Page 1

User Guide

UD77

DeviceNet

Option Module

For Uni dri ve

Part Number: 0460-0077

Issue Number: 2

Page 2

!

SAFETY INFORMATION

Persons supervising an d performing the electric al installation or maintenanc e of a

Drive and/or an exter nal Option Unit mus t be suitably qualified and c ompetent in

these d uties. T hey should be given t he opport unity to s tudy and i f necess ary to

discuss this User Guide before work is started.

The volt ages pr es ent in the Dr ive an d ext ern al Opt ion U nits are cap able of i nflic ting

a severe electric shock and may be lethal. The Stop function of the Drive does not

remove dangerous voltages from the terminals of the Drive and exter nal Option

Unit. Mains supplies should be removed before a n y se r vicing work is performed.

The inst allation ins tructi ons should b e adhered t o. Any questi ons or doubt s hould

be referred to the supplier of the equipment. It is the responsibility of the owner or

user to ens ure that th e installation of the Drive and external O ption Unit, and the

way in whic h they are op erated and maintain ed complies with the req uirements of

the Healt h an d Saf ety at W ork Act i n the U nit ed Ki ngd om and applicable l egis lati on

and regul ati ons an d c od es of pr act ice in the UK or elsewh ere.

The Drive software may incorporate an optional Auto-start facility. In order to

prevent the risk of injury to personnel working on or near th e motor or its driven

equipm ent and to prevent pot ential dam age to equipm ent, users and oper ators, all

necess ar y precauti ons m us t be tak en if operating t h e Dr i ve in th is m o d e.

The Stop and St art inp ut s of t he Drive should n ot b e r elied upon to ensure safety of

personn el. If a safety haz ard coul d exist from une xpect ed st arting of th e Drive, an

interlock should be in stalled to pre vent the motor be ing inadverte ntly started.

GENERAL INFORMATION

The manufacturer accepts no liability for any consequences resulting from

inappropriate, negligent or incorrect installation or adjustment of the optional

operating parameters of the equipment or from mismatching the Drive with the

motor.

The contents of this User Guide are believed to be correct at the time of printing. In

the interests of a commitment to a policy of continuous development and

improv em en t, the m an ufacturer res erves th e right to chan g e the sp ec if ic ation of th e

product or its performance, or the contents of the User Guide, without notice.

All rights reserved. No part of this User Guide may be reproduced or transmitted in

any form or by any means, electrical or mechanical including photocopying,

recordin g or by any inform ation storage or retri eval syst em, without permissi on in

writing f r om th e pu blisher.

Copyright © January 2001 Control Techniques SSPD

Author Paul Bennett

Issue Code Issue 2

System File V2.07.03 or later

Hardware (UD77) UD77 A Issue 2, UD77 B Issue 4, UD77TB Issu e 01.00

Firmware (UD77) V2.00.00

Page 3

Contents

1 Introduction 7

1.1 DeviceNet Interface for Unidrive 7

1.2 Product Conformance Certification 7

1.3 Overview Specification 7

2 Mechanical Installation 8

2.1 Unidrive 8

3 Electrical Installation 9

3.1 DeviceNet Connectors 9

3.2 DeviceNet Connections 10

3.3 DeviceNet Cable 10

3.4 DeviceNet Cable Screen Connections 10

3.5 DeviceNet Networ k Termi n atio n 11

3.6 Maximum Network Length 12

3.7 External Power Supply 12

4 Getting Started 13

4.1 Basic Communications Quick Start 13

4.2 DeviceNet Node Address 13

4.3 DeviceNet Data Rate 14

4.4 Product Code Elaboration 14

4.5 Data Format 14

4.6 Node Status 15

4.7 Network Status 15

4.8 Network Loss Trip 16

4.9 Initialising Set-up Changes 16

5 Polled Data 17

5.1 What is Polled Data?? 17

5.2 DeviceNet Data Format 17

5.3 Mapping Parameters on Unidrive 18

5.4 Internal 32-Bit Parameters on UD70 18

5.5 Storing Parameters 19

5.5.1 Saving Unidrive Parameters (Menu 1 to 19) 19

5.5.2 Saving UD70 Parameters (Menu 20 and Internal) 19

5.6 Mapping Conflicts 20

5.6.1 Control Word Mappi ng Conf lic ts 20

5.7 Fieldbus Control Word for Unidrive 21

5.8 Fieldbus Status Word for Unidrive 23

5.9 Disabling Cyclic Data Channels 23

6 Explicit Data 24

6.1 Exp licit P a rame ter Ac c ess 24

Page 4

7 Support Files 25

7.1 What are EDS Files? 25

7.2 Generic EDS Files 25

7.3 EDS File Revisions 26

7.4 Advanced EDS Files 26

8 Diagnostics 27

8.1 Fieldbus Code 27

8.2 Firmware Version 27

8.3 System File Version 28

8.4 Node Address 28

8.5 Network Data Rate 28

8.6 Number of Network Messages 28

8.7 Node Status 29

8.8 Network Status 29

8.9 No Data Transfer 29

8.10 Unidrive Trip Codes 30

9 Advanced Features 31

9.1 Network Loss Trip 31

9.2 Unidrive Sequencing Mode 3 32

9.3 Drive Reset Using The Devic eNet Network 33

9.3.1 Reset Without DPL Code 33

9.3.2 Reset Using Explicit Communications 33

9.3.3 Reset Using DPL Code 34

9.4 Non-Cyclic Parameter Store 34

9.5 EVENT Task Trigger on UD70 35

9.6 Multi-Master Networks 35

9.7 Supported Drive Prof iles 35

9.7.1 Basic Speed Control 36

9.7.2 Extended Speed Control 37

9.7.3 Basic Speed and Torque Control 37

9.7.4 Extend ed S p eed and Torque Control 38

9.7.5 Basic Speed Control 38

9.7.6 Basic Speed and Torque Control 39

9.8 Object Model 39

9.9 Iden tity Obje ct 40

9.9.1 Vendor ID 40

9.9.2 Device Type 40

9.9.3 Product Code 40

9.9.4 Revision 41

9.9.5 Status 41

9.9.6 Serial Nu mber 41

9.9.7 Product Name 41

9.10 DeviceNet Object 42

9.10.1 MAC-ID 42

9.10.2 Dat a Rat e 42

9.10.3 Bus Off Interrupt 43

9.10.4 Bus Of f Counter 43

Page 5

Allocati on Byte 43

9.10.5

9.11 Control Supervisor Object 44

9.11.1 RunFwd 44

9.11.2 RunRev 45

9.11.3 NetCtrl 45

9.11.4 RunningFwd 45

9.11.5 RunningRev 45

9.11.6 Ready 46

9.11.7 Faulted 46

9.11.8 FaultRst 46

9.11.9 FaultCode 46

9.11.10 OutputAssembly 47

9.11.11 InputAssembly 47

9.11.12 DriveEnable 48

9.11.13 ZeroParam 48

9.12 AC/DC Drive Object 48

9.12.1 AtReference 49

9.12.2 NetRef 49

9.12.3 DriveMode 49

9.12.4 SpeedActual 49

9.12.5 SpeedRef 50

9.12.6 TorqueActual 50

9.12.7 TorqueRef 50

9.13 Motor Data Object 50

9.13.1 MotorType 51

9.13.2 RatedCurrent 51

9.13.3 RatedVoltage 51

9.14 Control Techniques Object 51

10 Quick R eference 53

10.1 Complete Parameter Reference 53

10.2 DeviceNet Data Format 53

10.3 Fieldbus Control Word 54

10.4 Fieldbus Status Word 55

10.5 Unidrive Trip Codes 56

Page 6

Page 7

1 Introduction

NOTE

Unidrive paramet ers are denoted i n this ma nual by “ #MM .PP”, where

MM refers to the menu number, and PP refers to the parameter

number wi thi n that menu. Plea se ref er to t he Un idri ve Ad vanc ed User

Guide for a ful l list of parameter de f i ni t i o ns.

1.1 DeviceNet Interface for Unidrive

The Unidr ive Devi ceNet int erf ace is suppl ied as an opt ion m odule, wi th

the Devic eN et usi ng a UD 70 as th e host. T h e UD70 d oes n ot los e any

functi onality when the DeviceN et interfac e is fitted. T he fastest d ata

rate curr ent l y sup p or t ed i s 5 00 Kb its/sec.

The Unidrive supplies all power requirements for the Unidrive

DeviceNet interface. A DeviceNet network power supply must also be

connected, but this power supply does NOT keep the UD70 powered up

when the Unidrive is switched off.

1.2 Product Conformance Certification

The Uni dri v e D e viceNet int erface w as sub mi t ted to the O pen DeviceNet

Vendors Association for conformance testing. All tests were successful,

and the Unidrive DeviceNet interface was awarded full DeviceNet

Conformance Certification. Refer to the ODVA Web Site at

“www.odva.org“for further details.

1.3 Overview Specification

• Supported data rates (bits/sec): 500k, 250k, 12 5k

• T hree polled 16 bit input/ou tput words, all can be mapp ed to and

from Unidr i ve para mete rs

• Explicit data allows access to all Unidrive parameters

• 6 DeviceNet Drive Profiles supported

Issue Number: 2 7

Page 8

2 Mechanical Installation

The Unidrive must be disconnected from the mains supply

before installing or removing an option module.

Warning

2.1 Unidrive

1. Sli d e the option modu l e into the Unidri ve.

2. Pus h th e opt ion modul e int o th e Uni dr i ve u ntil it clicks into place.

8 Issue Number: 2

Page 9

3 Electrical Installation

3.1 DeviceNet Connectors

The Unidrive DeviceNet Interface provides a standard 5-way screw

terminal socket (A) to connect to the DeviceNet network. A small

converter board in provided to convert from the 9-way D-type connector

Connectors C and D on th e U nid r i ve D eviceNet int er face are th e RS 23 2

(C) and RS485 (D) ports of the UD70.

12345

AB

D

C

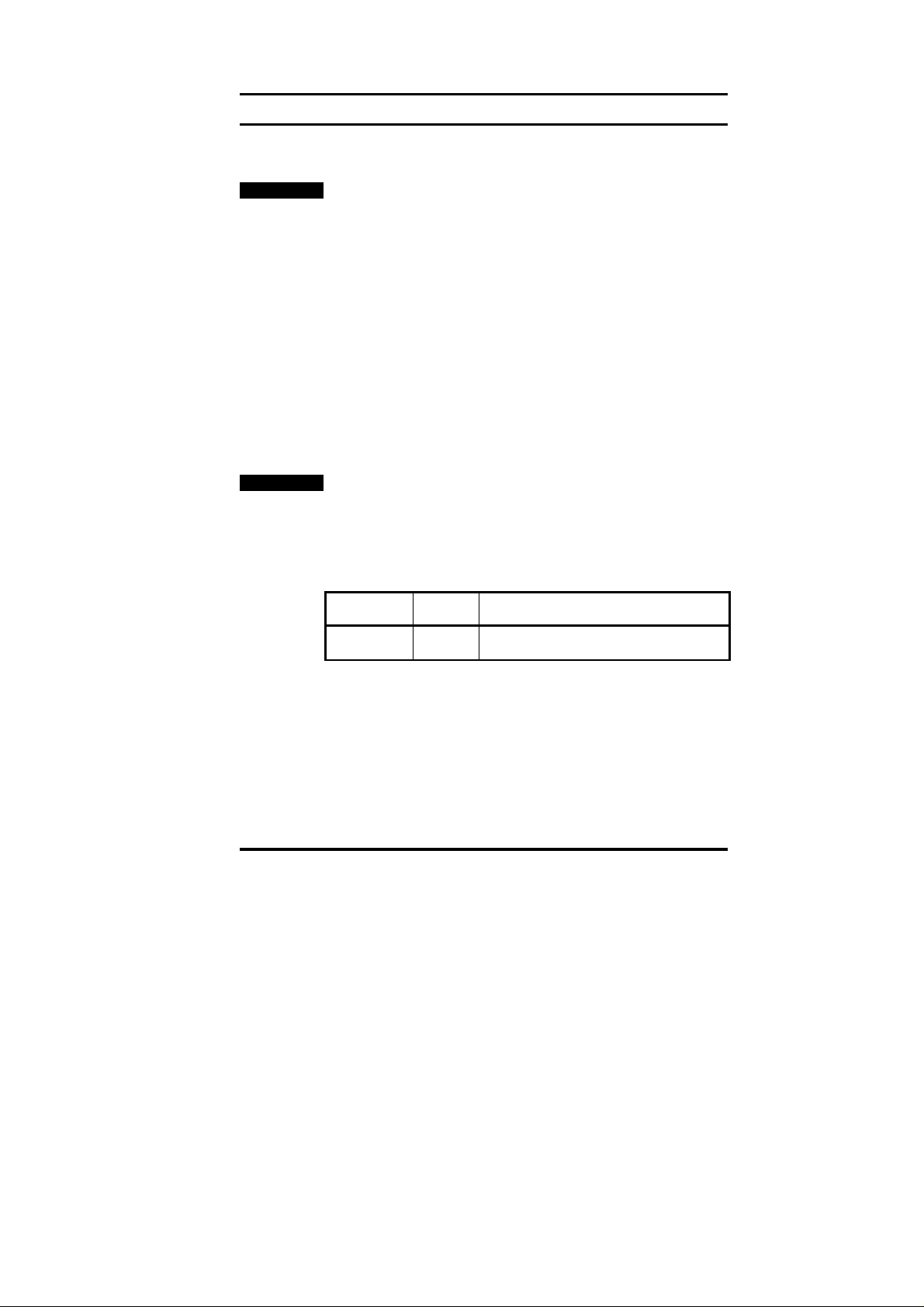

The pin c onnect ions f or th e D evic eN et c onnec tor ar e gi ven in t he t abl e

below. (Pins are numbered 1 to 5 from left to right on the above

diagrams.)

Terminal Signal Function

1 0v 0V Isolated

2 CAN_L Negative data line

3 SHIELD Cable braided shield connection

4 CAN_H Posi t ive data line

5 VDC +24V DeviceNet power supply

Issue Number: 2 9

Page 10

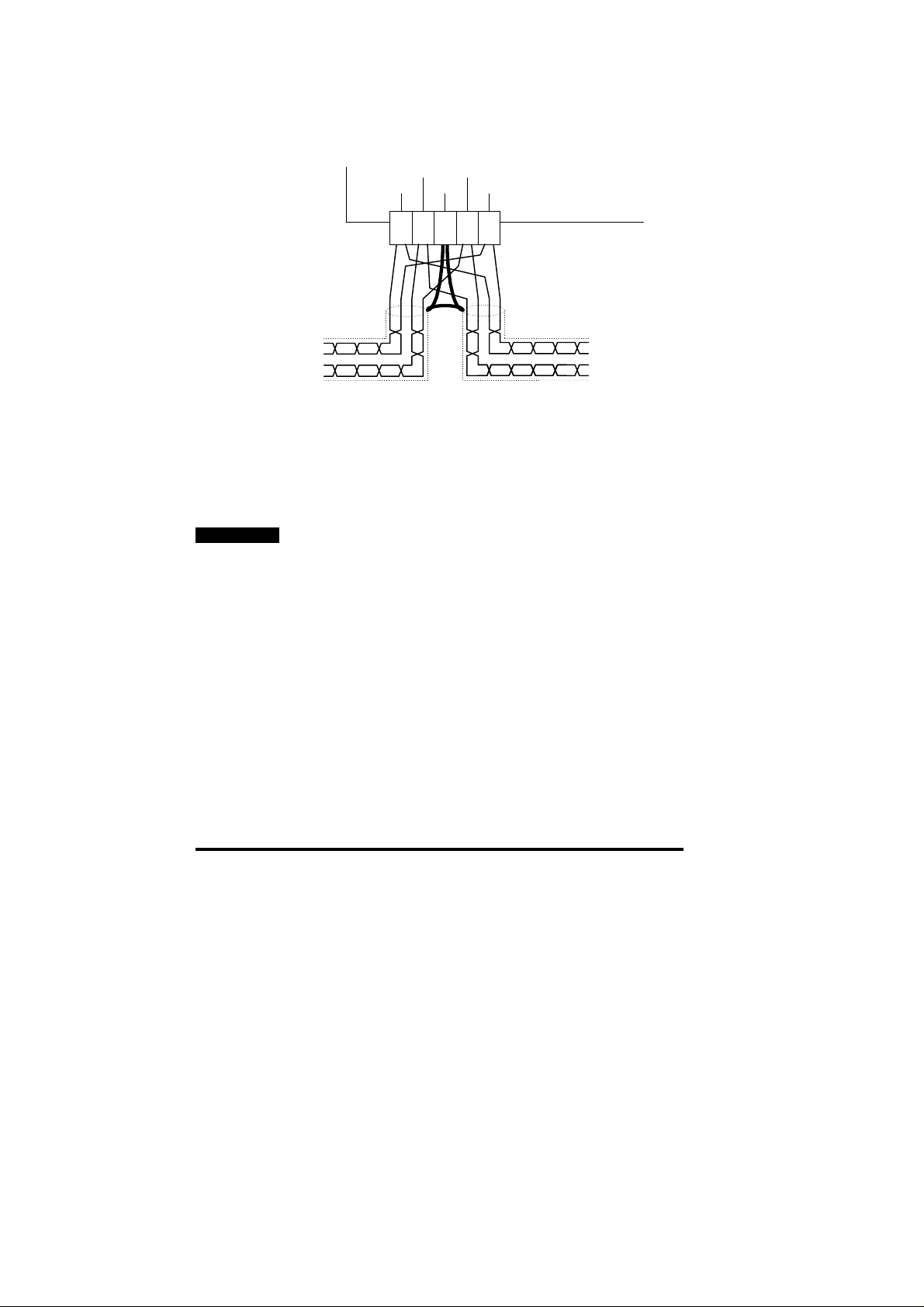

3.2 DeviceNet Connections

To conn ect the Commander SE to the Devic eNet networ k, make th e

connect ions as s hown in t he di agr am b elow. Th e leng th of th e "pi gtail"

shiel d connect ion should be ke pt as shor t as possible.

CAN-L CAN-H

0V +24VShield

1 2 3 4 5

3.3 DeviceNet Cable

Devic eNet n et works (lik e mos t f ieldbus s ystems ) r un at hi gh d ata r at es,

and consequently require cable specifically designed to carry high

frequency signals. Low quality cable may attenuate the signals, and

thus render the signal unreadable for the other nodes on the network.

Details of app roved cables t ypes and their manuf acturers can be found

on the Open DeviceNet Vendors Association web site at

“www.odva.org”.

NOTE

The Open DeviceNet Vendors Association and Control Techniques

can only guarantee correct and reliable operation of a DeviceNet

network if all components (including the network cable) installed have

full Product Conf orm an ce Certi f ic ati on from the OD VA.

0V

+24V

CAN-L

CAN-H

3.4 DeviceNet Cable Screen Connections

The Uni dri ve Devic eN et i nt er f ace shoul d be wired wit h th e cable sh i elds

isolat ed from ear th at each D rive. Th e cable sh ields sh ould be lin ked

together at the point where they emerge from the cable, and formed into

a short p igtail to be c onnected to p in 3 on the D eviceNet conn ector.

(See section 3.2)

10 Issue Number: 2

Page 11

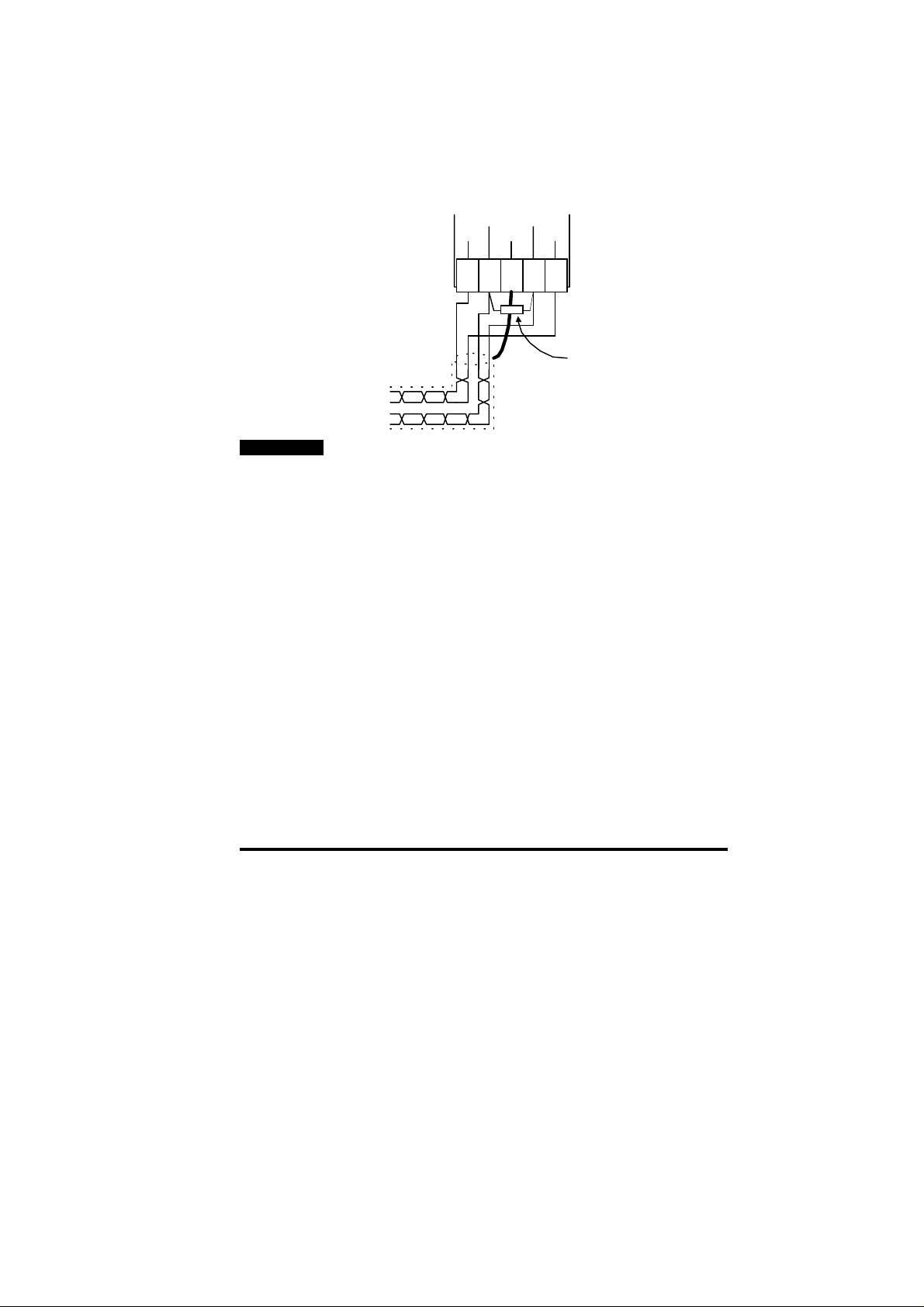

3.5 DeviceNet Network Termination

There is no termination resistor supplied on the Unidrive DeviceNet

interf ace. It is the us er’s res pons ibi lit y to ensu re that both en ds of each

secti on of n etwork c abl e are c or r ect l y t er mi n ated.

A 120Ω 0. 25W resistor shoul d be c onnect ed bet ween the CAN _H an d

CAN_L lines at each end of the main trunk cable, as shown in the

diagram below.

CAN-L CAN-H

0V +24VShield

1 2 3 4 5

Fit 120W 0.25W network

termination resistor between

CAN- L and CAN-H

0V

+24V

CAN-L

CAN-H

NOTE

The above method of connecting the termination resistor ensures that

the network remains terminated when the DeviceNet connector is

disconnected from the node.

It is very important in high-speed communications networks that the

network communications cable is correctly terminated. Failure to

terminate the network properly may mean that the network operates

with substantially reduced noise immunity, or in the worst case, the

network does n’t work at all.

Issue Number: 2 11

Page 12

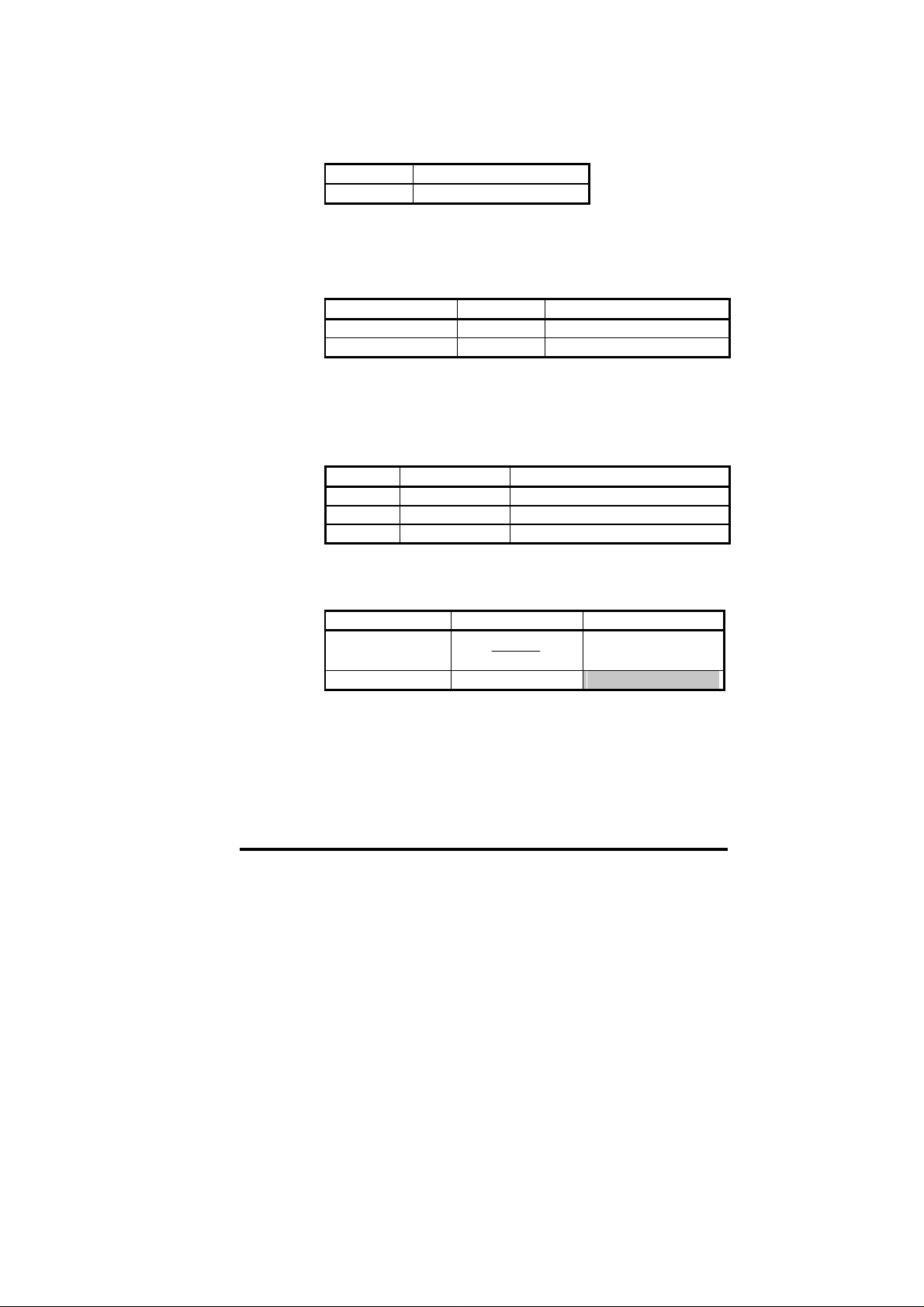

3.6 Maximum Network Length

The data rat e that can be us ed depends m ainly on the leng th of cable

that is b eing used in t he netw ork, so th e physic al layou t of th e network

must be considered during the network design stage of a project.

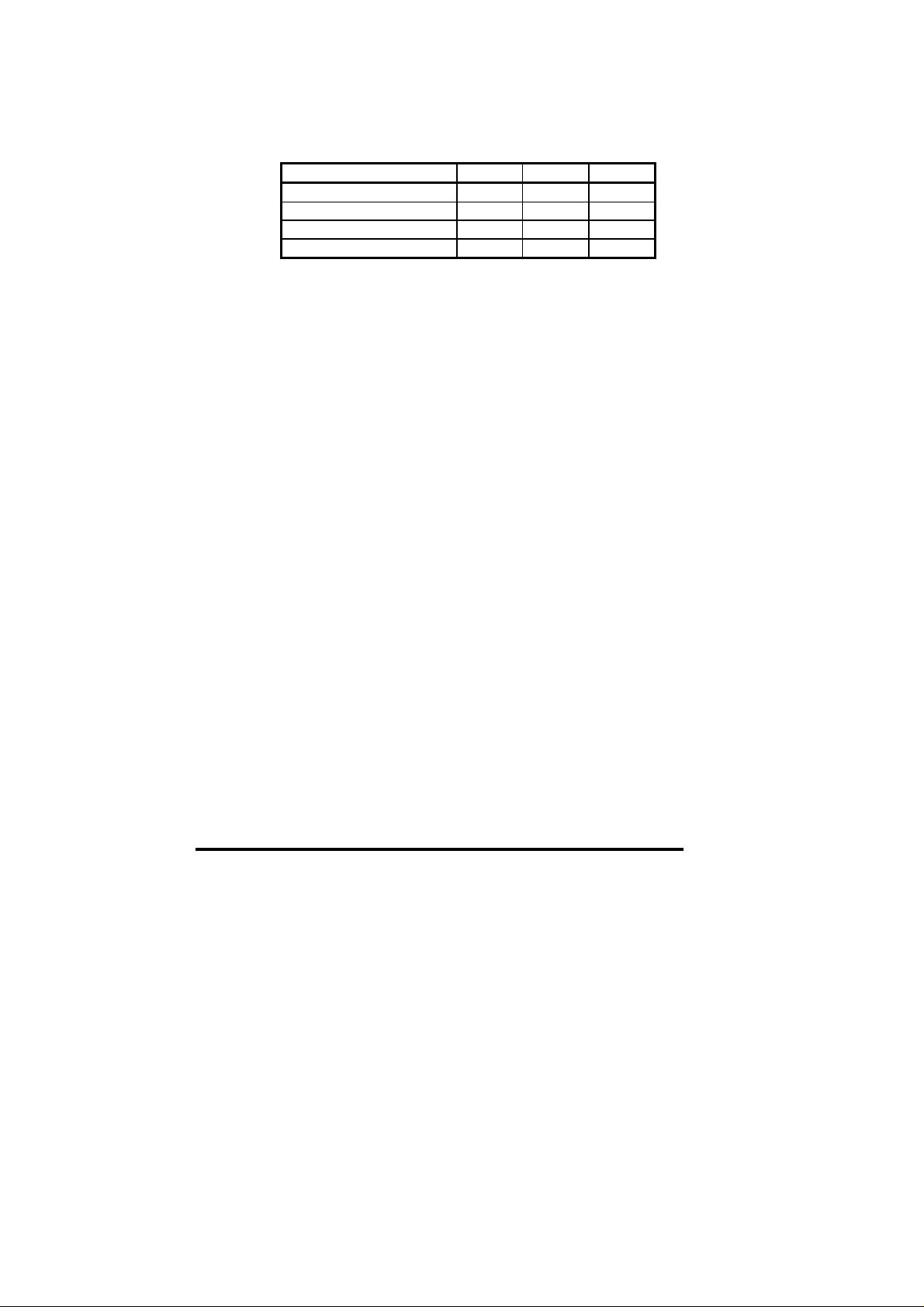

Data Rate (bits/sec) 125K 250K 500K

Max Trunk Distance 500m 250m 100m

Max Drop Length 6m 6m 6m

Cumulative Drop Length 156m 78m 39m

Number of Nodes 64 64 64

Devic eNet n etworks usu ally consist of a main ter minated tr unk cable

length, with a s eries of dr op c able l engt hs ( w ithou t ter min ati on) ru nning

off the main trunk cable.

For a detailed description about the limitations and requirements for

installing a DeviceNet network, refer to Allen Bradley Publication

Number DN-6.7.2. (This docu ment is avai lable fr om the Allen Br adley

web site at “www.ab.com”.)

3.7 External Power Supply

An external isolated +24V power supply is required to power the

transc ei ver ci r c uits in t h e DeviceNet n od es . Th e phys ical location of the

extern al +24V power supply can be very import ant, particul arly if the

networ k has several nodes th at dr aw signific ant power fr om th e su pply.

The Unidr ive DeviceNet int erface is powered b y the Unidrive internal

power supply. However, the external +24V power supply must be

connected to meet ODVA specifications. Each Unidrive DeviceNet

interface draws 5 mA max from the exter n al suppl y.

For detailed instructions on designing the layout of the network and

determining power supply requirements, Allen Bradley Publication

Number DN-6.7.2. (This docu ment is avai lable fr om the Allen Br adley

web site at “www.ab.com”.)

12 Issue Number: 2

Page 13

4 Getting Started

The Quick Start section shows the basic parameter configurations

required for the DeviceNet interfaces to establish communications.

Polled an d Exp lic it data exp lanations ar e gi ven i n chapters 5 and 6.

NOTE

Parameters #20.01 to #20.20 and #20.50 are reserved for configuring

the DeviceNet interface, and should not be used in DPL programs.

4.1 Basic Communications Quick Start

DeviceNet communications can be established with the Unidrive

Devic eNet interf ace simpl y by configur ing the n ode addr ess and data

rate.

• Plug the De viceNet module into the Unidrive.

• Power up the Unidrive.

• S et the MAC-ID (n od e ad dress) in #2 0. 05 as required.

• Set the Data Rate in #20.08 as required.

• Ensure Product Code Elaboration (#20.12) is set to 0.

• Set #17.19 to 1 to store and reset the UD70.

The DeviceNet interface will re-initialise, and configure itself with the

new node add ress and dat a rate.

Function Unidrive Recommended

Node Address #20.05 1 to 62

Data Rate #20.08 0 to 2

Network Loss Tri p #20.11 48

Product Code

Elaboration

#20.12 0

Setting

4.2 DeviceNet Node Address

Unidrive: #20.05

Every node must be given a unique network address. If a node is

assign ed an ad dress , and t hat ad dr ess alr eady e xists on the D evic eN et

network, the node will not join the network. The valid range of

addresses is fr om 1 an d 25 5.

Issue Number: 2 13

Page 14

4.3 DeviceNet Data Rate

Unidrive: #20.08

All nod es on D eviceNet mus t be configured to run at the same data

rate. The range of data rates available is shown in the table below.

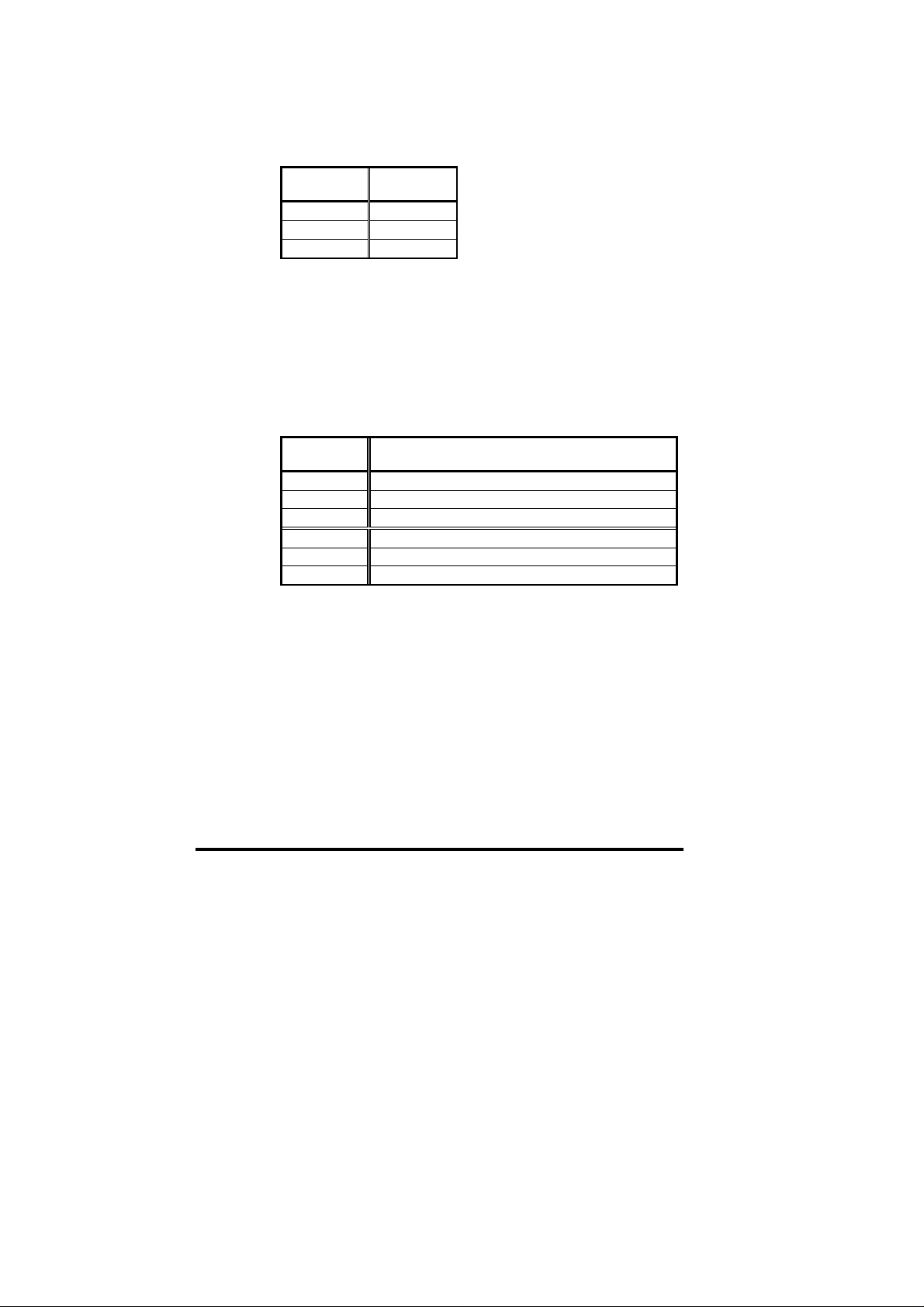

#20.08 Data Rate

0 125K

1 250K

2 500K

(bits/sec)

4.4 Product Code Elaboration

Unidrive: #20.12

Ensure that this parameter is set to 0. For details on using this

parameter, refer to section 7.4.

4.5 Data Format

The Unidr ive D eviceNet interf ace has a d ata form at of 3 Poll ed Wor ds,

as used on M entor II and C ommander S E. Each poll ed data word is

mapped to a U nidrive parameter with default mappings as shown in the

table below.

Cyclic

Channel

IN Word 0 Status word

IN Word 1 Post-ramp speed reference

IN Word 2 Motor active current

OUT Wor d 0 Con t rol wo rd

OUT Word 1 Digital speed reference 1

OUT Wo rd 2 Torq u e reference

Default Mapping Status

14 Issue Number: 2

Page 15

4.6 Node Status

Unidrive: #20.09

When the Un idrive is p owered up, th e Devic eNet interf ace will in itialis e

the inter nal hardwar e, and go into the standb y mode. The n ode will

switch to “Operational” mode when the master controller starts

communicating with the node.

#20.09 Status Description

1 Operational The node is configured, and is

2 Standby mode The node is configured and on-line,

5 No =+24V external

power supply

10 Hardware fault Internal hardwar e err or , the DeviceN et

4.7 Network Status

Unidrive: #20.10

When the Unidrive is powered up, and the DeviceNet interface has

initialis ed, th e node will attem pt to j oin the n etwor k. If an other n ode is

detected with th e sam e MAC-ID , it will not joi n th e netw ork .

#20.10 Status Description

1 Offline The node is offline. Check the wiring,

2 Online, not connected The node is on-line, but has not been

3 Online, connected The node is on-line and connected to

4 Online, connection

time-out

10 Critic al lin k f ail ure Internal hardwar e failure

communicating with a master

controller

but has not been initialised by a

master controller

The external +24V power supply is

not connected. This powe r supply

MUST be connected for the Unidrive

DeviceNet interface to operate

interface could n ot b e ini ti alised

and that there is no node with the

same MAC-ID

initialised by a mast er c ontroller

a master c ontroller

The polled connection is in the timed-

out st ate, or a Bus Off error has

occurred, The node should have

tripped either tr62 )if enabled) of tr60

Issue Number: 2 15

Page 16

4.8 Network Loss Trip

Unidrive: #17.14

If the DeviceNet network stops operating, the interface will trip the

Unidrive on "tr60". The default time delay between network loss and

Unidri ve trip is 48ms , so the act ual delay t o trip will be between 4 8ms

and 96ms . (See sect ion 9.1 for mor e details.) T he master c ontroll er

will autom aticall y det ect that the sl ave node h as gone mis sing fr om the

networ k, and w ill update relevant s t at us r egis ters.

NOTE

Changes to #17.PP parameters in the Unidrive do not take effe ct until

the UD70 h as b e en r es et. See section 4. 9.

4.9 Initialising Set-up Changes

UD70 (#1 7.PP) and D eviceNet ( #20.PP) conf iguration parameters are

only read dur ing t he in iti alis ati on s equenc e of the U D70. T his prev ents

corruption of the configuration while parameters are being edited.

When p arameters h ave been conf igured, the UD 70 must b e reset to

implement any changes made to the configuration parameters.

To reset f rom the UD70, set #M M.00 to 1070 , and press the red RE SET

button on the Unidrive. Any changes made to the DeviceNet

configu ration will n ow t ak e effect.

NOTE

Resetting the UD70 does not store the #20.PP configuration

parameters, so these changes will be lost when the Unidrive is

powered down. See section 5.5.2 for details on how t o store UD70

parameters.

16 Issue Number: 2

Page 17

5 Polled Data

The def aul t DeviceN et c onf ig uration c ontains thr ee 16-bit IN data words

and thr ee 16-bit O UT data words. Th ese data w ords are class ed as

“polled d ata channels ”.

NOTE

“OUT dat a” and “IN data” descr ibe the dir ection of dat a transfer as

seen by the PLC scanner.

5.1 What is Polled Data??

Polled data is a method data transfer that must be set-up during

network configuration, but is transmitted automatically once

configu rati on is c om pl ete. T he hi gh-s pe ed d ata tr ansf er is achie ved by

transmi tting only a 16-bit dat a value for each poll ed chann el over the

Devic eNet netw ork, and relying on loc al mappi ng infor mation w ithin th e

Unidrive to ensure the correct data is sent to the correct locations. This

method relies on the PLC progr am writing and r eading data v alues to

and from the registers allocated to the node during network

configu rati on, an d the sourc e and dest in ation of IN an d OUT data being

set-up correctly in the Unidrive itself.

The flexibility of the Unidrive DeviceNet interface means that each

polled data OUT channel c an be directed to any read-write Unidrive

parameter. Similarly, each polled data IN channel can use any Unidrive

parameter as a source of data.

NOTE

The mapping configuration cannot be changed dynamically, as the

UD70 must be re set bef ore change s to th e ma pping beco me ac tive.

5.2 DeviceNet Data Format

The Unidrive Devic eNet interface has a data format of 3 polled data

words. Explicit data must be used for non-cyclic communications.

Non-cyclic

mode

Explicit 3 This is the same data format as Mentor II,

Issue Number: 2 17

Polled

words

Comments

and Form at 0.03 on Com m an d er SE

Page 18

5.3 Mapping Parameters on Unidrive

The m apping for the cyclic data ch annels on the Unidr ive DeviceNet

interface can be set from the Unidrive keypad using #20.PP

parameters.

The mapping method is similar to the method used for mapping

analogue inputs and outputs. The value entered in the mapping

parameter takes the form MMPP, where MM = menu number of the

target parameter and PP = parameter number of the target parameter.

NOTE

#20.01 to #2 0.20, and #20. 50 are all reserved for Devi ceNet set -up and

configuration, and should not be used in DPL programs.

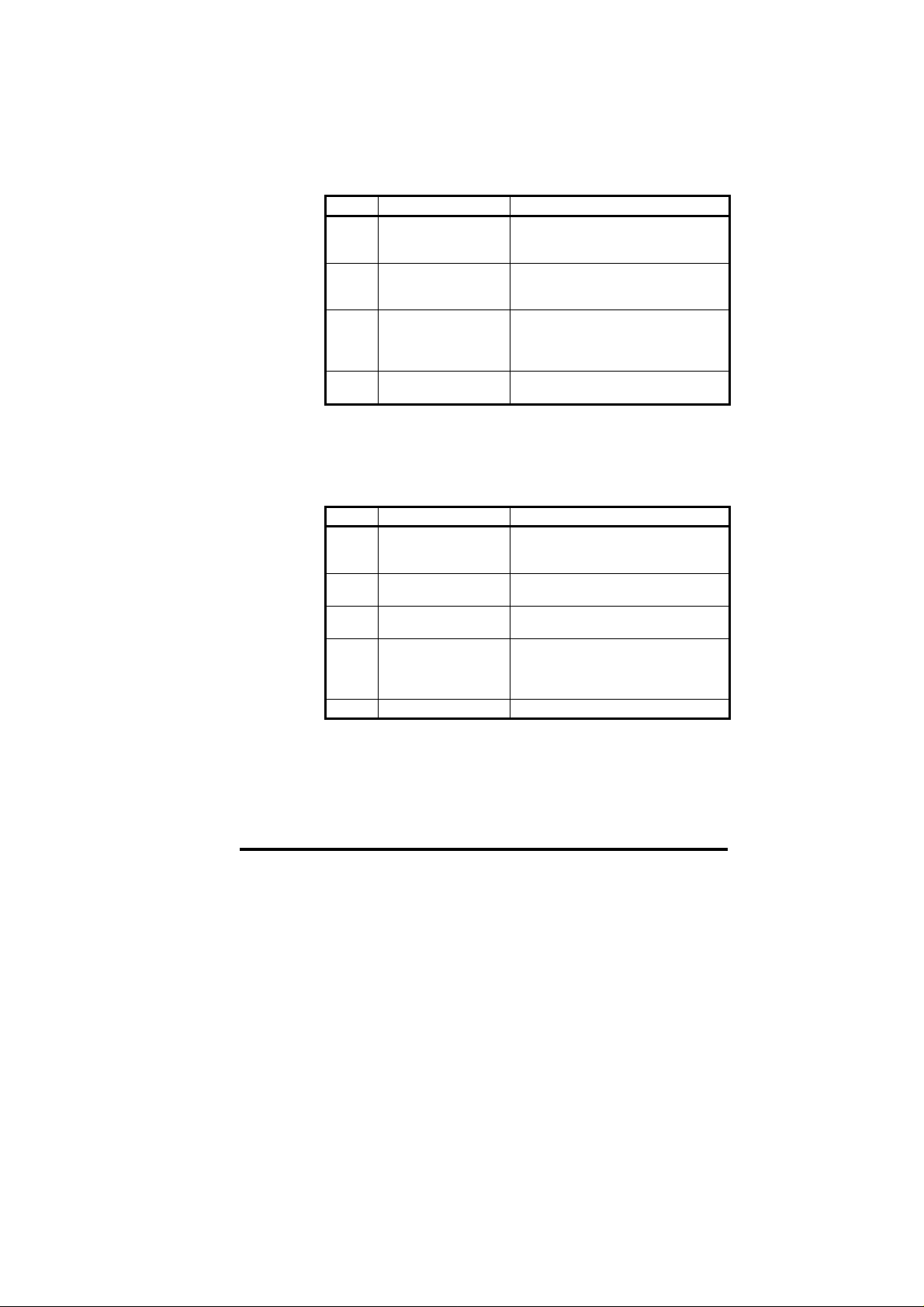

The default mapping values are shown in the table below.

Cyclic

Channel

IN Word 1 #20.07 #90. 11 , field bu s status wo rd

IN Word 2 #20.03 #2.01, post-ramp speed reference

IN Word 3 #20.04 #4.02, torque-producing current

OUT Word 1 #20.06 #90.11, fieldbus control word

OUT Word 2 #20.01 #1.21, digital speed reference 1

OUT Word 3 #20.02 #4.08, torque reference

NOTE

If a mapping parameter is set to an invalid value, e.g. destination

parameter i s read only, or param eter does not exist, th e Unidrive will

reset the mapping parameter (#20.PP) to its default value.

If a cyclic chann el is not req uired, s etting the m apping v alue to -1 will

disabl e it. The data word will sti ll be transmitt ed over the net work, but

the data value will not be written to any Unidrive parameter.

NOTE

The cyclic dat a channel s do not us e decim al point s. For exa mple, th e

digital speed reference 1 (#1.21) has units of Hertz, accurate to 1

decimal p lace. To writ e a val ue of 24. 6Hz to #1.21, t he valu e must b e

transmitted as 246.

Mapping

Parameter

Default Mapping Status

5.4 Internal 32-Bit Parameters on UD70

The Unidr i v e DeviceN et Interf ace has a s et of i nternal 32-bit regis t er s in

the UD70. Th ese are addr ess ed as _Pxx%, _Q xx%, _R xx% or _S xx%

from the DPL program, and the _Qxx% registers are used with the

internal position controller in the UD70.

A 32-bit cyclic channel can be created for IN data, OUT data or both, by

combin in g p oll ed c h annels 1 and 2,or chann els 2 and 3. This allows full

32-bit values to be directly transferred between the UD70 and the

controll ing PC or PLC. (S ee th e “User’s Guid e” for th e UD70 f or mor e

information.)

18 Issue Number: 2

Page 19

The 32- bit cyclic channel is configur ed by mapp ing IN or O UT poll ed

data ch annel 1 (#20 .06 or #20 .07) to a 3 2 bit regist er. Chan nel 2 will

contain the data high word (upper 16 bits of the 32-bit register),

irrespective of the mapping value set for channel 2. If channel 2 is

mapped to a 32-bit r egister, c hannel 2 will contain t he data l ow word

(lower 16 bits of the 32-bit register) and channel 3 will automatically

contain t h e data high word.

The 32-bit r egisters are addr essed as param eters in menu 70 to menu

73. (See table below.) To map a cyclic channel to one of these

regist ers, the param eter refer ence must b e entered in th e appropri ate

mappin g p aram eter.

Registers Parameter

_P00% - _P99% #70.00 to #70.99

_Q00% - _Q 99 % #71.00 to #7 1. 99

_R00% - _R99% #72.00 to #72.99

_S00% - _S99% #73.00 to #73.99

Reference

NOTE

If all polled chan nel s are mapp ed to 32 bit regis ter s, poll ed channe ls 1

and 2 will be c ombin ed to a 32-bit ch annel and w ritt en to or re ad fr om

the mapped p aram eter f or chan nel 1 . (The mappi ng for ch anne l 2 will

be ignored.) C hannel 3 wil l be read f rom or writt en to the l ow 16-bits

of the mapped parameter.

5.5 Storing Parameters

Although any changes to the mapping will take effect after a UD70 reset

sequence, the new values must be stored in non -volatile memory if they

are to be rest or ed au tomatic all y w h en the Interf ac e is ne xt pow ered up.

5.5.1 Saving Unidrive Parameters (Menu 1 to 19)

To initiate the Unidrive parameter save sequence, set #MM.00 to 1000

and press the red RESET but t on on the keypad.

All parameters in these menus are saved in the EEPROM in the

Unidri ve. If t he Unidr ive Devic eNet interf ace is repl aced, th e Unidr ive

will ret ain all val ues in m enu 1 thr ough m enu 19 when t he Unidr ive is

next powered up.

5.5.2 Saving UD70 Parameters (Menu 20 and Internal)

To initiate the non-volatile save sequence for these parameters, set

#17.19 t o 1. The UD 70 will then s tor e menu 20 and the int ernal 3 2-bit

paramet er s , cl ear #17.19 bac k t o zero and compl et ely reset itself .

All menu 20 parameters and internal 32-bit parameters (_Pxx% and

_Qxx%) are stored in the FLASH memory of the UD70. If the Unidrive

Devic eNet int erfac e is repl aced , the m enu 20 p aram eters m ay need to

be re-conf igu red. If the repl acem ent m odul e h as been us ed befo re, the

stored values may be different from the normal default settings.

The UD70 can also be configured to store these parameters

automatically when the Unidrive powers down. The store routine is

Issue Number: 2 19

Page 20

triggered when an under-voltage (UU) trip occurs. Set #17.20 to 1,

store the Unidrive parameters and reset the UD70 to enable this

feature.

5.6 Mapping Conflicts

When the m apping paramet ers for the Devic eNet cyclic c hannels are

set, c are must b e taken t o ensure th at there are no clas hes with the

mapping of the analogue and digital inputs within the Unidrive. The

Unidrive DeviceNet interface will not indicate any conflict of mapping

paramet ers. This only appli es to anal ogue and dig ital inpu ts, and OUT

data on the D eviceNet n etw or k.

If a num erical parameter is written to f rom two different sources, the

value of this parameter will depend entirely upon the scan times for the

analog ue or dig it al inpu t and t he Devic eN et n et work. Fur th er co nfus ion

may be caused due to the update rate of the display. A parameter may

appear to be st eady at a partic ular value, but occasi onally glitc h in the

value will b e s een. In r eal ity, this val ue m ay b e ch angi ng c ontin u ous ly,

leading to erratic behavi our.

Function Mapping

Parameter

Analogue I/P 1 #7.10 L ogic O/P 2 #9.20

Analogue I/P 2 #7.14 Motorised Pot O/P #9.25

Analogue I/P 3 #7.18 Binary Summer #9.33

Digital I/P 1 #8.10 Comparator 1 O/P #12.07

Digital I/P 2 #8.13 Comparator 2 O/P #12.17

Digital I/P 3 #8.16 Reference Input #13.06

Digital I/P 4 #8.19 PID O/P #14.16

Digital I/P 5 #8.21 Cyclic OU T Word 1 #20.06

Digital I/P 6 #8.23 Cyclic OU T Word 2 #20.01

Logic O/P 1 #9.10 Cyclic OUT Word 3 #20.02

Ensure th at eac h Unidri ve param eter in t he tab le abov e has a diff erent

value programmed. A value of 0 will disable analogue and digital

inpu ts, and -1 will disable the cyclic data channels.

5.6.1 Control Word Mapping Conflicts

The control w ord pr ovid es a method of writ in g to multipl e bit param eter s

using one dat a word. If one of the cyclic data channels is writing to the

control w ord, th e followi ng bi t paramet ers for each U nidri ve mus t not be

controll ed by a ny digi tal inpu ts.

Function Param

Enable #6.15 Pr es et ref selec t bit 1 #1.46

Run Forwards #6.30 Applic ation bit #18.31

Jog #6.31 Application bi t #18.3 2

Run Reverse #6.32 Applicati on bit #1 8.33

Preset ref selec t bit 0 #1.45

Function Mapping

Function Param

Parameter

20 Issue Number: 2

Page 21

5.7 Fieldbus Control Word for Unidrive

NOTE

This section assumes that the Unidrive is configured to use the

default Wire Proof PLC sequ encing mode (#6.04 = 4). If PLC mode is

selected (#6.04 = 3), the control word mapping is slightly different.

Refer to section 9.2 for details.

The Con trol W ord is an efficient way of r emot ely contr olli ng the m otion

of a Unidri ve. Each bit in the contr ol word h as a p ar ticular func ti on, an d

provides a method of controlling the function of the Unidrive (RUN,

JOG, etc.) with a single dat a word. The contr ol word is address ed in

the UD70 b y writ in g to #9 0.11.

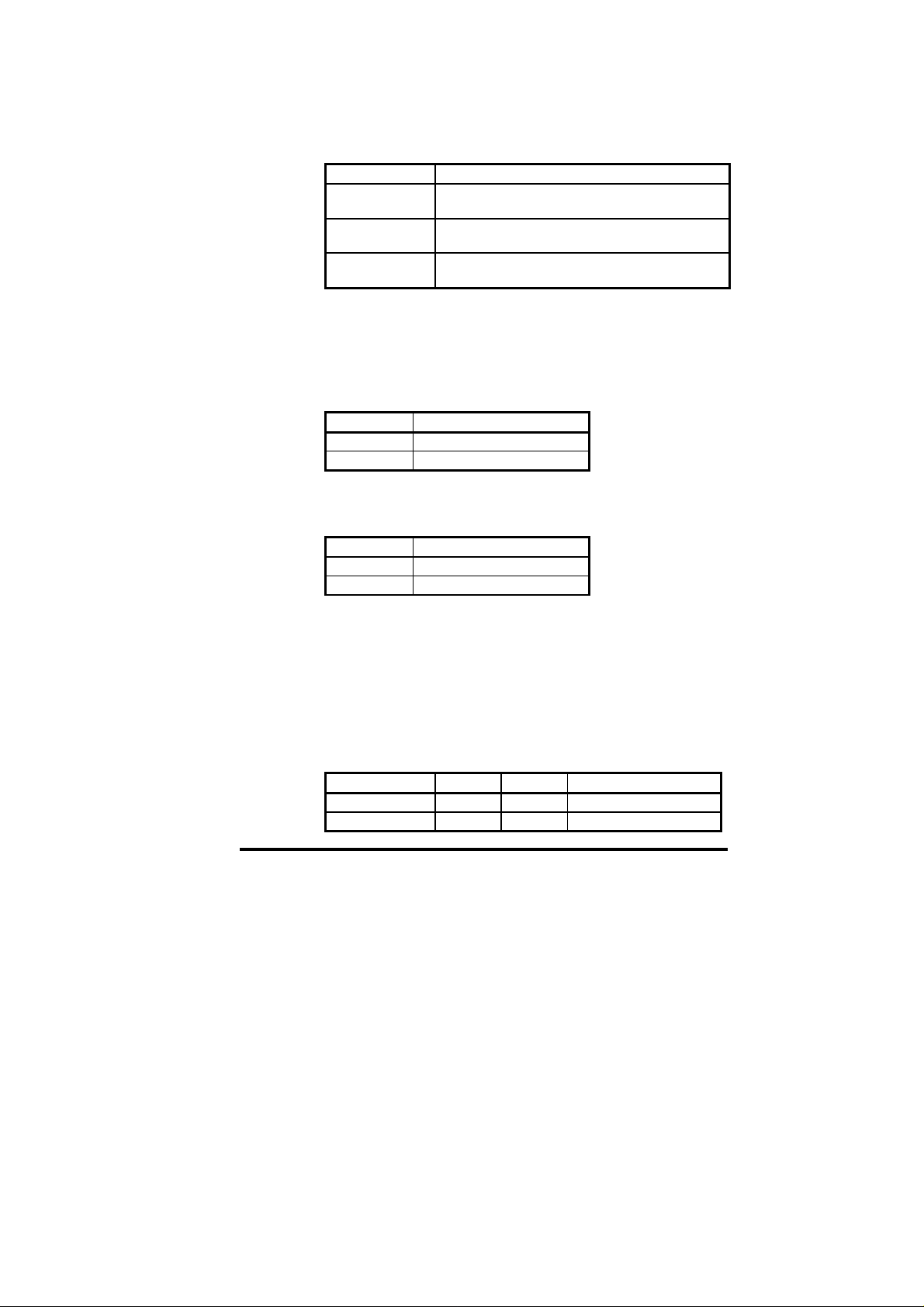

b15 b14 b13 B12 b11 b10 b9 b8

M6 M5 #18.33 M3 M2 M1 M0 #18.32

b7 b6 b5 b4 b3 b2 b1 b0

#18.31 #1.46 #1.45 TRIP RUN

REV

The bits shown as “Mx” are individual mask bits that allow the

corresp on ding "bx” to be masked , i.e. the MASK bits determi ne wh eth er

or not the data bit is written through to the corresponding parameter.

JOG RUN

FWD

ENABLE

#18.33

#18.32

#18.31

Trip

b0b1b2b3b4b5b6b7b8MOM1M2M3b13M5M6

1

0

1

0

1

0

1

0

1

0

1

0

#6.15

#6.30

#6.31

#6.32

#1.46

#1.47

If mask bits M0 and M1 are set to 1, ENABLE and RUN FWD are

updated with the values of b0 and b1 (either 0 or 1) every time the

control word value is received. JOG and RUN REV will not be up d ate d,

even if the val ues of b 2 and b3 chan ge, bec ause th eir mask bits ( M2

and M3) are n ot s et to 1. If M0 and M1 ar e res et t o 0, t he val u es in b0

and b1 will NOT be written to ENABLE and RUN FWD, and these

parameters will remain set to their current state.

Issue Number: 2 21

Page 22

The TRIP bit (b4) will cause a “tr52” trip when set to 1, but the trip

cannot be cleared until the TRIP bit (b4) has been reset to 0.

Paramet ers #18.3 1 to #18.33 are gener al user p arameters and do n ot

have mask bits.

Bit Function Description

0 ENABLE Set to 1 to put the Unidrive in READY mode. (The

1 RUN

FWD

2 JOG Set to 1 with RUN FWD or RUN REV bit also set to

3 RUN

REV

4 TRIP Set to 1 to trip the Unidrive on “tr52”. The TRIP bit

5 #1.45

6 #1.46

7 #18.31 User application bit

8 #18.32 User application bit

9 M0 ENABLE mask bit

10 M1 RUN FWD mask bit

11 M2 JOG mask bit

12 M3 RUN REV mask bit

13 #18.33 User application bit

14 M5

15 M6

Some exam pl e contr ol wor ds for Wir e-Pr oof P LC m ode are gi ven in th e

table below.

b15-b12 b11-b8 b7-b4 b3-b0 Value Action

0000 0010 0000 0000 0x0200 Drive disable

0001 1110 0000 0001 0x1E01 Enabled + stopped

0001 1110 0000 0011 0x1E03 Enabled + r un fwd

0001 1110 0000 1001 0x1E09 Enabled + run rev

0001 1110 0000 1101 0x1E0C Enabled + jog rev

hardware ENABLE must also be present.) The RUN

FWD, JOG and RUN REV bits will have no effect

unless t h e ENABLE bit is set to 1. The Unidriv e

outputs are disabled i mmediatel y wh en th e EN AB L E

bit is reset to 0, and the motor will coast to stop

Set to 1 to run the motor in the forwards direction.

Reset to 0 to dece lerate the moto r to a controlled

stop before the Unidrive output stage is disabled

jog th e mot or i n th e appropriate direction. The

Unidri ve will ramp the m otor to the normal speed or

stop when the JOG bit is reset to 0, depending on the

status of the RUN FWD and RUN REV bits.

Set to 1 to run the motor in the reverse direction.

When res et to 0, the Unid r i ve wil l decelera te the

motor to stop before the outputs are disabled

must be reset to 0 before the Unidrive can be reset.

Preset Reference Select. These bits are used to

sele ct the digital s pee d re ferences used. Refer t o t he

Unidrive User Guide for more information.

Mask bits for the Preset Reference Select bits

22 Issue Number: 2

Page 23

5.8 Fieldbus Status Word for Unidrive

The status word is an efficient way of remotely monitoring and

diagnosing the status of the Unidrive. Each bit in the status word

indic ates the st atus of a f unction of the Un idrive, e.g. At Sp eed, Dri ve

Healthy, etc. The s tatus word is addressed in the UD7 0 by reading

from #90.11.

b15 b14 b13 b12 b11 b10 b9 b8

X #10.15 #10.14 #10.13 #10.12 #10.11 #10.10 #10.09

b7 b6 b5 b4 b3 b2 b1 b0

#10.08 #10.07 #10.06 #10.05 #10.04 #10.03 #10.02 #10.01

The tab l e below sh ows the particular status of t h e Unidriv e indic ated b y

each bit when set to 1.

Bit Parameter Description

0 #10.01 Drive healthy

1 #10.02 Drive running

2 #10.03 Zero speed

3 #10.04 Running at or below min speed

4 #10.05 Below set speed

5 #10.06 At speed

6 #10.07 Above set speed

7 #10.08 Load reached

8 #10.09 In current limit

9 #10.10 Regenerating

10 #10.11 Dynamic brake active

11 #10.12 Dynamic brake alarm

12 #10.13 Direction commanded

13 #10.14 Direction running

14 #10.15 Mains Loss

15 Not used

5.9 Disabling Cyclic Data Channels

Set the appropriate channel mapping parameter to -1, and reset the

Unidrive DeviceNet Interface.

If an application only requires 2 cyclic data channels, the remaining

chann el can b e disab led. This means that t he dat a recei ved fr om th at

channel will not be written to any Unidrive parameter. It does not

actually remove the cha nn el from the Dev iceNet network.

Issue Number: 2 23

Page 24

6 Explicit Data

“Explici t data” is the non -c ycl ic data ch ann el on Devic eNet that provi des

allows access to any parameter within the Unidrive. Non-cyclic data

access to dr ive paramet ers is contr olled entir ely by the PLC progr am,

and is n ot config ured in any way when th e DeviceN et netw ork map is

defined.

The meth od of using n on-cyclic data wil l depend en tirel y on the type of

scanner used to control the DeviceNet network. For this reason,

Control Techniques is unab l e to offer an y s p ecif ic t ech nical sup p ort with

implementing non-cyclic data transfer on any particular DeviceNet

scanner and PLC combination..

6.1 Explicit Parameter Access

The Cont rol Tech niques obj ect (Class 1 00 or 0 x64) pr ovides access to

all Unidrive parameters, using the parameters as shown:

Class Code: 100 (0x64)

Instance: Menu

Attribute: Parameter

All supported pre-defined DeviceNet objects can also be accessed

using exp licit messagi ng. See sections 9.8 to 9.1 4 for full detai ls .

NOTE

Multiple parameter access is not supported by the Unidrive DeviceNet

interface.

Refer to the Scanner documentation for full details about explicit

messagi ng, an d h ow t o i mp lement exp lic i t mess aging usin g th e scann er

and PLC.

24 Issue Number: 2

Page 25

7 Support Files

7.1 What are EDS Files?

EDS (Electronic Data Sheets) files are text files that are used by

DeviceNet network configuration software tools. They contain

information about the device, such as manufacturer, product type,

product code, etc, and they also provide information on the default

settings and f unct ions supp ort ed by t he de vic e. Mapp in g inf ormati o n is

also included that allows access to device parameters over the

DeviceNet network.

EDS files are not downl oad ed to the PLC or sc anner, and ar e only us ed

during network configuration. It is actually possible to configure a

network without the EDS files, but they do help to provide a good

picture of t h e net w or k wi thin the netw or k c onf igurati on sof t w are.

7.2 Generic EDS Files

Generic EDS files are available that support Unidrive fitted with Version

2 and Versi on 3 soft ware, an d conf igur ed in op en loop , clos ed loop an d

servo m ode. Generic EDS files f or Mentor I I and Comm ander SE ar e

also supplied. These files are available from your local Control

Techniques Drive Centre.

These f iles c ontain a b asic c ommon s elect ion of the dr ive paramet ers,

allowing configurat ion of speed or t orque r efer ences, accel eration and

deceleration ramps, motor data set-up, digital and analogue I/O

configuration parameters, and DeviceNet configuration parameters.

Unidrive Open Loop G3_OPEN.EDS G2_OPEN.EDS

Unidrive Clos ed Loop G3_CLSD.EDS G2_CLSD.EDS

Unidri ve S er v o G3_SERVO.E D S G2_SERVO.EDS

Mentor II G410_M4Q.EDS G501_M4Q.EDS

Mentor II G502_M4Q.EDS G504_M4Q.EDS

Mentor II G505_M4Q.EDS

Commander SE G1_CSE .EDS

Drive icon files are also supplied for use with the DeviceNet

configu rati on soft ware bei ng us ed. EDS f iles m ust us ually b e inst alled

into the software package being used to configure a DeviceNet network.

Refer to the software documentation for instructions on how to install

EDS files. Control Techniques cannot provide specific technical

support for any of th ese software packag es .

Issue Number: 2 25

Page 26

7.3 EDS File Revisions

The EDS files from Control Techniques have undergone several

revisi ons as specifications have been ch anged or tigh tened up. The

table b elow sh ows th e compati bility w ith th e most c ommon Devi ceN et

configuration tools.

EDS

Revision

1.x OK Not compatible

2.x OK V2. xx.xx and ear lier

3.x OK V3.xx.xx

DeviceNet

Manager

7.4 Advanced EDS Files

Advanc ed EDS files pro vid e access to the compl et e drive par amet er set

for a specific version of soft war e. This al so incl udes param eters for any

small op ti on m odu le that may b e f it ted to the dr i ve. Advanced E DS files

must be cr eated usin g th e Advanc ed E DS F ile C ompi ler, avai labl e fr om

your local Control Techniques Drive Centre.

To use an adv anced EDS fil e:

1. Sp ecify the Unidr i ve m od e to be used.

2. Sp ecify the type of s mall option m od ule fitted

3. Sp ecify the near est m at c h in g s oftware version

4. Make a note of the “Product Code E labora tion” val ue spe cif ied for

#20.12.

5. Build the EDS file.

6. Install the EDS file into the DeviceNet configuration software.

7. S et #20.12 as s pe cified for t he Unidrive

8. Set #17.19 to 1 to store and reset the UD70. (See section 4.9)

When th e networ k is re-sc anned, th e product c ode of the Un idrive will

have ch ang ed, and th is s hould b e mat ch ed to th e EDS f ile th at has j us t

been created.

RSNetworx

26 Issue Number: 2

Page 27

8 Diagnostics

The inform ati on from t he par amet ers d escrib ed below should always be

noted be fore contactin g Cont rol Tec hnique s for te chnical support.

8.1 Fieldbus Code

Unidrive: #20.14

The fieldbus code identifies the hardware level in the DeviceNet

interface. This information is vital when trying to determine what

upgrad es can be performed on old er mod ul es .

The identif ication of the high-sp eed com munic ations opti on modul e can

be read fr om #20.1 4 on th e Unidri ve displ ay. This nu mber is shown in

the form X Y Z, where X is the fieldbus typ e, Y is the fieldbus flavour, and

Z is the hardware revision level.

Code Fieldbus

Type

500 5

(CAN) 0 (DeviceNet) 0 (UD77A Issue 2 and

NOTE

System f ile V2. 07.03 or later must be instal led in th e UD7 0 to indi cate

the full fieldbus code.

8.2 Firmware Version

Unidrive: #20.15

The vers ion of f irmware fit ted to the D eviceNet interface c an be read

from #20.15. The Hardware Revision column shows the hardware

levels that c an ac cept each vers i on of firmware.

#20.15 Firmware

200 V2.00.00 0

Version

Fieldbus

Flavour

Hardware

Revision

Hardware Revision

UD77B Issue 1)

Issue Number: 2 27

Page 28

8.3 System File Version

Unidrive: #17.02

The system file ins talled in th e UD70 mus t be the correc t file for the

communications option installed. The system file for the Unidrive

DeviceNet interface is “DNET.SYS”.

The system file that must be installed can depend on the level of

hardw are and f irm war e in th e modul e. In g ener al, new s ystem f il es ar e

backwar d compati ble with old er versions of firmware and har dware, but

there may be some limitations when upgrading older modules. (See

sections 8.1 and 8.2.)

The system file version can be read from parameter #17.02 on the

Unidrive.

Firmware Hardware

Revision

V2.00.00 0 V2.07.03

System

File

NOTE

System files can be downlo aded usi ng the WINFLA SHER utilit y, which

can be obtained from you local Drive Centre.

8.4 Node Address

Unidrive: #20.05

Every Devic eN et node must b e assign ed a uniqu e node addr ess . If two

or mor e nodes have the s ame address , this will caus e a c onflict when

the master attempts to initialise the network.

Ideall y, the node addr ess should be conf igur ed on each node BEFO RE

any a ttempt is made to conne ct it to the network.

Comments

8.5 Network Data Rate

Unidrive: #20.08

Every node must be configured to run at the same data rate. To

chang e the dat a rate, set the appr op riat e val ue in #20 .08, and res et t he

DeviceNet interface to make th e change tak e effect.

8.6 Number of Network Messages

Unidrive #20.50

#20.50 is increment ed by 1 each tim e a message is rec eived fr om the

DeviceNet network. This parameter can be used to monitor the network

activit y w ith in a DPL program.

This pr ovides an alter native to us ing the net work connect ion loss trip,

enabled using #20.11. #20.11 trips the drive instantly, but a DPL

program could monitor the state of the network, and bring the drive to a

controll ed s top before tr ip pi ng t h e dri ve.

28 Issue Number: 2

Page 29

8.7 Node Status

Unidrive #20.09

The Node Status is indicated in #20.09.

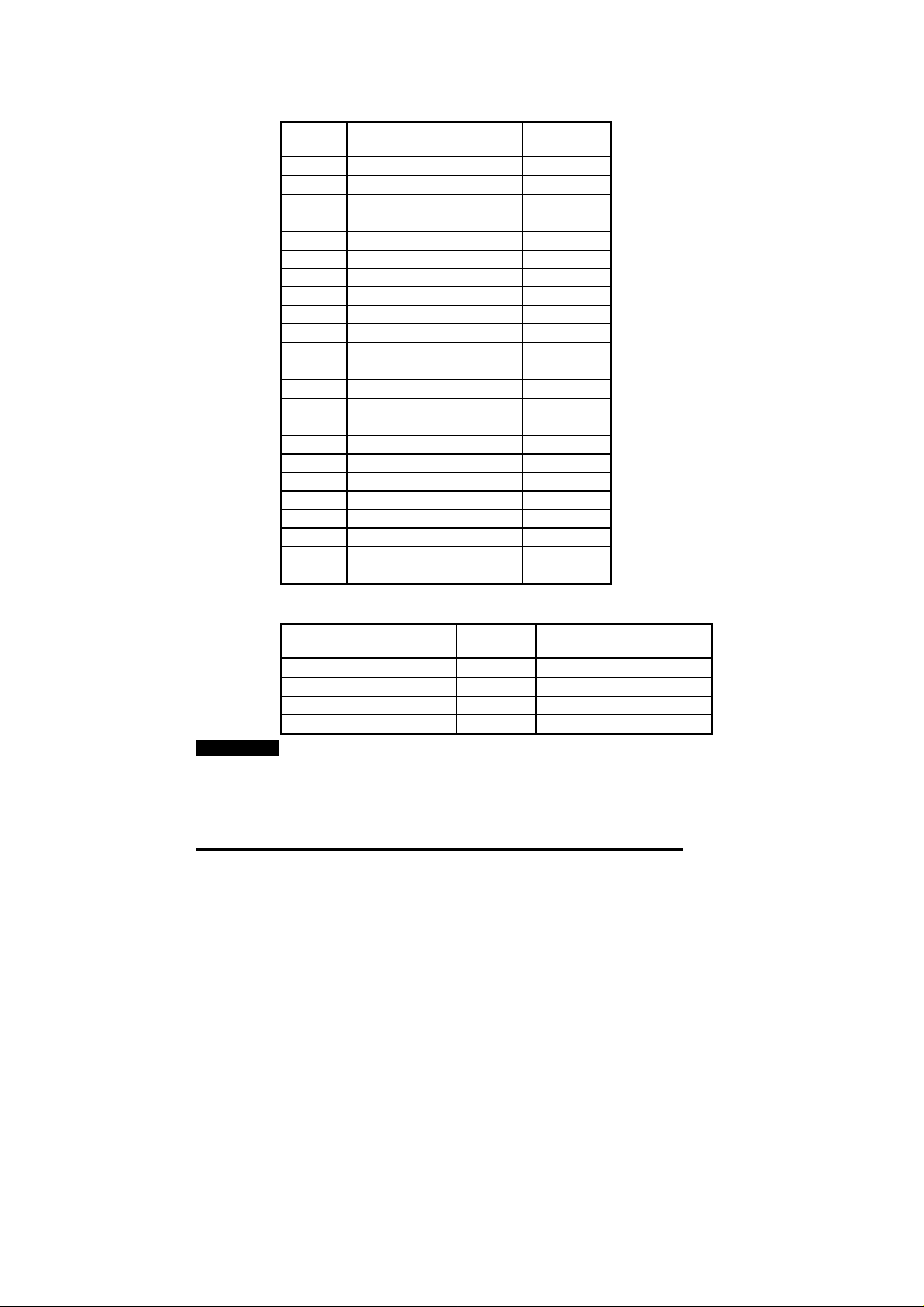

Status Node

Device

Operational

Device In

Standby Mode

No + 24V Power

Supply

Hardware Fault 10 Initialisation routine failed. The device has

Status

1 Device is operating correctly.

2 On Mentor II, the speed feedback scaling

5 D evice is operati ng i n a normal condi tion,

8.8 Network Status

Unidrive #20.10

The Net w or k S tatus is in dicated in #20.10.

Status Network

Not On-line 1 Device not on-line, or not powered up.

On-line, Not

Connected

On-line,

Connected

Connection

Time-out

Critic al Li nk

Failure

Status

2 Device on-line, but no connections have

3 D evice on-line and a connection ha s been

4 One or mor e of the I/O connecti ons are in

10 Fail ed c om mu nication d evice. The devic e

Description

parameter (#3.16) is set 0 . This must be set

to positive value to allow speed feedback to

be scaled correctly.

but no +24 V supply has been detec ted .

an unrec overable f ault .

Description

been est abl is h ed. The device is not

allocated to a master.

establi shed. Device is allocated to a master

the timed-out state, or a Bus Off error has

occurred. No response from the network.

has detected an error that has rendered it

incap abl e of communicating on t h e n et w ork.

8.9 No Data Transfer

If data is not being transferred from the master controller to the

Unidrive, make the fo llowing c hecks:

• T he mapping param eters ha ve been progr ammed corr ectly. If an

invalid m app in g w as entered, it will hav e be en r eset to 0.

• Check that there are no mapping parameter conflicts, i.e. an

analogue input is not trying to control the same parameter as a

cyclic OUT channels.

• OU T dat a has be en enab led in th e Devic eN et sc anner. (R efer to

Scanner documentation.)

Issue Number: 2 29

Page 30

8.10 Unidrive Trip Codes

The trip codes listed below may be caused by the Unidrive DeviceNet

interf ac e. Oth er tri ps may occur if a DP L prog r am is load ed. For a ful l

list of UD70 trips, refer to the UD70 User Guide

Trip

Error

Code

tr52 This code indi cates that the trip or ig in at ed from th e setting o f

bit 4 in the control Word

tr56 The UD70 does not contain the correct operating system for

the detected hardware. Download the system file

“IBSPROFI.SYS”. If the trip persists, ensure that the UD73A

and UD70 b oar ds inside the mod ule are prop erl y cl ip p ed

togeth er . (This s hould only b e attempted b y suit ab ly qualifi ed

personnel!!)

tr57 An illegal operating system call has been made, e.g. WRNET.

CTNet comman ds c annot be used with D eviceNet

tr60 Bus Off. This is a l ow-level CAN trip condit ion, and prev ents

the node from communicating with the network. A manual

reset is required to clear the Bus Off condition

tr62 This tr ip indic at es th at loss of the DeviceNet networ k has been

detected. This can be caused by disconnecting the node form

the network, a bad cable connection, or by resetting or

stoppin g th e network m ast er controll er

See section 9.3 for details on how to reset the Unidrive using the

DeviceNet network.

30 Issue Number: 2

Page 31

9 Advanced Features

9.1 Network Loss Trip

Unidrive: #20.11

0 = trip dis abled 16 to 992 = trip delay t i me (in m s )

The DeviceNet interface counts the number of valid network cycles

received in a time period specified by #20.11. The trip is triggered if no

messag es are recei ved in a given s ample peri od, and mess ages wer e

received in th e previ ous s ample period. T he d efault s ettin g for #2 0.11

is 48ms. T he UD7 0 Gl obal R un-Ti me T rips also ha ve to b e enabl ed by

setting # 17. 14 to 1.

Sample

points

#20.11

NOTE

Messages

per sec

Profibus-DP stops

communicating here

As can be s een fr om the diagr am, th e actual ti me fr om net work los s to

Unidri ve tri p will ran ge fr om #20.1 1 ms to 2 * #20.1 1 ms. If th e trip ti me

is set too low, spurious net w or k loss trips may be seen.

The actual network loss trip time depends entirely on the number of

messages per second being received under normal operation. As a

rough gu i de , t he net work loss trip time (#20 . 11) sho uld be set s uc h that

a minimu m of 5 mess ages will be recei ved in any given sam ple period

under normal operating conditions.

The network loss trip delay is specified in ms, but the time set will be

rounded up to the nearest multiple of 16ms. Hence, if the time delay is

set to 100ms, this will be rounded up to 112ms.

Unidrive trips

on "tr60"

Time

(ms)

Issue Number: 2 31

Page 32

9.2 Unidrive Sequencing Mode 3

The def au lt s equ encing m ode for Unid r i ve is t h e Wire -Proof P LC M o d e.

If PLC Mod e is selected (#6.04 = 3), the seque n c in g bits (#6. 30 - #6. 32)

have slightly different functions.

Control

Word

b0 #6.15 Enable Enable

b1 #6.30 0 Run

b2 #6.31 1 Jog

b3 #6.32 2 Reverse

ENABLE the disp lay will s how "Inh" when set at 0, and dep ends on

JOG the jog bit mus t be set, along with the appr opriate r un and

To reset t he Unidr ive using t he Devic eNet net work, us e the non-c yclic

channel to set #10.38 to 100. The Unidrive will clear #10.38 back to 0

and reset. (See Unidrive manual for more information.)

Some example control word values for the Unidrive are given in the

tables below.

b15–b12 b11-b8 b7-b4 b3–b0 Value Action (PLC mode)

0000 0010 0000 0000 0x0200 Drive disable

0001 1110 0000 0001 0x1E01 Enabled + stopped

0001 1110 0000 0011 0x1E03 Enabled + run fwd

0001 1110 00 00 1011 0 x1E0B Enabled + run rev

0001 1110 0000 1111 0x1E07 Enabled + jog rev

Parameter Sequencing Bit PLC Mode

#6.30 and #6.32 when set to 1. Setting #6.15 to 0 overrides

#6.30 and #6.32, and immediately disables the Unidrive.

The mot or will coast to res t if it is run ni ng w h en th e Unidrive

is disabled.

direction signals.

(#6.04 = 3)

32 Issue Number: 2

Page 33

9.3 Drive Reset Using The DeviceNet Network

The Uni drive c ontrol word d oes not pr ovid e a RESET bit to cl ear a trip

condition in the Unidrive. There are three methods of resetting the

Unidri ve from the mast er c ontroller via the Devic eNet netw or k.

9.3.1 Reset Without DPL Code

To implement a RESET function without using DPL code, one of th e

applic ation bi ts in the c ontr ol word (s ee sect ion 5.7) mus t be used. The

application bits d irectly contr ol #18.31, #18.32 and #18 .33, so one of

these p aramet ers must b e us ed to c ontr ol the RES ET funct ion (#1 0. 33)

of the Unidrive. A 0-1 transition of the application bit will reset the

Unidrive.

Assuming #18.31 is to be used as the RESET bit, one of the

program mable logic f unct ions i n menu 9 c an be us ed to li nk #1 8.31 to

#10.33, and control r esetting of t he Unidriv e. The table bel ow shows

the Unidr ive paramet er settings required. A n alternati ve configur ation

using l ogic funct ion 2 can b e implem ented by us ing the p aramet ers in

brackets instead.

Parameter Value

#9.04 (#9.14) 18.31 #9.08 (#9.18 ) 0

#9.05 (#9.15) 0 #9.09 (#9.19) 0.0

#9.06 (#9.16) 0.00 #9.10 (#9.20) 10.33

By default, #1 0.33 is directly c ontroll ed by digit al input 2. This mus t be

disabl ed by set ting th e mappin g par ameter f or digit al input 2 ( #8.13) to

another value.

If the ter minal reset f unction is r equired in addit ion to a field bus reset

functi on, logic functi on 1 or 2 can b e config ured as an OR func tion of

the fieldbus and terminal reset signals. The parameter settings for

menu 9 t o imp l em ent thi s are shown below.

Parameter Value

#8.13 <> 10.33 #9.07 (#9.17) 1

#9.04 (#9.14) 18.31 #9.08 (#9.18 ) 1

#9.05 (#9.15) 1 #9.09 (#9.19) 0.0

#9.06 (#9.16) 8.02 #9.10 (#9.20) 10.33

NOTE

The Unidr ive may ne ed to be reset several ti mes if mul tiple tr ips have

occurre d. As the reset will only occur on a 0 -1 tr ans i tion of #10.33, the

master controller should toggle the RESET bit until Drive Healthy (bit 0

of the status word) goes to 1.

9.3.2 Reset Using Explicit Communications

The Unidrive can be reset by writing a value of 100 to #10.38 using

Explicit communications. The Unidrive may require several reset

attempts if multipl e trips have occurred. Us e bit 0 of th e status wor d

(Drive Healthy) to check that the Unidrive has been successfully reset.

Parameter Value

Parameter Value

Issue Number: 2 33

Page 34

9.3.3 Reset Using DPL Code

If both of the menu 9 logic functions within the Unidrive are being used,

some DPL c ode c an be us ed t o m onit or th e contr ol w ord, and r es et th e

Unidrive. The code should be placed in the SPEED, ENCODER or

CLOCK task to ensure frequent scanning of the RESET bit.

ENCODER {

reset% = #18.31 ; new state of RESET signal

; check for 0 to 1 transition of RESET bit

IF reset% = 1 AND old_reset% = 0 THEN

; set #10.38 to 100 until Drive Healthy bit is set

DO

#10.38 = 100

LOOP WHILE #10.01 = 0

ENDIF

old_re set% = r es e t% ; store current state of RESET signal

}

If another trip condition occurs while the Unidrive is tripped, the Unidrive

must be r eset twic e befor e all trips are cleared. This is achiev ed by

using the

The DPL pr ogr am wil l also b e reset, and t he IN ITIA L tas k wil l run w hen

the reset sequence ins complete.

NOTE

If a run-time (program) error occurs in the UD70, the DPL program will

stop, and the master controller will not be able to reset th e Unidrive

using the DeviceNet network. In this case, the Unidrive node can only

be reset using non-cyclic data to access #10.38.

DO...WHILE

loop until the Drive Healthy bit (#10.01) is set.

9.4 Non-Cyclic Parameter Store

Unidrive: #17.19

0 = no action 1 = store DeviceNet configuration

Setting #1 7.1 9 to 1 wil l store al l #20. PP par am eters, and all i nter nal 32-

bit _Pxx% and _Qx x% regist ers. The D eviceNet interfac e will als o be

reset, and may c aus e th e De vic eNet m ast er to indic at e a net work er r or.

Any changes made to the configuration via the non-cyclic

communic ations c hannel w ill take eff ect wh en the res et sequenc e has

been completed.

NOTE

The Unidrive DeviceNet interface will take approximately 700ms to

complete the reset sequence, after which the network can be restarted.

34 Issue Number: 2

Page 35

9.5 EVENT Task Trigger on UD70

The EVENT task is a high priorit y task in th e UD70 that c an b e tri gg e red

either by the timer/counter unit, or by the Dev iceNet network.

W h en th e fi eld b u s ne tw ork is sele ct e d as the trig ger sou r ce, the EVENT

task is triggered in every DeviceNet network cycle.

#17.23 EVENT Task

Trigger Source

0 Timer/Count er Refer to UD70 Manual for more inf orm at i on.

1 DeviceNet T he EVENT task is tr igg ered every tim e

Care must be taken not to put too much code in the EVENT task. It has

a higher pri ority th an all oth er UD70 tasks except th e INITIAL t ask, so

an extended EVENT task could easily prevent t he SPEED task from

running, and cause the UD70 to trip on “tr54”.

Comments

polled d at a arri v es f rom th e DeviceNet

network, and is passed to the UD70.

NOTE

This feature is only available with system file V2.07.06 or later.

9.6 Multi-Master Networks

DeviceNet networks can operate with more than one master device

connect ed to the s ame lines. C ommand er SE, Unidri ve and Ment or II

DeviceNet interfaces can all operate on multi-master networks, but

each device can only be assigned to one of the master devices.

Consult the supplier of your master controller for more details about

implementing mult i-master DeviceNet n etw or ks .

9.7 Supported Drive Profiles

Class: 41 (0x29) Instance: 1 (0x1) Attribute: 100(0x64)

Class: 41 (0x29) Instance: 1 (0x1) Attribute: 101(0x65)

The input (attribut e 10 1) and output (attri bute 100) assembly obj ec ts ar e

set in the Control Supervisor. The default assembly objects are the

Control T echniques I nput (106) and O utput (107) objects, which allow

each data word to be mapped using #20.PP parameters. Refer to

section 5 for more details.

Th e D e vi c eNet sp ec i f i c at i o n i nc l u des a s er i es of s et prof i l es f or dif fer e n t

devices, including Drives, and the Unidrive DeviceNet interface

supports sever al of thes e pre-d efined as semb ly objec ts. The f ormat of

the DeviceNet pre-defined as sembl y obj ects is f i xed.

Issue Number: 2 35

Page 36

There are 3 ways to select a pre-defined Input or Output assembly

object:

1. Use the PLC Explicit communications to write directly to the

Control Supervisor. (See page 43 in DeviceNet User Guide Issue

1.) The relevant attributes are 100 (Output) and 101 (Input).

2. Use the Class Instance Editor within RSNetworx to modify the

Control Supervisor directly yourself. Refer to page 43 to che ck the

support ed s ervices for Unidri ve DeviceN et i nt erface.

3. Double-click on a node to go on-line to it, and look under the group

"DeviceNet Config". In this group, you will find the attributes

"Polled Input Ass embly" and "Polled Output Assembly". Update

with th e ap pr opr i ate value.

NOTE

The parameter mappi ng of the pre-def ined Devi ceNet objects CAN NOT

be changed .

9.7.1 Basic Speed Control

Output Assembly Object 20

The sc anner must be confi gured f or 4 Tx b ytes (or 2 T x words) if this

output assembly object is selected.

Word Function

Word 0 Basic Control Word (See section 9.11)

Word 1 Speed Reference (See section 9.11.13)

The Bas ic Control W ord uses a full 16-bit word , with the bi ts having

functi ons as sh own bel ow. R ef er t o sect ion 9. 11 f or m appin g det ai ls of

each f unc tion.

b15 b14 b13 B12 b11 B10 b9 b8

b7 b6 b5 b4 b3 B2 b1 b0

FaultRst RunFwd

36 Issue Number: 2

Page 37

9.7.2 Extended Speed Control

Output Assembly Object 21

The sc anner must be confi gured f or 4 Tx b ytes (or 2 T x words) if this

output assembly object is selected.

Word Function

Word 0 Extended Control Word (See section 9.11)

Word 1 Speed Reference (See section 9.11.13)

The Ext ended Control Word uses a ful l 16-bit word, wi th the bi ts h av ing

functi ons as sh own bel ow. R ef er t o sect ion 9. 11 f or m appin g det ai ls of

each f unc tion.

b15 b14 b13 B12 b11 b10 b9 b8

b7 b6 b5 B4 b3 b2 b1 b0

NetRef NetCtrl FaultRst RunRev RunFwd

9.7.3 Basic Speed and Torque Control

Output Assembly Object 22

The sc anner must be confi gured f or 6 Tx b ytes (or 3 T x words) if this

output assembly object is selected.

Word Function

Word 0 Basic Control Word (See section 9.11)

Word 1 Speed Reference (See section 9.11.13)

Word 2 Torque Reference (See section 9.11.13)

The Bas ic Control W ord uses a full 16-bit word , with the bi ts having

functi ons as sh own bel ow. R ef er t o sect ion 9. 11 f or m appin g det ai ls of

each f unc tion.

b15 b14 b13 b12 b11 b10 b9 b8

b7 b6 b5 b4 b3 b2 b1 b0

FaultRst RunFwd

Issue Number: 2 37

Page 38

9.7.4 Extended Speed and Torque Control

Output Assembly Object 23

The sc anner must be confi gured f or 6 Tx b ytes (or 3 T x words) if this

output assembly object is selected.

Word Function

Word 0 Basic Control Word (See section 9.11)

Word 1 Speed Reference (See section 9.11.13)

Word 2 Torque Reference (See section 9.11.13)

The Ext ended Control Word uses a ful l 16-bit word, wi th the bi ts h av ing

functi ons as sh own bel ow. R ef er t o sect ion 9. 11 f or m appin g det ai ls of

each f unc tion.

b15 b14 b13 B12 b11 b10 b9 b8

b7 b6 b5 b4 b3 b2 b1 b0

NetRef NetCtrl FaultRst RunRev RunFwd

9.7.5 Basic Speed Control

Input Assemb ly Ob ject 70

The sc anner must be c onfigur ed for 4 Rx byt es (or 2 Rx wor ds) if this

input assembly obj ect is selected.

Word Function

Word 0 Basic Status Word (See below)

Word 1 SpeedActual (See section 9.12.4)

The Basic Status Word uses a full 16-bit word, with the bits having

functi ons as sh own bel ow. R ef er t o sect ion 9. 11 f or m appin g det ai ls of

each f unc tion.

b15 b14 b13 B12 b11 b10 b9 b8

b7 b6 b5 b4 b3 b2 b1 b0

Running

Fwd

Faulted

38 Issue Number: 2

Page 39

9.7.6 Basic Speed and Torque Control

Input Assemb ly Ob ject 72

The sc anner must be c onfigur ed for 6 Rx byt es (or 3 Rx wor ds) if this

input assembly obj ect is selected.

Word Function

Word 0 Basic Status Word (See below)

Word 1 SpeedActual (See section 9.12.4)

Word 2 TorqueActual (See section 9.12.6)

The Ext ended Control Word uses a ful l 16-bit word, wi th the bi ts h av ing

functi ons as sh own bel ow. R ef er t o sect ion 9. 11 f or m appin g det ai ls of

each f unc tion.

b15 b14 b13 B12 b11 b10 b9 b8

b7 b6 b5 b4 b3 b2 b1 b0

Running

9.8 Object Model

The Object Model used to represent an AC or DC Drive has the

following object classes present.

Object Class Class Code Effect on behaviour

Identity 1 0x01 Supports the device reset service

Messag e R outer 2 0x02 Internally routes messages

DeviceNet 3 0x03 Configures device attributes

Assembly 4 0x04 Defines I/O data format, i.e.

Connect ion 5 0x05 Logical ports in t o or out of the d rive

Parameter Group 16 0x10 Pr ovid es an int er face to the AC/ DC

Motor Data 40 0x28 Defines the motor data

Control

Supervisor

AC/DC Drive 42 0x2A Provides drive configuration

Control

Techniques

41 0x29 Manages drive functions,

100 0x64 P r ovides an interface to all dri ve

Fwd

Faulted

parameter mapping

Drive, Motor Data and Control

Superv isor Objects

operational states and control

parameters

Issue Number: 2 39

Page 40

9.9 Identity Object

Class: 1 (0x1)

The identit y object pr ovid es devic e identific ati on informat ion, al ong with

general d evice inf orm ation. All attributes are inst ance 1.

Attribute Access Name Data Type

1 Get Vendor ID Word

2 Get Device Type Word

3 Get Product Code Word

4 Get Revision Word

5 Get Status Word

6 Get Serial Number Double Word

7 Get Product Name Short String

The following services are supported:

Service Code Class Instance Service Name

05 (0x05) No Yes R es et

16 (0x10) No Yes S et_Att r ibute_Single

14 (0x0E) Yes Yes Get_Attribute_Single

9.9.1 Vendor ID

Class: 1 (0x1) Instance: 1 (0x1) Attribute: 1 (0x1)

The Vendor ID is a unique code assigned to each manufacturer of

DeviceNet-compatible equipment by the Open DeviceNetVendors

Association. The code for Control Techniques is 257.

Action Value Comment

Read 257 257 is the Vendor ID code assigned to

9.9.2 Device Type

Class: 1 (0x1) Instance: 1 (0x1) Attribute: 2 (0x2)

The Device Type c ode indicates t o which product group the Unidr ive

DeviceNet belongs.

Action Value Comment

Read 2 2 is the “AC Drives“ group of devices

9.9.3 Product Code

Class: 1 (0x1) Instance: 1 (0x1) Attribute: 4 (0x4)

The produc t code for Unidr ive depends on th e mode of the drive. A

paramet er for product cod e elabor ati on is also provi ded to all ow the us e

of advanced EDS fil es if required .

Action Value

Read

()

Control Techniques

[]

#20.121#11.31*32 ++

40 Issue Number: 2

Page 41

9.9.4 Revision

Class: 1 (0x1) Instance: 1 (0x1) Attribute: 4 (0x4)

The revis ion cod e is the com bination of th e major and minor r evision

codes, where th e major r evision cod e is the l ow byte, and th e minor

revision code is the high byte.

Action Major Revision Minor Revision

Read

9.9.5 Status

Class: 1 (0x1) Instance: 1 (0x1) Attribute: 5 (0x5)

This attribute represents the current status of the entire device. Its value

changes as the state of the device changes.

b15 b14 b13 b12 b11 b10 b9 b8

Major

b7 b6 b5 b4 B3 b2 b1 b0

Configured Owned

R - Rec overable fault

U - Unrecoverable fault

9.9.6 Serial Number

Class: 1 (0x1) Instance: 1 (0x1) Attribute: 6 (0x6)

All Control Techniques DeviceNet interfaces have a unique serial

number stored in the non-volat i l e mem ory.

9.9.7 Product Name

Class: 1 (0x1) Instance: 1 (0x1) Attribute: 7 (0x7)

The Unidrive D eviceNet interface will r et ur n th e s tr i n g “ UD 7 7” when this

attribute is read.

#11.29

100

fault (U)

#11.29 M od 10 0

Major

fault (R)

Minor

fault (U)

Minor

fault (R)

Issue Number: 2 41

Page 42

9.10 DeviceNet Object

Class: 3 (0x3)

The DeviceNet Object provides the configuration and status of the

Unidri ve DeviceNet interf ac e. All att ributes are ins tance 1.

Attribute Access Name Data Type

1 Get/Set MAC-ID Byte

2 Get/Set Baud Rate Byte

3 Get/Set Bus Off Interrupt Byte

4 Get/Set Bus Off Counter Byte

5 Get Allocation Byte Byte

The following services are supported:

Service Code Class Instance Service Name

16 (0x10) No Yes Set _Attribut e_S in gle

14 (0x0E) Yes Yes Get _A tt r ib ute_Sin gl e

75 (0x4B) No Yes Alloc ate M aster/S l ave

76 (0x4C) No Yes Releas e Mas t er /S l av e

9.10.1 MAC-ID

Class: 3 (0x3) Instance: 1 (0x1) Attribute: 1 (0x1)

Specifies the MAC-ID to be used by the node. Valid range is from 0 to

63. If this value is ch anged, the n ode will assum e the new MAC-ID

immediately.

NOTE

It is not recommended to change the MAC-ID via DeviceNet. The MACID should be configure d using par ameter # 20.05 BEFOR E the n ode is

connected to the network.

9.10.2 Data Rate

Class: 3 (0x3) Instance: 1 (0x1) Attribute: 2 (0x2)

Specifies the data rate to be used by the node. If this value is changed,

the node will not be able to communicate with the scanner until the

scanne r’s data rate has bee n changed.

Value Data Rate (bits/sec)

0 125K

1 250K

2 500K

NOTE

It is not r ec omme nd ed to chan ge t he net w ork data r ate via Devi ce Net.

The data rate shoul d be configured using p arameter #20.08 B EFORE

the node is con n e cte d to th e netw ork.

42 Issue Number: 2

Page 43

9.10.3 Bus Off Interrupt

Class: 3 (0x3) Instance: 1 (0x1) Attribute: 3 (0x3)

Bus Off Interrupt (BOI) determines the action if the Bus Off state is

encountered. The following values are supported (default value = 0)

Value Action

0 CAN chip is not reset. Manual reset of the device is

required.

1 Device atte mpts to reset itself. After 10 attempts, an error

is raised, and a manu al res et is r equired.

9.10.4 Bus Off Counter

Class: 3 (0x3) Instance: 1 (0x1) Attribute: 4 (0x4)

The Bus Of f counter coun ts the numb er of times th e CAN chip went to

the “bus off” state. T he coun ter has val ues of 0 t o 255 deci mal. The

“bus off” counter is res et to zero whenever set regardless of the data

value wr itt en. T he Bus –off Counter is i niti alis ed t o zero at pow er–up or

device initialisation.

The transmission of a Set_Attribute_Single request to the Bus–off

Counter is all that’s required to reset the counter.

9.10.5 Allocation Byte

Class: 3 (0x3) Instance: 1 (0x1) Attribute: 5 (0x5)

b7 b6 b5 b4 b3 B2 b1 b0

Ack

Suppress

Any bit s et to 1 indicates that a requ est is being m ade to alloc ate th at

particular connection.

Polled Explicit

Message

Issue Number: 2 43

Page 44

9.11 Control Supervisor Object

Class: 41 (0x29)

Manag es drive functi ons such as st art/stop an d operation al states. All

attributes are instance 1. For each attribute, the READ and WRITE

mappin gs are s h ow n i n t h e t ab le. These are the actio n s that ta ke place

when each at t ri bute is accessed.

Attribute Access Name Data Type

Get/Set

3

4

5

7 Get RunningFwd Byte

8 Get RunningRev Byte

9 Get Ready Byte

10 Get Faulted Byte

12 Set FaultRst Byte

13 Get FaultCode Word

100

101

102

103

The following services are supported:

Service Code Class Instance Service Name

16 (0x10) N o Yes Set_At tribute_Single

14 (0x0E) Yes Yes Get_Attribute_Single

9.11.1 RunFwd

Class: 41 (0x29) Instance: 1 (0x1) Attribute: 3 (0x3)

Set to 1 to start the drive, and run forwards. Wire-proof PLC

sequencing mod e (#6.04 = 4) must be selec t ed on t h e Unid r i ve.

Action Mapping

Read #6.30

Write (0) #90.11 = 0x1C00

Write (1) #90.11 = 0x1C02

Get/Set

Get/Set

Get/Set

Get/Set

Get/Set

Get/Set

RunFwd Byte

RunRev Byte

NetCtrl Byte

OutputAssembly Byte

InputAssembly Byte

DriveEnable Byte

ZeroParam Byte

44 Issue Number: 2

Page 45

9.11.2 RunRev

Class: 41 (0x29) Instance: 1 (0x1) Attribute: 4 (0x4)

Set to 1 to start the drive, and run in reverse. Wire-proof PLC

sequencing mod e (#6.04 = 4) must be selec t ed on t h e Unidrive.

Action Mapping

Read #6.32

Write (0) #90.11 = 0x1C00

Write (1) #90.11 = 0x1C08

9.11.3 NetCtrl

Class: 41 (0x29) Instance: 1 (0x1) Attribute: 5 (0x5)

This attribute writes t o #18.31 in the Unid rive. If the c ontrol word is

being written to using a polled data connection, this parameter will be

over-wr it t en b y bit 7 in the c ontrol word.

Action Mapping

Read #18.31

Write (0) #18.31 = 0

Write (1) #18.31 = 1

NOTE

The user must implement DPL code in the UD70 to select between

local terminal control and network control. This attribute simply

writes t he NetCtrl attr ibute to #18.31.

9.11.4 RunningFwd

Class: 41 (0x29) Instance: 1 (0x1) Attribute: 7 (0x7)

Read only attribute that indicates that the motor is running forwards

when set to 1.

Action Mapping

Read (#90.11 & 0x2002) == 0x2000

9.11.5 RunningRev

Class: 41 (0x29) Instance: 1 (0x1) Attribute: 8 (0x8)

Read onl y attribut e that indic ates that th e motor is running in r everse

when set to 1.

Action Mapping

Read (#90.11 & 0x2002)==0x2002

Issue Number: 2 45

Page 46

9.11.6 Ready

Class: 41 (0x29) Instance: 1 (0x1) Attribute: 9 (0x9)

Read onl y at tribu t e that in dic at es th at th e dri ve is enabl ed an d r ead y t o

run.

Action Mapping

Read #6.15

9.11.7 Faulted

Class: 41 (0x29) Instance: 1 (0x1) Attribute: 10 (0xA)

Read only att r ibute that ind i cates that t h e drive tripped when s et to 1.

Action Mapping

Read !#10.01

NOTE

This is the opposite polarity to #10.01 on the Unidrive.

9.11.8 FaultRst

Class: 41 (0x29) Instance: 1 (0x1) Attribute: 12 (0xC)

Set to 1 to reset a drive from a tripped condition. Note that with

Unidrive, this will cause a complete reset of the DeviceNet interface.

Action Mapping

Write (0) No action

Write (1) #10.38 = 100

9.11.9 FaultCode

Class: 41 (0x29) Instance: 1 (0x1) Attribute: 13 (0xD)

Returns a fault code number, indicating the reason why the drive

tripped. Ref er to the Unidr ive or M entor II User’s Guid es for a full lis t of

fault codes.

Action Mapping

Read #10.20

Under n ormal oper atin g c onditi ons, t he Uni dri ve an d Ment or II will b e in

the “Drive Healthy” condition, indicating that the drives are operating

with no pr oblems. This condit ion is indicate d by a value of 1 in #10.0 1

on Unidrive.

If a dri ve tri ps for any r eason, the drive h ealt hy bit is r eset to 0, an d a

diagnostic code is provide d to indicate the reason for the trip. Thi s code

is available from #10.20 in the Uni dri ve.

46 Issue Number: 2

Page 47

The table below indicates which trip codes from the drive have predefined DeviceNet fault codes.

Unidrive T r ip

Display

OI.AC 3 0x2300

OI.br 4 0x7112

PS 5 0x5100

ENC.OVL 10 0x7305

Oh1 21 0x4300

OA 23 0x4110

OP.OVLd 26 0x5112

Ph 32 0x3120

If the dr ive trip c ode is not on the above list, t he c ode r eturned will b e

0x1000 + Unidrive trip code.

9.11.10 OutputAssembly

Class: 41 (0x29) Instance: 1 (0x1) Attribute: 100 (0x64)

The out put ass emb ly s elec ted d eter mi nes t he f orm at of th e dat a th at is

transf erred f rom th e sc anner t o the drive. Four pre-d efin ed Devic eN et

output assemblies are supported, and a Control Techniques output

assembl y is als o pr ov i ded . ( See sec t ion 9.7)

Value Description

20 Basic Speed Control

21 Extended Speed Control

22 Basic Speed and Torque Control

23 E xtended Speed and Torque Contr ol

107 User Defined Control Techniques Object

9.11.11 InputAssembly

Class: 41 (0x29) Instance: 1 (0x1) Attribute: 101 (0x65)

Th e in put ass em bl y s ele ct ed d ete rm in es t he f or mat of th e da ta t ha t is

transferred fr om the driv e to the P LC. Two pre- d efined DeviceNet in put

assemblies are supported. (See section 9.7)

Value Description

70 Basic Speed Control

72 Basic Speed and Torque Control

106 User Defined Control Techniques Object

Unidrive T r ip

Code

ODVA Fault

Code

Issue Number: 2 47

Page 48

9.11.12 DriveEnable

Class: 41 (0x29) Instance: 1 (0x1) Attribute: 102 (0x66)

Control the software enable of the Unidrive. Both the software and

hardware enable must be set before the Unidrive can run.

Action Mapping

Read #6.15

Write (0) #6.15 = 0

Write (1) #6.15 = 1

9.11.13 ZeroParam

Class: 41 (0x29) Instance: 1 (0x1) Attribute: 102 (0x66)

Provides access t o the #0. 00 in the Unidrive. Thi s allows fu n c t io n s that

use this parameter, suc h as Unidrive Parameter S tore, Unidrive Mode

Change, UD70 Reset, etc, to be controlled via the DeviceNet network.

Action Mapping

Read #0.00

Write #0.00

9.12 AC/DC Drive Object

Class: 42 (0x2A)

Models the drive specific functions, e.g. ramp times, torque control.

The pre- defined attrib utes list ed in th e tabl e below ar e supp orted. All

attributes are instance 1.

Attribute Access Name Data Type

3 Get AtReference Byte

4 Get/Set NetRef Byte

6 Get/Set DriveMode Byte

7 Get SpeedActual Word

8 Get/Set SpeedRef Word

11 Get TorqueActual Word

12 Get/Set TorqueRef (6) Word

The following services are supported:

Service Code Class Instance Service Name

16 (0x10) No Yes S et_Att r ibute_Single

14 (0x0E) Yes Yes Get_Attribute_Single

48 Issue Number: 2

Page 49

9.12.1 AtReference

Class: 42 (0x2A) Instance: 1 (0x1) Attribute: 3 (0x3)

When s et to 1, this attribute indic ates that th e motor is runn ing at the

demand ed s peed.

Action Mapping

Read #10.06

9.12.2 NetRef

Class: 42 (0x2A) Instance: 1 (0x1) Attribute: 4 (0x4)

This attrib ute selects the sourc e of the sp eed referenc e for th e drive.

The sourc e can only be changed when the Unidrive is configured in

speed control mode.

Action Mapping Comment