Control Techniques Unidrive 1201, UNI1204, Unidrive 1202, Unidrive 1203, Unidrive 1204 User Manual

...Page 1

EF

www.controltechniques.com

User Guide

Unidrive

Model sizes 1 to 5

Universal Variable Speed AC Drive

for induction and servo motors

Part Number: 0460-0083-09

Issue Number: 9

Page 2

General Information

The manufacturer accepts no liability for any consequences resulting from inappropriate, negligent or incorrect

installation or adjustment of the optional operating parameters of the equipment or from mismatching the variable speed

drive with the motor.

The contents of this guide are believed to be correct at the time of printing. In the interests of a commitment to a policy

of continuous development and improvement, the manufacturer reserves the right to change the specification of the

product or its performance, or the contents of the guide, without notice.

All rights reserved. No parts of this guide may be reproduced or transmitted in any form or by any means, electrical or

mechanical including photocopying, recording or by an information storage or retrieval system, without permission in

writing from the publisher.

Drive software version

This product is supplied with the latest version of user-interface and machine control software. If this product is to be

used in a new or existing system with other drives, there may be some differences between their software and the

software in this product. These differences may cause this product to function differently. This may also apply to drives

returned from a Control Techniques Service Centre.

If there is any doubt, contact a Control Techniques Drive Centre.

Environmental statement

Control Techniques is committed to minimising the environmental impacts of its manufacturing operations and of its

products throughout their life cycle. To this end, we operate an Environmental Management System (EMS) which is

certified to the International Standard ISO 14001. Further information on the EMS, our Environmental Policy and other

relevant information is available on request, or can be found at www.greendrives.com.

The electronic variable-speed drives manufactured by Control Techniques have the potential to save energy and

(through increased machine/process efficiency) reduce raw material consumption and scrap throughout their long

working lifetime. In typical applications, these positive environmental effects far outweigh the negative impacts of product

manufacture and end-of-life disposal.

Nevertheless, when the products eventually reach the end of their useful life, they can very easily be dismantled into their

major component parts for efficient recycling. Many parts snap together and can be separated without the use of tools,

whilst other parts are secured with conventional screws. Virtually all parts of the product are suitable for recycling.

Product packaging is of good quality and can be re-used. Large products are packed in wooden crates, whilst smaller

products come in strong cardboard cartons which themselves have a high recycled fibre content. If not re-used, these

containers can be recycled. Polyethylene, used on the protective film and bags for wrapping product, can be recycled in

the same way. Control Techniques' packaging strategy favours easily-recyclable materials of low environmental impact,

and regular reviews identify opportunities for improvement.

When preparing to recycle or dispose of any product or packaging, please observe local legislation and best practice.

Copyright © August 2003 Control Techniques Drives Limited

Issue Number: 9

Software: V03.02.12 onwards

Page 3

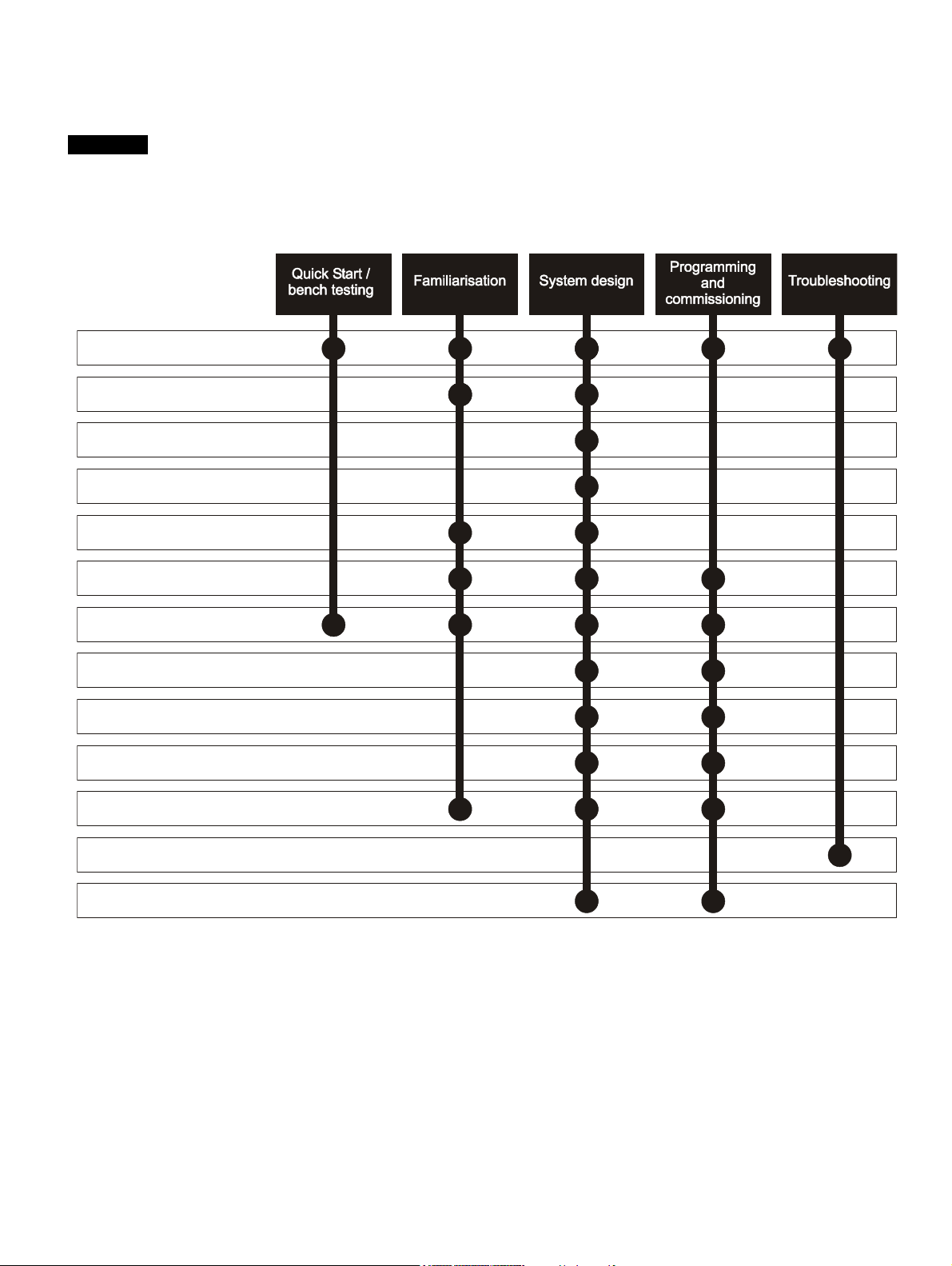

How to use this User Guide

This User Guide provides complete information for installing and operating a Unidrive from start to finish.

The information is in logical order, taking the reader from receiving the drive through to fine tuning the performance.

NOTE

There are specific safety warnings throughout this guide, located in the relevant sections. In addition, Chapter 1 Safety

Information on page 7 contains general safety information. It is essential that the warnings are observed and the

information considered when working with or designing a system using the drive.

This map of the user guide helps to find the right sections for the task you wish to complete:

1 Safety information

2 Product information

3 Mechanical installation

4 Electrical installation

5 Getting started

6 Menu 0

7 Running the motor

8 Optimisation

9 Macros

10 Advanced parameters

11 Technical data

12 Diagnostics

13 UL listing information

Page 4

Contents

Declaration of Conformity ................... 6

1 Safety Information .................................7

1.1 Warnings, Cautions and Notes .............................7

1.2 Electrical safety - general warning ........................7

1.3 System design and safety of personnel ................7

1.4 Environmental limits ..............................................7

1.5 Compliance with regulations .................................7

1.6 Motor .....................................................................7

1.7 Adjusting parameters ............................................7

2 Product Information ..............................8

2.1 Ratings ..................................................................8

2.2 Model number .......................................................8

2.3 Nameplate description - drive identification ..........9

2.4 Model variants .......................................................9

2.5 Operating modes .................................................10

2.6 Drive features ......................................................11

2.7 Option Modules ...................................................12

2.8 More information .................................................12

2.9 Items supplied with the drive ...............................13

3 Mechanical Installation .......................14

3.1 Safety information ...............................................14

3.2 Planning the installation ......................................14

3.3 Terminal cover removal .......................................14

3.4 Ingress protection ................................................15

3.5 Option module fitting / removal ...........................15

3.6 Mounting methods ...............................................16

3.7 Enclosure ............................................................24

3.8 Ventilation ...........................................................26

3.9 Baffle plates ........................................................28

3.10 Ambient temperature ...........................................28

3.11 RFI filters .............................................................29

3.12 Power terminals ..................................................35

3.13 Routine maintenance ..........................................36

4 Electrical Installation ...........................37

4.1 Power connections ..............................................37

4.2 AC supply requirements ......................................40

4.3 Supplying the drive with DC / DC bus paralleling 40

4.4 Ratings ................................................................40

4.5 Output circuit and motor protection .....................41

4.6 Braking ................................................................43

4.7 Ground leakage ...................................................44

4.8 EMC (Electromagnetic compatibility) ..................44

4.9 Control connections ............................................49

4.10 Encoder connections ...........................................54

4.11 Configuring a Unidrive size 5 system ..................56

5 Getting Started .................................... 58

5.1 Understanding the display .................................. 58

5.2 Keypad operation ............................................... 58

5.3 Menu structure ................................................... 59

5.4 Advanced keypad functions ............................... 60

5.5 Menu 0 ............................................................... 60

5.6 Advanced menus ............................................... 60

5.7 Changing the operating mode ............................ 61

5.8 Saving parameters ............................................. 61

5.9 Defaulting the drive ............................................ 61

5.10 Parameter security ............................................. 62

5.11 Serial Communications ...................................... 63

6 Menu 0 ................................................. 64

6.1 Single line descriptions ...................................... 64

6.2 Menu 0 full descriptions ..................................... 72

7 Running the motor .............................. 81

7.1 Quick start set-up ............................................... 81

7.2 Quick Start commissioning ................................. 84

7.3 Quick start P.C. commissioning (UniSoft /

VTCSoft) ............................................................ 87

8 Optimisation ........................................ 92

8.1 Motor map parameters ....................................... 92

8.2 Current limits ...................................................... 98

8.3 Motor thermal protection .................................... 99

8.4 Switching frequency ........................................... 99

8.5 High speed operation ......................................... 99

9 Macros ............................................... 101

9.1 Introduction ...................................................... 101

9.2 How to load a macro ........................................ 102

9.3 Macro terminal connection changes ................ 102

9.4 Macro logic diagrams and Menu 0 parameter

changes ............................................................ 106

9.5 Unidrive VTC macro differences ...................... 122

4 Unidrive User Guide

www.controltechniques.com Issue Number: 9

Page 5

10 Advanced Parameters ......................123

10.1 Menu 1: Speed references and limits ...............124

10.2 Menu 2: Ramps (accel. / decel.) .......................128

10.3 Menu 3: Speed feedback / frequency slaving ...131

10.4 Menu 4: Current control ....................................135

10.5 Menu 5: Machine control ...................................139

10.6 Menu 6: Sequencing logic .................................143

10.7 Menu 7: Analog I/O ...........................................145

10.8 Menu 8: Digital I/O ............................................148

10.9 Menu 9: Programmable logic ............................152

10.10 Menu 10: Status flags / trip log .........................155

10.11 Menu 11: Menu 0 customisation / drive specific

ratings ...............................................................156

10.12 Menu 12: Programmable thresholds .................157

10.13 Menu 13: Digital lock / orientation .....................160

10.14 Menu 14: Programmable PID function ..............166

10.15 Menu 15: Regen ...............................................169

10.16 Menu 16 Small option module set-up ...............171

10.17 Menu 17: Large option module set-up ..............179

10.18 Menu 18: Application menu 1 ...........................179

10.19 Menu 19: Application menu 2 ...........................180

10.20 Menu 20: Large option module .........................180

10.21 Unidrive VTC parameter range and default

differences ........................................................181

10.22 Advanced Features ...........................................182

11 Technical Data ...................................190

11.1 Drive ..................................................................190

11.2 Optional RFI filters ............................................197

12 Diagnostics ........................................198

12.1 Trip indications ..................................................198

12.2 Alarm indications ...............................................204

12.3 Status indications ..............................................204

12.4 Displaying the trip history ..................................204

13 UL Listing Information ......................205

13.1 AC supply specification .....................................205

13.2 Maximum continuous output current .................205

13.3 Safety label .......................................................205

Index ...................................................206

Unidrive User Guide 5

Issue Number: 9 www.controltechniques.com

Page 6

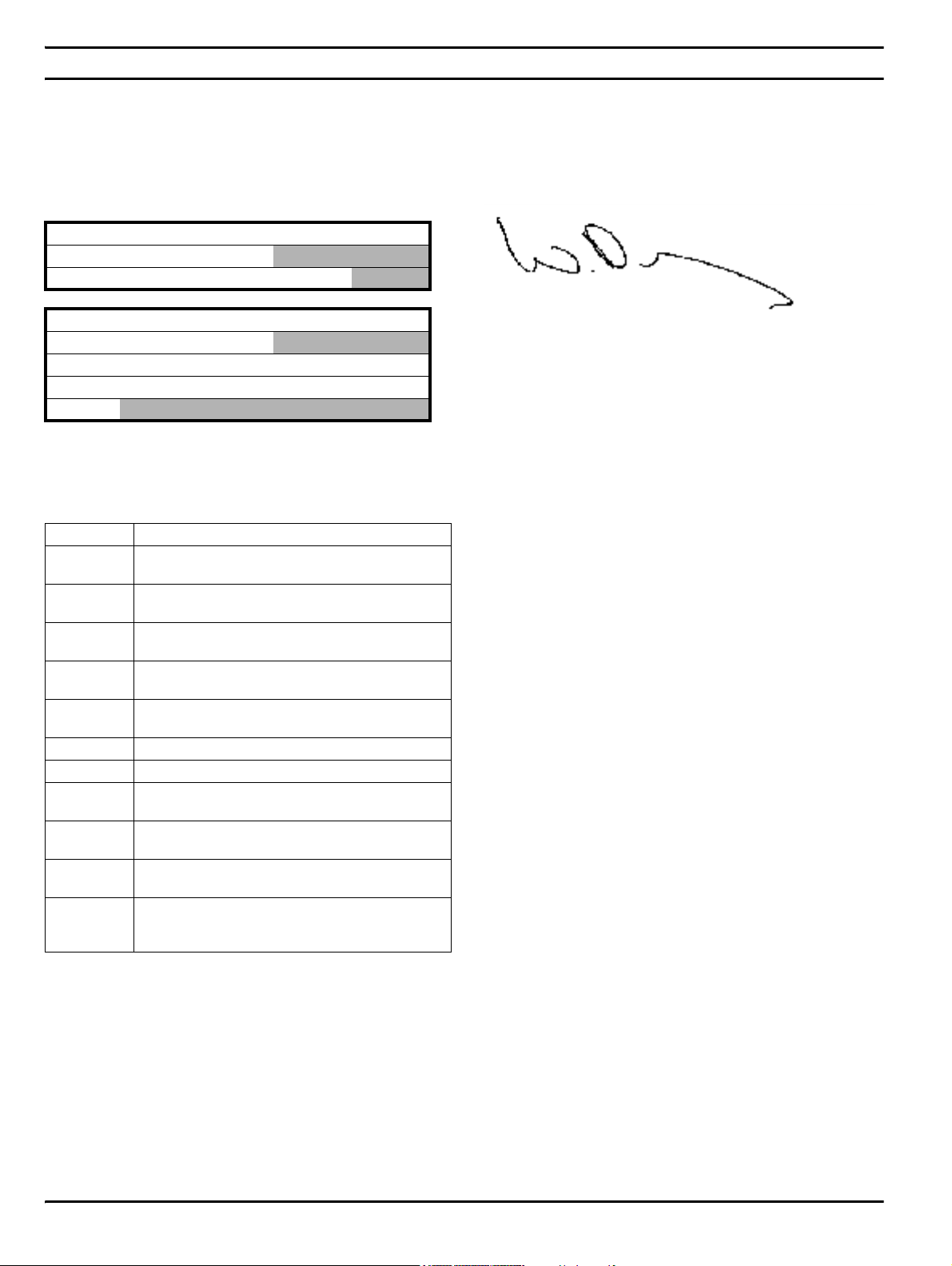

Declaration of Conformity

Control Techniques Ltd

The Gro

Newtown

Powys

UK

SY16 3BE

UNI1201 UNI1202 UNI1203 UNI1204 UNI1205

UNI2201 UNI2202 UNI2203

UNI3201 UNI3202 UNI3203 UNI3204

UNI1401 UNI1402 UNI1403 UNI1404 UNI1405

UNI2401 UNI2402 UNI2403

UNI3401 UNI3402 UNI3403 UNI3404 UNI3405

UNI4401 UNI4402 UNI4403 UNI4404 UNI4405

UNI5401

The AC variable speed drive products listed above, including the VTC,

LFT (all sizes) and REGEN (UNI3401 to UNI4405 only) variants, have

been designed and manufactured in accordance with the following

European harmonised, national and international standards:

EN 60249 Base materials for printed circuits

IEC326-1

IEC326-5

IEC326-6

IEC664-1

EN 60529

UL94 Flammability rating of plastic materials

UL508C Standard for power conversion equipment

EN 50081-1

EN 50081-2

EN 50082-2

EN 61800-3

Printed boards: general information for the

specification writer

Printed boards: specification for single- and doublesided printed boards with plated-through holes

Printed boards: specification for multilayer printed

boards

Insulation co-ordination for equipment within lowvoltage systems: principles, requirements and tests

Degrees of protection provided by enclosures (IP

code)

Generic emission standard for the residential,

1

commercial and light industrial environment

Generic emission standard for the industrial

environment

Generic immunity standard for the industrial

environment

Adjustable speed electrical power drive systems - Part

3: EMC product standard including specific test

methods

These products comply with the Low Voltage Directive 73/23/EEC, the

Electromagnetic Compatibility (EMC) Directive 89/336/EEC and the CE

Marking Directive 93/68/EEC.

W. Dru ry

Executive Vice President, Technology

Newtown

Date: 26 September 2001

These electronic drive products are intended to be used with

appropriate motors, controllers, electrical protection components

and other equipment to form complete end products or systems.

Compliance with safety and EMC regulations depends upon

installing and configuring drives correctly, including using the

specified input filters. The drives must be installed only by

professional assemblers who are familiar with requirements for

safety and EMC. The assembler is responsible for ensuring that the

end product or system complies with all the relevant laws in the

country where it is to be used. A Unidrive EMC Data Sheet is also

available giving detailed EMC information.

1

Conducted emission sizes 1 to 3, not size 4 or 5. See the relevant EMC

Data Sheet.

6 Unidrive User Guide

www.controltechniques.com Issue Number: 9

Page 7

Safety

Information

Product

Information

Mechanical

Installation

Electrical

Installation

Getting

Star ted

Menu 0

Running

the motor

Optimisation Macros

Advanced

Parameters

Technical

Data

Diagnostics

UL Listing

Information

1 Safety Information

1.1 Warnings, Cautions and Notes

A Warning contains information which is essential for

avoiding a safety hazard.

WARNING

A Caution contains information which is necessary for

avoiding a risk of damage to the product or other equipment.

CAUTION

NOTE

A Note contains information which helps to ensure correct operation of

the product.

1.2 Electrical safety - general warning

The voltages used in the drive can cause severe electrical shock and/or

burns, and could be lethal. Extreme care is necessary at all times when

working with or adjacent to the drive.

Specific warnings are given at the relevant places in this User Guide.

1.3 System design and safety of

personnel

The drive is intended as a component for professional incorporation into

complete equipment or a system. If installed incorrectly, the drive may

present a safety hazard. The drive uses high voltage and currents,

carries a high level of stored electrical energy, and is used to control

equipment which can cause injury.

Close attention is required to the electrical installation and the system

design to avoid hazards, either in normal operation or in the event of

equipment malfunction. System design, installation, commissioning and

maintenance must be carried out by personnel who have the necessary

training and experience. They must read this safety information and this

User Guide carefully.

The STOP function of the drive does not remove dangerous voltages

from the output of the drive or from any external option unit.

Careful consideration must be given to the functions of the drive which

might result in a hazard, either through their intended functions or

through incorrect operation due to a fault.

In any application where a malfunction of the drive could lead to

damage, loss or injury, a risk analysis must be carried out, and where

necessary, further measures taken to reduce the risk.

The STOP and START controls or electrical inputs of the drive must

not be relied upon to ensure safety of personnel. If a safety hazard

could exist from unexpected starting of the drive, an interlock that

electrically isolates the drive from the AC supply must be installed

to prevent the motor being inadvertently started.

To ensure mechanical safety, additional safety devices such as electromechanical interlocks and overspeed protection devices may be

required. The drive must not be used in a safety critical application

without additional high integrity protection against hazards arising from a

malfunction.

Under certain conditions, the drive can suddenly discontinue control of

the motor. If the load on the motor could cause the motor speed to be

increased (e.g. in hoists and cranes), a separate method of braking and

stopping must be used (e.g. a mechanical brake).

1.4 Environmental limits

Instructions in this User Guide regarding transport, storage, installation

and use of the drive must be complied with, including the specified

environmental limits. Drives must not be subjected to excessive physical

force.

1.5 Compliance with regulations

The installer is responsible for complying with all relevant regulations,

such as national wiring regulations, accident prevention regulations and

electromagnetic compatibility (EMC) regulations. Particular attention

must be given to the cross-sectional areas of conductors, the selection

of fuses or other protection, and protective earth (ground) connections.

This User Guide contains instruction for achieving compliance with

specific EMC standards.

Within the European Union, all machinery in which this product is used

must comply with the following directives:

98/37/EC: Safety of machinery.

89/336/EEC: Electromagnetic Compatibility.

1.6 Motor

Ensure the motor is installed in accordance with the manufacturer’s

recommendations. Ensure the motor shaft is not exposed.

Standard squirrel cage induction motors are designed for single speed

operation. If it is intended to use the capability of the drive to run a motor

at speeds above its designed maximum, it is strongly recommended that

the manufacturer is consulted first.

Low speeds may cause the motor to overheat because the cooling fan

becomes less effective. The motor should be fitted with a protection

thermistor. If necessary, an electric forced vent fan should be used.

1.7 Adjusting parameters

Some parameters have a profound effect on the operation of the drive.

They must not be altered without careful consideration of the impact on

the controlled system. Measures must be taken to prevent unwanted

changes due to error or tampering.

Unidrive User Guide 7

Issue Number: 9 www.controltechniques.com

Page 8

Safety

Information

Product

Information

Mechanical

Installation

Electrical

Installation

Getting

Star ted

2 Product Information

2.1 Ratings

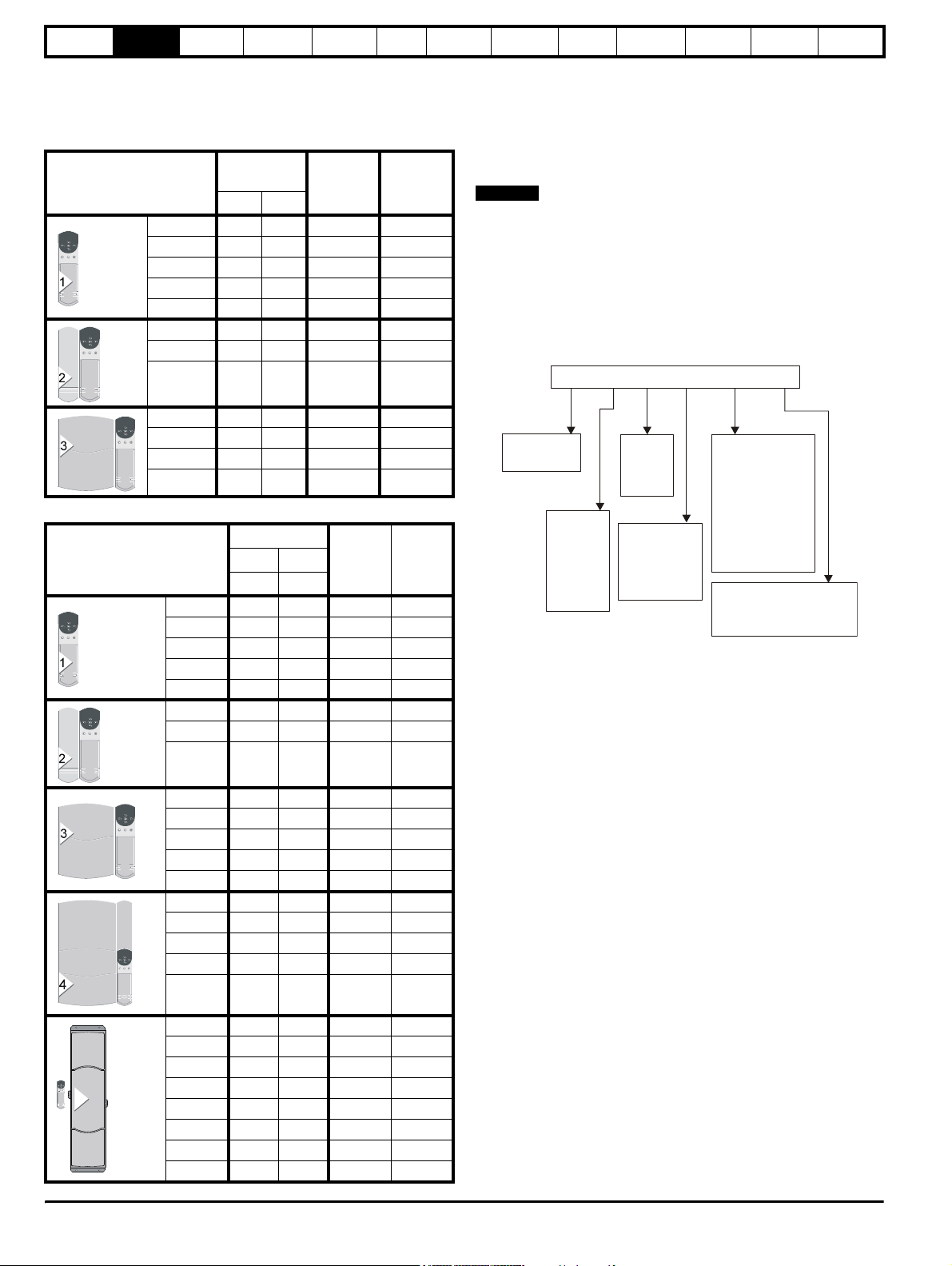

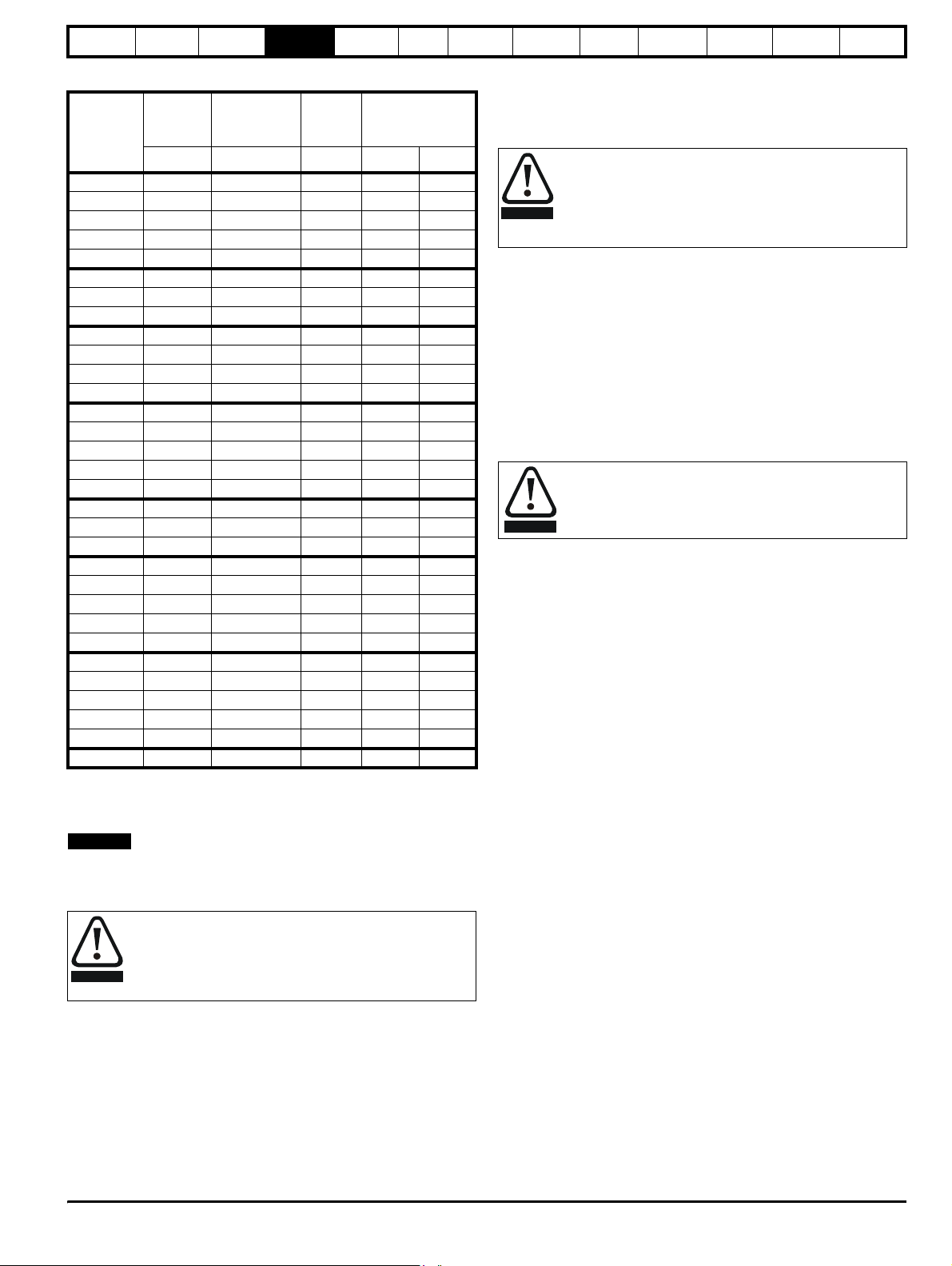

Table 2-1 200V drive ratings (200V to 240V ±10%)

Model

Nominal

rating

kW hp

1201 0.37 0.5 2.1 2.4

1202 0.55 0.75 2.8 3.5

1203 0.75 1 3.8 4.6

1204 1.1 1.5 5.6 6.5

1205 2.2 3 9.5 8.6

2201 3 4 12 10.8

2202 4 5 16 14.3

Output

current*

(A)

Menu 0

the motor

Typical

Input

current (A)

Running

Optimisation Macros

Advanced

Parameters

Technical

Data

Diagnostics

* The output currents are given for maximum 40°C (104°F)

ambient, 1,000m altitude and 3kHz switching. Derating is

required for higher switching frequencies, ambient temperatures

>40°C (104°F) and high altitudes. For further information, refer

to section 11.1.1 Power and current ratings on page 190.

** Multiples of 300A output current with 120% overload or multiples

of 240A with 150% overload

NOTE

N

A Unidrive size 5 consists of a control module with one or more power

modules connected in parallel.

i.e. UNI5401 = 1 x control module and 1 x power module

UNI5402 = 1 x control module and 2 x power modules etc.

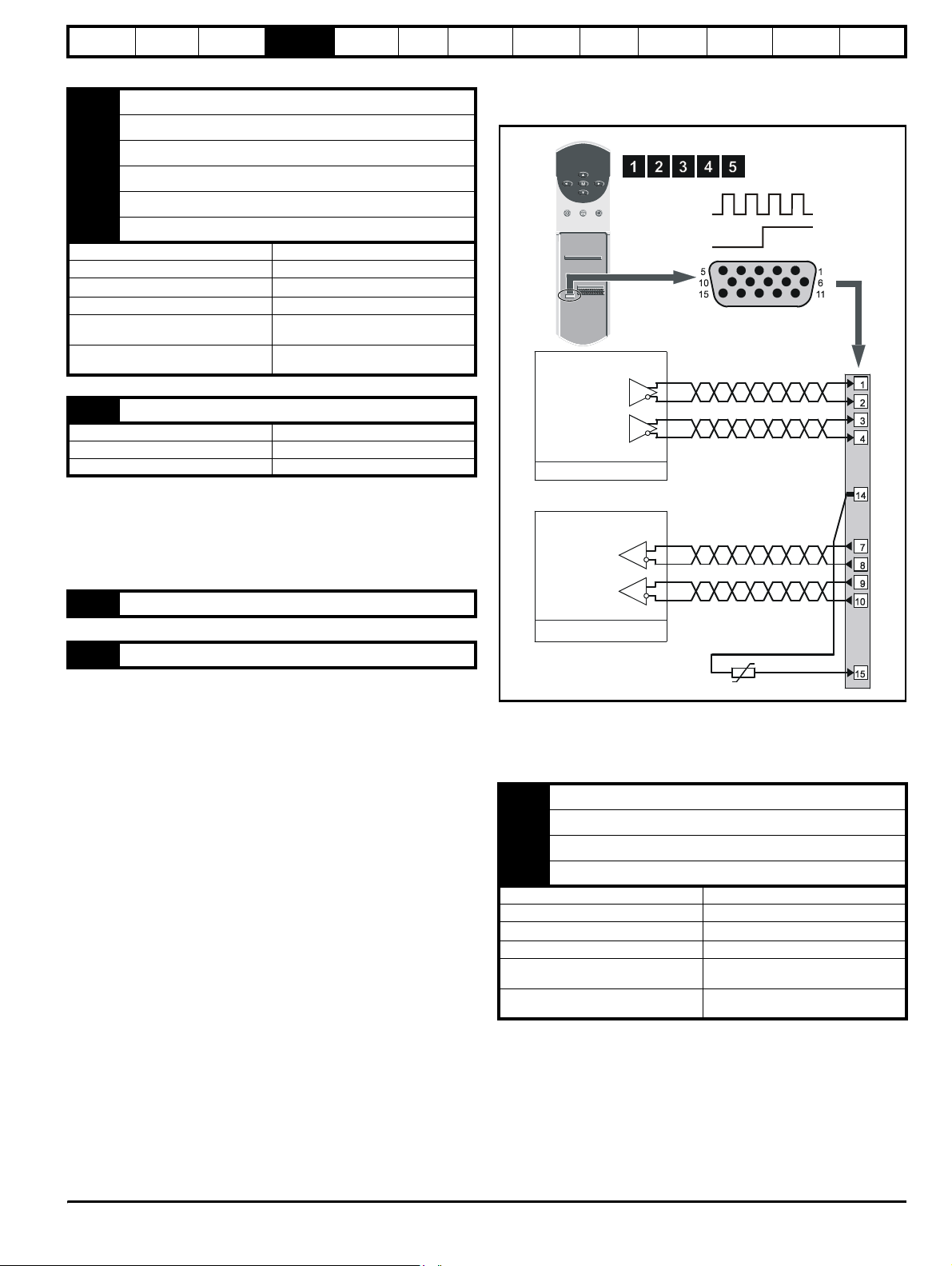

2.2 Model number

The way in which the model numbers for the Unidrive range are formed

is illustrated below.

UL Listing

Information

2203 5.5 10 25 19.8

3201 7.5 15 34 26

3202 11 20 46 39

3203 15 25 60 53

3204 22 30 74 78

Table 2-2 400V drive ratings (380V to 480V ±10%)

Model

Nominal rating

@380V @460V

kW hp

1401 0.75 1 2.1 3.0

1402 1.1 1.5 2.8 4.3

1403 1.5 2 3.8 5.8

1404 2.2 3 5.6 8.2

1405 4 5 9.5 10.0

2401 5.5 7.5 12 13.0

2402 7.5 10 16 17.0

2403 11 15 25 21.0

3401 15 25 34 27

3402 18.5 30 40 32

3403 22 30 46 40

3404 30 40 60 52

3405 37 50 70 66

4401 45 75 96 76

4402 55 100 124 91

4403 75 125 156 123

4404 90 150 180 145

Output

current*

(A)

Typical

Input

current

(A)

UNI

Model:

UNI - Unidrive

Model

size:

1 - Size 1

2 - Size 2

3 - Size 3

4 - Size 4

5 - Size 5

12

Voltage

rating:

2 - 200V

4 - 400V

Power rating:

Depends on

model size.

See section 2.1

Ratings

05

LFT LV

Model variant:

- Standard

variant

LFT - LFT variant

VTC - VTC variant

REGEN - Regen

variant

See section 2.4

Model variants

more details

Voltage rating:

LV - Low voltage (200V)

- Medium voltage (400V)

for

4405 110 150 202 181

5401 160 200 300** 280

5402 320 400 600** 560

5403 480 600 900** 840

5404 640 800 1200** 1120

5

5405 800 1000 1500** 1400

5406 960 1200 1800** 1680

5407 1120 1400 2100** 1960

5408 1280 1600 2400** 2240

8 Unidrive User Guide

www.controltechniques.com Issue Number: 9

Page 9

Safety

Dri

s

Model

Model

g

0

p

Information

Product

Information

Mechanical

Installation

Electrical

Installation

Getting

Star ted

Menu 0

Running

the motor

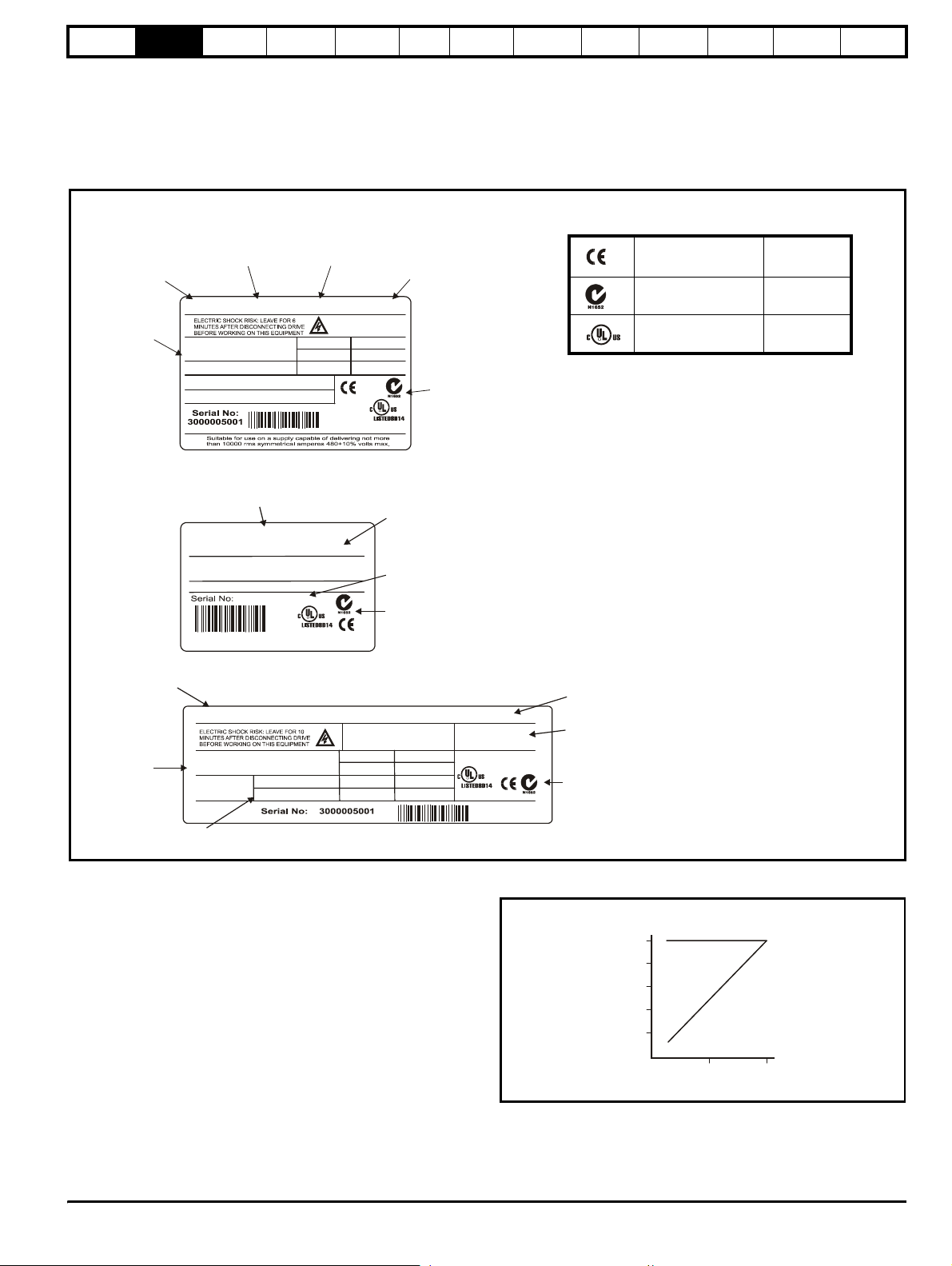

2.3 Nameplate description - drive

identification

The drive label is found on the top surface of the control pod (right

angles to the display) on Unidrive sizes 1 to 3 and size 5 control module,

and on the side of the Unidrive size 4 and size 5 power module.

Figure 2-1 Typical drive rating labels

Optimisation Macros

Advanced

Parameters

Technical

Data

Diagnostics

UL Listing

Information

Unidrive size 1 to 4 rating label

ve type

(STD,LV,

VTC, LFT)

Power rating

Model

UNI3401 VTC 15kW

Drive

ratings

VOLTAGE 50/60 Hz 3Ph

CURRENT (A)

OVERLOAD: 40.8A FOR 60 SECS

SOFTWARE VERSION: 03.02.11

Unidrive size 5 control module rating label

UNIDRIVE SIZE 5

CONTROL MODULE HW2

IT IS ESSENTIAL TO READ

THE MANUAL BEFORE

CONNECTING THE DRIVE.

SOFTWARE VERSION: 03.02.11

3000005001

INPUT OUTPUT

380/480V 380/480V

27A 34.0A

TO BE USED IN CONJUNCTION

WITH UNIDRIVE SIZE 5 HW2

POWER MODULES (S)

STDL01

IND.

R

CONT..

EQ.

MADE IN THE U.K.

STDJ41

IT IS ESSENTIAL TO READ

THE MANUAL BEFORE

CONNECTING THE DRIVE.

IND.

CONT..

EQ.

MADE IN THE U.K.

Customer and

date code

R

Hardware

revision

Customer and

date code

Approvals

Approval

Key to Approvals

CE approval Europe

C Tick approval Australia

UL / cUL approval

R

USA &

Canada

Unidrive size 5 power module rating label

Drive

ratings

UNI5401 POWER MODULE HW2 110V FAN FITTED

VOLTAGE 50/60 Hz 3Ph

CURRENT (A)

Dual current

ratin

OVERLOAD: 150 FOR 60 SECS

OVERLOAD: 120 FOR 60 SECS

IT IS ESSENTIAL TO READ

THE MANUAL BEFORE

CONNECTING THE DRIVE.

INPUT OUTPUT

380/480V 380/480V

220.0A 240.0A

280.0A 300.0A

2.4 Model variants

2.4.1 Unidrive standard industrial (STD)

...for constant torque loads (All frame sizes)

Operating modes:

Open Loop

Closed Loop vector

Servo

Regen

Overload:

Open loop 150% for 60s

Closed loop vector 175% for 60s (sizes 1 to 4), 150%* for 60s (size

5)

Servo 175% for 4s (sizes 1 to 4), 150%* for 4s (size 5)

Regen 150% for 60s

* Multiples of 300A output current with 120% overload or multiples of

240A with 150% overload

Customer and

STDL01

HEATSINK FAN

110V/120V 50/60HZ

IND.

CONT..

R

EQ.

MADE IN

THE U.K.

date code

Heatsink fan

ratings

Approvals

Figure 2-2 Constant torque load

Percent kW

and torque

100

80

60

40

20

0

Torque

50 10

Percent s

kW

eed

Unidrive User Guide 9

Issue Number: 9 www.controltechniques.com

Page 10

Safety

060

0

0

P

p

Information

Product

Information

Mechanical

Installation

Electrical

Installation

Getting

Star ted

Menu 0

Running

the motor

Optimisation Macros

Advanced

Parameters

Technical

Data

Diagnostics

UL Listing

Information

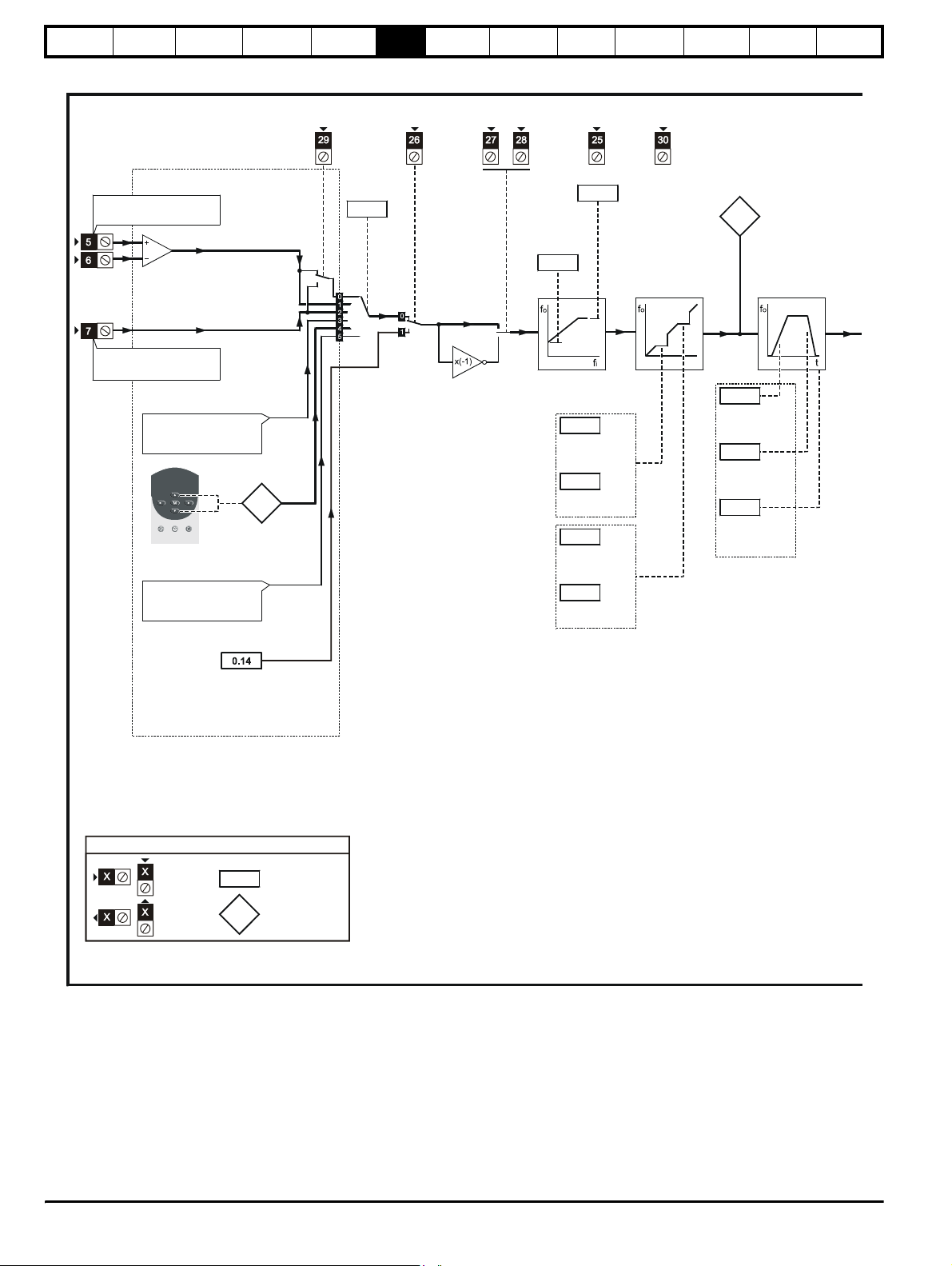

2.4.2 Unidrive LFT

...for lift applications

Overloads and operating modes as Unidrive standard industrial, in

addition:

low acoustic noise

9kHz default switching frequency

S4/S5 duty cycle only

Figure 2-3 Standard S4/S5 duty cycle (Unidrive LFT)

150%

100%

Frequency / speed

0

Current

0

2

50Hz

RPM

1500

2

2.4.3 Unidrive VTC

...for quadratic load (variable torque) applications (fans and pumps)

Open loop fixed boost mode only

120% overload for 60s

Figure 2-4 Variable torque mode

ercent kW

and torque

100

80

60

40

20

0

Torque

50 10

Percent s

kW

eed

2.4.4 Unidrive REGEN

All sizes of Unidrive can be used in regen mode. However, Unidrive

sizes 3 and 4 require an internal modification before being used in a

regen system.

This modification is already completed if the drive has been ordered as a

Unidrive REGEN.

2.5 Operating modes

All variants of Unidrive (except VTC) are designed to operate in any of

the following modes:

1. Open loop mode

V/f mode (V/ Hz)

Open loop vector

2. Closed loop vector

3. Servo

4. Regen

Unidrive VTC can only operate in open loop quadratic V/f mode.

2.5.1 Open Loop mode (OL)

For use with standard AC induction motors.

The drive applies power to the motor at frequencies varied by the user.

The motor speed is a result of the output frequency of the drive and slip

due to the mechanical load. The drive can improve the performance of

the motor by applying slip compensation. The performance at low speed

depends on whether V/f mode or open loop vector mode is selected.

V/f mode

The voltage applied to the motor is directly proportional to the frequency

except at low speed where a voltage boost is provided which is set by

the user. This mode should used for multi-motor applications.

Typically 100% torque at 4Hz.

Open loop vector mode

The voltage applied to the motor is directly proportional to the frequency

except at low speed where the drive uses motor parameters to apply the

correct voltage to keep the flux constant under varying load conditions.

Typically 100% torque at 1Hz.

2.5.2 Closed loop vector mode (VT)

For use with induction motors with a speed feedback device fitted.

The drive directly controls the speed of the motor using the feedback

device to ensure the rotor speed is exactly as demanded. Motor flux is

accurately controlled at all times to provide full torque all the way down

to zero speed.

Typically 175% torque at 0rpm.

2.5.3 Servo (SV)

For use with permanent magnet brushless motors with a speed and

position feedback device fitted.

The drive directly controls the speed of the motor using the feedback

device to ensure the rotor speed is exactly as demanded. Flux control is

not required because the motor is self excited by the permanent

magnets which form part of the rotor.

Absolute position information is required from the feedback device to

ensure the output voltage is accurately matched to the back EMF of the

motor.

Typically 175% torque at 0rpm

2.5.4 Regen

For use as a regenerative front end for four quadrant operation.

Regen operation allows bi-directional power flow to and from the AC

supply. This provides far greater efficiency levels in applications which

would otherwise dissipate large amounts of energy in the form of heat in

a braking resistor.

The harmonic content of the input current is negligible due to the

sinusoidal nature of the waveform when compared to a conventional

bridge rectifier or thyristor front end.

See the Regen Installation Guide for more information on this operating

mode.

2.5.5 Key to operating mode abbreviations

Abbreviations are throughout this User Guide to define the operating

mode for which the information applies as follows:

OL> Open loop

CL> Closed loop (which incorporates closed loop vector and

servo mode)

VT> Closed loop vector mode

SV> Servo

10 Unidrive User Guide

www.controltechniques.com Issue Number: 9

Page 11

Safety

A

Information

Product

Information

Mechanical

Installation

Electrical

Installation

Getting

Star ted

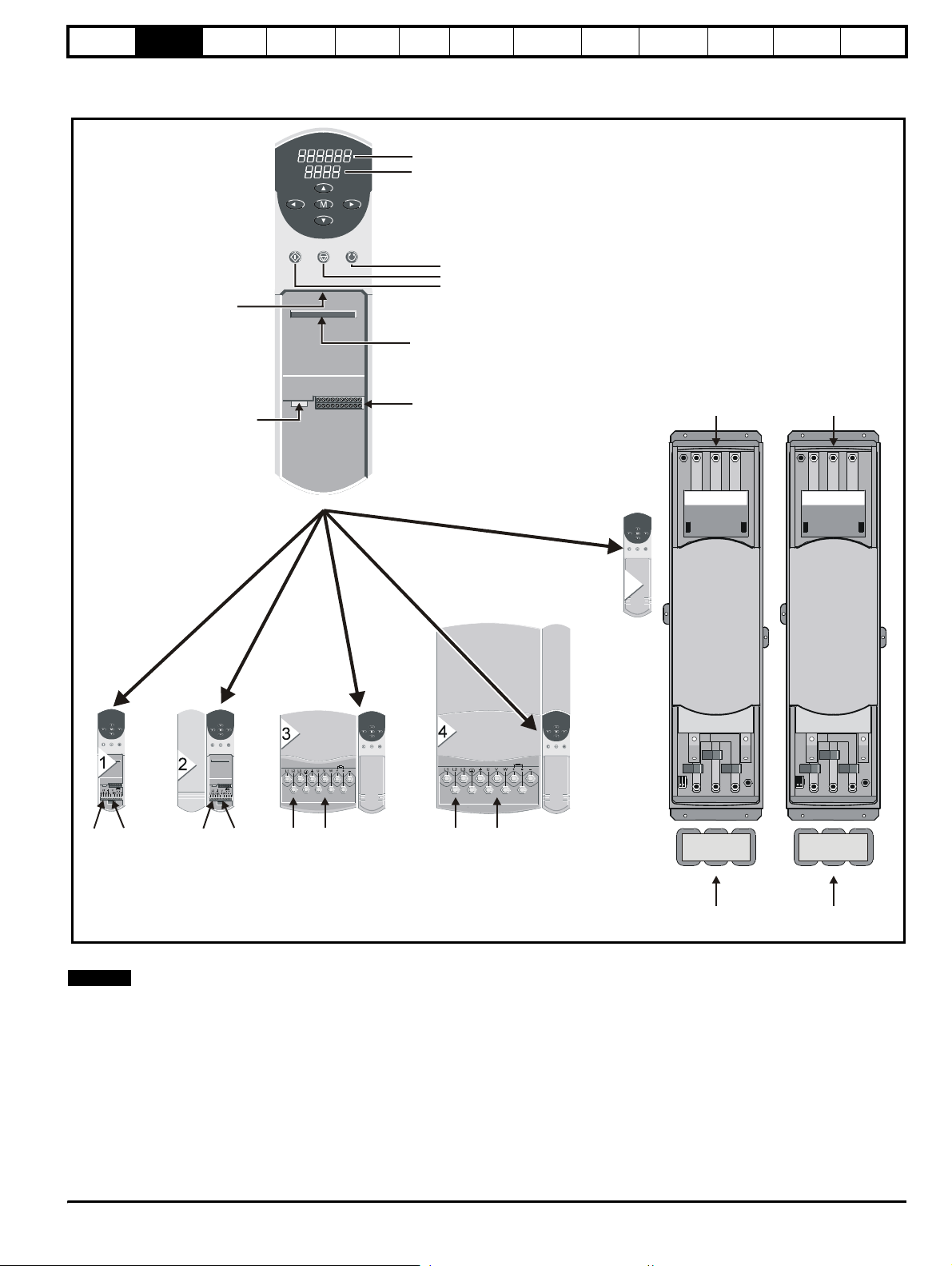

2.6 Drive features

Figure 2-5 Features of the drive (Size 1 to 5)

Menu 0

Running

the motor

Upper display

Lower display

Optimisation Macros

Advanced

Parameters

Technical

Data

Diagnostics

UL Listing

Information

Programming keys

Large option

module connection

Encoder connection

{

Control keys

Forward / Reverse

Stop / Reset

Run

Small option

module connection

Control connectors

AC

In

AC

In

5

NOTE

CInAC

Out

ACInAC

Out

N

ACInAC

Out

ACInAC

Out

Sharing

choke

AC

Out

Sharing

choke

AC

Out

Unidrive size 5 consists of a control module and one or more power

modules.

For power ratings greater than 160kW / 200hp, multiple power modules

(up to a maximum of 8) can be connected in parallel.

When multiple power modules are used, an output sharing choke is

required before the drive outputs are connected together.

Unidrive User Guide 11

Issue Number: 9 www.controltechniques.com

Page 12

Safety

us

et

Information

Product

Information

Mechanical

Installation

Electrical

Installation

Getting

Star ted

Menu 0

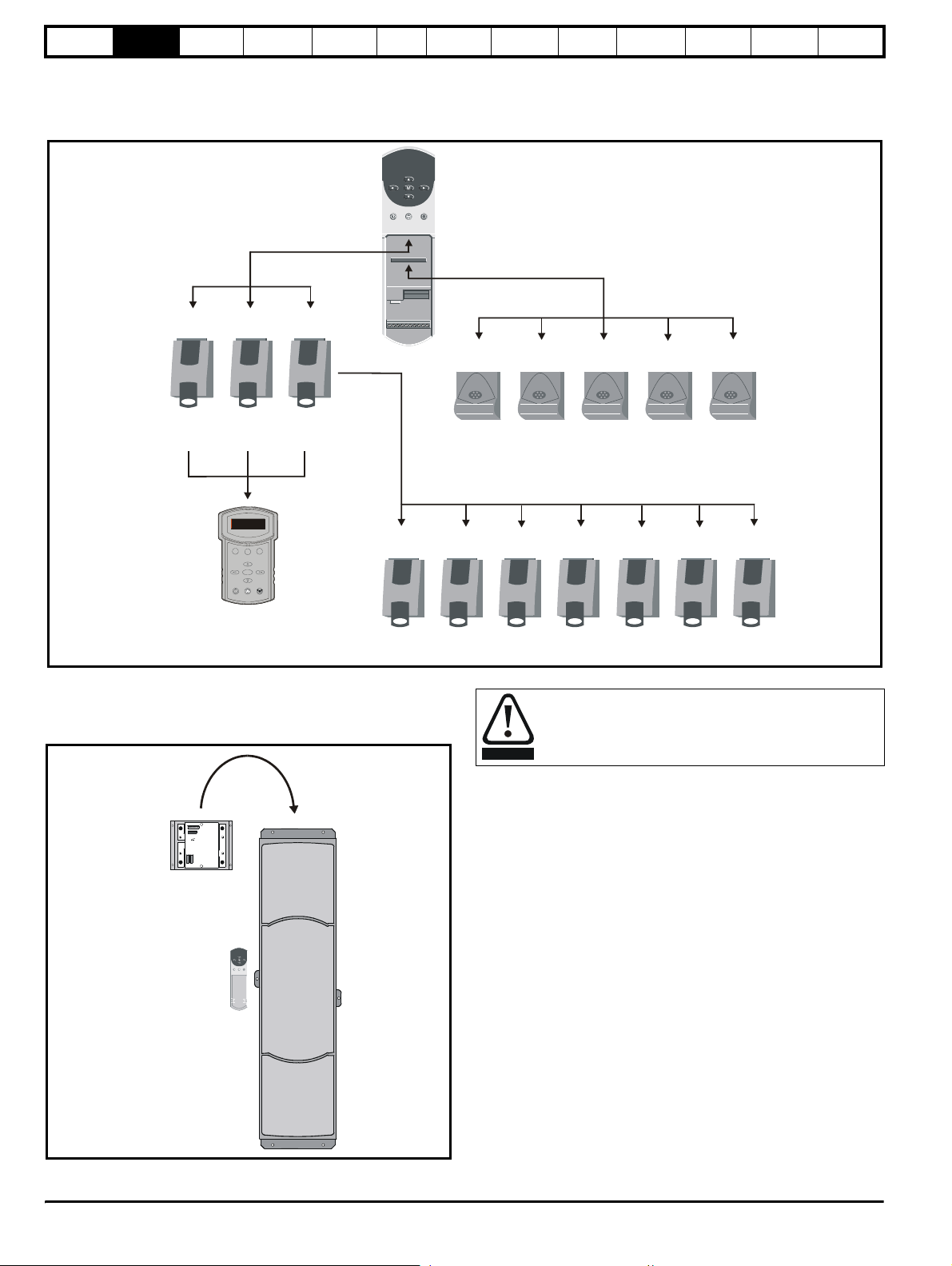

2.7 Option Modules

The following option modules are available for use with Unidrive.

Figure 2-6 Unidrive options available for all sizes

Running

the motor

Optimisation Macros

Advanced

Parameters

Technical

Data

Diagnostics

UL Listing

Information

Applications

Applications

F3

UD70

module

module

UD73 UD74 UD75

Profibus-DP Interbus CT Net Modbus

UD78 UD71

Servo RS232

RS485

9901 11

destination addr

F1

F2

M

Universal

Keypad

Unidrive sizes 1 to 4 have built in braking transistors; for Unidrive size 5

a braking option can be fitted if required as shown below:

Figure 2-7 Braking option available for Size 5

UD55 UD53 UD52 UD51 UD50

Cloning

module

Resolver Sin Cos

Encoder

UD76

Pl

Second

Encoder

UD77 UD77

Device

N

CAN CANopen

Extra I/O

The drive must be powered down for a minimum duration of

10 minutes before an option module is fitted or removed.

WARNING

UD77

2.8 More information

The following manuals are also available providing full information on the

various option modules, regen mode and advanced product use:

• Unidrive Advanced User Guide

• Regen Installation Guide

Size 5 Braking

option

• UD50 User Guide (Additional I/O small option module)

• UD51 User Guide (Second encoder small option module)

• UD52 User Guide (SINCOS encoder interface small option module)

• UD53 User Guide (Resolver interface small option module)

• UD55 User Guide (Cloning interface small option module)

• UD70 User Guide (Large option module and software)

• UD71 User Guide (Serial communications large option module)

• UD73 User Guide (Profibus-DP large option module)

• UD74 User Guide (Interbus large option module)

• UD75 CT Net User Guide (Large option module)

• UD76 User Guide (Modbus Plus large option module)

• UD77 User Guide (Device Net large option module)

• UD78 User Guide (Servo large option module)

• CAN User Guide (Large option module)

• CANopen User Guide (Large option module)

• Universal Keypad User Guide

• Universal Keypad Advanced User Guide

Please also see the Unisoft drive commissioning software which

contains a help file detailing full advanced parameter descriptions and

other useful information.

12 Unidrive User Guide

www.controltechniques.com Issue Number: 9

Page 13

Safety

Information

Product

Information

Mechanical

Installation

Electrical

Installation

Getting

Star ted

Menu 0

Running

the motor

Optimisation Macros

Advanced

Parameters

Technical

Data

Diagnostics

Information

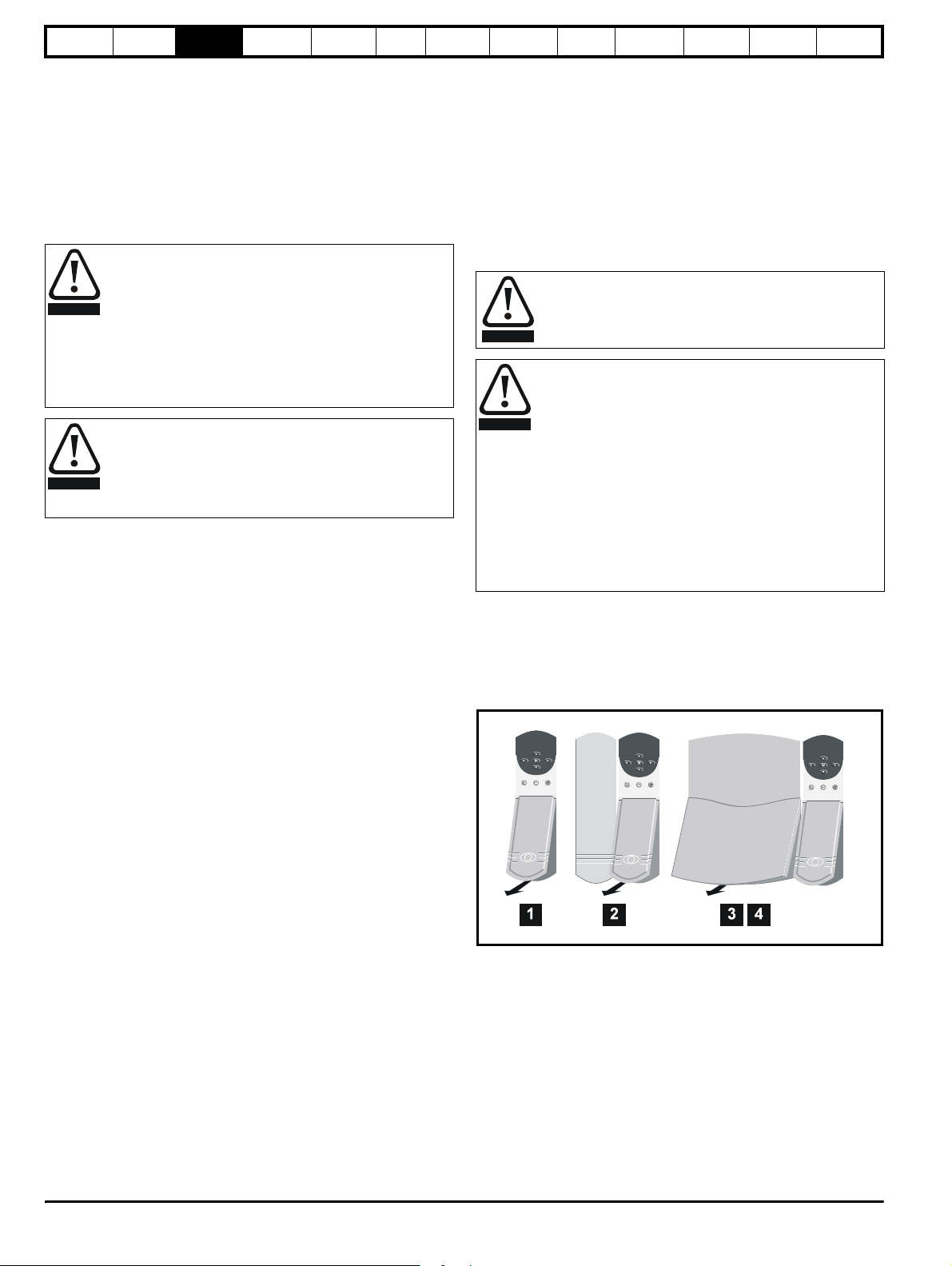

2.9 Items supplied with the drive

Size 1 Size 2 Size 3 Size 4 Size 5 control Size 5 power

Certificate of quality Certificate of quality Certificate of quality Certificate of quality Certificate of quality Certificate of quality

Safety Booklet Safety Booklet Safety Booklet Safety Booklet Safety Booklet

Mounting brackets Mounting brackets Mounting brackets Mounting brackets Mounting brackets

Interface leads

UL Listing

Control connectors Control connectors Control connectors Control connectors Control connectors

345678910

12

21 22 23 24 25 26 27 28 29 30 3121 22 23 24 25 26 27 28 29 30 31

11

345678910

12

21 22 23 24 25 26 27 28 29 30 3121 22 23 24 25 26 27 28 29 30 31

11

345678910

12

21 22 23 24 25 26 27 28 29 30 3121 22 23 24 25 26 27 28 29 30 31

11

345678910

12

21 22 23 24 25 26 27 28 29 30 3121 22 23 24 25 26 27 28 29 30 31

11

345678910

12

21 22 23 24 25 26 27 28 29 30 3121 22 23 24 25 26 27 28 29 30 31

Gasket foam Gasket foam Gasket foam Gasket foam UL Warning label

CAUTION

Risk of Electric Shock

Power down unit 10minutes

before removing cover

-

.

+

Power connector

UL Warning label UL Warning label

CAUTION

Risk of Electric Shock

Power down unit 10minutes

before removing cover

CAUTION

Risk of Electric Shock

Power down unit 10minutes

before removing cover

Power connector

L3

L1 L2

U

VW

UL Warning label UL Warning label

CAUTION

Risk of Electric Shock

Power down unit 10minutes

before removing cover

CAUTION

Risk of Electric Shock

Power down unit 10minutes

before removing cover

11

Unidrive User Guide 13

Issue Number: 9 www.controltechniques.com

Page 14

Safety

Information

Product

Information

Mechanical

Installation

Electrical

Installation

Getting

Star ted

Menu 0

Running

the motor

3 Mechanical Installation

This chapter describes how to use all mechanical features to install the

drive. Key features of this chapter include:

• Option module fitting

• Mounting methods

• Enclosure sizing and layout

• Terminal location and torque settings

3.1 Safety information

Follow the instructions

The mechanical and electrical installation instructions must

be adhered to. Any questions or doubt should be referred to

WARNING

WARNING

3.2 Planning the installation

The following considerations must be made when planning the

installation:

3.2.1 Access

Access must be restricted to authorised personnel only. Safety

regulations which apply at the place of use must be complied with.

3.2.2 Environmental protection

The drive must be protected from:

• moisture, including dripping water or spraying water and

• contamination with electrically conductive material

• contamination with any form of dust which may restrict the fan, or

• temperature beyond the specified operating and storage ranges

3.2.3 Cooling

The heat produced by the drive must be removed without its specified

operating temperature being exceeded. Note that a sealed enclosure

gives much reduced cooling compared with a ventilated one, and may

need to be larger and/or use internal air circulating fans.

For further information, please refer to section 3.7.2 Enclosure sizing on

page 24.

3.2.4 Electrical safety

The installation must be safe under normal and fault conditions.

Electrical installation instructions are given in Chapter 4 Electrical

Installation on page 37.

the supplier of the equipment. It is the responsibility of the

owner or user to ensure that the installation of the drive and

any external option unit, and the way in which they are

operated and maintained, comply with the requirements of

the Health and Safety at Work Act in the United Kingdom or

applicable legislation and regulations and codes of practice in

the country in which the equipment is used.

Competence of the installer

The drive must be installed by professional assemblers who

are familiar with the requirements for safety and EMC. The

assembler is responsible for ensuring that the end product or

system complies with all the relevant laws in the country

where it is to be used.

condensation. An anti-condensation heater may be required, which

must be switched off when the drive is running.

impair airflow over various components

Optimisation Macros

If it is necessary to meet strict emission limits, or if it is known that

electromagnetically sensitive equipment is located nearby, then full

precautions must be observed. These will include the use of RFI filters at

the drive inputs, which must be located very close to the drives. Space

must be made available for the filters and allowance made for carefully

segregated wiring. Both levels of precautions are covered in section

4.8 EMC (Electromagnetic compatibility) on page 44.

Advanced

Parameters

Technical

Data

Diagnostics

UL Listing

Information

3.2.7 Hazardous areas

The drive must not be located in a classified hazardous areas unless it is

installed in an approved enclosure and the installation is certified.

3.3 Terminal cover removal

Isolation device

The AC supply must be disconnected from the drive using an

approved isolation device before any cover is removed from

WARNING

WARNING

3.3.1 Removing the terminal covers

Unidrive sizes 1 to 4 and the size 5 control module are fitted with one or

two terminal covers depending on the model size. When model sizes 1,

3 and 4 are through-panel mounted, the terminal cover(s) must first be

removed in order for access to be gained to the lower mounting holes.

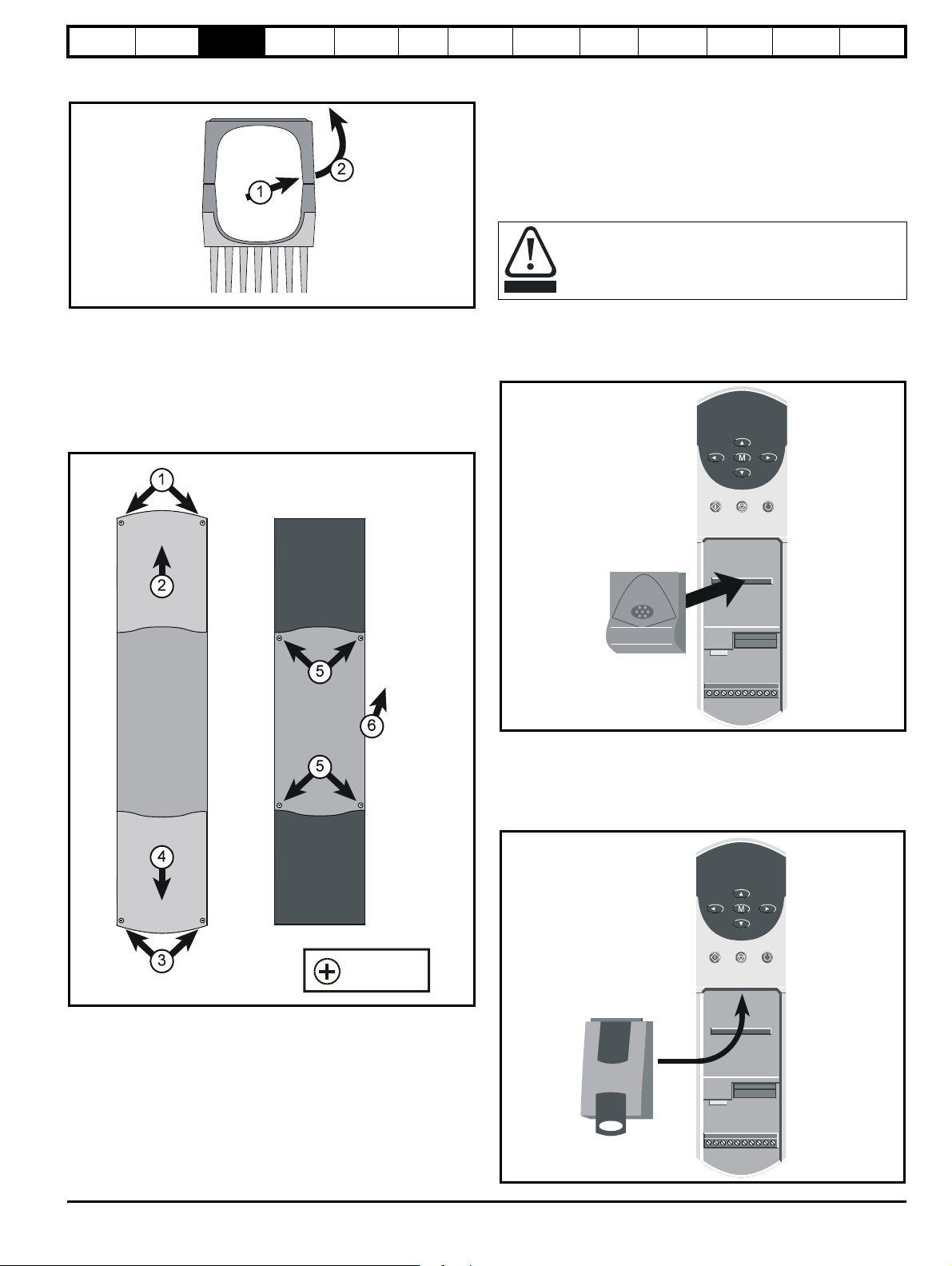

Figure 3-1 Removing the terminal covers

The terminal cover(s) of all models must be removed for access to the

electrical connectors.

the drive or before any servicing work is performed.

Stored charge

The drive contains capacitors that remain charged to a

potentially lethal voltage after the AC supply has been

disconnected. If the drive has been energised, the AC

supply must be isolated at least ten minutes before work

may continue.

Normally, the capacitors are discharged by an internal

resistor. Under certain, unusual fault conditions, it is possible

that the capacitors may fail to discharge, or be prevented

from being discharged by a voltage applied to the output

terminals. If the drive has failed in a manner that causes the

display to go blank immediately, it is possible the capacitors

will not be discharged. In this case, consult Control

Techniques or their authorised distributor.

3.2.5 Fire protection

The drive enclosure is not classified as a fire enclosure. A separate fire

enclosure must be provided.

3.2.6 Electromagnetic compatibility

Variable speed drives are powerful electronic circuits which can cause

electromagnetic interference if not installed correctly with careful

attention to the layout of the wiring.

Some simple routine precautions can prevent disturbance to typical

industrial control equipment.

14 Unidrive User Guide

www.controltechniques.com Issue Number: 9

Page 15

Safety

Information

Product

Information

Mechanical

Installation

Electrical

Information

Getting

Star ted

Menu 0

Running

the motor

Figure 3-2 View from the underside showing how a terminal cover

is removed from the drive

Remove terminal covers, as follows:

1. Working on either side of the terminal cover, push the inner edge of

the cover firmly outward until it becomes unclipped.

2. Swing the side of the cover outward and upward until the remaining

clips become released.

3. Remove the gland plate

Figure 3-3 Removing the three terminal covers on the Size 5

power module

Optimisation Macros

Advanced

Parameters

Technical

Data

Diagnostics

UL Listing

Information

3.4 Ingress protection

Size 1 to 4:

Gland plate(s) not fitted: IP00

Gland plate(s) fitted; cable glands not fitted: IP10

Gland plate(s) fitted; cable-glands fitted: IP40, NEMA 1

Size 5 power and control modules: IP00

3.5 Option module fitting / removal

Power down the drive before fitting / removing an option

module. Failure to do so may result in damage to the product.

CAUTION

The small option module should be placed under the two green securing

clips in the main housing beneath the drive display and pushed firmly

into place. Ensure the two connectors mate securely.

Figure 3-4 Fitting of a Unidrive small option module

The large option module slides into the space directly beneath the drive

display so that only the front face of the module can be seen. Ensure the

module clicks into place indicating that the two connectors have mated

successfully.

Figure 3-5 Fitting of a Unidrive large option module

M5 pozidriv

screw

Remove the three terminal covers on the power module, as follows:

1. Remove the two pozidriv screws.

2. Remove the upper cover.

3. Remove the two pozidriv screws.

4. Remove the lower cover until it is released from the middle cover.

5. Remove the four screws that are now revealed.

6. Remove the middle cover.

All the power terminals and ribbon-cable connectors are now accessible.

Unidrive User Guide 15

Issue Number: 9 www.controltechniques.com

Page 16

Safety

n

Information

Product

Information

Mechanical

Installation

Electrical

Installation

Getting

Star ted

Menu 0

Running

the motor

Optimisation Macros

Advanced

Parameters

Technical

Data

Diagnostics

UL Listing

Information

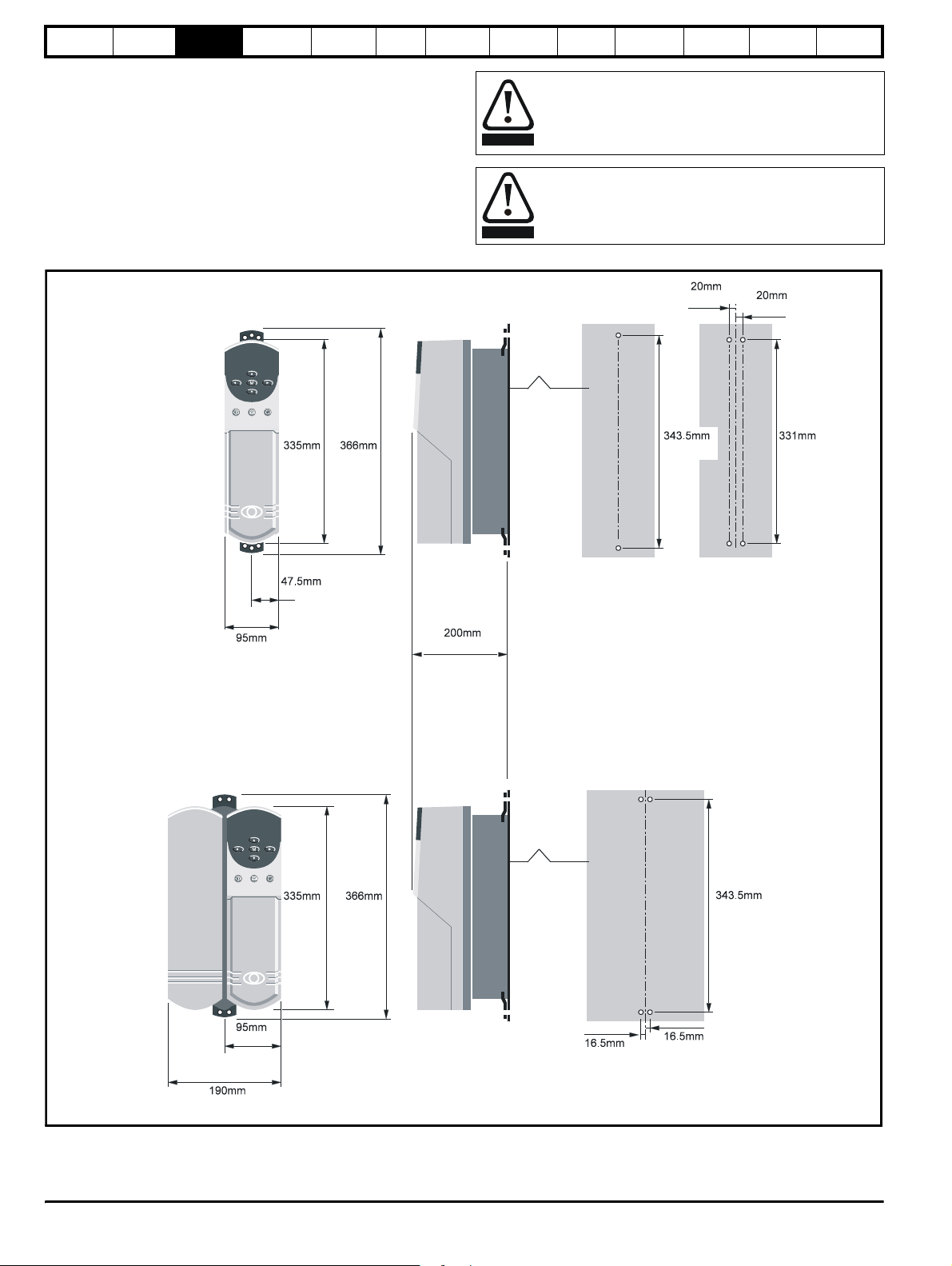

3.6 Mounting methods

Unidrive sizes 1 to 4 can be either through hole or surface mounted

using the appropriate brackets.

The Unidrive size 5 consists of two modules:

• the control module should be surface mounted

• the power module must be through hole mounted.

The following drawings show the dimensions of the drive and mounting

holes for each method to allow a back plate to be prepared.

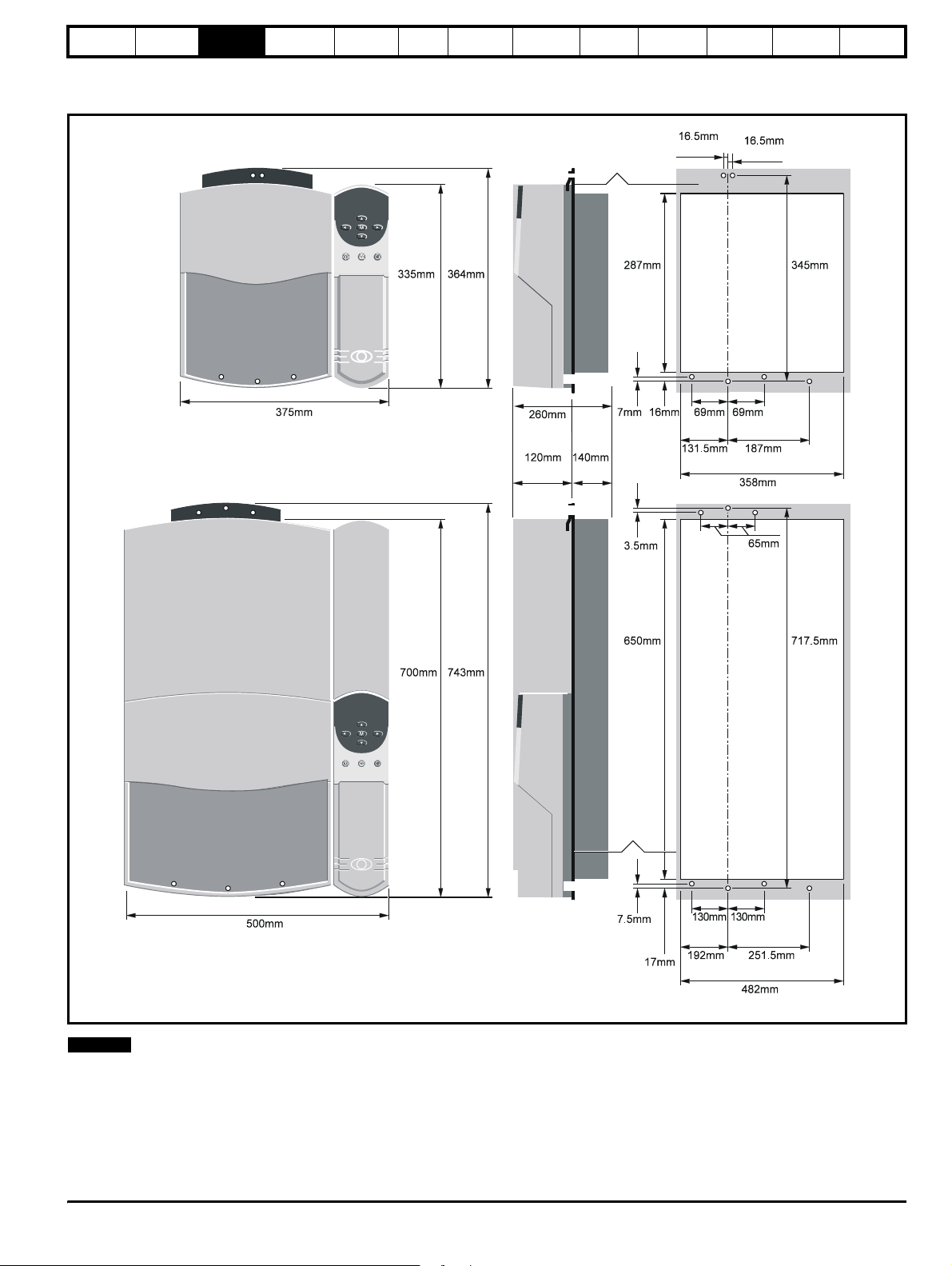

Figure 3-6 Surface mounting of model sizes 1 and 2

Model

size 1

13.189in 14.409in

WARNING

WARNING

Lifting the drive

The weights of model sizes 3 and 4 are 22kg (49lbs) and

70kg (154lbs) respectively; the size 5 power module exceeds

100kg (220lbs). Use appropriate safeguards when lifting

these models.

If the drive has been used at high load levels for a period of

time, the heatsink may be hot. Human contact with the

heatsink should be restricted.

0.787in

Back-plate

13.524in

0.787in

13.031i

Model

size 2

3.740in

3.740in

1.870in

13.189in 14.409in

7.874in

Back-plate

0.650in

13.524in

0.650in

7.480in

16 Unidrive User Guide

www.controltechniques.com Issue Number: 9

Page 17

Safety

n

Information

Product

Information

Mechanical

Installation

Electrical

Information

Getting

Star ted

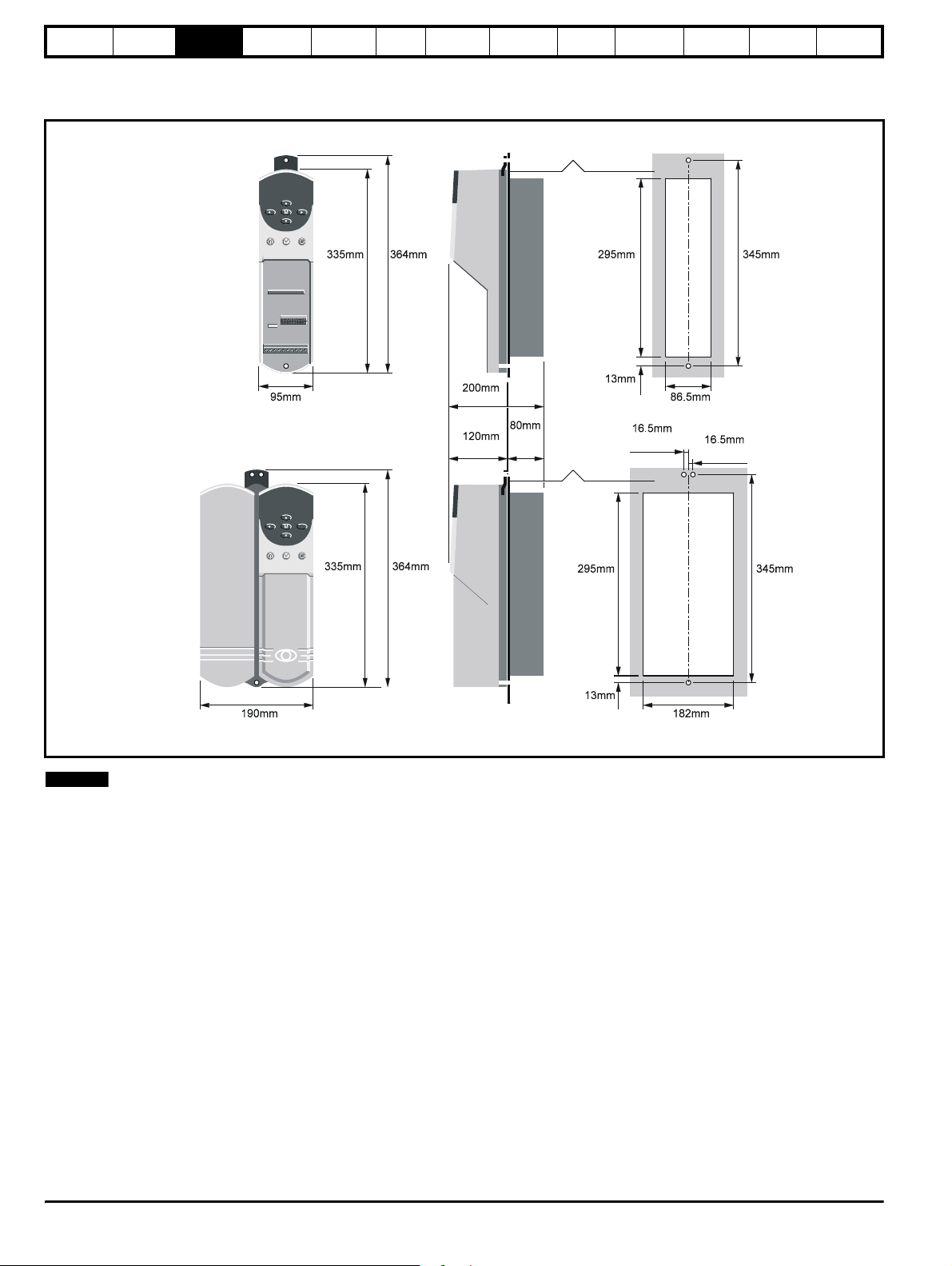

Figure 3-7 Surface mounting of model sizes 3 and 4

Model

size 3

Menu 0

Running

the motor

Optimisation Macros

Advanced

Parameters

Back-plate

Technical

Data

1.772in

Diagnostics

UL Listing

Information

Model

size 4

14.764in

7.382in

9.843in

13.189in 14.488in

27.559in30.118

in

10.236in

Back-plate

0.650in

0.669in

13.622i

6.890in

0.650in

0.669in

28.071in

19.685in

2.559in 2.559in5.650in 5.650in

Unidrive User Guide 17

Issue Number: 9 www.controltechniques.com

Page 18

Safety

Back-pl

n

Information

Product

Information

Mechanical

Installation

Electrical

Installation

Getting

Star ted

Menu 0

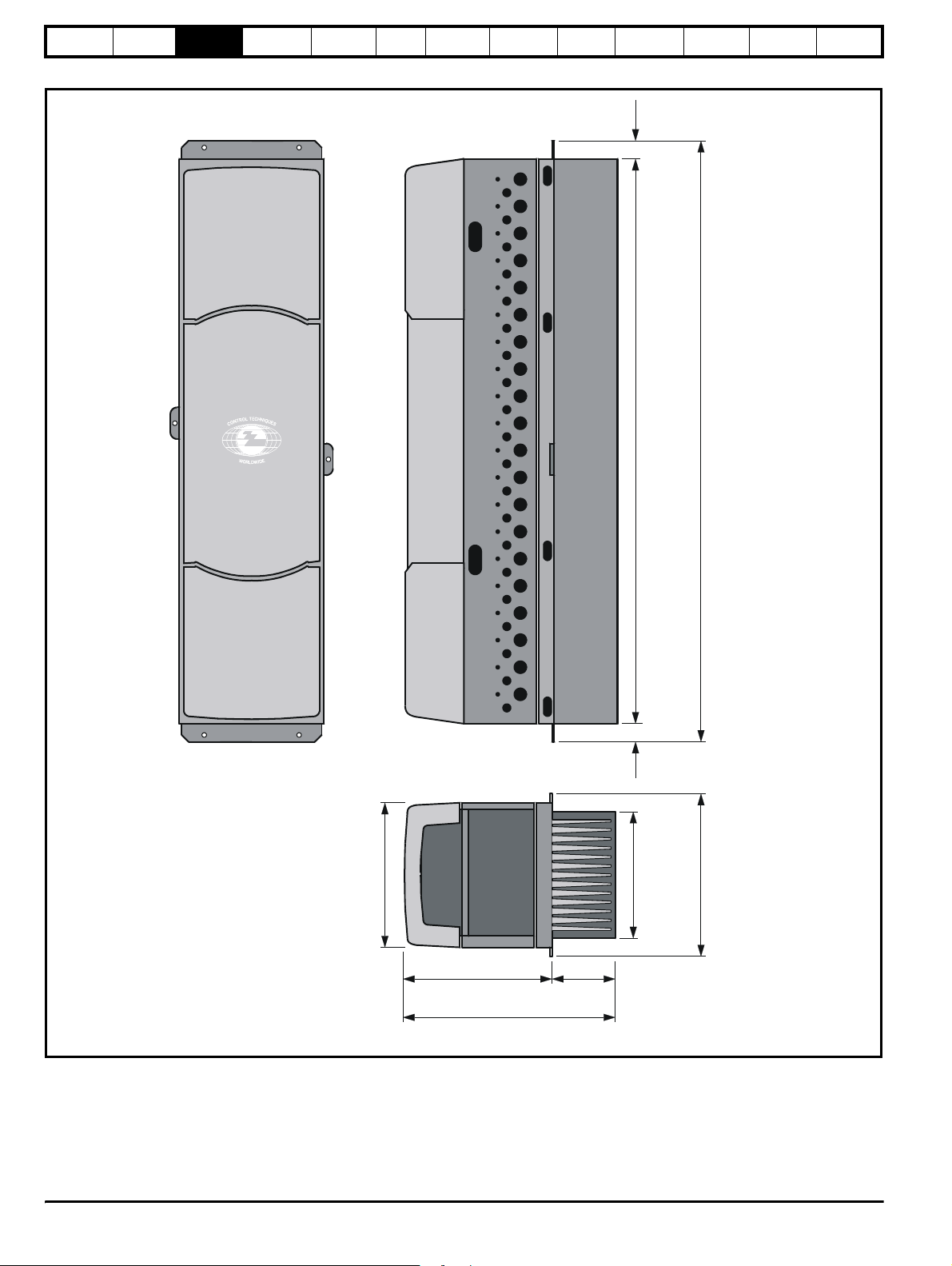

Figure 3-8 Through-panel mounting of model sizes 1 and 2

Model

size 1

Running

the motor

Optimisation Macros

ate

Advanced

Parameters

Technical

Data

Diagnostics

UL Listing

Information

Model

size 2

7.480in

3.740in

13.189in

13.189in

14.331in

14.331in

7.874in

4.724in

3.150

in

11.614in 13.583in

0.512in

3.406in

0.650in

Back-plate

11.614in 13.583i

0.512in

0.650in

7.165in

NOTE

N

When drives are through-panel mounted, a baffle plate is required to

ensure the correct level of air-flow is maintained through the heatsink.

For further information, please refer to section 3.9 Baffle plates on

page 28.

18 Unidrive User Guide

www.controltechniques.com Issue Number: 9

Page 19

Safety

8.9

Information

Product

Information

Mechanical

Installation

Electrical

Information

Getting

Star ted

Menu 0

Figure 3-9 Through-panel mounting of model sizes 3 and 4

Running

the motor

Optimisation Macros

Advanced

Parameters

Technical

Data

Diagnostics

UL Listing

Information

Model

size 3

Model

size 4

14.764in

13.189in 14.331in

10.236in

4.724in 5.512in

Back-plate

11. 299 in

0.276in0.630

0.138in 2.559in

0.650in

in

5.177in 7.362in

0.650in

13.583in

2.717in2.717in

14.094in

27.559in 29.252in

19.685in

NOTE

N

When drives are through-panel mounted, a baffle plate is required to

ensure the correct level of air-flow is maintained through the heatsink.

For further information, please refer to section 3.9 Baffle plates on

page 28.

25.591in 28.248in

Back-plate

0.295in

0.669in

5.118in 5.118in

7.559in 9.902in

1

72in

Unidrive User Guide 19

Issue Number: 9 www.controltechniques.com

Page 20

Safety

)

Information

Product

Information

Mechanical

Installation

Electrical

Installation

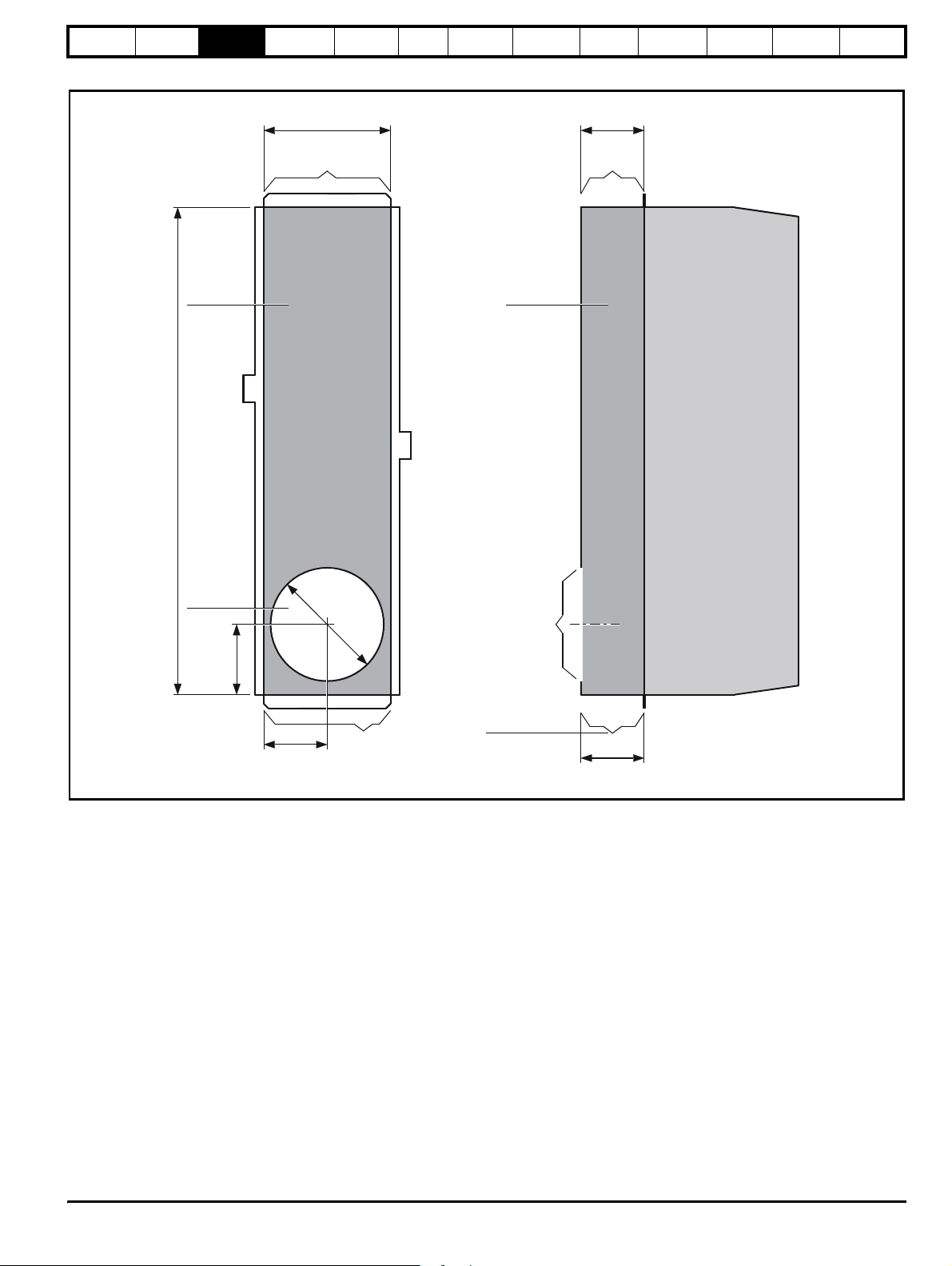

Figure 3-10 Unidrive Size 5 overall dimensions

Getting

Star ted

Menu 0

Running

the motor

Optimisation Macros

35.5mm

(1.398in)

Advanced

Parameters

Technical

Data

Diagnostics

UL Listing

Information

315mm

(12.402in)

1248mm

(49.134in)

35.5mm

(1.398in)

278mm

(10.945in)

1319mm

(51.926in)

355mm

(13.976in

340mm

(13.386in)

484mm

(19.055in)

144mm

(5.669in)

20 Unidrive User Guide

www.controltechniques.com Issue Number: 9

Page 21

Safety

(

Information

Product

Information

Mechanical

Installation

Electrical

Information

Getting

Star ted

Figure 3-11 Unidrive Size 5 mounting dimensions

Menu 0

Running

the motor

Optimisation Macros

Advanced

Parameters

Technical

Data

Diagnostics

UL Listing

Information

Rear view of

power module

Heatsink

duct

1248mm

(49.134in)

278mm

(10.945in)

Exhaust port

Heatsink

duct

144mm

(5.669in)

Exhaust

port

Side view of

power module

Inlet port

(internal fan)

154mm

(6.063in)

139mm

(5.472in)

256mm

(10.079in)

Inlet port

(external fan)

Inlet port

(internal fan)

Alternative

inlet port

(external fan)

144mm

5.669in)

Unidrive User Guide 21

Issue Number: 9 www.controltechniques.com

Page 22

Safety

∅

0.433

m

20

Information

Product

Information

Mechanical

Installation

Electrical

Installation

Getting

Star ted

Menu 0

Running

the motor

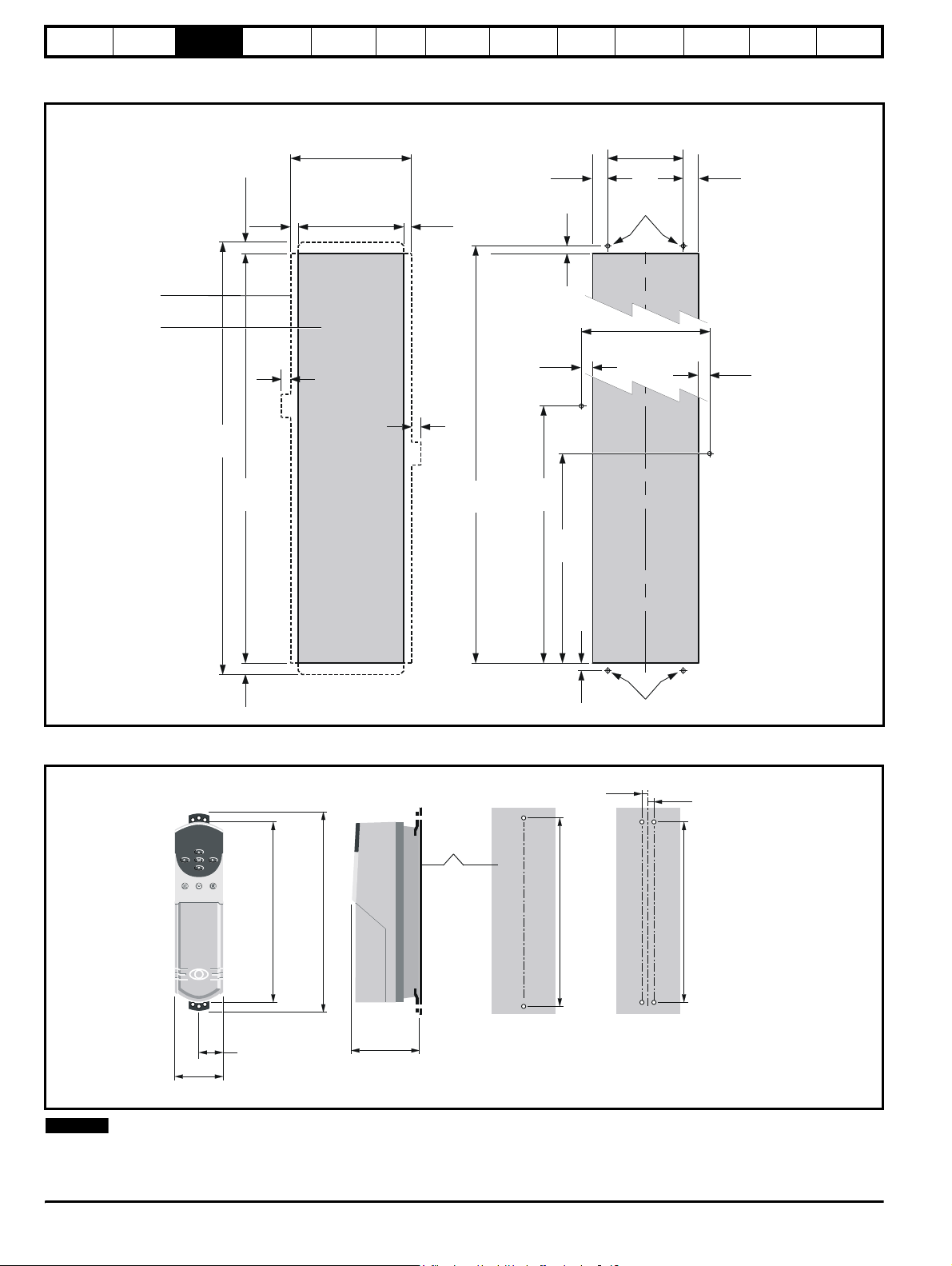

Figure 3-12 Unidrive size 5 backplate mounting holes and aperture

Optimisation Macros

Advanced

Parameters

Technical

Data

Diagnostics

UL Listing

Information

Outline of

the power

module

Aperture

Location of aperture in relation to

the outline of the power module

16.5mm

33.5mm

0.650in

1.319in

20mm

0.787in

1319mm

51.929in

1252mm

49.291in

315mm

12.402in

282mm

11.102in

16.5mm

0.650in

20mm

0.787in

1286mm

50.630in

Locations and dimensions of the

mounting holes in relation to the aperture

203mm

7.992in

∅

11m m

0.433in

339mm

13.346in

23.5mm

0.925in

28.5mm

1.122in

670mm

26.378in

37.5mm

1.476in

∅

8mm

0.315in

590mm

23.228in

37.5mm

1.476in

28.5m

1.122in

8mm

∅

0.315in

33.5mm

1.319in

Figure 3-13 Unidrive Size 5 control module surface mounting

Back-plate

NOTE

335mm

(13.189in)

47.5mm

(1.870in)

95mm

(3.740in)

N

368mm

(14.488in)

143mm

(5.630in)

The Unidrive size 5 control module should be located within 2m of the

power module to allow the interconnections to be made using the ribbon

cables supplied with the power module.

10mm

0.413in

(0.787in)

345mm

(13.583in)

mm

11m m

in

20mm

(0.787in)

332mm

(13.071in)

22 Unidrive User Guide

www.controltechniques.com Issue Number: 9

Page 23

Safety

Information

Product

Information

Mechanical

Installation

Electrical

Information

Getting

Star ted

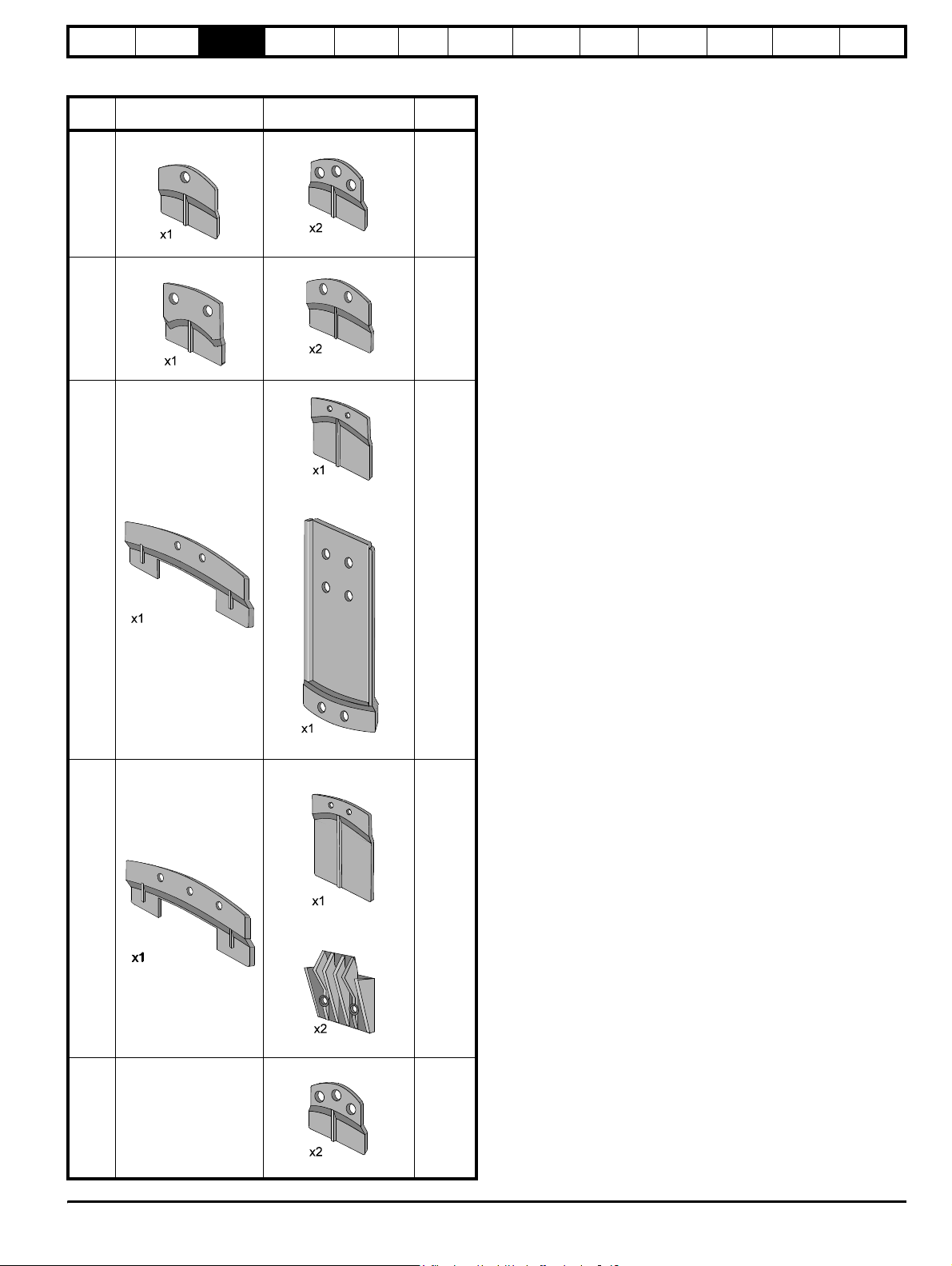

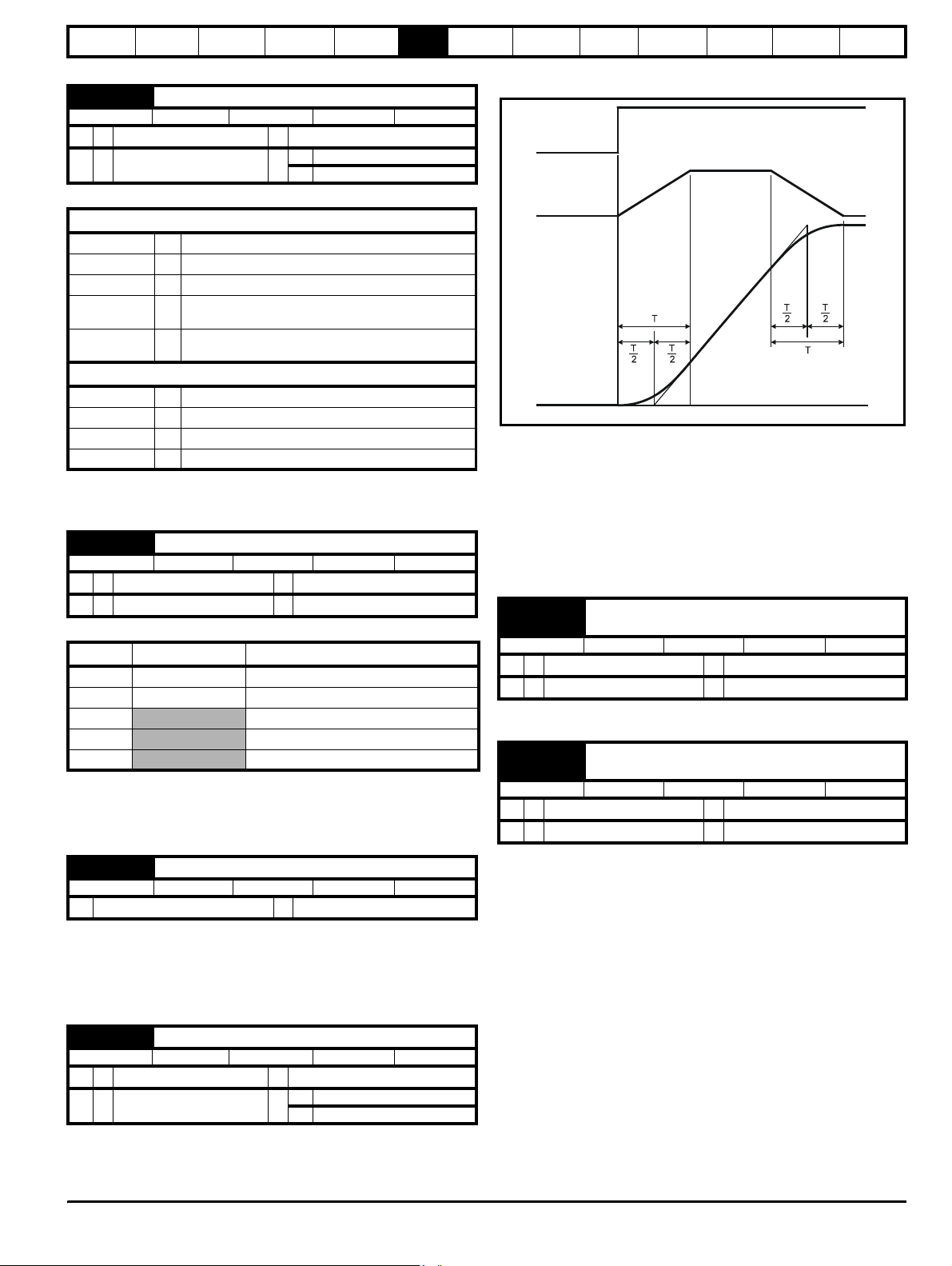

Table 3-1 General views of the mounting brackets

Menu 0

Running

the motor

Optimisation Macros

Advanced

Parameters

Technical

Data

Diagnostics

UL Listing

Information

Model

size

1

2

3

Through-panel Surface Hole size

M6

Upper and lower

M6

Upper and lower

Upper

M6

Lower

M6

(through-

panel)

4

Upper

M8

(surface)

Lower

5

M6

Upper and lower

Unidrive User Guide 23

Issue Number: 9 www.controltechniques.com

Page 24

Safety

m

Information

Product

Information

Mechanical

Installation

Electrical

Installation

Getting

Star ted

Menu 0

Running

the motor

3.7 Enclosure

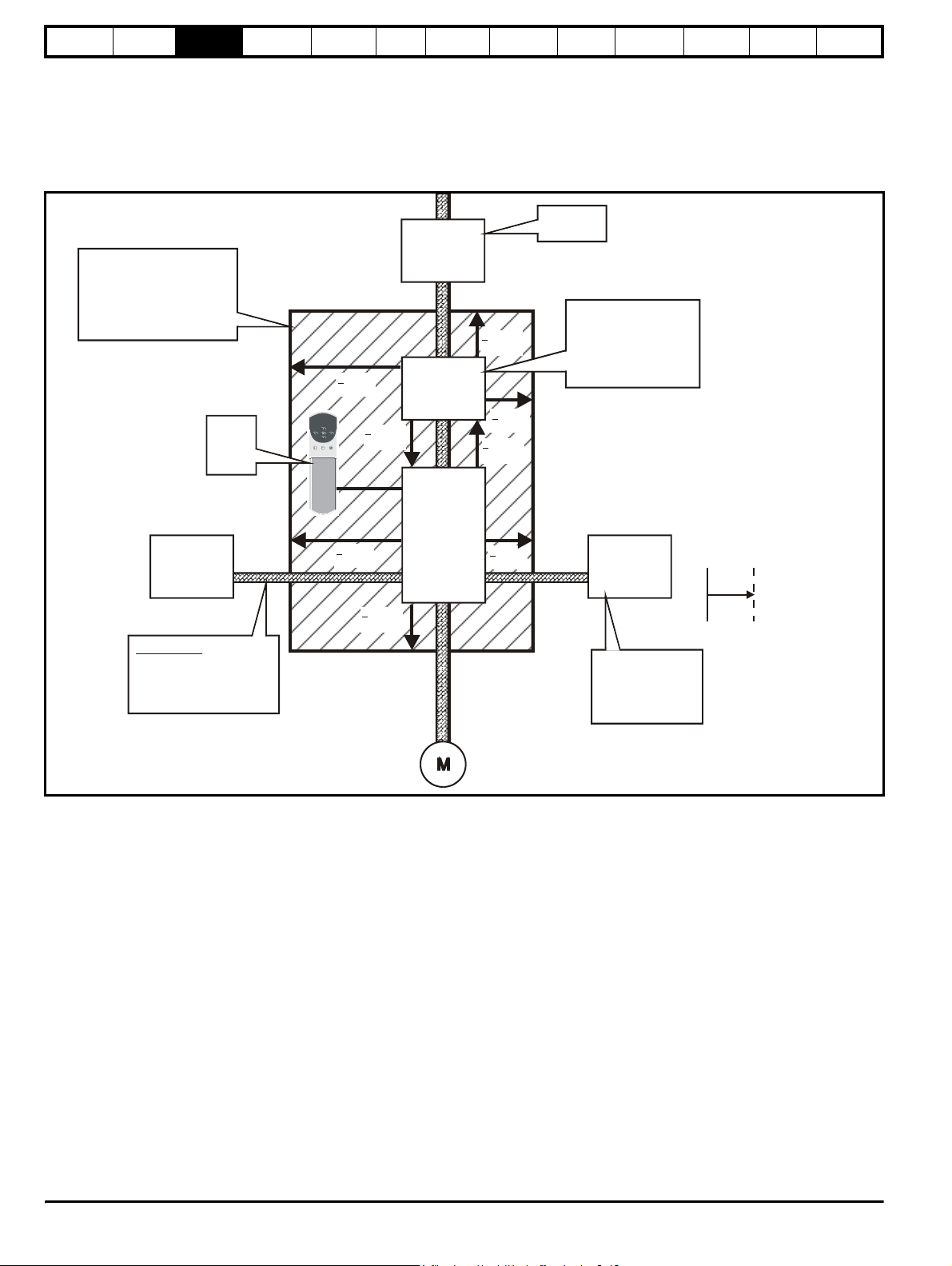

3.7.1 Enclosure Layout

Please observe the clearances in the diagram below taking into account

any appropriate notes for other devices / auxiliary equipment when

planning the installation.

Figure 3-14 Enclosure layout

AC supply

> 100mm

(3.937in)

contactor and

fuses or MCB

Optional

RFI filter

Ensure minimum clearances

are maintained for the

drive and RFI filter

Forced or convection air-flow

must not be restricted by any

object or cabling

Control

module

(size 5

only)

> 5mm

(0.197in)

Optimisation Macros

Locate

as required

> 100mm

(3.937in)

> 5mm

(0.197in)

> 100mm

(3.937in)

Advanced

Parameters

Locate as close to

the drive as possible

(to keep the cable

as short as possible)

respecting the minimum

clearances

Technical

Data

Diagnostics

Note: for EMC compliance

1) A separate RFI filter is

required for each drive

2) Power cabling must be

at least 100mm (4in) from

the drive in all directions

UL Listing

Information

Drive

> 5mm

Controller

Signal cables

Plan for all signal cables

to be routed at least

300mm (12in) from the drive

and any power cable

(0.197in)

> 100mm

(3.937in)

3.7.2 Enclosure sizing

1. Add the dissipation figures from section 11.1.2 Power dissipation (all

versions) on page 191 for each drive that is to be installed in the

enclosure.

2. If an RFI filter is to be used with each drive, add the dissipation

figures from section 11.2.1 Ratings on page 197 for each RFI filter

that is to be installed in the enclosure.

3. If the braking resistor is to be mounted inside the enclosure, add the

average power figures for each braking resistor that is to be installed

in the enclosure.

4. Calculate the total heat dissipation (in Watts) of any other equipment

to be installed in the enclosure.

5. Add the heat dissipation figures obtained above. This gives a figure

in Watts for the total heat that will be dissipated inside the enclosure.

Note: Footprint RFI filters

are available for Unidrive

> 5mm

(0.197in)

Optional

braking resistor

and overload

Locate resistor

external to cubicle

(preferably near to

or at the top of the

cubicle)

frame sizes 1 and 2

Indicates minimu

clearance required

from device

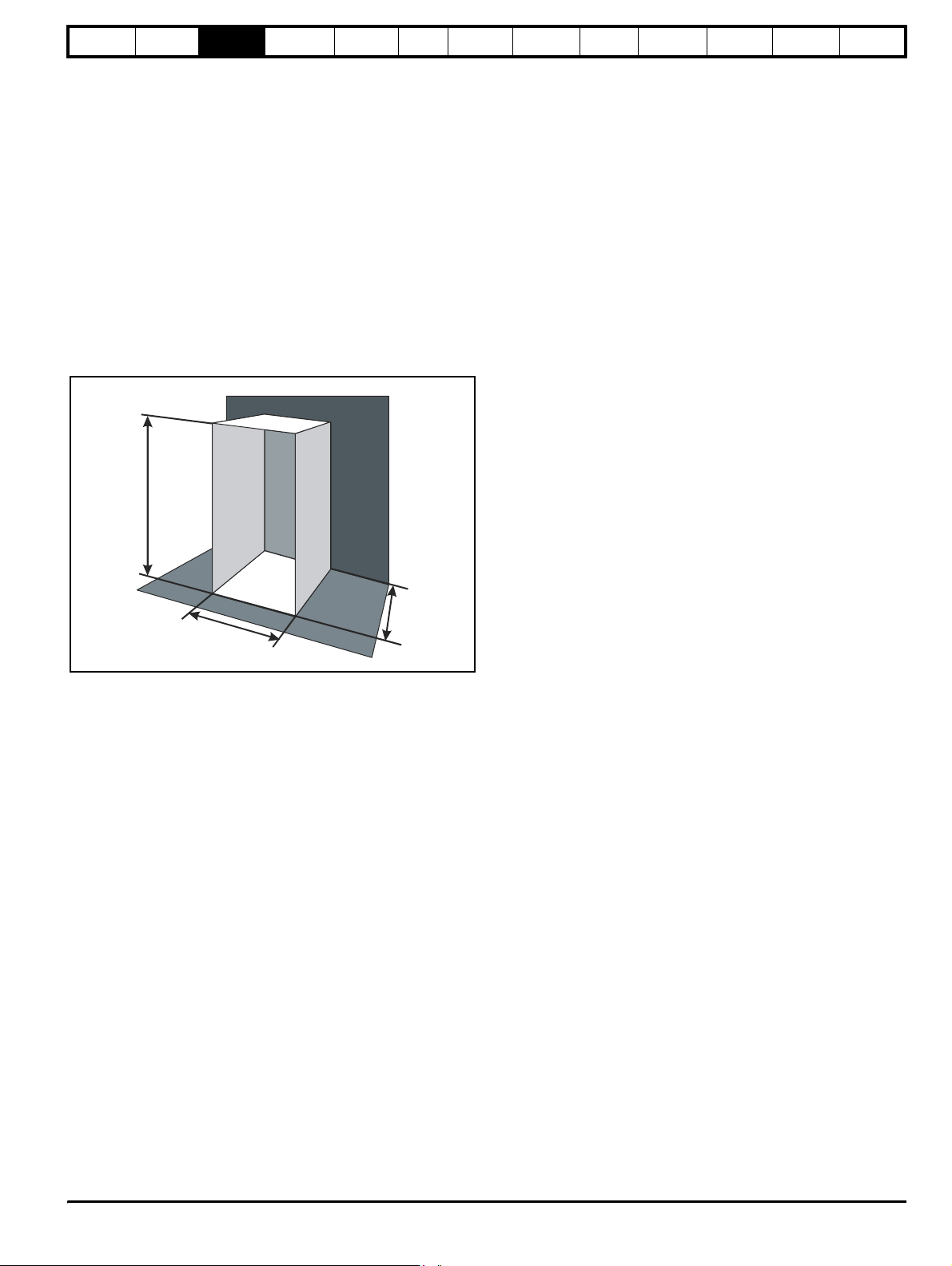

Calculating the size of a sealed enclosure

The enclosure transfers internally generated heat into the surrounding

air by natural convection (or external forced air flow); the greater the

surface area of the enclosure walls, the better is the dissipation

capability. Only the surfaces of the enclosure that are unobstructed (not

in contact with a wall or floor) can dissipate heat.

Calculate the minimum required unobstructed surface area A

enclosure from:

e

–()

kT

intText

P

-----------------------------------

A

=

Where:

A

Unobstructed surface area in m2 (1m2 = 10.8 ft2)

e

T

Maximum expected ambient temperature in

ext

enclosure

Maximum permissible ambient temperature in oC inside the

T

int

enclosure

P Power in Watts dissipated by all heat sources in the

enclosure

k Heat transmission coefficient of the enclosure material

2/o

in Wm

C

for the

e

o

C outside the

24 Unidrive User Guide

www.controltechniques.com Issue Number: 9

Page 25

Safety

Information

Product

Information

Mechanical

Installation

Electrical

Information

Getting

Star ted

Menu 0

Example

To calculate the size of an enclosure for the following:

• Two UNI1405 models

• Each drive to operate at 4.5kHz PWM switching frequency

• RFI filter for each drive

• Braking resistors are to be mounted outside the enclosure

• Maximum ambient temperature inside the enclosure: 40°C

• Maximum ambient temperature outside the enclosure: 30°C

Dissipation of each drive: 190W

Dissipation of each RFI filter: 7.7W (max)

Total dissipation: 2 x (190 + 7.7) = 395.4W

The enclosure is to be made from painted 2mm (0.079 in) sheet steel

having a heat transmission coefficient of 5.5W/m

2/o

C. Only the top, front,

and two sides of the enclosure are to be free to dissipate heat.

Figure 3-15 Enclosure having front, sides and top panels free to

dissipate heat

Running

the motor

Optimisation Macros

Advanced

Parameters

Technical

Data

Diagnostics

Calculating the air-flow in a ventilated enclosure

The dimensions of the enclosure are required only for accommodating

the equipment. The equipment is cooled by the forced air flow.

Calculate the minimum required volume of ventilating air from:

3kP

---------------------------

=

V

Where:

V Air-flow in m

T

ext

T

int

P Power in Watts dissipated by all heat sources in the

k Ratio of

Where:

Typically use a factor of 1.2 to 1.3, to allow also for pressure-drops in

dirty air-filters.

–

T

intText

3

per hour

Maximum expected ambient temperature in

enclosure

Maximum permissible ambient temperature in oC inside the

enclosure

enclosure

P

o

-------

P

l

P

is the air pressure at sea level

0

is the air pressure at the installation

P

I

UL Listing

Information

o

C outside the

H

D

W

Insert the following values:

T

40°C

int

30°C

T

ext

k 5.5

P 395.4W

The minimum required heat conducting area is then:

395.4

---------------------------------

A

=

e

5.5 40 30–()

2

=7.2m

(78ft2) (1m = 3.3 ft)

Estimate two of the enclosure dimensions - the height (H) and depth (D),

for instance. Calculate the width (W) from:

2HD–

A

e

--------------------------

=

W

HD+

Inserting H = 2m and D = 0.6m, obtain the minimum width:

7.2 2 2× 0.6×()–

----------------------------------------------

W

=

20.6+

= 1.8m (6ft)

If the enclosure is too large for the space available, it can be made

smaller only by attending to one or all of the following:

• Using a lower PWM switching frequency to reduce the dissipation in

the drives

• Reducing the ambient temperature outside the enclosure, and/or

applying forced-air cooling to the outside of the enclosure

• Reducing the number of drives in the enclosure

• Removing other heat-generating equipment

Example

To calculate the size of an enclosure for the following:

• Three UNI3401 models

• Each drive to operate at 6kHz PWM switching frequency

• RFI filter for each drive

• Braking resistors are to be mounted outside the enclosure

• Maximum ambient temperature inside the enclosure: 40

• Maximum ambient temperature outside the enclosure: 30

Dissipation of each drive: 670W

Dissipation of each RFI filter: 12.8W (max)

Total dissipation: 3 x (670 + 60) = 2048.4W

Insert the following values:

T

40°C

int

30°C

T

ext

k 1.3

P 2048.4W

Then:

31.3× 2048.4×

------------------------------------------

V

=

40 30–

3

/ hr (471ft3 / min)

3

/min)

(1m

= 799m

3

/ hr = 0.59ft

o

C

o

C

Unidrive User Guide 25

Issue Number: 9 www.controltechniques.com

Page 26

Safety

Information

Product

Information

Mechanical

Installation

Electrical

Installation

Getting

Star ted

Menu 0

Running

the motor

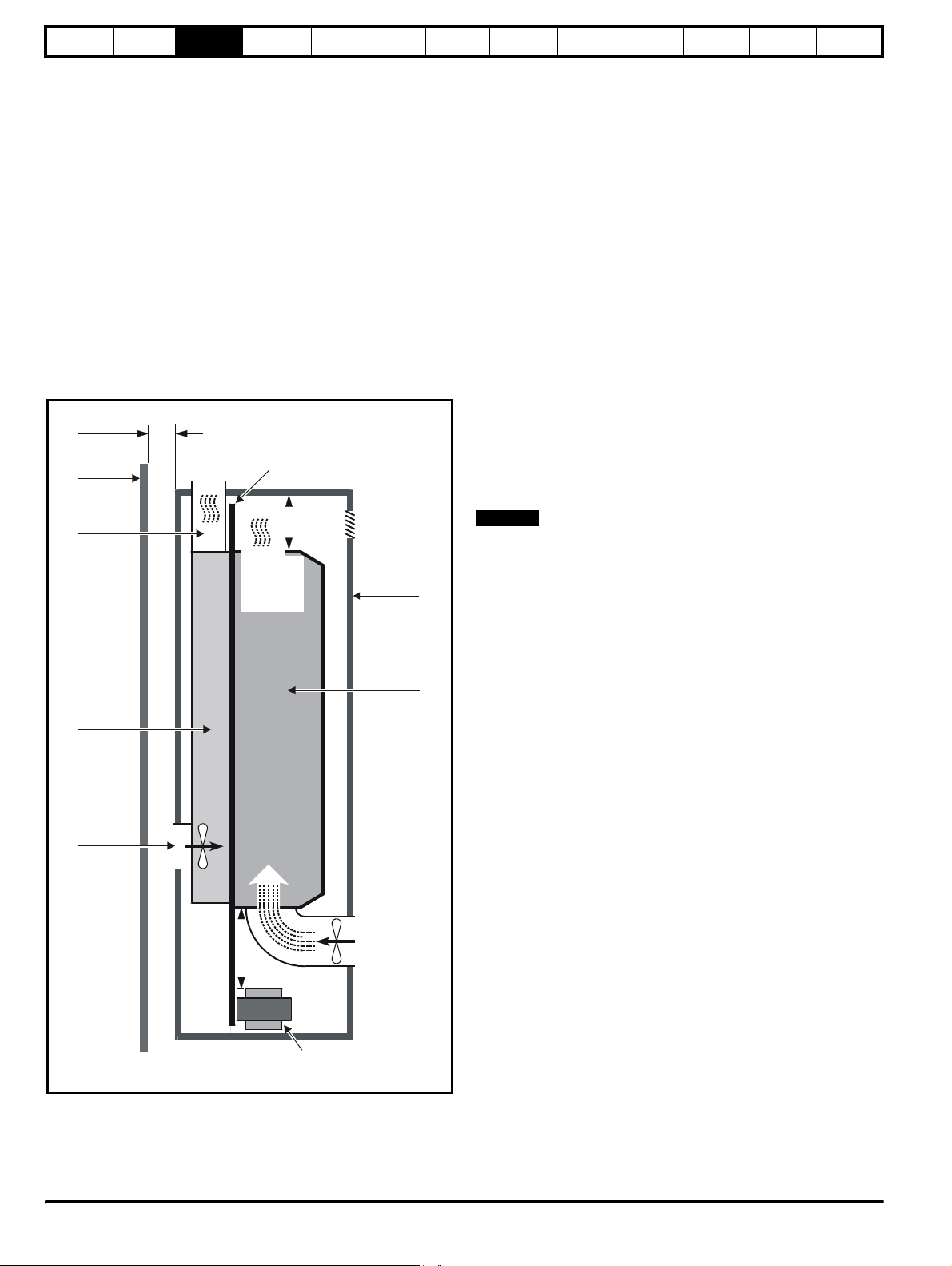

3.8 Ventilation

Unidrive sizes 1-4 are ventilated by internally supplied heatsink fans.

Ensure the minimum clearances around the drive are maintained to

allow air to flow freely.

The Unidrive size 5 requires ventilation at the front (control) and rear

(heatsink) of the module.

Two parallel independent paths must be provided as shown to ensure

the heat produced is dispersed.

A heatsink fan is fitted as standard on request however this requires

either a 110Vac or 240Vac external single phase power supply to be

connected at the bottom left hand corner of the power module.

The choice of fan power supply must be made when ordering the power

module.

3.8.1 Ventilation requirements for the Size 5 power

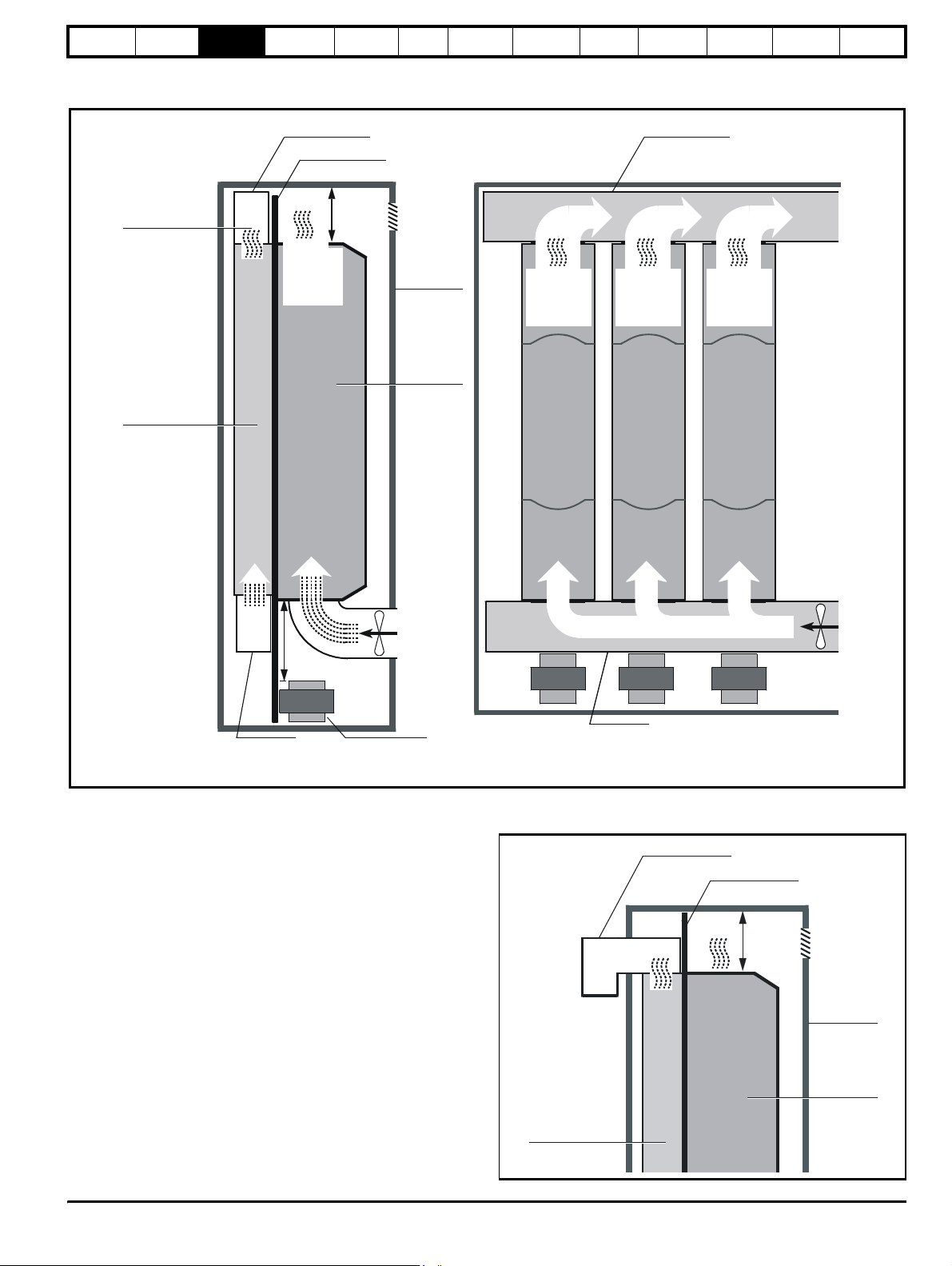

Figure 3-16 Typical ventilation arrangement using the internal

module

≥

300mm

(12 in)

Wall

heatsink fan

3

≥

1000m /hr

3

(588ft /min)

≥

7 m/s (23 ft/s)

Back-plate

Optimisation Macros

Advanced

Parameters

Technical

Data

Diagnostics

UL Listing

Information

If a fan is not fitted internally, the air flow must be obtained by an external

fan and ducting. The blanking plate at the lower end of the duct must be

removed in order to expose the inlet port (see Figure 3-17).

The air supply must be obtained from outside the enclosure and the

exhaust air must exit the enclosure. The maximum permissible heatsink

temperature is 95°C (203°F). Take the following precautions to help

ensure this is not exceeded:

1. Ensure the temperature of the air at the inlet port of the heatsink

does not exceed 40°C (104°F).

2. Ensure that the upward flow of the exhaust air from the top of the

heatsink will be unobstructed. Fit additional ducting having the same

cross-sectional area as the heatsink to extract all the exhaust air

from the enclosure.

3. Ensure the volume of the exhaust air is not less than 1,000m

3

/min), equivalent airspeed 7m/s (23 ft/s). Measure the air-flow

(588ft

3

/hr

to ensure it is adequate.

4. If the power module has a ventilation fan fitted in the heatsink, to

ensure that a sufficient amount of air is available to supply the fan,

locate the enclosure at least 300mm (12 in) from a wall or large

object that will be behind the enclosure. Fit a duct between the rear

panel of the enclosure and the inlet port at the rear of the heatsink.

If the power module does not have an internal fan, a forced air-flow

must be ducted into the inlet port at the bottom of the heatsink.

5. Ensure that the exhaust air is not recycled into the inlet port of the

heatsink or into the enclosure.

Exhaust

duct

Heatsink

Inlet duct

3

400m /hr

≥

3

(235 ft /min)

1 m/s

≥

(3.3 ft/s)

≥

150mm (6 in)

≥

150mm

(6 in)

Vent

Enclosure

Power

module

Fan for

cooling the

control

section

NOTE

N

The solutions shown for Unidrive size 5 ventilation are to illustrate the

important points which must be considered. Many variations of this are

possible to suit the specific site conditions.

Sharing choke

(for parallel

operation only)

Cooling the heatsink

When designing the cooling system, allow for the rear of the power

module to produce 4kW of heat. This heat is dissipated in a heatsink that

is inside a vertical duct at the rear of the power module. Forced air-flow

is required through the duct in order to cool the heatsink.

26 Unidrive User Guide

www.controltechniques.com Issue Number: 9

Page 27

Safety

Exh

Exh

≤

Information

Product

Information

Mechanical

Installation

Electrical

Information

Getting

Star ted

Menu 0

Figure 3-17 Typical ventilation arrangement using an external

heatsink fan

Running

the motor

Optimisation Macros

Advanced

Parameters

Technical

Data

Diagnostics

UL Listing

Information

≥

1000m /hr

3

(588ft /min)

≥

7 m/s

(23 ft/s)

Heatsink

aust duct

aust duct

Back-plate

3

≥

3

400m /hr

≥

3

(235 ft /min)

1 m/s

≥

(3.3 ft/s)

150mm

(6 in)

Vent

Enclosure

module

Power

≥

1000m /hr

3

(588ft /min)

≥

7 m/s

(23 ft/s)

3

3

≥

1000m /hr

3

(588ft /min)

≥

7 m/s

(23 ft/s)

≥

1000m /hr

(588ft /min)

≥

7 m/s

(23 ft/s)

3

3

Inlet duct

≥

150mm (6 in)

Fan for

cooling the

control

section

Sharing choke

(for parallel

operation only)

Cooling the control components in the Size 5 power module

The circuit boards, DC-bus capacitors, etc., in the front part of the power

module generate about 700W of heat when the power module is

operating at full load. Since the heatsink fan does not ventilate these

components, a separate air-flow must be used to remove the heat. The

following precautions must be taken:

1. It is recommended that a fan is installed in the lower part of the

enclosure door to drive air into the enclosure. An air vent should be

added to the upper part of the door to remove the exhaust air.

2. It is recommended that the airflow is ducted into the front of the

drive. This airflow must be at least 400m

air speed of 1m/s (3.3ft/s) through the front control section of the

size 5 power module.

If the airflow is not ducted into the front of the drive, the airflow into

the enclosure must be at least 1000m

speed of 7m/s (23ft/s) for a enclosure of 800mm x 800mm

x 2200mm.

3. The maximum temperature of the air in the enclosure must not

exceed 40°C (104°F).

3

/hr (235ft3/min), equivalent

3

/hr (588ft3/min), equivalent air

0

40 C

0

(104 F)

Inlet duct

Inlet duct

Figure 3-18 Alternative location of the exhaust duct in order to

minimize overall height

Exhaust duct

Back-plate

≥

150mm

(6 in)

Vent

Enclosure

Power

module

Heatsink

Unidrive User Guide 27

Issue Number: 9 www.controltechniques.com

Page 28

Safety

0.256

Information

Product

Information

Mechanical

Installation

Electrical

Installation

Getting

Star ted

Menu 0

Running

the motor

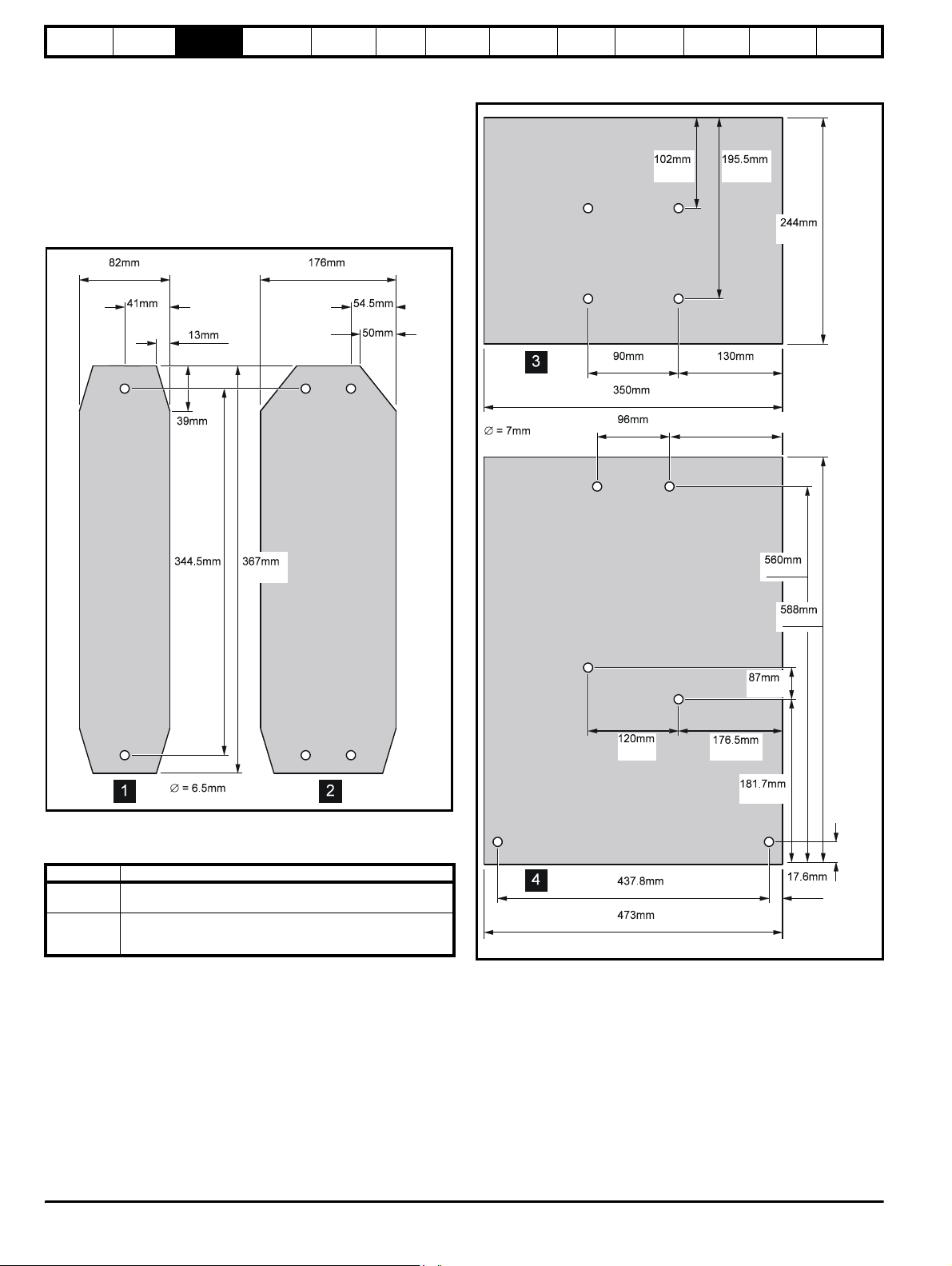

3.9 Baffle plates

When a Unidrive size 1 to 4 is through-panel mounted, the fitting of a

baffle plate causes the heatsink to act as a chimney; this enhances the

air flow along the heatsink fins to aid cooling (this naturally occurs when

the drive is surface mounted).

You may make a baffle plate from any suitable conducting or nonconducting material and attach it to the heatsink by the method

described as follows.

Figure 3-19 Dimensions for the fabrication of baffle plates for

model sizes 1 and 2

3.228in 6.929in

Optimisation Macros

Advanced

Parameters

Technical

Data

Diagnostics

UL Listing

Information

Figure 3-20 Dimensions for the fabrication of baffle plates for

model sizes 3 and 4

4.016in 7.697in

9.606in

1.614in

0.512in

1.535in

13.563in 14.449in

2.146in

1.969

in

0.276in

3.583in 5.118in

13.780in

189.5mm

3.780in

4.724in

7.461in

6.949in

22.047in

23.150in

3.425in

in

7.154in

Attaching a fabricated baffle plate to the heatsink

Table 3-2 Methods of attaching the baffle plate

Model size Method of attachment

1

2

3

4

Use M6 x 12mm max (or equivalent) thread-forming screws to

screw into the holes in the heatsink, or tap the holes to a suitable

Use the surface mounting brackets.

thread size.

17.236in

18.622in

0.693in

76mm

2.992in

3.10 Ambient temperature

The maximum ambient temperature under which the drive can operate

without derating is 40°C.

Derating can be applied to allow operation up to 50°C ambient

temperature.

Please see section 11.1.1 Power and current ratings on page 190 if

derating is required.

28 Unidrive User Guide

www.controltechniques.com Issue Number: 9

Page 29

Safety

Information

Product

Information

Mechanical

Installation

Electrical

Information

Getting

Star ted

Menu 0

Running

the motor

Optimisation Macros

Advanced

Parameters

Technical

Data

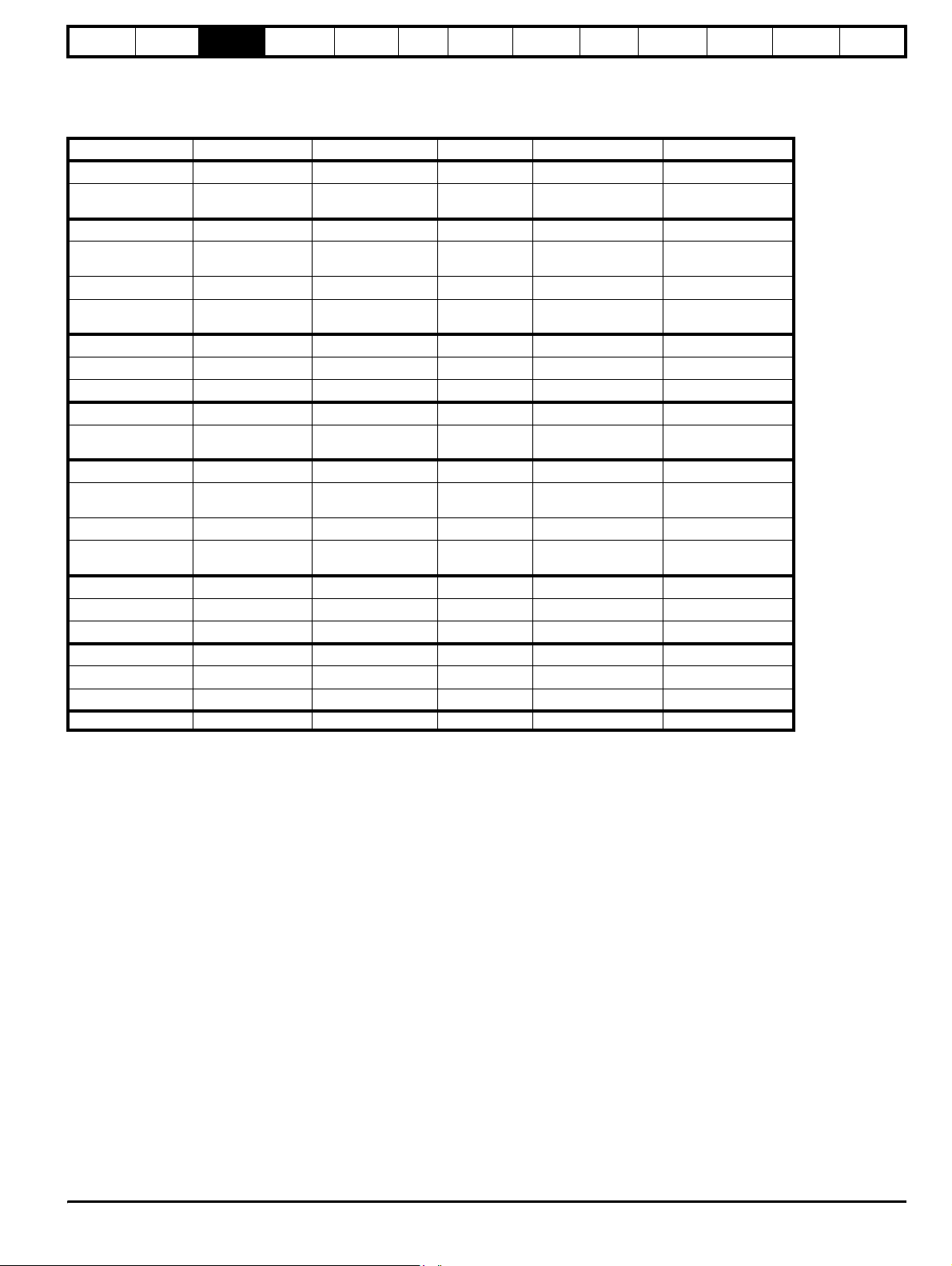

3.11 RFI filters

RFI filters are available for all sizes of Unidrive as follows:

Table 3-3 RFI filters

Drive Filter type Schaffner part no. CT part no. Max cable size Weight

UNI1201 to 1205 Bookcase FS5111-10-29 4200-6105

UNI1201 to 1205

Footprint or

Bookcase

FS5101-10-07 4200-6104

UNI2201 to 2202 Bookcase FS5112-16-07 4200-6109

UNI2201 to 2202

Footprint or

Bookcase

FS5106-16-07 4200-6108

UNI2203 Bookcase FS5113-25-29 4200-6114

UNI2203

Footprint or

Bookcase

FS5106-25-07 4200-6113

UNI3201 to 3202 Bookcase FS5113-50-53 4200-6116

UNI3203 Bookcase FS5113-63-34 4200-6117

UNI3204 Bookcase FS5113-100-35 4200-6106

UNI1401 to 1405 Bookcase FS5111-10-29 4200-6105

UNI1401 - 1405

Footprint or

Bookcase

FS5101-10-07 4200-6104

UNI2401 Bookcase FS5112-16-07 4200-6109

UNI2401

Footprint or

Bookcase

FS5106-16-07 4200-6108

UNI2402 to 2403 Bookcase FS5113-25-29 4200-6114

UNI2402 to 2403

Footprint or

Bookcase

FS5106-25-07 4200-6113

UNI3401 to 3403 Bookcase FS5113-50-53 4200-6116

UNI3404 Bookcase FS5113-63-34 4200-6117

UNI3405 Bookcase FS5113-100-35 4200-6106

UNI4401 to 4402 Bookcase FS5113-150-40 4200-6107

UNI4403 to 4404 Bookcase FS5113-180-40 4200-6111

UNI4405 Bookcase FS5113-220-37 4200-6112

4 mm

4 mm

4 mm

4 mm

4 mm

4 mm

10 mm

10 mm

50 mm

4 mm

4 mm

4 mm

4 mm

4 mm

4 mm

10 mm

10 mm

50 mm

95 mm

95 mm

150 mm

2

10 AWG

2

10 AWG

2

10 AWG

2

10 AWG

2

10 AWG

2

10 AWG

2

6 AWG

2

6 AWG

2

1/0 AWG

2

10 AWG

2

10 AWG

2

10 AWG

2

10 AWG

2

10 AWG

2

10 AWG

2

6 AWG

2

6 AWG

2

1/0 AWG

2

4/0 AWG

2

4/0 AWG

2

6/0 AWG

UNI5401 Bookcase FS113-300-99 4200-6115 M12 stud 16kg (35lb)

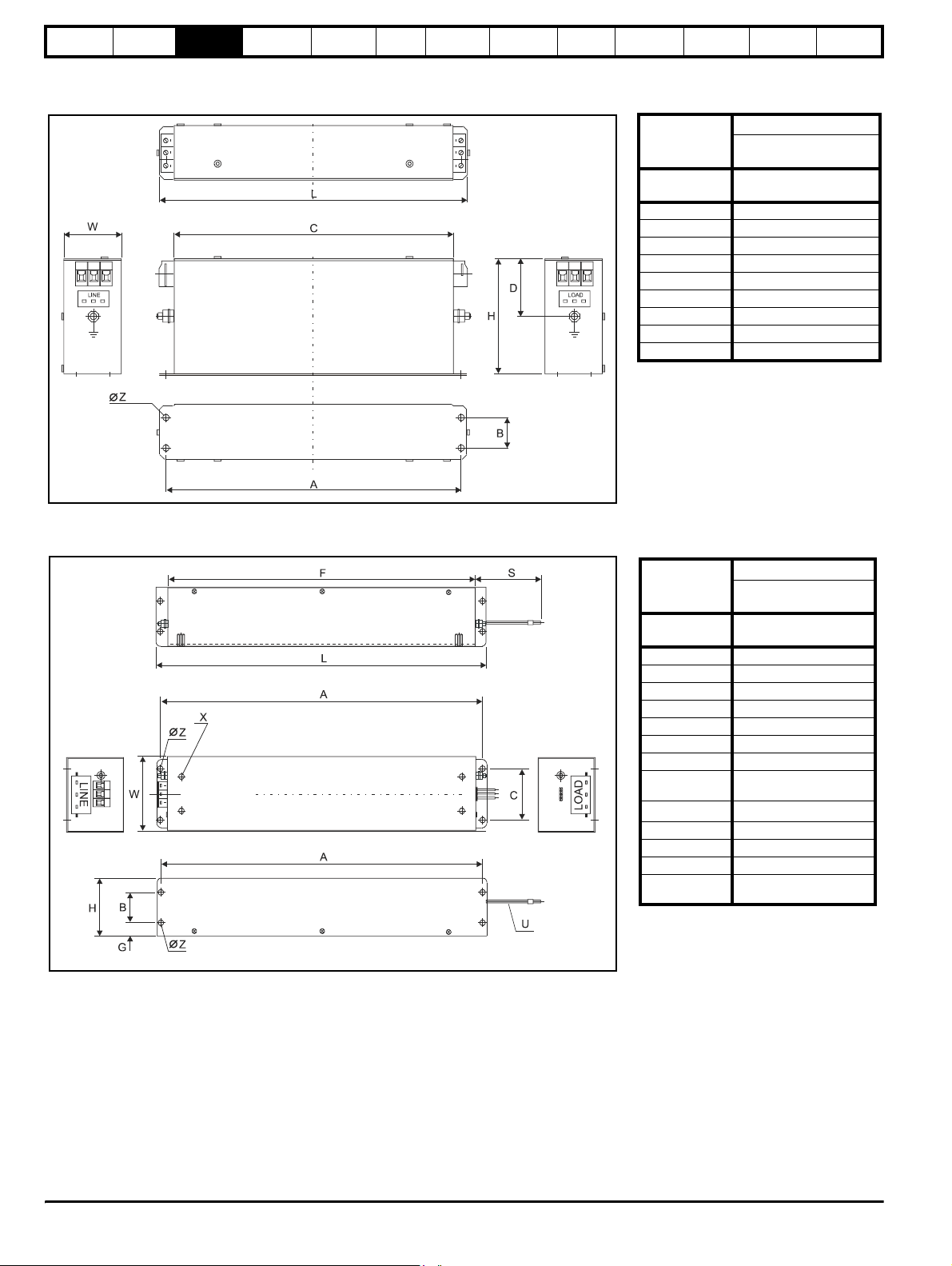

The RFI filters can be surface-mounted only.

Mount the RFI filter following the guidelines in Figure 4-12 EMC

compliance on page 48.

1.4kg (3lb)

2.1kg (5lb)