Page 1

............

............

............

............

............

............

............

............

............

............

............

............

............

............

............

............

............

............

............

............

............

............

............

............

............

............

............

............

............

............

............

............

Unidrive Servo &

Unimotor

product data

The performance matched AC Servo

solution for all applications

Page 2

2

Page 3

servo drive

Drive Overview 4

Introduction to Macros 7

Drive Technical Specification 12

Connections 16

Drive Installation 19

Electro Magnetic Compatibility (EMC) & Radio 24

Frequency Interference (RFI)

servo motor

Motor Overview 26

Motor Technical Specification 27

Motor Installation 32

Accessories 34

servo drive & motor

combinations

Torque Speed Curves & Tables 42

Servo Sizing Software 48

motion intelligence

Options 50

Typical Applications 54

3

Chapter 1

Chapter 2

Chapter 3

Chapter 4

..........

..........

..........

..........

Page 4

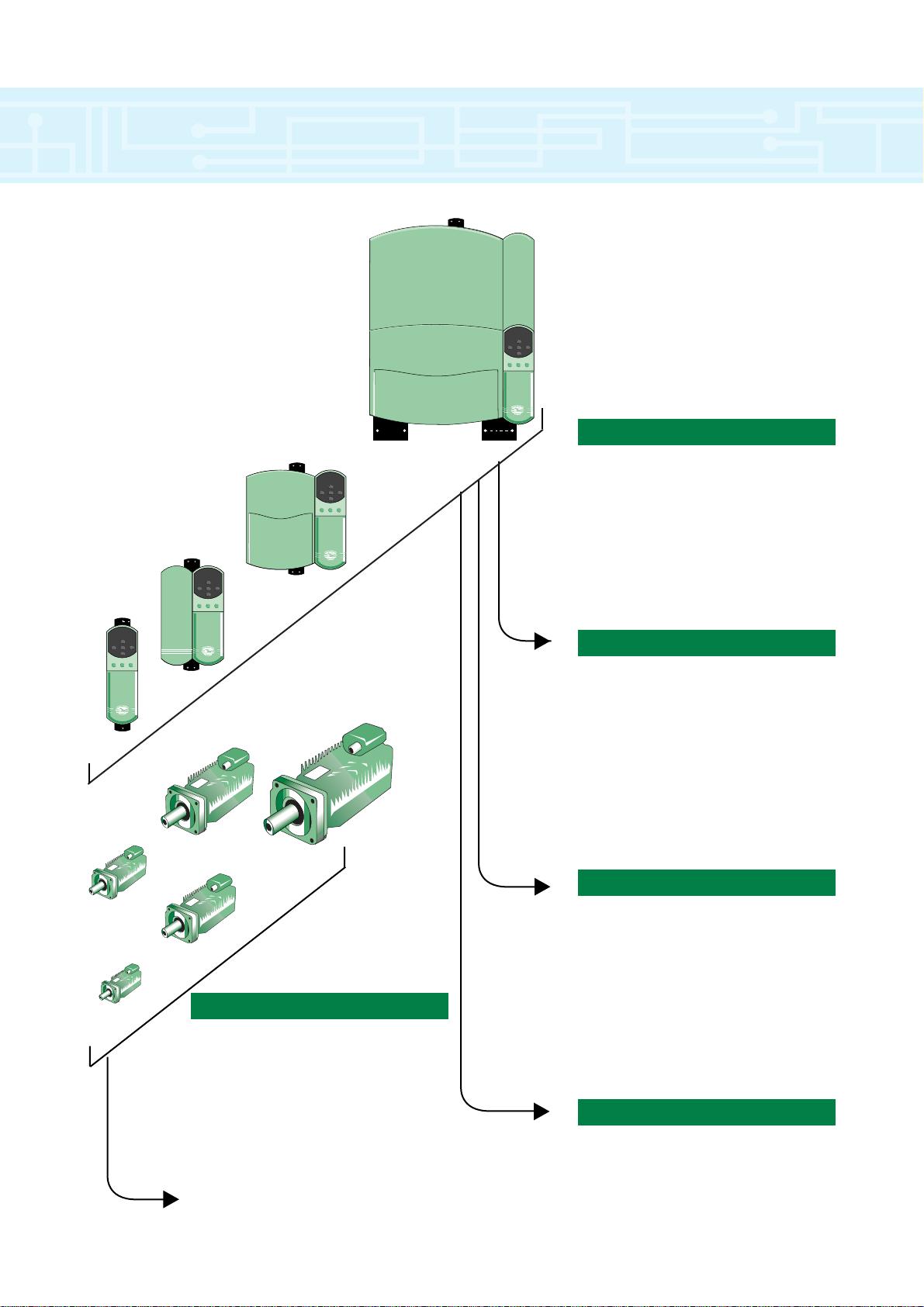

drive overview

Connectivity

UD73 - Profibus DP

UD74 - Interbus S

UD77 - DeviceNet

UD75 - CT Net

UD76 - Modbust +

UD71 - RS232/485

HMI - Operator Interfaces

Feedback

Standard - Encoder

UD53 - Resolver

UD52 - Sin/cos encoder

Unimotor

Brushless AC Servo motors to 70Nm

On request:

- Brushless >70NM-1850Nm

- Asynchronous >70NM-2500Nm

Motor accessories: - cables, fan

cowlings, brakes, planetary geared

motors

Unidrive Servo

& Unimotor

The complete multi purpose

Servo package with

high flexibility

& functionality

Model size 3

Model size 2

Model size 1

Model size 4

Motion Intelligence

UD70 - Applications module

UD78 - High performance servo

UD50 - Extended I/O

UD51 - 2nd Encoder

Unisoft - Programming software

SYPT - Systems programming tool

CTSS - Servo sizing software tool

Power Range 380-480V

Size 1 - 0.75 to 4kW

Size 2 - 5.5 to 11kW

Size 3 - 15 to 37kW

Size 4 - 45 to 110kW

Size 5 - >110kW

Line regeneration capability

4

75

95

115

142

190

Page 5

Unidrive

The Unidrive is an advanced AC drive for use with

AC brushless permanent magnet servo motors. The

Unidrive’s set up can be easily and quickly changed

from the on-board keypad, a remote keypad, or

through UniSoft, a Windows™based configuration

software tool.

Sizes

There are five physical sizes comprising 26

different models ranging from 1NM to 2500 NM*. The

drive is designed for stand alone as well as

coordinated systems applications. There are hundreds

of configurable functions in 20 logically organised

menus. All functions are factory defaulted to typical

values to facilitate easy set-up.

Parameters

The Unidrive’s most commonly used parameters

are stored in Menu 0. This menu is defaulted with

those parameters which are typically accessed, but

the user may map any of the drive’s other

parameters to this menu for easier access. This

approach means easy access for those parameters

the user selects.

Flexibility

In addition Unidrive has many other of embedded

configurable functions which are easily adapted for

virtually any application. Some of these configurable

functions include items such as assignable I/O,

autotune, encoder feedback, frequency and direction

pulse signal input and output, axis limit control, ratio

control, electronic holding brake, S-ramps, position

control and many others.

Technology

Many of these important product features would not

be possible without the use of advanced technology in

the Unidrive. The drive employs advanced

microprocessor technology which controls all drive

functions including input to the inverter ASIC

(Application Specific Integrated Circuit) which

synthesises an adjustable carrier frequency PWM

(Pulse Width Modulation) output. The ASIC output

controls the IGBT (Insulated Gate Bipolar Transistor)

inverter section. All printed circuit boards are

manufactured using surface mount technology.

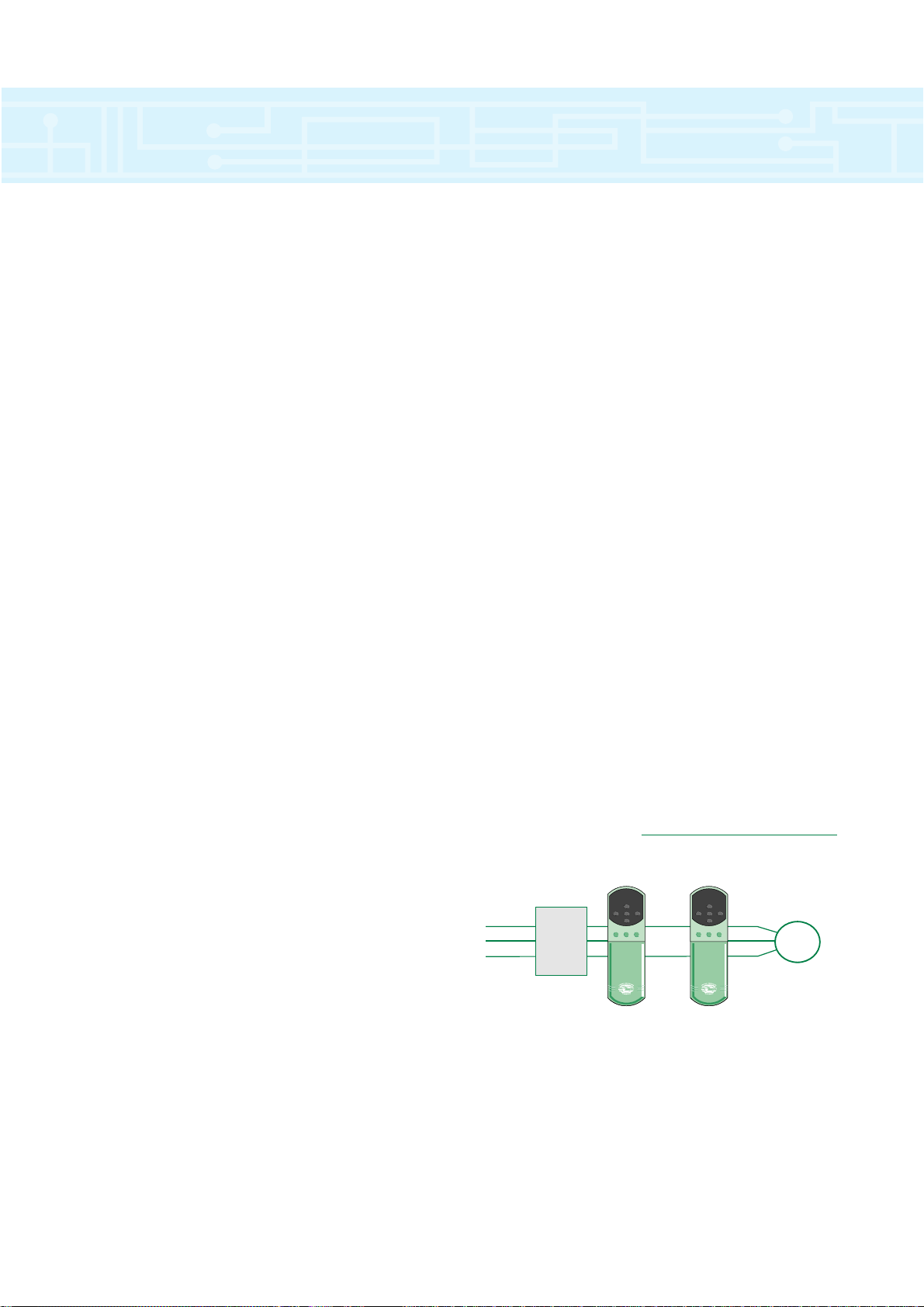

Regeneration

The Regeneration mode is used for four-quadrant

operation. A Drive can be operated in Regeneration mode

only when it is connected to other Drive(s) operating in

one of the other (motoring) modes.

Regeneration mode allows the following:

●

AC supply to be fed from the Regeneration Drive to

the Drive(s) that are controlling the motor

● Regenerated power to be returned to the AC supply

by the Regeneration Drive instead of being dissipated

in braking resistors

Regeneration Module Control Mode

▼

drive overview

* For ratings above 65NM please consult your local Drive/Application centre

5

Regenerating

Unidrive

AC Supply

Filter

and

Start

Circuit

+

DC Bus

—

Motoring

Unidrive

AC

Motor

Page 6

Key Features

General Features

●

Coast & Ramp to Stop modes

●

8 Preset speeds & Ramps

●

3 Skip frequencies

●

S Ramp

●

Motorised potentiometer

●

Internal braking transistor as standard

●

Encoder input as standard

●

Programmable security code

●

Bright two line LED display

Advanced Features

●

Position control

●

Digital lock

●

Mains dip ride through

●

Frequency slaving

●

Catch a spinning motor

●

Programmable logic functions

●

Orientation

Performance Features

●

336µs speed loop sample time

●

176µs current loop sample time

●

16 bit speed loop

●

12 bit current loop

●

Dynamic injection/braking

●

Fast current loop with PI control

Flexibility Features

●

Speed reference selector

●

Full I/O programmability

●

Unisoft

●

Well structured menu system

●

Encoder I/P

●

Programmable logic functions

●

Configurable menu zero

●

Programmable thresholds

●

Resolver feedback

●

Sin/cos feedback

●

High speed communications

●

Applications module

●

High performance module

Ease of Use Features

●

Macros

●

Bright two line LED display

●

Cloning module

●

Unisoft

Maintenance Features

●

Clock

●

Full internal protection & diagnostics

●

Last ten trips stored

●

Programmable security code

●

Common control board

●

Pluggable terminals

drive overview

6

Page 7

introduction to macros

7

Introduction

The Unidrive’s more than 700 parameters are

organised so that similar parameters are grouped within

the same menu. For example, Menu 1 holds the

parameters associated with the selection of a speed

reference. Menu 2 holds parameters associated with

the selection of acceleration and deceleration rates etc.

Menu zero

This menu holds parameters that are quick access

duplicates of the most used advanced parameters.

Categories:

0.0 Configuration

0.01 – 0.02 Speed limits

0.03 – 0.06 Ramps

Speed reference selection

Current limit

0.07- 0.09 PID gains (closed loop)

0.10 – 0.13 Monitoring

0.14 – 0.17 Jog reference

Ramp mode selector

Stop and torque mode selectors

0.18 – 0.19 S-ramp

0.20 – 0.23 Skip bands

0.24 – 0.26 Analogue input modes

0.27 – 0.34 Miscellaneous

0.35 Keypad reference monitoring

0.36 – 0.38 Serial communications

Parameter displayed at power up

0.39 – 0.41 Spinning motor

Autotune

PWM switching frequency

0.42 – 0.47 Motor parameters

0.48 Operating mode selection

0.49 – 0.50 Status information

Menu 1 Frequency / speed reference selection

Frequency / speed limits

Skip frequencies / speeds

Menu 2 Acceleration and deceleration ramps

Ramp selection, enable selected

Braking mode selection

S-ramp

Menu 3 Speed indications

Speed loop PID gain

Speed sensing thresholds

Frequency slaving

Hard speed reference

Encoder set up

Menu 4 Current monitoring

Current limiting in speed control

Current loop gains

Torque control

Motor protection

Menu 5 Motor monitoring

Motor ratings

Autotune

PWM switching frequency

Menu 6 Drive sequencer

Auto-start

AC supply loss

Jog time

Limit switches

Injection braking

Synchronise to a spinning motor

Keypad enable

Run-time log

Electricity cost

Menu 7 Analogue I/O

Temperatures

Menu 8 Digital I/O

Menu 9 Programmable logic

Motorised potentiometer

Binary-sum logic

Menu 10 Status and diagnostic information

Process generated trips

UD78 power supply indicator

Menu 11 Menu 0 assignments

Scale factors

Initial parameters displayed

Serial communications

Drive information

Menu 12 Programmable comparators

Menu 13 Position control

Menu 14 PID controller

Menu 15 Regeneration

Menu 16 Small Option Module

Menu 17 Large Option Module

Menu 18 User parameters LOM

Menu 19 User LOM

Menu 20 UD70 only

Menu Overview

Page 8

8

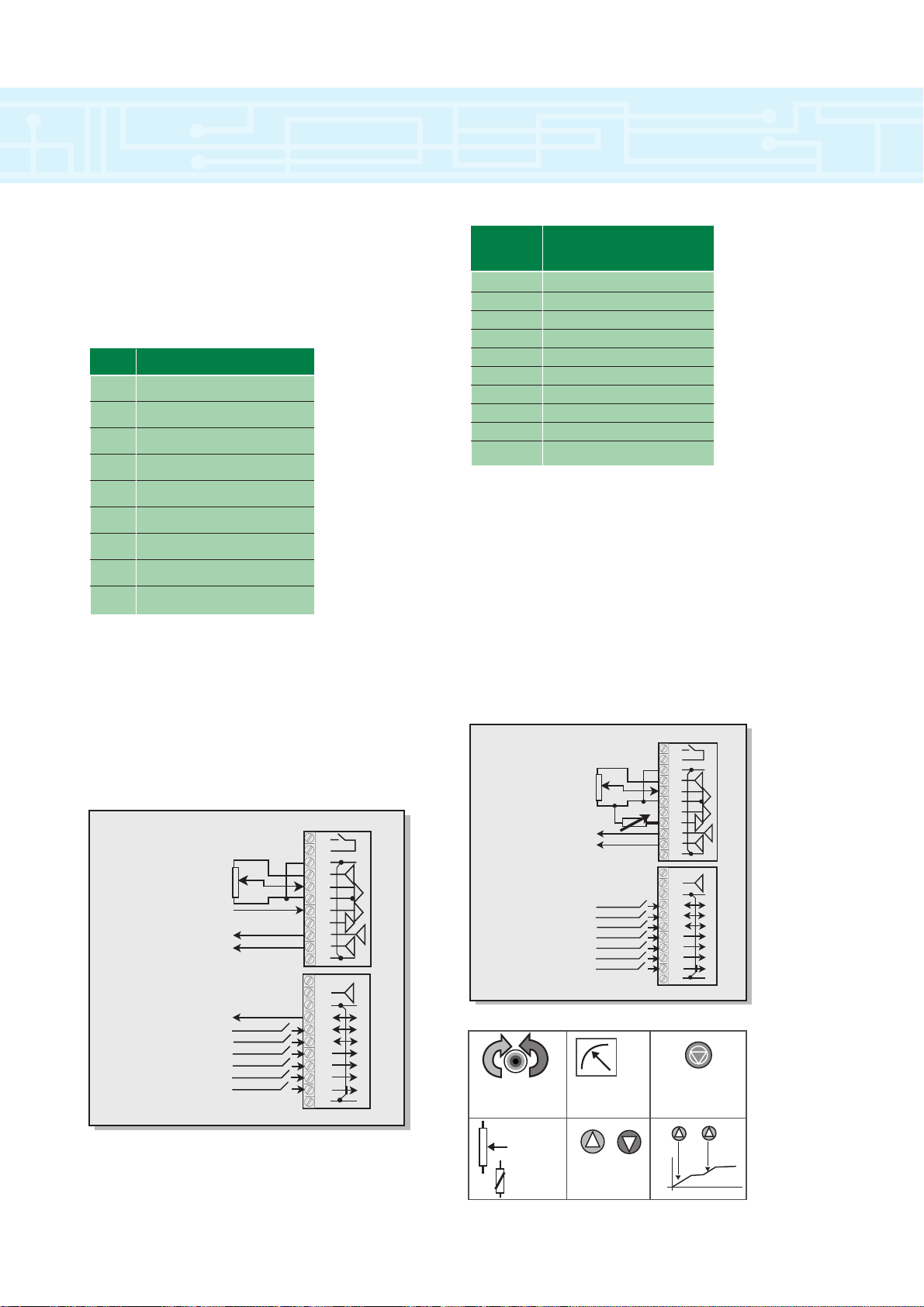

introduction to macros

Unidrive operation can be simplified by using preconfigured application macros. These macros are held in

the internal memory of the drive and are user selectable.

Macro summary

Macro 1 – Easy Mode

Easy mode defines the most commonly used

features with only 10 parameters. These parameters

are numbered 0.01 to 0.10

Macro Function

0 Default mode

1 Easy mode

2 Motorised potentiometer

3 Preset speeds

4 Torque control

5 PID macro

6 Axis Limit control

7 Hoist control/brake release

8 Digital Lock

0.01 1.07 Minimum Speed

0.02 1.06 Maximum Speed

0.03 2.11 Acceleration time

0.04 2.21 Deceleration time

0.05 1.14 Reference select

0.06 4.07 Current limit

0.07 3.10 Proportional gain

0.08 3.11 Integral gain

0.09 3.12 Derivation gain

0.10 3.02 Speed feedback

Macro 2 – Motorised Potentiometer

With this function it is possible to emulate a

motorised potentiometer within the Unidrive by simply

supplying two logic input signals to increase or

decrease the “potentiometer”. The output of the

“potentiometer” may be routed to control any of the

drive’s non-bit parameters such as speed, torque or

current limit. The function may be configured to reset

upon power cycling or to memorise its value.

Menu 0

Parameter

Param. Description

When a Macro is not enabled, the drive operates in a default

configuration (EURO USA)

Drive Connections

Analog Ch 1

0-10v DC

Analog Ch 2

4-20mA Input

Speed Output

Load Output

At Speed Output

Drive Reset Input

Jog Input

Run Forward Input

Run Reverse Input

Analog 1/2 Select Input

External Trip Input

1

2

3

4

5

6

7

8

9

10

11

21

22

23

24

25

26

27

28

29

30

31

Drive Connections

Analog Ch 1

0-10v DC

Thermistor

Speed Output

Load Output

Motorised Pot Up Input

Drive Reset Input

Motorised Pot Down Up

Run Forward Input

Run Reverse Input

An/Mot Pot Select Input

External Trip Input

Run Forward

& Reverse

Speed

& Current

x 2

1

2

3

4

5

6

7

8

9

10

11

21

22

23

24

25

26

27

28

29

30

31

External

Reset Input

x 1

0-10V DC

Thermistor

Motorised pot

Increase &

Decrease

Page 9

introduction to macros

Terminal 24 Terminal 26 Speed

Open Open As set in Pr 0.25

Open Closed As set in Pr 0.26

Closed Open As set in Pr 0.27

Closed Closed As set in Pr 0.28

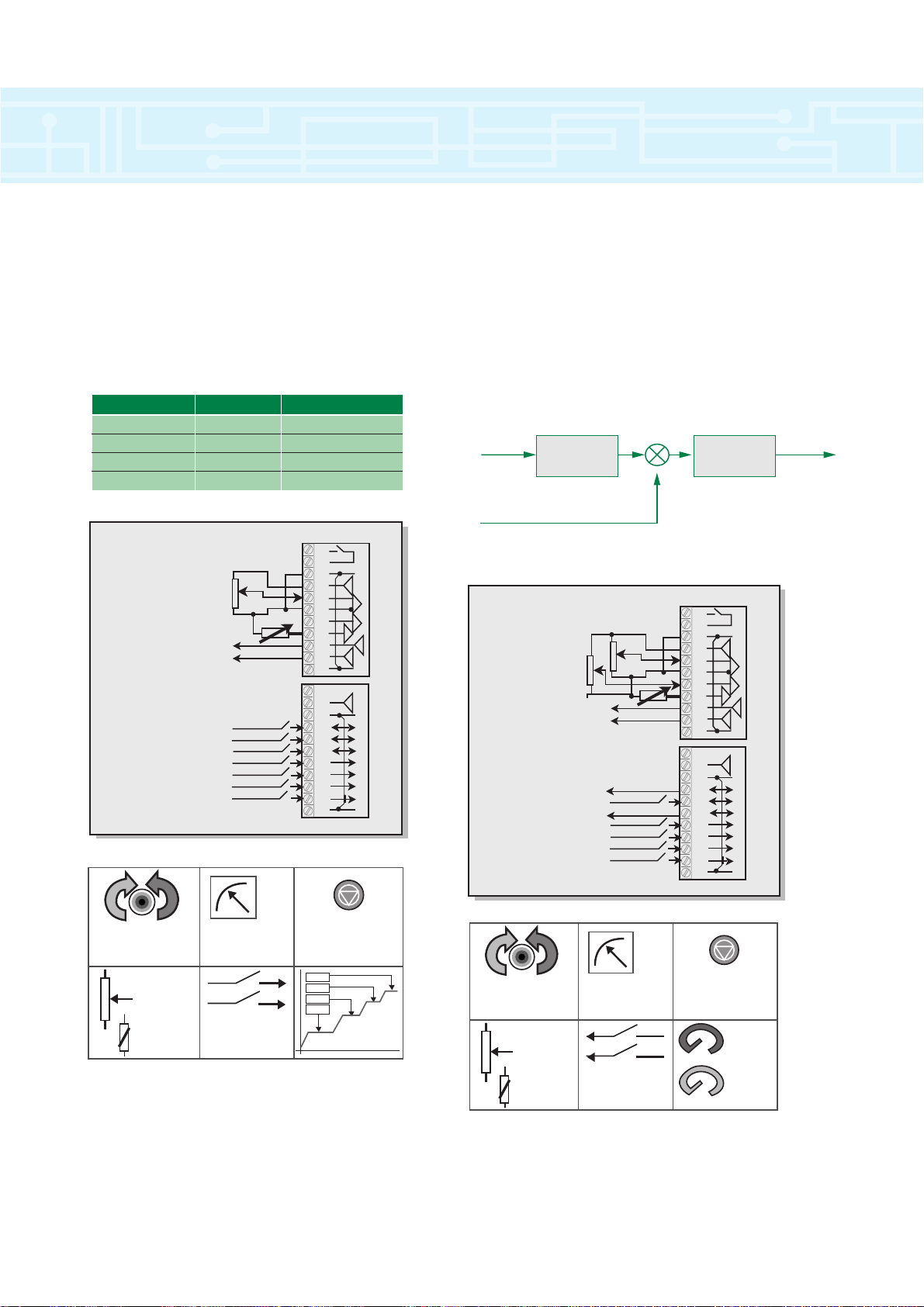

Macro 3 – Preset Speeds

By using this macro up to four preset frequencies /

speeds can be used. Preset values must be

programmed into individual parameters. Frequency /

speed selection is done by activating terminal 29 and

putting a binary combination on terminals 24 and 26.

Macro 4 – Torque control

When this macro is selected a drive can be operated

in Speed or Torque control by using terminal 29.

If in Speed control mode, speed is maintained

independent of load within the limits of the drive. In

Torque control mode the drive will attempt to reach the

speed set point but only with the torque available as

defined by the torque reference signal.

Torque/Current

PI (Current)

Current Feedback (torque component)

Torque Ref. Post Ramp

Ref

9

Drive Connections

Analog Ch 1

0-10v DC

Thermistor

Speed Output

Load Output

Preset Select 1 Input

Drive Reset Input

Preset Select 2 Input

Run Forward Input

Run Reverse Input

An/Preset Select Input

External Trip Input

1

2

3

4

5

6

7

8

9

10

11

21

22

23

24

25

26

27

28

29

30

31

Drive Connections

Torque Ref.

Speed Ref.

Thermistor

Speed Output

Load Output

Drive Speed Output

Drive Reset Input

Min. Speed Output

Run Forward Input

Run Reverse Input

Speed/Torque Select Input

External Trip Input

1

2

3

4

5

6

7

8

9

10

11

21

22

23

24

25

26

27

28

29

30

31

x 2

Run Forward

& Reverse

Speed

& Current

x 1

0-10V DC

Thermistor

2 Inputs

for 4

Preset Speeds

External

Reset Input

P1 and 1

P1 and 2

P1 and 3

P1 and 4

Run Forward

& Reverse

0-10V DC

Thermistor

x 1

x 2

Speed

& Current

2 Outputs

for A1 Speed

& At Min.Speed

External

Reset Input

0%

100%

0%

100%

RPM

(Speed)

Amps

(Torque)

Page 10

10

introduction to macros

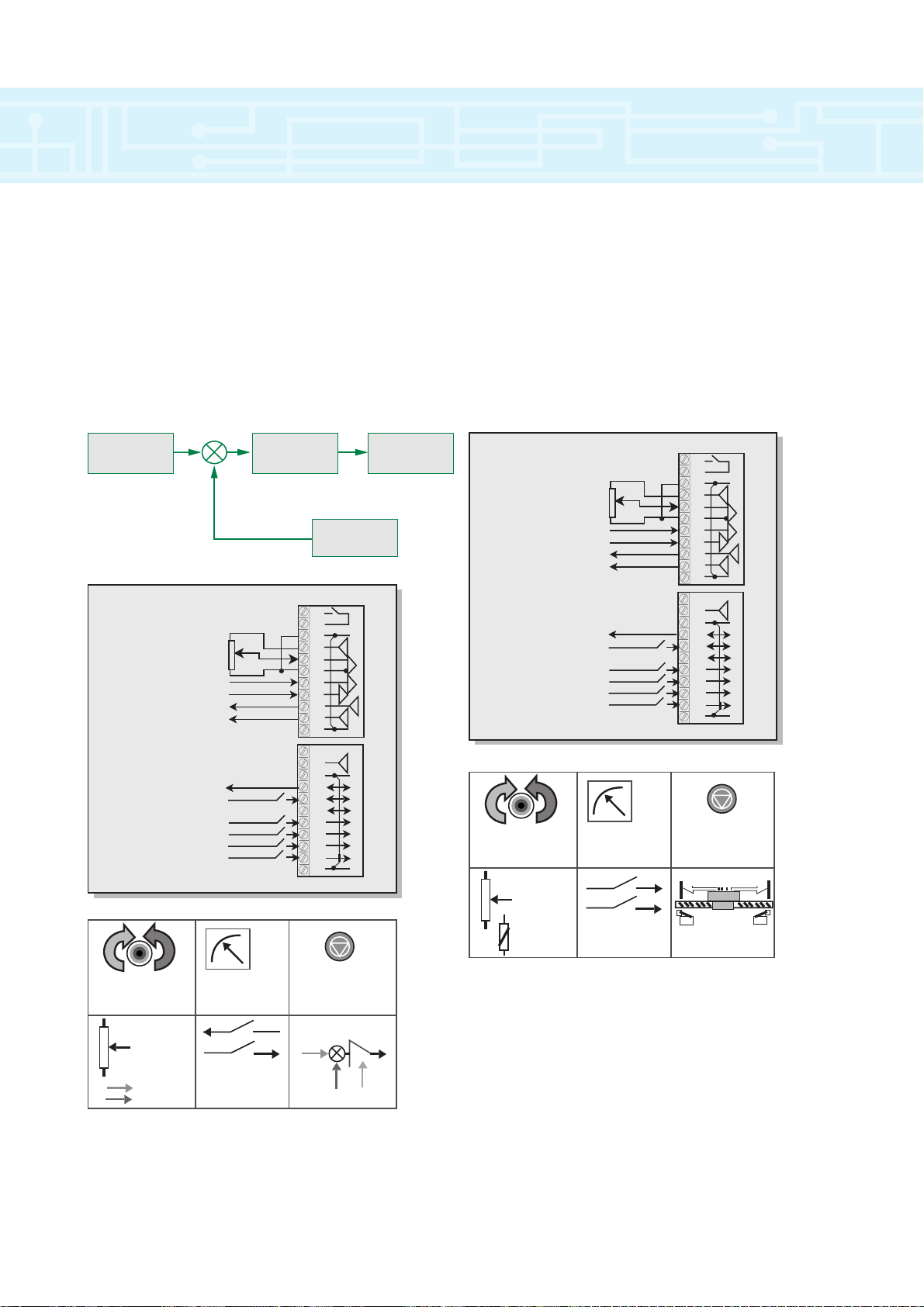

Macro 6 – Axis Limit control

Using this macro enables two digital inputs to be

re-programmed so providing limit switch lockout for

axis position control systems. The drive would normally

be run from a +/- 10v reference and controlled forward

/ backwards from this. If a limit switch level is reached

the drive will be forced to stop independent of the

speed setting.

Macro 5 – PID control

This macro configures the drive to control a motor

with reference to PID control signal. In PID control, the

error resulting from differences between the PID

feedback and PID reference is passed through a limiter,

a scaling stage and finally the error is added to the

frequency / speed signal.

Setpoint

Source

PID

Output

Source

Feedback

Source

Drive Connections

Torque Ref.

Main Ref.

PID Reference

PID Feedback

Speed Output

Load Output

Drive At Speed Output

Drive Reset Input

Run Forward Input

Run Reverse Input

PID Enable Input

External Trip Input

x 2

1

2

3

4

5

6

7

8

9

10

11

21

22

23

24

25

26

27

28

29

30

31

Drive Connections

Torque Ref.

Main Ref.

PID Reference

PID Feedback

Speed Output

Load Output

Drive At Speed Output

Drive Reset Input

Run Forward Input

Run Reverse Input

PID Enable Input

External Trip Input

Run Forward

& Reverse

x 1

0-10V DC

Thermistor

Speed

& Current

2 Inputs

for Forward &

Reverse limits

x 2

1

2

3

4

5

6

7

8

9

10

11

21

22

23

24

25

26

27

28

29

30

31

External

Reset Input

Run Forward

& Reverse

0-10V DC

PID Ref

PID F/bk

x 1

Speed

& Current

Input for

PID Enable &

At Speed O/P

PID Ref

External

Reset Input

P

I

D

PID F/bk

PID

Enable

Page 11

introduction to macros

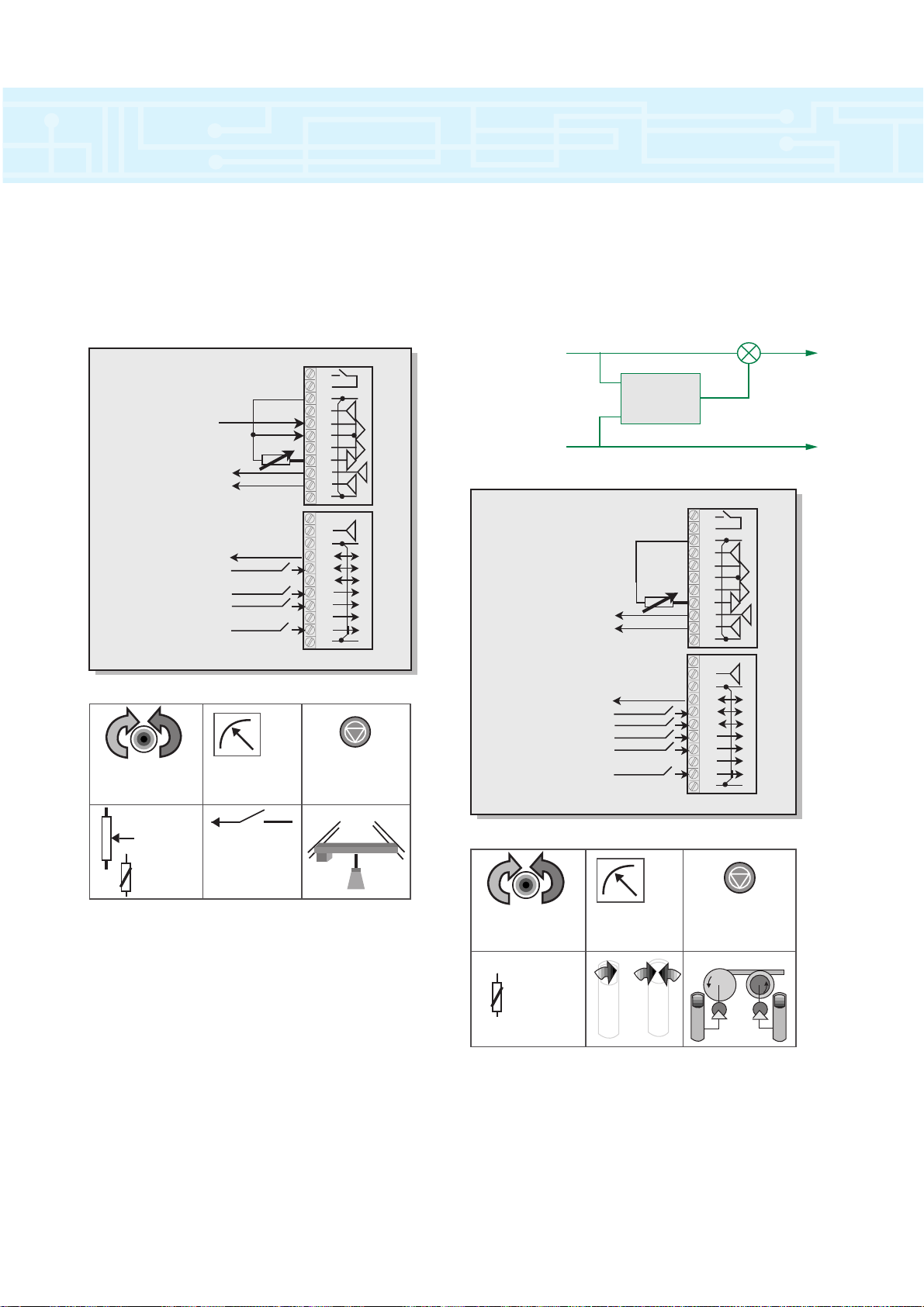

Macro 8 – Digital Lock

The digital lock macro enables a drive to be

operated so that it will lock two motor shafts together

pulse for pulse.

Macro 7 – Brake control

This macro essentially allows the control of an

external brake. The brake is released when the drive is

running and there is current in the motor.

11

Drive Connections

Speed Input

from PLC

Thermistor

Speed Output

Load Output

Brake Release Output

Drive Reset Input

Run Forward Input

Run Reverse Input

External Trip Input

Run Forward

& Reverse

Speed

& Current

x 2

1

2

3

4

5

6

7

8

9

10

11

21

22

23

24

25

26

27

28

29

30

31

External

Reset Input

Reference Counts

Accumultor

Feedback Counts

Drive Connections

Thermistor

Speed Output

Load Output

Drive At Speed Output

Drive Reset Input

Relative Jog Input

Run Forward Input

Run Reverse Input

Enable Input

+/- Error

1

2

3

4

5

6

7

8

9

10

11

21

22

23

24

25

26

27

28

29

30

31

Feed Forward

Feedback

x 1

0-10V DC

Thermistor

Brake Release

Output

Run Forward

& Reverse

Thermistor

only

Speed

& Current

Relative Jog

Input

x 2

External

Reset Input

Take Up

M

Capatan

M

Page 12

12

AC supply requirements

380V to 480V ±10%, 3-phase, 48 to 62 Hz

Maximum supply imbalance: 2% negative phase sequence

(equivalent to 3% voltage imbalance between phases)

Line reactors

When one of the following model sizes...

UNI 1401, UNI 1402, UNI 1403, UNI 1404

....is used on an AC supply of 175kVA or larger, it is

recommended that a line reactor of 2% reactance is

included between the AC supply and the Drive. Model

sizes 1405 and larger have an internal dc-bus choke.

A line reactor reduces the risk of damage to the Drive

resulting from severe disturbances on the supply network.

Temperature, humidity and cooling method

Ambient temperature range:

–10°C to 50°C (14°F to 122°F). Output current de-rating

may apply at high ambient temperatures.

Cooling method: Natural convection

Maximum humidity: 95% non-condensing at 40°C (104°F)

Storage temperature range: –40°C to 50°C (–40°F to 122°F)

Maximum storage time: 12 months

Altitude

Altitude range: 0 to 4000m (13000 ft), subject to the

following conditions:

1000m to 4000m (330 feet to 13000 ft) above sea level:

de-rate the maximum output current from the specified

figure by 1% per 100m (330 ft)

Vibration

Maximum vibration:²0.5g as specified in IEC 68–2–61; 1982

Ingress protection

Gland plate(s) not fitted: IP00

Gland plate(s) fitted; cable glands not fitted: IP10

Cable-glands fitted; glands fitted: IP40, NEMA 1

Accuracy and Resolution

The following data applies to the Drive only; it does not

include the performance of the source of the control signals.

Output-frequency accuracy:² ±0.1%

Output-frequency resolution: ² ± 0.01

RPM

Starts per hour

By electronic control: unlimited

By interrupting the AC supply:

model sizes 1 and 2: ² 20, model sizes 3 and 4: ² 10

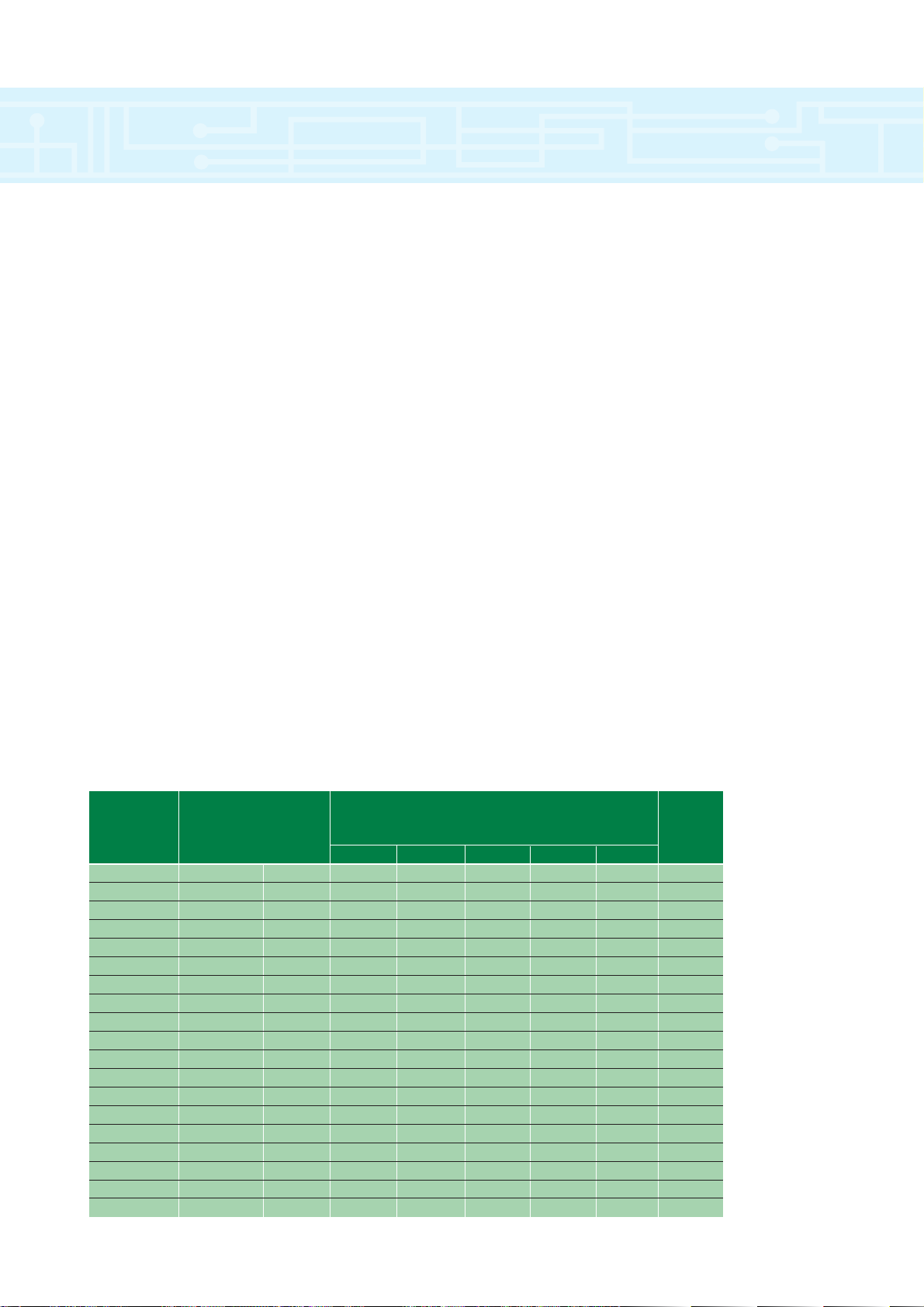

Nominal Maximum permissible continuous output current Nominal

rating AC

supply

current

@380V @460V 3kHz ✝ 4.5kHz 6kHz 9kHz 12kHz

UNI 1401 0.75 kW 1.0 HP 2.1 A 2.1 A 2.1 A 2.1 A 2.1 A 3.1 A

UNI 1402 1.1 kW 1.5 HP 2.8 A 2.8 A 2.8 A 2.8 A 2.8 A 3.2 A

UNI 1403 1.5 kW 2.0 HP 3.8 A 3.8 A 3.8 A 3.8 A 3.8 A 5.5 A

UNI 1404 2.2 kW 3.0 HP 5.6 A 5.6 A 5.6 A 5.6 A 4.5 A 8.4 A

UNI 1405 4.0 kW 5.0 HP 9.5 A 9.5 A 8.5 A 7.0 A 5.5 A 9.5 A

UNI 2401 5.5 kW 7.5 HP 12.0 A 12.0 A 12.0 A 12.0 A 11.7 A 13.7 A

UNI 2402 7.5 kW 10.0 HP 16.0 A 16.0 A 16.0 A 14.2 A 11.7 A 16.3 A

UNI 2403 11.0 kW 15.0 HP 25.0 A 21.7 A 18.2 A 14.2 A 11.7 A 24.3 A

UNI 3401 15.0 kW 25.0 HP 34.0 A 34.0 A 34.0 A 28.0 A 23.0 A 34.0 A

UNI 3402 18.5 kW 30.0 HP 40.0 A 40.0 A 37.0 A 28.0 A 23.0 A 39.0 A

UNI 3403 22.0 kW 30.0 HP 46.0 A 46.0 A 40.0 A 32.0 A 26.6 A 46.0 A

UNI 3404 30.0 kW 40.0 HP 60.0 A 47.0 A 40.0 A 32.0 A 26.7 A 59.0 A

UNI 3405 37.0 kW 50.0 HP 70.0 A 56.0 A 46.0 A 35.0 A 28.0 A 74.0 A

UNI 4401 45.0 kW 75.0 HP 96.0 A 96.0 A 88.0 A 70.0 A 96.0 A

UNI 4402 55.0 kW 100.0 HP 124.0 A 104.0 A 88.0 A 70.0 A 120.0 A

UNI 4403 75.0 kW 125.0 HP 156.0 A 124.0 A 105.0 A 80.0 A 151.0 A

UNI 4404 90.0 kW 150.0 HP 180.0 A 175.0 A 145.0 A 110.0 A 173.0 A

UNI 4405 110.0 kW 150.0 HP 202.0 A 175.0 A 145.0A 110.0 A 190.0 A

UNI 5401 160.0 kW 200.0 HP 300.0 A 240.0 A

Power and Current ratings

40°C (104°F)

ambient

Model

drive technical specifications

✝ Peak current: up to 175% of the rated current for 4 seconds

✝ Factory setting

Page 13

13

drive technical specifications

Frequencies and

speed

PWM switching

frequency:

3kHz nominal (selectable

up to 12kHz)

Maximum speed

30 000 RPM

Speed regulation: 0.01%

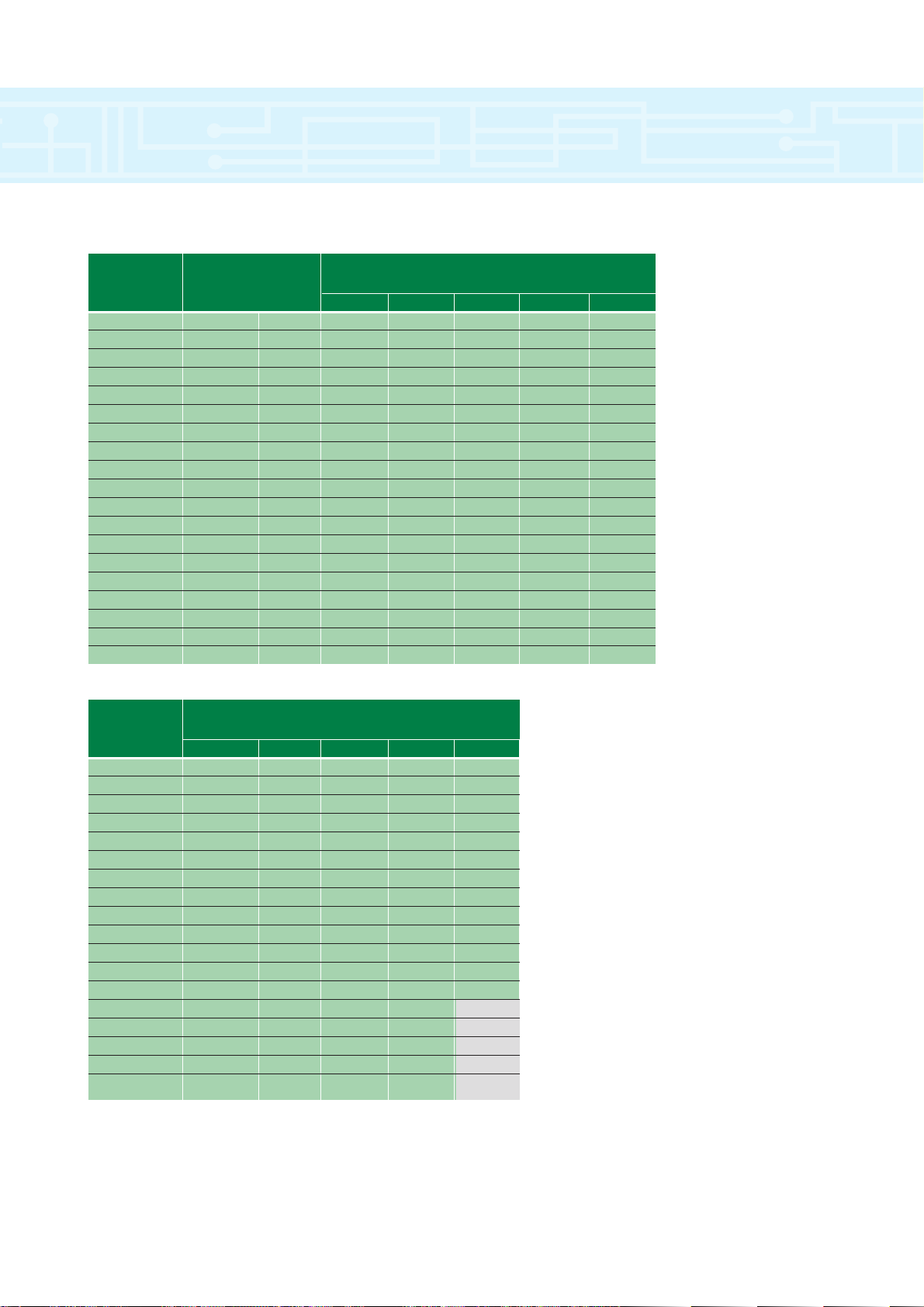

Model Nominal Maximum total power dissipation

rating

@380V @460V 3kHz 4.5kHz 6kHz 9kHz 12kHz

UNI 1401 0.75kW 1.0HP 80 W 80 W 90 W 90 W 90 W

UNI 1402 1.1kW 1.5HP 90 W 90 W 100 W 100 W 110 W

UNI 1403 1.5kW 2.0HP 100 W 110 W 110 W 120 W 130 W

UNI 1404 2.2kW 3.0HP 130 W 130 W 140 W 150 W 150 W

UNI 1405 4.0kW 5.0HP 180 W 190 W 190 W 190 W 170 W

UNI 2401 5.5kW 7.5HP 210 W 230 W 250 W 280 W 310 W

UNI 2402 7.5kW 10HP 270 W 290 W 310 W 320 W 310 W

UNI 2403 11.0kW 15HP 400 W 380 W 360 W 330 W 310 W

UNI 3401 15.0kW 25HP 570 W 620 W 670 W 660 W 630 W

UNI 3402 18.5kW 30HP 660 W 720 W 730 W 660 W 630 W

UNI 3403 22.0kW 30HP 730 W 800 W 770 W 730 W 700 W

UNI 3404 30.0kW 40HP 950 W 830 W 790 W 740 W 710 W

UNI 3405 37.0kW 50HP 1090 W 990 W 920 W 850 W 800 W

UNI 4401 45kW 75HP 1460 W 1610 W 1630 W 1530 W

UNI 4402 55kW 100HP 1910 W 1780 W 1670 W 1560 W

UNI 4403 75kW 125HP 2370 W 2130 W 2030 W 1860 W

UNI 4404 90kW 150HP 2640 W 2890 W 2700 W 2470 W

UNI 4405 110kW 150HP 2970 W 2910 W 2720 W 2490 W

UNI 5401 160kW 200HP 5000 W

Dissipation

50°C (122°F) Maximum permissible

ambient continuous output current

Model 3kHz 4.5kHz 6kHz 9kHz 12kHz

UNI 1401 2.1 A 2.1 A 2.1 A 2.1 A 2.1 A

UNI 1402 2.8 A 2.8 A 2.8 A 2.8 A 2.8 A

UNI 1403 3.8 A 3.8 A 3.8 A 3.8 A 3.3 A

UNI 1404 5.6 A 5.6 A 5.1 A 4.0 A 3.3 A

UNI 1405 6.9 A 5.9 A 5.1 A 4.0 A 3.3 A

UNI 2401 12.0 A 12.0 A 12.0 A 11.6 A 9.7 A

UNI 2402 16.0 A 16.0 A 14.7 A 11.6 A 9.7 A

UNI 2403 20.0 A 17.3 A 14.7 A 11.6 A 9.7 A

UNI 3401 34.0 A 34.0 A 28.0 A 21.0 A 17.9 A

UNI 3402 40.0 A 34.0 A 28.0 A 21.0 A 17.9 A

UNI 3403 44.0 A 36.0 A 31.0 A 24.0 A 20.6 A

UNI 3404 44.0 A 36.0 A 31.0 A 24.0 A 20.9 A

UNI 3405 50.0 A 41.0 A 34.0 A 26.0 A 23.0 A

UNI 4401 95.0 A 85.0 A 75.0 A 60.0 A

UNI 4402 105.0 A 85.0 A 75.0 A 60.0 A

UNI 4403 135.0 A 105.0 A 85.0 A 65.0 A

UNI 4404 180.0 A 150.0 A 125.0 A 95.0 A

UNI 4405 190.0 A 150.0 A 125.0 A 95.0 A

Page 14

14

Dynamic Braking

Resistor Connections

The external braking resistor should be connected

to the Unidrive terminals labelled (+) and (-) on the

terminal strip on Unidrive size 1 & 2 or the stud

connections on Unidrive size 3 & 4. The resistor must

be thermally protected in the unlikely event that the

braking transistor fails. This thermal device must either

disconnect the input AC power to the Inverter or

disconnect the resistor from the circuit. Please contact

the a Drive Centre for additional application information.

Custom Resistor Values

The resistor ohmic value is based on the torque

required to stop the motor (and connected load) in the

time dictated by the application. The first equation to

be solved is the torque required knowing the required

stop time.

T = J x N

(Ft - Lb) or

T = 2¹ J x N

(Nm)

t

d x 307 td x 60

Where:

J= Total Inertia (Lb-Ft

2

or Kgm2)

N = Motor Max. Speed (RPM)

t

d = Decel Time (Sec.)

T = Torque (Ft-Lb or Nm)

The torque required must be equal or less than 1.5

x motor/drive capability.

HP

(brake) = T x N

or

P(kW) = T x N

5250 30

The ohmic value of the resistor can now be

calculated using the following formula:

R = (V

b)

2

or

R = (Vb)

2

HP(brake) x 746 P(kW)

Where:

V

b = Bus voltage level when braking

= 750 VDC

Minimum Values

The calculated minimum ohmic value is limited by

the braking transistor supplied in the Unidrive being

used. The following is a list of the minimum values.

Average Power Dissipation

The average power dissipated in the resistor for

intermittent operation is then simply the number of

watts dissipated per stop times the duty cycle (D).

Where:

D = t

d

td + toff

In order to use this formula for average power

dissipation, the brake resistor must be off long enough

for the temperature of the resistor to return to ambient

temperature between braking cycles. Also, the

maximum on time (or decel time) should not exceed

the peak capabilities of the power resistor. Typically, a

power resistor has the capability of dissipating 10

times rated wattage for 5 to 10 seconds.

Peak Power Rating

The peak power handling ability of the resistor

must meet or exceed the following:

PPK = (Vb)2/R

Unidrive Size 1 40 Ohms

Unidrive Size 2 40 Ohms

Unidrive Size 3 10 Ohms

Unidrive Size 4 5 Ohms

MODEL MINIMUM VALUE

drive technical specifications

Page 15

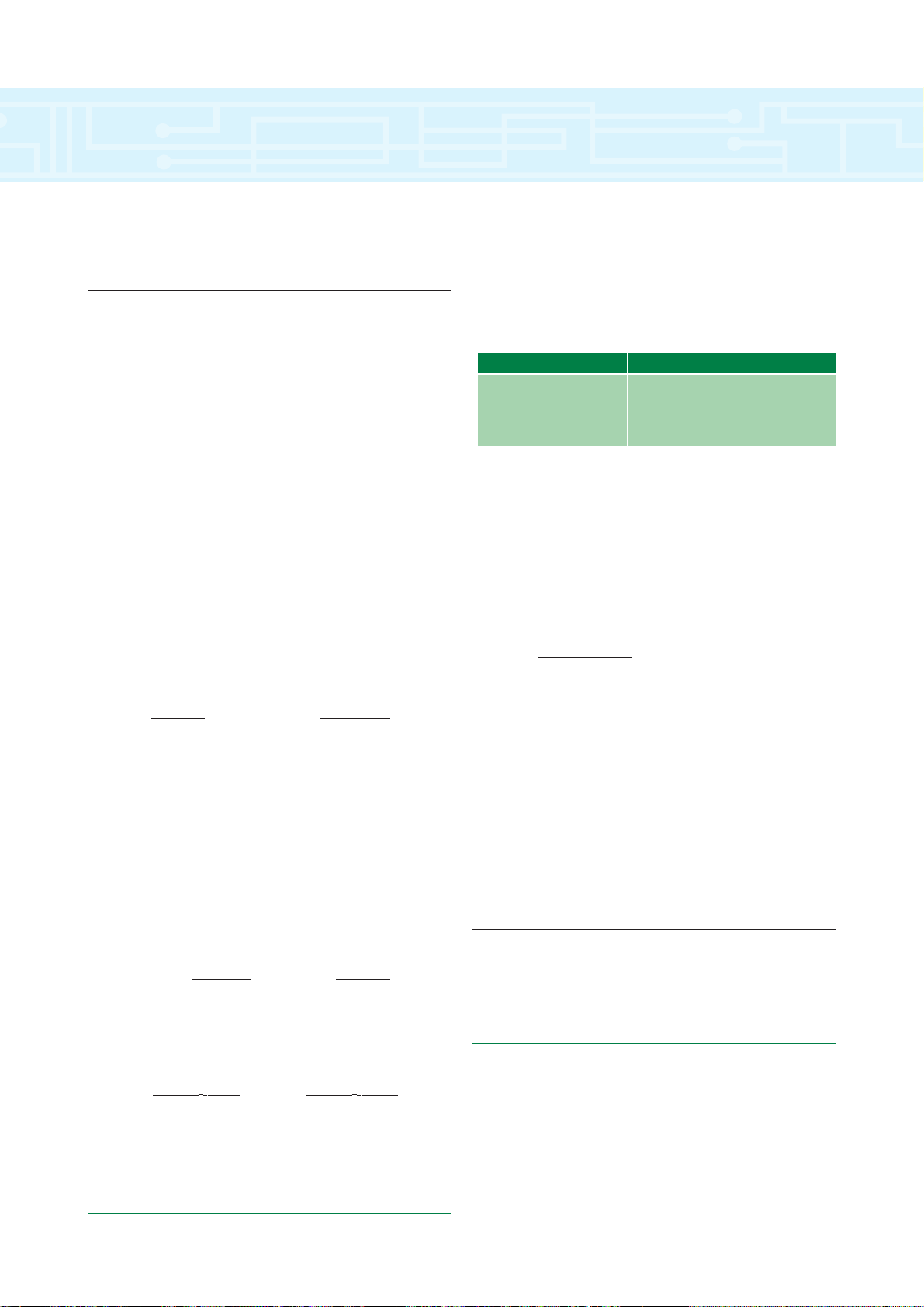

Protection

DC Bus Undervoltage Trip 350 VDC

DC Bus Overvoltage Trip 830 VDC

MOV Voltage Transient Protection 160 Joules, 1400 Volts Clamping

(Line to Line & Line to Ground)

Drive Overload Trip Current overload value is exceeded.

Programmable to allow up to 175% of Drive Current for one minute.

Instantaneous Overcurrent Trip 215% of Drive rated current

Phase Loss Trip DC bus ripple threshold exceeded

Overtemperature Trip Drive heatsink temperature exceeds 95°C

Short Circuit Trip Protects against output phase fault

Ground Fault Trip Protects against output phase to ground fault

Motor Thermal Trip Electronically protects the motor from overheating due to

Loading conditions

15

drive technical specifications

Page 16

Status Relay 1 Normally open contacts

1 Dry contact output pole 1/2 5A, 240 VAC resistive

Drive OK (default)

2 Status Relay 1

Dry contact output pole 2/2

3 Circuit Common

0 VDC Analogue reference

4 +10 VDC ± 1% Voltage tolerance

User supply for external analogue signal device 10 mA output current (current limit protected)

5 Analogue Input 1 (non-inverting input) Bipolar ±10 VDC

Programmable Differential Analogue Input 100k½ input impedance

Analogue Speed Reference 1 (default) 12-bit plus sign resolution, ² 2mS sampling period OL

6 Analogue Input 1 (inverting input) <45 Oµs C.L.

Programmable Differential Analogue Input

7 Analogue Input 2 Programmable: ±10 VDC (default), 4-20mA,

Programmable Single-ended Analogue Input 20-4mA, 0-20mA inputs,

Analogue Speed Reference 2 (default) 100k½ input impedance

10-bit plus sign resolution

² 2mS sampling period

8 Motor Thermistor Input

Programmable Single-ended Analogue Input

9 Analogue Output 1 Programmable: ±10 VDC @ 10mA (max) (default)

Programmable Single-ended Analogue Output 4-20mA, or 0-20mA

Output Frequency (open loop default) 1k½ minimum load resistance

Speed Feedback (closed loop default) 10-bit plus sign resolution, 8mS update period

Short circuit protected

10 Analogue Output 2

Programmable Single-ended Analogue Output

Torque Output (default)

11 Circuit Common

0 VDC Analogue reference

21 OV Common

22 +24 VDC Voltage Tolerance: ±10%

User Supply Nominal Output: 200 mA

Overload Output: 240 mA with current foldback

protection

23 Circuit Common

0 VDC Digital reference

24 Programmable Logic I/O F1 Output Mode:

Output: At speed (open loop) User-defined: Negative or positive logic

At zero speed (closed loop) Negative logic (default)

Push-pull output, 0 - +24 VDC

100mA max output, 120mA overload current

Input Mode:

User-defined: Positive logic (V > +15 VDC)

or negative logic (V < +5 VDC) (default)

Voltage range: 0 - +24 VDC

3.2 mA max load at +24 VDC

25 Programmable Logic I/O F2

Input: Drive reset (default)

26 Programmable Logic I/O F3

Input: Jog (default)

27 Programmable Logic Input F4 User-defined: Positive logic (V > +15 VDC)

Latched Run Forward (default) or negative logic (V < +5 VDC) (default)

Voltage range:

0 - +24VDC, 3.2 mA max load @ +24 VDC

28 Programmable Logic Input F5

Latched Run Reverse (default)

29 Programmable Logic Input F6

Local (default)/Remote

30 Logic Input: Drive Enable (closed loop)

External Trip (open loop)

31 Circuit Common

0 VDC digital reference

Control Inputs and Outputs

TERMINAL I/O TYPE & FUNCTION RATING

NOTE: There are no terminals numbered 12, 13...., 20 on the Unidrive

connections

16

Page 17

connections

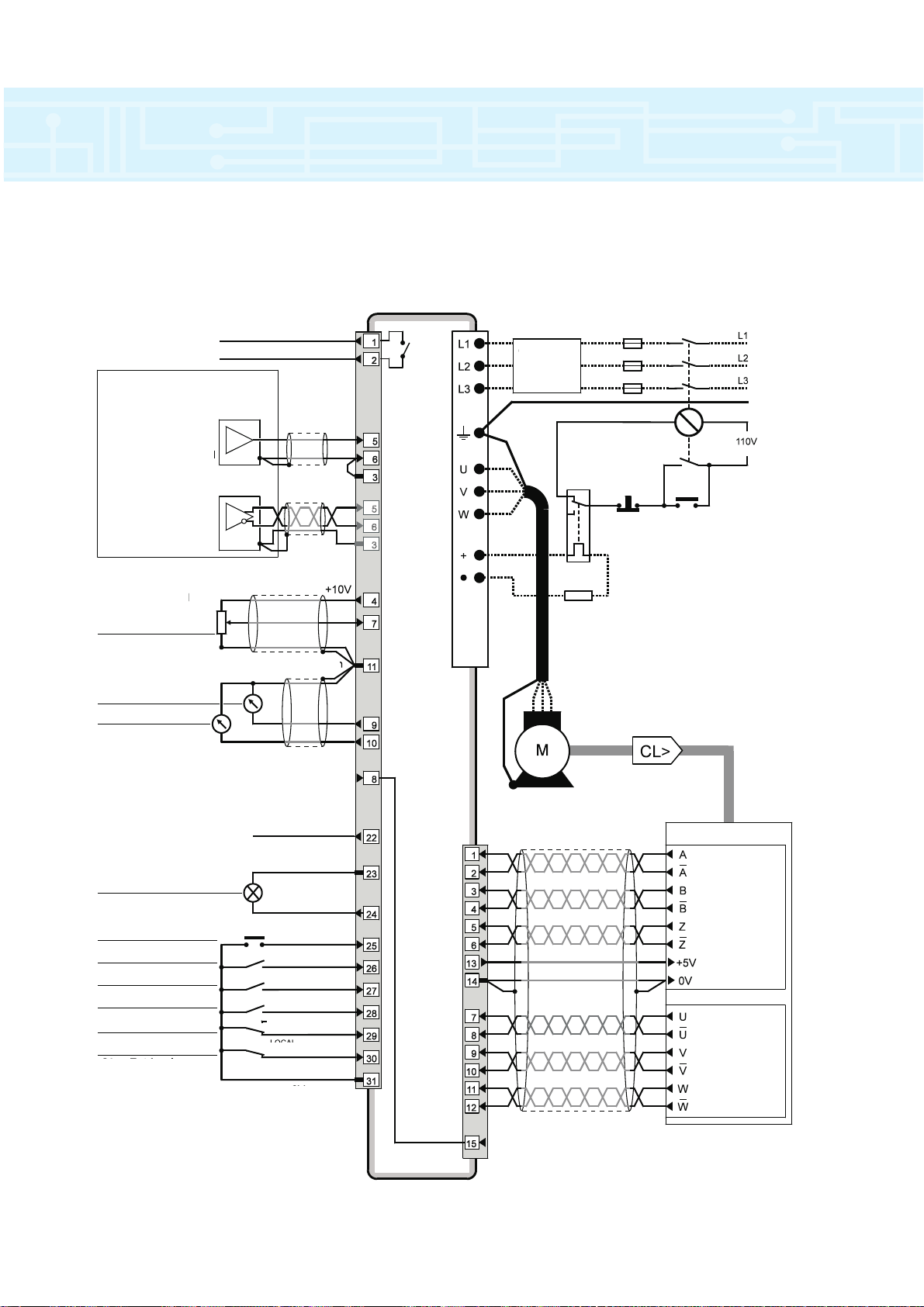

17

Typical power and default signal connections for speed

control in terminal mode

Status relay

Drive normal

Connections for

single-ended input

signal

Connections for

differential input

signal

Signal

connector

Power

terminals

Analog frequency/speed

reference 1 (remote)

Analog

frequency/speed

reference 2 (local)

SPEED

TORQUE

Analog input 3

Motor thermistor

RESET

JOG SELECT

RUN FORWARD

RUN REVERSE

LOCAL/REMOTE

DRIVE ENABLE

REMOTE

OV common

OV common

OV common

OV common

OV common

Optional

RFI filter

Thermal

protection

device

Stop

Braking resistor

Encoder

Incremental

signal

connections for

all encoders

communication

signal

connectiona for

servo-encoders

Encoder

connector

15-way

D-type

Start/

Reset

+24V

LOCAL

Page 18

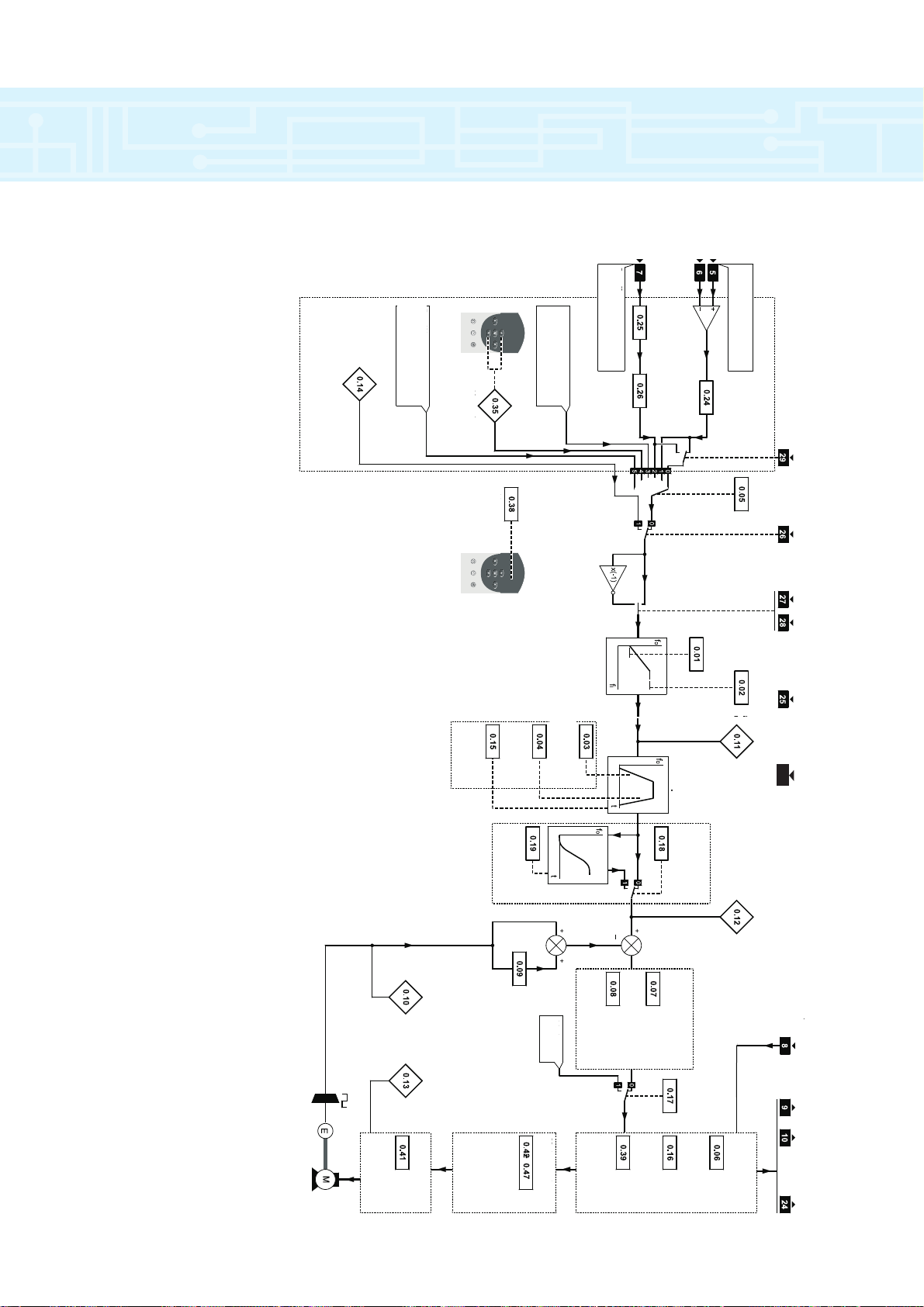

connections

AT ZERO

SPEED

Reference

selector

Menu 0 logic diagram

Speed-loop PID gains

Power stage

Motor control

Jog

reference

Keypad

reference

Reference

selector

Precision reference (not

used with Menu 0)

Preset references

(not used with Menu 0)

Speed reference 1

(remote)

Analog input 1

mode selector

All parameters are shown at their default setting

Minimum

speed

Maximum

speed

initial

parameter

displayed

Speed-loop

proportional

gain

Speed-loop

integral gain

Speed-loop

derivative

gain

Current

limit

Stop mode

selector

Torque

mode

selector

Synchronize to

a spinning

motor

No. of poles

Rated voltage

Rated speed

Rated current

Rated

frequency

PWM switching

frequency

Menu4

S-ramp

S-ramp

enable

Speed reference 2

(local)

Analog input 2

destination

select

Analog input 2

mode select

Acceleration

rate

Deceleration

rate

Ramp mode

selector

S-ramp

da/dt limit

Post-ramp

speed

reference

Motor parameters

THERMISTOR SPEED

TORQUE

Reference selection

Ramps

LOCAL/

REMOTE

JOG

SELECT

RUN

FORWARD

RUN

REVERSE

RESET

DRIVE

ENABLE

Motor

active-current

Motor

speed

Pre-ramp

speed

reference

30

18

Page 19

drive installation

➀ Consult Drive Centre for Filter details.

Panel Wiring Guidelines for Routine EMC Precautions

Panel Wiring Guidelines for Compliance with EMC Emission Standards

19

Optional braking resistors as required for the Drives

External: Mount on top surface of enclosure.

Internal: Mount in top part of enclosure.

Drives

Ensure minimum

clearances are

respected.

System controller

Locate as required.

Signal cables

Plan for all signal

cables to be routed at

least 300mm (12in)

distant from any

power cable.

Power cables

AC supply isolator,

contactor, and

fuses or MCBs

Locate as required.

³100mm

(4in)

³5mm

(…in)

Location of overload

protection device

³100mm

(4in)

Location

of optional

terminal

block

Alternative

location of

fuses or

MCBs

Locate as

required.

³5mm

(…in)

Back-plate

Enclosure

Optional braking resistors as required for the Drives

External: Mount on top surface of enclosure.

Internal: Mount in top part of enclosure.

Location of overload

protection device

Alternative location

of fuses or MCBs

Drives and

RFI filters

Ensure minimum

clearances are

respected.

System controller

Locate as required.

Signal cables

Plan for all signal

cables to be routed at

least 300mm (12in)

distant from any power

cable.

RFI filters

Install a separate RFI

filter for each Drive.

Power cables

AC supply isolator,

contactor, and

fuses or MCBs

Locate as required.

Locate as required.

³5mm

(…in)

³100mm

(4in)

³5mm

Alternative location of

fuses or MCBs

Locate as required.

(…in)

150mm

(6in)

Back-plate

Location

of optional

terminal

block

Enclosure

³5mm

(…in)

Page 20

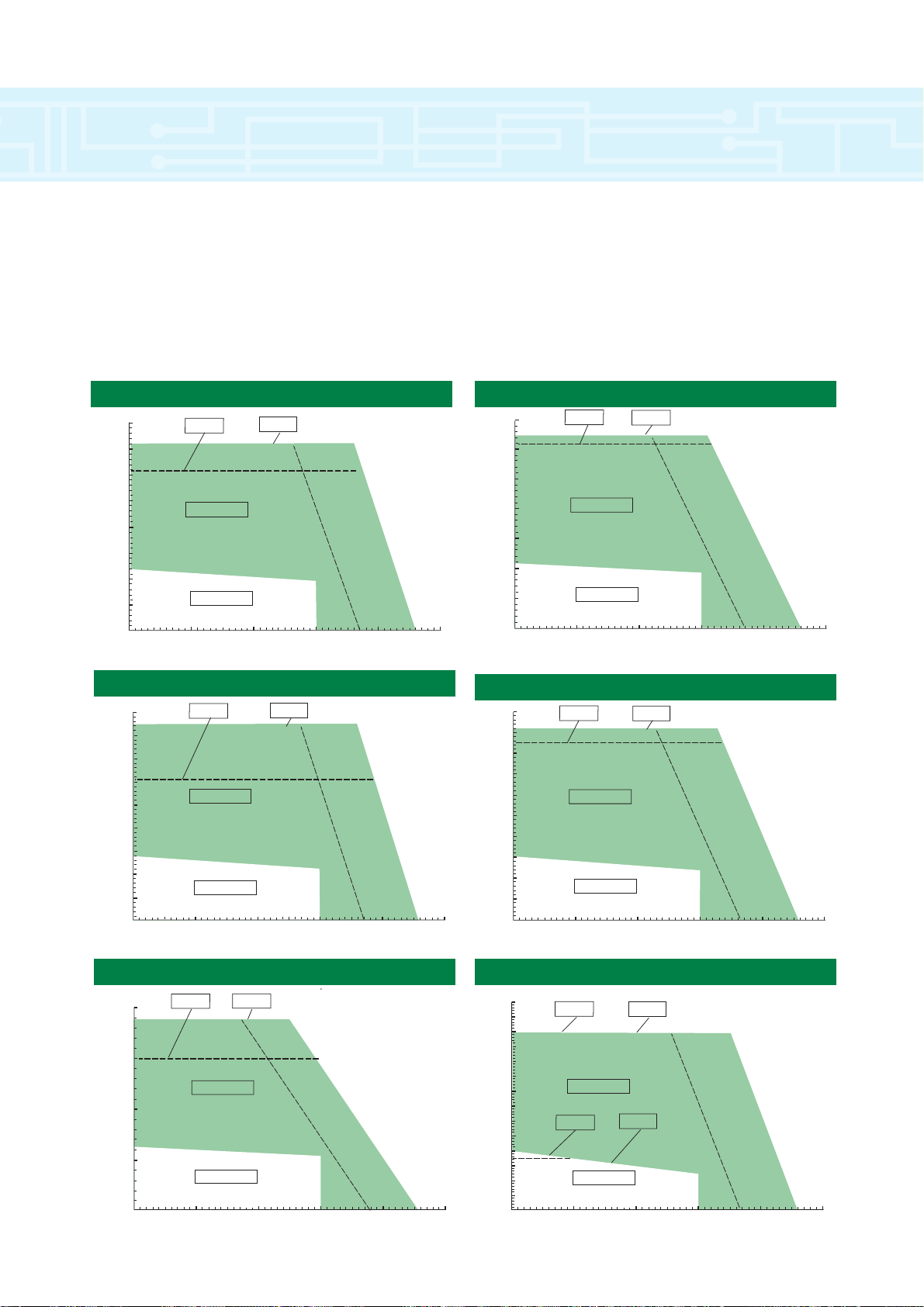

Model size 1

Model size 2

Model size 3

Model size 4

Panel

Panel

LFA

H

C

G

LFA

C

G

E

E

Panel

LF

A

C

G

E

E

H

C

E1

E1

Panel

E3

E2

L

FA

G

E2

E3

A 345 345 345 716

[13.56] [13.56] [13.56] [28.19]

C 47.5 95 187.5 250

[1.88] [3.75] [7.38] [9.81]

E 16.5 16.5

[.63] [.63]

E1 17

[.63]

E2 65

[2.56]

E3 143.5

[5.63]

F 368 368 368 743

[14.25] [14.25] [14.25] [29.25]

G 95 190 375 500

[3.75] [7.50] [14.75] [19.69]

H 200 200 260 260

[7.88] [7.88] [10.25] [10.25]

L 335 335 335 700

[13.19] [13.19] [13.19] [27.56]

Mounting 6.5 [.16]clearance or

hole diam.

1

/

4

UNF M6 thread

Model Size 1 2 3 4

Dimension

➀

Surface Mounting

➀ Dimensions in mm and [inches].

drive installation

20

Page 21

drive installation

21

A 345 345 345 717.5

[13.56] [13.56] [13.56] [28.25]

B 295 295 287 650

[11.63] [11.63] [11.31] [25.56]

C 86.5 182 358 482

[3.38] [7.19] [14.13] [19]

D1313

(0.5) (0.5)

D1 16 17

[.63] [ .63]

D2 7 7.5

[.25] [.31]

D3 3.5

[.13]

E 16.5

[.13]

E1 131.5 192

[5.19] [7.56]

E2 69 130

[2.69] [5.13]

E3 16.5 65

[.63] [2.56]

F 364 364 364 743

[14.31] [14.31] [14.31] [29.25]

G 95 190 375 500

[3.75] [7.50] [14.75] [19.69]

H 200 200 260 260

[7.88] [7.88] [10.25] [10.25]

J 120 120 120 120

➁

[7.88] [7.88] [10.25] [10.25]

K 80 80 140 140

➂

[3.13] [3.13] [5.50] [5.50]

L

335 335 335 700

[13.19] [13.19] [13.19] [27.56]

Mounting 6.5 [.16]clearance or

hole diam. M6

1

/

4

UNF thread

Model Size 1 2 3 4

Dimension

➀

Through-panel Mounting

Model size 2

Model size 3

Model size 4

Panel

Panel

LFA

H

G

LF A

G

Panel

LF

A

G

E2

E2

H

E3

E3

Panel

E2

L

FA

G

E1

E2

Aperture

B

D

C

J

K

E

E

Aperture

B

D

C

E1

C

Aperture

B

D1

D2

J

K

E3

E3

D3

Aperture

B

D1

D2

C

Model size 1

F

A

D

D

Half size in proportion

Model size 5

K

J

H

G

➀ Dimensions in mm and [inches].

➁ Plus thickness of gasket.

➂ Minus thickness of gasket

Model Size 5

Dimension

➀

A 1319

[51

15

/16

]

D 35.5

[1

7

/16

]

F 1248

[49

1

/8

]

G 315

[12

3

/8

]

H 484

[19]

J 340

[13

1

/16

]

K 144

[5

11

/16

]

Page 22

drive installation

22

Model size kg lb

1 4 8.8

2817

32249

4 70 154

5 102 224

Weights

*Power Module only

*

Motor cable

Since capacitance in the motor cable causes loading

on the output of the Drive, ensure the cable length

does not exceed the values given in Table 2-3.

The maximum cable length is reduced from that

shown in the table under the following conditions:

● PWM switching frequency exceeding 3kHz in

model sizes 3 and 4

The maximum cable length is reduced in

proportion to the increase in PWM switching

frequency, eg. at 9kHz, the maximum length is

1/

3

of that shown.

● High capacitance cables

Most cables have an insulating jacket between

the cores and the armour or shield; these cables

have a low capacitance and are recommended.

Cables that do not have an insulating jacket

tend to have high capacitance; if a cable of this

type is used, the maximum cable length is half

that quoted in the table. (figure 2-1 shows

shows how to identify the two types.)

UNI1401 65 210 50 160

UNI1402 100 330 75 250

UNI1403 130 430 100 330

UNI1404 200 660 150 490

UNI1405 300 990 250 820

UNI2401- 300 990 300 990

UNI2403

UNI3401- 200 660 120 410

UNI3405

UNI4401- 200 660 120 410

UNI4405

mftmft

Model

Nominal AC

supply

voltage

400V

480V

Maximum cable length*

(PWM switching frequency at 3kHz)

* Cable lengths in excess of the specified values may be used only when

special techniques are adopted; refer to the supplier of the Drive.

Normal capacitance

Shield or armour

separated from the cores

High capacitance

Shield or armour

close to the cores

UNI1401 1.5 16 1.5 16 6

UNI1402 2.5 14 2.5 14 10

UNI1403 2.5 14 2.5 14 10

UNI1404 2.5 14 2.5 14 10

UNI1405 2.5 14 2.5 14 16

UNI2401 2.5 14 2.5 14 16

UNI2402 4.0 10 4.0 10 35

UNI2403 4.0 10 4.0 10 20

UNI3401 6 8 6 8 40

UNI3402 10 6 10 6 50

UNI3403 10 6 10 6 60

UNI3404 16 4 16 4 70

UNI3405 25 4 25 4 80

UNI4401 35 2 35 2 100

UNI4402 35 2 35 2 125

UNI4403 50 2/0 50 2/0 160

UNI4404 70 2/0 70 2/0 200

UNI4405 95 3/0 95 3/0 250

UNI5401 95 3/0 95 3/0 450

FUSES and CABLES

CATALOGUE

AC Supply Motor Fuse ➀

NUMBER

Cables Cables Rating

mm2 AWG mm2 AWG Amps

➀ Use Fuse class RK1 or similar HRC fuse.

➀

Cable & Fuse Recommendations

Page 23

Enclosure Guidelines

Heat Dissipation in a Sealed Enclosure

If possible, locate heat-generating equipment in the

lower part of the enclosure to encourage internal

convection. Otherwise, use a taller enclosure or install

stirrer fans.

The enclosure must be of adequate size to maintain

sufficient cooling of the drive when it is installed inside a

sealed enclosure. Heat generated by all the equipment

in the enclosure must be taken into account. To

calculate the minimum acceptable size of an enclosure,

use the following procedure:

Calculate the minimum required surface area Ae

for the enclosure from:

P

Ae=

k(Ti - Tamb)

Where:

Tamb Maximum ambient temperature in °C

external to the enclosure.

Ae Unobstructed heat-conducting are in

mm2.

k Heat transmission coefficient of the

enclosure material.

Ti Maximum permissible operating

temperature in °C.

P Power in watts dissipated by all heat

sources in the enclosure.

Example:

To calculate the size of an enclosure for model

UNI 1403 (1.5kW, 2HP).

The following conditions are assumed:

The Drive is surface-mounted inside the

enclosure.

Only the top, front, and two sides of the

enclosure are free to dissipate heat.

The enclosure is made from painted 2mm

(.079in) sheet steel.

Maximum external air temperature: 30°C (86°F).

Insert the following values:

Ti = 40°C

Tamb = 30°C

k = 5.5 (typical for painted 2mm (.079in)

sheet steel)

P = 100 at 3kHz (see pages 18 &19)

Note:

It is essential to include any other heat sources in

the value of P.

The minimum required heat conducting area is

then:

100

Ae=

5.5(40 - 30)

= 1.81m

2

Estimate two of the enclosure dimensions — the

height (H) and depth (D), for instance. Calculate the

width (W) from:

Ae - 2HD

W =

H + D

Inserting H = D = 0.5m, obtain the minimum

width:

1.81 - (2 x 0.5 x 0.5)

W =

0.5 + 0.5

= 0.81m

Heat Dissipation in a Ventilated Enclosure

If a high ingress protection rating is not required,

the enclosure may be smaller. A ventilating fan can be

used to exchange air between the inside and outside

of the enclosure.

To calculate the volume of ventilating air, use the

following equation:

3.1P

V =

Ti - Tamb

Where V = Air-flow in m3per hour.

Example:

P = 100

Ti = 40°C

Tamb = 30°C

Then:

3.1 x 73

V =

40 - 30

= 31m3/ hr

drive installation

23

Page 24

Electromagnetic compatibility (EMC)

conducted emission

This is a summary of the EMC performance of the

Drive. For full details, refer to the Unidrive EMC Data

Sheet which can be obtained from a Drive Centre or

distributor listed on the back cover.

Immunity

Compliance with immunity standards does not

depend on installation details. The Drive meets

EN50082–2 (generic immunity standard for the

industrial environment) and the following specifications

from the IEC1000–4 group (derived from IEC801):

Part 2, Electrostatic discharge: Level 3

Part 3, Radio frequency field: Level 3

Part 4, Transient burst: Level 4 at the control

terminals

Part 4 Transient burst:

Level 4 at the control terminals

Level 3 at the power terminals

Part 5, Surge (at the AC supply terminals):

Level 4 line-to-ground

Level 3 line-to-line (as specified by

EN50082–2 informative annex)

Part 6, Conducted radio frequency:

Level 3

Emission

Compliance with emission standards depends on

rigorous adherence to the installation guidelines,

including the use of the specified RFI filter in the AC

supply circuit. Compliance also depends on the PWM

switching frequency used in the output stage of the

Drive, and the length of the motor cable. For full

details, refer to the Unidrive EMC Data Sheet which

can be obtained from a Drive Centre or distributor

listed at the end of this Product Data Guide.

electro magnetic compatibility (EMC)

& radio frequency interference (RFI)

24

Page 25

electro magnetic compatibility (EMC)

& radio frequency interference (RFI)

25

Main Ratings

* Above 40°C (104°F), the current rating is

reduced by 1.6A/

°C (0.88A/°F)

AC Supply Ratings

Voltage (phase-to-phase and phase-to-ground):

480V +10%

AC supply frequency: 48 to 62 Hz

Ground Leakage Current

The ground-leakage current, phase-to-phase and

phase-to-ground, when the AC supply is 400V at

50Hz is as follows:

For other AC supply voltages and currents, scale

the value of leakage current proportionally.

Discharge Resistors

A and B: 330 KΩ internally between phases, with

the star point connected by a 1M resistor to ground.

C to G: 10 MΩ internally between each phase

and ground.

Maximum Current Overload

150% of rated current for 60 seconds.

Overall Dimensions

Balanced 5.6mA 7.4mA 55mA

One phase disconnected 41mA 57.9mA 350mA

CONDITION A B C toG

A25

B 2.7 6

C 7.4 16

D818

E 12.3 27

F1635

G3577

FILTER TYPE kg lb

Filter type Dimension

HWD

A 396mm 50mm 113mm

15

9

/16 in 1 15/16 in 4 7/16 in

B 396mm 75mm 113mm

15

9

/16 in 2 15/16 in 4 7/16 in

C 330mm 190 mm 145mm

13 in 7

1

/2 in 5 11/16 in

D 330mm 190mm 145mm

13 in 7

1

/2 in 5 11/16 in

E 440mm 200mm 145mm

17

5

/16 in 7 7/8 in 5 11/16 in

F 490mm 200mm 145mm

19

1

/4 in 7 7/8 in 5 11/16 in

G 380mm 495mm 250mm

14

5

/16 in 19 1/2 in 9 13/16 in

Weights

RFI Filter Ratings

A 4200-0010 10A 25W IP20 50°C (122°F) <30°C (86°F)

B 4200-0027 27A 40W IP20 50°C (122°F) <40°C (104°F)

C 4200-1051 50A 60W IP00 50°C (122°F) <40°C (104°F)

D 4200-1071 75A 100W IP00 50°C (122°F) <40°C (104°F)

E 4200-1111 110A 120W IP00 50°C (122°F) <40°C (104°F)

F 4200-1171 170A 150W IP00 40°C (104°F) <55°C (131°F)

G 4200-1302 300A 300W IP00 50°C (122°F) <40°C (104°F)

Type Part number

Max.

continuous

current

Power

dissipation at

rated current

Ingress

protection

Max. ambient

temperature at

rated current

Case

temperature rise

at rated current

Page 26

26

Introducing Unimotor

Unimotor is a new range of brushless AC servo

motors from Control Techniques. They are three phase,

6 or 8 pole, permanent magnet motors exhibiting a

sinusoidal back EMF characteristic. The motors supply

high torque with either low or high rotor inertia and

minimal cogging torque.

The unique ‘finned’ motor housing is a highstrength aluminium alloy casting, that improves heat

dissipation by conduction, radiation and convection.

The single-piece integral construction permits accurate

bearing to housing alignment and maintains air gap

concentricity. This arrangement optimises torque

output and reduces cogging torque. The compact

design gives increased torsional stiffness. Laminations

and coils are optimised both for high efficiency and to

provide low harmonic distortion in the airgap flux.

Combined with the high energy magnets, and a choice

of rotor inertia, these features provide superb dynamic

performance to suit all requirements.

The integral housing and front flange design

increases thermal dissipation and improves sealing

(IP65 standard, when mounted and connected).

Standard Features

• Unique 'finned' design - high thermal dissipation

• Encoder for high precision feedback integral

commutation

• PTC thermistors for thermal monitoring and overload

protection

• Low inertia is standard for fast acceleration

• IEC mounting flange

• Plain shaft is standard (non keyed)

• IP65 standard (when connected) - sealed against

water spray and dust

• Low cogging torque & THD

(Total Harmonic Distortion)

• Rotor assembly balanced to ISO 1940 grade 6

• High standard of mechanical design and precision

manufacture - for improved performance and quality

• W inding insulation is to Class H

• Bearing system designed for prolonged motor life

• Modular construction

• UL approval under application

• CE marked

Optional Features

• Absolute encoder - 4096 multi-turns

• Resolver feedback for high temperature applications

• Sine/Cosine encoder for high resolution consult factory for availability

• High inertia option

• NEMA mounting flange

• Output key to shaft

• ‘Tropicalised’ motor option, - electrical components

are sealed against humid conditions

• Optional dimensional accuracy to DIN 42955 Class R

• Gearbox options

• Stainless steel shaft option

• Brake

• Fan Cowlings

motor overview

Page 27

27

B95

Specification

Physical

Insulation Class Class H, BS EN 60034-1.

Dimensional Accuracy IEC 72-1, Class N (normal

class), Class R (precision

class) is optional.

Degree of Balance Rotor balanced to ISO 1940

(BS 6861) G 6.3 (half key

convention to ISO 8821).

Temperature Monitoring PTC thermistor, 170˚C

switch temperature.

Bearing System Preloaded ball bearings.

Electrical Connections Connector or terminal box

for power and brake;

connector for feedback

devices and thermistor.

Flange Mounting IEC 72-1 as standard/

NEMA MG-7 optional.

Output Shaft Plain shaft as standard.

Output key is optional

(to IEC 72-1).

Environmental

Ingress Protection Motor fitted with mating

connector and cable:

IP65.

Speed up to 3000RPM:

IP65.

Speed above 3000RPM:

IP54.

Operating Temperature Specified performance at

40˚C ambient.

Storage Temperature -20˚C to 70˚C.

Insulation Class H (180˚C)

Temperature Rise 125˚C over ambient of

40˚C Max.

100˚C over ambient of

40˚C Typical.

Relative Humidity 90% Non condensing

Use the information given in the illustration below to

create an order code for a Unimotor. The details in the blue

band are an example of an order reference.

Ordering Information

Frame

Size:

75

95

115

142

190

Rated Speed (Standard):

30 - 3000 rpm

20 - 2000 rpm

40 - 4000 rpm ***

Stator Length:

A, B, C, D, E

Brake:

0 - Non fitted

1 - Brake fitted 24V dc

Connection Type:

C - Connection

H - Hybrid

T - Terminal*

Output Shaft Key:

B - Standard without Key

A - With Key

Inertia:

A - Standard

B - High

Feedback Device:

C - Incremental Encoder

D - CT Coder + SL Electronics**

G - Sin/Cos Encoder SCM60 (multi-turn)

H - Sin/Cos Encoder SCS60 (single turn)

A - Resolver 55RSS116

Flange Mounting

A - IEC, B - NEMA

Motor Type:

UM - Unimotor

SL - Speed Loop

Control

* Available with resolver

feedback only.

** Available for SL Motors

only.

*** Other speeds are available

on special request

UM

ORDER REFERENCE EXAMPLE

B300 C B C A

motor technical specification

Page 28

28

∆T 100˚C, 40˚ Ambient with

Encoder Feedback

75

95

Motor Frame Size

ABCDAB CDE

1.2 2.1 2.8 3.6 2.3 3.9 5.5 6.9 8.4

3.5 6.2 8.4 10.8 6.8 11.7 16.4 20.7 25.1

1.2 1.6 2.1 2.5 3.5 4.5 5.6 6.7 7.8

0.6 1.0 1.5 1.9 1.4 2.5 3.6 4.7 5.8

3.0 3.7 4.4 5.1 5.0 6.1 7.2 8.3 9.5

1315 1431 1500 1587 1422 1618 1800 1997 2178

0.02 0.03 0.04 0.05 0.03 0.06 0.08 0.10 0.13

All Versions (rpm)

Continuous Stall (Nm)

Peak (Nm)

High (kgcm2)

Standard (kgcm2)

Weight(kg)

Thermal Time Constant (sec)

Maximum Cogging (Nm)

Rated Speed: 2000(rpm)

Rated Torque (Nm)

Continuous Stall Current (Arms)

Rated Power (kW)

R (ph-ph) (Ohms)

L (ph-ph) (mH)

Rated Speed: 3000(rpm)

Rated Torque (Nm)

Continuous Stall Current (Arms)

Rated Power (kW)

R (ph-ph) (Ohms)

L (ph-ph) (mH)

Rated Speed: 4000(rpm)

Rated Torque (Nm)

Continuous Stall Current (Arms)

Rated Power (kW)

R (ph-ph) (Ohms)

L (ph-ph) (mH)

1.1 1.9 2.6 3.4 2.1 3.7 5.1 6.5 7.8

0.49 0.86 1.16 1.50 0.95 1.63 2.28 2.88 3.49

0.23 0.40 0.55 0.71 0.44 0.77 1.06 1.37 1.64

172.55 56.14 28.80 19.88 52.00 16.50 8.79 5.81 4.25

243.1 106.4 67.9 49.3 138.9 64.9 41.2 29.6 23.2

Kt (Nm/A

rms

): 2.4 Ke (V

rms

/krpm): 147.0

Kt (Nm/A

rms

): 1.6

Ke (V

rms

/krpm): 98.0

1.1 1.9 2.5 3.3 2.1 3.6 5.0 6.3 7.6

0.73 1.29 1.74 2.25 1.42 2.45 3.41 4.32 5.23

0.34 0.60 0.80 1.03 0.66 1.13 1.56 1.99 2.40

73.44 23.42 13.88 8.67 24.92 7.51 4.12 2.75 1.92

109.2 47.7 31.5 22.8 63.5 28.5 18.3 13.2 10.3

Kt (Nm/A

rms

): 1.2 Ke (V

rms

/krpm): 73.5

1.0 1.8 2.2 2.7 1.8 2.8 3.7 4.5 5.3

0.98 1.73 2.33 3.00 1.88 3.23 4.50 5.70 6.90

0.42 0.76 0.91 1.14 0.77 1.16 1.54 1.89 2.24

43.66 14.17 7.70 4.60 13.80 4.40 2.40 1.70 1.20

61.7 27.2 18.1 12.7 35.9 16.1 10.1 7.6 5.8

Note: 1kgcm

2

= 1x10

-4

kgm

2

Note 2: All performance data is subject to a tolerance of ±10%

servo motor technical specification

Page 29

29

115 142

190

ABCDEABCD

4.1 6.7 9.5 12.0 14.1 6.3 10.8 15.3 19.8

12.2 20.0 28.4 35.9 42.4 18.9 32.4 45.9 59.4

9.7 12.0 14.3 16.6 18.8 21.6 28.0 34.3 40.7

3.2 5.5 7.8 10.0 12.3 7.8 14.1 20.5 26.8

6.5 8.2 9.9 11.6 13.2 10.9 13.2 15.5 17.8

1436 1614 1792 1980 2158 2093 2316 2548 2700

0.06 0.10 0.14 0.18 0.21 0.09 0.16 0.23 0.30

EABCD

23.4 21.8 41.1 58.7 73.2

70.2 66.4 123.3 176.1 219.6

47.0 93.5 140.5 187.5 234.5

33.1 50.0 97.0 144.0 191.0

26.0 26.0 33.0 40.0 48.0

3003 3220 3645 3960 4500

0.35 0.30 0.54 0.72 0.99

21.3 20.0 36.9 50.4 54.7

9.75 9.10 17.20 24.50 30.50

4.47 4.19 7.73 10.56 11.46

0.98 1.90 0.67 0.39 0.24

10.7 18.8 8.60 5.90 4.10

18.0 19.2 33.0 35.0 36.8

14.63 13.60 25.70 36.70 45.80

5.65 6.03 10.37 10.99 11.56

0.44 0.89 0.32 0.20 0.13

4.8 9.24 4.28 3.29 2.48

12.2

19.50

5.09

0.24

2.7

3.7 6.0 8.6 10.8 12.8 5.9 10.3 14.6 18.4

1.69 2.78 3.94 4.99 5.89 2.63 4.50 6.38 8.25

0.77 1.26 1.79 2.26 2.68 1.23 2.15 3.05 3.85

27.80 8.55 4.55 2.96 2.17 13.40 4.00 2.10 1.35

94.6 40.5 25.7 18.6 14.7 58.0 29.8 18.7 13.6

3.3 5.5 7.7 9.7 11.4 5.4 9.0 12.2 15.8

2.53 4.16 5.91 7.48 8.83 3.94 6.75 9.56 12.38

1.05 1.72 2.43 3.05 3.59 1.70 2.83 3.82 4.95

12.55 3.86 2.02 1.34 1.10 6.00 1.82 0.94 0.59

43.1 18.6 11.4 8.6 7.4 31.0 13.3 8.3 6.1

2.8 4.4 6.0 7.0 7.7 3.6 7.0 8.9 10.7

3.38 5.55 7.88 9.98 11.78 5.25 9.00 12.75 16.50

1.17 1.85 2.53 2.94 3.24 1.51 2.94 3.73 4.49

6.91 2.14 1.16 0.73 0.57 3.35 1.00 0.53 0.35

23.5 10.2 6.6 4.7 3.9 17.6 7.5 4.7 3.6

servo motor technical specification

Page 30

30

Motor Frame Size

All versions (rpm)

Continuous Stall Torque (Nm)

Peak Torque (Nm)

High Inertia (kgcm2)

Standard Inertia (kgcm2)

Weight (kg)

Thermal Time Constant (sec)

Maximum Cogging (Nm)

Rated Speed: 2000(rpm)

Rated Torque (Nm)

Continuous Stall Current (Arms)

Rated Power (kW)

R (ph-ph) (Ohms)

L (ph-ph) (mH)

Rated Speed 3000 (rpm)

Rated Torque (Nm)

Continuous Stall Current (Arms)

Rated Power (kW)

R (ph-ph) (Ohms)

L (ph-ph) (mH)

Rated Speed 4000 (rpm)

Rated Torque (Nm)

Continuous Stall Current (Arms)

Rated Power (kW)

R (ph-ph) (Ohms)

L (ph-ph) (mH)

ABCD ABCDE

1.3 2.3 3.1 4.0 2.6 4.4 6.1 7.8 9.4

3.9 6.9 9.3 12.0 7.8 13.2 18.3 23.4 28.2

1.2 1.6 2.1 2.5 3.5 4.5 5.6 6.7 7.8

0.6 1.0 1.5 1.9 1.4 2.5 3.6 4.7 5.8

3.0 3.7 4.4 5.1 5.0 6.1 7.2 8.3 9.5

1315 1431 1500 1587 1422 1618 1800 1997 2178

0.02 0.03 0.04 0.05 0.03 0.06 0.08 0.10 0.13

1.2 2.1 2.9 3.7 2.3 4.1 5.6 7.2 8.7

0.54 0.96 1.29 1.67 1.08 1.83 2.54 3.25 3.92

0.25 0.44 0.61 0.77 0.48 0.86 1.17 1.51 1.82

172.55 56.14 28.80 19.88 52.00 16.50 8.79 5.81 4.25

243.1 106.4 67.9 49.3 138.9 64.9 41.2 29.6 23.2

1.2 2.1 2.8 3.6 2.3 4.0 5.5 7.0 8.5

0.81 1.44 1.94 2.50 1.63 2.75 3.81 4.88 5.88

0.38 0.66 0.88 1.13 0.72 1.26 1.73 2.20 2.67

73.44 23.42 13.88 8.67 24.92 7.51 4.12 2.75 1.92

109.20 47.70 31.50 22.80 63.50 28.50 18.30 13.20 10.30

1.1 2.0 2.4 3.0 2.0 3.1 4.1 5.0 5.9

1.08 1.92 2.58 3.33 2.17 3.67 5.08 6.50 7.83

0.46 0.84 1.01 1.26 0.84 1.30 1.72 2.09 2.47

43.66 14.17 7.70 4.60 13.80 4.40 2.40 1.70 1.20

61.70 27.20 18.10 12.70 35.90 16.10 10.10 7.60 5.80

75 95

Kt (Nm/A

rms

): 2.4 Ke (V

rms

/krpm): 147.0

Kt (Nm/A

rms

): 1.6 Ke (V

rms

/krpm): 98.0

Kt (Nm/A

rms

): 1.2 Ke (V

rms

/krpm): 73.5

∆T 125˚C, 40˚ Ambient with

Resolver Feedback only

Note: 1kgcm2 = 1x10

-4

kgm

2

Shaded areas indicate preferred types.

Note 2: All performance data is subject to a tolerance of ±10%

servo motor technical specification

Page 31

31

AB CD E AB C D

4.6 7.6 10.8 13.7 16.2 7.3 12.5 17.7 22.9

13.8 22.8 32.4 41.1 48.6 21.9 37.5 53.1 68.7

9.7 12.0 14.3 16.6 18.8 21.6 28.0 34.3 40.7

3.2 5.5 7.8 10.0 12.3 7.8 14.1 20.5 26.8

6.5 8.2 9.9 11.6 13.2 10.9 13.2 15.5 17.8

1436 1614 1792 1980 2158 2093 2316 2548 2700

0.06 0.10 0.14 0.18 0.21 0.09 0.16 0.23 0.30

4.3 7.0 9.9 12.5 14.8 6.8 12.0 17.0 21.4

1.92 3.17 4.50 5.71 6.75 3.04 5.21 7.38 9.54

0.90 1.47 2.07 2.62 3.10 1.42 2.51 3.56 4.48

27.80 8.55 4.55 2.96 2.17 13.40 4.00 2.10 1.35

94.6 40.5 25.7 18.6 14.7 58.0 29.8 18.7 13.6

3.8 6.3 8.9 11.2 13.2 6.3 10.5 14.2 18.4

2.88 4.75 6.75 8.56 10.13 4.56 7.81 11.06 14.31

1.19 1.98 2.80 3.52 4.15 1.98 3.30 4.46 5.78

12.55 3.86 2.02 1.34 1.10 6.00 1.82 0.94 0.59

43.10 18.60 11.40 8.60 7.40 31.00 13.30 8.30 6.10

3.2 5.1 7.0 8.1 8.9 4.2 8.2 10.4 12.5

3.83 6.33 9.00 11.42 13.50 6.08 10.42 14.75 19.08

1.34 2.14 2.93 3.39 3.73 1.76 3.43 4.36 5.24

6.91 2.14 1.16 0.73 0.57 3.35 1.00 0.53 0.35

23.50 10.20 6.60 4.70 3.90 17.60 7.50 4.70 3.60

EABCD

27.0 23.2 43.2 62.8 78.0

81.0 69.6 129.6 188.4 234.0

47.0 93.5 141 187.5 234.5

33.1 50.0 97.0 144.0 191.0

20.5 26.0 33.0 40.0 48.0

3003 3220 3645 3960 4500

0.35 0.34 0.60 0.80 1.10

24.9 20.8 38.1 53.0 60.0

11.25 9.67 18.00 26.20 32.50

5.21 4.36 7.98 11.10 12.56

0.98 1.90 0.67 0.39 0.24

10.7 18.80 8.60 5.90 4.10

21.0 20.1 36.2 38.3 4.2

16.88 14.5 27.0 39.3 48.8

6.60 6.31 11.37 12.03 12.63

0.44 0.89 0.32 0.20 0.13

4.80 9.24 4.28 3.29 2.48

14.2

22.50

5.95

0.24

2.70

115 142 190

servo motor technical specification

Page 32

32

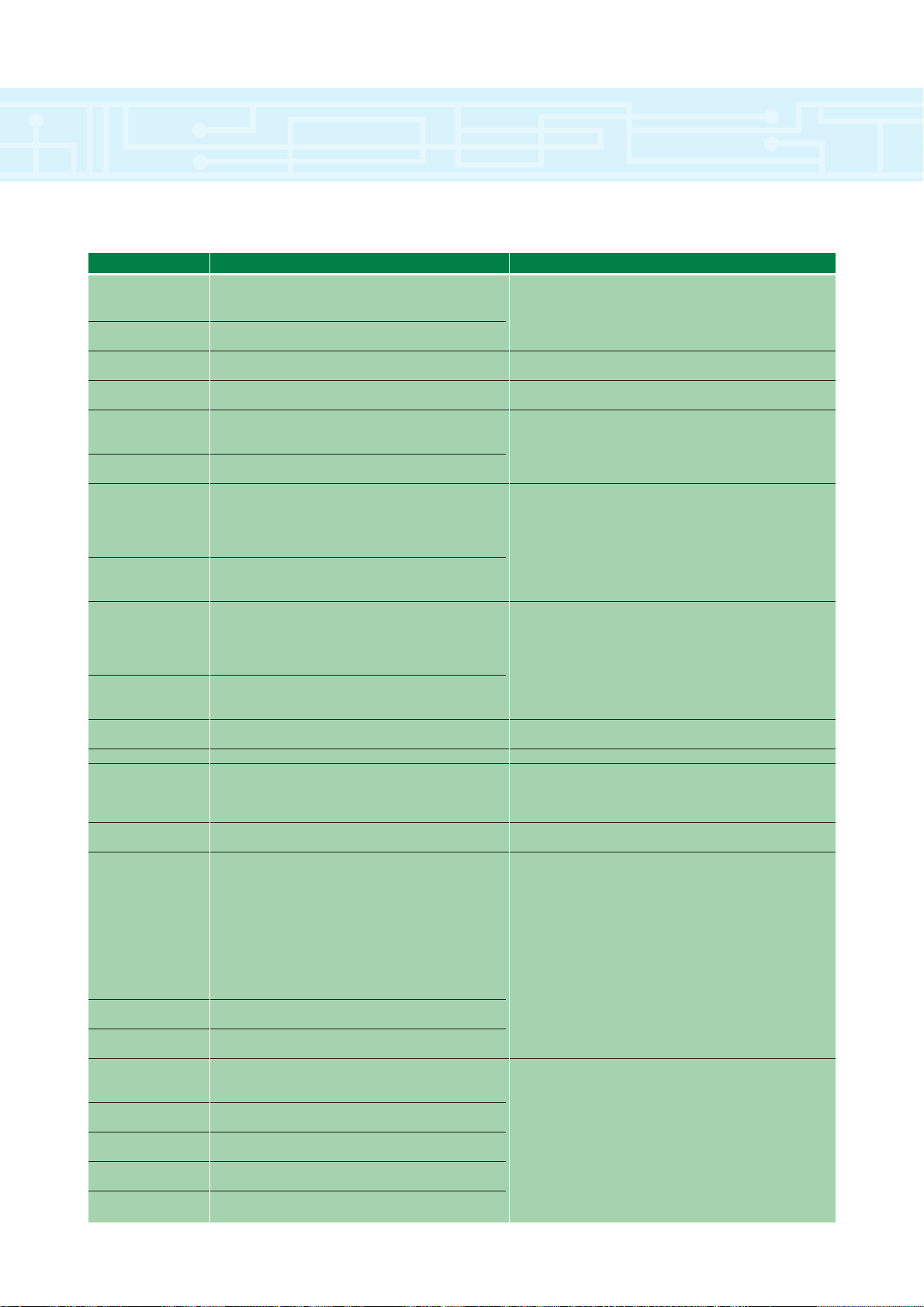

Outline Drawings - Frame Sizes 75 - 142

Dimensions - Frame Sizes 75 - 142

FRAME SIZE 75 95 115 142

Dimension / Length suffix

A Length Overall (Unbraked) 211 241 271 301 222 252 282 312 342 242 272 302 332 362 225 255 285 315 345

A Length Overall (Braked) 241 271 301 331 252 282 312 342 372 272 302 332 362 392 285 315 345 375 405

B Body Length (Unbraked) 146 176 206 236 157 187 217 247 277 177 207 237 267 297 160 190 220 250 280

B Body Length (Braked) 176 206 236 266 187 217 247 277 307 207 237 267 297 327 220 250 280 310 340

C Flange Square 75.0 95.0 115.0 142.0

D Flange Thickness 7.0 9.0 11.0 12.3

E Register Diameter 60.0 (J6) 80.0 (J6) 95.0 (J6) 130.0 (J6)

F Register Length 2.4 2.9 2.9 3.4

G Power to Connect C/L 61.0 62.5 66.0 80.0

G

1

Front Flange to power C/L

(Unbraked)

116 146 176 203 125 155 185 215 245 141 171 201 231 261 111 141 171 201 231

G

1

Front Flange to power C/L

(Braked)

146 176 206 236 155 185 215 245 275 171 201 231 261 291 171 201 231 261 291

H Fixing Holes Diameter 5.8 (H14) 7.0 (H14) 10.0 (H14) 12.0 (H14)

J Fixing Hole p.c.d. 75.0 100.0 115.0 165.0

K Overall Height 126.0 146.0 166.0 193.0

L Signal Connector Height (UM) 107.0 117.0 127.0 140.0

M Signal Connector Height (SL) 88.0 98.0 108.0 121.0

N Shaft Length (front) 23.0 30.0 30.0 30.0 30.0 40.0 40.0 40.0 40.0 40.0 40.0 40.0 50.0 50.0 50.0 50.0 50.0 50.0 50.0

P Shaft Diameter (front) 11.0 14.0 14.0 14.0 14.0 19.0 19.0 19.0 19.0 19.0 19.0 19.0 24.0 24.0 24.0 24.0 24.0 24.0 24.0

Shaft Key Dimensions (option A)

R Key Length 14.0 22.0 22.0 22.0 22.0 32.0 32.0 32.0 32.0 32.0 32.0 32.0 40.0 40.0 40.0 40.0 40.0 40.0 40.0

S Key Height 12.4 15.9 15.9 15.9 15.9 21.4 21.4 21.4 21.4 21.4 21.4 21.4 26.9 26.9 26.9 26.9 26.9 26.9 26.9

T Key to Shaft End 3.5 3.0 3.0 3.0 3.0 3.0 3.0 3.0 3.0 3.0 3.0 3.0 4.0 4.0 4.0 4.0 4.0 4.0 4.0

V Key W idth 4.0 5.0 5.0 5.0 5.0 6.0 6.0 6.0 6.0 6.0 6.0 6.0 8.0 8.0 8.0 8.0 8.0 8.0 8.0

UNIMOTOR UM

TR

S

N

V

ABCDAB CD EABCDEA B CDE

Shaft Key Detail

(Option A)

(MAX)

(MAX)

(MAX)

(REF)

(REF)

(REF)

motor installation

C

B

A

SIGNAL

CONNECTOR

N

F

POWER CONNECTOR

D

DANGER CAUTION

This machine runs hot

C

UNIMOTOR UM

High Voltage

DO NOT USE

COVER FOR LIFTING

P

4 HOLES DIA. 'H'

EQUI-SPACED ON A

G

'J' P.C.D.

E

P

M

L

75.0

K

Page 33

33

Outline Drawings - Frame Size 190

Dimensions - Frame Size 190

UNIMOTO

TR

S

N

V

Shaft Key Detail

(Option A)

FRAME SIZE 190

Dimension / Length suffix A B C D

A Length Overall (Unbraked) 273 327 381 435

A Length Overall (Braked) 327 381 435 489

B Body Length (Unbraked) 210 264 318 372

B Body Length (Braked) 264 318 372 425

C Flange Square 190.0

D Flange Thickness 14.5

E Register Diameter 180.0 (J6)

F Register Length 4.0

G Terminal Box to Power Connect C/L 173.0

G

1

Terminal Box to Front Flange (Unbraked) 69 123 177 231

G

1

Terminal Box to Front Flange (Braked) 123 177 231 285

H Fixing Holes Diameter 14.5 (H14)

J Fixing Hole p.c.d. 215.0

K Overall Height 256.0

L Signal Connector Height 161.1

N Shaft Length (front) 58.0

P Shaft Diameter (front) 32.0

Shaft Output Key Dimensions (option A)

R Shaft Key Length 49.0

S Shaft Key Height 35.0

T Shaft Key to Shaft End 3.1

V Shaft Key W idth 10.0

G1 (REF)

G (REF)

N

R

T

K

L

C (REF)

DIRECTION

OF ROTATION

FOR UVW=

CLOCKWISE

4 HOLES

DIA ‘H’

EQUI-SPACED

ON ‘J’ P.C.D.

C

S

A (MAX)

B (MAX)

E

D

75.0

P

V

1 HOLE

DRILL 34.0

DEEP &

TAP M12 x

1.75 - 6H

x 28 DEEP

F

motor installation

Page 34

34

Accessories

Control Techniques offers a number of products, which add

power, flexibility and value to the Unimotor range:

For further information on planetary gearmotors and fan

cowlings please contact your local Drive Centre

Cable Assemblies and

Connectors

Control Techniques’ cable assemblies

simplify motor connection and reduce

installation time. Made to order in lengths

up to 100 metres, they have a PUR sheath

for high resistance to oil, grease and

solvents and have an excellent dynamic

performance. CSA and UL approved.

Planetary Gearmotors

Gearmotors deliver greater torque

output whilst maintaining high standards

of precision and reliability. They may be

mounted in any orientation and are

available with single or double stage

gearbox options.

Fan Cowlings

Fan cowlings force cool air through

the fins on the Unimotor housing to

increase torque output by up to 70%.

Available to fit all motor frame sizes, the

units may be retrofitted and maximise

power density in tight spaces.

accessories

Accessories also available from your local

Control Techniques Drive Centre

Page 35

35

Cable Assemblies

Characteristics - Power and Signal Cables

Cables are an important part of a servo system

installation. Not only must the noise immunity and

integrity of the cabling and connectors be correct, but

SAFETY and EMC regulations must be complied with

to ensure successful, reliable and fail-safe operation.

One of the most frequent problems experienced by

motion systems engineers is incorrect wiring

connections of the motor to the drive.

Control Techniques’ ready-made cables mean

system installers can avoid the intricate, time

consuming assembly normally associated with

connecting servo systems. Installation and set-up

time are greatly reduced - there is no fiddling with wire

connections and crimp tools, and no fault finding. The

cables are made to order in lengths from 3m to 100m

and are available for all standard Unimotor options.

Features

• UL and CSA approved

• Power and signal cables available

• No need for crimp and insertion / removal tools

• Production build gives quality and price benefits

• Compatible with Unimotor and Unidrive

• Optimum noise immunity

• Oil resistant PVC signal cable for industrial

environments and some dynamic applications

• PUR power cable for oil resistance and long life

dynamic applications

• Brake wires are separately shielded within power cable

• Thermistor wire pair is separately shielded in signal cable

• Encoder power pair each 1mm

2

conductors in

signal cable for low volt drop

• Braided screen for greater flexibility and wear

• Power cables with or without brake

• Shielded brake supply wires

• Cable assembly type identification label

Applications

• For general applications choose PVC type. This has

good all round performance.

• Use PUR for high dynamic applications where cable

is frequently in motion.

• Use PUR for machine tools where the cable is

sprayed with coolant fluid.

• 2.5 mm

2

conductors are applicable to all motors in

the range to 142 frame size.

• 4.0mm

2

conductors are applicable to 190 frame sizes.

accessories

Page 36

36

Cable Description (2.5mm2) PUR (2.5mm2) PUR

Shielded Power, Shielded Power,

without Brake with Brake

Cable Type PSBA-- PBBA-Power Conductors 4 x 2.5mm

2

4 x 2.5mm

2

Brake Supply Wires

-

1 x (2x1) mm

2

Conductor Type Copper stranded to DIN VDE 0295

Class 6, IEC 228 Class 6, CEI 20-29

Class 6; 147 x 0.15mm;13 AWG

Insulation Material PET - complies: VDE 0250 part 1 tab 4

Core Identification Black, printed white: U, VV, WWW, GY

Brake Signal Pair

Brake Conductors - Copper stranded 19 x 0.25mm

Brake Insulation - PET - complies: VDE 0250 part 1 tab 4

Brake Pair Shield - Tinned copper spiralled covering ³90%

Brake Core Identification - Black and white

Taping - Soft tape

Shield Tinned copper braid Tinned copper braid

covering ³85% covering ³85%

Shield Diameter 10.5mm 10.5mm

Outer Jacket Polyurethane complies: Polyurethane complies:

VDE 025-818 black VDE 025-818 black

Outer Jacket Diameter 12.8 mm± 4% 12.8 mm ± 4%

Voltage (power) 600 V / 1000 V 600 V / 1000 V

Voltage (brake pair) - 250 V

Dielectric Strength 3000 V 3000 V

(power)

Dielectric Strength - 1000V

(brake pair)

Insulation Resistance >10 MOhm/km >10 MOhm/km

(power)

Capacitance 110 pf/m 110 pf/m

(phase - phase)

Capacitance 190 pf/m 190 pf/m

(phase - screen)

Bending Radius (min) 10 x diameter, dynamic

laying (150 mm)

Speed (max) 180 m/min 180 m/min

Acceleration (max) 7 m/s

2

7 m/s

2

Bending Life (min) 5 million cycles 5 million cycles

Operating Temperature -10˚C to + 80˚C -10˚C to + 80˚C

Storage Temperature -30˚C to + 80˚C -30˚C to + 80˚C

Pulling Strength 20 N/mm

2

20 N/mm

2

(max, dynamic)

Pulling Strength 50 N/mm

2

50 N/mm

2

(max, fixed)

Weight 160 kg/km 160 kg/km

Specification - Shielded Power Cable Options 2.5mm

2

accessories

PUR Power Cables

Page 37

37

Cable Description (4.0 mm2) PUR (4.0 mm2) PUR

Shielded Power, without Brake Shielded Power, with Brake

Cable Type PSBB-- PBBB-Power Conductors 4 x 4.0mm

2

4 x 4.0mm

2

Brake Supply Wires - 1 x (2x1) mm

2

Conductor Type Copper stranded to DIN VDE

0295 Class 6, IEC 228 Class 6, CEI

20-29 Class 6; 245 x 0.15mm; 11 AWG

Insulation Material PET - complies: VDE 0250 part 1 tab 4

NFC & CEI

Core Identification Black, printed white: U, VV, WWW, G/Y

Brake Signal Pair

Brake Conductors - Copper stranded 19 x 0.25mm

Brake Insulation - PET

Brake Pair Shield - Tinned copper spiralled covering ³ 90%

Brake Core Identification - Black and white

Taping - Soft tape

Shield Tinned copper braid covering ³85% Tinned copper braid covering ³85%

Shield Diameter 11.3 mm

Outer Jacket Polyurethane complies: VDE 025 - 818, black

Outer Jacket Diameter 14.4 mm± 4%

Voltage (power) 600 V / 1000 V

Voltage (brake pair) - 250 V

Dielectric Strength 3000 V 3000 V

(power)

Dielectric Strength - 1000 V

(brake pair)

Insulation Resistance >10 MOhm/km >10 MOhm/km

(power)

Capacitance 120 pf/m 120 pf/m

(phase - phase)

Capacitance 200 pf/m

(phase - screen)

Bending Radius (min) 10 x diameter, dynamic laying (150 mm)

Speed (max) 180 m/min 180 m/min

Acceleration (max) 7 m/s

2

7 m/s

2

Bending Life (min) 5 million cycles 5 million cycles

Operating Temperature -10˚C to + 80˚C -10˚C to + 80˚C

Storage Temperature -30˚C to + 80˚C -30˚C to + 80˚C

Pulling Strength

20 N/mm

2

20 N/mm

2

(max, dynamic)

Pulling Strength

50 N/mm

2

50 N/mm

2

(max, fixed)

Weight 230 kg/km 230 kg/km

Specification - Shielded Power Cable Options 4.0 mm

2

accessories

Page 38

38

Outline Drawing - Power Cable With Brake

Drive End

Termination

(Motor End)

(Motor End)

Drive End

Termination

Pin Conductor Function

1 ‘1’ Phase U

2 ‘2’ Phase V

3 Y/G Earth

4 ‘3’ Phase W

5- 6- CONNECTOR BODY Scree n

Pin Conductor Function

1 ‘1’ Phase U

2 ‘2’ Phase V

3 Y/G Earth

4 ‘3’ Phase W

5 ‘5’ Brake

6 ‘6’ Brake

CONNECTOR BODY Screen

Power Cable Connections - with Brake

Power Cable Connections - without Brake

PB B B B 095

Cable Type:

PS - Power (Standard)

PB - Power (With brake)

Conductor Size:

A - 4x 2.5mm2 conductor

(75A - 190A)

B - 4x 4.0mm2 conductor

(190B - 190D)

Insulator:

B - PUR

Cable Length (metres):

Min - 003 (3 metres)

Max - 100 (100 metres)

Connector Types:

A - Ferrule ends at Drive, Inter-

connectron at Motor (not 190)

B - Ferrule ends at Drive,

unfinished cut end at Motor

C - Ferrule ends at Drive and

Motor for hybrid or terminal box

X - Cable only

Ordering Information - Power Cables

Use the information on the following chart to create an

order code. The top line is an example of an order code.

accessories

Outline Drawing - Power Cable Without Brake

115.0 ±10

Brake

Earth

Power U

Power V

Power W

Screen

130.0 ±10

Drive End

Termination

Identity Label

Cable length: min.= 3.0 metres / max.= 100 metres

Tolerance: -0.0 / +50mm

115.0 ±10

Earth

Power U

Power V

Power W

Screen

130.0 ±10

Drive End

Termination

Identity Label

Cable length: min.= 3.0 metres / max.= 100 metres

Tolerance: -0.0 / +50mm

Connector

Assembly

Connector

Assembly

5

4

(3)

Connector

Face

5

4

(3)

Connector

Face

1

6

2

1

6

2

Page 39

39

accessories

Specification - Shielded Signal Cable