Page 1

Installation Guide

Universal Variable Speed Drive

for induction and servo motors

0.37kW to 22kW

(0.5HP to 30HP)

Part Number: 0460–0037

Issue Number: 1

Unidrive

LV

Unidrive VTC

Unidrive LFT

model sizes 1 to 3

LV

LV

Page 2

General information

The manufacturer accepts no liability for any

consequences resulting from inappropriate ,

negligent or incorrect installation or adjustment of

the optional operating parameters of the equipment

or from mismatching the variable speed drive

(Drive) with the motor.

The contents of this User Guide are believed to be

correct at the time of printing. In the interests of a

commitment to a policy of continuous development

and improvement, the manufacturer reserves the

right to change the specification of the product or

its performance, or the contents of the User Guide,

without notice.

All rights reserved. No parts of this User Guide may

be reproduced or transmitted in any form or by any

means, electrical or mechanical including

photocopying, recording or by any informationstorage or retrieval system, without permission in

writing from the publisher.

Important...

Drive software version

This product is supplied with the latest version of

user-interface and machine-control software. If this

product is to be used with other Control Techniques

variable speed drives in an existing system, there

may be some differences between their software

and the software in this product. These differences

will cause a difference in functions. This may also

apply to variable speed drives returned from a

Control Techniques Service Centre.

If there is any doubt, contact a Control Techniques

Drive Centre.

Copyright © September 1999 Control Techniques Drives Ltd

Author: RFD

Issue Code: uliu1

Issue Date: September 1999

S/W Version: 03.XX.XX

Page 3

Contents

Chapter

1 Safety Information 1-1

1.1 Warnings, Cautions and Notes 1-1

1.2 Electrical safety – general warning 1-1

1.3 System design 1-1

1.4 Environmental limits 1-1

1.5 Compliance with regulations 1-1

1.6 Safety of personnel 1-1

1.7 Risk analysis 1-2

1.8 Motor 1-2

1.9 Adjusting parameters 1-2

2 Installing the Drive 2-1

2.1 Environmental requirements 2-1

2.2 EMC considerations 2-2

2.3 Planning the installation 2-3

2.4 Calculating the enclosure size 2-14

Appendix

A Motor Connections A-1

A.1 Cable length A-1

A.2 Multiple motors A-1

B UL Listing Information B-1

C Data C-1

C.1 Drive C-1

C.2 Optional RFI filters C-6

2.5 Installing the Drive and RFI filter 2-16

2.6 Power connections 2.27

2.7 Wiring recommendations 2-30

2.8 Variations in the EMC wiring

recommendations 2-36

2.9 Signal connections 2-37

Unidrive LV model sizes 1 to 3 Installation Guide

Issue code: uliu1

i

Page 4

Declaration of Conformity

Control Techniques plc

The Gro

Newtown

Powys

UK

SY16 3BE

UNI1201 UNI1202 UNI1203 UNI1204 UNI1205

UNI2201 UNI2202 UNI2203

UNI3201 UNI3202 UNI3203 UNI3204

The AC variable speed drive products listed above,

including the VTC and LFT variants, have been

designed and manufactured in accordance with the

following European harmonised, national and

international standards:

EN60249 Base materials for printed circuits

IEC326-1 Printed boards: general information for the

IEC326-5 Printed boards: specification for single- and

IEC326-6 Printed boards: specification for multilayer

IEC664-1 Insulation co-ordination for equipment

EN60529 Degrees of protection provided by

UL94 Flammability rating of plastic materials

UL508C Standard for power conversion equipment

EN50081-11Generic emission standard for the

EN50081-2 Generic emission standard for the industrial

EN50082-2 Generic immunity standard for the

EN61800-3 Adjustable speed electrical power drive

1

Conducted emission. See the relevant EMC Data

Sheet.

specification writer

double-sided printed boards with

plated-through holes

printed boards

within low-voltage systems: principles,

requirements and tests

enclosures (IP code)

residential, commercial and light industrial

environment

environment

industrial environment

systems – Part 3: EMC product standard

including specific test methods

These products comply with the Low Voltage

Directive 73/23/EEC, the Electromagnetic

Compatibility (EMC) Directive 89/336/EEC and the

CE Marking Directive 93/68/EEC.

W. Drury

Executive Vice President, Technology

Newtown

Date: 20th September 1999

These electronic Drive products are

intended to be used with appropriate

motors, controllers, electrical

protection components and other

equipment to form complete end

products or systems. Compliance with

safety and EMC regulations depends

upon installing and configuring Drives

correctly, including using the specified

input filters. The Drives must be

installed only by professional

assemblers who are familiar with

requirements for safety and EMC. The

assembler is responsible for ensuring

that the end product or system

complies with all the relevant laws in

the country where it is to be used.

Refer to the Installation Guide. A

Unidrive EMC Data Sheet is also available

giving detailed EMC information.

ii

Unidrive LV model sizes 1 to 3 Installation Guide

Issue code: uliu1

Page 5

1 Safety Information

1.1

Warnings, Cautions

and Notes

A Warning contains information which is essential

for avoiding a safety hazard.

A Caution contains information which is necessary

for avoiding a risk of damage to the product or

other equipment.

A Note contains information which helps to ensure

correct operation of the product.

1.2 Electrical safety –

general warning

1.4 Environmental limits

Instructions in this Installation Guide regarding

transport, storage, installation and use of Drives

must be complied with, including the specified

environmental limits. Drives must not be subjected

to excessive physical force.

1.5 Compliance with

regulations

The installer is responsible for complying with all

relevant regulations, such as national wiring

regulations, accident prevention regulations and

electromagnetic compatibility (EMC) regulations.

Particular attention must be given to the

cross-sectional areas of conductors, the selection of

fuses or other protection, and protective earth

(ground) connections.

This Installation Guide contains instructions for

achieving compliance with specific EMC standards.

The voltages used in the Drive can cause severe

electric shock and/or burns, and could be lethal.

Extreme care is necessary at all times when working

with or adjacent to the Drive.

Specific warnings are given at the relevant places in

this Installation Guide and the accompanying User

Guide.

The installation must comply with all relevant safety

legislation in the country of use.

1.3 System design

The Drive is intended as a component for

professional incorporation into complete equipment

or systems. If installed incorrectly the Drive may

present a safety hazard. The Drive uses high

voltages and currents, carries a high level of stored

electrical energy, and is used to control mechanical

equipment which can cause injury.

Close attention is required to the electrical

installation and the system-design to avoid hazards

either in normal operation or in the event of

equipment malfunction. System-design,

installation, commissioning and maintenance must

be carried out by personnel who have the necessary

training and experience. They must read this safety

information and this Installation Guide carefully.

To ensure mechanical safety, additional safety

devices such as electro-mechanical interlocks may

be required. The Drive must not be used in a safetycritical application without additional high-integrity

protection against hazards arising from a

malfunction.

Unidrive LV model sizes 1 to 3 Installation Guide

Issue code: uliu1

Within the European Union, all machinery in which

this product is used must comply with the following

directives:

98/37/EC: Safety of Machinery

89/336/EEC: Electromagnetic Compatibility.

1.6 Safety of personnel

The STOP function of the Drive does not remove

dangerous voltages from the output of the Drive or

from any external option unit.

The Stop and Start controls or electrical inputs of

the Drive must not be relied upon to ensure safety

of personnel. If a safety hazard could exist from

unexpected starting of the Drive, an interlock that

electrically isolates the Drive from the

must be installed to prevent the motor being

inadvertently started.

Careful consideration must be given to the

functions of the Drive which might result in a

hazard, either through their intended functions

(eg. Auto-start) or through incorrect operation due

to a fault or trip (eg. stop/start, forward/reverse,

maximum speed).

Under certain conditions, the Drive can suddenly

discontinue control of the motor. If the load on the

motor could cause the motor speed to be increased

(eg. hoists and cranes), a separate method of

braking and stopping the motor must be used (eg. a

mechanical brake).

Safety Information 1-1

AC supply

Page 6

Before connecting the AC supply to the Drive, it is

important that you understand the operating

controls and their operation. If in doubt, do not

adjust the Drive. Damage may occur, or lives put at

risk. Carefully follow the instructions in this

Installation Guide.

Standard squirrel-cage induction motors are

designed for single-speed operation. If it is

intended to use the capability of the Drive to run a

motor at speeds above its designed maximum, it is

strongly recommended that the manufacturer is

consulted first.

Before making adjustments to the Drive, ensure all

personnel in the area are warned. Make notes of all

adjustments that are made.

1.7 Risk analysis

In any application where a malfunction of the Drive

could lead to damage, loss or injury, a risk analysis

must be carried out, and where necessary, further

measures taken to reduce the risk. This would

normally be an appropriate form of independent

safety back-up system using simple electromechanical components.

1.8 Motor

Ensure the motor is installed in accordance with the

manufacturer’s recommendations. Ensure the

motor shaft is not exposed.

Low speeds may cause the motor to over-heat

because the cooling fan becomes less effective.

The motor should then be fitted with a protection

thermistor. If necessary, a separate cooling fan

should be used.

If a Drive is to be used to control a number of

motors, special measures need to be taken to ensure

protection of the motors; refer to Motor protection

in Appendix A Motor Information.

1.9 Adjusting parameters

Some parameters have a profound effect on the

operation of the Drive. They must not be altered

without careful consideration of the impact on the

controlled system. Measures must be taken to

prevent unwanted changes due to error or

tampering.

1-2 Safety Information

Unidrive LV model sizes 1 to 3 Installation Guide

Issue code: uliu1

Page 7

2 Installing the Drive

Adhere to the instructions

Warning

Warning

Note

Unless otherwise stated, instructions and

information in this Installation Guide relate

to all versions of the Unidrive.

2.1 Environmental

Warning

The mechanical and electrical

installation instructions must be

adhered to. Any questions or

doubt should be referred to the

supplier of the equipment. It is

the responsibility of the owner

or user to ensure that the

installation of the Drive and any

external option unit, and the way

in which they are operated and

maintained, comply with the

requirements of the Health and

Safety at Work Act in the United

Kingdom or applicable

legislation and regulations and

codes of practice in the country

in which the equipment is used.

Competence of the installer

The Drive must be installed only

by professional assemblers who

are familiar with the

requirements for safety and EMC.

The assembler is responsible for

ensuring that the end-product or

system complies with all the

relevant laws in the country

where it is to be used.

requirements

Installation in an enclosure

The Drive must be protected

against water, condensation and

electrically conductive

contamination. When the gland

plate and appropriate glands are

fitted, the Drive can attain

ingress protection to NEMA 1 and

IP40 (in accordance with

IEC529). UL listing is valid when

the Drive is installed in a type 1

enclosure as defined in UL 50.

Authorized access

Warning

The enclosure should prevent

access by anyone except for

authorized, trained service

personnel.

Fire enclosure

Warning

The Drive case is not classified

as a fire enclosure. When this

protection is required, the

Drive should be installed in a

fire enclosure.

Hazardous areas

Warning

Warning

1. Refer to Appendix C Data for details of the

environmental requirements.

2. If condensation is likely to occur when the Drive

is not in use, an anti-condensation heater must

be installed. This heater must be switched off

when the Drive is in use; automatic switching is

recommended.

3. If the Drive is to be mounted directly above any

heat-generating equipment (such as another

Drive), the maximum temperature of the air

immediately below the Drive should be taken as

the ambient temperature for the Drive.

4. If the Drive is to be mounted beneath other

equipment, such as another Drive, the Drive

should not cause the ambient temperature

requirements of the equipment to be exceeded.

5. When compliance with EMC emission standards

is required, the enclosure must be made of

metal but does not require special EMC

features.

UL-listing requirements are given in Appendix B.

The Drive must not be located

in a classified hazardous area

unless the Drive is installed in

an approved enclosure and the

installation is certified.

Before a Drive is used in the

fully sinusoidal Regeneration

mode, the Drive and the

accompanying motoring

Drive(s) must be modified.

Contact the supplier of the

Drive for details.

Unidrive LV model sizes 1 to 3 Installation Guide

Issue code: uliu1

Installing the Drive 2-1

Page 8

2.2 EMC considerations

Depending on the requirements of the installation,

one of the following levels of electromagnetic

compatibility (EMC) should be adopted:

Routine EMC precautions

These precautions are recommended when

strict compliance with emission standards is not

required. The risk of disturbing adjacent

electronic equipment is minimized by adopting

these precautions.

Compliance with EMC emission

standards

These precautions are recommended when

strict compliance with emission standards is

required. In addition, it is recommended that

these precautions are taken when the Drive is

installed in a residential area, or adjacent to

sensitive electronic equipment such as radio

receivers or similar.

Compliance with EN61800-3

(standard for Power Drive Systems)

Meeting the requirements of this standard

depends on the environment that the Drive is

intended to operate in, as follows:

Operation in the first environment

Observe the guidelines given in Compliance with

EMC emission standards. An RFI filter will always

be required. Some model sizes may require

additional filtering techniques to be applied.

Operation in the second environment

An RFI filter may not be required. Follow the

guidelines given in Routine EMC precautions or

Compliance with EMC emission standards

depending on the requirements of the end user.

The second environment

typically includes an industrial

low-voltage power supply

Caution

Instructions are given later in this chapter for these

levels of EMC. Refer to Appendix C Data for further

information on compliance with EMC standards and

definitions of environments.

Detailed instructions and EMC information are given

in the Unidrive LV EMC Data Sheet which is available

from the Drive Centres and distributors listed at the

end of this Installation Guide.

Compliance data is given in Appendix C Data.

network which does not supply

buildings used for domestic

purposes. Operating the Drive

in this environment without an

RFI filter may cause

interference to nearby

electronic equipment whose

sensitivity has not been

appreciated. The user must

take remedial measures if this

situation arises. If the

consequences of unexpected

disturbances are severe, it is

recommended that the

emission limits of EN50081-2 be

adhered to.

Note

The installer of the Drive is responsible for

ensuring compliance with the EMC

regulations that apply where the Drive is to

be used.

The Drive will comply with the standards

for emission, such as EN50081–2, only when

the instructions given in Planning the

installation and Wiring recommendations later

in this chapter are followed closely.

2-2 Installing the Drive

Unidrive LV model sizes 1 to 3 Installation Guide

Issue code: uliu1

Page 9

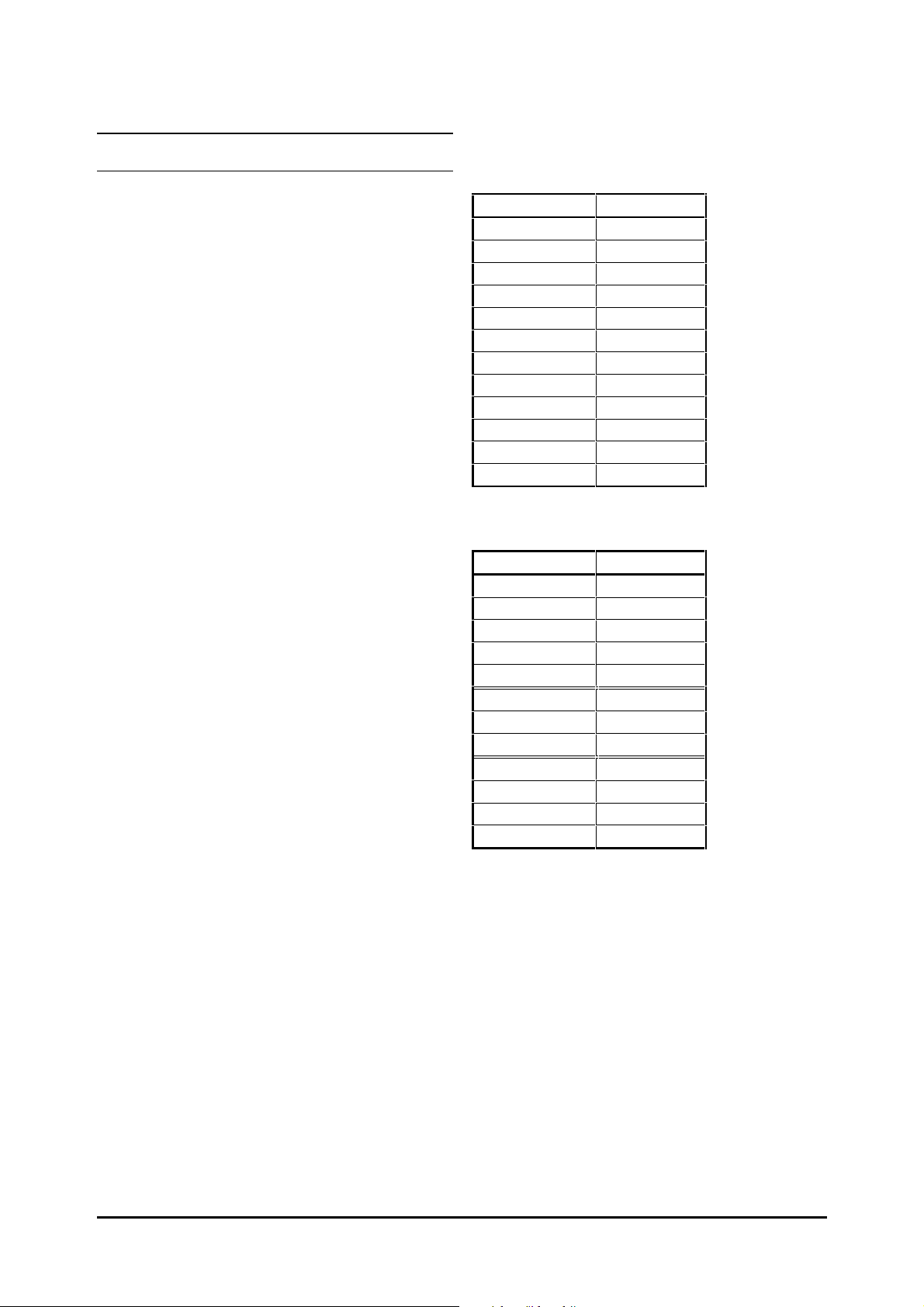

2.3 Planning the installation

Model

UNI 1201

UNI 1202

UNI 1203

UNI 1204

UNI 1205

UNI 2201

UNI 2202

UNI 2203

UNI 3201

UNI 3202

UNI 3203

UNI 3204

Table 2–1 Fuse ratings for all versions of

the Unidrive LV

Instructions in numbered steps

The instructions in this section are contained in

numbered steps. In some of these steps you will

need to make a note of a value for future reference

and, to help with identification, the number of the

step.

AC supply protection

The

AC supply to the Drive must

be fitted with suitable

Warning

protection against overload

and short-circuits. Table 2–1

shows recommended fuse

ratings. Failure to observe this

recommendation will cause a

risk of fire.

TEP 1 Include a fuse of the specified rating in

S

each phase of the

AC supply. The use of the

following types of fuse is recommended:

• Europe: Type gG HRC industrial fuses to

IEC 269 (BS88)

• USA: RK1 600V

AC

An MCB or MCCB having the correct thermal

and magnetic trip ratings may be used in place

of fuses, on condition the fault-current clearing

capacity is sufficient for the installation.

Power cables

Wiring must be in accordance

with local regulations and

Warning

Cable type and size

codes of practice. The table

below shows typical cable sizes

for power input and output

wiring. In the event of a

conflict, local regulations

prevail.

Fuse rating

6 A

10 A

10 A

16 A

16 A

16 A

20 A

35 A

40 A

60 A

70 A

80 A

Note

UL listing is dependent on the use of the

correct type of UL-listed fuse, and applies

when the symmetrical short-circuit current

does not exceed 5kA. Refer to Appendix B

UL Listing Information.

STEP 2 For the following power connections...

•

AC supply to RFI filter (when used)

•

AC supply (or RFI filter) to Drive

• Drive to motor

• Drive to braking resistor

... use 105°C (221°F) pvc-insulated cable of

suitable voltage rating and having copper

conductors, as shown in Table 2–2.

Unidrive LV model sizes 1 to 3 Installation Guide

Issue code: uliu1

Installing the Drive 2-3

Page 10

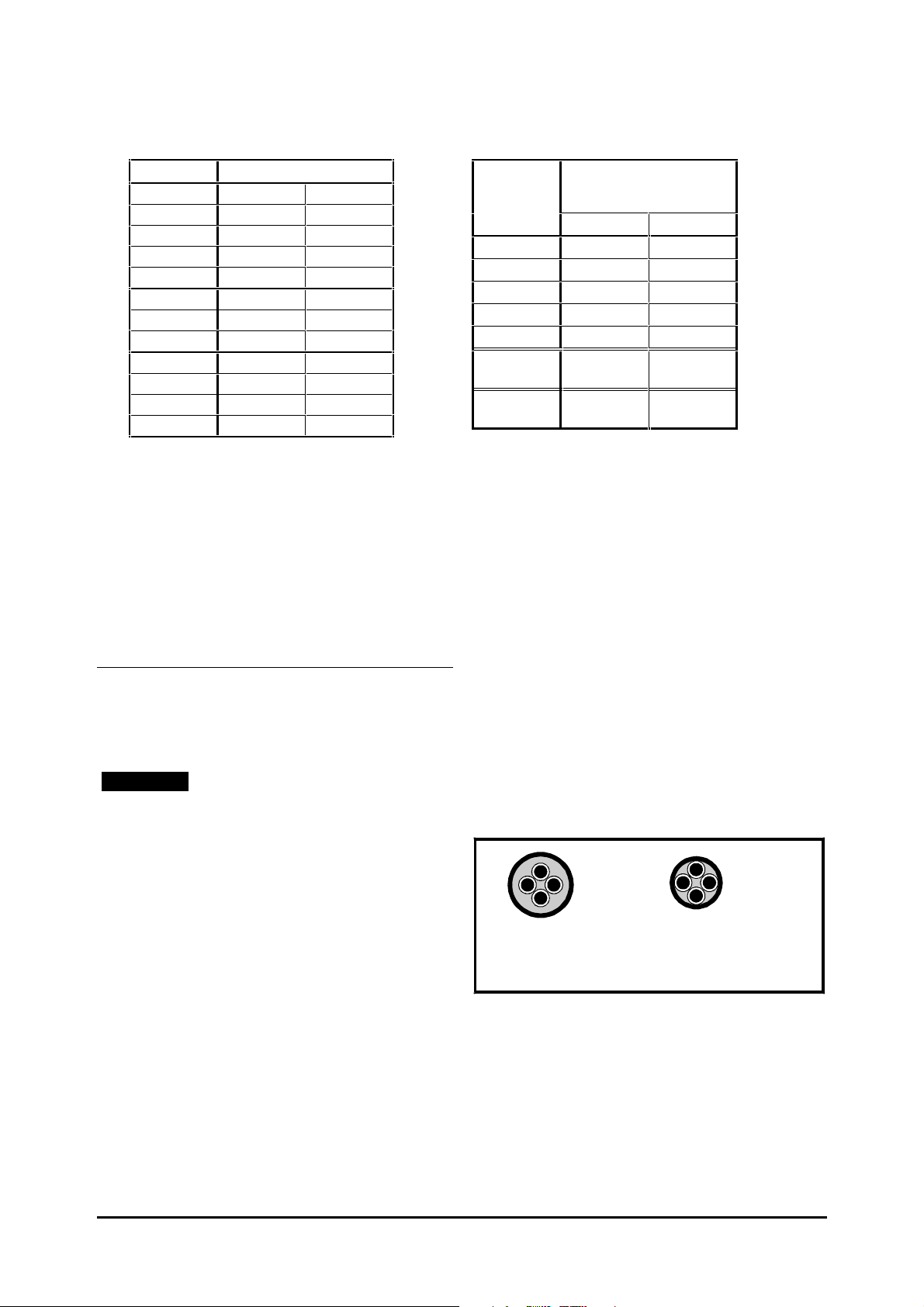

Table 2–2 Cable sizes

ft

210

330

430

660

990

990

660

Table 2–3 Maximum cable lengths

Model Cable size

UNI 1201 1.5 mm

UNI 1202 2.5 mm

UNI 1203 2.5 mm

UNI 1204 2.5 mm

UNI 1205 2.5 mm

UNI 2201 2.5 mm

UNI 2202 4 mm

UNI 2203 4 mm

UNI 3201 6 mm

UNI 3202 10 mm

UNI 3203 16 mm

UNI 3204 25 mm

2

16 AWG

2

14 AWG

2

14 AWG

2

14 AWG

2

14 AWG

2

2

2

2

2

2

2

14 AWG

10 AWG

10 AWG

8 AWG

6 AWG

4 AWG

4 AWG

When EMC emission requirements are to be

met, shielded cable or steel wire armoured

cable may be required for the following:

AC supply to enclosure

•

• Drive to motor

• Drive to braking resistor when part of the

cable is outside the enclosure

For further details, see Wiring guidelines later in this

chapter.

Motor cable

STEP 3 Since capacitance in the motor cable

causes loading on the output of the Drive,

ensure the cable length does not exceed the

values given in Table 2–3.

Note

Maximum length of the encoder cable

Model Maximum cable length *

UNI 1201 65

UNI 1202 100

UNI 1203 130

UNI 1204 200

UNI 1205 300

UNI 2201 ~

UNI 2203

UNI 3201 ~

UNI 3204

* Cable lengths in excess of the specified values may be

used only when special techniques are adopted; refer to

the supplier of the Drive.

(

PWM switching

frequency at 3kHz)

m

300

200

The maximum cable length is reduced from that

shown in the table under the following

conditions:

PWM switching frequency exceeding

•

3kHz in model size 3 The maximum

cable length is reduced in proportion to the

increase in

9kHz, the maximum length is

PWM switching frequency, eg. at

1

/3 of that

shown.

• High-capacitance cables Most cables

have an insulating jacket between the cores

and the armour or shield; these cables have a

low capacitance and are recommended.

Cables that do not have an insulating jacket

tend to have high capacitance; if a cable of

this type is used, the maximum cable length

is half that quoted in the table. (Figure 2–1

shows how to identify the two types.)

When a Unidrive LV or Unidrive LFT LV is to

be used in a closed-loop system and with

long motor cables, the corresponding

length of the encoder cable may cause an

excessive supply-voltage drop between the

Drive and encoder. In this case, do not use

the Drive to supply the encoder; install a

separate

DC supply close to the encoder.

2-4 Installing the Drive

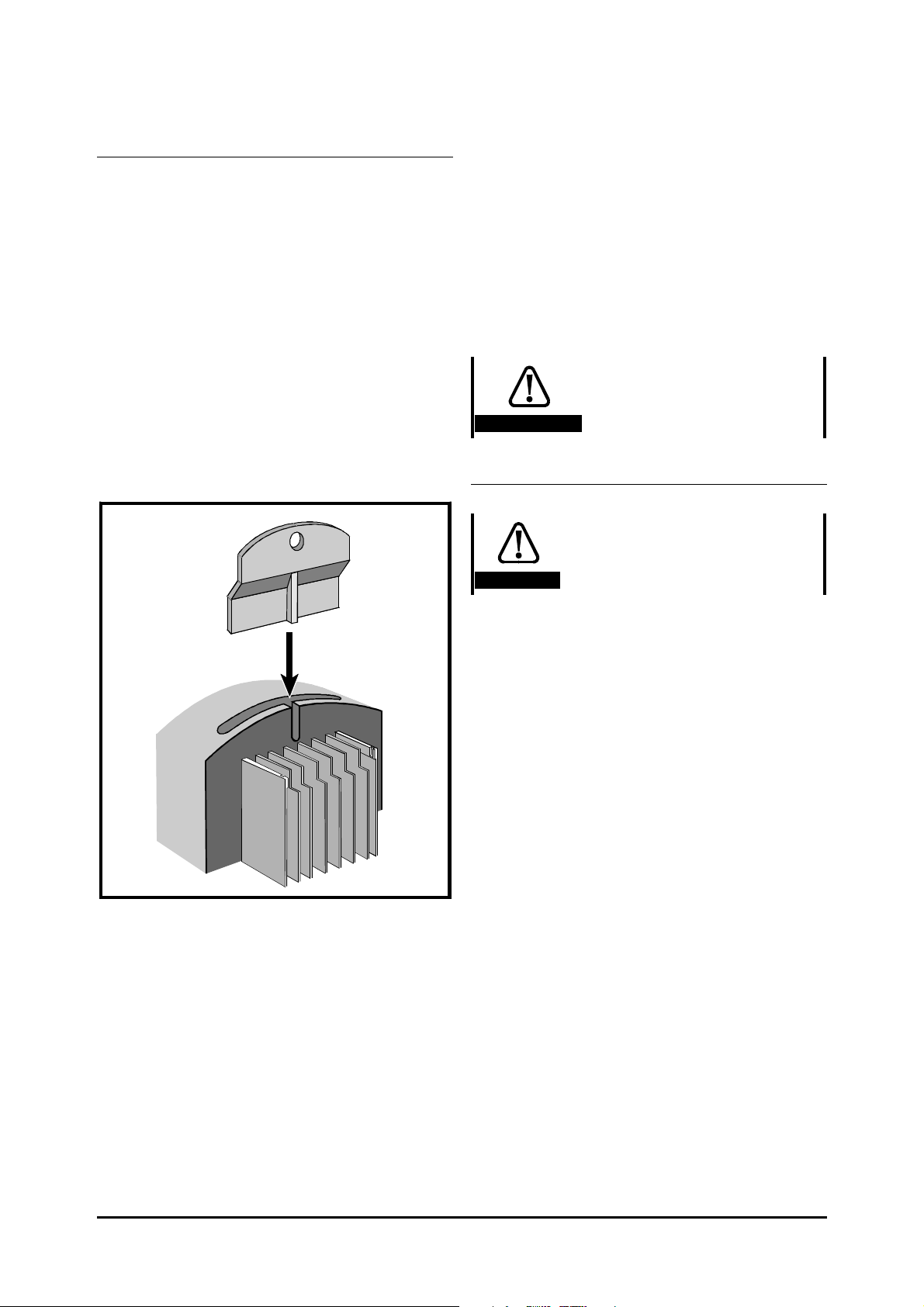

Normal capacitance

Shield or armour

separated from the cores

High capacitance

Shield or armour close

to the cores

Figure 2–1 Cable construction influencing

the capacitance

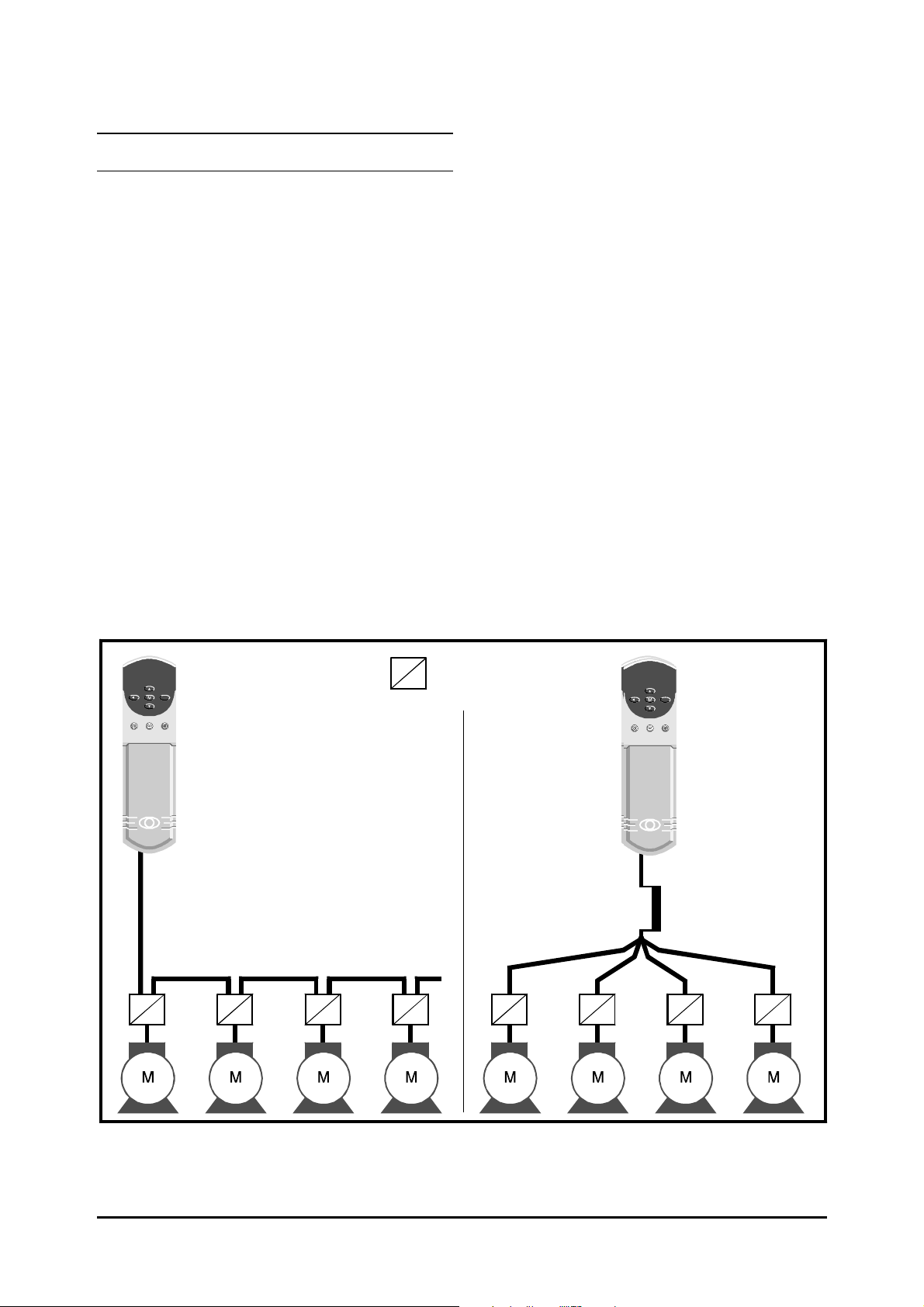

Multiple motors

Special requirements apply when the Drive is to

control more than one motor. Refer to

Appendix A Motor Connections.

Unidrive LV model sizes 1 to 3 Installation Guide

Issue code: uliu1

Page 11

Isolator switch in the motor cable

An isolator switch may be connected in the

motor cable for safety purposes. Refer to the

following Warning and Note.

The isolator switch must not be

operated when the Drive is

AC-rated switch

Warning

enabled. (If an

is used and the Drive is

producing a low output

frequency when the switch is

opened, severe arcing can occur

which will prevent the switch

from breaking the circuit.)

A suitable interlock

arrangement can be used, such

as an isolator switch fitted

with additional contacts that

open before the main contacts.

These additional contacts

should be used to disable the

Drive.

Note

If the isolator switch is closed when the

Drive is enabled, the Drive may trip.

When EMC compliance is required, refer to Variations

in the EMC wiring recommendations later in this

chapter.

The Drive has two forms of thermal protection for

the power output stage (IGBT bridge), as follows:

1. A thermistor mounted on the heatsink monitors

the heatsink temperature. If this exceeds 95°C

(203°F), the thermistor will cause the Drive to

trip. The display will indicate Oh2.

2. Intelligent thermal modelling estimates (by

calculation) the junction temperature of the

IGBTs. There are two temperature thresholds

which cause the following to occur:

• If the first threshold is reached, the

PWM

switching frequency is halved in order to

reduce dissipation in the IGBTs. (When the

frequency is halved, the value of parameter

PWM switching frequency remains at the

0.41

value set by the user; if the frequency is 3kHz

or 4.5kHz, no halving occurs). Then at one

second intervals, the Drive will attempt to

restore the original

PWM switching

frequency. This will be successful if the

estimated temperature has reduced

sufficiently.

• If the estimated temperature has continued

to rise and reaches a second threshold, the

Drive will trip. The display will indicate Oh1.

TEP 4 Note that the Drive can deliver an

S

overload current, as shown in Table 2–4.

Table 2–4 Overload current

Output current,

PWM switching frequency,

Ambient temperature

Thermal protection

Note

The Drive can supply the rated current up

to an ambient temperature of 40

(depending on the

PWM switching frequency

used).

The Drive can be operated in an ambient

temperature up to 50

o

C (122oF) at de-rated

output current. In this case, ensure the

value of parameter 0.46 Motor rated current

does not exceed the value given in

Table 2-5.

o

C (104°°F)

Unidrive LV

Open-loop

Up to 150% of the rated current for 60 seconds

Closed-loop Vector

Up to 175% of the rated current for 60 seconds

Closed-loop Servo

Up to 175% of the rated current for 4 seconds

Unidrive VTC LV

For a variable-torque load

Up to 120% of the rated current for 60 seconds

Unidrive LFT LV operating on

standard S4/S5 duty cycle

Open-loop

Up to 150% of the rated current

Closed-loop Vector

Up to 175% of the rated current

Closed-loop Servo

Up to 175% of the rated current

Unidrive LV model sizes 1 to 3 Installation Guide

Issue code: uliu1

Installing the Drive 2-5

Page 12

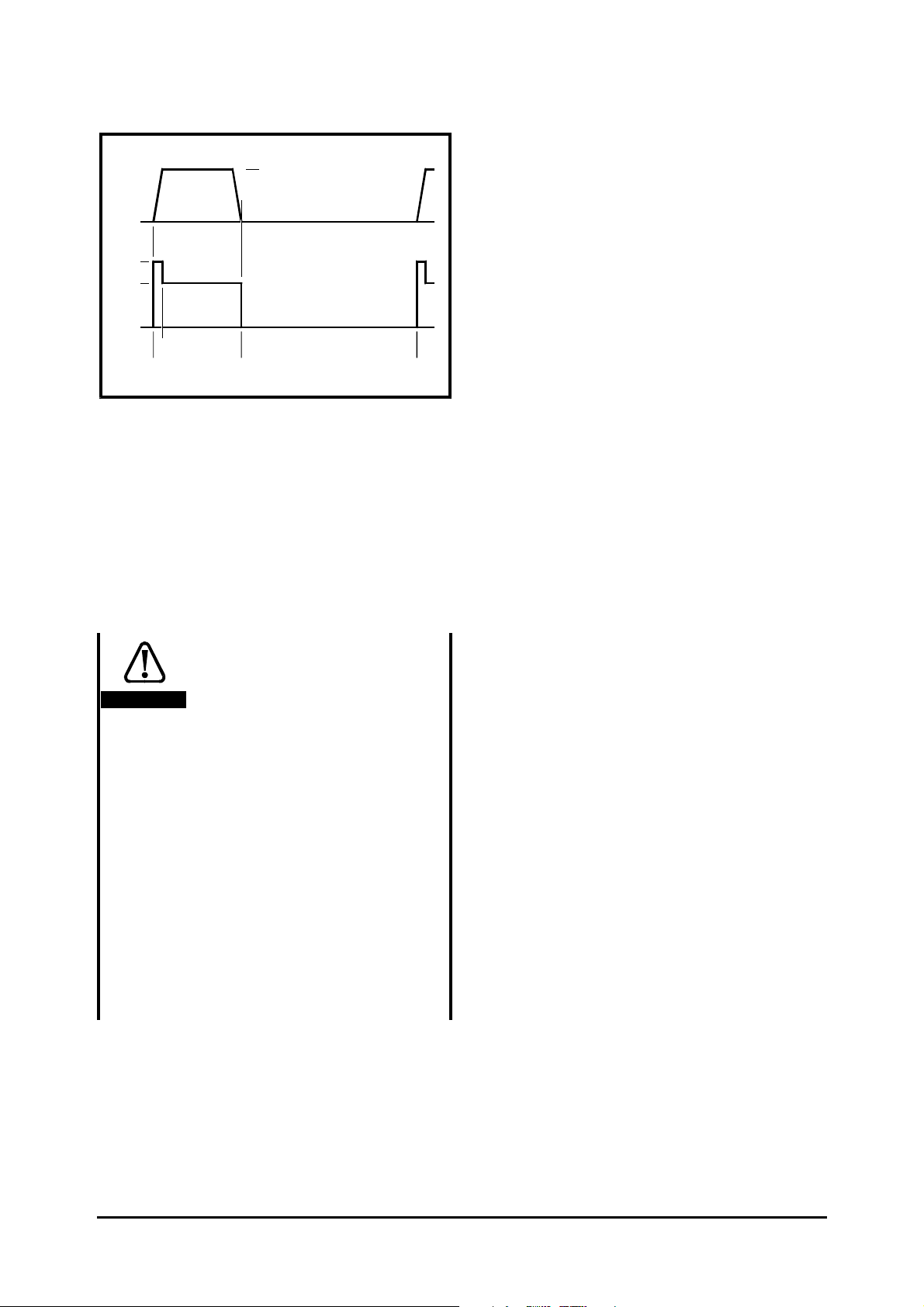

150%

100%

Frequency / speed

0

Current

0

2

0

50Hz

1500

RPM

20 60

Figure 2–2 Standard S4/S5 duty cycle

(Unidrive LFT LV)

Unidrive LV and Unidrive VTC LV Refer

to Table 2–5 to find the maximum continuous

output current that can be obtained for the

required ambient temperature and

PWM switching frequency. The maximum

ambient temperature can be 40°C or 50°C

(104°F or 122°F). Note that the nominal power

rating of the Drive may not be achieved above

40°C.

Unidrive LFT LV Refer to Table 2–6 to find

the maximum continuous output current that

can be obtained for the ambient temperature

for a standard S4/S5 duty-cycle or for

continuous operation. Refer to a Drive Centre

or distributor for information on other duty

ratios.

Make a note of this step number and the

following:

• Unidrive LV and Unidrive VTC LV

Chosen maximum ambient temperature.

• Unidrive LV and Unidrive VTC LV

Chosen

PWM switching frequency for

each Drive.

• All Unidrive LV versions From Table 2–

7, the maximum power dissipation (heat)

figure (PP

) at the chosen PWM switching

DISSDISS

frequency for each Drive (this figure is the

total power dissipation at the maximum

continuous output current available at the

chosen

PWM switching frequency, and

includes power dissipated in option modules

when fitted). Power dissipation in the

Unidrive LFT is the same as that for the

standard Unidrive when operating at 9kHz

PWM switching frequency.

Caution

Operation in a maximum

ambient temperature of 50°°C

(122°°F)

Unless the precaution described

here is taken, the Drive will

limit the maximum continuous

output current only to the

value for 40°°C, and not to the

value stated in Table 2–5 for

50°°C.

Make a note of the value for

50°°C; you will need to refer to

it when you reach Configuring

the Drive for the motor in

Chapter 2 of the User Guide.

At that point, ensure that the

value to be entered in

parameter 0.46 Motor – rated

current does not exceed the

noted value.

• Unidrive LV and Unidrive VTC LV If

the maximum ambient temperature will be

50°C (122°F), note the value of the

maximum permissible output current

obtained from Table 2–5. This will be the

maximum value that parameter 0.46 Motor

– rated current should be set at.

2-6 Installing the Drive

Unidrive LV model sizes 1 to 3 Installation Guide

Issue code: uliu1

Page 13

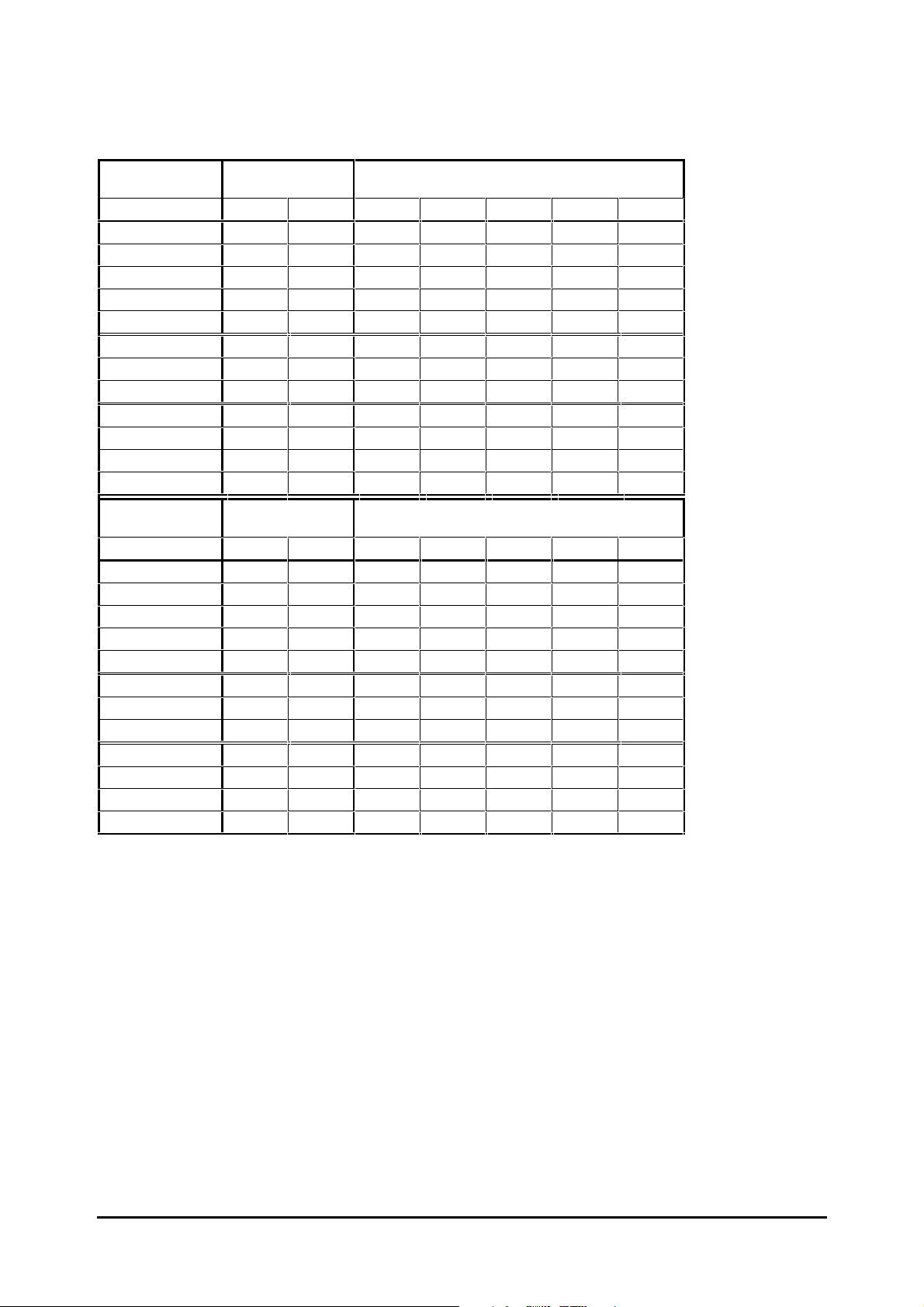

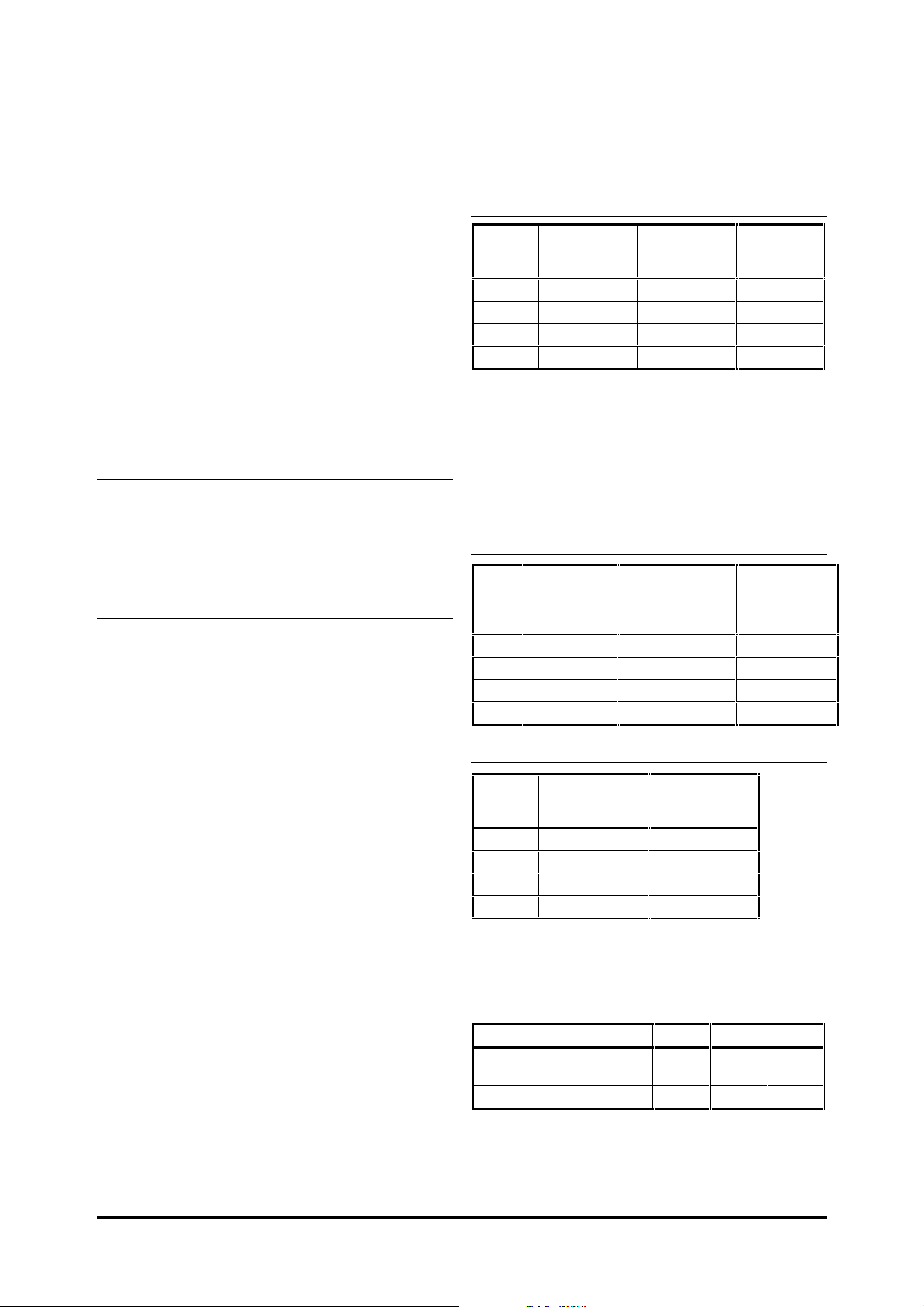

Table 2–5 Maximum permissible continuous output current for Unidrive LV and Unidrive VTC LV

40°°C (104°F)

ambient

Model kW HP 3kHz 4.5kHz 6kHz 9kHz 12kHz

UNI 1201 0.37 kW 0.5 2.1 A 2.1 A 2.1 A 2.1 A 2.1 A

UNI 1202 0.55 kW 0.75 2.8 A 2.8 A 2.8 A 2.8 A 2.8 A

UNI 1203 0.75 kW 1.0 3.8 A 3.8 A 3.8 A 3.8 A 3.8 A

UNI 1204 1.1 kW 1.5 5.6 A 5.6 A 5.6 A 5.6 A 4.5 A

UNI 1205 2.2 kW 3.0 9.5 A 9.5 A 8.5 A 7.0 A 5.5 A

UNI 2201 3.0 kW 4.0 12.0 A 12.0 A 12.0 A 12.0 A 11.7 A

UNI 2202 4.0 kW 5.0 16.0 A 16.0 A 16.0 A 14.2 A 11.7 A

UNI 2203 5.5 kW 10.0 25.0 A 21.7 A 18.2 A 14.2 A 11.7 A

UNI 3201 7.5 kW 15.0 34.0 A 34.0 A 34.0 A 28.0 A 23.0 A

UNI 3202 11 kW 20.0 46.0 A 46.0 A 40.0 A 32.0 A 26.6 A

UNI 3203 15 kW 25.0 60.0 A 47.0 A 40.0 A 32.0 A 26.7 A

UNI 3204 22 kW 30.0 74.0 A 56.0 A 46.0 A 35.0 A 28.0 A

50°°C (122°F)

ambient

Model kW HP 3kHz 4.5kHz 6kHz 9kHz 12kHz

UNI 1201 0.37 kW 0.5 2.1 A 2.1 A 2.1 A 2.1 A 2.1 A

UNI 1202 0.55 kW 0.75 2.8 A 2.8 A 2.8 A 2.8 A 2.8 A

UNI 1203 0.75 kW 1.0 3.8 A 3.8 A 3.8 A 3.8 A 3.3 A

UNI 1204 1.1 kW 1.5 5.6 A 5.6 A 5.1 A 4.0 A 3.3 A

UNI 1205 2.2 kW 3.0 6.9 A 5.9 A 5.1 A 4.0 A 3.3 A

UNI 2201 3.0 kW 4.0 12.0 A 12.0 A 12.0 A 11.6 A 9.7 A

UNI 2202 4.0 kW 5.0 16.0 A 16.0 A 14.7 A 11.6 A 9.7 A

UNI 2203 5.5 kW 10.0 20.0 A 17.3 A 14.7 A 11.6 A 9.7 A

UNI 3201 7.5 kW 15.0 34.0 A 34.0 A 28.0 A 21.0 A 17.9 A

UNI 3202 11 kW 20.0 44.0 A 36.0 A 31.0 A 24.0 A 20.6 A

UNI 3203 15 kW 25.0 44.0 A 36.0 A 31.0 A 24.0 A 20.9 A

UNI 3204 22 kW 30.0 50.0 A 41.0 A 34.0 A 26.0 A 23.0 A

Nominal

rating

Nominal

rating

Maximum permissible

continuous output current

Maximum permissible

continuous output current

Unidrive LV model sizes 1 to 3 Installation Guide

Issue code: uliu1

Installing the Drive 2-7

Page 14

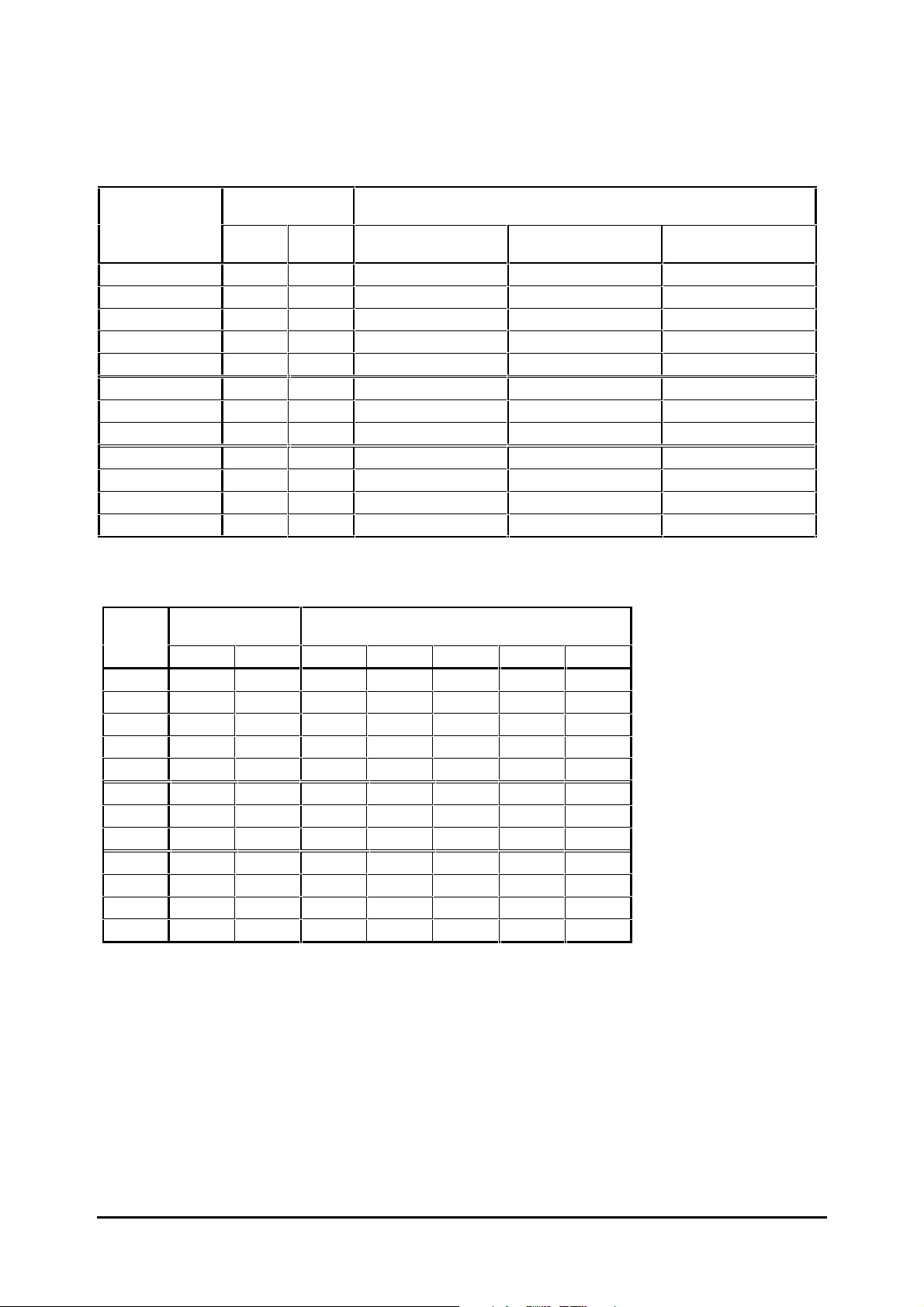

Table 2–6 Maximum permissible output current for Unidrive LFT LV

Continuous

operation at 40°C

2.1 A

2.8 A

3.8 A

4.0 A

4.3 A

12.0 A

14.2 A

14.2 A

28.0 A

32.0 A

33.0 A

35.0 A

Model

UNI 1201

UNI 1202

UNI 1203

UNI 1204

UNI 1205

UNI 2201

UNI 2202

UNI 2203

UNI 3201

UNI 3202

UNI 3203

UNI 3204

(at 9kHz

PWM switching frequency)

Model Nominal

rating

kW HP Standard duty cycle

at 40°°C

UNI 1201 LFT 0.37 kW 0.5 2.1 A

UNI 1202 LFT 0.55 kW 0.75 2.8 A

UNI 1203 LFT 0.75 kW 1.0 3.8 A

UNI 1204 LFT 1.1 kW 1.5 5.6 A

UNI 1205 LFT 2.2 kW 3.0 9.5 A

UNI 2201 LFT 3.0 kW 4.0 12.0 A

UNI 2202 LFT 4.0 kW 5.0 16.0 A

UNI 2203 LFT 5.5 kW 10.0 25.0 A

UNI 3201 LFT 7.5 kW 15.0 34.0 A

UNI 3202 LFT 11 kW 20.0 46.0 A

UNI 3203 LFT 15 kW 25.0 60.0 A

UNI 3204 LFT 22 kW 30.0 74.0 A

Maximum permissible output current

Continuous

operation at 50°°C

2.1 A

2.8 A

3.3 A

3.3 A

3.3 A

11.0 A

11.0 A

11.0 A

21.0 A

24.0 A

24.0 A

26.0 A

Table 2–7 Maximum total power dissipation (Unidrive LV, Unidrive VTC LV and Unidrive LFT LV)

Nominal

rating

kW HP 3kHz 4.5kHz 6kHz 9kHz 12kHz

0.37kW 0.5 80 W 80 W 90 W 90 W 90 W

0.55kW 0.75 90 W 90 W 100 W 100 W 110 W

0.75kW 1.0 100 W 110 W 110 W 120 W 130 W

1.1kW 1.5 130 W 130 W 140 W 150 W 150 W

2.2kW 3.0 180 W 190 W 190 W 190 W 170 W

3.0kW 4.0 210 W 230 W 250 W 280 W 310 W

4.0kW 5.0 270 W 290 W 310 W 320 W 310 W

5.5kW 10.0 400 W 380 W 360 W 330 W 310 W

7.5kW 15.0 570 W 620 W 670 W 660 W 630 W

11kW 20.0 730 W 800 W 770 W 730 W 700 W

15kW 25.0 950 W 830 W 790 W 740 W 710 W

22kW 30.0 1090 W 990 W 920 W 850 W 800 W

Maximum total power dissipation

The default PWM switching frequency is a follows...

2-8 Installing the Drive

Unidrive LV and Unidrive VTC LV: 3kHz

Unidrive LFT LV: 9kHz

Unidrive LV model sizes 1 to 3 Installation Guide

Issue code: uliu1

Page 15

Using an RFI filter

Using a braking resistor

STEP 5 For compliance with the emission

standards such as EN 50081-1 or EN 50081-2, use

the recommended RFI filter as shown in

Table 2–8. Use one RFI filter for each Drive.

(Standards that are met are specified in

Appendix C Data)

Make a note of this step number and the

following for each filter to be used:

• Size code or part number

• Maximum power dissipation figure

• IP rating

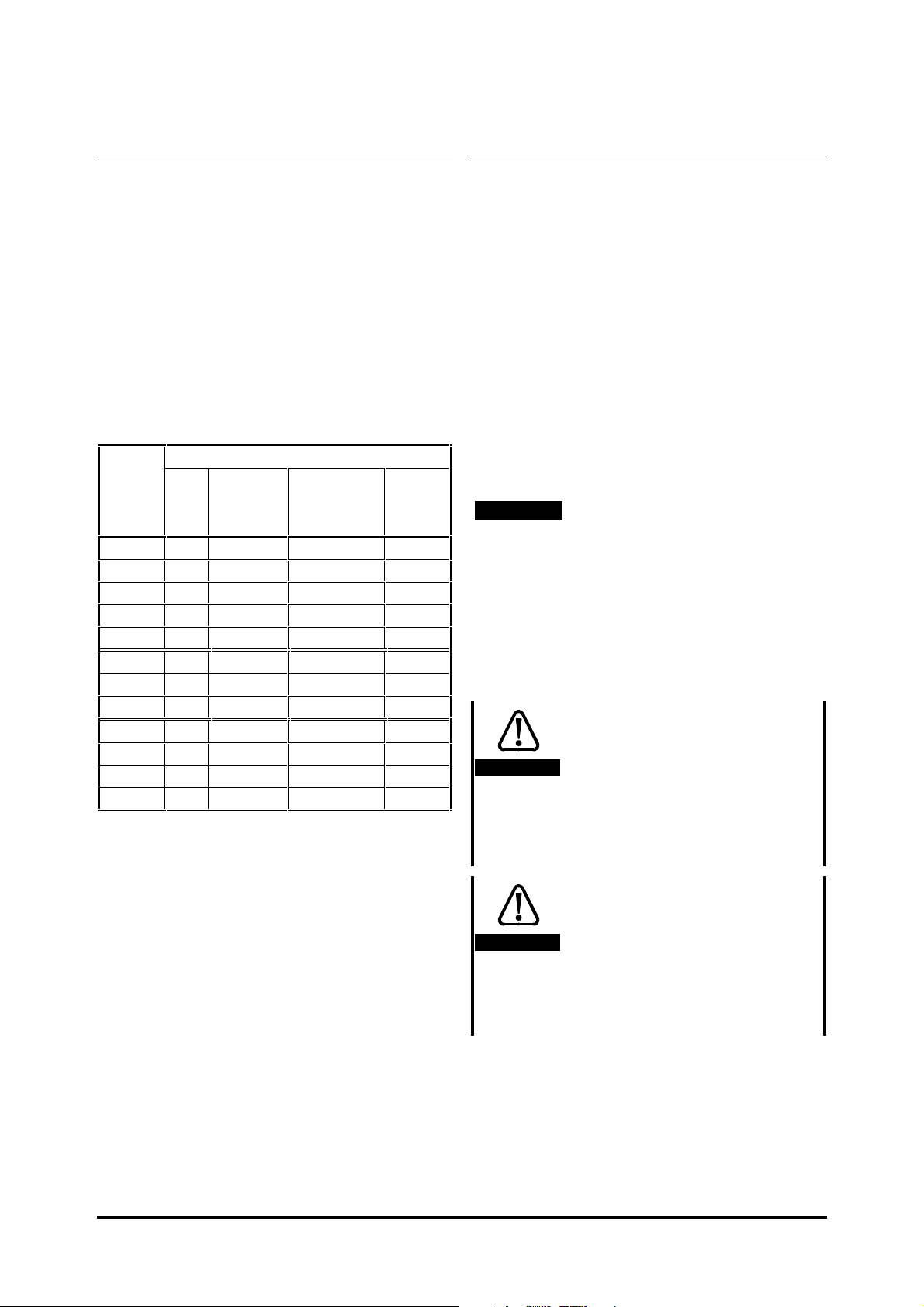

Table 2–8 RFI filter data

Model RFI filter

IP

rating

UNI 1201

UNI 1202

UNI 1203

UNI 1204

UNI 1205

UNI 2201

UNI 2202

UNI 2203

UNI 3201

UNI 3202

UNI 3203

UNI 3204

Size Part

number

A

4200–0010 25 IP20

A

4200–0010 25 IP20

A

4200–0010 25 IP20

A

4200–0010 25 IP20

A

4200–0010 25 IP20

B

4200–0027 40 IP20

B

4200–0027 40 IP20

B

4200–0027 40 IP20

C

4200–1051 60 IP00

C

4200–1051 60 IP00

D

4200–1071 100 IP00

D

4200–1071 100 IP00

Maximum

power

dissipation

(W)

Model size 1

When the motor cable is to exceed 50m (165 feet),

use RFI filter size B (4200–0027).

Braking occurs when the Drive is decelerating the

motor, or is preventing the motor from gaining

speed due to mechanical influences. During braking,

energy is returned to the Drive by the motor.

When the motor is being braked by the Drive, the

maximum regenerated power that the Drive can

absorb is equal to the power dissipation (losses) of

the Drive.

When the regenerated power is likely to exceed

these losses, a braking resistor must be connected.

By default, the Drive brakes the motor under

PI control which extends the deceleration time as

necessary in order to keep the

DC bus at a constant

voltage. The method of braking can be changed; if

required, refer to Appendix D Menu 0 Parameters in

the User Guide.

Note

When a braking resistor is used, the Drive

should be operated in FASt ramp mode. If

this is not done, instability may arise. See

Braking resistor in Chapter 2 of the User

Guide.

Housing the resistor, and routing the

connecting cable

High temperatures

Braking resistors can reach

Warning

high temperatures. Locate

braking resistors so that

damage cannot result.

Use cable having insulation

capable of withstanding high

temperatures.

Overload protection

Unidrive LV model sizes 1 to 3 Installation Guide

Issue code: uliu1

Warning

It is essential that an overload

protection device is

incorporated in the braking

resistor circuit; this is

described in Protection circuit

for an optional braking resistor in

TEP 8.

S

Installing the Drive 2-9

Page 16

STEP 6 When a braking resistor is to be mounted

outside the enclosure, ensure that it is mounted

in a ventilated metal housing that will perform

the following functions:

• Prevent inadvertent contact with the

resistor

• Allow adequate ventilation for the resistor

When compliance with EMC emission standards

is required, external connection requires the

cable to be armoured or shielded, since it is not

fully contained in a metal enclosure.

Internal connection does not require the cable

to be armoured or shielded.

Minimum resistances and power ratings

Table 2–9 Minimum resistance values and

peak power rating for the

braking resistor at 40°°C (104°°F)

Model Minimum

resistance

UNI 1201 ~ UNI 1205 20Ω 15kW

UNI 2201 20Ω 15kW

UNI 2202, UNI 2203 15Ω 20kW

UNI 3201 ~ UNI 3204 5Ω 60kW

The minimum resistance allows the braking resistor

to dissipate up to approximately 300% of the power

rating of the Drive for up to 60 seconds.

For high-inertia loads or under continuous braking,

the continuous power dissipated in the braking

resistor may be as high as the power rating of the

Drive. The total energy dissipated in the braking

resistor is dependent on the amount of energy to be

extracted from the load.

The instantaneous power rating refers to the

short-term maximum power dissipated during the on

intervals of the pulse width modulated braking

control cycle. The braking resistor must be able to

withstand this dissipation for short intervals

(milliseconds). Higher resistance values require

proportionately lower instantaneous power ratings.

In most applications, braking occurs only

occasionally. This allows the continuous power

rating of the braking resistor to be much lower than

the power rating of the Drive. It is essential,

though, that the instantaneous power rating and

energy rating of the braking resistor are sufficient

for the most extreme braking duty that is likely to

be encountered.

Instantaneous

power rating

Optimization of the braking resistor requires a

careful consideration of the braking duty. This is

described more fully in Optimizing an optional braking

resistor in the Unidrive Advanced User Guide.

TEP 7 Select a value of resistance for the braking

S

resistor that is not less than the specified

minimum resistance. Larger resistance values

may give a cost saving, as well as a safety

benefit in the event of a fault in the braking

system. Braking capability will then be

reduced, which may cause the Drive to trip

during braking. If this occurs, refer to

Deceleration rate in Chapter 2 of the User Guide.

TEP 8 Estimate the average power that will be

S

dissipated in the resistor. A method of

estimating this power is described in Optimizing

an optional braking resistor in the Unidrive

Advanced User Guide. Make a note of this step

number and the average power to be dissipated

in the resistor.

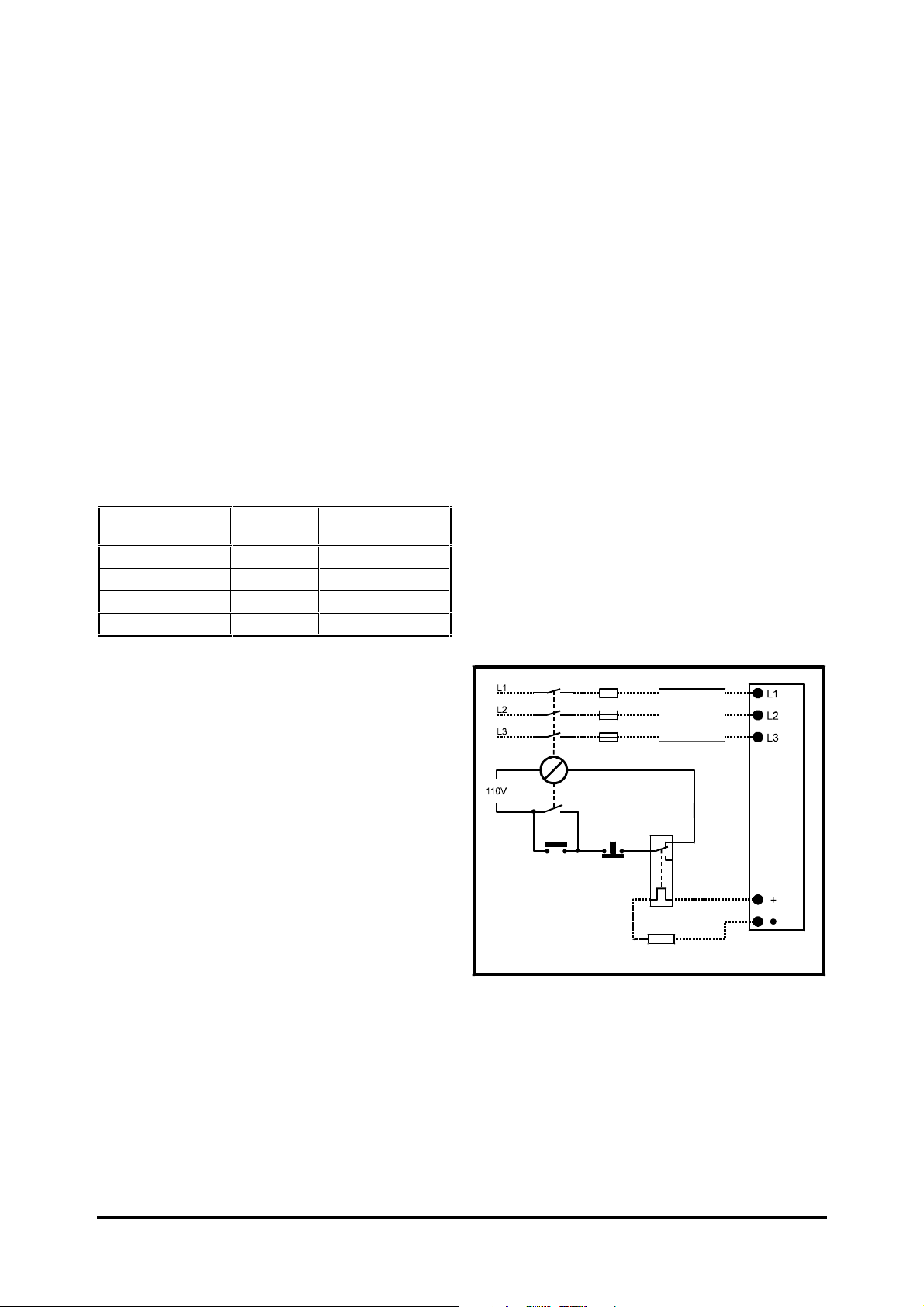

Thermal protection circuit for the

braking resistor

The thermal protection circuit must disconnect the

AC supply from the Drive if the resistor becomes

overloaded. Figure 2–3 shows a typical circuit

arrangement.

Optional

RFI filter

Stop

Start /

Reset

Thermal

protection

device

Braking resistor

Figure 2–3 Typical protection circuit for a

braking resistor

Drive

2-10 Installing the Drive

Unidrive LV model sizes 1 to 3 Installation Guide

Issue code: uliu1

Page 17

Enclosure layout

STEP 9 Use one of the following enclosure

layouts, depending on the requirements of the

installation:

Routine EMC precautions Refer to

Figure 2–4 which shows the recommended

layout for two Drives, and the signal and power

cables.

Compliance with EMC emission

standards Refer to Figure 2–5 which shows

the recommended layout for two Drives, two

RFI filters, and the signal and power cables.

TEP 10 Decide whether the enclosure is to be

S

sealed or ventilated, as follows:

A sealed enclosure can give a high ingress-

protection rating, but with reduced heat

removal capabilities. If possible, locate heatgenerating equipment (other than braking

resistors) in the lower part of the enclosure to

encourage internal convection. If necessary, a

taller enclosure, and/or air-circulation fans

inside the enclosure, can be used. For

calculating the minimum size of sealed

enclosure that will adequately cool the Drive(s),

refer later in this chapter to Calculating the size

of a sealed enclosure.

If a high ingress-protection rating is not

required, a ventilated enclosure can be used

with a fan to supply forced air cooling; this can

give a lower ambient temperature than a sealed

enclosure. For calculating the minimum

required volume of cooling air, refer later in this

chapter to Calculating the air-flow in a ventilated

enclosure.

TEP 11 For compliance with EMC emission

S

standards, ensure the enclosure is fitted with an

unpainted metal back-plate for mounting the

Drive and RFI filter. For example, a zinc plated

steel back-plate is suitable (see Figure 2–5).

TEP 12 Ensure the Drive is installed vertically for

S

best flow of cooling air through the Drive and

heatsink.

TEP 13 Ensure the clearances around the Drive are

S

as follows:

Above and below: ≥100mm (4 in)

1

Both sides: ≥5mm (

/4 in)

Note

When surface mounting a model size 3,

allow a clearance of 150mm (6in) above the

Drive; this is required for dismounting. A

minimum clearance of 100mm (4in) is

required for ventilation.

For overall dimensions and weights of the Drive

and RFI filter, see Appendix C Data.

TEP 14 When compliance with EMC emission

S

standards is required, the RFI filter must be

installed at the specified position for each Drive

(see Figure 2–5).

TEP 15 When a braking resistor is to be used, it

S

can be installed outside or inside the enclosure.

When installed inside, it must be mounted in

the upper part of the enclosure to prevent it

heating the other equipment by convection.

Unidrive LV model sizes 1 to 3 Installation Guide

Issue code: uliu1

Installing the Drive 2-11

Page 18

Optional braking resistors as required for the Drives

External: Mount on top surface of enclosure.

Internal: Mount in top part of enclosure.

Drives

Ensure minimum

clearances are

respected.

System controller

Locate as required.

Signal cables

Plan for all signal

cables to be routed at

least 300mm (12in)

distant from any

power cable.

Power cables

AC supply isolator,

contactor, and

fuses or MCBs

Locate as required.

≥100mm

(4in)

≥5mm

(¼in)

Overload protection

device

≥100mm

(4in)

Location

of optional

terminal

block

Alternative

location of

fuses or

MCBs

Locate as

required.

≥5mm

(¼in)

Back-plate

Enclosure

Figure 2–4 Recommended layout for routine EMC precautions (wiring recommendations

are given in Figure 2–21)

2-12 Installing the Drive

Unidrive LV model sizes 1 to 3 Installation Guide

Issue code: uliu1

Page 19

Optional braking resistors as required for the Drives

External: Mount on top surface of enclosure.

Internal: Mount in top part of enclosure.

Overload protection

device

Alternative location

of fuses or MCBs

Drives and

RFI filters

Ensure minimum

clearances are

respected.

Locate as required.

≥5mm

(¼in)

≥100mm

(4in)

≥5mm

(¼in)

System controller

Locate as required.

Signal cables

Plan for all signal

cables to be routed at

least 300mm (12in)

distant from any power

cable.

RFI filters

nstall a separate RFI

I

filter for each Drive.

Power cables

AC supply isolator,

contactor, and

fuses or MCBs

Locate as required.

Alternative location of

fuses or MCBs

Locate as required.

≥5mm

(¼in)

150mm

(6in)

Location

of optional

terminal

block

Enclosure

Figure 2–5 Recommended layout for compliance with EMC emission standards

(wiring recommendations are given in Figures 2–22 and 2–23)

Back-plate

Unidrive LV model sizes 1 to 3 Installation Guide

Issue code: uliu1

Installing the Drive 2-13

Page 20

2.4 Calculating the

enclosure size

STEP 1 Add the dissipation figures from step 4 of

Planning the installation for each Drive that is to

be installed in the enclosure. Make a note of

this step number and the total value.

TEP 2 If an RFI filter is to be used with each

S

Drive, add the dissipation figures from step 5 of

Planning the installation for each RFI filter that is

to be installed in the enclosure. Make a note of

this step number and the total value.

TEP 3 If the braking resistor is to be mounted

S

inside the enclosure, add the average power

figures from step 8 of Planning the installation for

each braking resistor that is to be installed in

the enclosure. Make a note of this step number

and the total value.

TEP 4 Make a note of this step number and the

S

total heat dissipation (in Watts) of any other

equipment to be installed in the enclosure.

TEP 5 Add the heat dissipation figures obtained

S

(as appropriate) from steps 1, 2, 3 and 4 above.

This gives a figure in Watts for the total heat

that will be dissipated inside the enclosure.

Make a note of this figure and the step number.

Calculating the size of a

sealed enclosure

P Power in Watts dissipated by all heat

sources in the enclosure

k Heat transmission coefficient of the

enclosure material in W/m

2

/°C

Example

To calculate the size of an enclosure for the

following:

• Two UNI 1205 models

• Each Drive to operate at 4.5kHz

switching frequency

• RFI filter for each Drive

• Braking resistors are to be mounted outside

the enclosure

• Maximum ambient temperature inside the

enclosure: 40°C

• Maximum ambient temperature outside the

enclosure: 30°C

Dissipation of each Drive: 190W (from step 4 in

Planning the installation)

Dissipation of each RFI filter: 25W (max) (from

step 5 in Planning the installation)

Total dissipation: 2 x (190 + 25) = 430W

The enclosure is to be made from painted 2mm

3

/32in) sheet steel having a heat transmission

(

coefficient of 5.5W/m

2

/°C. Only the top, front, and

two sides of the enclosure are to be free to

dissipate heat.

PWM

The enclosure transfers internally generated heat

into the surrounding air by natural convection (or

external forced air flow); the greater the surface

area of the enclosure walls, the better is the

dissipation capability. Only the surfaces of the

enclosure that are unobstructed (not in contact

with a wall or floor) can dissipate heat.

Calculate the minimum required unobstructed

surface area A

A=

e

for the enclosure from:

e

P

k(T - T )

int ext

Where:

A

e

Unobstructed surface area in m

2

(1m2 = 10.8 ft2)

T

ext

Maximum expected ambient

temperature in °C outside the enclosure

T

int

Maximum permissible ambient

temperature in °C inside the enclosure

Figure 2–6 Enclosure having front, sides and

top panels free to dissipate heat

2-14 Installing the Drive

Unidrive LV model sizes 1 to 3 Installation Guide

Issue code: uliu1

Page 21

Insert the following values:

T

40°C

int

T

30°C

ext

k 5.5

P 430W

The minimum required heat conducting area is then:

A=

e

430

5.5(40 - 30)

22

= 7.8m (85ft )

(1m = 3.3 ft)

Estimate two of the enclosure dimensions — the

height (H) and depth (D), for instance. Calculate

the width (W) from:

A - 2HD

e

W=

H+D

Inserting H = 2m and D = 0.6m, obtain the minimum

width:

××××

7.8 - (2 )

W=

20621.

2+0.6

m (6ft 10in)

==

.

If the enclosure is too large for the space available,

it can be made smaller only by attending to one or

all of the following:

• Using a lower

PWM switching frequency to

reduce the dissipation in the Drives (return

to step 4 in Planning the installation)

• Reducing the ambient temperature outside

the enclosure, and/or applying forced-air

cooling to the outside of the enclosure

• Reducing the number of Drives in

the enclosure

• Removing other heat-generating equipment

Calculating the air-flow in a

ventilated enclosure

Where:

V Air-flow in m

T

ext

Maximum ambient temperature in °C

3

per hour

outside the enclosure

T

int

Maximum ambient temperature in °C

inside the enclosure

P Power in Watts dissipated by all heat

sources in the enclosure

p

k Ratio of

0

P

I

Where:

P

is the air pressure at sea level

0

P

is the air pressure at the

I

installation

Typically use a factor of 1.2 to 1.3, to

allow also for pressure-drops in dirty

air-filters.

Example

To calculate the size of an enclosure for the

following:

• Three UNI 3201 models

• Each Drive to operate at 6kHz

frequency

• RFI filter for each Drive

• Braking resistors are to be mounted outside

the enclosure

• Maximum ambient temperature inside the

enclosure: 40°C

• Maximum ambient temperature outside the

enclosure: 30°C

Dissipation of each Drive: 670W (from step 4 in

Planning the installation)

Dissipation of each RFI filter: 60W (max) (from

step 5 in Planning the installation)

Total dissipation: 3 x (670 + 60) = 2190W

PWM switching

The dimensions of the enclosure are required only

for accommodating the equipment. The equipment

is cooled by the forced air flow.

Calculate the minimum required volume of

ventilating air from:

3kP

V=

T-T

ext

int

Unidrive LV model sizes 1 to 3 Installation Guide

Issue code: uliu1

Insert the following values:

40°C

T

int

T

30°C

ext

k 1.3

P 2190W

Then:

32190

××××

V=

.

40-30

==13854

(1m3/hr = 0.59ft3/min)

Installing the Drive 2-15

33

m / hr (504 ft

/min)

Page 22

2.5 Installing the Drive

and RFI filter

Lifting the Drive

Warning

The weight of model size 3 is

22kg (49 lbs). Use appropriate

safeguards when lifting this

model.

Removing the terminal covers

The Drive is fitted with one or two terminal covers

depending on the model size. When model sizes 1

and 3 are through-panel mounted, the terminal

cover(s) must first be removed in order for access

to be gained to the lower mounting holes.

Figure 2–8 View from the underside showing

how a terminal cover is removed

from the Drive

Remove terminal covers, as follows:

1. Working on either side of the terminal cover,

push the inner edge of the cover firmly outward

until it becomes unclipped.

2. Swing the side of the cover outward and

upward until the remaining clips become

released.

3. Remove the gland plate (you may need to

replace it later).

Figure 2–7 Removing the terminal covers

The terminal cover(s) of all models must be

removed for access to the electrical connectors.

2-16 Installing the Drive

Unidrive LV model sizes 1 to 3 Installation Guide

Issue code: uliu1

Page 23

Mounting brackets supplied

with the Drive

Table 2–10 General views of the

mounting brackets

Model

size

1

2

3

Through-panel Surface

Upper and lower

Upper and lower

Surface-mounting the Drive

1. Use the two surface-mounting brackets. These

are manufactured from metal. Ensure the

brackets make direct electrical contact with the

back-plate; for example, tap M6 (

threaded holes in the back-plate in the positions

shown in Figure 2–10 to accept the mounting

screws. (For model size 1, you may use the

central or, preferably, the two outer screw

holes in the mounting bracket.)

2. Insert the surface mounting brackets into the

slots in the top and bottom of the Drive

heatsink, as shown in Figure 2–9.

1

/4 in)

Upper

Lower

Rear view of the brackets. The brackets are not shown to

scale.

Fixing hole size: M6 (1/4 in)

Figure 2–9 General representation showing

the fitting of a surface mounting

bracket in a heatsink

3. Retain the mounting brackets to the back-plate

using electrically conducting screws.

Note

When surface mounting a model size 3,

allow a clearance of 150mm (6in) above the

Drive; this is required for dismounting. A

minimum clearance of 100mm (4in) is

required for ventilation.

Unidrive LV model sizes 1 to 3 Installation Guide

Issue code: uliu1

Installing the Drive 2-17

Page 24

Model

size 1

Model

size 2

Back-plate

Back-plate

Figure 2–10 Surface mounting of model sizes 1 and 2

2-18 Installing the Drive

Unidrive LV model sizes 1 to 3 Installation Guide

Issue code: uliu1

Page 25

Model

size 3

Figure 2–11 Surface mounting of model size 3

Back -plate

Unidrive LV model sizes 1 to 3 Installation Guide

Issue code: uliu1

Installing the Drive 2-19

Page 26

Model

size 1

Model

size 2

Back-plate

Back-plate

Figure 2–12 Through-panel mounting of model sizes 1 and 2

2-20 Installing the Drive

Unidrive LV model sizes 1 to 3 Installation Guide

Issue code: uliu1

Page 27

Model

size 3

Figure 2–13 Through-panel mounting of model size 3

Back-plate

Unidrive LV model sizes 1 to 3 Installation Guide

Issue code: uliu1

Installing the Drive 2-21

Page 28

Through-panel mounting the Drive

1. Cut an aperture in the back-plate as shown in

Figure 2–12 or 2–13 as appropriate.

2. Use the through-panel mounting bracket. This

is manufactured from metal and is used to

secure the top of the Drive to the back-plate;

the bottom of the Drive is secured to the backplate by screw(s) passed through a hole in the

casing and heatsink.

Ensure the bracket and heatsink make direct

electrical contact with the back-plate; for

example, tap M6 (

back-plate in the positions shown in Figure 2–12

or 2–13 to accept the mounting screws.

3. Insert the through-panel mounting bracket into

the recess in the top of the Drive heatsink, as

shown in Figure 2–14.

1

/4 in) threaded holes in the

4. If a seal is required between the Drive and the

back-plate, attach the foam sealing strip

(supplied with the Drive) around the edges of

the aperture in the back-plate so that the flange

on the heatsink will press against the foam strip.

5. Insert the Drive into the aperture.

6. Secure the bottom of the Drive to the panel

using electrically conducting screw(s).

7. Secure the through-panel mounting bracket to

the panel using electrically conducting screw(s).

When the Drive is throughpanel mounted, a baffle plate

must be fitted at the rear of

Caution

the heatsink.

Fitting a baffle plate

If the Drive has been used, the

heatsink may be hot. Human

contact with the heatsink

Warning

should be restricted.

Figure 2–14 General representation showing

the fitting of a through-panel

mounting bracket in the top

of the Drive

When the Drive is through-panel mounted, the

fitting of a baffle plate causes the heatsink to act as

a chimney; this enhances the air flow along the

heatsink fins to aid cooling (this naturally occurs

when the Drive is surface mounted).

You may make a baffle plate from any suitable

conducting or non-conducting material and attach it

to the heatsink by the method described as follows.

2-22 Installing the Drive

Unidrive LV model sizes 1 to 3 Installation Guide

Issue code: uliu1

Page 29

Figure 2–15 Dimensions for the fabrication

of baffle plates for model

sizes 1 and 2

Attaching a fabricated baffle plate to

the heatsink

Table 2–12 Methods of attaching

the baffle plate

Figure 2–16 Dimensions for the fabrication

of baffle plates for model size 3

Model

size

1

Use the surface mounting brackets.

2

3 Use M6 x 12mm max (or equivalent)

thread-forming screws to screw into the holes

in the heatsink, or tap the holes to a suitable

thread size.

Unidrive LV model sizes 1 to 3 Installation Guide

Issue code: uliu1

Method of attachment

Installing the Drive 2-23

Page 30

This page is intentionally not used

2-24 Installing the Drive

Unidrive LV model sizes 1 to 3 Installation Guide

Issue code: uliu1

Page 31

Mounting the RFI filter

RFI filter size

B

4200–0027

388mm

151/4 in

114.5mm

41/2 in

335mm

133/16 in

37.5mm

11/2 in

6.4mm

1

/4 in

406mm

16 in

10mm

3

/8 in

75mm

215/

16

in

The RFI filters can be surface-mounted only.

Mount the RFI filter at the specified location in

relation to the Drive. In the case of filter sizes C to

D, ensure the

LOAD terminals face the Drive.

Dimension

C 378mm

D 114.5mm

E 335mm

F 25mm

G 6.4mm

H 396mm

J 10mm

W 50mm

A

4200–0010

7

14

/8 in

1

4

/2 in

3

13

/16 in

1 in

1

/4 in

9

15

/16 in

3

/8 in

15

1

/16 in

Figure 2–17 Principal dimensions of RFI filters

sizes A and B, and the locations of

the terminals

Unidrive LV model sizes 1 to 3 Installation Guide

Issue code: uliu1

Installing the Drive 2-25

Page 32

Figure 2–18 Principal dimensions of RFI filters sizes C and D, and the locations of the terminals

2-26 Installing the Drive

Unidrive LV model sizes 1 to 3 Installation Guide

Issue code: uliu1

Page 33

Dimension RFI filter size

C

4200–1051D4200–1071

A 15mm

B 160mm

6

9

/16 in

5

/16 in

C 305mm

12 in

D 15mm

F 12.5mm

G 6.5mm

H 145mm

J 280mm

5

11

9

/16 in

1

/2 in

1

/4 in

11

/16 in

3

/16 in

K 25mm

1 in

L 330mm

13 in

M 35mm

N 60mm

P 45mm

Q 240mm

S 80mm

T 30mm

1

2

1

9

3

1

3

/8 in

3

/8 in

3

/4 in

7

/16 in

1

/8 in

3

/16 in

U 50mm

2 in

V 40mm

W 190mm

X 40mm

1

7

1

9

/16 in

1

/2 in

9

/16 in

15mm

9

160mm

65/16 in

305mm

12 in

15mm

9

12.5mm

1

6.5mm

1

145mm

511/16 in

280mm

113/16 in

25mm

1 in

330mm

13 in

35mm

13/8 in

60mm

23/8 in

45mm

13/4 in

240mm

97/16 in

80mm

31/8 in

30mm

13/16 in

50mm

2 in

40mm

19/16 in

190mm

71/2 in

40mm

19/16 in

Z M5 x 10mm M5 x 10mm

Terminals M8 M8

/16 in

/16 in

/2 in

/4 in

2.6 Power connections

Electric shock risk

Warning

Warning

Warning

Warning

The voltages present in the

following locations can cause

severe electric shock and may

be lethal:

AC supply cables and

connections

Output cables and

connections

Many internal parts of the

Drive, and external option

units

Isolation device

The AC supply must be

disconnected from the Drive

using an approved isolation

device before any cover is

removed from the Drive or

before any servicing work is

performed.

Stored charge

The Drive contains capacitors

that remain charged to a

potentially lethal voltage after

AC supply has been

the

disconnected. If the Drive has

been energized, the

must be isolated at least

ten minutes before work may

continue.

AC

supply by plug and socket

Special attention must be given

if the Drive is installed in

equipment which is connected

to the

socket. The

terminals of the Drive are

connected to the internal

capacitors through rectifier

diodes which do not give

isolation. If the plug terminals

can be touched when the plug

is disconnected from the

socket, a means of

automatically isolating the

plug from the Drive must be

used (eg. a latching relay).

AC supply by a plug and

AC supply

AC supply

Unidrive LV model sizes 1 to 3 Installation Guide

Issue code: uliu1

Installing the Drive 2-27

Page 34

STOP function

Warning

The STOP function does not

remove dangerous voltages

from the Drive or any external

option units.

Ground leakage current –

model size 3

Warning

Ground leakage current is

typically 5mA at 220V 50Hz. A

fixed ground connection must

be made before

applied. In some applications,

safety regulations require a

duplicate ground connection.

Measured by the method

described in IEC950 Annex D.

AC power is

Ground connections

(earthing, equi-potential bonding)

The ground terminal of the Drive must be

connected to the system ground of the

The ground wiring must conform to local

regulations and codes of practice.

AC supply.

Power and ground terminals

Refer to Wiring recommendations later in this chapter.

The ground loop impedance

must conform to the

Warning

requirements of local safety

regulations.

The Drive must be grounded by

a connection capable of

carrying the prospective fault

current until the protective

device (fuse, etc) disconnects

AC supply.

the

The ground connections must

be inspected and tested at

appropriate intervals.

Figure 2–20 Locations of the power and

ground terminals

Terminal sizes and tightening torques

To avoid a fire hazard and

maintain validity of the UL

listing, adhere to the specified

Warning

tightening torques for the

power and ground terminals.

Refer to the following tables.

2-28 Installing the Drive

Unidrive LV model sizes 1 to 3 Installation Guide

Issue code: uliu1

Page 35

Drive

Power cables

20mm

3

/4 in

20mm

3

/4 in

28mm

11/16 in

Table 2–13 Mechanical data for the

Drive terminals

Model

size

1 Plug-in

2 Plug-in

3 M10 stud 15 N.m

Torque tolerance ±10%

terminals

Size

Type

terminal

block

terminal

block

Power

Torque Size

0.5 N.m

4.4 lb.inM4(Torx/

0.5 N.m

4.4 lb.inM4(Torx/

11 lb.ft

Ground

terminal

Type

slot-head

screw)

slot-head

screw)

M10 stud 15 N.m

RFI filter

Table 2–14 Mechanical data for the

RFI filter terminals

Size Power

A

B

C

D

Torque tolerance ±10%

terminals

Size

Type

Screw

terminals

Screw

terminals

M8 stud 12.6 N.m

M8 stud 12.6 N.m

Torque Size

0.7 N.m

6. lb.in

0.7 N.m

6. lb.in

9 lb.ft

9 lb.ft

Ground

terminal

Type

Screw

terminals

Screw

terminals

M8 stud 12.6 N.m

M8 stud 12.6 N.m

Torque

3 N.m

2.2 lb.ft

3 N.m

2.2 lb.ft

11 lb.ft

Torque

0.7 N.m

6. lb.in

0.7 N.m

6. lb.in

9 lb.ft

9 lb.ft

Using the gland plate and cable glands

When the gland plate(s) are not

fitted, objects less than 60mm

1

/2 in) wide can pass through

Warning

Fit the gland plate and cable glands as required.

Before fitting cable glands, push out sufficient

blanking caps from the gland plate.

Note that the IP rating of the Drive is reduced if any

holes in the gland plate are left open. The rating is

affected as follows:

Gland plate not fitted IP00

Gland plate fitted

Unused holes uncovered

Gland plate and glands fitted

Blanking caps covering unused holes

Table 2–15 Diameters of the holes in

Model

size

1 20mm

2 20mm

3 20mm

(2

the cable entry opening and

possibly make contact with live

parts inside the Drive.

IP10

IP40

the gland plate

Gland plate hole diameter

Control signal

wiring

3

/4 in

3

/4 in

3

/4 in

Unidrive LV model sizes 1 to 3 Installation Guide

Issue code: uliu1

Installing the Drive 2-29

Page 36

2.7 Wiring recommendations

Observe the wiring recommendations given in this

section. Recommendations are given separately for

the following:

Routine EMC precautions

• Recommended when strict compliance with

emission standards is not required.

• Minimized risk of disturbing adjacent

electronic equipment.

Key to symbols

Single power cable

Three-core power cable or

three single power cables

Four-core power cable

(3-phase + ground)

Ground cable

No sensitive circuits permitted

in this zone

Compliance with EMC emission

standards

• Strict compliance with emission standards.

• When the Drive is installed in a residential

area, or adjacent to sensitive electronic

equipment such as radio receivers or similar.

The details of individual installations may vary, but

details which are indicated in the recommendations

to be important for EMC must be adhered to

closely.

For further details when EMC emission requirements

are to be met, refer to the Unidrive LV EMC Data Sheet

for the size of Drive used.

Optional external

braking resistor

AC

supply

L1

L2

L3

Ground

Output 3

Output 2

Output 1

Ground

Host

controller

0V

Isolator

Contactor

Fuses or

MCB

Control cables

to the Drives

Power-ground

bus-bar

Drive

L1 L2 L3 U VW+

_

Back-plate

Enclosure

Figure 2–21 Wiring guidelines for routine EMC precautions (model sizes 1 to 3)

2-30 Installing the Drive

Unidrive LV model sizes 1 to 3 Installation Guide

Issue code: uliu1

Page 37

Routine EMC precautions (model sizes 1 to 3)

General features

1. Single power-ground bus-bar, or low-

impedance ground terminal.

2. Incoming

power ground bus-bar.

3. Connect grounds of any other circuits to the

power ground bus-bar.

4. Site ground, if required.

5. Metal back-plate, safety bonded to the power

ground bus-bar.

6. System isolator, circuit contactors and

fuses/MCB.

7. Alternative position for Drive fuses/MCB.

8. Motor-frame ground connection, if required.

9. Optional braking resistor mounted externally,

protected by a metal grille.

10. Thermal protection device to protect the

braking resistor.

AC supply ground connected to the

Routine EMC precautions

11 Use four-core cable to connect the motor to

the Drive as shown. The ground conductor in

the motor cable must be connected only to the

ground terminals of the Drive and motor; it

must not be connected directly to the powerground bus-bar.

12. If the wiring for sensitive signal circuits is to be

parallel to an unshielded motor cable (or cables

for an unfiltered power supply) for more than

1 metre (3 feet), ensure the separation is at

least 0.3m (12 in).

If the parallel run is to exceed 10 metres (30

feet), increase the separation proportionally.

For example, if the parallel run is to be

40 metres, the spacing must be 0.3 x 40 ÷ 10 =

1.2 metres.

When a motor-thermistor is used, this

constraint does not apply to the cable

connecting the thermistor to the Drive. The

motor-thermistor cable must be shielded (as

shown in Figures 3–4 and 3–5 in the User Guide).

13. Do not place sensitive signal circuits in a zone

extending 0.3m (12 in) all around the Drive.

14. If the control circuit 0V is to be grounded, this

should be done at the system controller (eg.

PLC) and not at the Drive. This is to avoid

injecting noise currents into the 0V circuit.

15. When the braking-resistor wiring is unshielded,

ensure a minimum spacing of 0.3m (12 in) from

signal wiring.

Unidrive LV model sizes 1 to 3 Installation Guide

Issue code: uliu1

Installing the Drive 2-31

Page 38

Key to symbols

AC

supply

L1

L2

L3

Ground

Single power cable

Three-core power cable or

three single power cables

Ground cable

Connection to cable armour or

shield

Maximu m length: 50mm (2 in)

Alternative safety ground

connection

Armoured or shielded cable

(3-phase + ground)

No sensitive circuits permitted

in this zone

Output 3

Output 2

Output 1

0V

Ground

Host

controller

Isolator

Contactor

Fuses or

MCB

Control cables

to the Drives

≤100mm

(4 in)

Optional external

braking resistor

5 − 10mm

13

( /4 − /8 in)

Drive

L1 L2 L3 U VW+

L1 L2 L3

RFI filter

_

Back-plate

Power-ground

bus-bar

Enclosure

Figure 2–22 Wiring guidelines for compliance with EMC emission standards (model sizes 1 and 2)

2-32 Installing the Drive

Unidrive LV model sizes 1 to 3 Installation Guide

Issue code: uliu1

Page 39

Compliance with EMC emission standards (model sizes 1 and 2)

General features

1. Single power ground bus-bar or low-impedance

ground terminal.

2. Incoming

power ground bus-bar.

3. Connect grounds of any other circuits to the

power ground bus-bar.

4. Site ground if required.

5. Metal back-plate, safety bonded to the power

ground bus-bar.

6. System isolator, circuit contactors and

fuses/MCB.

7. Alternative position for Drive fuses.

8. Optional braking resistor mounted externally,

protected and shielded by a metal grille.

9. Thermal overload device to protect the

braking resistor.

10. Alternative safety ground for the motor.

11. Motor-frame ground connection, if required.

AC supply ground connected to the

Special features for EMC

12. Drive heatsink directly grounded to the

back-plate using the metal mounting-brackets.

Ensure that the screws make direct electrical

connection to the back-plate, for example by

using screw threads tapped in the backplate.

13. RFI filter mounted at the side of the Drive.

Ensure a separation of 5 to 10mm (

from the Drive. The RFI filter casing is directly

grounded to the back-plate by the fixing

screws.

14. A shielded (screened) or steel-wire armoured

cable must be used to connect the Drive to the

motor. The shield must be bonded to the

back-plate using an uninsulated metal cableclamp. The clamp must be positioned no

further than 100mm (4 in) from the Drive.

15. Connect the shield of the motor cable to the

ground terminal of the motor frame using a link

that is as short as possible and not exceeding

50mm (2 in) in length. A full 360° termination

of the shield to the terminal housing of the

motor is beneficial.

16. Ensure the

AC supply and ground cables are at

least 100mm (4 in) from the Drive.

1

/4 to 3/8 in)

17. Avoid placing sensitive signal circuits in a zone

extending 0.3m (12 in) all around the Drive.

18. Unshielded wiring to the optional braking

resistor(s) may be used, provided the resistor is

either in the same enclosure as the Drive or the

wiring does not run external to the enclosure.

When the braking-resistor wiring is unshielded,