Page 1

User Guide

UD55UD55

Cloning interface

small option module

for Unidrive

and

Commander GP

Part Number: 0460 - 0095

Issue Number: 3

Page 2

General Information

The manufacturer accepts no liability for any consequences resulting from

inappropriate, negligent or incorrect installation or adjustment of the

operating parameters of the equipment or from mismatching the Drive

with the motor.

The contents of this Guide are believed to be correct at the time of

printing. In the interests of a commitment to a policy of continuous

development and improvement, the manufacturer reserves the right to

change the specification of the product or its performance, or the

contents of this Guide, without notice.

All rights reserved. No part of this Guide may be reproduced or

transmitted in any form or by any means, electrical or mechanical including

photocopying, recording or by any information storage or retrieval system,

without permission in writing from the publisher.

Use within the European Union, etc

The following information applies where the end use of the Drive is within

the European Union, the European Economic Area, or other regions which

have implemented Directives of the European Council or equivalent

measures.

The Drive complies with the Low Voltage Directive 73/23/EEC.

The installer is responsible for ensuring that the equipment into which the

Drive is incorporated complies with all relevant Directives.

The complete equipment must comply with the EMC Directive 89/336/EEC.

If the Drive is incorporated into a machine, the manufacturer is responsible

for ensuring that the machine complies with the Machinery Directive

89/392/EEC. In particular, the electrical equipment should generally

comply with European Harmonised standard EN60204-1.

Important...

Drive software version

This product is supplied with the latest version of user-interface and

machine-control software. If this product is to be used with other Control

Techniques variable speed drives in an existing system, there may be some

differences between their software and the software in this product.

These differences will cause a difference in functions. This may also apply

to variable speed drives returned from a Control Techniques Service

Centre.

If there is any doubt, contact a Control Techniques Drive Centre.

Copyright © January 2002 Control Techniques Drives Ltd

Issue Code: 55nu3

Page 3

Chapter

Contents

1 Introduction 1

1.1 Main features of the UD55 1

2 Safety Information 2

2.1 Warnings, Cautions and Notes 2

2.2 Electrical safety – general warning 2

2.3 System design 2

2.4 Environmental limits 3

2.5 Compliance with regulations 3

2.6 Safety of personnel 3

2.7 Risk analysis 4

2.8 Signal connections 4

2.9 Adjusting parameters 4

3 Inserting the UD55 in a Drive 5

4 Making Connections 7

4.1 Locations of the terminals 7

4.2 Functions of the terminals 7

5 Saving Parameters 8

6 Loading Parameters 10

6.1 Loading a Parameter-set from the UD55 10

6.2 Transferring parameter-sets between Drives

6.3 Using the UD55 with other small option modules 12

6.4 Avoiding prob le ms with inter-re late d p ara mete rs 12

7 Erasing the entire flash memory

8 Related parameters 14

Appendix

A Diagnostics A-1

UD55 User Guide

Issue code: 55nu3

of different ratings 11

of the UD55 13

Page 4

UD55 User Guide

Issue code: 55nu3

Page 5

1 Introduction

1.1 Main features of the UD55

Note

The UD55 can be used only with Drives equipped with

version 3 (or later) software. (Parameter 0.50 indicates

the software version.)

All references to the Advanced Menus in this User Guide

are not applicable when using the UD55 with the

Commander GP Drive.

Parametersets

Operating

modes

Installation

The UD55 Cloning small option module can store up to eight parameter-sets

which contain all the read–write parameters for a Drive, and include those

in Menus 16 and 20, when applicable. These parameter-sets can be

individually recalled for loading into the same or another Drive.

Cloning of Drives can be performed only when the operating mode

(Open-loop, Closed-loop Vector, Servo or Regen) of the destination Drive

is the same as that of the source Drive.

The UD55 must be fitted in the small option module bay of the Unidrive. All

connections to the Drive are made by a multi-way connector. Connections

from external equipment are made to a plug-in 16-way screw-terminal block

on the UD55.

UD55 User Guide

Issue code: 55nu3

1

Page 6

2 Safety Information

2.1

Warnings, Cautions and Notes

A Warning contains information which is essential for avoiding a safety

hazard.

A Caution contains information which is necessary for avoiding a risk of

damage to the product or other equipment.

A Note contains information which helps to ensure correct operation of the

product.

2.2 Electrical safety – general warning

The voltages used in the Drive can cause severe electric sho ck and/or burns,

and could be lethal. Extreme care is necessary at all times when working

with or adjacent to the Drive.

Specific warnings are given at the relevant places in this User Guide.

The installation must comply with all relevant safety legislation in the

country of use.

The Drive contains capacitors that remain charged to a poten tially lethal

voltage after the

energized, the AC supply must be isolated at least ten minutes before work

may continue.

AC supply has been disconnected. If the Drive has been

2.3 System design

The Drive is intended as a component for professional incorporation into

complete equipment or systems. If installed in correctly the Dr ive may

present a safety hazard. The Drive uses high voltages and currents, carries

a high level of stored electrical energy, and is used to control m echanical

equipment which can cause injury.

Close attention is required to the electrical installation and the systemdesign to avoid hazards either in normal operation or in the event of

equipment malfunction. System-design, installation, commissioning and

maintenance must be carried out by personnel who have the necessary

training and experience. They must read this safety information and this

User Guide carefully.

To ensure mechanical safety, ad ditional safety devic es such as

electro-mechanical interlocks m ay be required. The Dr ive must not be u sed

in a safety-critical application without additional high-integrity protection

against hazards arising from a malfunction.

2

UD55 User Guide

Issue code: 55nu3

Page 7

2.4 Environmental limits

Instructions in the Unidrive Installation Guide regarding transport, storage,

installation and use of Drives must be complied with, including the specified

environmental limits. Drives must no t be subjected to exc essive physical

force.

2.5 Compliance with regulations

The installer is responsible for complying with all relevant regulations, such

as national wiring regulations, accident prevention regulations and

electromagnetic compatibility (EMC) regulations. Particular attention must

be given to the cross-sectional areas of conductors, the selection of fuses or

other protection, and protective earth (ground) connections.

The Installation Guide for the Drive contains instructions for achieving

compliance with specific EMC standards.

Within the European Union, all machinery in which this product is used must

comply with the following directives:

89/392/EEC: Safety of Machinery

89/336/EEC: Electromagnetic Compatibility.

2.6 Safety of personnel

The STOP function of the Drive does not remove dangerous voltages from

the output of the Drive or from any external option unit.

The Stop and Start controls or electrical inpu ts of the Drive m ust not be

relied upon to ensure safety of personnel. If a safety hazard could exist

from unexpected starting of the Drive, an interlo ck that electric ally isolates

the Drive from the

inadvertently started.

Careful consideration must be given to the functions of the Drive which

might result in a hazard, either through their intended functions

(eg. Auto-start) or through incorrect operation due to a fault or trip

(eg. stop/start, forward/reverse, maximum speed).

Under certain conditions, the Drive can suddenly discontinue control of the

motor. If the load on the motor cou ld cause the moto r speed to be

increased (eg. hoists and cranes), a separate method of braking and stopping

the motor must be used (eg. a mechanical brake).

Before connecting the

understand the operating controls and their operation. If in doubt, do not

adjust the Drive. Damage may occur, or lives put at risk. Carefully follow

the instructions in this User Guide.

Before making adjustments to the Drive, ensure all personnel in the area are

warned. Make notes of all adjustments that are made.

AC supply must be installed to prevent the motor being

AC supply to the Drive, it is important that you

UD55 User Guide

Issue code: 55nu3

3

Page 8

2.7 Risk analysis

In any application where a malfunction of the Drive could lead to damage,

loss of life or injury, a risk analysis must be carried out, and where necessary,

further measures taken to reduce the risk. This would normally be an

appropriate form of independent safety back-up system using simple

electro-mechanical components.

2.8 Signal connections

The control circuits are isolated from the po wer circuits in the Drive by basic

insulation only, as specified in IEC664–1. The installer must ensure that the

external control circuits are insulated from human contact by at least one

layer of insulation rated for use at the AC supply voltage.

If the control circuits are to be connected to other circuits classified as

Safety Extra Low Voltage (SELV) (eg. to a personal computer), an additional

isolating barrier must be included in order to maintain the SELV

classification.

2.9 Adjusting parameters

Some parameters have a profound effect on the operation of the Drive.

They must not be altered without careful consideration of the impact on

the controlled system. Measures must be taken to prevent un wanted

changes due to error or tampering.

UD55 User Guide

4

Issue code: 55nu3

Page 9

3 Inserting the UD55 in a Drive

Before following these instructions, refer to the Warnings

and Notes at the beginning of Chapter 3 Setting up the Drive

Warning

in the Unidrive User Guide.

The power terminals of the Drive retain a high voltage

charge for up to 10 minutes from the time of disconnection

of the AC supply. Take care to avoid contact with the

power terminals during this time.

Figure 1 Inserting the UD55 in the Unidrive

UD55 User Guide

Issue code: 55nu3

5

Page 10

1 Disconnect the AC supply from the Drive.

2 Check that the exterior of the UD55 is not damaged, and that the

multi-way connector is free from dirt and debris. Do not fit a

damaged or dirty UD55 in a Drive.

3 Remove the terminal cover from the Drive (for removal instructions,

see Installing the Drive in Chapter 2 of the Unidrive Installation Guide).

4 If a small option module is already fitted in the Drive, grip the recesses

at the ends of the module and pull the module out of the D rive. Keep

the module for re-fitting.

5 Position the multi-way connector on the rear of the UD55 over the

connector in the Drive (see Figure 1), and press on the thumb pad to

push the UD55 into place.

UD55 User Guide

6

Issue code: 55nu3

Page 11

4 Making Connections

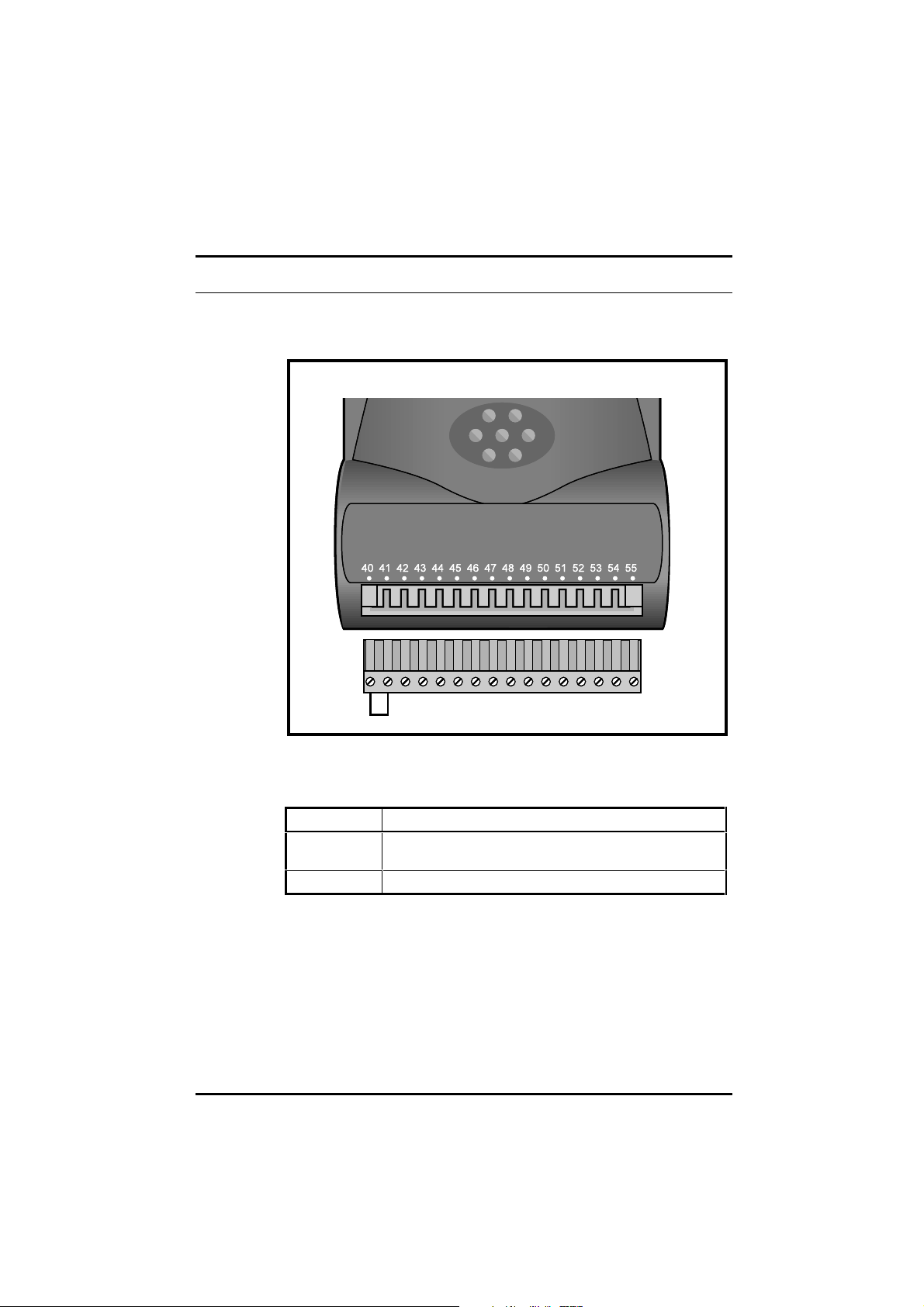

4.1 Locations of the terminals

Figure 2 Location of the plug-in terminal block on the UD55

4.2 Functions of the terminals

Terminal Function

40

41

42 to 55 No connection

UD55 User Guide

Issue code: 55nu3

To enable the save function, terminals 40 and 41 should be directly

connected together

7

Page 12

5 Saving Parameters

If the Drive trips and a trip code is displayed while this procedure is being

followed, refer to Appendix A, Diagnostics. Ensure that all the required

parameters have been set up in the source Drive and that new parameter

values have been saved.

If a small option module was fitted in the Drive, its assoc iated Menu 16

parameters will be copied to the UD55 in addition to the parameters in the

other menus.

1 Insert the UD55 in the source Drive (refer to Chapter 3, Inserting the

UD55 in a Drive).

2 Ensure terminal 30 of the Drive Signal connector is open-circuit so that

the Drive does not become enabled when powered-up.

3 On the UD55 connector, connect terminal 40 directly to terminal 41 to

enable the save function (see Figure 2).

4 Re-fit the terminal cover to the Drive.

5 Connect the AC supply to the Drive.

6 Decide which parameter-set number is to be used in the UD55. If a

parameter-set already contains parameter values, these will be

over-written without warning. It is recommended that a record is

made of at least the following for each parameter-set number:

• A means of identifying the configuration of the source Drive

• The model size of the source Drive

• The type(s) of option module(s) fitted

• Motor ratings

7 Set parameter .00 (in any menu) at 300X, where X is the required

parameter-set number (1 to 8).

8 Press . The parameter values are now copied (saved) to the

UD55.

Saving takes approximately 5 seconds. When it has finished,

parameter .00 returns to zero.

9 It is recommended that parameter 11.38 is set at the number of the

parameter-set (value of

UD55 full parameter check sum noted, as a means of identifying the

parameter-set at a later date.

10 Disconnect the AC supply from the Drive.

8

X in step 7) and the value of parameter 11.40

UD55 User Guide

Issue code: 55nu3

Page 13

11 Remove the terminal cover.

12 Disconnect the link between terminals 40 and 41 on the UD55

connector.

13 Remove the UD55 from the Drive.

14 If a small option module was previously fitted in the Drive, re-fit the

module.

15 Replace the terminal cover.

16 The Drive can now be used.

UD55 User Guide

Issue code: 55nu3

9

Page 14

6 Loading Parameters

6.1 Loading a Parameter-set from the UD55

If the Drive trips and a trip code is displayed while this procedure is being

followed, refer to Appendix A, Diagnostics.

1 Ensure the destination Drive is configured in the same operating mode

as the source Drive. (The UD55 cannot change the operating mode of

the Drive.)

2 Ensure terminals 40 and 41 on the UD55 are not connected.

3 Insert the UD55 in the source Drive.

4 Ensure terminal 30 of the Drive Signal connector is open-circuit so that

the Drive does not become enabled when powered-up.

5 Re-fit the terminal cover to the Drive.

6 Connect the AC supply to the Drive.

7 It is recommended that the following is performed:

• Set parameter 11.38 at the number of the parameter-set to be used.

• Note the value of 11.40 UD55 full parameter checksum.

• Compare this value against the value noted when the parameter-set

was saved in the UD55.

If the values differ, this indicates that a different parameter-set has

been selected or the values contained in the parameter-set have been

changed.

8 Set parameter .00 (in any menu) at 400X, where X is the parameter-set

number of the configuration to be loaded in the destination Drive.

10

9 Press . The parameter values are now copied from the UD 55

(loaded) to the Drive. (If the operating mode of the destination

differs from that of the source, parameter values will not be loaded

and the Drive will trip; the display will indicate

Loading is almost instantaneous. Parameter .00 returns to zero.

10 Set parameter .00 at 1000 and press in order to save the

parameter values.

11 Disconnect the AC supply from the Drive.

12 Remove the terminal cover.

FSH.TYP).

UD55 User Guide

Issue code: 55nu3

Page 15

13 Remove the UD55 from the Drive; if no other small option module is

required in the Drive, the UD55 can remain perman ently fitted.

14 If required, fit a small option module.

15 Replace the terminal cover. The Drive can n ow be used.

6.2 Transferring parameter-sets between

Drives of different ratings

Values of certain motor parameters are not scaled correctly

when the current or voltage rating of the destination Drive

differs from that of the source Drive. For safety, refer to

Warning

the next instruction.

When transferring a parameter-set between Drives of different current or

voltage rating a FSH.rng trip will occur. All parameters will be copied

except those below:

• 2.08 Standard ramp voltage

• 4.05 – 4.07 Current limits

• 4.08 Torque reference

• 4.09 Torque offset

• 5.07 Motor – rated current

• 5.09 Motor – rated voltage

• 5.17 Stator Resistance

• 5.18 Switching frequency

• 5.24 Motor leakage inductance

• 5.33 Thermal model enable

• 6.06 D.C. injection braking current

• 15.07 Regen unit voltage setpoint

These parameters will need to be manually entered into the destinatio n

Drive if the trip occurs.

Note

UD55 User Guide

Issue code: 55nu3

With software versions before V03.xx.07, no trip will

occur and all parameters will be copied. The above

parameters should be manually entered into the

destination Drive and any other parameters that need to

be set up for the application.

11

Page 16

6.3 Using the UD55 with other small option modules

When a UD55 is fitted to the Drive it replaces any small option m odule that

may have been fitted previously. If parameters were last saved in the Drive

with a small option module fitted, other than a UD55, then m enu 16 will be

present and visable via the keypad when a UD55 is subsequently fitted. (If

no option module is fitted menu 16 will not be visable.) Therefore menu 16

parameters previously saved for the small option module can be transferred

to/from the UD55. To prevent incorrec t Drive operation, bec ause the

option module is not present, the Drive cannot be enabled when a UD55 is

fitted and the Drive contains a parameter set for a small option module.

These parameters can be removed from the Drive by saving parameters

with no small option module fitted.

Note

With software versions prior to V03.xx.07, it is possible to

enable a Drive with the UD55 fitted and Menu 16 present.

Terminal 30 of the Drive Signal connector must be opencircuit to prevent incorrect Drive operation when using

the UD55.

6.4 Avoiding problems with inter-related parameters

The maximum values of some parameters depend on other parameters, i.e.

the current limits (04.05 – 04.07) depend on the rated current (05.07).

With software versions before V03.xx.07 the parameter values for the

dependent parameters, i.e. in this case the current limits, may not be correct

after they are transferred from a UD55 to the Drive. A second tran sfer from

the UD55 to the Drive will give the correct values. With software versions

V03.xx.07 and onwards the parameters are automatically transferred twic e

from the UD55, and so the resulting values in the Drive will always be

correct.

12

UD55 User Guide

Issue code: 55nu3

Page 17

7 Erasing the entire flash memory of the UD55

1 Ensure terminals 40 and 41 on the UD55 are connected.

2 Insert the UD55 in a Drive (refer to Chapter 3, Inserting the UD55 in a

Drive).

3 Ensure terminal 30 of the Drive Signal connector is open-circuit so that

the Drive does not become enabled when powered-up.

4 Re-fit the terminal cover to the Drive.

5 Connect the AC supply to the Drive.

6 Set parameter .00 (in any menu) at 3099. All the parameter values are

now erased from the UD55.

Erasing takes from 2 to 14 seconds. When it is completed,

parameter .00 returns to zero.

7 Disconnect the AC supply from the Drive.

8 Remove the terminal cover (refer to Chapter 3, Inserting the UD55 in a

Drive).

9 Remove the UD55 from the Drive.

10 If a small option module was previously fitted in the Drive, re-fit the

module.

11 Replace the terminal cover. The Drive can n ow be used.

UD55 User Guide

Issue code: 55nu3

13

Page 18

8 Related parameters

(Not applicable to the Commander GP Drive)

Use parameters 11.38 and 11.39 find the operating mode for a particular

parameter-set, or to find if a parameter-set is empty.

11.38 UD55 parameter-set selector

ô

(See below)

Range

UD55 fitted 1 ~ 8

UD55 not fitted 0

Use 11.38 to select a parameter-set in the UD55.

11.39 UD55 operating-mode indicator

ô

OPEN.LP

CL.VECt

SErVO

rEGEn

FrEE

11.39 indicates the operating mode related to the parameter-set selected

in 11.38. When the selected parameter-set contains no values, 11.39

indicates FrEE.

ð

0 RWUni P

ð

0

1

2

3

4

RO Uni P

14

11.40UD55 full parameter checksum

ô

0 ~ 16383

When parameter values are copied to the UD55, a check sum is calcu lated

from all the parameter values. 11.40 contains the value of the checksum of

the parameter values contained in the parameter-set selected in 11.38.

ð

RO Uni P

UD55 User Guide

Issue code: 55nu3

Page 19

A Diagnostics

A.1 Trip Codes

The following trip codes are associated with the UD55.

Drive

display

FSH.Err 182

The UD55 memory has been found to be corrupt. If the trip has been produced at

power-up then the memory of the UD55 is automatically reformatted and all

parameter-sets are erased. If errors are detected after power-up, the trip will occur

but the memory of the UD55 will not be reformatted automatically.

FSH.DAt 183

No values in the selected parameter-set; no values are copied to the

destination Drive.

FSH.TYP 184

The operating mode of the destination Drive differs from that related to the

parameter-set; no parameter values are copied to the destination Drive. Either

select an appropriate parameter-set, or change the operating mode of the

destination Drive.

FSH.ACC 185

Write access to the UD55 has not been enabled (terminal 40 not connected to 41 );

no parameter values are copied to the UD55.

FSH.LO 186

The parameter-set contains values for Menu 20 parameters, but a large option

module is not fitted in the destination Drive. Values of Menu 20 parameters are not

copied to the destination Drive.

FSH.20 187

The parameter-set does not contain values for Menu 20 parameters, but a large

option module is fitted in the destination Drive. Values of Menu 20 parameters are

not copied to the destination Drive.

FSH.rng 188

The current or voltage rating of the destination Drive differs from that related to the

parameter-set in the UD55. Parameters are copied except for those listed in

Section 6.2 of this User Guide.

No. Conditions

UD55 User Guide

Issue code: 55nu3

A-1

Page 20

A-2

UD55 User Guide

Issue code: 55nu3

Loading...

Loading...