Control Techniques Unidrive SP1203, Unidrive SP1201, Unidrive SP1202, Unidrive SP1204, Unidrive SP2201 Installation Manual

...Page 1

EF

www.controltechniques.com

Installation Guide

U

Low Voltage DC

Part Number: 0471-0060-01

Issue Number: 1

Page 2

General Information

The manufacturer accepts no liability for any consequences resulting from

inappropriate, negligent or incorrect installation or adjustment of the optional

operating parameters of the equipment or from mismatching the variable speed

drive with the motor.

The contents of this guide are believed to be correct at the time of printing. In the

interests of a commitment to a policy of continuous development and improvement,

the manufacturer reserves the right to change the specification of the product or its

performance, or the contents of this guide, without notice.

All rights reserved. No parts of this guide may be reproduced or transmitted in any

form or by any means, electrical or mechanical including photocopying, recording or

by an information storage or retrieval system, without permission in writing from the

publisher.

Copyright © October 2005 Control Techniques Drives Ltd

Issue Code: 1

Page 3

Unidrive SP Low Voltage DC Installation Guide 3

Issue Number: 1 www.controltechniques.com

Contents

1 Safety Information ..........................................................4

1.1 Warnings, Cautions and Notes ................................................................4

1.2 Electrical safety - general warning ..........................................................4

1.3 System design and safety of personnel ..................................................4

1.4 Environmental limits ................................................................................5

1.5 Compliance with regulations ...................................................................5

1.6 Motor .......................................................................................................5

1.7 Adjusting parameters ..............................................................................5

2 Introduction ....................................................................6

2.1 Advantages of Low Voltage DC operation ..............................................6

2.2 Principles of operation .............................................................................6

2.3 Operating modes .....................................................................................7

2.4 Low Voltage DC speed limitation ............................................................7

3 Product information .......................................................9

3.1 Ratings ....................................................................................................9

4 System design ..............................................................11

4.1 Required connections for Low Voltage DC operation ...........................11

4.2 Low Voltage DC power supply ..............................................................11

4.3 Low Voltage DC supply types ...............................................................12

4.4 External softstart resistor .......................................................................12

4.5 Important considerations and information .............................................13

4.6 System configurations ...........................................................................14

4.7 Power circuit control logic and sequencing ...........................................24

4.8 External soft start circuit control ............................................................27

4.9 Running the motor .................................................................................29

5 Component data ...........................................................30

5.1 Fusing ....................................................................................................30

5.2 Discharge resistor and protection ..........................................................32

5.3 Brake resistor ........................................................................................33

5.4 External soft start resistor ......................................................................37

5.5 Blocking diode (D1) ...............................................................................39

5.6 Supply capacitor (C1) ............................................................................39

5.7 Supplier websites ..................................................................................40

Page 4

4 Unidrive SP Low Voltage DC Installation Guide

www.controltechniques.com Issue Number: 1

1 Safety Information

1.1 Warnings, Cautions and Notes

1.2 Electrical safety - general warning

The voltages used in the drive can cause severe electrical shock and/or burns, and

could be lethal. Extreme care is necessary at all times when working with or adjacent to

the drive.

Specific warnings are given at the relevant places in this User Guide.

1.3 System design and safety of personnel

The drive is intended as a component for professional incorporation into complete

equipment or a system. If installed incorrectly, the drive may present a safety hazard.

The drive uses high voltages and currents, carries a high level of stored electrical

energy, and is used to control equipment which can cause injury.

Close attention is required to the electrical installation and the system design to avoid

hazards either in normal operation or in the event of equipment malfunction. System

design, installation, commissioning and maintenance must be carried out by personnel

who have the necessary training and experience. They must read this safety information

and this User Guide carefully.

The STOP and SECURE DISABLE functions of the drive do not isolate dangerous

voltages from the output of the drive or from any external option unit. The supply must

be disconnected by an approved electrical isolation device before gaining access to the

electrical connections.

With the sole exception of the SECURE DISABLE function, none of the drive

functions must be used to ensure safety of personnel, i.e. they must not be used

for safety-related functions.

Careful consideration must be given to the functions of the drive which might result in a

hazard, either through their intended behaviour or through incorrect operation due to a

fault. In any application where a malfunction of the drive or its control system could lead

to or allow damage, loss or injury, a risk analysis must be carried out, and where

necessary, further measures taken to reduce the risk - for example, an over-speed

protection device in case of failure of the speed control, or a fail-safe mechanical brake

in case of loss of motor braking.

A Warning contains information, which is essential for avoiding a safety hazard.

A Caution contains information, which is necessary for avoiding a risk of damage to the

product or other equipment.

A Note contains information, which helps to ensure correct operation of the product.

WARNING

CAUTION

NOTE

Page 5

Unidrive SP Low Voltage DC Installation Guide 5

Issue Number: 1 www.controltechniques.com

Safety Information

Introduction Product information System design Component data Index

The SECURE DISABLE function has been approved as meeting the requirements of

EN954-1 category 3 for the prevention of unexpected starting of the drive. It may be

used in a safety-related application. The system designer is responsible for

ensuring that the complete system is safe and designed correctly according to

the relevant safety standards.

1.4 Environmental limits

Instructions in the Unidrive SP User Guide regarding transport, storage, installation and

use of the drive must be complied with, including the specified environmental limits.

Drives must not be subjected to excessive physical force.

1.5 Compliance with regulations

The installer is responsible for complying with all relevant regulations, such as national

wiring regulations, accident prevention regulations and electromagnetic compatibility

(EMC) regulations. Particular attention must be given to the cross-sectional areas of

conductors, the selection of fuses or other protection, and protective earth (ground)

connections.

The Unidrive SP User Guide contains instruction for achieving compliance with specific

EMC standards.

Within the European Union, all machinery in which this product is used must comply

with the following directives:

98/37/EC: Safety of machinery.

89/336/EEC: Electromagnetic Compatibility.

1.6 Motor

Ensure the motor is installed in accordance with the manufacturer’s recommendations.

Ensure the motor shaft is not exposed.

Standard squirrel cage induction motors are designed for single speed operation. If it is

intended to use the capability of the drive to run a motor at speeds above its designed

maximum, it is strongly recommended that the manufacturer is consulted first.

Low speeds may cause the motor to overheat because the cooling fan becomes less

effective. The motor should be fitted with a protection thermistor. If necessary, an

electric forced vent fan should be used.

The values of the motor parameters set in the drive affect the protection of the motor.

The default values in the drive should not be relied upon.

It is essential that the correct value is entered in parameter 0.46 motor rated current.

This affects the thermal protection of the motor.

1.7 Adjusting parameters

Some parameters have a profound effect on the operation of the drive. They must not

be altered without careful consideration of the impact on the controlled system.

Measures must be taken to prevent unwanted changes due to error or tampering.

Page 6

6 Unidrive SP Low Voltage DC Installation Guide

www.controltechniques.com Issue Number: 1

2 I ntroduction

Before reading this document it is assumed that the user has familiarised themselves

with the Unidrive SP User Guide.

Any Unidrive SP can be configured for Low Voltage DC (LVDC) operation, however

there are differences in the electrical connections and operating voltage range

depending on the frame size of the drive.

This installation guide covers the following:

• Principles and advantages of Low Voltage DC operation

• Safety information

• Detailed information on required external components

• System design

• Electrical Installation

2.1 Advantages of Low Voltage DC operation

Low Voltage DC operation is intended for motor operation in an emergency back-up

situation following failure of the AC supply, for example in elevators, or to limit the motor

speed of servo motors during commissioning of equipment, for example a robot cell.

Even though Low Volt age DC operation is intended for an emergency back-up situation,

it is also possible to run the drive permanently in this mode. In the case were the Low

Voltage DC power supply is in the form of a battery the length of time that the drive will

run is limited by the battery capacity.

2.2 Principles of operation

The Unidrive SP is normally operated from a 3-phase AC supply (200V, 400V etc.) or a

DC supply of the equivalent rectified voltage. This provides power for all control circuits

via the SMPS (Switch Mode Power Supply), and power for the motor via the inverter.

Instead of powering the drive from a 3-phase AC supply it is also possible to operate the

Unidrive SP from an external Low Voltage DC supply, the supply voltage is dependant

on the drive frame size as detailed in Table 2-1.

Note that this method of drive operation will be referred to as Low Voltage DC (LVDC)

operation through the remainder of this document.

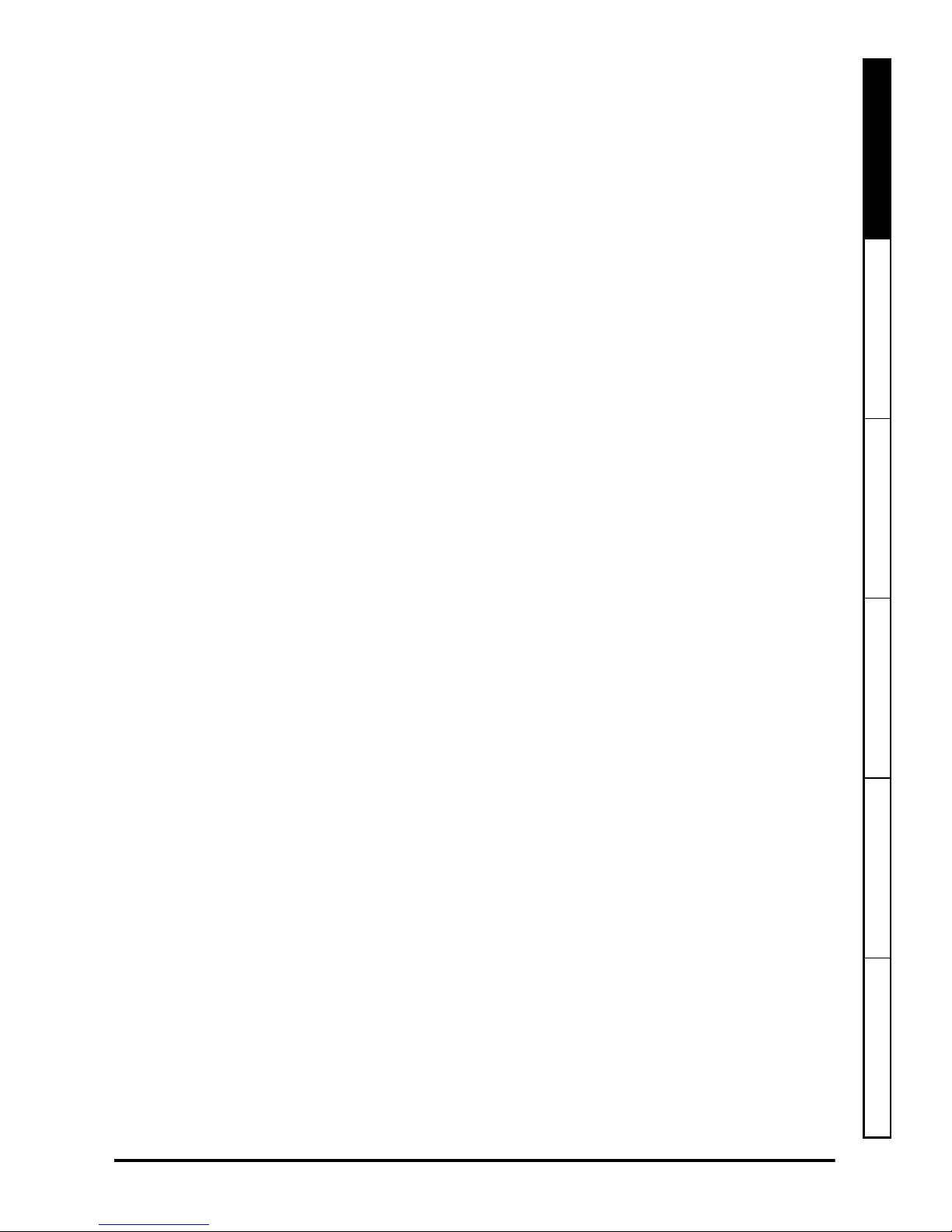

Table 2-1 Low Voltage DC operating range

*Size 4 200V drives have a continuous Low Voltage DC range of 48V to 72V.

The values given in Table 2-1 above are for a typical battery supplied system, this

includes charging of the battery.

If no regen energy is present it is possible to use slightly higher voltage levels.

The AC supply and DC supply must not be connected at the same time, seamless

Drive size

Continuous operating range of a drive

supplied by low voltage DC (Vdc)

148

248-72

348-72

4 48-96*

548-96

648-96

SPMA/D 48-96

Page 7

Unidrive SP Low Voltage DC Installation Guide 7

Issue Number: 1 www.controltechniques.com

Safety Information

Introduction

Product information System design Component data Index

change-over from AC to DC or DC to AC is not possible. See Chapter 4.7 Power circuit

control logic and sequencing on page 24.

For Low Volt age DC operation, as well as the main Low V olt age DC supply the following

external supplies are required.

• For Unidrive SP sizes 1 to 6, a 24Vdc supply must be connected to the +24V

external input on the green control terminal block of the drive (see Chapter

4 System design ). This supplies the control circuitry and may be connected

permanently.

• For Unidrive SP4 SP5 SP6 a 24V external supply needs to be connected to the

24V Low Voltage DC mode enable terminal of the drive. This supply should only be

connected when in Low Voltage DC operation (this supply is in addition to the +24V

external input).(see Chapter 4 System design )

2.3 Operating modes

Low Voltage DC operation can be used in any of the following modes:

1. Open loop mode

• Open loop vector

• Fixed V/F mode (V/Hz)

• Quadratic V/F mode (V/Hz)

2. RFC mode

3. Closed loop vector

4. Servo

2.4 Low Voltage DC speed limitation

When set up for Low V oltage DC operation, the drive can provide rated torque to the motor

at low speeds. The maximum speed that can be achieved whilst operating from this supply

is dependent on the type of motor connected to the drive as described below.

2.4.1 Operation with an induction motor

When operating with an induction motor the drive will effectively start to field weaken at

the point that the output voltage requirement (based on the programmed V/F) reaches

the maximum that the DC bus voltage of the drive can support (about 34V based on a

DC bus of 48V). e.g. The drive would begin to field weaken the motor at around 4Hz for

a 50Hz 400V motor.

The drive may continue to rotate the motor up to base speed. However, even with no

external load (just a bare motor shaft) the motor could stall due to the reduced torque

available whilst so far into field weakening.

Be aware that reduced torque may be experienced in instances where the motor

requires significant volts to magnetise; the reasons for this are listed below.

• The external Low Voltage DC power supply has reached it's maximum supply

voltage to the drive.

• The drive has reached the maximum allowable output voltage available in this mode

of operation.

Low Voltage DC operation CANNOT be used to limit the speed of an induction motor.

The drive can only provide rated torque at low speeds as described above. It is very

important to consider this when operating with an overhauling load such as lift

applications, even with the correct braking resistor selection, the drive may not be able

to maintain control of the load if the drive goes into field weakening.

WARNING

WARNING

Page 8

8 Unidrive SP Low Voltage DC Installation Guide

www.controltechniques.com Issue Number: 1

2.4.2 Operation with a servo motor

The speed of a servo motor is limited based on the Ke (voltage constant) value as

shown in the example below: -

A Unidrive SP with a Low Voltage DC supply of 48V running a 3000rpm unimotor which

has a Ke value of 98V/Krpm.

• Calculate rpm per Volt.

• Calculate drive output voltage.

• From the above calculations the motor speed will be limited to:

When in Low Voltage DC operation the Unidrive SP may NOT be able to limit the speed

of a servo motor with an overhauling load.

If a permanent magnet motor is made to rotate at a high enough speed by an external

torque, the DC bus of the drive and its associated wiring could rise above the lo wer

voltage DC operating level.

WARNING

WARNING

1000rpm 98V⁄ 10.2rpm per volt=

48V 2()⁄ 34V=

10.2 34× 347rpm=

The calculation above gives an estimated value and does not take into account motor

volt drops etc.

NOTE

Page 9

Unidrive SP Low Voltage DC Installation Guide 9

Issue Number: 1 www.controltechniques.com

Safety Information Introduction

Product information

System design Component data Index

3 Product information

3.1 Ratings

3.1.1 Drive output current ratings

For drive output current ratings please refer to the Unidrive SP User Guide.

3.1.2 Low Voltage DC rating

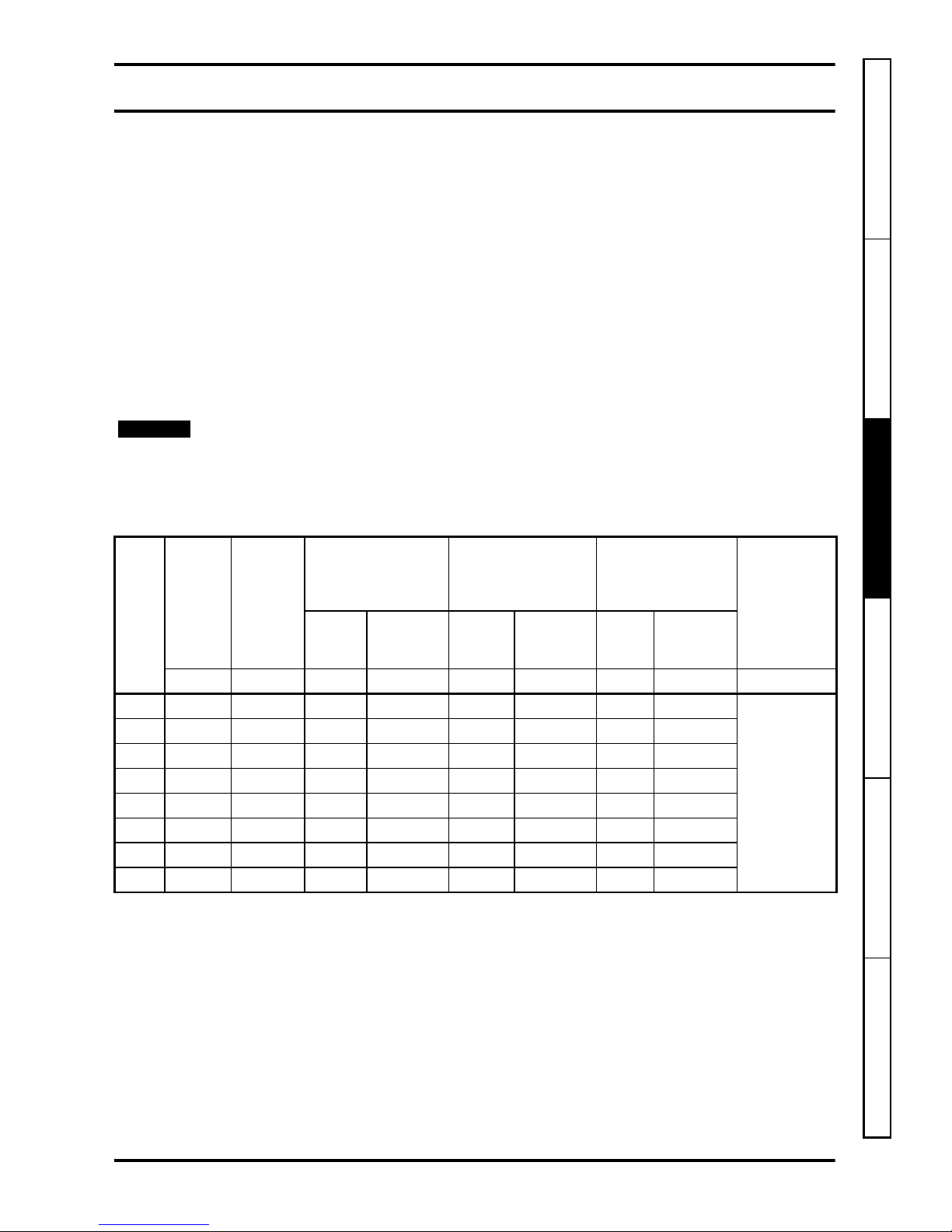

On all but size 1, the applied Low Voltage DC supply level is set by the user in Pr 6.46.

On the size 1 drive this value is non adjustable. The value set by the user will be within

limits as detailed below.

The default setting is 48V for all the drive sizes. The over voltage trip threshold and braking

IGBT turn on voltage are scaled from this value as follows :

• Brake IGBT turn on = 1.325 x Pr 6.46 (V)

• Over voltage trip = 1.45 x Pr 6.46 (V)

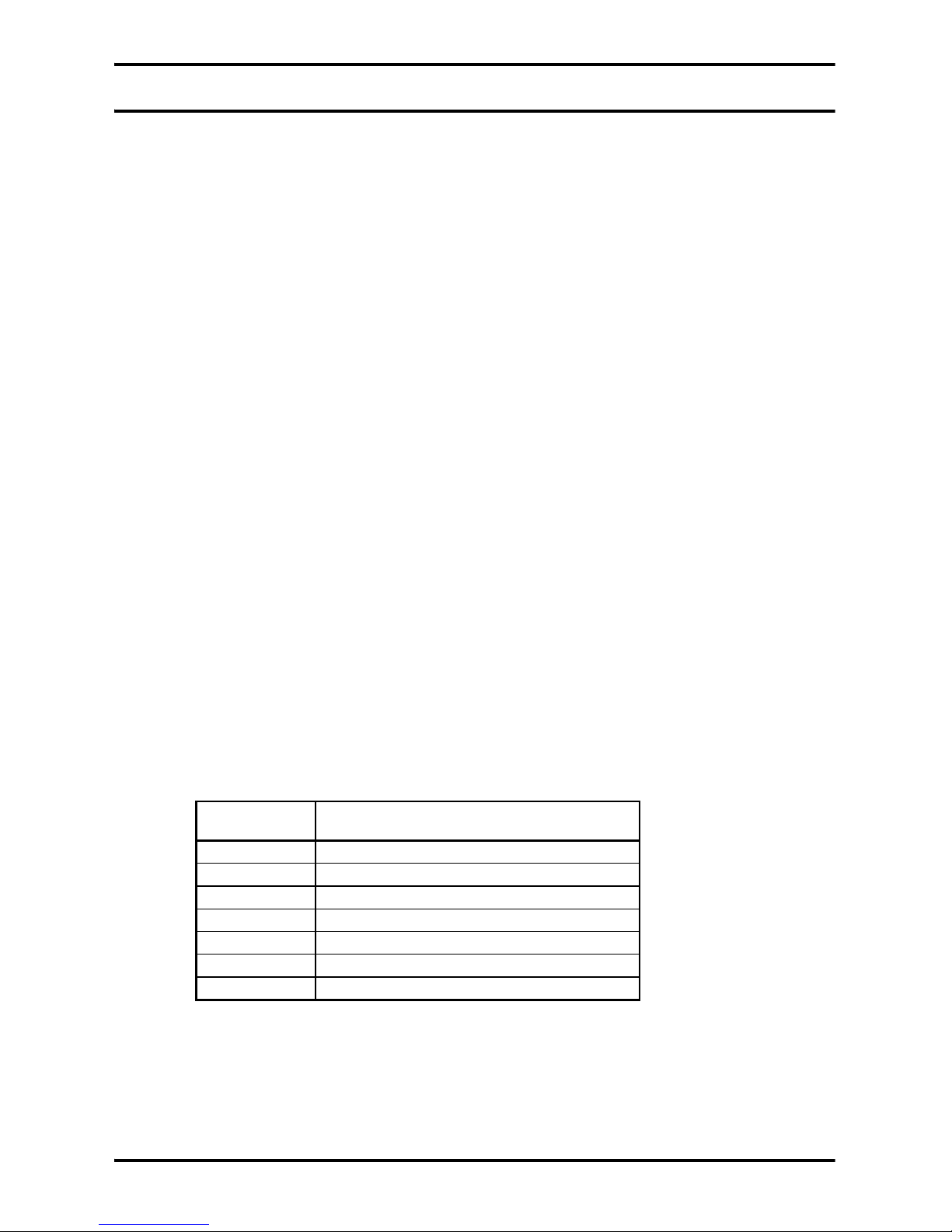

Table 3-1 Low Voltage DC drive rating

Minimum and maximum voltage values include ripple and noise. Ripple and noise levels

must not exceed 5%.

Minimum start up voltage

This is the minimum voltage that is required to initially start up the drive.

Maximum braking IGBT turn on voltage

This is the voltage level that the drive braking IGBT will turn on.

Maximum over voltage trip threshold

This is the voltage level that the drive will trip OV. (Over Voltage).

The maximum supply voltage is governed by the 0V trip level and brake turn-on level.

The drive may be supplied with a greater voltage than the nominal continuous operating

voltage, providing there is suitable headroom between the applied DC voltage and the

brake IGBT turn-on voltage and that regen energy has been taken into account.

NOTE

Drive

size

Under

voltage

trip level

Minimum

start up

voltage

Nominal

continuous

operating voltage

(Pr 6.46)

Maximum braking

IGBT turn on voltage

(Pr 5.05)

Maximum over

voltage trip

threshold

(Pr 5.05)

Required

current rating

of low

voltage DC

supply

200V

drive

variant

400V/575V/

690V drive

variant

200V

drive

variant

400V/575V/

690V drive

variant

200V

drive

variant

400V/575V/

690V drive

variant

VVVVVVVV A

135 40 48 48 63 63 69 69

2 x drive

output current

(heavy duty

current rating)

2 35 40 48 to 72 48 to 72 95 95 104 104

3 35 40 48 to 72 48 to 72 95 95 104 104

4 35 40 48 to 72 48 to 96 95 127 104 139

5 35 40 N/A 48 to 96 N/A 127 N/A 139

6 35 40 N/A 48 to 96 N/A 127 N/A 139

SPMA 35 40 N/A 48 to 96 N/A 127 N/A 139

SPMD 35 40 N/A 48 to 96 N/A 127 N/A 139

Page 10

10 Unidrive SP Low Voltage DC Installation Guide

www.controltechniques.com Issue Number: 1

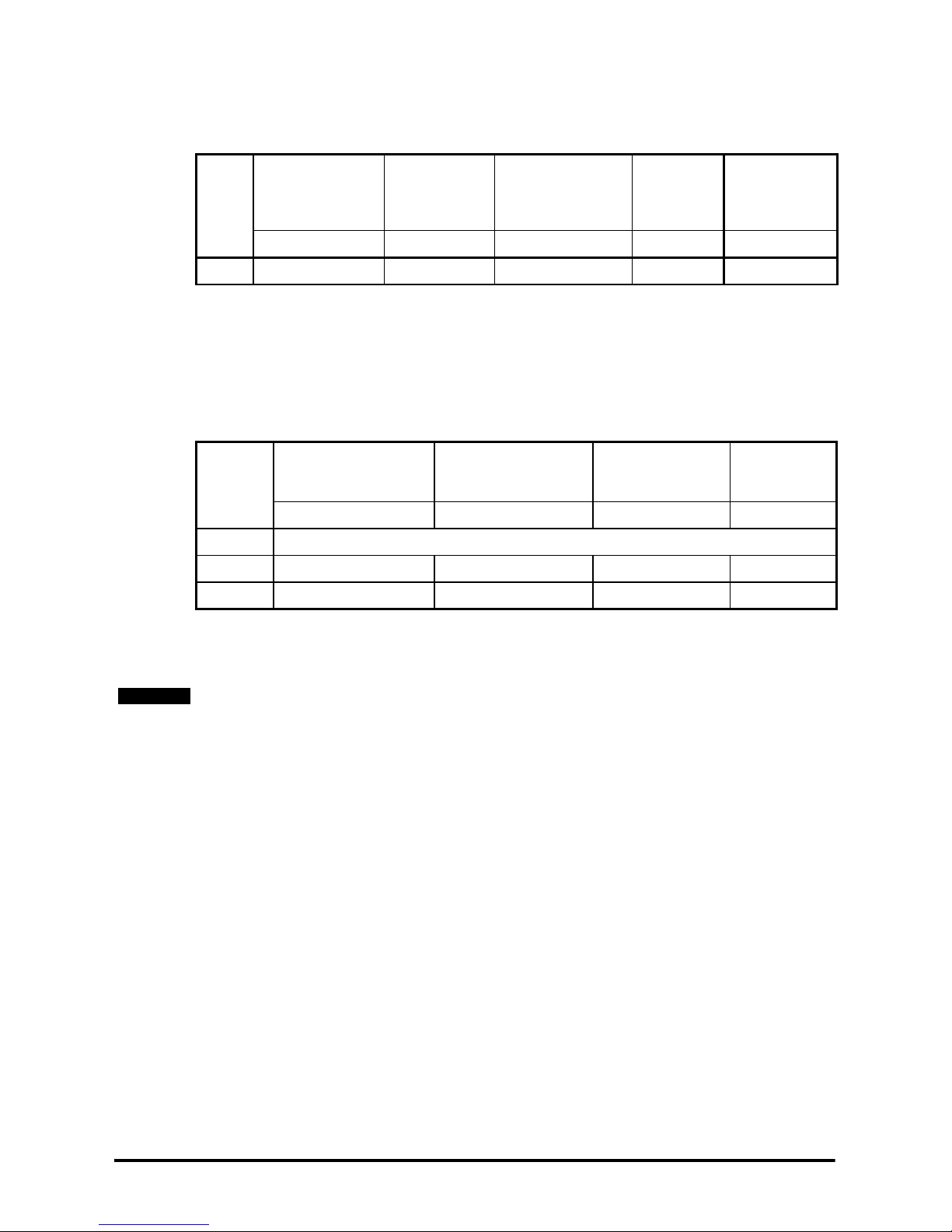

3.1.3 Drive control 24V rating

The table below shows the specification of the control +24V external input terminal that

the user supply should meet.

Table 3-2 Drive control 24V rating

Minimum and maximum voltage values include ripple and noise. Ripple and noise levels

must not exceed 5%.

3.1.4 24V Low Vo ltage DC mode enable rating

Table 3-3 shows the specification of the 24V Low Voltage DC mode enable terminal that

the user supply should meet.

Table 3-3 Low voltage DC mode enable rating

Minimum and maximum voltage values include ripple and noise. Ripple and noise levels

must not exceed 5%.

Drive

size

Maximum

continuous

operating voltage

Minimum

continuous

operating

voltage

Nominal

continuous

Operating voltage

Minimum

start up

voltage

Nominal

current

consumption

VV VVmA

All 30 19.2 24 21.6 500

Drive size

Maximum continuous

operating voltage

Minimum continuous

operating voltage

Nominal

continuous

operating voltage

Nominal

current

consumption

VVVmA

1 to 3 N/A

4 to 6 30 19.2 24 500

SPMA/D 30 19.2 24 500

A common supply can be used for the drive control 24V and 24V Low V oltage DC mode

enable.

NOTE

Page 11

Unidrive SP Low Voltage DC Installation Guide 11

Issue Number: 1 www.controltechniques.com

Safety Information Introduction Product information

System design

Component data Index

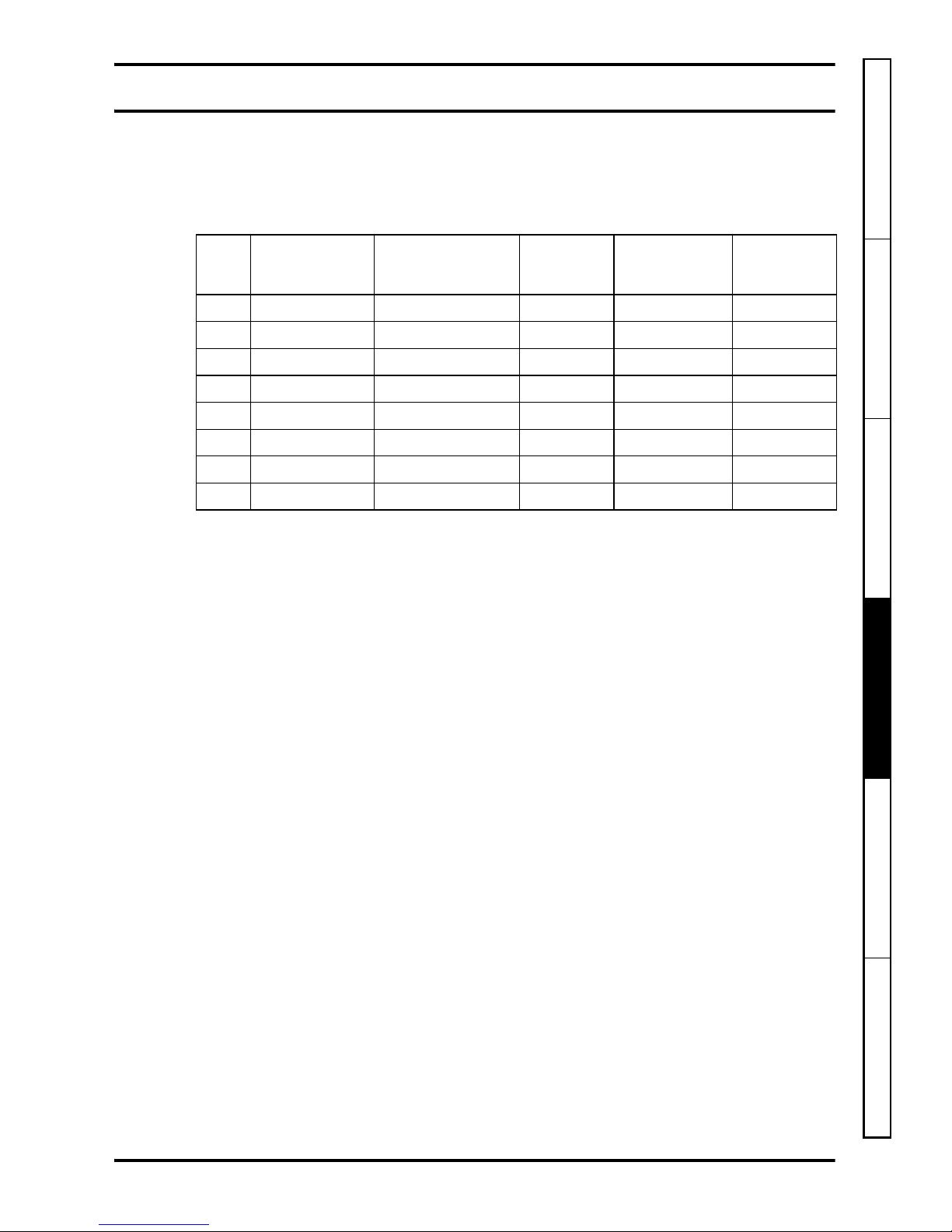

4 System design

4.1 Required connections for Low Voltage DC operation

Table 4-1 illustrates what connections and voltage supplies are required for Low Volt age

DC operation.

Table 4-1 Required connections for Low Voltage DC operation

4.2 Low Voltage DC power supply

The supply should meet the requirements set out in section 3.1.2 Low Voltage DC

rating on page 9.

If the Low Voltage DC supply is in the form of a battery and the voltage drops below 36V

a UV trip will occur. A UV trip automatically resets if the DC bus is back within

specification, which means it is possible for the drive to cycle in and out of the trip state

if the drop in voltage only occurs under load.

I.e. The drive is in the 'rdy' condition and the DC bus is within specification. The drive is

given the run command, which enables the output causing current to flow. The DC bus

drops and a UV trip is seen, the drive output is thus disabled. The DC bus then rises

back to the previous level and the UV trip resets. If the run command is still present the

drive output is enabled, which causes current to flow etc.

One of the following should be implemented to prevent this loop from occurring:

1. SM-Applications module not used: A threshold from menu 12 should be used to

monitor the DC bus and trip the drive should it drop below normal operating levels

with a charged battery.

2. SM-Applications module used: A software trap should be added to prevent this loop

from occurring.

Drive

size

Control +24V

external input

24V Low Voltage

DC mode enable

Connection

to 48V

terminal

LVDC supply

+DC/ -DC

External soft

start resistor

1 3 x 33 x

2 3 x 33 x

3 3 x 33 x

4 33x 33

5 33x 33

6 33x 33

SPMA 33x 33

SPMD 33x 33

Page 12

12 Unidrive SP Low Voltage DC Installation Guide

www.controltechniques.com Issue Number: 1

4.3 Low Voltage DC supply types

The DC supply may be connected to ground or left floating. In the event of a contactor

sticking, high voltage would be present at the negative terminal of the drive.

The instructions below ensure user safety in both cases.

4.3.1 Systems with an isolated DC supply

The supply can be floating with respect to ground, although it may have a high

impedance ground to drain leakage currents.

In the event of a fault where AC and DC supplies are connected at the same time a high

current would have no fault path to ground.

In this case:

• The 48V, +DC, -DC terminals of the drive and DC terminals of the Low Voltage DC

source must be protected from user contact.

• The Low Voltage DC supply must be able to withstand mains potential with respect

to ground and be suitable for use in an industrial environment (category 2 supply).

• Cables rated for the voltage of the rectified 3-phase AC supply must be used to

connect the drive to the Low Voltage DC supply.

4.3.2 Systems with a grounded DC supply

The ground connection for the supply must be a high current connection with an I2t

rating greater than the fuses F2a & F2b (see section 5.1 Fusing on page 30).

This is so that in the event of a fault where AC and DC supplies are connected at the

same time a high current will flow to ground and blow the fuses in the Low Voltage DC

path.

• The wiring from the drive to fuses F2a, F2b & F2c must be protected to a voltage

rating equal to or exceeding the rectified 3-phase AC supply voltage (see section

5.1 Fusing on page 30).

• The wiring from the fuse to the supply must be rated correctly for the supply.

4.4 External softstart resistor

When Unidrive SP size 1 to 3 operates from AC or DC there is a built in soft start

resistor to limit the inrush current. However when Unidrive SP size 4 and larger operate

from Low Voltage DC there is no inbuilt soft start resistor and therefore an external soft

start resistor is required between the Low Voltage DC supply and the drive.

In the event of a fault, the 48V, +DC, -DC terminals of the drive and DC terminals of the

Low Voltage DC source (including any wiring in between) could be at a potentially lethal

voltage.

WARNING

If the I2t of the ground connection is not greater than that of the fuses used, then the 48V/

DC terminal and associated wiring could be at a potentially lethal voltage in the event of

a fault.

WARNING

Failure to fit a soft start resistor may damage the drive or/and external components.

NOTE

Page 13

Unidrive SP Low Voltage DC Installation Guide 13

Issue Number: 1 www.controltechniques.com

Safety Information Introduction Product information

System design

Component data Index

4.5 Important considerations and information

• It is possible to run the drive permanently in Low Voltage DC operation.

• The AC supply and DC supply must not be connected at the same time, Seamless

change-over from AC to DC or DC to AC is not possible.

• The drive must be disabled during change over of supplies.

• The DC bus must be forcibly discharged to less than the low voltage braking IGBT

turn on level or less when changing from one supply to another to ensure that the

pre-charge circuits operate correctly. If the load motor is a permanent magnet type,

steps must be taken to ensure that it is stationary or rotating slowly enough that the

emf induced in the windings is less than 25V rms.

• To achieve a reasonably short discharge time an external discharge resistor is

normally required.

• Software should not be used to interlock the supplies, discharge resistor and drive

enable. A software failure could result in hardware damage. Software may however

be used for time delays and selection logic

• All thermal overload devices used must be connected to the supply selection

interlocks, removing AC and DC supplies in the event of a device tripping.

• For Low Voltage DC operation under AC supply loss conditions; all relays and

contactors must be driven from a maintained supply.

• The system design must adhere to one of the system configurations discussed in

section 4.6 System configurations .

•Pr 6.44 indicates which supply the drive is currently operating from:

0 = Normal high voltage supply

1 = Low Voltage DC supply.

Page 14

14 Unidrive SP Low Voltage DC Installation Guide

www.controltechniques.com Issue Number: 1

4.6 System configurations

The following diagrams show different system configurations for a Unidrive SP

operating from a Low Voltage DC supply.

The choice of system configuration depends on the amount of regen energy the DC

supply can absorb.

4.6.1 System configuration 1

This system configuration is suitable for systems were the power supply cannot absorb

any energy from the load through the drive, hence the reason for blocking diode D1

being fitted in series with the DC supply.

Figure 4-1 System configuration 1 circuit diagram for Unidrive SP size 1 to 3

*C1 is only required with Unidrive SP size 1

See Chapter 5 Component data on page 30 for details on components.

F1a

3-phase

AC supply

K1

F2a

F2b

F2c

K2c

K2b

K2a

C1*

Rdis

PS1

D1

K1b K2d

-DC

48V

+DC

L1

L2

L3

48V

DC1/-DC

DC2/+DC

Size 2 and 3

connections

F3

T2

T1

Ovld.1

Aux.1

Control + 24V

external input

Page 15

Unidrive SP Low Voltage DC Installation Guide 15

Issue Number: 1 www.controltechniques.com

Safety Information Introduction Product information

System design

Component data Index

Table 4-2 Key for Figure 4-1

4.6.2 Control implementation for system configuration 1

In order to achieve the required Low Voltage DC operation sequencing as detailed in

section 4.7 Power circuit control logic and sequencing on page 24. The circuitry shown

in Figure 4-1 and Figure 4-2 below are required.

Some of the circuitry shown in Figure 4-2 can be reduced by using SM-Applications, this

is further discussed in section 4.7.2 Control implementation using SM-Applications on

page 26.

Figure 4-2 Control circuitry for system configuration 1

Key Description

Aux.1 Ovld.1 auxillary contact

C1 DC supply capacitor (SP1 only)

D1 Blocking diode to prevent energy from being returned to the LVDC supply

Ovld.1 Thermal overload relay to protect the discharge resistor

F1a 3 phase AC supply fusing

F2a Fuse for LVDC supply feed to drive +DC terminal

F2b Fuse for LVDC supply feed to drive -DC terminal

F2c Fuse for LVDC supply feed to drive 48V terminal

F3 Fuse for drive control 24V external input

K1 Normally open contacts supplying the drive with 3 phase AC when energized

K1b

Normally closed contacts that b ring in t he discharge resistor when the AC supply is

removed

K2a

Normally open contact, which when closed supplies the d rive wit h th e positive fe ed

from the LVDC power supply

K2b

Normally open contact, which when closed supplies th e drive with th e negative feed

from the LVDC power supply

K2c

Normally open contacts whic h when closed supply the 48V terminal of the drive

with LVDC

K2d

Normally closed contacts that br ing in the discharge resist or when the DC supply is

removed

PS1 LVDC power supply

Rdis DC bus discharge resistor

K1

c

K2d

K3a K2e

K3b K1d

K4a

K5a

K2

K1

K5

K4

K3

A

C Supply

select

Enable

input

Drive

enable

Aux.1

Timer Coil, Delay ON

Relay Coil

Normally Open Contacts

Normally Closed Contacts

Key:

Page 16

16 Unidrive SP Low Voltage DC Installation Guide

www.controltechniques.com Issue Number: 1

Figure 4-3 System configuration 1 circuit diagram for Unidrive SP size 4 to 6, SPMA/D

See Chapter 5 Component data on page 30 for details on components.

See section 4.8 External soft start circuit control on page 27 for external soft start circuit

control.

F1a

3-phase

AC supply

K1

F2a

F2b

F2d

K1a

K2b

K2a

Rdis

PS1

D1

K1b K2d

-DC

24V Low voltage DC

mode enable (T51)

L3

L2

L1

0V (T50)

+DC

F3

T1 T2

Rs

41

42

24V

RLY1

Drive

terminals

Aux.1

Ovld.1

F4

Control + 24V

external input

24V

Page 17

Unidrive SP Low Voltage DC Installation Guide 17

Issue Number: 1 www.controltechniques.com

Safety Information Introduction Product information

System design

Component data Index

Table 4-3 Key for Figure 4-3

4.6.3 Control implementation for system configuration 1

In order to achieve the required Low Voltage DC operation sequencing as detailed in

section 4.7 Power circuit control logic and sequencing on page 24. The circuitry shown

in Figure 4-3 and Figure 4-4 below are required.

Some of the circuitry shown in Figure 4-4 can be reduced by using SM-Applications, this

is further discussed in section 4.7.2 Control implementation using SM-Applications on

page 26.

Figure 4-4 Control relays for system configuration 1

Key Description

Aux.1 Ovld.1 auxillary contact

D1 Blocking diode to prevent energy from being returned to the LVDC supply

Ovld.1 Thermal overload relay to protect the discharge resistor

F1a 3 phase AC supply fusing

F2a Fuse for LVDC supply feed to drive +DC terminal

F2b Fuse for LVDC supply feed to drive -DC terminal

F2d Fuse for 24V LVDC mode enable input.

F3 Fuse for drive control 24V external input

F4 Fuse to protect Rs

K1 Normally open contacts supplying the drive with 3 phase AC when energized

K1a Normally closed contacts supplying the 24V LVDC mode enable terminal

K1b

Normally closed contacts that bring in the discharge resistor when the AC supply

is removed

K2a

Normally open contact, which when closed supplies the drive with the positive

feed from the LVDC power supply

K2b

Normally open contact, which when closed supplies the drive with t he negative

feed from the LVDC power supply

K2d

Normally closed contacts that bring in the discharge resistor when the DC supply

is removed

PS1 LVDC power supply

Rly1 Soft start relay that brings the soft start resistor in/out of the DC supply circuit

Rdis DC bus discharge resistor

Rs External soft start resistor

K1

c

K2d

K3a K2e

K3b K1d

K4a

K5a

K2

K1

K5

K4

K3

A

C Supply

select

Enable

input

Drive

enable

Aux.1

Timer Coil, Delay ON

Relay Coil

Normally Open Contacts

Normally Closed Contacts

Key:

Page 18

18 Unidrive SP Low Voltage DC Installation Guide

www.controltechniques.com Issue Number: 1

4.6.4 Preventing over-voltage trips from occurring without the use of a brake

resistor

In the above systems in the case where the load is transferring energy back to the drive

through the motor, the DC bus voltage will rise. If the Low Voltage DC supply is unable

to absorb this energy, the DC bus voltage will continue to rise until the drive trips out on

over-voltage (OU). The drive over-voltage level is dependant on the drive frame size

(See section 3.1.2 Low Voltage DC rating on page 9 for details).

Below are recommendations for preventing this from happening:

1. Lower the setting of the regen current limit (Pr 4.06). This limits how much energy

the drive will absorb from the load.

2. Ensure that the drive is operating in one of the Standard ramp modes (Pr 2.04) and

lower the setting of the Standard ramp voltage (Pr 2.08) to 65.

The changing of the St andard ramp voltage can be automated by the use of the variable

select function, (menu 12) and the programmable logic function, (menu 9).

Reducing the regen current limit can result in the drive losing control of the load under

overhauling load conditions.

WARNING

If the above recommendations are unsuccesfull and the drive still trips OV , then it is likely

that the regen energy is significant enough to require a braking resistor. If this is the case

refer to section 4.6.5 System configuration 2 on page 20.

NOTE

Page 19

Unidrive SP Low Voltage DC Installation Guide 19

Issue Number: 1 www.controltechniques.com

Safety Information Introduction Product information

System design

Component data Index

Page 20

20 Unidrive SP Low Voltage DC Installation Guide

www.controltechniques.com Issue Number: 1

4.6.5 System configuration 2

This configuration is suitable for systems where the drive may be expected to absorb

energy from the load at drive rated current (including overload current if applicable), and

dissipate this energy into a brake resistor. However, further consideration is required

when using a brake resistor in Low Voltage DC mode.

As the DC bus voltage varies the motor power available varies in proportion to the

voltage but the power that may be dissipated in a brake resistor varies with the square

of the voltage. To enable the maximum brake power to match that from the motor in Low

Volt age DC mode, the brake resistor value must be reduced in proportion to the volt age.

The arrangement shown in the circuit below automatically connects the appropriate

brake resistor depending on the supply voltage. Note that the brake resistor thermal

overload devices are also connected to the supply selection interlocks. If either resistor

overheats, then the Low Voltage DC and AC supplies are both tripped off. As shown in

Figure 4-6 Control circuitry for system configuration 2 on page 21

Figure 4-5 System configuration 2 circuit diagram for Unidrive SP size 1 to 3

*C1 is only required with Unidrive SP size 1

See Chapter 5 Component data for details on components.

F2a

F2b

F2c

C1*

Rdis

PS1

D1

K1b K2d

-DC

48V

+DC

48V

DC1/-DC

DC2/+DC

Size 2 and 3

connections

Brake

Brake

F1a

3-phase

AC supply

K1

L1

L2

L3

F3

T2

T1

K2c

K2b

K2a

Aux.1

Ovld.1

R_LVDC

K2f

R_norm

Aux.3

Aux.2

Ovld.3

Ovld.2

Control + 24V

external input

The total brake resistance used in Low Volt age DC mode is the parallel configuration of

R_ LVDC and R_norm.

NOTE

Page 21

Unidrive SP Low Voltage DC Installation Guide 21

Issue Number: 1 www.controltechniques.com

Safety Information Introduction Product information

System design

Component data Index

Table 4-4 Key for Figure 4-5

4.6.6 Control implementation for system configuration 2

In order to achieve the required Low Voltage DC operation sequencing as detailed in

section 4.7 Power circuit control logic and sequencing on page 24. The circuitry shown

in Figure 4-5 and Figure 4-6 below are required.

Some of the circuitry shown in Figure 4-6 can be reduced by using SM-Applications, this

is further discussed in section 4.7.2 Control implementation using SM-Applications on

page 26.

Figure 4-6 Control circuitry for system configuration 2

Key Description

Aux.1 Ovld.1 auxillary contact

Aux.2 Ovld.2 auxillary contact

Aux.3 Ovld.3 auxillary contact

Ovld.3 Thermal overload relay for high voltage braking resistor

Ovld.2 Thermal overload relay for low voltage braking resistor

C1 DC supply capacitor (SP1 only)

D1 Blocking diode to prevent energy from being returned to the LVDC supply

Ovld.1 Thermal overload relay to protect the discharge resistor

F1a 3 phase AC supply fusing

F2a Fuse for LVDC supply feed to drive +DC terminal

F2b Fuse for LVDC supply feed to drive -DC terminal

F2c Fuse for LVDC supply feed to drive 48v terminal

F3 Fuse for drive control 24V external input

K1 Normally open contacts supplying the drive with 3 phase AC when energized

K1b

Normally closed contacts that bring in the discharge resistor when the AC supply is removed

K2a

Normally open contact, which when closed supplie s the drive with the positive fe ed from

the LVDC power supply

K2b

Normally open contact, which when closed supplies the drive with the negative feed

from the LVDC power supply

K2c

Normally open contacts which when closed supply the 48V terminal of the drive with

LVDC

K2d

Normally closed contacts that bring in the discharg e res isto r wh en t he DC supply is removed

K2f Normally open contacts which when closed bring R_LVDC into circuit

PS1 LVDC power supply

Rdis DC bus discharge resistor

R_LVDC Low voltage braking resistor

R_norm High voltage braking resistor

K1c

K2d

K3a K2e

K3b K1d

K4a

K5a

K2

K1

K5

K4

K3

AC Supply

select

Enable

input

Drive

enabl

e

Aux.1

Aux.2 Aux.3

Timer Coil, Delay ON

Relay Coil

Normally Open Contacts

Normally Closed Contacts

Key:

Page 22

22 Unidrive SP Low Voltage DC Installation Guide

www.controltechniques.com Issue Number: 1

Figure 4-7 System configuration 2 circuit diagram for Unidrive SP size 4 to 6, SPMA/D

See Chapter 5 Component data on page 30 for details on components.

See section 4.8 External soft start circuit control on page 27 for external soft start circuit

control.

The total brake resistance used in Low Volt age DC mode is the parallel configuration of

R_ LVDC and R_norm.

F2d

K1a

24V Low voltage DC

mode enable (T51)

0V (T50)

Brake

F3

T1 T2

-DC

+DC

F2a

F2b

K2b

K2a

Rdis

PS1

D1

K1b K2d

Rs

41

42

F1a

3-phase

AC supply

K1

L3

L2

L1

24V

RLY1

Drive

terminals

R_LVDC

K2f

R_norm

Aux.3

Aux.2

Ovld.3

Ovld.2

F4

Aux.1

Ovld.1

Control + 24V

external input

24V

NOTE

Page 23

Unidrive SP Low Voltage DC Installation Guide 23

Issue Number: 1 www.controltechniques.com

Safety Information Introduction Product information

System design

Component data Index

Table 4-5 Key for Figure 4-7

4.6.7 Control implementation for system configuration 2

In order to achieve the required Low Voltage DC operation sequencing as detailed in

section 4.7 Power circuit control logic and sequencing on page 24. The circuitry shown

in Figure 4-7 and Figure 4-8 below are required.

Some of the circuitry shown in Figure 4-8 can be reduced by using SM-Applications, this

is further discussed in section 4.7.2 Control implementation using SM-Applications on

page 26..

Figure 4-8 Control relays for system configuration 2

Key Description

Aux.1 Ovld.1 auxillary contact

Aux.2 Ovld.2 auxillary contact

Aux.3 Ovld.3 auxillary contact

Ovld.3 Thermal overload relay for high voltage braking resisto r

Ovld.2 Thermal overload relay for low voltage braking resist or

D1 Blocking diode to prevent energy from being returned to the LVDC supply

Ovld.1 Thermal overload relay to protect the discharge resistor

F1a 3 phase AC supply fusing

F2a Fuse for LVDC supply feed to drive +DC terminal

F2b Fuse for LVDC supply feed to drive -DC terminal

F2d Fuse for LVDC mode enable input.

F3 Fuse for drive control 24V external input

K1 Normally open contacts supplying the drive with 3 phase AC when energized

K1a Normally closed contacts supplying the LVDC mode enable terminal

K1b

Normally closed contacts th at br in g in the dis char ge resi st or when the AC supp ly is removed

K2a

Normally open contact, which when closed supplies the drive with the positive feed

form the LVDC power supply

K2b

Normally open contact, which when closed supplies the drive with the negative feed

from the LVDC power supply

K2d

Normally closed contact s t hat bri ng in the dischar ge r esis tor when the DC sup ply i s removed

K2f Normally open contacts which when clo se d bring R_LVDC into circuit

PS1 LVDC power supply

Rly1 Softstart relay that brings the softstart resistor in/out of the DC supply circuit

Rdis DC bus discharge resistor

Rs External softstart resistor

R_LVDC Low voltage braking resistor

R_norm High voltage braking resistor

K1c

K2d

K3a K2e

K3b K1d

K4a

K5a

K2

K1

K5

K4

K3

AC Supply

select

Enable

input

Drive

enabl

e

Aux.1

Aux.2 Aux.3

Timer Coil, Delay ON

Relay Coil

Normally Open Contacts

Normally Closed Contacts

Key:

Page 24

24 Unidrive SP Low Voltage DC Installation Guide

www.controltechniques.com Issue Number: 1

4.7 Power circuit control logic and sequencing

Control logic is required to interlock and sequence the contactors set out in section

4.6 System configurations on page 14 to ensure correct operation. This can be

accomplished using relays and timers or an SM-Applications option module.

Figure 4-9 shows the basic logic that is required. The logic provides the following

functions:

• Change-over delay.

• Prevention of both supplies being connected to the drive at the same time.

• The discharge contactor is closed when neither supply is connected.

• Automatic change over of the supply if the AC supply fails, or change-over by switch

selection.

• The drive is disabled when neither supply is connected.

Figure 4-9 Control logic diagram

*Supply loss detection signal could also be the output of a supply selector switch (Low

Voltage DC or nominal AC supply).

AC supply

loss detection*

Drive enable

AC supply

Delay

on t2

Drive enable

Close AC contactor

Close DC contactor

Close discharge contactor

Delay

on t1

Key:

Timer coil, delay ON

Logic AND gate

Logic NOT gate

Logic OR gate

Logic NOR gate

Page 25

Unidrive SP Low Voltage DC Installation Guide 25

Issue Number: 1 www.controltechniques.com

Safety Information Introduction Product information

System design

Component data Index

4.7.1 Control logic sequencing

Figure 4-10 shows the sequencing of the signals which must be accomplished with this

logic.

Figure 4-10 Control logic and sequencing

A

C SUPPLY

SELECT

A

C SUPPLY

CONTACTOR

LOW VOLTAGE

DC SUPPLY

CONTACTOR

DISCHARGE

RESISTOR

DRIVE ENABLE

SIGNAL

AC SUPPLYLOSS, OPEN AC

CONTACTO R& REMOVE ENABLE

CLOSE DISCHARGE RESISTOR

OPEN DISCHARGE RESISTOR

& PROVIDE ENABLE

AC SUPPLYRETURN

REMOVE ENABLE

CLOSE DISCHARGE RESISTOR

OPEN DISCHARGE RESISTOR

CLOSE AC CONTACTOR

& PROVIDE ENABLE

AC SUPPLY SELECTED

DC SUPPLY SELECTED

CONTACTOR CLOSED

CONTACTOR OP EN

CONTACTOR CLOSED

CONTACTOR OP EN

CONTACTOR CLOSED

CONTACTOR OP EN

DRIVE ENABLE PROVIDE

D

DRIVE ENABLE REMOVED

t1 t2

Both delays t1 & t2 should have a mi nimum value of 1s.

CLOSE LOW VOLTAGE CONTACTOR

OPEN LOW VOL TAGE CONTACTOR

Page 26

26 Unidrive SP Low Voltage DC Installation Guide

www.controltechniques.com Issue Number: 1

4.7.2 Control implementation using SM-Applications

Using a second processor simplifies some of the external circuits that are required as

some of the logic and timing can be implemented in software, for example as DPL code.

To use this option for automatic change-over of supplies under mains loss conditions,

the control circuits must be fed from a maintained supply so that when AC power fails

the control circuits stay live.

This circuit below uses the control board and second processor to control the power

contactors K1 & K2. AC/Low V oltage DC supply selection relay K3 (not shown) provides

a supply status signal to the processor. The software then provides time delays and

some interlocks. Note that hardware interlocks are used for supply switching and drive

enable. Software should not be used for the interlocks as a software fault could result in

hardware damage.

Figure 4-11 Control relays with SM-Applications

4.7.3 Sequencing for the SM-Applications option module

Figure 4-12 Sequencing for the SM-Applications option module

The SM-Applications program should be based on the above sequencing, controlling

two of the drive’s digital outputs depending on the state of the AC supply select digital

input.

K1c

K2d

Enable

input

AC Supply

select

Controlboard &

SM-Applications option

Enable

Dig I/P

Dig O/P

Dig O/P

K1

K2

K2e

K1d

Relay Coil

Normally Open Contacts

Normally Closed Contacts

Key:

A

C VOLTAGE

SUPPLY SELECT

A

C SUPPLY

CONTACTOR k1

LVDC SUPPLY

CONTACTOR k2

k1 de-energised

AC SUPPLY SELECTED

CONTACTOR CLOSED

CONTACTOR OPEN

CONTACTOR CLOSED

CONTACTOR OPEN

t1 t2

k2 energised k2 de-energised k1 energised

LVDC SUPPLY SELECTE

D

Both delays t1 & t2 should have a minimum value of 1s.

Page 27

Unidrive SP Low Voltage DC Installation Guide 27

Issue Number: 1 www.controltechniques.com

Safety Information Introduction Product information

System design

Component data Index

4.8 External soft start circuit control

As discussed in section 4.4 External softstart resistor on page 12 an external soft start

resistor is required for Unidrive SP size 4 and larger.

The soft start resistor only needs to be in circuit at certain times as shown in the flow

diagram below.

Figure 4-13 Soft start control circuit sequencing

The above sequencing can be achieved using the drive internal function blocks as

shown in Figure 4-14 on page 28.

Yes

Is the drive powered

from LVDC ?

(Read Pr

6.44

)

Yes

Is the drive in

UV state?

(Read Pr

10.16

)

No

No

Close the drive

relay

(soft start resitor

out of circuit)

Wait 2.5.s

Allow drive

enable

(write 1 to Pr

6.15

)

Page 28

28 Unidrive SP Low Voltage DC Installation Guide

www.controltechniques.com Issue Number: 1

Figure 4-14 Soft start control circuit using drive internal logic

Table 4-6 Parameter set up required for Figure 4-14

The soft start control circuit provides the following functions:

• Opens and closes the external soft start relay contacts, which brings the external

soft start resistor in and out of circuit.

• Prevents the drive from running whilst the soft start resistor is in circuit (when in Low

Voltage DC mode only).

• Ensures that the drive DC bus has reached a voltage level in which the soft start

resistor can be taken out of circuit.

Figure 4-15 Logic function diagram

41

42

6.15

To drive +DC

F4

Rs

From LVDC

supply

PS2

Internal to drive External to drive

Drive

enable

x(-1)

10.16

6.44

2.5s

delay

x(-1)

x(-1)

Normal high voltage

supply = 0

Low voltage DC

supply = 1

Under voltage

active

Healthy = 0

UV trip = 1

Disable = 0

Enable = 1

0V

Parameter Default value Value to be entered

Pr 9.04 Function 1 input 1 source para meter 0.00 10.16

Pr 9.05 Function 1 input 1 invert OFF(0) ON(1)

Pr 9.06 Function 1 input 2 source para meter 0.00 6.44

Pr 9.09 Function-1 delay 0.0 1.5

Pr 8.27 Drive relay source 10.01 9.01

Pr 9.14 Function 2 input 1 source para meter 0.00 9.01

Pr 9.15 Function 2 input 1 invert OFF(0) ON(1)

Pr 9.16 Function 2 input 2 source para meter 0.00 6.44

Pr 9.17 Function 2 input 2 invert OFF(0) ON(1)

Pr 9.20 Function 2 destination parameter 0.00 6.15

Drive enable

Active supply Pr

6.44

Under voltage activePr

10.16

Relay coil

Low voltage DCsupply

Normal high voltage

UV trip

Drive Healthy

Contact closed

Contact open

Enable

Disable

2.5s

Page 29

Unidrive SP Low Voltage DC Installation Guide 29

Issue Number: 1 www.controltechniques.com

Safety Information Introduction Product information

System design

Component data Index

4.9 Running the motor

For information on tuning of the drive for best performance please refer to the Running

the motor and optimization section of the Unidrive SP User Guide.

4.9.1 Autotuning

In order for the drive to obtain the correct motor parameter values, the autotune should

be carried out when operating from a normal high voltage supply and not when in Low

Voltage DC operation. If it is not possible to autotune the drive when operating from a

normal high voltage supply the motor parameters should be obtained from the motor

nameplate and entered into the drive manually.

Ensure that no damage or safety hazard could arise from the motor starting

unexpectedly.

WARNING

The values of the motor parameters affect the protection of the motor.The default

values in the drive should not be relied upon. It is essential that the correct value is

entered in Pr 0.46 Motor rated current. This affects the thermal protection of the motor.

CAUTION

If the keypad mode has been used previously, ensure that the keypad reference has

been set to 0 using the buttons as if the drive is started using the keypad it will

run to the speed defined by the keypad reference (Pr 0.35).

CAUTION

If the intended maximum speed affects the safety of the machinery, additional

independent over-speed protection must be used.

WARNING

Page 30

30 Unidrive SP Low Voltage DC Installation Guide

www.controltechniques.com Issue Number: 1

5 Component data

5.1 Fusing

Table 5-1 Recommended Low Voltage DC supply fuse current ratings (Unidrive

SP size 1 to 3)

Drive

The fuse voltage rating must be suitable for the rectified drive

AC supply voltage, e.g. ≥400Vdc for a SPx20x, ≥750Vdc for a

SPx40x, ≥890Vdc for a SPx50x, and ≥1000Vdc for a SPx60x

F3 (A)

USA fuse

F2a & F2b (A)

European fuse

F2a & F2b (A)

F2c (A)

SP1201 7 8

13A 50Vdc

SP1202 10 10

SP1203 15 16

SP1204 20 20

SP2201 25 25

SP2202 32 35

SP2203 45 50

SP3201 60 63

SP3202 90 100

SP1401 3 4

SP1402 6 6

SP1403 7 8

SP1404 10 10

SP1405 15 16

SP1406 20 20

SP2401 25 25

SP2402 32 35

SP2403 45 50

SP2404 60 63

SP3401 60 63

SP3402 80 80

SP3403 90 100

SP3501 7 8

SP3502 10 10

SP3503 15 16

SP3504 16 20

SP3505 25 25

SP3506 32 35

SP3507 45 50

Page 31

Unidrive SP Low Voltage DC Installation Guide 31

Issue Number: 1 www.controltechniques.com

Safety Information Introduction Product information System design

Component data

Index

Table 5-2 Recommended Low Voltage DC supply fuse current ratings (Unidrive

SP size 4 to 6, SPMA/D)

Drive

The fuse voltage rating must be suitable for the

rectified drive AC supply voltage, e.g. ≥400Vdc for a

SPx20x, ≥750Vdc for a SPx40x, ≥890Vdc for a SPx50x,

and ≥1000Vdc for a SPx60x

F2d F3

USA fuse

F2a & F2b

(A)

European fuse

F2a & F2b (A)

F2c (A)

SP4201 110 125

1

8A 600V AC

fast acting

class CC

type fuse

3A 50Vdc

SP4202 150 160

SP4203 160 175

SP4401 125 125

SP4402 150 160

SP4403 175 200

SP5401 225 250

SP5402 300 315

SP6401 350 350

SP6402 450 450

SPMA 1401 350 350

SPMA 1402 450 450

SPMD 1401 350 350

SPMD 1402 450 450

SPMD 1403 500 500

SPMD 1404 600 630

SP4601 35 40

SP4602 45 50

SP4603 50 50

SP4604 70 80

SP4605 90 100

SP4606 100 100

SP5601 125 125

SP5602 175 200

SP6601 200 200

SP6602 250 250

SPMA 1601 200 200

SPMA 1602 250 250

SPMD 1601 200 200

SPMD 1602 250 250

SPMD 1603 300 300

SPMD 1604 350 355

Page 32

32 Unidrive SP Low Voltage DC Installation Guide

www.controltechniques.com Issue Number: 1

5.2 Discharge resistor and protection

The discharge resistor is required to discharge the DC bus of the drive whilst changing

from one supply to the other.

Table 5-3 Discharge resistor and protection values

*The chosen thermal overload relay must have a class 10 trip characteristic.

Drive

Rdis

(Ω)

Total Power

rating

(W)

Short term (1s)

energy rating

(J)

Thermal overload

relay trip setting

(A)*

SP1201 to SP1202 220 6 3950 0.13

SP1203 to SP1204 100 4 2580 0.25

SP2201 to SP2203 100 6 4030 0.34

SP3201 to SP3202 100 12 8670 0.48

SP4201 to SP4203 100 9 6470 0.48

SP1401 to SP1406 680 17 12180 0.1

SP2401 to SP2404 220 6 3940 0.25

SP3401 to SP3403 220 11 7720 0.32

SP4401 220 9 6660 0.3

SP4402 to SP4403 100 18 13050 0.6

SP5401 to SP5402 100 25 18330 0.79

SP6401 100 33 24510 1.0

SP6402 100 49 36250 1.1

SPMA1401 100 33 24510 1.0

SPMA1402 100 49 36250 1.1

SPMD1401 100 33 24510 1.0

SPMD1402 100 49 36250 1.1

SPMD1403 to SPMD1404 100 62 46560 1.1

SP3501 to SP3507 220 12 8870 0.35

SP5601 to SP5602 100 23 17210 0.8

SP6601 to SP6602 100 35 25850 0.9

SPMA1601 100 35 25850 0.9

SPMA1602 100 35 25850 0.9

SPMD1601 100 35 25850 0.9

SPMD1602 100 35 25850 0.9

SPMD1603 100 37 27230 1.0

SPMD1604 100 37 27230 1.1

High temperatures

The discharge resistor can reach high temperatures. Locate the resistors so that

damage cannot result. Use cable having insulation capable of withstanding high

temperatures.

WARNING

Page 33

Unidrive SP Low Voltage DC Installation Guide 33

Issue Number: 1 www.controltechniques.com

Safety Information Introduction Product information System design

Component data

Index

5.3 Brake resistor

As the DC bus voltage varies the motor power available varies in proportion to the

voltage but the power that may be dissipated in a brake resistor varies with the square

of the voltage. To enable the maximum brake power to match that from the motor in Low

Volt age DC mode, the brake resistor value must be reduced in proportion to the volt age,

therefore a resistor is required in parallel with the normal operation brake resistor.

Please refer to the Unidrive SP User Guide for normal operation brake resistor values.

The table below shows the R_LVDC value resistor that is to be fitted in parallel with the

normal operation brake resistor.

Table 5-4 Brake resistor values (R_LVDC) Unidrive SP 1 to 6

Pr 6.46 48V

60V 72V 84V 96V

Drive

(Ω)

Peak

power

(kW)

Average

power

over 60s

(kW)

(Ω)

Peak

power

(kW)

Average

power

over 60s

(kW)

(Ω)

Peak

power

(kW)

Average

power

over 60s

(kW)

(Ω)

Peak

power

(kW)

Average

power

over 60s

(kW)

(Ω)

Peak

power

(kW)

Average

power

over 60s

(kW)

SP1201

to 1203

7.4 0.55 0.49 N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A

SP1204 4.9 0.83 0.72 N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A

SP2201

to 2203

3.0 1.35 1.35 3.8 1.66 1.66 4.8 1.90 1.90 N/A N/A N/A N/A N/A N/A

SP3201

to 3202

1.1 3.68 3.14 1.5 4.21 3.92 1.8 5.06 4.71 N/A N/A N/A N/A N/A N/A

SP4201

to 4203

0.75 5.62 5.38 1.0 6.32 6.32 1.2 7.58 7.58 N/A N/A N/A N/A N/A N/A

SP1401

to 1404

6.9 0.59 0.36 N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A

SP1405

to 1406

4.5 0.90 0.65 N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A

SP2401

to 2404

1.7 2.38 1.83 2.2 2.87 2.29 2.7 3.37 2.75 N/A N/A N/A N/A N/A N/A

SP3401

to 3403

1.4 2.89 2.69 1.8 3.51 3.36 2.2 4.14 4.04 N/A N/A N/A N/A N/A N/A

SP4401

to 4402

1.0 4.40 4.40 1.2 5.27 5.27 1.5 6.07 6.07 1.7 7.29 7.29 2.0 8.09 8.09

SP4403 0.7 5.86 5.50 0.9 7.02 6.88 1.1 8.27 8.26 1.3 9.53 9.53 1.5 10.79 10.79

SP5401 0.45 8.99 6.73 0.6 10.53 8.41 0.7 13.0 10.09 0.9 13.76 11.77 1.0 16.18 13.45

SP5402 0.45 8.99 8.99 0.6 10.53 10.53 0.7 13.0 13.0 0.7 13.76 13.76 0.8 20.22 18.35

SP6401

to 6402

0.35 11.9 11.90 0.5 12.64 12.64 0.6 15.17 15.17 0.7 17.70 17.70 0.7 23.11 23.11

SP3501

to 3507

1.4 3.00 1.54 1.8 3.51 1.92 2.1 4.33 2.31 N/A N/A N/A N/A N/A N/A

SP4601

to 4606

0.9 4.49 3.83 1.2 5.27 4.79 1.4 6.50 5.75 1.7 7.29 6.71 1.9 8.52 7.67

SP5601

to 5602

0.7 5.95 5.95 0.9 7.02 7.02 1.1 8.27 8.27 1.3 9.53 9.53 1.5 10.79 10.79

SP6601

to 6602

To be confirmed

Page 34

34 Unidrive SP Low Voltage DC Installation Guide

www.controltechniques.com Issue Number: 1

Table 5-5 Brake resistor values (R_LVDC) Unidrive SPMA/D

5.3.1 Brake resistor rating and positioning

When a braking resistor is to be mounted outside the enclosure, ensure that it is

mounted in a ventilated metal housing that will perform the following functions:

• Prevent inadvertent contact with the resistor

• Allow adequate ventilation for the resistor

For high-inertia loads or under continuous braking, the continuous power dissipated in

the braking resistor may be as high as the power rating of the drive. The total energy

dissipated in the braking resistor is dependent on the amount of energy to be extracted

from the load.

The resistor ratings given in Table 5-4 are calculated for maximum braking power for the

particular drive and operating voltage.

In most applications, braking occurs only occasionally . This allows the continuous power

rating of the braking resistor to be much lower. It is essential, though, that the power

rating and energy rating of the braking resistor are sufficient for the most extreme

braking duty that is likely to be encountered.

Optimisation of the braking resistor requires a careful consideration of the braking duty.

Select a value of resistance for the braking resistor that is not less than the specified

minimum resistance. Larger resistance values may give a cost saving, as well as a

safety benefit in the event of a fault in the braking system. Braking capability will then be

reduced, which could cause the drive to trip during braking if the value chosen is too

large.

Pr 6.46 48V

60V 72V 84V 96V

Drive

(Ω)

Peak

power

(kW)

Average

power

over 60s

(kW)

(Ω)

Peak

power

(kW)

Average

power

over 60s

(kW)

(Ω)

Peak

power

(kW)

Average

power

over 60s

(kW)

(Ω)

Peak

power

(kW)

Average

power

over 60s

(kW)

(Ω)

Peak

power

(kW)

Average

power

over 60s

(kW)

SPMA

1401/2

0.35 11.9 11.9 0.5 12.64 12.64 0.6 15.17 15.17 0.7 17.70 17.70 0.7 23.11 23.11

SPMD

1401/2

SPMD

1403

0.23 18 16.5 0.3 21.1 20.5 0.35 26 24.5 0.41 30.25 28.5 0.5 32.5 32.5

SPMD

1404

0.23 18 18 0.3 21.1 21.1 0.35 26 26 0.41 30.5 30.5 0.5 32.5 32.5

SPMA

1601/2

To be confirmed

SPMD

1601/2

SPMD

1603

SPMD

1604

Braking resistor: High temperatures and overload protection

Braking resistors can reach high temperatures. Locate the braking resistors so that

damage cannot result. Use cable having insulation capable of withstanding the high

temperatures. It is essential that the braking resistor is protected against overload

caused by a failure of the brake control. Unless the resistor has in-built protection, a

thermal overload relay should be fitted. In the event of the resistor becoming overloaded,

the protection device must disconnect the AC and Low Voltage DC supply from the drive.

WARNING

Page 35

Unidrive SP Low Voltage DC Installation Guide 35

Issue Number: 1 www.controltechniques.com

Safety Information Introduction Product information System design

Component data

Index

5.3.2 Sizing an appropriate thermal overload relay to protect the brake resistor

The 3 main considerations when calculating the thermal overload relay are as follows:

1. The thermal overload relay with the minimum tripping time must not trip with the

brake current pulse.

2. The peak current through the resistor must not damage the overload relay, this can

be checked by the following equation.

3. The brake resistor capability must be greater than the thermal overload relay with

maximum tripping time.

Worked example

Select a thermal overload relay for an SP1401 operating in normal duty, which will be

braking at 150% of the normal duty rating with a deceleration time of 5 seconds.

Additional data

From Table 5-4 on page 33 the value of R_LVDC will be 6.9Ω.

From section 3.1.2 Low Voltage DC rating on page 9 the LVDC brake turn on voltage

will be:

1.325 x Pr 6.46 (48V) = 63.6V

Normal operation brake turn on voltage = 780V

1. To calculate the thermal overload relay setting (I

set

)

Power from motor at 48V =

Peak current over the braking period =

Nominal motor power Overload %

LVDC brake turn on voltage

Normal operation brake turn on voltage

----------------------------------------------------------------------------------------------------------------

××

1100W 150%

63.6V

780V

---------------

×× 135W==

I

rms

peak()

Peak power at beginning of brake period (W)

Brake resistor value (Ω)

-------------------------------------------------------------------------------------------------------------------------------=

135W

6.9Ω

--------------- -= 4.4A=

Page 36

36 Unidrive SP Low Voltage DC Installation Guide

www.controltechniques.com Issue Number: 1

Use the minimum tripping curves for the chosen manufacturer of thermal overload relay

in order to find the overload factor (F) that will cause the relay to trip after 5 seconds.

The tripping curve below is for a class 10A thermal overload relay.

Figure 5-1 Class 10A thermal overload relay tripping characteristics

From the thermal overload relay-tripping curve above it can be seen that at 5 seconds

the overload factor (F) will be approximately 3.5.

From the above information the thermal overload relay setting (I

set

) will be:

Select a model of thermal overload relay that can be set at 1.26A. (e.g. Telemacanique

LRD-06).

2. Calculate the maximum fault current under fault conditions [I

r

(peak)]

Calculate the maximum current that could flow through the resistor (e.g. due to the

braking transistor becoming short circuit ).

Check that the maximum current under fault conditions is less than 17 times the current

setting of the thermal overload relay.

Overload factor (F) with short circuit =

This is less than 17 times so this thermal overload relay would be suitable.

0.1

1

10

100

1000

10000

110100

overload factor, F

time (s))

thermal overload

mintimecold(s)

thermal overload

average operating

time cold (s)

thermal overload

maxtimecold(s)

I

set

I

rms

peak()

Overload factor(F)

--------------------------------------------------- -=

I

set

4.4

3.5

------- - 1.26A==

I

r

peak()

LVDC brake turn on voltage (V)

R

----------------------------------------------------------------------------------------

63.6V

6.9Ω

--------------- - 9.2A===

I

r

peak )()

I

set

--------------------------

9.2A

1.26A

---------------- 7.3==

If the overload factor (F) is more than 17 times the current setting of the thermal overload

relay , then an in-line fuse would need to be considered. In this case refer to the thermal

overload relay manufacturers recommendations.

NOTE

Page 37

Unidrive SP Low Voltage DC Installation Guide 37

Issue Number: 1 www.controltechniques.com

Safety Information Introduction Product information System design

Component data

Index

3. Check that the chosen resistor can tolerate the overload

Use the maximum time tripping curve to determine the time that corresponds to a factor

(F) of 7.3

From the maximum time tripping curve you get a time of approximately 10 seconds for a

factor (F) of 7.3.

Check that the braking resistor can tolerate 9.2A for 10 seconds.

5.4 External soft start resistor

Table 5-6 Resistor values

5.4.1 External soft start resistor protection

To protect the soft start resistor from becoming damaged in a failure situation a suitable

fuse needs to be fitted in series with the resistor. The fuse must meet the specification

as detailed below.

Table 5-7 Fuse values

Alternative fuse types.

An alternative to the fuses recommended in Table 5-7 can be used providing the fuse

time vs current characteristic lies between the curves shown in the graphs below and

the voltage rating is as per the value shown in Table 5-7.

Drive

Rs

(Ω)

Power

rating

(W)

Energy

rating

(J)

Resistor

part

number

Resistor

combination

SP1202 to SP1204

N/ASP2201 to SP2203

SP3201 to SP3202

SP4201 to SP4203 48 148 1700 1270-2483 1270-2483

SP1401 to SP1406

N/ASP2401 to SP2404

SP3401 to SP3403

SP4401 to SP4403

96 296 3400 1270-2483 2x1270-2483 in series

SP5401 to SP5402

SP6401 to SP6402

SPMA1401 to SPMA1402

SPMD1401 to SPMD1404

SP3501 to SP3507 N/A N/A N/A N/A N/A

SP5601 to SP5602

96 296 3400 1270-2483 2x1270-2483 in series

SP6601 to SP6602

SPMA1601 to SPMA1602

SPMD1601 to SPMD1604

Drive voltage rating

(V)

F4 current

rating

(A)

F4 DC voltage

rating

(V)

Recommended Fuse

type

(Ferraz)

Alternative fuse

type

200 1 500 ATM As set out below

400/575/690 1 1000 A 120X As set out below

Page 38

38 Unidrive SP Low Voltage DC Installation Guide

www.controltechniques.com Issue Number: 1

Figure 5-2 200V drive time vs current fuse characteristic specification

Figure 5-3 400V drive time vs current fuse characteristic specification

0.01

0.1

1

10

100

1000

0.01 0.1 1 10 10

0

current (Arms)

time

(

s

)

0.01

0.1

1

10

100

1000

0.01 0.1 1 10 10

0

current (Arms)

time

(

s

)

Page 39

Unidrive SP Low Voltage DC Installation Guide 39

Issue Number: 1 www.controltechniques.com

Safety Information Introduction Product information System design

Component data

Index

Figure 5-4 575V/690V drive time vs current fuse characteristic specification

5.5 Blocking diode (D1)

The blocking diode D1 is used to prevent energy from being returned into the Low

Voltage DC supply.

Table 5-8 D1 specification

A suitable supplier for the above diode can be Semikron™ with the SKKE isolated base

module diode. The diode must be mounted on a suitable heatsink. See manufacturer

data for heatsink requirements of the device.

5.6 Supply capacitor (C1)

Table 5-9 C1 specification

0.01

0.1

1

10

100

1000

0.01 0.1 1 10 10

0

current (Arms)

time

(

s

)

Drive voltage rating

(V)

Diode type

Working current

(A)

Voltage rating

(V)

200

Standard recovery

3 x drive output

current rating

600

400 1200

575

1500

690

Suitable capacitor

type

Capacitor value

(nF)

Voltage rating

(V)

Metalised polyester 100 ≥250

This capacitor is only required with the Unidrive SP size 1. The capacitor should be

connected directly to the drive terminals.

NOTE

Page 40

40 Unidrive SP Low Voltage DC Installation Guide

www.controltechniques.com Issue Number: 1

5.7 Supplier websites

Resistors

• www.pentagonelectric.co.uk

• www.cressall.com

• www.reo.co.uk

Contactors and thermal overload relays

• www.telemecanique.com

• www.abb.com

• www.omron.co.uk

Fuses

• www.ferrazshawmut.com

• www.bussmann.co.uk

Diodes

• www.semikron.com

• www.ixys.com

This capacitor is only required with the Unidrive SP size 1. The capacitor should be

connected directly to the drive terminals.

NOTE

Page 41

Unidrive SP Low Voltage DC Installation Guide 41

Issue Number: 1 www.controltechniques.com

Safety Information Introduction Product information System design Component data

Index

Index

A

Autotuning ..................................................................................................29

B

Brake resistor .............................................................................................33

C

Cautions .......................................................................................................4

Compliance ..................................................................................................5

D

Discharge resistor and protection ............................................................... 32

Drive control 24V rating ............................................... ...............................10

E

Electrical safety ............................................................................................4

Environmental limits .....................................................................................5

External soft start circuit control .................................................................27

External soft start resistor ...........................................................................37

F

Fusing .............................................................................................30, 31, 37

I

Important considerations and information ..................................................13

L

Low Voltage DC mode enable rating ..........................................................10

Low Voltage DC operating range .................................................................6

Low Voltage DC rating ................................................................................. 9

Low Voltage DC speed limitation .................................................................7

Low Voltage DC Supply types ....................................................................12

O

Operating modes ......................................................... .................................7

P