Page 1

User Guide

UD78UD78

Servo

large option module

for Unidrive

Part Number: 0460 - 0086

Issue Number: 2

Page 2

General Information

The manufacturer accepts no liability for any consequences resulting from

inappropriate, negligent or incorrect installation or adjustment of the

operating parameters of the equipment or from mismatching the Drive

with the motor.

This option module is intended for use only with Control Techniques

Unidrive products. Any other use invalidates the warranty and may cause a

safety hazard.

The contents of this Guide are believed to be correct at the time of

printing. In the interests of a commitment to a policy of continuous

development and improvement, the manufacturer reserves the right to

change the specification of the product or its performance, or the

contents of this Guide, without notice.

All rights reserved. No part of this Guide may be reproduced or

transmitted in any form or by any means, electrical or mechanical including

photocopying, recording or by any information storage or retrieval system,

without permission in writing from the publisher.

Use within the European Union, etc

The following information applies where the end use of the Drive is within

the European Union, the European Economic Area, or other regions which

have implemented Directives of the European Council or equivalent

measures.

The Drive, together with its associated option modules, complies with the

Low Voltage Directive 73/23/EEC.

The installer is responsible for ensuring that the equipment into which the

Drive is incorporated complies with all relevant Directives.

The complete equipment must comply with the EMC Directive 89/336/EEC.

If the Drive is incorporated into a machine, the manufacturer is responsible

for ensuring that the machine complies with the Machinery Directive

89/392/EEC. In particular, the electrical equipment should generally

comply with European Harmonised standard EN60204-1.

Copyright © January 2002 Control Techniques Drives Ltd

Issue Code: 78nu2

Page 3

Contents

Chapter

1 Introduction 1

1.1 Main features of the UD78 1

2 Safety Information 3

3 Installing the UD78 6

4 Making Connections 8

4.1 Locations of the connectors 8

4.2 SK1

4.3 SK2

4.4 PL1

Precision analog input

Functions of the terminals............................................................................................9

Specification.......................................................................................................................10

Back-up DC supply input

Functions of the terminals............................................................................................11

Specification.........................................................................................................................11

Operation.............................................................................................................................12

Serial communications

Functions of the terminals...........................................................................................13

Specification........................................................................................................................13

Serial communications modes.................................................................................14

Ground connection........................................................................................................16

Routing the serial communications cable...........................................................17

Terminating the cable....................................................................................................17

Operation..............................................................................................................................17

connector 9

connector 11

connector 13

5 Related Parameters 18

5.1 Introduction 18

5.2

5.3

5.4

UD78 User Guide

Issue code: 78nu2

Precision analog input

Back-up DC supply

parameter 22

Serial communications

parameters 19

parameters 21

Page 4

Appendix

A Serial Comms. ANSI Message Formats A-1

A.1 Fundamentals of data transmission A-1

A.2 Reading a parameter value A-4

A.3 Re-reading a parameter value A-5

A.4 Writing a parameter value A-5

A.5 Re-writing a parameter value A-6

A.6 Calculating the block checksum (BCC) A-6

B Setting up the Drive using UniSoft B-1

UD78 User Guide

Issue code: 78nu2

Page 5

1 Introduction

1.1 Main features of the UD78

Note

The UD78 can be used only with Drives equipped with

version 3 (or later) software. (Parameter 0.50 indicates

the software version.)

Main

functions

Back-up

DC

supply

The UD78 large option module is an interface module for installation in a

Unidrive and has the following functions:

• Precision analog input

• EIA RS485, 4-wire or 2-wire, serial communications interface (fully

opto-isolated)

• Back-up +24V

Drive (and the UD78) operating when the AC supply to the Drive is

disconnected.

DC supply input for keeping the control circuits of the

Serial communications

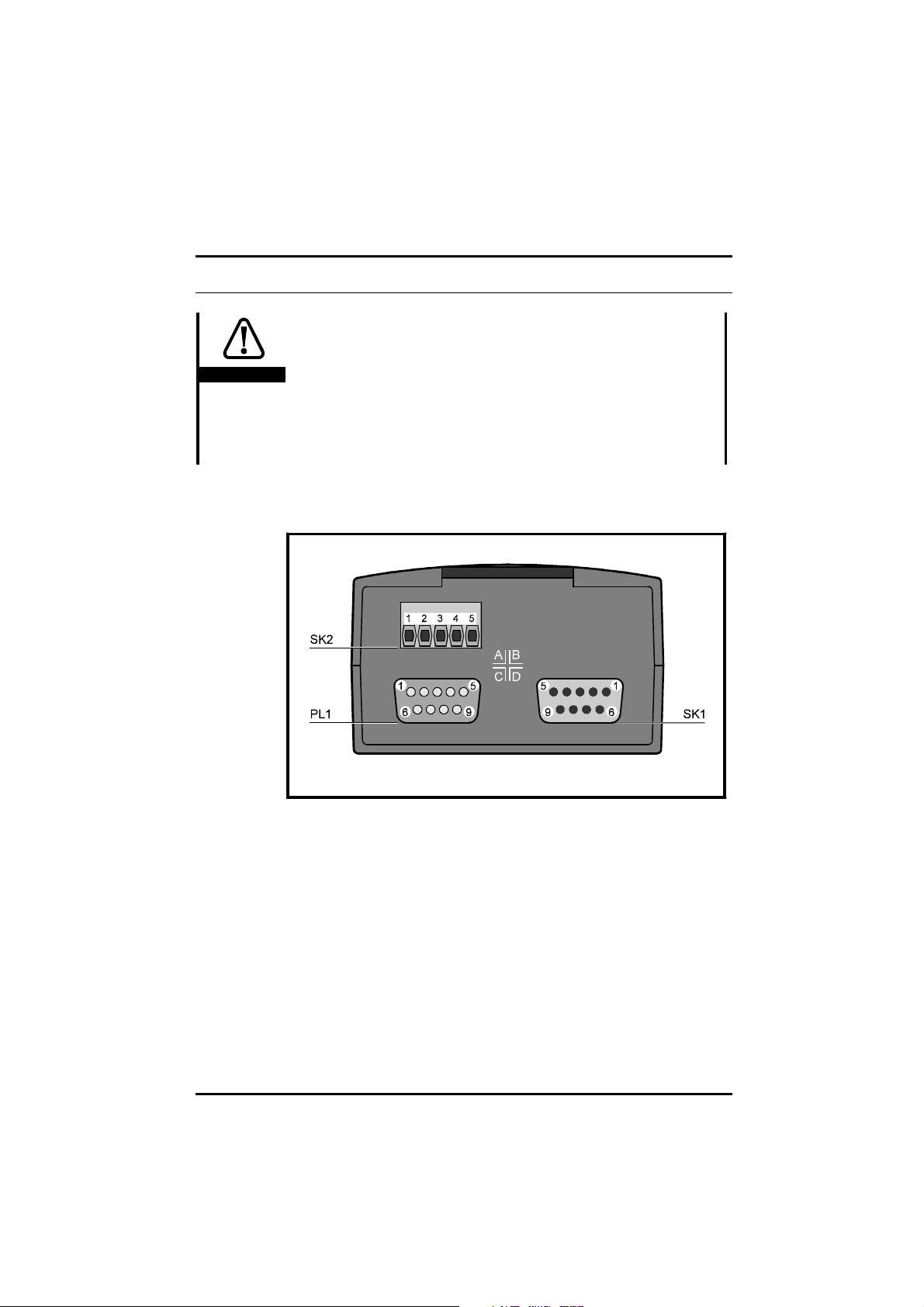

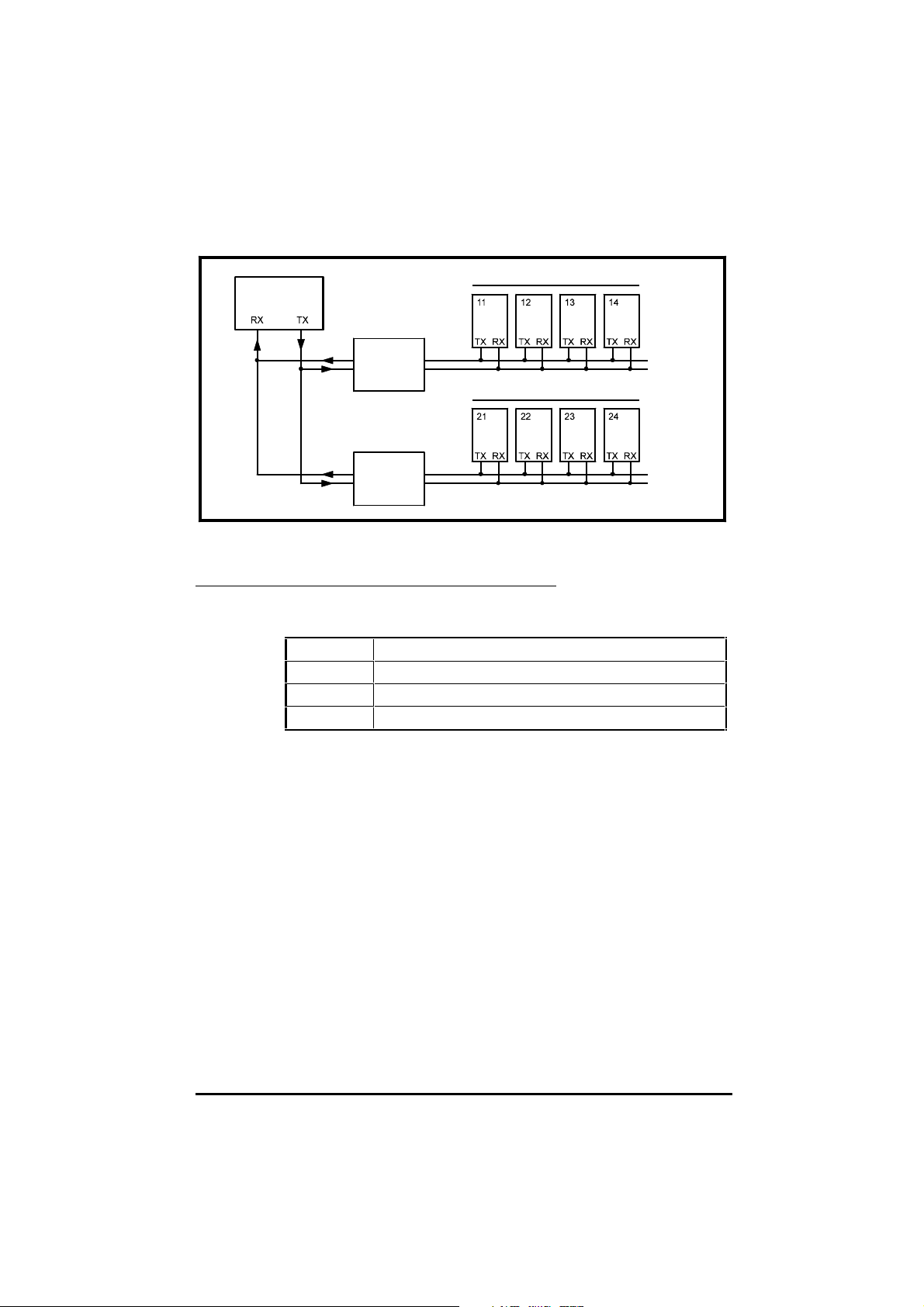

Figure 1 The functions of the UD78 connectors

UD78 User Guide

Issue code: 78nu2

Precision analog input

1

Page 6

Precision

analog input

Serial

comms.

interface

Installation

The precision analog input replaces terminals 5 and 6 Analog input 1 in the

Drive. Terminals 5 and 6 can then not be used for any purpo se. The

parameters associated with Analog input 1 now relate to the pr ecision

input.

The serial communications interface allows the following:

• The Drive to be controlled and monitored remotely by a

system controller

• The Drive to control or monitor another Drive

The UD78 must be fitted in the large option module bay of the Unidrive.

Precision analog input and serial communications connections are made by

9-way D-type connectors. The external Back-up

made by a pluggable 5-way screw-terminal block.

DC supply connections are

UD78 User Guide

2

Issue code: 78nu2

Page 7

2 Safety Information

2.1

Warnings, Cautions and Notes

A Warning contains information which is essential for avoiding a safety

hazard.

A Caution contains information which is necessary for avoiding a risk of

damage to the product or other equipment.

A Note contains information which helps to ensure correct operation of the

product.

2.2 Electrical safety – general warning

The voltages used in the Drive can cause severe electric sho ck and/or burns,

and could be lethal. Extreme care is necessary at all times when working

with or adjacent to the Drive.

Specific warnings are given at the relevant places in this User Guide.

The installation must comply with all relevant safety legislation in the

country of use.

The Drive contains capacitors that remain charged to a poten tially lethal

voltage after the

energized, the AC supply must be isolated at least ten minutes before work

may continue.

AC supply has been disconnected. If the Drive has been

2.3 System design

The Drive is intended as a component for professional incorporation into

complete equipment or systems. If installed in correctly the Dr ive may

present a safety hazard. The Drive uses high voltages and currents, carries

a high level of stored electrical energy, and is used to control m echanical

equipment which can cause injury.

Close attention is required to the electrical installation and the systemdesign to avoid hazards either in normal operation or in the event of

equipment malfunction. System-design, installation, commissioning and

maintenance must be carried out by personnel who have the necessary

training and experience. They must read this safety information and this

User Guide carefully.

To ensure mechanical safety, ad ditional safety devic es such as

electro-mechanical interlocks m ay be required. The Dr ive must not be u sed

in a safety-critical application without additional high-integrity protection

against hazards arising from a malfunction.

UD78 User Guide

Issue code: 78nu2

3

Page 8

2.4 Environmental limits

Instructions in the Unidrive Installation Guide regarding transport, storage,

installation and use of Drives must be complied with, including the specified

environmental limits. Drives must no t be subjected to exc essive physical

force.

2.5 Compliance with regulations

The installer is responsible for complying with all relevant regulations, such

as national wiring regulations, accident prevention regulations and

electromagnetic compatibility (EMC) regulations. Particular attention must

be given to the cross-sectional areas of conductors, the selection of fuses or

other protection, and protective earth (ground) connections.

The Unidrive Installation Guide contains instructions for achieving compliance

with specific EMC standards.

Within the European Union, all machinery in which this product is used must

comply with the following directives:

89/392/EEC: Safety of Machinery

89/336/EEC: Electromagnetic Compatibility

2.6 Safety of personnel

The STOP function of the Drive does not remove dangerous voltages from

the output of the Drive or from any external option unit.

The Stop and Start controls or electrical inputs of the Drive should not be

relied upon to ensure safety of personnel. If a safety hazard could exist

from unexpected starting of the Drive, an interlo ck that electric ally isolates

the Drive from the

inadvertently started.

Careful consideration must be given to the functions of the Drive which

might result in a hazard, either through their intended functions (eg.

Auto-start) or through incorrect operation due to a fault or trip (eg.

stop/start, forward/reverse, maximum speed).

Under certain conditions, the Drive can suddenly discontinue control of the

motor. If the load on the motor cou ld cause the moto r speed to be

increased (eg. hoists and cranes), a separate method of braking and

stopping the motor should be used (eg. a mechanical brake).

Before connecting the

understand the operating controls and their operation. If in doubt, do not

adjust the Drive. Damage may occur, or lives put at risk. Carefully follow

the instructions in this User Guide.

Before making adjustments to the Drive, ensure all personnel in the area are

warned. Make notes of all adjustments that are made.

AC supply should be installed to prevent the motor being

AC supply to the Drive, it is important that you

UD78 User Guide

4

Issue code: 78nu2

Page 9

2.7 Risk analysis

In any application where a malfunction of the Drive could lead to damage,

loss of life or injury, a risk analysis must be carried out, and where necessary,

further measures taken to reduce the risk. This would normally be an

appropriate form of independent safety back-up system using simple

electro-mechanical components.

2.8 Signal connections

The control circuits are isolated from the po wer circuits in the Drive by basic

insulation only, as specified in IEC664–1. The installer must ensure that the

external control circuits are insulated from human contact by at least one

layer of insulation rated for use at the AC supply voltage.

If the control circuits are to be connected to other circuits classified as

Safety Extra Low Voltage (SELV) (eg. to a personal computer), an additional

isolating barrier must be included in order to maintain the SELV

classification.

2.9 Adjusting parameters

Some parameters have a profound effect on the operation of the Drive.

They must not be altered without careful consideration of the impact on

the controlled system. Measures must be taken to prevent un wanted

changes due to error or tampering.

UD78 User Guide

Issue code: 78nu2

5

Page 10

3 Installing the UD78

Before using the following procedure, refer to the

Warnings at the beginning of Chapter 2 Installing the Drive in

Warning

the Unidrive Installation Guide.

1 Before installing the UD78 in the Unidrive, ensure the AC supply has

been disconnected from the Drive for at least 10 minutes.

2 Check that the exterior of the UD78 is not damaged, and that the

multi-way connector is free from dirt and debris. Do not install a

damaged or dirty UD78 in the Drive.

3 Remove the terminal cover from the Drive (for removal instructions,

see Installing the Drive and RFI filter in Chapter 2 of the Unidrive

Installation Guide).

4 Push the UD78 into the cavity immediately behind the keypad and

display until the UD78 locks in place.

5 Re-fit the terminal cover to the Drive.

6 Connect the AC supply to the Drive.

7 Set parameter .00 at 149 to unlock security.

8 Check that parameter 7.31 is set at 1 to indicate that the module is

fitted.

9 If the check in step 8 fails, perform the following:

• Remove the

• Wait at least 10 minutes.

• Remove the terminal cover.

• Check that the UD78 is fully inserted.

• Replace the terminal cover.

• Re-apply the

• Check again that parameter 7.31 is set at

AC supply from the Drive.

AC supply.

1.

UD78 User Guide

6

Issue code: 78nu2

Page 11

Figure 2 Installing the UD78 in the Unidrive

Do not remove the UD78 from the Drive when either the

DC back-up supply is applied to the Drive. If the UD78 is removed when the

Drive is powered-up, the Drive will trip; the display will indicate ANI.diS.

If the UD78 is deliberately removed, it may be necessary to re-adjust the

parameters related to analog input 1, since they will now relate to termin als

5 and 6.

UD78 User Guide

Issue code: 78nu2

AC supply or a

7

Page 12

4 Making Connections

The control circuits are isolated from the power circuits in

the Drive by basic insulation only, as specified in IEC664–1.

The installer must ensure that the external control circuits

Warning

4.1 Locations of the connectors

are insulated from human contact by at least one layer of

insulation rated for use at the

If the control circuits are to be connected to other circuits

classified as Safety Extra Low Voltage (SELV) (eg. to a

personal computer), an additional isolating barrier must be

included in order to maintain the SELV classification.

AC supply voltage.

Figure 3 Locations of the connectors on the UD78

8

UD78 User Guide

Issue code: 78nu2

Page 13

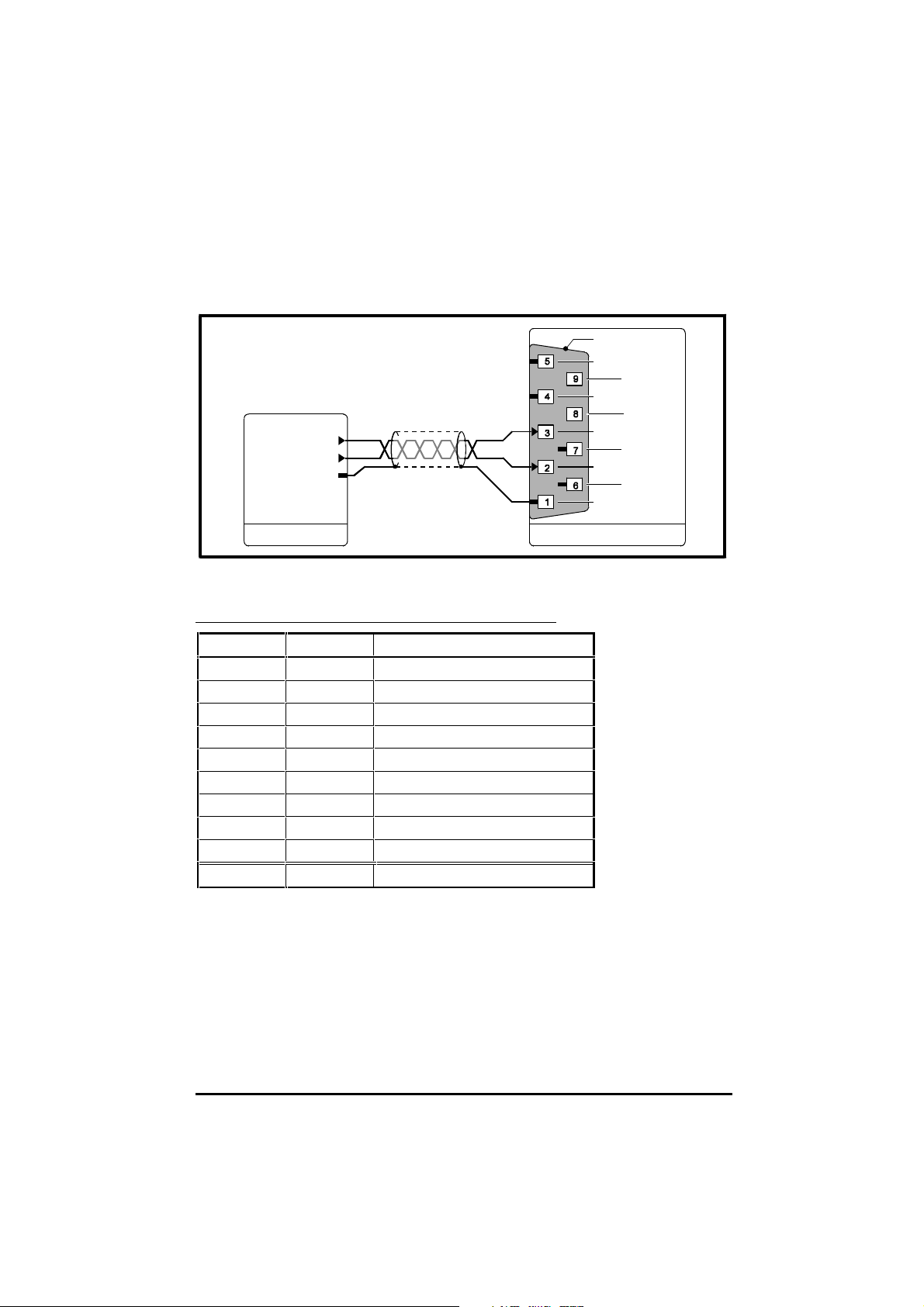

4.2 SK1

Precision analog input connector

−Vout

+Vout

SK1 [UD78]System controller

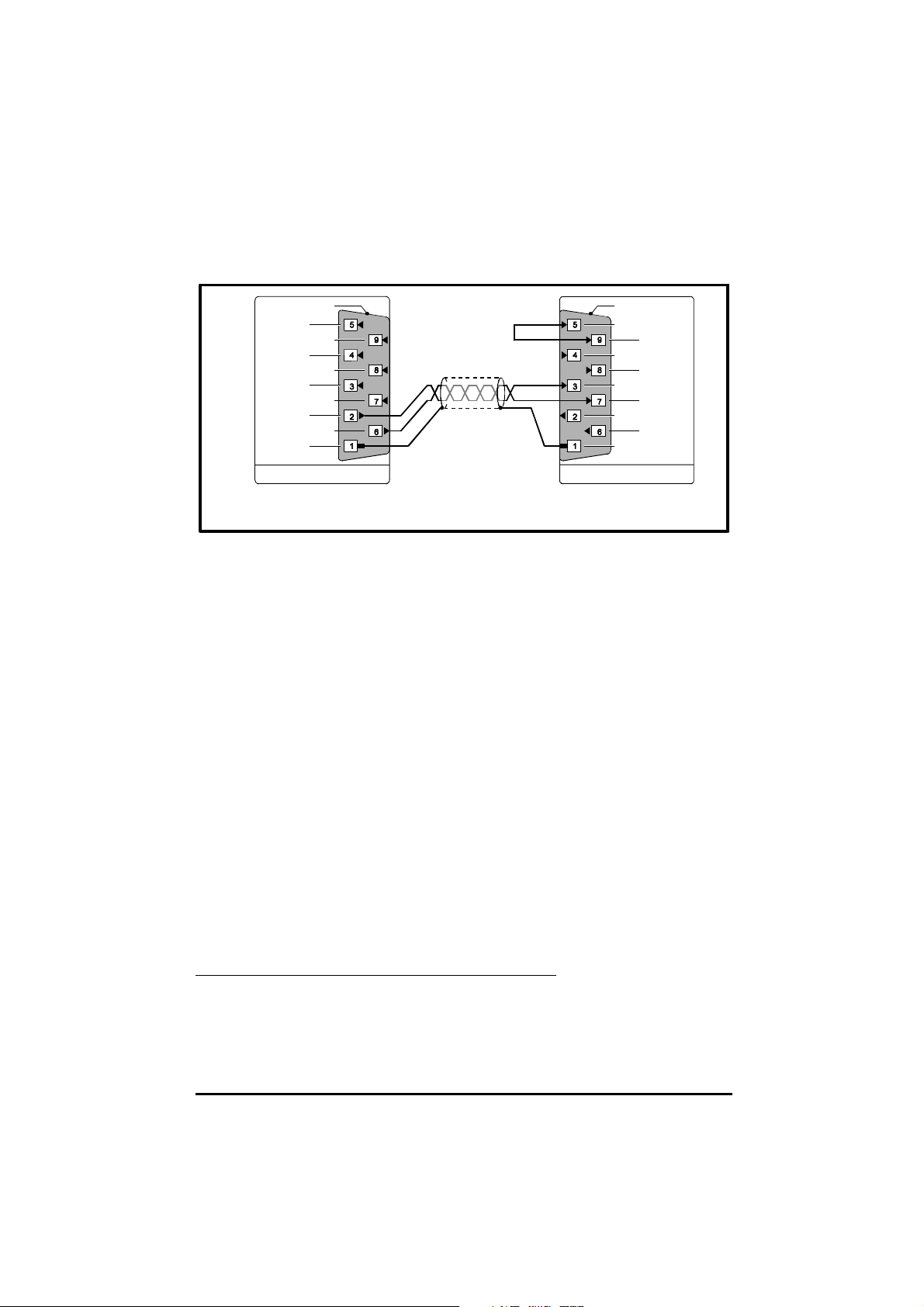

Figure 4 Connections to the precision analog input

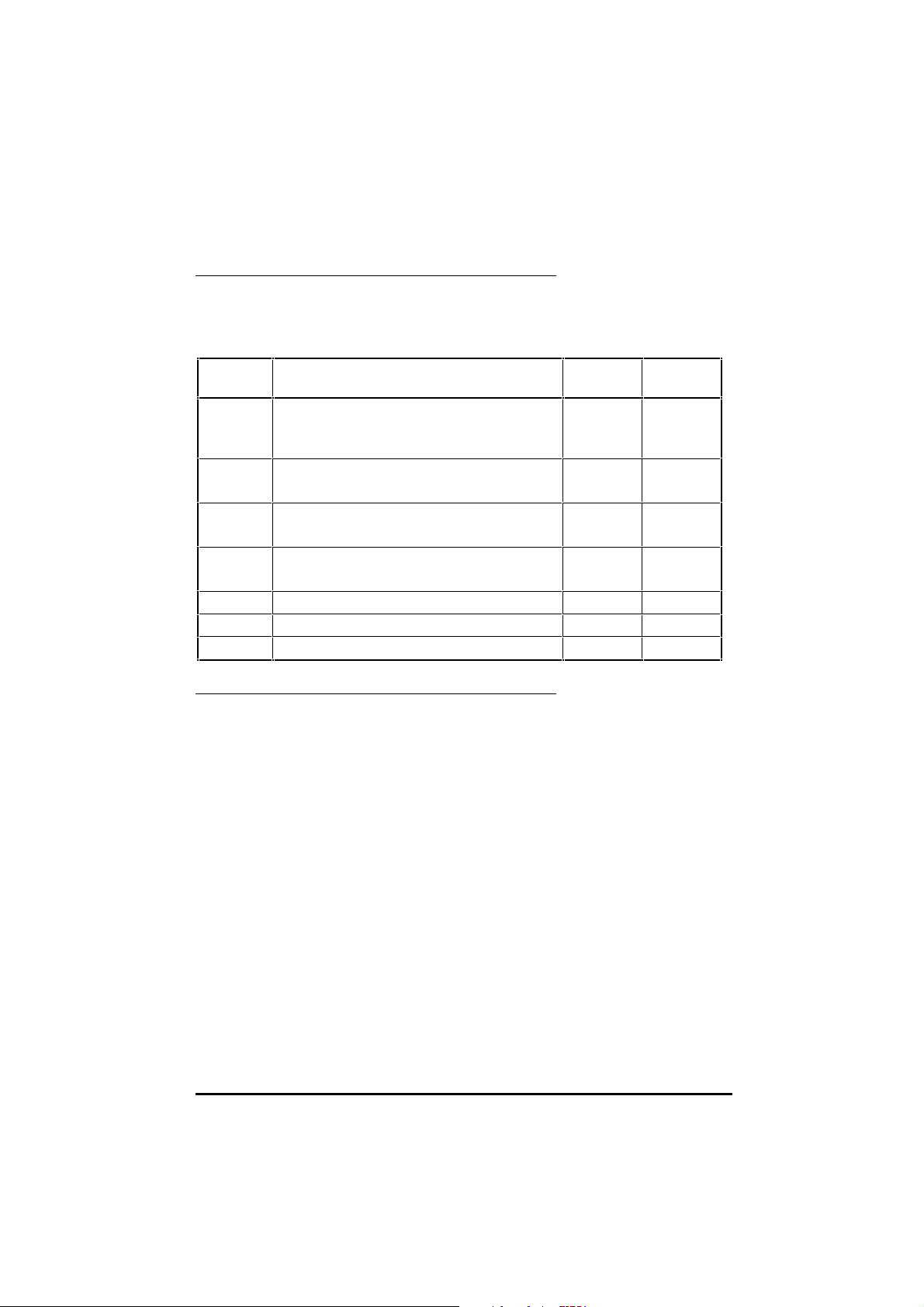

Functions of the terminals

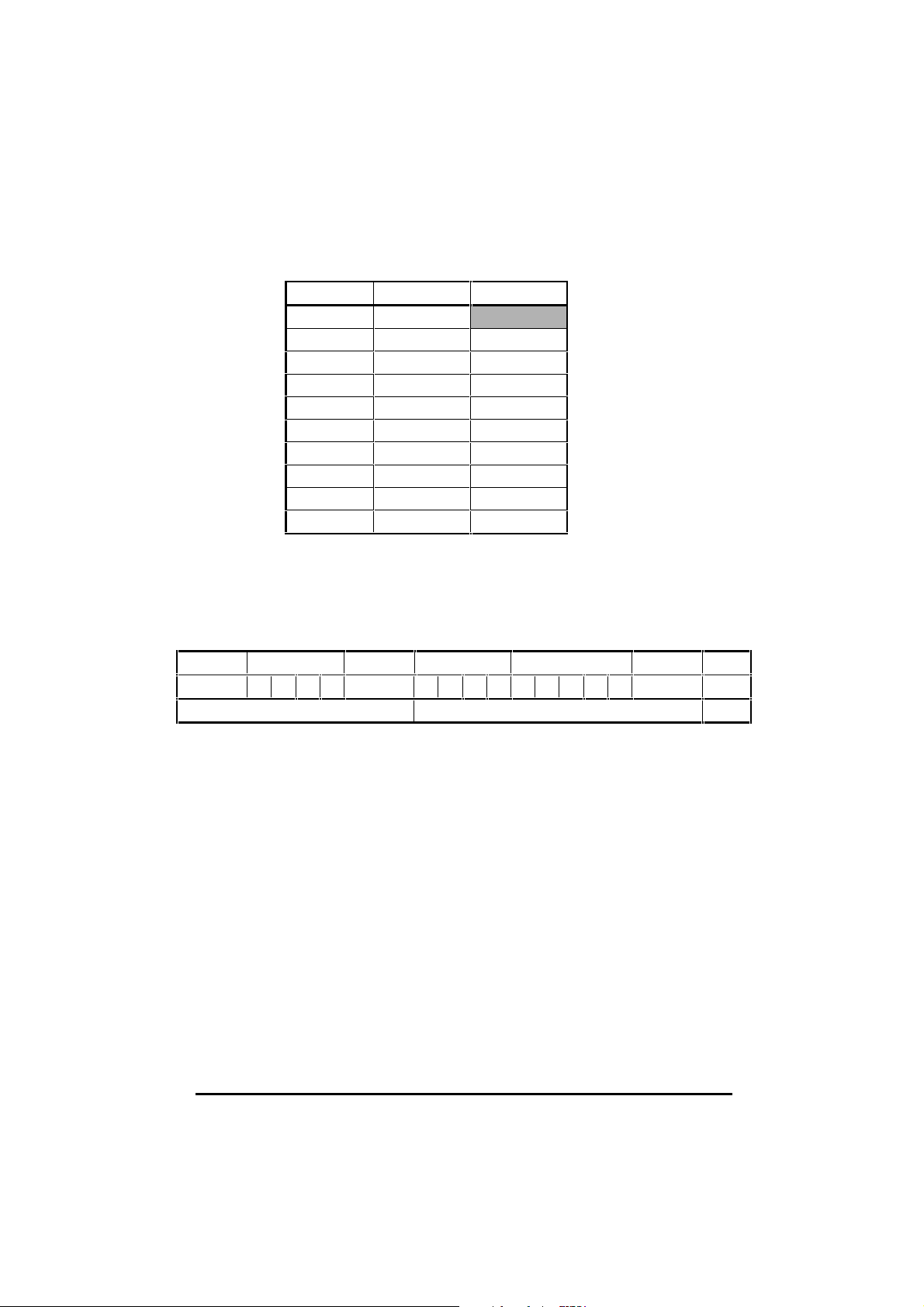

Terminal Name Function

10VD0V

2 +Vin Reference input +

3 –Vin Reference input –

40VD0V

5 NC Not connected

60VD0V

70VD0V

80VD0V

9 NC Not connected

Shell 0VD 0V

0VD

NC

NC

0VD

0VD

−Vin

0VD

+Vin

0VD

0VD

UD78 User Guide

Issue code: 78nu2

9

Page 14

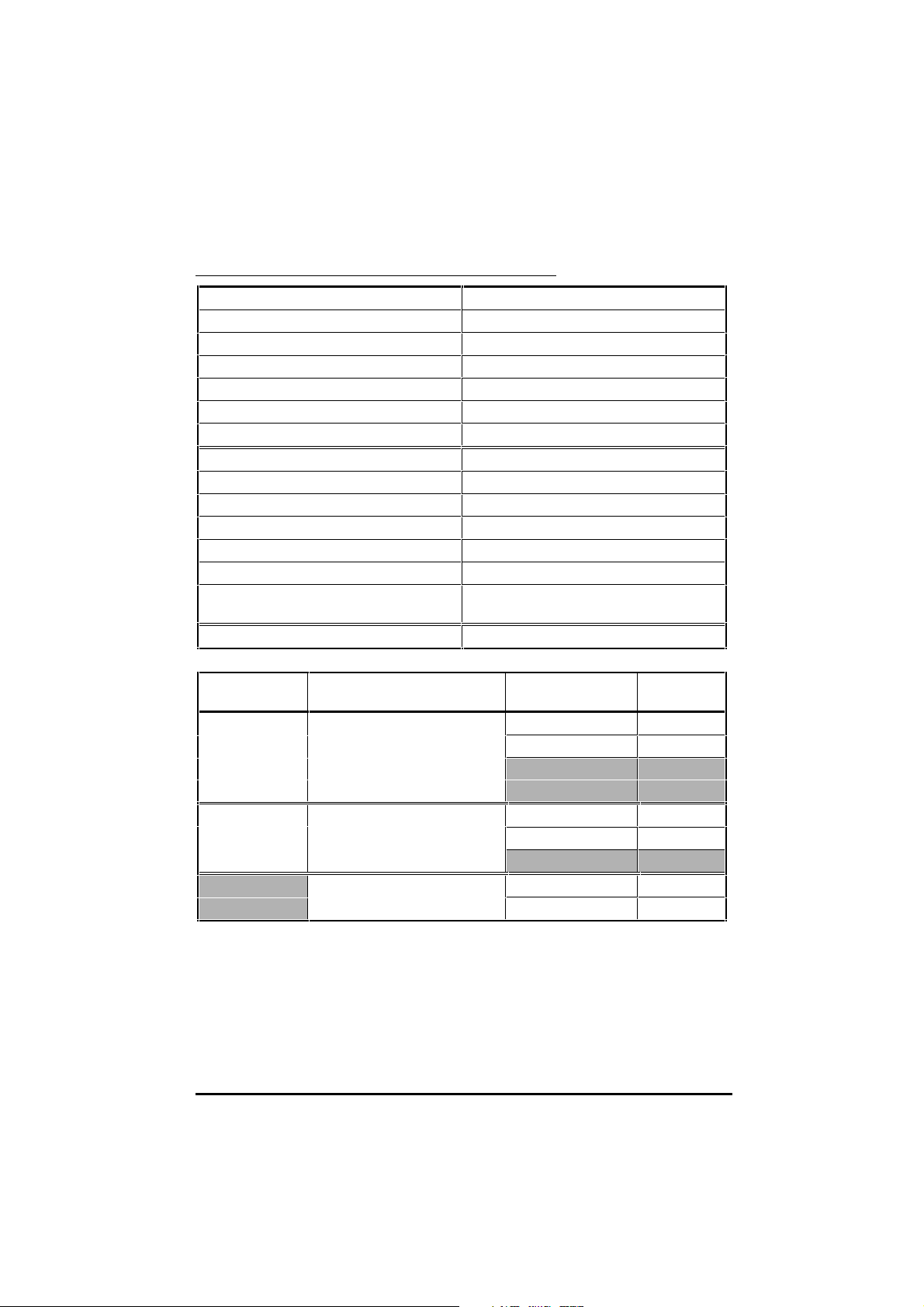

Specification

Input type Differential

Mode Bipolar voltage

Full-scale differential input voltage ±9.8V ±1% (see parameter 7.25)

Absolute maximum differential input voltage ±30V

Absolute maximum input voltage ±50V relative to 0VD

Common mode rejection ratio 95dB

Input resistance 20kΩ

Full-scale asymmetry ±0.1% maximum

Offset error <150µV

Dead-band at zero input <150µV

Zero-crossing error <150µV

Linearity error ±0.1% of full scale

Input-filter time-constant 10µs

Resolution Open-loop: 12-bit plus sign

Closed-loop: ∞ (pulses are accumulated)

Sample period (See below)

Operating mode Destination parameter

for the analog input

Closed-loop 1.36 Analog reference 1 3, 6, 12 345µs

1.37 Analog reference 2 4, 5, 9 460µs

3.19 Hard speed reference

4.08 Torque reference

Open-loop 1.36 Analog reference 1 3, 6, 12 1.38ms

1.37 Analog reference 2 4, 5, 9 1.84ms

4.08 Torque reference

All other parameters 3, 6, 12 5.5ms

PWM switching

frequency (kHz)

4, 5, 9 7.4ms

Sample period

UD78 User Guide

10

Issue code: 78nu2

Page 15

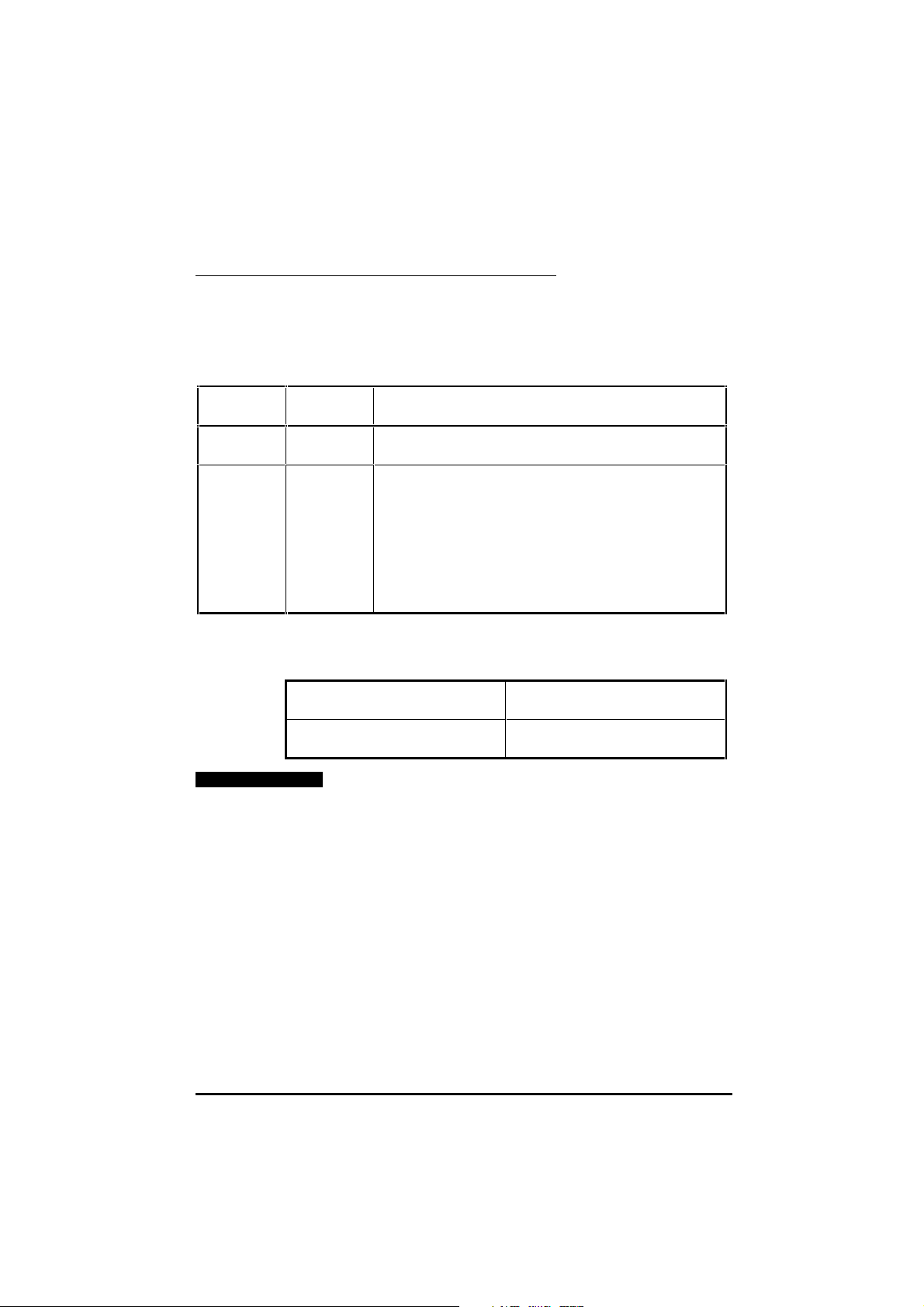

4.3 SK2

Back-up DC supply input connector

Functions of the terminals

Terminal Name Function

10VD0V

2 +DC +24 Volts supply input

3 NC Not connected

40VD0V

5 +DC +24 Volts supply input

Terminals 2 and 5 are internally connected to allow chain connection for up

to three Drives. When four or more Drives are connected, a star wiring

configuration should be used.

Specification

Required supply voltage (including ripple) 22.8V ~ 26.4V

Maximum ripple at 100Hz 1V RMS

Absolute maximum voltage +50V

Absolute maximum reverse voltage –30V

Continuous current when the AC supply is

disconnected from the Drive

Continuous current when the AC supply is

connected to the Drive

Temperature limits (See below)

<1A

20mA

Drive powered only by the back-up DC supply Up to 30°C

(86°F)

Up to 40°C

(104°F)

Drive powered by the AC supply

UD78 User Guide

Issue code: 78nu2

Up to 40°C

(104°F)

Up to 50°C

(122°F)

The Drive can be powered

indefinitely

The Drive can be powered for

15 minutes maximum

The Drive can be powered

indefinitely

Refer to the Unidrive Installation

Guide

11

Page 16

Operation

For automatic operation of the back-up DC supply, this supply should be

connected continuously.

The following table shows the results of a combination of supply conditions.

AC supply is considered to be removed when it is below

A 400V

approximately 230V RMS.

AC supply Back-up

DC supply

Present Present or

absent

Absent Present If the AC supply is present, then removed, parameters that are saved

Resulting effect

Control circuits and power stages operate

(Drive fully operational, including the precision analog input)

at power-down are saved

Only the control circuits operate

The Drive cannot power a motor

The Drive displays LOPS

The Drive can be programmed either manually or via

serial communications, but parameter values cannot be saved

Model sizes 1 and 2: Heatsink fan operates

Model sizes 3 and 4: Heatsink fans do not operate

Power-up delays

The following delays occur:

AC supply disconnected

DC supply being connected

Back-up

Back-up DC supply already connected

AC supply being connected

5 second delay for Drive display and serial

communications to become active

5 second delay before the Drive can be

enabled

Note

Stator resistance test (open-loop only)

If parameter 5.14 (0.07) is set at Ur_I for the Drive to perform a stator

resistance test at power-up, and the AC supply is disconnected, the Drive

will trip if the Back-up DC supply is connected. The Drive will display trip

code rS, indicating failure to perform the stator resistance test.

To prevent this occurring, set parameter 5.14 ( 0.07) at one of the

following, and refer to Voltage boost in Chapter 4 Menu 0 parameters in the

Unidrive User Guide:

Ur_S, Ur, Fd

12

UD78 User Guide

Issue code: 78nu2

Page 17

4.4 PL1

Serial communications connector

Functions of the terminals

Terminal Name Function

1 0VSC 0V

2 TX\ Transmit output (inverted)

3 RX\ Receive input (inverted)

4TXTERM TX termination-resistor

connection

5RXTERM RX termination-resistor

connection

6 TX Transmit output

7 RX Receive input

8TX\TERM TX\ termination-resistor

connection

9RX\TERM RX\ termination-resistor

connection

Shell 0VSC 0V

Specification

RX (input) 2 unit-loads (EIA RS485)

TX (output) 2 unit-loads (EIA RS485)

2-wire (Transceiver mode) 4 unit-loads (EIA RS485)

Termination resistance 120Ω ±5% (no series capacitor)

In accordance with the EIA RS485 specification, the total load on a line must

not exceed 32 unit-loads. Each transmitter an d receiver of the UD7 8 loads

the line by two unit-loads (in two-wire mode, each UD78 loads the line by

four unit-loads). This allows the following to be operated:

• 15 units in 4-wire mode

• 7 units in 2-wire mode

When line repeaters are used, up to 81 Control Techniques devices can be

operated. In this case the devices must be arranged in up to nine groups of

nine. A particular group or groups can be given commands without

affecting other devices or groups of devices.

UD78 User Guide

Issue code: 78nu2

13

Page 18

System

controller

Line

repeater

Line

repeater

Group 1

Group 2

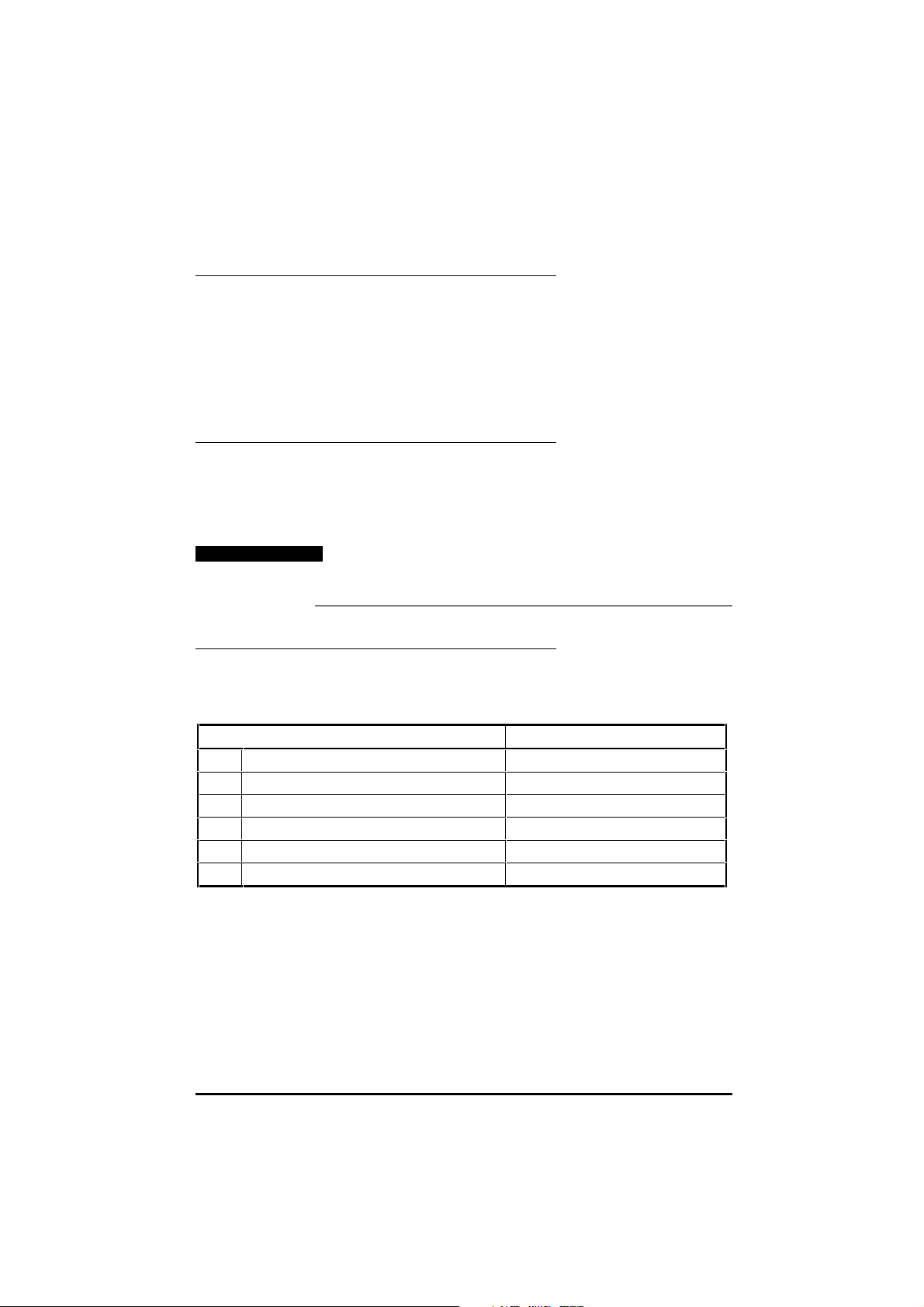

Figure 5 RS485 multi-drop link having two groups of four units

Serial communications modes

The serial communications interface can be set up for operation in the

following modes:

2-wire ANSI Half-duplex communications (transceiver mode)

4-wire ANSI Half-duplex communications, independent RX and TX channels

Output The Drive is to control another Drive (CT protocol)

Input The Drive is to be controlled by another Drive (CT protocol)

14

Make connections as shown in Figure 6, 7 or 8 as required. If the Drive is to

be set up using Unisoft on a PC, see Appendix B Setting up the Drive using

Unisoft.

UD78 User Guide

Issue code: 78nu2

Page 19

Four-wire ANSI

TX\

TX

RX\

RX

0VSC

RXTERM

RX\TERM

TXTERM

TX\TERM

RX\

RX

TX\

TX

0VSC

System controller

PL1 [UD78]

Figure 6 4-wire serial communications connections

Ensure parameter 11.24 Serial comms. mode selector is set at

ANSI 4 (1)

(default setting).

Two-wire ANSI

0VSC

RXTERM

RX\

TERM

TXTERM

TX\TERM

RX\

RX

TX\ RX\

TX RX

System controller

PL1 [UD78]

TX\

TX

0VSC

Figure 7 2-wire (transceiver mode) serial communications connections

Set parameter 11.24 Serial comms. mode selector at

ANSI 2 (0).

UD78 User Guide

Issue code: 78nu2

15

Page 20

Output and Input modes

0VSC

TERM

RX

RX\TERM

TXTERM

TX\TERM

RX\

RX

TX\

TX

0VSC

PL1 [UD78]

Parameter 11.24 set at

OUtPUt (2)

PL1 [UD78]

Parameter 11.24 set at

InPUt (3)

0VSC

RX

TXTERM

RX\

TX\

0VSC

Figure 8 Serial communications connections for the Input and

Output modes

Data is transferred at a rate of at least 140Hz. The protocol and range of

baud rates allow communications with the Mentor II and CDE models, as

well as other Unidrive models.

Only the value of a variable parameter can be transmitted and received. Bit

parameters are excluded.

Set parameter 11.24 Serial comms. mode selector as follows:

Output mode:

Input mode:

OutPUt (2)

InPUt (3)

TERM

RX\TERM

TX\TERM

RX

TX

Output mode

The value of a variable parameter selected by parameter 11.27 Serial comms.

source selector is sent (after scaling by 11.28 Serial comms. parameter

scaling) to the serial communications port for transmission.

If the Drive trips, the value

Input mode

The value received by the serial communications port is applied (after

scaling by 11.28 Serial comms. parameter scaling) to an unprotected variable

parameter selected by parameter 11.27 Serial comms. destination selector.

If communications fail, the Drive will trip; the display will indicate

Ground connection

In addition to each end of the cable shield being connected to 0V, it can be

connected by a single path to a ‘clean’ ground.

16

0 is transmitted.

SCL.

UD78 User Guide

Issue code: 78nu2

Page 21

Routing the serial communications cable

A data communications cable should not run parallel to any power cables,

especially ones that connect Drives to motors. If parallel runs are

unavoidable, ensure a minimum spacing of 300mm (12 in) between the

communications cable and the power cable.

Where cables are required to cross, they should be at right-angles to each

other in order to minimize coupling.

The maximum cable length for an EIA

Terminating the cable

It is recommended that UD78 modules, the system controller and other

equipment on a serial communications link are chain connected. The link

must be terminated at the unit that is at the end of the link. If this unit is a

UD78, the RX line can be terminated by linking terminals 5 and 9; the TX line

by linking terminals 4 and 8.

Note

When 2-wire mode (transceiver) is used, link terminals 5

and 9 as shown in Figure 7. Do not link terminals 4 and 8.

Operation

Internal bias resistors ensure that logic 1 is detected when the RX lines are

not driven.

The following parameters apply to the serial commu nications port.

RS485 link is 1200 metres (4000 feet).

Parameter Applies to...

11.23 Serial comms. address ANSI 2 and ANSI 4 modes

11.24 Serial comms. mode selector All serial comms. modes

11.25 Serial comms. baud rate ANSI 2 and ANSI 4 modes

11.26 Serial comms. 2-wire mode delay ANSI 2 mode

11.27 Serial comms. source/destination selector Input and Output modes only

11.28 Serial comms. parameter scaling Input and Output modes only

See Serial communications parameters in Chapter 5 Related parameters and to

Appendix A Serial communications message formats.

UD78 User Guide

Issue code: 78nu2

17

Page 22

5 Related Parameters

5.1 Introduction

The parameters listed in this chapter are used for programming and

monitoring the UD78 when it is fitted in a Drive. Refer to the Unidrive User

Guide for programming instructions.

Before attempting to adjust any parameters, refer to the

Warnings and Notes at the beginning of Chapter 3 Setting up

Warning

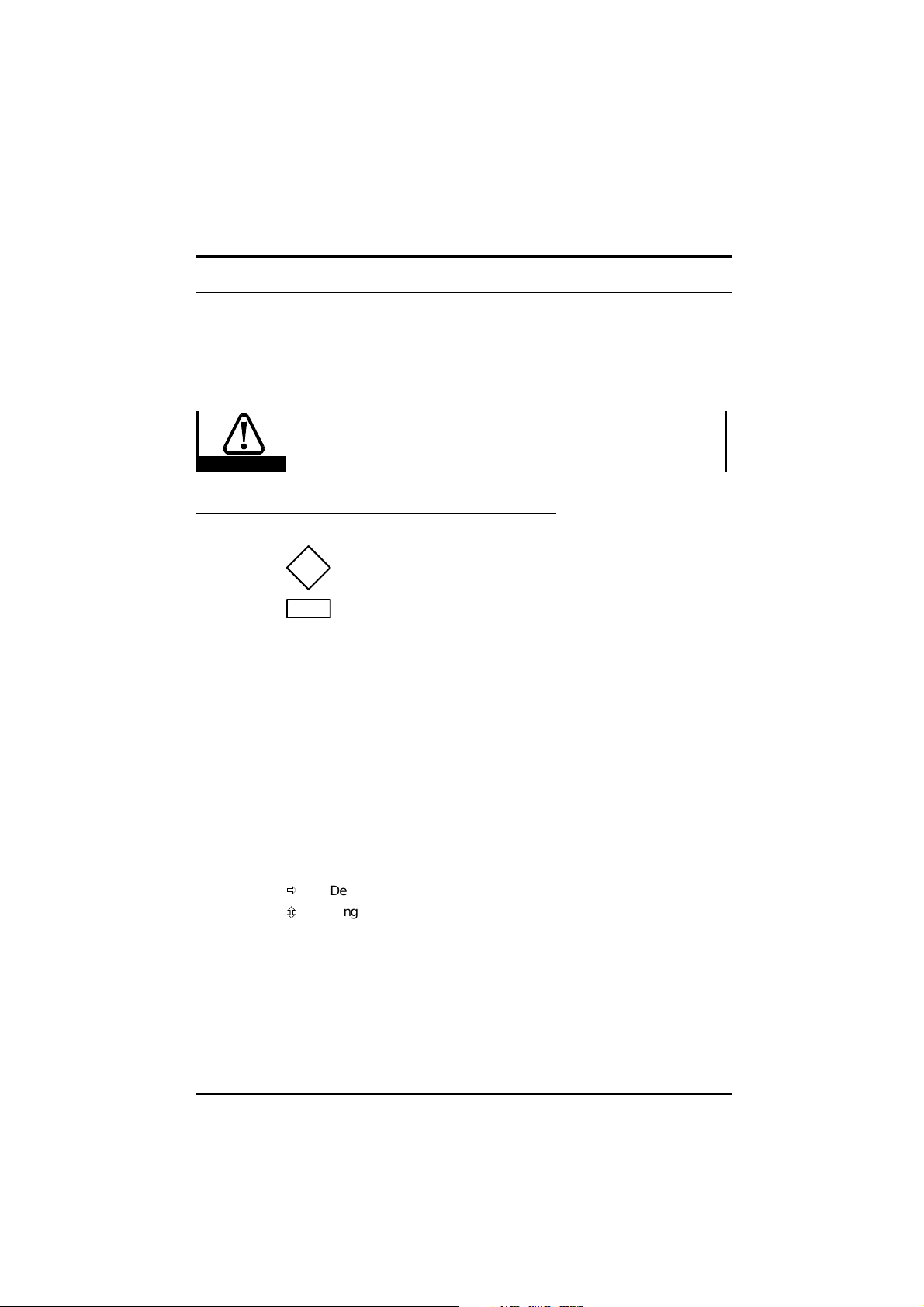

Key

the Drive in the Unidrive User Guide.

Type of parameter

RO Read-only

RW Read–write

...selector Select from a number of settings

...enable Make or allow a function to operate

...indicator The value can only be read

Limitations of use

R The Drive must be reset for a new value to take effect.

P Protected parameter; the parameter cannot be used as the

destination parameter for a programmable input.

Range

Bi Variable parameter having bipolar value range.

Uni Variable parameter having unipolar value range.

Bit Bit parameter

Symbols

ð

Default value

ô

Range of values

~ Indicates a range of values

(in the case of bit parameters, ~ indicates or).

18

UD78 User Guide

Issue code: 78nu2

Page 23

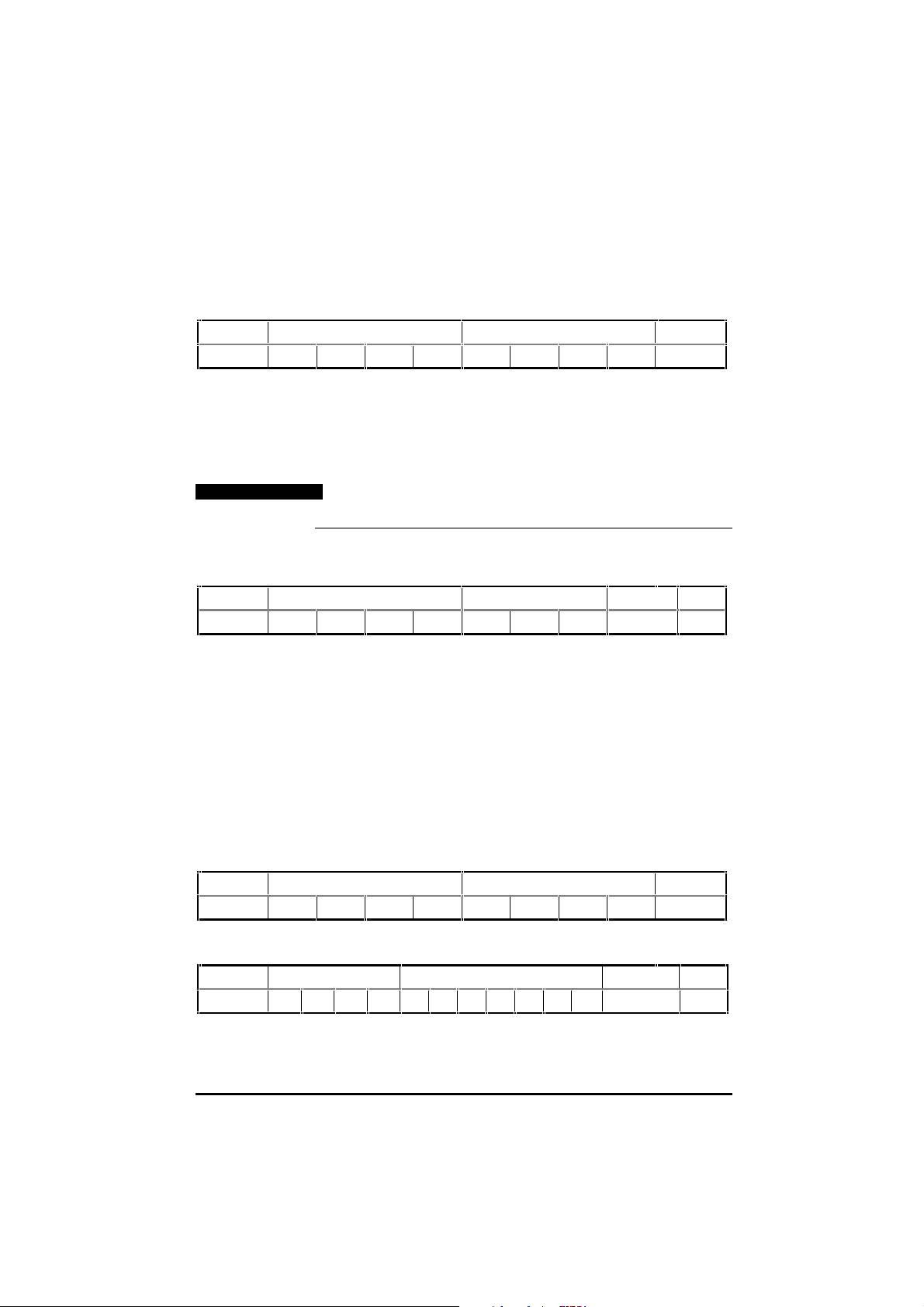

5.2 Precision analog input parameters

Precision analog

input

2

3

SK1

[UD78]

7.26

V/f sample

time

7.25

Calibrate

analog input 1

full scale

V/f

7.06

Analog input 1

mode

7.08

Analog

input 1

scaling

Analog input 1

offset trim

7.07

x(-1)

Analog input 1

7.01

Function-1

destination

selector

7.10

7.09

Any

unprotected

variable

parameter

Analog input 1

invert

??.??

??.??

The parameters are shown at their default settings.

The logic diagram is valid when

their default settings but may not be valid when certain

parameters are adjusted.

Figure 9 Logic diagram for the precision analog input

UD78 User Guide

Issue code: 78nu2

all

parameters are at

19

Page 24

7.01 Analog input 1 indicator

ô

±100

ð

% RO Bi P

7.01 indicates the value of the precision analog input after o ffset trim has

been applied by parameter 7.07 Analog input 1 offset trim. The indicated

value is a percentage of the full-scale amplitude (see parameter 7.25

Calibrate analog input 1 full-scale enable).

7.06 Analog input 1 mode selector

ô

VOLt

ð

VOLt RWTxt P

The setting of 7.06 cannot be changed.

7.07 Analog input 1 offset trim

ô

±10.000

ð

0 % RW Bi P

If an unwanted offset exists in the analog reference signal, adjust 7.07 to

cause 7.01 Analog input 1 indicator to indicate zero.

7.08 Analog input 1 scaling

ô

0 ~ 4.000

Set 7.08 at the required value to alter the scaling of the analog reference.

The scaling takes place after full-scale calibration (see parameter 7.25

Calibrate analog input 1 full-scale enable). 7.01 Analog input 1 indicator is not

affected by the setting of 7.08.

ð

1 RWUni

20

7.09 Analog input 1 invert

ô

0 ~ 1

ð

0 RW Bit

Set 7.09 at 1 to invert the value of the analog input.

7.10 Analog input 1 destination selector

ô

0.00 ~ 20.50 ð 1.36 Menu.

parameter

The default setting of 7.10 assigns terminals 2 and 3 of SK1 to 1.36 Analog

reference 1. If required, use 7.10 to change the function of the precision

analog input by entering the required menu.parame ter number (eg. 4.08 for

torque reference).

RWUni R P

UD78 User Guide

Issue code: 78nu2

Page 25

Only a variable parameter that is not protected can be specified. If any

other type of parameter is specified, the input is not assigned to any

parameter.

To make the new setting take effect, press

7.25 Calibrate analog input 1 full-scale enable

ô

0 ~ 1

ð

0 RW Bit

By default, the input is calibrated so that 9.8V sets 7.01 at 100%. Use the

following procedure to chan ge the full-scale value:

1 Apply the required full-scale value to terminals 2 and 3, as follows:

• If the applied value is greater than 2.5V, it will become the new

full-scale value

• If the applied value is less than 1.5V, the new full-scale value will be

the default value (9.8V)

2 Set 7.25 at 1.

The input scaling automatically c hanges acc ording to the applied valu e

(see step 1). This new value will set 7.01 at 100% and will remain

effective until this procedure is next performed.

The new setting is saved at power-down.

7.26 V/f sample time

Closed-loop only

When 7.10 is set at 1.36 (default), 1.37, or 3.19, if required set 7.26 for the

best compromise between low-speed operation and dynamic response.

Low values give good dynamic response but noisy operation at low speeds.

High values give smooth low-speed operation but a poorer dynamic

response.

7.31 is set at 1 when a UD78 module is fitted in the Drive.

UD78 User Guide

Issue code: 78nu2

ô

CL> 0 ~ 5.0

ð

4 ms RWUni

7.31 UD78 large option module fitted indicator

ô

0 ~ 1

ð

RO Bit P

21

Page 26

5.3 Back-up DC supply parameter

10.41Back-up DC supply active

ô

0 ~ 1

10.41 Indicates...

0 AC supply connected

Control circuits and power stages operate (Drive fully operating)

1 AC supply disconnected, back-up DC supply active

Only the control circuits operate

The Drive cannot power a motor

The Drive displays LOPS

The Drive can be programmed either manually or via serial communications,

but parameter values cannot be saved

Model sizes 1 and 2: Heatsink fan operates

Model sizes 3 and 4: Heatsink fans do not operate

ð

5.4 Serial communications parameters

11.23 Serial comms. address

ô

0 ~ 9.9

Enter the required address (group number and unit number) in 11.23. The

address cannot contain 0 (eg. addresses 01, 10, 20, 30 are not permissible).

Each UD78 on a serial communications network must have a unique address.

Up to nine groups can be created, and up to nine units can be assigned to a

group. (See Appendix A Serial communications message formats.)

ð

1.1 group.unit RWUni P

RO Bit P

22

UD78 User Guide

Issue code: 78nu2

Page 27

11.24 Serial comms. mode selector

ô

(See below)

ð

ANSI 4 (1) RWTxt R P

Set 11.24 as follows:

11.24 Mode Special parameter

ANSI 2 (0) 2-wire half-duplex

(transceiver mode)

ANSI 4 (1) 4-wire half-duplex, independent

RX and TX channels

OUtPUt (2) The Drive can control another

Drive

InPUt (3) The Drive can be controlled by

another Drive

11.26 Serial comms. 2-wire mode

delay

11.27 Serial comms. source

selector

11.27 Serial comms. destination

selector

See PL1 Serial communications connector in Chapter 4 Making Connections.

11.25Serial comms. baud rate

ô

4800 (0)

9600 (1)

19200 (2)

ð

4800 baud RWTxt P

Applicable only in ANSI 2 and ANSI 4 modes.

11.26Serial comms. 2-wire mode delay

When 11.24 is set at ANSI 2 for 2-wire (transceiver) operation, it is possible

for the UD78 to reply to an interrogation from the system controller before

the system controller returns from transmit to receive mode. If this occurs,

data will be lost.

Use 11.26 to set sufficient delay before the UD78 replies to an

interrogation.

UD78 User Guide

Issue code: 78nu2

ô

0 ~ 255

ð

0 ms RWUni

23

Page 28

11.27 Serial comms. source/destination selector

ô

0.00 ~ 20.50

ð

0 Menu.

RWUni R P

parameter

Use 11.27 to select the following...

Output mode: Required source parameter

Input mode: Required destination parameter

Output mode

Only a variable parameter can be specified.

If any other type of parameter is specified, no value is transmitted.

Input mode

Only a variable parameter that is not protected can be specified

If any other type of parameter is specified, the input is not assigned to any

parameter.

Both modes

To make the new setting take effect, press

11.28Serial comms. parameter scaling

ô

0 ~ 4.000

ð

1 RWUni

Input and output modes

If required, use 11.28 to scale the value being transmitted or received.

24

UD78 User Guide

Issue code: 78nu2

Page 29

A Serial Communications

ANSI Message Formats

A.1 Fundamentals of data transmission

Data frame

Data is transmitted at a fixed speed or baud rate in the form of a charac ter.

A character comprises seven bits.

In order for a receiver to recognize valid data, a frame is placed around each

character. This frame contains a start bit, a stop bit, and a parity bit.

Without this frame, the receiver will be unable to synchronize itself with the

transmitted data.

The frame used in the ANSI protocol is as follo ws:

Low ASCII character byte

1st hex character 2nd hex character

Start bit 7 data bits Parity bit Stop bit

0LSB MSB 1

This is known as a 10-bit frame, since there are 10 bits tran smitted in total.

The format is described as follows:

1 start bit, 7 data bits, even parity, 1 stop bit.

lsb refers to the least significant bit (ie. bit 0)

msb refers to the most significant bit (bit 6)

The Parity bit is used by the receiver to check the integrity of the data

it has received (even parity is used)

The character set used is called the low

characters decimally numbered from 0 to 127. The first 32 characters in the

ASCII set (hex. 00 to 1F) are used to represent special codes. These ar e the

control codes, each of which has a particular meaning (eg. start of text is

called STX and is ASCII code 02.)

ASCII set. The set comprises 128

UD78 User Guide

Issue code: 78nu2

A-1

Page 30

Control characters

Commands and requests are sent in message pac kets. Each message is

started with a special control character, and may contain additional control

characters. A list of all the control characters that can be used when a

message is being sent or received is as follows:

Character Meaning ASCII code

(decimal)

EOT Reset

Instructs the Drive to prepare for a new message.

Also indicates parameter does not exist.

ENQ Enquiry

Used when interrogating the Drive.

STX Start of text

Used to start a command.

ETX End of text

Used at the end of a command.

ACK Acknowledge (message accepted) 06 Ctrl F

NAK Negative acknowledge (message not understood) 21 Ctrl U

BS Backspace (go to previous parameter) 08 Ctrl H

04 Ctrl D

05 Ctrl E

02 Ctrl B

03 Ctrl C

Addressing

Each Drive on an ANSI communications bus must be given a unique identity

or address so that only the target Drive will respond to a com mand

transmitted by the system controller. The address comprises the following

two parts:

• Group address (first digit)

• Unit address (second digit)

Both the group address and unit address have a range of 1 to 9. A group or

unit address of 0 is not allowed (addresses 01, 10, 20, etc. are invalid). The

reason for this is that Drives can be grouped together (up to 9 units per

group), and a message can be sent over the

units of the group. To address a particular group, the unit address zero (0)

is used. For example, to address all units of group 6, the full address will be

60.

An additional feature is that a message can be sent to all units of all groups

simultaneously using the address 00. This address can be used to send a

Start command to a group of Drives which are mechanically coupled

together to drive a conveyer line. All the Drives will then start

simultaneously.

ANSI communications bus to all

Keyed as...

A-2

UD78 User Guide

Issue code: 78nu2

Page 31

Note

It is important to realize that when using group

addressing, the Drives will not acknowledge the command.

(If several Drives try to reply at the same time, they would

cause meaningless data to appear on the serial

communications bus.)

For security, the format of the transmitted address requires that each digit

of the two-digit address is repeated: the address of Drive number 23 is sent

as four characters, eg:

2 2 3 3

The serial address follows immediately after the first control character of

the message (

Parameter identification

For transmission of their values, all parameters are identified by four digits

representing the menu and the parameter number, but witho ut the decimal

point.

EOT).

Example

To send a message to menu 4, parameter 26, write 0426 (the leading zero

must be included)

To send a message to menu 16, parameter 3, write

Data field

Data to be sent or requested occupies the charac ters immediately after the

parameter number. The minimum len gth of the data field within a message

structure is two characters.

The data is normally expressed as a decimal numeric valu e; the first

character of the data field (

Space (32 dec.)

+

–

Block checksum (BCC)

In order to protect the system against messages that have beco me

corrupted in transmission, all wr ite messages and data respo nses are

terminated by the block checksum character (BCC). See Calculating the

block checksum (BCC) later in this appendix.

1603.

D1) can be only one of the following:

UD78 User Guide

Issue code: 78nu2

A-3

Page 32

A.2 Reading a parameter value

To read the value of a parameter, the following message is sent:

Control Address Parameter Control

EOTGAGAUAUAM1M2P1P2ENQ

Where:

GA = Group Address

UA = Unit Address

M1 M2 = Menu number

P1 P2 = Parameter number

Note

No BCC character is sent in this message.

The Drive will reply with the following structure if the message is

understood:

Control Parameter Data Control BCC

STX M1 M2 P1 P2 D1 ... Dn ETX BCC

Where:

M1 M2 = Menu number

P1 P2 = Parameter number

D1...Dn = Data

First character:

+ or Space for positive values

– for negative values

BCC = Block checksum

If a requested parameter does not exist, the Drive will reply with an

character (ASCII 04).

EOT

Example

Control Address Parameter Control

STX11220121ENQ

To read the value of parameter 1.21 in a Drive that is unit 2 of group 1, send:

The Drive replies as follows:

Control Parameter Data Control BCC

STX 0121–0047.6 ETX 7

UD78 User Guide

A-4

Issue code: 78nu2

Page 33

A.3 Re-reading a parameter value

Once a read message has been received and understood (ie. valid data was

returned), to request the parameter value again, request the value of the

next parameter, or the previous parameter, a single control code character

may be sent. These control codes are as fo llows:

Control code Function Keyed as...

NAK Return the value of the same parameter Ctrl U

ACK Read the next parameter Ctrl F

BS Read the previous parameter Ctrl H

This facility can be used to save time when monitoring a parameter over a

period of time.

A.4 Writing a parameter value

To write a value to a parameter, the message structure is com prised

as follows:

Control Address Control Parameter Data Control BCC

EOT GAGAUAUA STX M1M2P1P2D1 ...Dn ETX

Where:

GA = Group address

GU = Unit address

M1 M2 = Menu number

P1 P2 = Parameter number

D1...DN = Data

First character:

+ or Space for positive values

–– for negative values

BCC = Block checksum

The data field can be of a variable length with the maximum length bein g

dependent on the parameter being edited.

The Drive will respond with a single control character, as follows:

Control code Meaning

ACK Acknowledge — Message has been understood and implemented.

NAK Message invalid

Data is too long or out of range

Parameter is invalid

Parameter is read-only

BCC is incorrect

UD78 User Guide

Issue code: 78nu2

A-5

Page 34

Example

Control Address Control Parameter Data Control BCC

EOT 2 2 6 6 STX 0 1 2 5 + 0 7 6 . 4 ETX %

To set parameter 1.25 at +76.4 for a Drive that is unit 6 of group 2, send:

A.5 Re-writing a parameter value

Once a write message which includes the address field has been sent to a

Drive and accepted with either a <ACK> or <NAK> response, subsequent

write messages to that particular Drive can use a r e-write message struc ture

in which the address does not need to be re-transmitted. The re-write

structure is as follows:

STX M1 M2 P1 P2 D1 ... Dn ETX BCC

When a different Drive is addressed, or an invalid character is received, the

re-write facility no longer functions. The first Drive can be addressed again

only by using the full write message with the address.

A.6 Calculating the block checksum

(BCC)

The block checksum is calculated by applying an exclusive OR function to all

of the characters of a message after the STX control character.

XOR truth table

ABOut

000

011

101

110

A-6

Example

To set parameter 1.25 at –34.5

The first character of the

of which is taken as a starting or result value. The next character is 1

(00110001 in binary), which now has the exclusive OR (XOR) operator act

upon it. With the previous result value, a new result occurs of 00000001 in

binary.

BCC calculation is 0 (00110000 in binary), the value

UD78 User Guide

Issue code: 78nu2

Page 35

The complete calculation is show in the table below:

Character Binary Value XOR result

0 0011 0000

1 0011 0001 0000 0001

2 0011 0010 0011 0011

5 0011 0001 0000 0110

– 0010 1101 0010 1011

3 0011 0011 0001 1000

4 0011 0100 0010 1100

. 0010 1110 0000 0010

5 0011 0101 0011 0111

ETX 0000 0011 0011 0100

The final value is the BCC, provided that its equivalent decimal value exc eeds

31 (ASCII characters from 00 to 31 are used as control codes).

When the final

XOR result produces a decimal value less than 32, 32 is added.

In this example, 0011 0100 is 52 decimal which is above 31, so this is the final

BCC value. 52 decimal is the character 4. The complete message will be as

follows:

Control Address Control Parameter Data Control BCC

EOT 1 1 2 2 STX 0 1 2 5 – 3 4 . 5 ETX 4

Not included in the calculation Included in the calculation Result

Example

QuickBasic program to calculate BCC

UD78 User Guide

Issue code: 78nu2

mess$ = CHR$(4)+”1122”+CHR$(2)+”0125”+”-34.5”+CHR$(3)

bcc% = 0

FOR n% = 7 to LEN(mess$)‘start at the character after ‘chr$(2).

bcc% = bcc% XOR ASC(MID$(mess$, n%, 1))

NEXT

IF bcc% < 32 THEN bcc% = bcc% + 32

mess$ = mess$ + CHR$(bcc%)

PRINT mess$

A-7

Page 36

A-8

UD78 User Guide

Issue code: 78nu2

Page 37

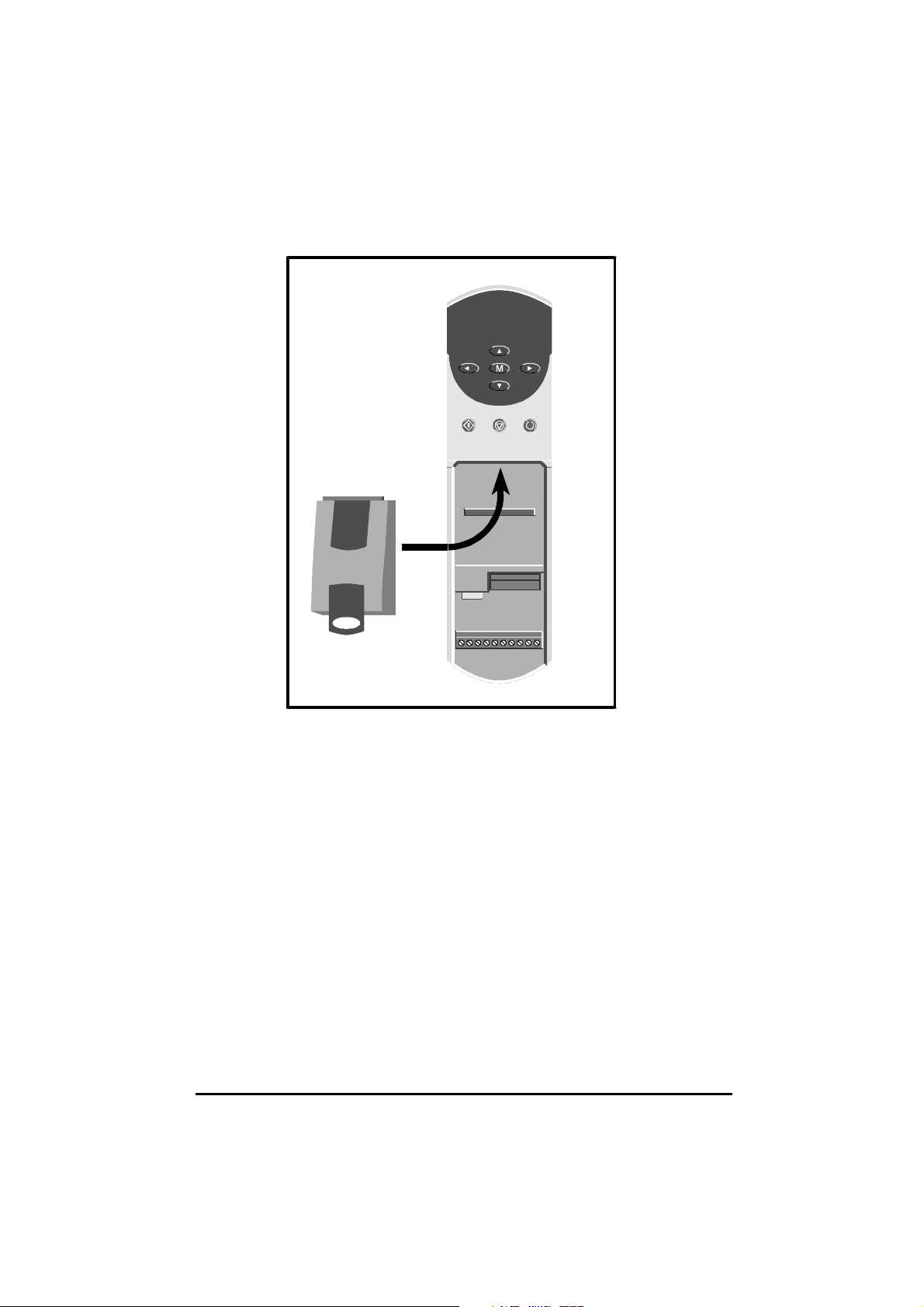

B Setting up the Drive using UniSoft

The UniSoft package is a Windows-based Drive set-up and commissioning

program that is designed to enable complete control and display of all

parameters in a Unidrive. UniSoft provides the user with a graphical

interface that is logically split into a series of screens, offering quick and easy

viewing and, where appropriate, editing of a parameter value. Individual

detailed parameter information can at any time be displayed defining the

parameters function, type and min/max permitted valu e.

Unisoft is available from your local Drive Centre.

PCs have an RS232 serial communications interface. To enable the PC to

communicate with the Drive, either of the follo wing must be used:

• RS232 to RS485 converter.

• A special serial communications cable having the connections

shown below:

PC UD78

Terminal Name Terminal Name

–––– 1 0VSC

50V–––– 6 TX

–––– 7 RX

2RXD–––– 2 TX\

3TXD–––– 3 RX\

Connect terminals 1, 6, 7 of the UD78 together.

Recommended maximum cable length: 3m (10 ft)

Note

UD78 User Guide

Issue code: 78nu2

The special serial communications cable connected as

shown above must be used only for temporary connection

to the Drive. It must not be used for permanent

installations.

B-1

Page 38

B-2

UD78 User Guide

Issue code: 78nu2

Loading...

Loading...