

SinCos

differential non-linearity

(total

(differential non-linearity-t-/-

ST)

SC

En

Oat or

motor

derating factors (these figures are

M_e_d_iu_m

.,.

- 280 arc second

integral non-linearity-t-/-45 arc second

accuracy-t-/-52

-t-/

at

_~------1

High

arc second)

Very

high

-20 arc second

higher switching

-t-

/-7 arc second

1%

signal period)

Ambient Temperatures

For ambient temperatures above 104

be derated using

to

3000

up

the

following formula as a guideline for motors

rpm. Consult factory for higher-speed

information.

New

de.rated

Specified

*Measured in

torque

=

torquex b -([ambient temperature"' -40} /

•c

For example, with an ambient

new

derated

torque

will

be 0.8 x specified torque.

32

°F

(40

temperature

°C),

of

the

169

torque

motor

100)

°F

(76

must

derating

°C),

the

Switching

Frequency

3kHz 0.92 0.93 0.89 0.89 0.83 0.90

4kHz 0.93 0.94 0 .

5/6

kHz

8kHz

10/12/16

kHz

0.

95

0.95 0.95 0.96 0.88 1

0.96 0.98 0.97 0.98 0.

1 1 1 1 1 1

91

0.92 0.85 0.95

Mounting Arrangements

In

general,

mounting surface

gearbox,

the

motor

motor

the

motor

is

mounted

torque

should be derated

is

heated from an external source such as a

is

connected

in

a confined space with restricted air

to a poor

if

the

motor

thermal conductor,

91

'I

1

or

flow.

Page 10

Thermal Test Conditions

The performance

t

emperature

thermally

-isolat

data

of

68

°F

(20

ed

aluminum plate.

shown was r

°C)

and

the

ecorded with

motor

mounted

an

ambient

on

Thermal Protection

Thermist

a

windings and gives an indication

The installer must connect

to

out

or

do

so

will invalidate

.

protection

to

293

the

°F

(145

of seri

the

thermistor

motor

°()

is built into the mot

ous overheating probl

to

the

drive. Failure

warranty

if

winding burns

or

ems

.

Environmental Conditions

Any

liquids or gases

be

must

in

confirmed

ternational standards.

that

to

ensure

may

come into

compliance with

contact

with

the

corr

the

ect

motor

Brake Operation

Do

not

app

ly the brake while the mot

brake can only

ope

rations

and

take

a limi

must not

ted

number

be

used for repeated dynamic braking.

or

shaft

is

rotating . The

of

emergency braking

055 4.3

067, 089

5to 142

11

190

Unimotor

Motor Frame Size Power Supply Power Static Tor

(mml

055

067

089

11

142

190

190 F

NOTES

:

• Figures shown in individual motor sections are

Apply a de

•

'Backlash will increase

hd Holding Brake Specifications

5

C-D

ratefactor

of0.7

overtime

x4.3

X 1.06

9.8 X 9.8 X 0.6 250 X 250 X 15

13.8

X 13.8 X 0.8

19.7x19.7x0.8

(Vdcl

24

24

24

24

24

24

24

to

standard brake torque figures if mot

110x110x27

350x350x20

500x

500x20

(W

I (lb-inl

6.3 15.9 1.8 22 0.00003

10.2

23.4 88.5 10

19.5 117

25

25 592 67 120 0.00404

54.5 885 100

at

68 'F (20 'C) ambient

35.4 4

371

Ingress Protection

IP

65

conformance; sealed

mounted

ml

Release

(msl

que

(N

20 120 0.00029

42 95 0.00225

or

temperature is above 212 'F (100 'C)

and

Time

nom. (lb-in-sec'I

<50

<50

CF

connected

Added Inertia

0.00006

0.00010

0.00683

aga

.

(kgcm'I

0.

03

0.073

0.115

0.327

2.54

4.57

72

7.

inst wat

er

spray

and

Backlash Added Weight

Degrees•

0.73 0.88

0.75

0.75

0.75 2.6 1.2

0.77 6.2 2.8

0.77

0.75

dust when

(lbsl (kgl

.1

1

1.3 0.6

11

.7 5.3

11

.7 5.3

0.4

0.5

33

Loading...

Loading...