Unidrive M Options

System Integration Modules

Drive Interface Units

Keypads

EMERSON

Leading the way in variable

speed drive technology

Unidrive M – the drive for industrial

applications

Unidrive M is a family of six variable speed drives designed for

industrial applications. Each Unidrive M model has been designed

for specic application needs identied through extensive market

research. Unidrive M is evolving the future of industry with the

latest drive technology which includes 21 patents granted and 42

patents pending.

Integrate, automate and communicate with

Unidrive M options

Unidrive M supports a wide range of option modules and

interface units which allow the drive to integrate seamlessly with

existing systems. Options include feedback, communications,

applications (onboard PLCs), I/O and enhanced safety features.

Unidrive M uses a high speed parallel bus between the drive and

SI modules, improving reaction time. Communications interfaces

are independently certied for conformance with the relevant

standards to ensure performance and interoperability.

MCi200/MCi210 options substantially extend Unidrive M’s

machine control capability using the latest generation of

microprocessor technology. These modules are congured using

the industry standard IEC61131-3 programing environment.

Combined with its onboard performance, this makes Unidrive M

the market-leading industrial drive.

2

www.emersonindustrial.com/automation

This guide is designed to give an overview of Unidrive M’s

comprehensive range of option modules, including:

• An explanation of their function

• Key specication details

• Compatibility with Unidrive M drives

• Terminal descriptions

INDEX

Machine Control pages 6 - 9

Safety pages 10 - 11

Communications pages 12 - 17

Feedback pages 18 - 20

Additional I/O page 21

Keypads page 22

Drive Interface Units pages 23

www.emersonindustrial.com/automation

3

Unidrive M Option Module Overview

The table below summarizes all the option modules that function with the Unidrive M product family drives. More detailed

information on each can be found later in this guide.

Unidrive M option module summary table

Option Typ e

System Integration (SI) Modules

MCi200

MCi210

SI-Applications Plus

SI-Safety

SI-Ethernet

SI-PROFINET

SI-EtherCAT

SI-CANopen

SI-PROFIBUS

SI-DeviceNet

SI-Encoder

SI-Universal Encoder

SI-I/O

Keypads

Fixed LED keypad

Fixed LED keypad with speed

reference potentiometer

CI-Keypad

Remote keypad

KI-Keypad

KI-Keypad RTC

Drive interface units

SD Card Adaptor

Smartcard

AI-Back-up Adaptor

AI-Smart Adaptor

AI-485 Adaptor

CI-485 Adaptor

KI-485 Adaptor

CT USB Comms cable

Machine Control

Safety

Communications

Feedback

Additional I/O

User interface

Back-up

Communications

Applicable to

M100 M200 M300 M400 M600 M700

•

•

•

• •

• • • • •

• • • • •

• • • • •

• • • • •

• • • • •

• • • • •

• •

• •

• • • • •

M100 M200

M101 M201

•

•

• • • • •

• •

• •

• •

• •

• • • •

• • • •

• • •

•

• •

•* •* •* •

M701

*also requires an adaptor

4

www.emersonindustrial.com/automation

Option module interface locations on Unidrive M

M100 to M400

AI-485 Adaptor for RS485 communications (M200 to M400 only)

AI-Back-up Adaptor allows the drive to use an SD card for

parameter cloning and acts as an input for 24 V back-up

CI-Keypad - intuitive plain text multilingual

back-lit LCD keypad for rapid set-up and

superior diagnostics (M400 only)

Adaptor that allows the drive to

communicate via RS485

System Integration (SI) module slot for optional

communications and additional I/O (M200 to M400 only)

AI-Smart Adaptor contains built

in 4 GB memory for parameter

cloning and applications programs,

and an input for 24 V back-up

Optional IP66 (NEMA4) Remote

Keypad available for Panel

mounting (M200 to M700)

M600 to M700

Range of multi-language LCD keypads available

for rapid set-up and superior diagnostics; KI-485

Adaptor available for additional communications

via RS485 on Modbus RTU

System Integration (SI) module slots for

communications, I/O, additional feedback

devices and automation/motion controllers

(MCi)

• 3 slots on M600 and M700

Slot for Smartcard / SD card for parameter,

PLC and motion program storage

Optional IP66 (NEMA4) Remote

Keypad available for Panel

mounting (M200 to M700)

www.emersonindustrial.com/automation

5

MACHINE CONTROL

Machine Control Modules

Unidrive M’s MCi200 and MCi210 modules extend machine

control capability when combined with the Advanced Motion

Controller embedded in Unidrive M700. Enabling easy

connectivity of additional machine components and application

software, MCi200 and MCi210 create a complete application

solution. As a result of the highly exible plug-in option module

format, system design is streamlined by removing the need

for PLCs and additional external equipment. Machine control

is fast and easy to achieve thanks to Unidrive M’s user friendly

programming software - Machine Control Studio - utilizing the

industry-standard open IEC 61131-3 programming environment.

The MCi200 and MCi210 machine control modules provide:

High performance machine control – high speed

communications of 250 µs enables optimum performance.

High bandwidth – control multiple drive and motor axes thanks

to MCi210’s second Ethernet port.

Optimum ease of use – rapidly create machine control

programs with Unidrive M’s programming software, developed

with extensive human centred design research and based on the

industry-standard IEC 61131-3 programming environment.

Open environment – Standard IEEE 1588 Ethernet and IEC

61131 software enable open machine control programming,

boosting the choice of component connectivity.

Streamlined machine design – plug-in option module format

means less wiring, less physical space required and less nancial

cost, while increasing design simplicity.

User programming

The MCi200 and MCi210 modules are capable of running

Machine Control Studio programs. It is an integrated

development environment that supports all ve of the

programming languages of the IEC 61131-3 standard, including

Structured Text (ST), Ladder Diagram (LD), Function Block

Diagram (FBD), Sequential Function Chart (SFC) and Instruction

List (IL). Continuous Function Chart (CFC) is also supported.

Optimum connectivity

Simple integration with external components such as I/O, HMIs

and other networked drives can be achieved using Unidrive M’s

integrated standard Ethernet ports (with RTMoE or standard

protocols), or eldbuses supported by SI option modules (EtherCAT,

PROFINET, PROFIBUS, CANopen).

6

www.emersonindustrial.com/automation

MCi200 & MCi210

Build high performance systems and

productive machines

• MCi modules execute comprehensive programs that can

control multiple drives and motors simultaneously across realtime networks

• M700’s onboard Ethernet using RTMoE (Real Time Motion

over Ethernet) provides synchronization and communication

between drives using the Precision Time Protocol as dened by

IEEE1588 V2

• Performance is optimized by having a motion controller

embedded in each networked drive

MACHINE CONTROL

M100 M200 M300 M400 M600 M700

✓

The user has a number of tasks available to them as shown in the following table.

Task Interval

Initial

Freewheeling

Clock0

Clock1

Clock2

Clock3

Position

Event0

Event1

Event2

Event3

ErrorTask

The Clock and Position tasks are cyclic and will run at an interval set by the user. The Freewheeling task is the lowest priority task and will

run when processor resource allows.

MCi210 ensures higher performance by delivering:

• Two additional Ethernet ports with an internal switch

• Support for standard Ethernet protocols, along with RTMoE for

PTP (IEEE 1588) synchronization

• Modbus TCP/IP master (up to 5 nodes)

• Parallel interface with drive processor provides faster data

exchange

• Machine control over two segregated Ethernet networks

enables greater exibility in machine design

• Extends connectivity with 3 x digital inputs, 1 x digital output

and 1 x digital I/O

Executes once when the user program starts

No timebase

User-specied timebase from 1 ms to 24 hours in 1 ms increments

User-specied timebase from 250 μs to < 8 ms in 250 μs increments

No timebase. This task is triggered (e.g. by the Timer Unit, Ethernet cyclic data etc.)

No timebase. This task is triggered on a user program error

www.emersonindustrial.com/automation

7

8 7 6 5 4 3 2 1

1

4 536

2

B

A

1

4 536

2

MACHINE CONTROL

SF

CPU314C-2 DP

BF

DC5V

FRCE

RUN

STOP

PUSH

RUN

STOP

MRES

0

1

2

3

4

5

6

7

IN IN OUT

DI+2 DI+0

DI+1

D0+0

D0+1

DI8xDC24V

AI5/A02x12Bit

DI16/D016xDC24V

0

1

2

3

4

5

6

7

0

1

2

3

4

5

6

7

0

1

2

3

4

5

6

7

0

1

2

3

4

5

6

7

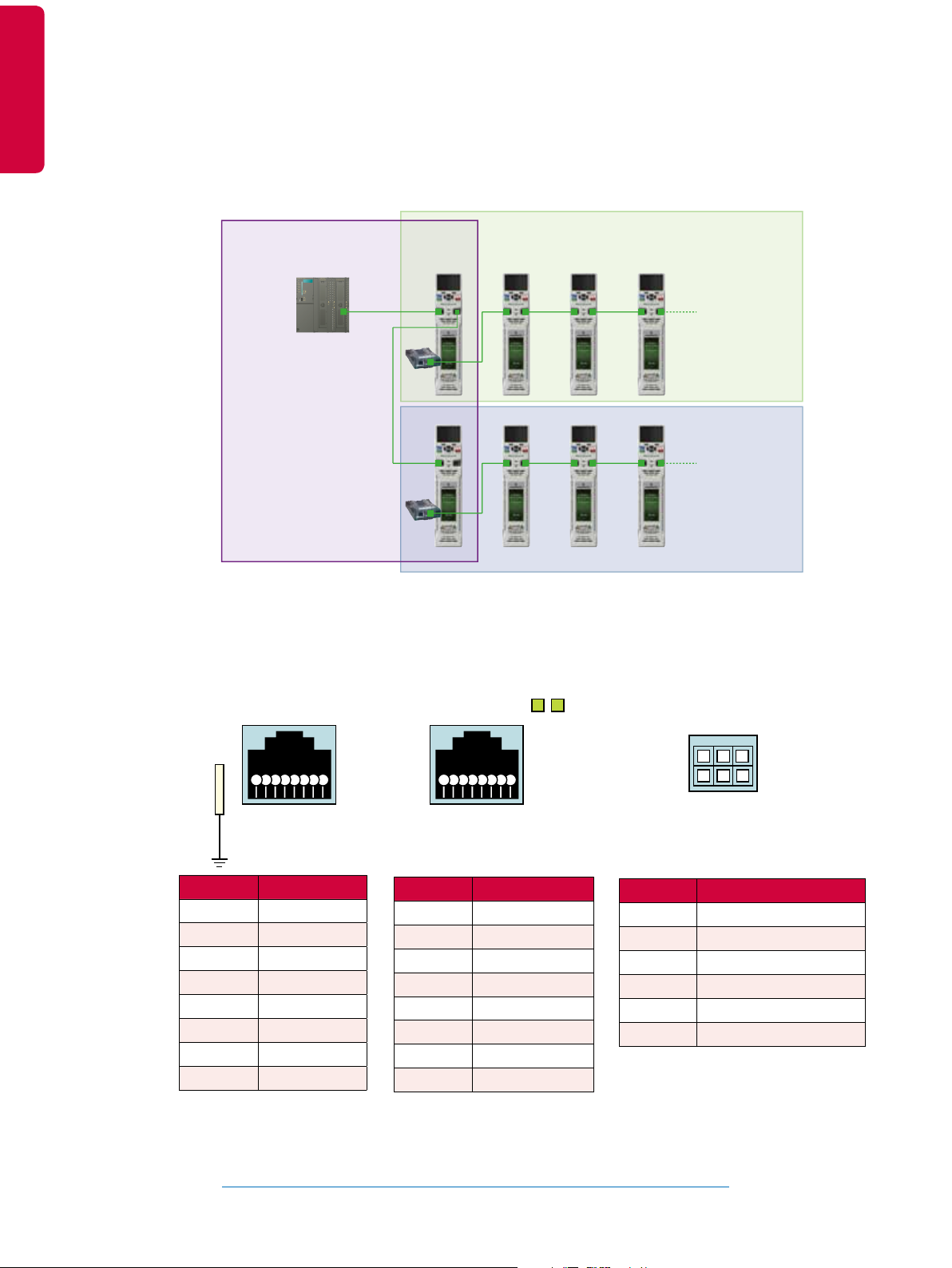

Segregated network control

Terminal descriptions

Network 1 Network 2

System

Controller

Machine 1

MCi

Controller

Network 3

Machine 2

MCi

Controller

Link / activity

indicators

Port A Port B Digital I/O

A

B

Spade

connector

8 7 6 5 4 3 2 1

Terminal Description

1 Transmit +

2 Transmit -

3 Receive +

4 N/A

5 N/A

6 Receive -

7 N/A

8 N/A

8 7 6 5 4 3 2 1

Terminal Description

1 Transmit +

2 Transmit -

3 Receive +

4 N/A

5 N/A

6 Receive -

7 N/A

8 N/A

Terminal Description

1 Digital input 1

2 Digital input 2

3 Digital input 3

4 Digital I/O 4

5 Digital output 5

6 0 V common

362

1

5

4

8

www.emersonindustrial.com/automation

SI-Applications Plus

SI-Applications Plus modules allow SyPTPro application programs

to be recompiled and executed with Unidrive M700 to enable rapid

and simple upgrade for Unidrive SP users. Applications comprising

networked Unidrive SP drives with SM-Applications using CTNet or

CTSync for real-time control can be quickly replaced with Unidrive

M and the SI-Applications Plus module without any compromise to

system performance.

Features include

• Enhanced high speed dedicated microprocessor

• 384 kB Flash memory for user program

• 80 kB user program memory

• EIA-RS485 port offering ANSI, Modbus-RTU follower and

master and Modbus-ASCII follower and master protocols

• CTNet high speed network connection offering up to 5

Mbit/s data rate

• Two 24 V digital inputs

• Two 24 V digital outputs

• Task based programming system for real-time control

• CTSync distributes a master position to multiple drives on a

network. Hardware synchronization of speed, position and

torque loops achieving a time base of 250 μs

MACHINE CONTROL

M100 M200 M300 M400 M600 M700

✓

Terminal descriptions

1 2 3 4 5

Terminal Function Description

1 0 V SC 0 V connection for EIA-RS485 port

2 /RX EIA-RS485 Receive line (negative). Incoming

3 RX EIA-RS485 Receive line (positive). Incoming

4 /TX EIA-RS485 Transmit line (negative). Outgoing

5 TX EIA-RS485 Transmit line (positive). Outgoing

6 CTNET A CTNet data line

7 CTNET

Shield

8 CTNET B CTNet data line

9 0 V 0 V connection for digital I/O

10 DIO Digital input 0

11 DI1 Digital input 1

12 DO0 Digital output 0

13 DO1 Digital output 1

Shield connection for CTNet

6 7 8

9 10 11 12 13

www.emersonindustrial.com/automation

9

Safety System Integration Module

S

I

L

3

Safety Integrity Level

M100 M200 M300 M400 M600 M700

SI-Safety

The SI-Safety module enhances the safety capability of Unidrive M for the protection of end users. The module also increases

machine productivity with safety features which reduce the frequency of machine power-downs. Ensuring machines achieve

stringent safety standards, SI-Safety can reduce machine size and cost by removing the need for external safety PLCs and other

components.

SAFETY

• Increase productivity: SI-Safety minimises downtime as its functionality enables a machine to slow-down or stop, removing the need

to power-down the machine after interruption.

• Enhanced user safety: Features including Safe Stop and Safe Operating Stop dramatically increase end user safety, as well as safe

machine operation with Safe Limited Speed and Safe Limited Position.

• Achieves the highest safety level: SI-Safety is approved by TUV as meeting SIL3, the highest safety level attainable for industrial

electrical components according to functional safety standards as IEC 61800-5-2.

Standard Safety Functions:

The following SIL3 safety functions dened by IEC 61800-5-2 are available with SI-Safety:

SAFETY

Safe Torque Off STO Prevents torque from being generated by the motor. This function is integrated within the

drive itself as standard

Safe Stop 1 SS1 Ensures a controlled stop with power available to the motor. Once the stop is achieved the

power is then removed.

Safe Stop 2 SS2 Ensures a controlled stop with power left available to the motor

Safe Limited Speed SLS Prevents the motor from exceeding a specied speed limit

Safe Limited Position SLP Monitors absolute position to ensure the motor operates within specied limits

Safe Brake Control SBC Provides a safe output signal to control an external safety brake

Safe Operating Stop SOS Prevents the motor from deviating from the stopped position

Safe Direction SDI Prevents the motor from moving in the unintended direction

Safe Limited Increment SLI Prevents the motor from exceeding the specied limit of position increment

Safe CAM SCA Provides a safe signal when the motor position is within a specied range

Safe Speed Monitor SSM Provides an indication when the motor speed is below a given limit

✓ ✓

Flexible programming environment

CTSafePro

CTSafePro unlocks the full safe PLC functionality within the

SI-Safety module. It allows users to combine elements to

develop their own safety function blocks to meet the specic

needs of more advanced applications.

Terminal descriptions

RJ45

Diagnostic

programming

Port

Connection

www.emersonindustrial.com/automation

I/O connection

10

1

10 17 (OV) 18 (+Ub)

9

Encoder 2

power

connection

Status LED

HDMI

Encoder

Safety Standards

The module is designed to meet the following safety standards:

• IEC and EN 61508: Functional safety of safety-related electric,

electronic and programmable electronic systems

• IEC and EN 62061: Safety of machinery, Functional safety

of safety-related electrical, electronic and programmable

electronic control systems

• ISO and EN ISO 13849-1: Safety of machinery - Safety-related

parts of control systems - Part 1: General principles for design

• IEC and EN 61800-5-2: Adjustable speed electrical power drive

systems - Part 5-2: Safety requirements - Functional

I/O Interface

Terminal Designation Function

1 SMF11 Digital IN SMF11

2 SMF12 Digital IN SMF12

3 SMF21 Digital IN SMF21

4 SMF22 Digital IN SMF22

5 SMF31 Digital IN SMF31

6 SMF32 Digital IN SMF32

7 SMF41 Digital IN SMF41

8 SMF42 Digital IN SMF42

9 E0.5 Digital IN E0.5

10 P1 Clocking output P1

11 P2 Clocking output P2

12 STO HISIDE output STO

13 SBC1 HISIDE output SBC1

14 SBC2 HISIDE output SBC2

15 A0.1 Signal and auxiliary output A0.1

16 A0.2 Signal and auxiliary output A0.2

17 L-ENC 1/2 Sensor power supply for sensor interface GND ENC 1/2

18 L+ENC2 Sensor power supply for sensor interface SUPPLY ENC2

SAFETY

Encoder interface HDMI

Pin Designation Encoder Function

1 A+(COS+)/DATA+ ENC1 Incremental track A+ / data wire DATA+

2 SHIELD

3 A-(COS-)/DATA- ENC1 Incremental track A- / data wire DATA-

4 B+(SIN+)/CLK+ ENC1 Incremental track B+ / data wire CLOCK+

5 SHIELD

6 B-(SIN-)/CLK ENC1 Incremental track B- / data wire CLOCK-

7 A+(COS+)/DATA+ ENC2 Incremental track A+ / data wire DATA+

8 SHIELD

9 A-(COS-)/DATA- ENC2 Incremental track A- / data wire DATA-

10 B+(SIN+)/CLK- ENC2 Incremental track B+ / data wire CLOCK+

11 SHIELD

12 B-(SIN)/CLK- Incremental track B- / data wire CLOCK-

13 L+ ENC1 Power supply for SUPPLY sensor interface

14 L+ ENC1 Power supply for SUPPLY sensor interface

15 L- ENC1/2 Power supply for GND sensor interface

16 L- ENC1/2 Power supply for GND sensor interface

17 L+ ENC2 Power supply for SUPPLY sensor interface

18 L+ ENC2 Power supply for SUPPLY sensor interface

19 NC

www.emersonindustrial.com/automation

11

Communications System Integration Modules

1 32

M100 M200 M300 M400 M600 M700

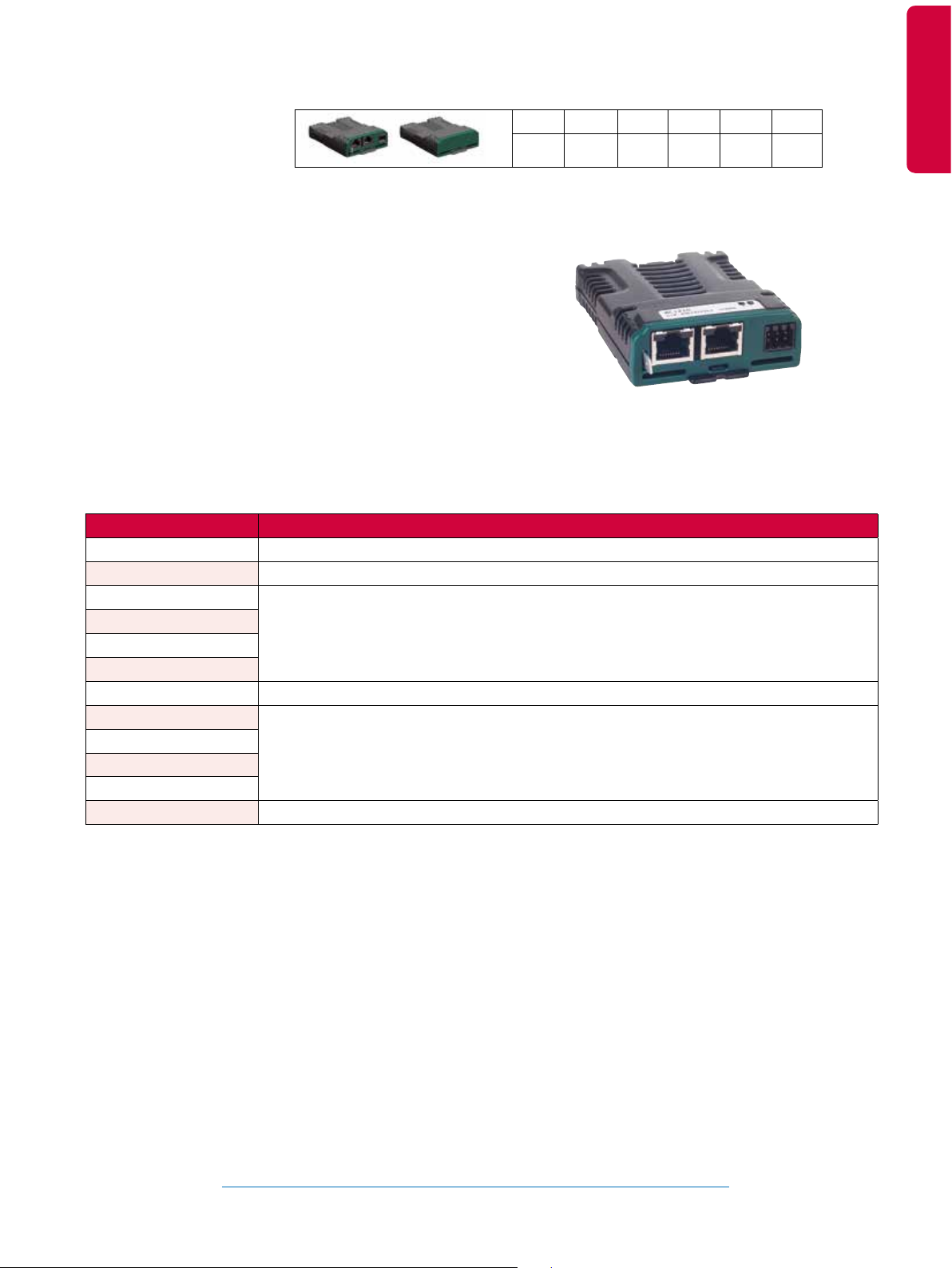

SI-Ethernet

* Does not support synchronous cyclic data exchange

SI-Ethernet supports real-time Ethernet (IEEE 1588 V2 Precision

Time Protocol), HTTP, SMTP, EtherNet/IP and Modbus TCP/IP. The

module can be used to provide high speed drive access, global

connectivity and integration with IT network technologies, such as

wireless networking.

Features include:

• Real-time Ethernet (IEEE 1588 V2 Precision Time Protocol),

Modbus TCP/IP, EtherNet/IP

• Network synchronization of less than 1 μs jitter (typically <200

ns)

COMMUNICATIONS

• 1 ms cycle time for synchronous cyclic data

• Bandwidth protection through a network gateway that

manages non-real-time Ethernet messages

• Master/follower and peer-to-peer communications capabilities

• Addressing is IP based

• Dual 100 BASE-TX RJ45 connectors with support for shielded

twisted pair, full-duplex 100 Mbps connectivity with auto

crossover correction

• Integrated switches allow for use of line networks i.e. daisy

chaining

• Both ports operate in full duplex mode as a network switch

• LED indication of network port activity

✓* ✓* ✓* ✓*

Terminal descriptions

Spade

connector

Terminal Description

1 Transmit +

2 Transmit -

3 Receive +

4 N/A

5 N/A

6 Receive -

7 N/A

8 N/A

✓

Port A Port B

8 7 6 5 4 3 2 1 8 7 6 5 4 3 2 1

Terminal Description

1 Transmit +

2 Transmit -

3 Receive +

4 N/A

5 N/A

6 Receive -

7 N/A

8 N/A

Link / activity

indicators

A

B

COMMUNICATIONS

12

Assembly line

www.emersonindustrial.com/automation

SI-PROFINET

1 32

M100 M200 M300 M400 M600 M700

✓ ✓ ✓ ✓ ✓

SI-PROFINET allows Unidrive M to communicate and interface with

PROFINET PLCs and networks.

Features include:

• Dual 100 BASE-TX RJ45 connectors with support for shielded

COMMUNICATIONS

twisted pair, full-duplex 100 Mbps connectivity with auto

crossover correction

• Integrated switches allow for use of line networks i.e. daisy

chaining

• Both ports operate in full duplex mode as a network switch

• PROFINET Real-time class RT_Class_1 and conformance

class A

• Cycle times from 2 ms to 512 ms specied during conguration

• Automatic device replacement using the LLDP and DCP

protocols

• LED indication of network port activity

• Up to 64 cyclic I/O module slots (maximum of 32 in and 32 out)

congured by network conguration tool and GSDML le

• Identication and maintenance functions I&M0 to I&M4

supported

Terminal descriptions

Port A Port B

Spade

connector

8 7 6 5 4 3 2 1 8 7 6 5 4 3 2 1

Terminal Description

1 Transmit +

2 Transmit -

3 Receive +

4 N/A

5 N/A

6 Receive -

7 N/A

8 N/A

Link / activity

indicators

A

B

Terminal Description

1 Transmit +

2 Transmit -

3 Receive +

4 N/A

5 N/A

6 Receive -

7 N/A

8 N/A

COMMUNICATIONS

www.emersonindustrial.com/automation

13

1 32

SI-EtherCAT

M100 M200 M300 M400 M600 M700

✓ ✓ ✓ ✓ ✓

SI-EtherCAT allows Unidrive M to connect and interface with

EtherCAT networks.

Features include:

• Up to 64,535 nodes on a segment

• Data rate of 100 Mbps (100BASE-TX)

• Update 40 axes in 250 μs (assuming 2 words command data

and 3 words feedback data per axis, a control word and basic

cyclic synchronization data)

• Jitter of less than 1 μs with Unidrive M600 to M700

• Non-cyclic data using the CoE mailbox

• CANopen DS-402 prole supported (drives and motion control)

COMMUNICATIONS

• LED indication of network port activity

Terminal descriptions

Port A Port B

Spade

connector

8 7 6 5 4 3 2 1 8 7 6 5 4 3 2 1

Terminal Description

1 Transmit +

2 Transmit -

3 Receive +

4 N/A

5 N/A

6 Receive -

7 N/A

8 N/A

Link / activity

indicators

A

B

Terminal Description

1 Transmit +

2 Transmit -

3 Receive +

4 N/A

5 N/A

6 Receive -

7 N/A

8 N/A

14

Bottle lling line

www.emersonindustrial.com/automation

SI-CANopen

M100 M200 M300 M400 M600 M700

✓ ✓ ✓ ✓ ✓

Unidrive M’s CANopen interface module supports various

proles including several drive proles. SI-CANopen has

been designed to offer optimum exibility: in particular the

process data objects (PDO) numbering system has been

specically designed to offer maximum versatility while

maintaining conformance to CiA specications.

Features include:

• Supported data rates (bits/s): 1 M, 800 k, 500 k,

250 k,125 k, 100 k and 50 k

• 4 transmit and 4 receive PDOs A, B, C and D supported

• Independently congurable transmit and receive PDO

numbers (1-511) for maximum application exibility

• All synchronous and asynchronous PDO communication

modes supported

• Total of 32 bytes (16 words) in each direction using PDOs

(4 TxPDOs of 64 bits and 4 RxPDOs of 64 bits)

• Service Data Objects (SDO) provide access to all drive

and option module parameters

• Consumer heartbeat

• Emergency message completed ag

• RxPDO, SYNC and missed heartbeat event handling

• RxPDO event triggers

• TxPDO event triggers

• Object association for un-dened DSP-402 objects

• +24 V back-up power supply capability

Terminal descriptions

1 2 3 4 5

+24 V external power supply (red)

CAN-H positive data line (white)

Cable screen (braided shield)

CAN-L negative data line (blue)

0 V external power supply (black)

COMMUNICATIONS

www.emersonindustrial.com/automation

15

SI-PROFIBUS

M100 M200 M300 M400 M600 M700

✓ ✓ ✓ ✓ ✓

COMMUNICATIONS

Unidrive M’s PROFIBUS-DP interface module enables follower

connectivity. It is possible to use multiple SI-PROFIBUS modules

or a combination of SI-PROFIBUS and other option module types

to add additional functionality such as extended I/O, gateway

functionality or additional PLC features.

Features include:

• Supported data rates (bits/s): 12 M, 6.0 M, 3.0 M, 1.5 M, 500 k,

187.5 k, 93.75 k, 45.45 k, 19.2 k, 9.6 k

• Maximum of 32 input and 32 output cyclic data words

supported

• PROFIdrive prole (V2 & V4) supported

• Non-cyclic data channel supported

COMMUNICATIONS

• Parallel acyclic/cyclic data communication

M100 M200 M300 M400 M600 M700

SI-DeviceNet

SI-DeviceNet enables follower connectivity. It is possible to use

multiple SI-DeviceNet modules or a combination of SI-DeviceNet

and other option module types to provide additional functionality

such as extended I/O, gateway functionality or additional PLC

features.

Features include:

• Supported data rates (bits per s): 500 k, 250 k, 125 k

• 1 to 28 input/output polled data words supported

• Explicit communications (non-cyclic) provide access to all

drive parameters

• 8 pre-dened DeviceNet proles supported

Terminal descriptions

RxD/TxD-P (Red)

CNTR-P

0 V ISO

(for termination only)

9 7

RxD/TxD-N (Green)

+5 V ISO

(for termination only)

✓ ✓ ✓ ✓ ✓

Terminal descriptions

1 2 3 4 5

1

25 4 3

8 6

+24 V external power supply (red)

CAN-H positive data line (white)

Cable screen (braided shield)

CAN-L negative data line (blue)

0 V external power supply (black)

Cable screen

(braided shield)

Shell

16

www.emersonindustrial.com/automation

COMMUNICATIONS

www.emersonindustrial.com/automation

Metal rolling machine

17

Feedback System Integration Modules

M100 M200 M300 M400 M600 M700

SI-Encoder

Terminal descriptions

SI-Encoder has an incremental encoder input to provide Closed loop

Rotor Flux Control for induction motors (RFC-A) on M600 and an

additional encoder input on M700.

Features include:

• Supports AB quadrature encoders without marker pulse

1

*

the encoder cable can be independently connected to

0 V without requiring dual wire (twin) crimp ferrules.

This provides a system which is easier to wire and debug

electrical noise issues.

✓ ✓

1 2 3 4 5 6 7

Pin Number Function

1 A

2 /A

3 B

4 /B

5 Power Supply +

6 Power Supply 0 V *

7 Power Supply 0 V *

: Two 0 V terminals are provided so that the shield of

1

1

FEEDBACK

SI-Universal Encoder

The dual encoder port on the Unidrive M700 supports two position

feedback interfaces, P1 & P2, through a 15-way high density

D-type connector. The SI-Universal Encoder complements this by

enabling additional input and output formats to be used that could

not otherwise be supported by the single 15 pin connector. It also

provides Closed loop Rotor Flux Control for induction motors (RFC-A)

on M600.

Features include:

Support for:

• SinCos with communications

• SinCos with or without commutation

• Quadrature incremental with or without commutation

• Pulse and direction

• SSI and EnDat

The module also provides a simulated encoder output that can be

programmed to operate in the following modes:

• Quadrature incremental

• Pulse and direction

• SSI

The module also incorporates high speed inputs for position capture.

M100 M200 M300 M400 M600 M700

✓ ✓

Functions

P1 Position

feedback interface

AB Servo

FD Servo

FR Servo

SC Servo

AB

FD

FR

SC

SC Hiperface

SC EnDat

SC SSI

EnDat

SSI

P2 Position

feedback interface

None None

AB, FD, FR, EnDat,

SSI

None Full

AB, FD, FR (No Z

marker pulse input)

EnDat, SSI

None

AB, FD, FR None

EnDat, SSI

None Full

Encoder simulation

outputs

None

None

No Z marker pulse

output

No Z marker pulse

output

18

www.emersonindustrial.com/automation

Position feedback device interface connections

The SI-Universal Encoder has two position feedback interfaces and an encoder simulation output on the 15-way D-type. The

availability of the encoder simulation output and the 2nd position interface (P2) depends on the feedback device type selected

for the 1st position interface (P1) as some feedback devices use all pins of the 15-way D-type.

The drive supports the following encoder types:

Position feedback device type Drive name

Quadrature incremental encoders with or without marker pulse AB

Frequency and direction incremental encoders with or without marker pulse FD

Forward / reverse incremental encoders with or without marker pulse FR

Quadrature incremental encoders with or without marker pulse and UVW commutation signals for absolute position

for permanent magnet motors

Frequency and direction incremental encoders with or without marker pulse and UVW commutation signals for

absolute position for permanent magnet motors

Forward / reverse incremental encoders with or without marker pulse and UVW commutation signals for absolute

position for permanent magnet motors

Sincos incremental encoders with or without marker pulse SC

Sick sincos encoders with Hiperface communications for absolute position SC Hiperface

Heidenhain EnDat 2.1 or 2.2 communication only encoders EnDat

Heidenhain sincos encoders with EnDat communication for absolute position SC EnDat

SSI encoders (Gray code or binary) SSI

Sincos encoders with SSI comms for absolute position (Gray code or binary) SC SSI

Sincos incremental encoders with or without marker pulse and UVW commutation signals for absolute position for

permanent magnet motors

AB Servo

FD Servo

FR Servo

SC Servo

FEEDBACK

The marker inputs can be used without their associated position feedback as freeze trigger inputs, therefore these are present

where possible even if the associated incremental or SINCOS position feedback is not possible. The table below gives the

connection functions associated with the codes used.

Connection Function Connection Definition

Position Interface inputs

A A input for AB, or AB Servo encoders, F input for FD, FD Servo, FR or FR Servo encoders

B B input for AB, or AB Servo encoders, D input for FD or FD Servo encoders, R input for FR or FR

Z Z input for AB, AB Servo, FD, FD Servo, FR, FR Servo, SC encoders, Freeze input

U, V, W Commutation signals for AB Servo, FD Servo, FR Servo, or SC Servo

Cos, Sin Cosine and Sine inputs for SC, SC EnDat, SC Hiperface, SC SSI or SC Servo encoders

D Data input/output for SC EnDat, SC Hiperface or EnDat encoders

Clk Clock output for SC EnDat, SC SSI, EnDat or SSI encoders

Encoder Simulation Output

AOut A output for AB mode, F output for FD or FR modes, Data output for SSI Gray or SSI Binary

BOut B output for AB mode, D output for FD or FR modes, Clock input for SSI Gray or SSI Binary

Zout Z output for AB, FD or FR modes

Power Supply and Temperature Measurement

PS1 Power supply output (13 = Supply, 14 = 0 V)

Th Temperature measurement input

Servo encoders

Data input for SC SSI, SSI encoders

modes

modes

www.emersonindustrial.com/automation

19

Terminal descriptions

1 2 3 4 5

6 7 8 9 10

The table below shows the functions that can be provided simultaneously, along with the

connections required for each combination of functions.

D-type connector

Functions Connections

FEEDBACK

P1 Position feedback

interface

AB Servo

FD Servo

FR Servo

SC Servo Cos1 Sin1 Z1 U1 V1 W1 PS1 Th

AB, FD, FR AB, FD, FR A1 B1 Z1 A2 B2 Z2 PS1 Th

AB, FD, FR EnDat, SSI A1 B1 Z1 D2 Clk2 Z2 PS1 Th

AB, FD, FR Full A1 B1 Z1 AOut BOut ZOut PS1 Th

SC AB, FD, FR Cos1 Sin1 Z1 A2 B2 Z2 PS1 Th

SC EnDat, SSI Cos1 Sin1 Z1 D2 Clk2 Z2 PS1 Th

SC Full Cos1 Sin1 Z1 AOut BOut ZOut PS1 Th

SC Hiperface AB, FD, FR Cos1 Sin1 D1 A2 B2 Z2 PS1 Th

SC Hiperface EnDat, SSI Cos1 Sin1 D1 D2 Clk2 Z2 PS1 Th

SC Hiperface Full Cos1 Sin1 D1 AOut BOut ZOut PS1 Th

SC EnDat

SC SSI

SC EnDat

SC SSI

SC EnDat

SC SSI

EnDat, SSI AB, FD, FR D1 Clk1 Z1 A2 B2 Z2 PS1 Th

EnDat, SSI EnDat, SSI D1 Clk1 Z1 D2 Clk2 Z2 PS1 Th

EnDat, SSI Full D1 Clk1 Z1 AOut BOut ZOut PS1 Th

EnDat, SSI EnDat, SSI No Z marker pulse D1 Clk1 D2 AOut BOut Clk2 PS1 Th

P2 Position feedback

interface

AB, FD, FR No Z Cos1 Sin1 D1 A2 B2 ClK1 PS1 Th

EnDat, SSI Cos1 Sin1 D1 D2 Clk2 Clk1 PS1 Th

Encoder Simulation

Output

No Z marker pulse Cos1 Sin1 D1 AOut BOut Clk1 PS1 Th

1/2 3/4 5/6 7/8 9/10 11/12 13/14 15

A1 B1 Z1 U1 V1 W1 PS1 Th

25104 3 1

79 8 6

1215 14 13 11

Blue text indicates P1 interface connections|Green text indicates P2 interface connections|Red text indicates encoder simulation

output connections| A1 means A = Pin1, A\ = Pin2

Screw terminal connector

Terminal Description

1 24 V Freeze input

2 0 V

3 (7) Encoder simulation output: A, F or DATA | P2 input: A, F, DATA

4 (8) Encoder simulation output: A\, F\ or DATA\ | P2 input: A\, F\, DATA\

5 (9) Encoder simulation output: B, F, D or Clock | P2 input: B, F, D, Clock

6 (10) Encoder simulation output: B\, F\, D\ or Clock\ | P2 input: B\, F\, D\, Clock\

7 0 V

8 (11) Encoder simulation output: Z | P2 input: Z

9 (12) Encoder simulation output: Z\ | P2 input: Z\

10 (13) Power supply output

1 2 3 4 5

6 7 8 9 10

The termination resistors are

always enabled on the P2 position

interface. Wire break detection is

not available when using AB, FD or

FR position feedback device types

on the P2 position interface.

The value in brackets corresponds

to the pin on the 15-way D-type to

which this terminal is connected.

20

www.emersonindustrial.com/automation

Additional I/O System Integration Modules

M100 M200 M300 M400 M600 M700

SI-I/O

✓ ✓ ✓ ✓ ✓

Unidrive M’s extended I/O interface module increases the number

of I/O points on a drive. All connections from the option module

to the drive are made via the drive connector. Connections from

external equipment to the SI-I/O are made via a 3-way pluggable

screw connector for the two relays and an 11-way pluggable screw

connector for the digital and analog I/O.

Features include:

• 4 x Digital inputs/outputs

• 3 x Analog inputs (default) / Digital inputs

• 1 x Analog output (default)* / Digital input

• 2 x Relays

Digital I/O

By default, the SI-I/O Module is set up for four programmable

digital inputs/outputs. By conguring the analog I/O as

digital inputs, it is possible for the SI-I/O module to have four

programmable inputs/outputs and also four digital inputs.

The functionality of these terminals is as follows:

• The logic sense selected can be positive (default) or negative

• The logic state of each input is monitored by a read-only

parameter

• The logic state can be inverted

• The digital input can be programmed to any suitable

destination bit parameter

• The digital output can be sourced from any suitable bit

parameter

• The outputs can operate either as a push-pull or an open

collector output

The SI-I/O has a maximum output current of 250 mA at 24 V

across all four digital outputs.

Analog I/O

By default, the SI-I/O is set-up for three single-ended analog

inputs and one analog output or one high resolution* differential

analog input*, one single-ended analog input and one analog

output.

Analog inputs 1 and 2 can only be congured as ±10 Vdc voltage

inputs or digital inputs. When both are congured as analog

voltage inputs, they can be used as a single high resolution

differential analog input.

Analog input 3 can operate in voltage mode (±10 Vdc), current

mode (0 to 20 mA) or as a digital input.

Analog output 1* can operate in voltage mode (±10 Vdc),

current mode (0 to 20 mA) or as a digital input.

Relays

The two relays can be used to convey the logic state of any

suitable parameter to external equipment. The logic state is

processed as follows:

• A suitable source parameter is assigned to each relay

• The logic state can be inverted

• The state of the relay is monitored by a parameter

ADDITIONAL I/O

Terminal descriptions

PL1

Terminal Function

1 0 V common

2 Digital input/output 1

3 Digital input/output 2

4 Digital input/output 3

5 Digital input/output 4

6 0 V common

7 Analog input 1/digital input 5

8 Analog input 2/digital input 6

9 Analog input 3/digital input 7

10 0 V common

11 Analog output 1/digital input 8

* Only supported by M600 and M700

6 7 8 9 10 111 2 3 4 5

Terminal Function

21 Relay 1

22 Relay common

23 Relay 2

www.emersonindustrial.com/automation

21 22 23

PL2

21

Keypads

Unidrive M’s range of keypad options is hot-swappable and is designed to enhance ease of use. From easy commissioning to rapid

diagnostics, enhanced usability is achieved by a range of keypad options including plain text LCD display, support of multiple

languages and exible mounting options.

Typ e Benefit M100 M200 M300 M400 M600 M700

Fixed LED keypad

Fixed LED

keypad with

speed reference

potentiometer

CI-Keypad

Remote keypad

KI-Keypad

KI-Keypad RTC

Simple LED keypad tted as standard for

quick and easy commissioning and use.

Simple LED keypad with user friendly

speed reference potentiometer for

convenient speed control.

Intuitive plain text, multi-language LCD

keypad for rapid set-up and superior

diagnostics maximizes machine up-time.

All the features of the CI-Keypad LCD, but

remote mountable. This allows exible

mounting on the outside of a panel and

meets IP66 (NEMA 4).

Plain text, multi-language LCD keypad

with up to four lines of text for in-depth

parameter and data descriptions, for an

enhanced user experience.

All the features of the KI-Keypad, but with

battery operated real-time clock. This

allows accurate time stamping of events,

aiding diagnostics.

• • •

M101 M201

•

• • • • •

• •

• •

Drive interface units

Back-up

M100 M200 M300 M400 M600 M700

AI-Back-up Adaptor

Port adaptor that allows the drive to use an SD card for parameter cloning, and an input for 24 V back-up.

SD card

KEYPADS

Unidrive M uses readily available SD cards for quick and easy parameter and program storage. SD cards provide a large memory

capability allowing a complete system reload if required.

24 Vdc supply

+24 V 0 V

The 24 Vdc supply connected to the +24 V supply terminals on the AI-Back-up Adaptor and Smart Adaptor provides the following

functions:

• Back-up power supply to keep the control circuits of the drive powered-up when the line power supply is removed. Fieldbus

modules and serial communications can continue to operate.

• Clone or load parameters when the line power supply is not available. The keypad can be used to set-up parameters.

22

✓ ✓ ✓ ✓

www.emersonindustrial.com/automation

M100 M200 M300 M400 M600 M700

AI-Smart Adaptor

Contains built-in 4 GB memory for parameter cloning and applications programs, and an input for 24 V back-up

✓ ✓ ✓ ✓

Smartcard

www.controltechniques.com

The optional Smartcard memory device can be used to back-up parameter sets and PLC programs, as well as copying them from

one drive to another, including from a Unidrive SP. It also allows:

• Simplied drive maintenance and commissioning

• Quick set-up for sequential build of machines

• Upgrades to be stored on a Smartcard and sent to the customer for installation

SD-Smartcard Adaptor

Conversion device that allows an SD card to be inserted into the Smartcard slot, for parameter cloning and application programs.

M100 M200 M300 M400 M600 M700

✓ ✓

M100 M200 M300 M400 M600 M700

✓ ✓

Communications

AI-485 Adaptor

Adaptor that allows the drive to communicate via RS485 using Modbus RTU can be used to connect remote keypad.

Terminal descriptions

PL2

1 2 3 4 5 6

Terminal Function

1 0V

2 RX\ TX\

3 RX TX

4 120 Ω termination resistor

5 TX Enable

6 +24 V (100 mA)

PL2

M100 M200 M300 M400 M600 M700

✓ ✓ ✓

PL1

8 7 6 5 4 3 2 1

Terminal Function

1 120 Ω Termination resistor

2 RX TX

3 0V

4 +24 V (100 mA)

5 Not connected

6 TX enable

7 RX\ TX\

8 RX\ TX\ (if termination resistors are required, link to pin 1)

PL1

M100 M200 M300 M400 M600 M700

CI-485 Adaptor

Port adaptor that allows the drive to communicate via RS485 on Modbus RTU. This can be used to connect the Remote keypad.

M100 M200 M300 M400 M600 M700

KI-485 Adaptor

Allows the drive to communicate via RS485 on Modbus RTU. This is commonly used for programming if the drive has no keypad and is

recommended for use with the Remote keypad.

CT USB Comms cable

The USB Comms cable allows the drive to connect to a PC for use with Unidrive M’s PC tools

www.emersonindustrial.com/automation

✓

✓ ✓

DRIVE INTERFACE UNITS

23

Connect with us at:

twitter.com/ctandls

facebook.com/ctandls

youtube.com/controltechniquesandleroysomer

theautomationengineer.com (blog)

P.N. 0778-0084-05 01/16

www.emersonindustrial.com/automation

© Emerson 2015. The information contained in this brochure is for guidance only and does not form part of

any contract. The accuracy cannot be guaranteed as Emerson have an ongoing process of development and

reserve the right to change the specication of their products without notice.

Control Techniques Limited. Registered Ofce: The Gro, Newtown, Powys SY16 3BE. Registered in England

and Wales. Company Reg. No. 01236886.

Moteurs Leroy-Somer SAS. Headquarters: Bd Marcellin Leroy, CS 10015, 16915 Angoulême Cedex 9, France.

Share Capital: 65 800 512 €, RCS Angoulême 338 567 258.

Loading...

Loading...