Page 1

User Guide

UD52UD52

SIN-COS encoder

interface

small option module

for Unidrive

Part Number: 0460 - 0085

Issue Number: 3

Page 2

General Information

The manufacturer accepts no liability for any consequences resulting from

inappropriate, negligent or incorrect installation or adjustment of the

operating parameters of the equipment or from mismatching the Drive

with the motor.

This option module is intended for use only with Control Techniques

Unidrive products. Any other use invalidates the warranty and may cause a

safety hazard.

The contents of this Guide are believed to be correct at the time of

printing. In the interests of a commitment to a policy of continuous

development and improvement, the manufacturer reserves the right to

change the specification of the product or its performance, or the

contents of this Guide, without notice.

All rights reserved. No part of this Guide may be reproduced or

transmitted in any form or by any means, electrical or mechanical including

photocopying, recording or by any information storage or retrieval system,

without permission in writing from the publisher.

Use within the European Union, etc

The following information applies where the end use of the Drive is within

the European Union, the European Economic Area, or other regions which

have implemented Directives of the European Council or equivalent

measures.

The Drive, together with its associated option modules, complies with the

Low Voltage Directive 73/23/EEC.

The installer is responsible for ensuring that the equipment into which the

Drive is incorporated complies with all relevant Directives.

The complete equipment must comply with the EMC Directive 89/336/EEC.

If the Drive is incorporated into a machine, the manufacturer is responsible

for ensuring that the machine complies with the Machinery Directive

89/392/EEC. In particular, the electrical equipment should generally

comply with European Harmonised standard EN60204-1.

Copyright © January 2002 Control Techniques Drives Ltd

Issue Code: 52nu3

Page 3

Contents

Chapter

1 Introduction 1

1.1 Main features of the UD52 1

1.2 Principle of operation 2

2 Safety Information 3

3 Installing the UD52 6

4 Making Connections 8

4.1 Locations of the terminals 8

4.2 Functions of the terminals 9

4.3 Serial communications 11

5 Setting Up the UD52 12

5.1 Initial setting up 12

5.2 Phase offset 12

5.3 Position information 13

5.4 Simulated-encoder outputs (terminals 50, 51, 53, 54) 15

5.5 Freeze inputs (terminals 48, 49) 16

5.6 Further setting up 16

6 Related Parameters 17

6.1 Introduction 17

6.2 Programmable software 17

6.3 Parameter descriptions 19

Appendix

A Specifications A-1

A.1 Inputs and outputs A-1

B Advanced Functions B-1

B.1 Alternative configurations B-1

B.2 Aligning the encoder mechanically B-2

C Diagnostics C-1

C.1 Trip codes C-1

UD52 User Guide

Issue code: 52nu3

Page 4

UD52 User Guide

Issue code: 52nu3

Page 5

1 Introduction

1.1 Main features of the UD52

Note

The UD52 can be used only with Drives equipped with

version 3 (or later) software. (Parameter 0.50 indicates

the software version.)

ApplicationsThe UD52 SIN-COS encoder small option module is an interface module for

installation in a Unidrive. The UD52 operates with encoders havin g 256,

512, 1024, 2048 or 4096 lines per revolution, and has a maximum operating

frequency of 102.4kHz (3000RPM with a 2048-line encoder).

The UD52 can be used in a Drive operating in either the Closed-lo op Vector

or Closed-loop Servo mode in order to obtain speed feedbac k and very

high resolution shaft position. The UD52 is fully co mpatible with the

following Stegmann

SCS60, SCM60, SCS70, SCM70

These encoders are compatible with the two-wire serial com munic ations

port in the UD52.

Absoluteposition

information

Selection of

encoder

function

Simulated

encoder

outputs

InstallationThe UD52 must be fitted in the small option module bay of the Unidrive.

The UD52 can determine the absolute position within a revolutio n of a

single-turn encoder, or in many revolutions of a multi-turn encoder. Unlike

the case for a standard encoder, which must be rotated past its marker

pulse in order to obtain absolute-position information, absolute-position

information from a (suitable) SIN-COS encoder is obtained when the Drive is

powered-up.

Speed and position information is displayed in parameters which can be

read on the Drive display and/or via serial communications.

When a UD52 is fitted in the Drive, the Drive automatically uses the SIN-COS

encoder as speed and position feedback for the motor. Alternatively, a

standard quadrature encoder can be used for speed and position feedback,

and the SIN-COS encoder used as an incremental reference.

The UD52 has simulated encoder outputs which normally use the SIN-COS

encoder as the source, but can be reconfigu red to use the main encoder

(Encoder 1) connected to the 15-way D-type on the Drive as the source.

These outputs produce quadrature A/B signals correspondin g to the line

counts from the source encoder. Also, these outputs can be configured for

frequency and direction (F/D) signals.

All connections to the Drive are made by a multi-way connector.

Connections from external equipment are made by a pluggable 16-way

screw-terminal block on the UD52.

SIN-COS encoders:

UD52 User Guide

Issue code: 52nu3

1

Page 6

1.2 Principle of operation

The UD52 converts the sinusoidal output signals of a SIN-COS encoder into

square waves and counts the edges (as in the case of a standard encoder) to

yield position counts at a rate of four times the number of lines per

revolution of the encoder. The constantly varying amplitudes of the sine

waves are also measured by the UD52 in order to produce 211 (2048)

interpolated counts between encoder lines.

The overall resolution is the product of the number of interpolated counts

and the number of encoder lines. For example, the UD 52 used with a

512-line (2

revolution).

9

) encoder can give a resolution of 220 (1 048 576) counts per

UD52 User Guide

2

Issue code: 52nu3

Page 7

2 Safety Information

2.1

Warnings, Cautions and Notes

A Warning contains information which is essential for avoiding a safety

hazard.

A Caution contains information which is necessary for avoiding a risk of

damage to the product or other equipment.

A Note contains information which helps to ensure correct operation of the

product.

2.2 Electrical safety –

general warning

The voltages used in the Drive can cause severe electric sho ck and/or burns,

and could be lethal. Extreme care is necessary at all times when working

with or adjacent to the Drive.

Specific warnings are given at the relevant places in this User Guide.

The installation must comply with all relevant safety legislation in the

country of use.

The Drive contains capacitors that remain charged to a poten tially lethal

voltage after the

energized, the AC supply must be isolated at least ten minutes before work

may continue.

AC supply has been disconnected. If the Drive has been

2.3 System design

The Drive is intended as a component for professional incorporation into

complete equipment or systems. If installed in correctly the Dr ive may

present a safety hazard. The Drive uses high voltages and currents, carries

a high level of stored electrical energy, and is used to control m echanical

equipment which can cause injury.

Close attention is required to the electrical installation and the systemdesign to avoid hazards either in normal operation or in the event of

equipment malfunction. System-design, installation, commissioning and

maintenance must be carried out by personnel who have the necessary

training and experience. They must read this safety information and this

User Guide carefully.

To ensure mechanical safety, ad ditional safety devic es such as

electro-mechanical interlocks m ay be required. The Dr ive must not be u sed

in a safety-critical application without additional high-integrity protection

against hazards arising from a malfunction.

UD52 User Guide

Issue code: 52nu3

3

Page 8

2.4 Environmental limits

Instructions in this User Guide regarding transport, storage, installation and

use of Drives must be complied with, including the specified environmental

limits. Drives must not be subjected to excessive ph ysical force.

2.5 Compliance with regulations

The installer is responsible for complying with all relevant regulations, such

as national wiring regulations, accident prevention regulations and

electromagnetic compatibility (EMC) regulations. Particular attention must

be given to the cross-sectional areas of conductors, the selection of fuses or

other protection, and protective earth (ground) connections.

The Unidrive Installation Guide contains instructions for achieving compliance

with specific EMC standards.

Within the European Union, all machinery in which this product is used must

comply with the following directives:

89/392/EEC: Safety of Machinery

89/336/EEC: Electromagnetic Compatibility

2.6 Safety of personnel

The STOP function of the Drive does not remove dangerous voltages from

the output of the Drive or from any external option unit.

The Stop and Start controls or electrical inpu ts of the Drive m ust not be

relied upon to ensure safety of personnel. If a safety hazard could exist

from unexpected starting of the Drive, an interlo ck that electric ally isolates

the Drive from the

inadvertently started.

Careful consideration must be given to the functions of the Drive which

might result in a hazard, either through their intended functions (eg.

Auto-start) or through incorrect operation due to a fault or trip (eg.

stop/start, forward/reverse, maximum speed).

Under certain conditions, the Drive can suddenly discontinue control of the

motor. If the load on the motor cou ld cause the moto r speed to be

increased (eg. hoists and cranes), a separate method of braking and

stopping the motor must be used (eg. a mechanical brake).

Before connecting the

understand the operating controls and their operation. If in doubt, do not

apply AC power to the Drive. Damage may occur, or lives put at risk.

Carefully follow the instructions in this User Guide.

Before making adjustments to the Drive, ensure all personnel in the area are

warned. Make notes of all adjustments that are made.

AC supply must be installed to prevent the motor being

AC supply to the Drive, it is important that you

UD52 User Guide

4

Issue code: 52nu3

Page 9

2.7 Risk analysis

In any application where a malfunction of the Drive could lead to damage,

loss of life or injury, a risk analysis must be carried out, and where necessary,

further measures taken to reduce the risk. This would normally be an

appropriate form of independent safety back-up system using simple

electro-mechanical components.

2.8 Signal connections

The control circuits are isolated from the po wer circuits in the Drive by basic

insulation only, as specified in IEC664–1. The installer must ensure that the

external control circuits are insulated from human contact by at least one

layer of insulation rated for use at the AC supply voltage.

If the control circuits are to be connected to other circuits classified as

Safety Extra Low Voltage (SELV) (eg. to a personal computer), an additional

isolating barrier must be included in order to maintain the SELV

classification.

2.9 Adjusting parameters

Some parameters have a profound effect on the operation of the Drive.

They must not be altered without careful consideration of the impact on

the controlled system. Measures must be taken to prevent un wanted

changes due to error or tampering.

UD52 User Guide

Issue code: 52nu3

5

Page 10

3 Installing the UD52

Before using the following procedure, refer to the

Warnings at the beginning of Chapter 2 Installing the Drive in

Warning

the Unidrive Installation Guide.

1 Ensure the Drive is operating in either the Closed-loop Vector or the

Closed-loop Servo mode (this is indicated by parameter 11.31 (0.48).

2 Before installing the UD52 in the Unidrive, ensure the AC supply has

been disconnected from the Drive for at least 10 minutes.

3 Check that the exterior of the UD52 is not damaged, and that the

multi-way connector is free from dirt and debris. Do not install a

damaged or dirty UD52 in the Drive.

4 Remove the terminal cover from the Drive (for removal instructions,

see Installing the Drive in Chapter 2 of the Unidrive Installation Guide).

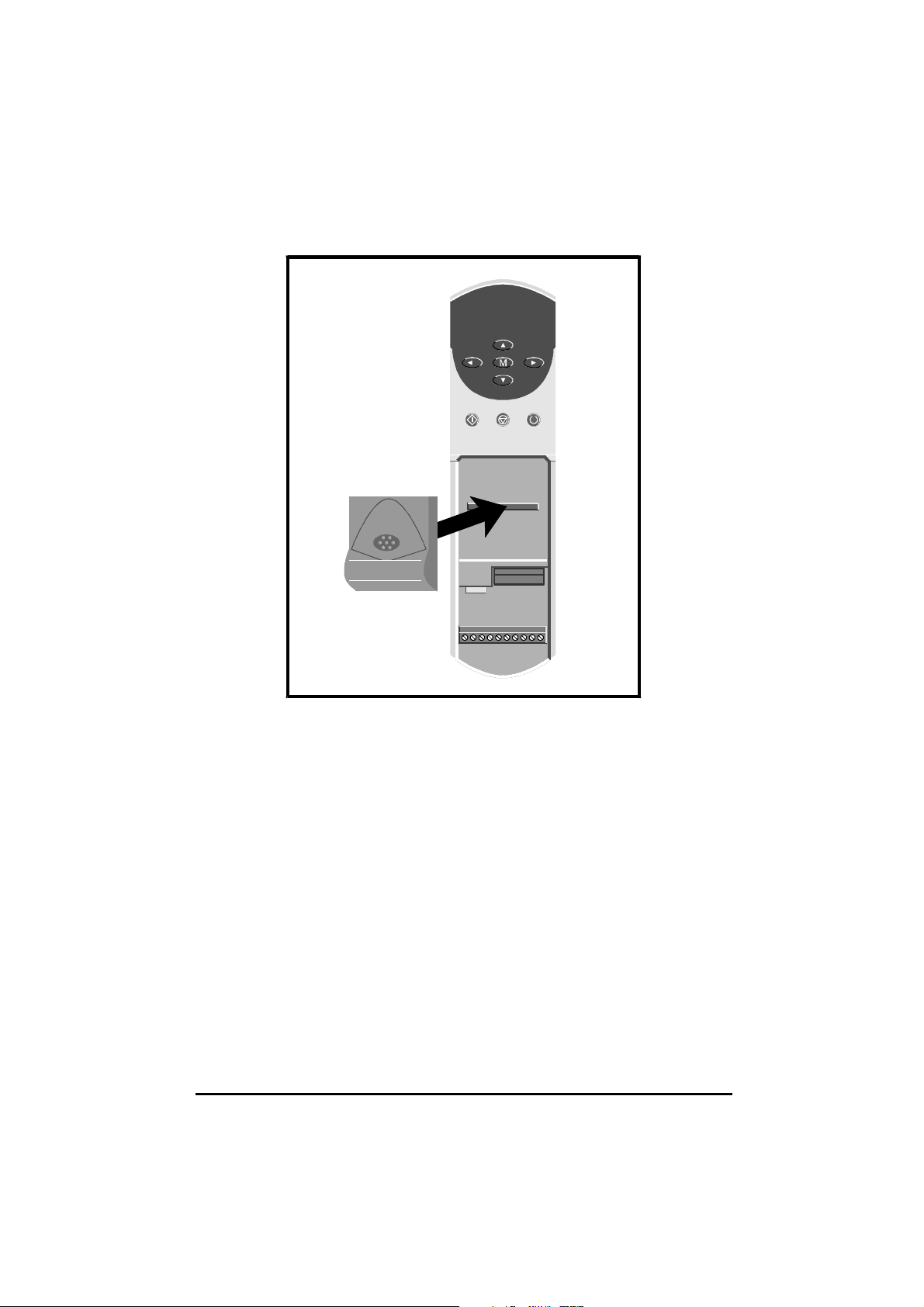

5 Position the multi-way connector on the rear of the UD52 over the

connector in the Drive (see Figure 1), and press on the thumb pad to

push the UD52 into place.

6 Re-fit the terminal cover to the Drive.

7 Connect the AC supply to the Drive.

8 Set parameter .00 at 149 to unlock security.

9 Check that Menu-16 parameters are now available.

10 Check that parameter 16.01 is set at 4.

11 If the checks in steps 8 and 9 fail, perform the following:

• Remove the

• Wait at least 10 minutes.

• Remove the terminal cover.

• Check that the UD52 is fully inserted.

• Replace the terminal cover.

• Re-apply the

• Check again that parameter 16.01 is set at

AC supply from the Drive.

AC supply.

4.

UD52 User Guide

6

Issue code: 52nu3

Page 11

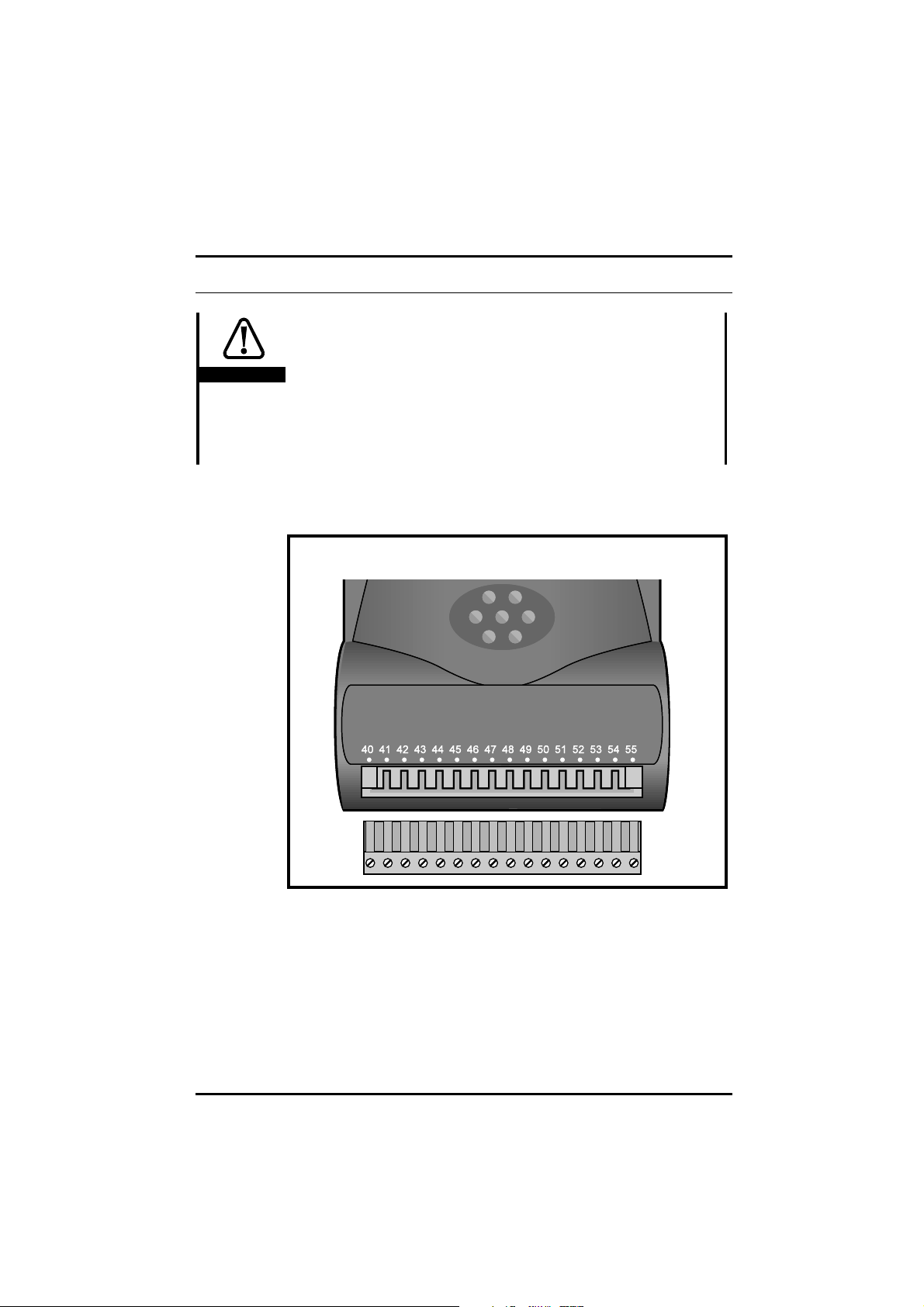

Figure 1 Installing the UD52 in the Unidrive

UD52 User Guide

Issue code: 52nu3

7

Page 12

4 Making Connections

The control circuits are isolated from the power circuits in

the Drive by basic insulation only, as specified in IEC664–1.

The installer must ensure that the external control circuits

Warning

4.1 Locations of the terminals

are insulated from human contact by at least one layer of

insulation rated for use at the

If the control circuits are to be connected to other circuits

classified as Safety Extra Low Voltage (SELV) (eg. to a

personal computer), an additional isolating barrier must be

included in order to maintain the SELV classification.

AC supply voltage.

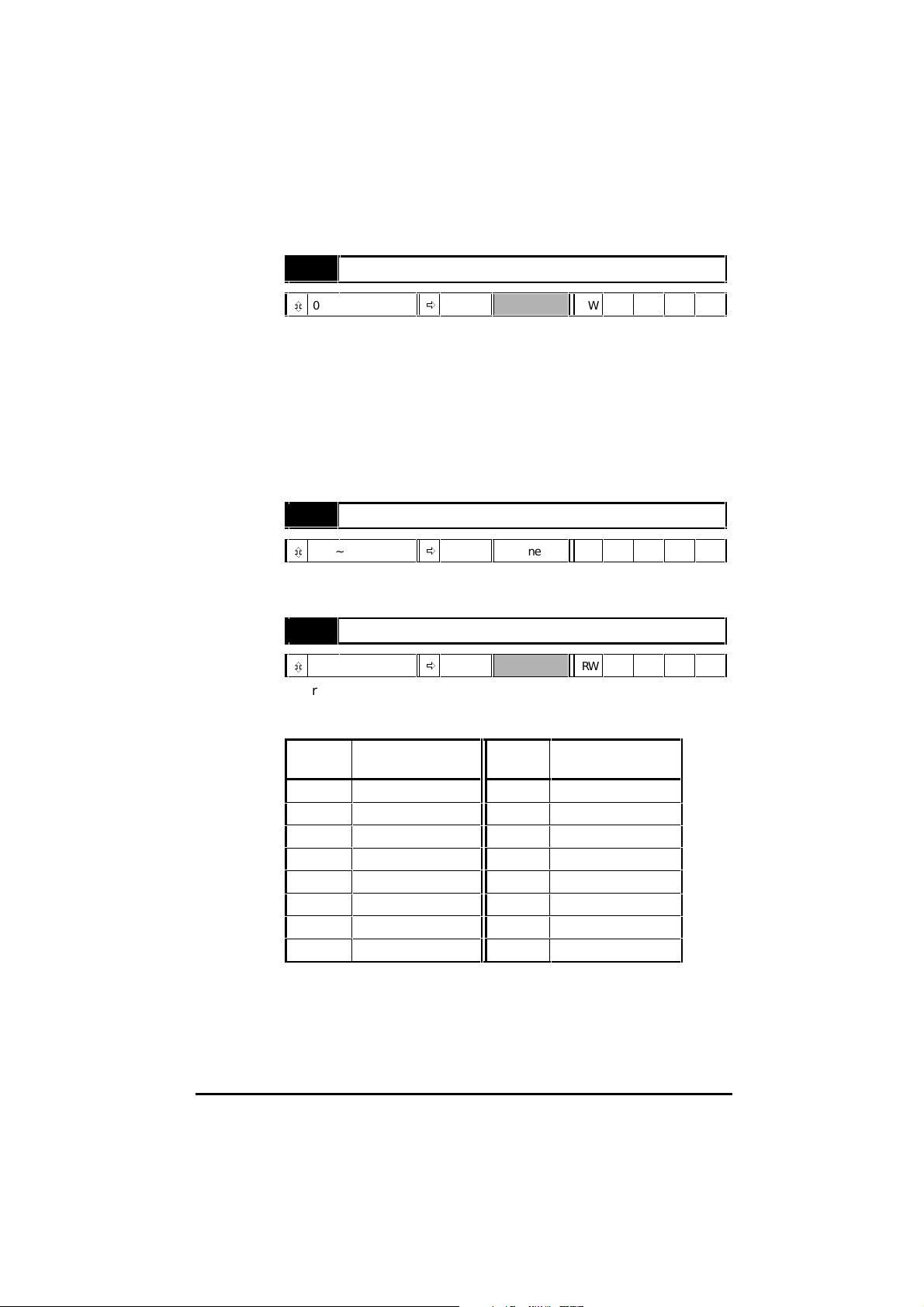

Figure 2 Location of the two-part terminal block

8

UD52 User Guide

Issue code: 52nu3

Page 13

4.2 Functions of the terminals

(Note that \ indicates not (eg. F\ indicates not F)

Terminal Name Function Comments

40 SININ Sine input signal Always required

41 SINREF Sine input reference

42 COSIN Cosine input signal

43 COSREF Cosine input reference

44 0V 0V common

45 +VENC DC supply to encoder

46 SC DATA Serial comms. EIA485 input and output

47 SC DATA\ Serial comms. EIA485 input and output

48 FREEZE Freeze SC DATA input Optional

49 FREEZE\ Freeze SC DATA\ input

50 A

(F)

51 A\

(F\)

52 0V 0V common

53 B

(D)

54 B\

(D\)

55 0V 0V common

Simulated-encoder

phase quadrature output A

or frequency output F

(EIA485 serial link)

Simulated-encoder

phase quadrature output A\

or frequency output F\

(EIA485 serial link)

Simulated-encoder

phase quadrature output B

or direction output D

(EIA485 serial link)

Simulated-encoder

phase quadrature output B\

or direction output D\

(EIA485 serial link)

Use for Closed-loop

Servo mode or

when absolute position

is required

Optional

UD52 User Guide

Issue code: 52nu3

9

Page 14

SIN

COS

Main feedback

SIN-COS

encoder

Figure 3 Standard wiring configuration

SCDATA

Sine

output

Cosine

output

0V

+V

Serial

comms.

SIN-COS encoder

SININ

SINREF

COSIN

COSREF

0V

+VENC

SCDATA

SCDATA\

UD52

Figure 4 Grounding and screening recommendations for the UD52

The sinusoidal signals from a

SIN-COS encoder are low-voltage analog signals.

Ensure that electrical noise from the Drive o r motor do es not adversely

affect the encoder feedback. Ensure that moto r cables are shielded (see

Chapter 2 Installing the Drive in the Installation Guide). Refer to Figure 3 for

grounding and screening recommendations for the UD52.

For the simulated encoder connections, refer to the instructions for the

equipment that is to receive the signals.

UD52 User Guide

10

Issue code: 52nu3

Page 15

4.3 Serial communications

When absolute positioning is required, connect terminals 46, 47 Serial

communications to the appropriate connections on the encoder.

The serial link allows the Drive (at power-up) to interrogate the

encoder in order to determine the initial absolute position of the encoder

shaft. When the interrogation is completed, the serial link is disabled.

If the serial link fails, the Drive will trip, showing trip code

When a

SIN-COS encoder is used with a Drive operating in the Closed-loop

Servo mode, absolute-position and phase-offset information is always

required. In the Closed-loop Vector mode for controlling an induction

motor, absolute-position and phase-offset information are optional.

When this information is not required, serial communications connections to

the encoder do not need to be made. In this case, set parameter 16.16

S

IN-COS encoder – serial comms disable at 1 (otherwise a SEP EC trip will occur

at power-up).

SIN-COS

SEP EC.

Operating mode Terminals

Closed-loop Servo mode

Closed-loop Vector mode when absolute-position

information is required

Closed-loop Vector mode when absolute-position

information is not required

Parameter

46, 47

Connect to serial comms. port

SIN-COS encoder

of

No connections 1

16.16

0

UD52 User Guide

Issue code: 52nu3

11

Page 16

5 Setting Up the UD52

The instructions in this chapter apply when the Drive is being set up for the

first time with a UD52 fitted.

5.1 Initial setting up

The default supply voltage to the encoder from terminal 45 is +5.15V. If the

encoder requires 8V, set parameter 16.15 SIN-COS encoder– voltage select

at 1.

Enter the number of lines per revolution for the

parameter 16.12 SIN-COS encoder – No. of lines per revolution. The value can

be only a power of 2.

5.2 Phase offset

When the Drive is operating in the Closed-loop Servo mode, the phaseoffset of the SIN-COS encoder in relation to the mo tor shaft must be

entered in parameter 16.09 SIN-COS encoder – phase offset.

The phase offset can be entered in either of the following ways:

• Performing an encoder phasing test. The UD52 measures the phase

error automatically and enters the value in 16.09.

• If the phase offset is known, you can enter the value manually in

parameter 16.09.

See also Aligning the encoder mechanically in Appendix B Advanced functions.

Encoder phasing test (Closed-loop Servo mode)

SIN-COS encoder in

Warning

12

During the phasing test, the motor shaft rotates slowly.

Before starting, make sure it will be safe for the motor to

be run.

During the phasing test, the motor shaft rotates in two stages, as follo ws:

1

• Initial jump in position by

• Subsequent rotation by

Where

N is the number of motor poles.

revolution

N

4

revolution

N

Examples

No. of poles Initial jump Subsequent rotation

2

6

1

revolution 2 revolutions

2

1

revolution

6

2

revolution

3

UD52 User Guide

Issue code: 52nu3

Page 17

Procedure

1 Ensure the motor is unloaded (any load will create errors in the

phase-offset measurement).

2 Set parameter 16.10 SIN-COS encoder phasing test at 1.

3 Enable the Drive.

The motor shaft rotates (as described above) and the measured value of

phase offset is automatically entered in parameter 16.09 S

phase offset.

If a phasing test is attempted with a motor that has any of the following...

• High inertia

• No damping

• Small load on the shaft

...an incorrect value for the phase offset will be measured. Refer to

parameter 5.27 in the Unidrive Advanced User Guide.

Note

If the Drive trips and the display indicates trip code

ENC.PH7, this indicates either of the following:

The

SIN and COS input connections from the

encoder are incorrectly made

The phase sequence of the motor is reversed

After correcting the connections, repeat the procedure.

Magnetizing current test (Closed-loop Vector)

IN-COS encoder –

Refer to Autotune in Chapter 3 Setting Up the Drive in the Unidrive User Guide,

or to parameter 5.12 in the Unidrive Advanced User Guide. If the Drive trips

while Autotune is being performed see the Note above.

5.3 Position information

Counting revolutions

Single-turn encoder

Revolutions are not counted.

Multiple-turns encoder

Revolutions are indicated in parameter 16.03 S

count. When the serial communications link to the encoder is used, at

power-up the value stored in the encoder is transferred to 16.03. When

the value of 16.03 reaches a maximum limit that is defined in parameter

16.13 SIN-COS encoder – No. of revolutions, 16.03 is reset and the count

starts again from zero.

UD52 User Guide

Issue code: 52nu3

IN-COS encoder – revolution

13

Page 18

By default, 16.03 will not count. When a multi-turn encoder is used, enter

the required value in 16.13, as follows:

16.13 16.03 counts up

to...

008255

119511

2 3 10 1023

37112047

415124095

531138191

6631416383

71271532767

Absolute-position parameters

When the following conditions are met...

• A compatible

connections are made

• 16.16 S

• 16.14 S

...the absolute position is indicated by the following parameters:

16.04 S

16.05

IN-COS encoder – serial comms. disable is set at 0 (default)

IN-COS as reference encoder is set at 0 (default)

IN-COS encoder incremental position (coarse)

SIN-COS encoder incremental position (fine)

16.13 16.03 counts up

to...

SIN-COS encoder is used and serial communications

14

UD52 User Guide

Issue code: 52nu3

Page 19

Using position information for orientation

The position value in parameter 16.04 SIN-COS encoder incremental position

(coarse) (at 16384 counts per revolution) is used as an input to the position-

control algorithms in Menu 13. This allows orientation to be performed

within one revolution.

Using position information for digital lock

The digital-lock algorithm uses only incremental changes in position

obtained from parameter 16.04 and ignores the multi-turn information in

parameter 16.03 SIN-COS encoder – revolution count.

Only incremental digital lock is performed; multi-turn absolute orientation is

not supported.

5.4 Simulated-encoder outputs

(terminals 50, 51, 53, 54)

The simulated-encoder outputs can be connected to external equipment for

monitoring the output of either a SIN-COS encoder connected to the UD52

or the main encoder (Encoder 1) that is connected to the 15-way D-type on

the Drive. By default, the SIN-COS encoder is used as the source. To select

Encoder 1, set parameter 16.06 Simulated-encoder output select at 1.

Quadrature AB, or frequency and direction

By default, the simulated-encoder outputs are phase-quadrature A and B

signals. For frequency (F) and direction (D) signals, set parameter 16.08

Simulated encoder – F/D output enable at 1.

Pulses per revolution

The simulated-encoder outputs are derived from the polarity changes in the

SIN-COS encoder outputs, giving a resolution of four times the number of

encoder lines per revolution.

The number of pulses per revolution (

lines per revolution of the SIN-COS encoder as well as on the value 16.07

Simulated-encoder output scaling.

By default, the outputs are scaled 1:1 . To chan ge the scaling, enter the

required value in parameter 16.07 Simulated-encoder output scaling. The

scaling factor is given by the following:

1

1607[.]

2

UD52 User Guide

Issue code: 52nu3

PPR) is dependent on the number of

15

Page 20

5.5 Freeze inputs

(terminals 48, 49)

If the Freeze function is required, a UD70 large option module must be fitted

in the Drive in order to read the freeze position, and pass the data to the

system controller or PLC. The initiating signal for the freeze function must

be applied to terminals 48 and 49 on the UD52.

Related UD70 parameters

_Q20%.5 Control word (bit 5)

Set at 1 for the current absolute positions of the feedback and reference

encoders to be entered in _Q21% and _Q22% when the Freeze input is

activated.

_Q20%.5 is reset to zero when the values have been entered.

_Q21% Feedback-encoder freeze value

Units Encoder lines

Range –231 to 2

Reset H = S/V S = N/A P = N/A

_Q22% Reference-encoder freeze value

Units Encoder lines

Range –231 to 2

Reset H = S/V S = N/A P = N/A

31

31

5.6 Further setting up

Refer to Parameters descriptions in Chapter 6 Related Parameters for setting

up the following:

Disable interpolation 16.17

Disable updating the position parameters when reading 16.11

16

Function Parameter

UD52 User Guide

Issue code: 52nu3

Page 21

6 Related Parameters

6.1 Introduction

The parameters listed in this chapter are used for programming and

monitoring the UD52. Refer to the Unidrive User Guide for programming

instructions.

Before attempting to adjust any parameters, refer to the

Warnings and Notes at the beginning of Chapter 3 Setting up

Warning

6.2 Programmable software

Key

the Drive in the Unidrive User Guide.

Type of parameter

RO Read-only

RW Read–write

...select Select from two settings

...enable Make or allow a function to operate

...disable Stop or disallow a function from operating

...indicator The value can only be read

Limitations of use

S The new parameter-value is saved when the

disconnected from the Drive.

P Protected parameter; the parameter cannot be used as the

destination parameter for a programmable input.

Range

Bi Variable parameter having bipolar value range.

Uni Variable parameter having unipolar value range.

Bit Bit parameter

Symbols

ð

Default value

ô

Range of values

~ Indicates a range of values

(in the case of bit parameters, ~ indicates or).

AC supply is

UD52 User Guide

Issue code: 52nu3

17

Page 22

SIN-COS encoder −

16.12

No. of lines per

revolution

SIN-COS encoder −

16.13

SININ

40

41

SINREF

COSIN

42

43

COSREF

SIN-COS encoder

phase offset

SIN-COS encoder

Encoder 1

position

phasing test

No. of revolutions

SIN-COS as

16.14

reference encoder

SIN-COS encoder

16.15

voltage

select

SIN-COS encoder −

16.16

serial comms. disable

16.09

16.10

3.27

Simulated-encoder

output

select

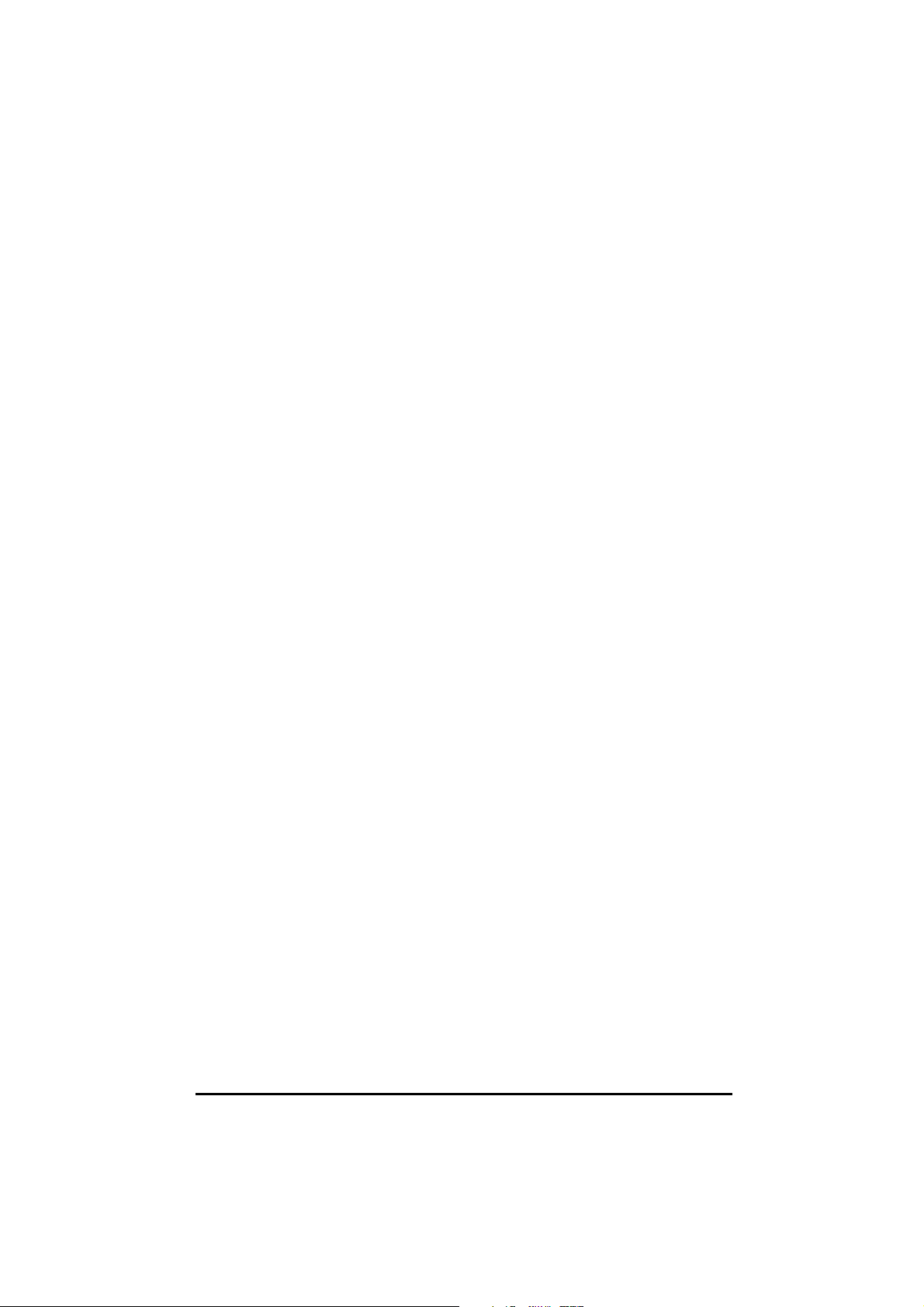

Figure 5 Logic diagram for the UD52

16.06

SIN-COS encoder

16.11

update

16.02

SIN-COS encoder

RPM

1

[16.07]

2

16.07

Simulated-encoder

output scaling

disable

16.03

SIN-COS encoder

revolution count

16.04

SIN-COS encoder

incremental

position (coarse)

16.05

SIN-COS encoder

incremental

position (fine)

Simulated encoder

F/D output enable

16.08

A (f)

A\ (f\)

B (D)

B\ (D\)

50

51

53

54

18

UD52 User Guide

Issue code: 52nu3

Page 23

6.3 Parameter descriptions

16.01 Option module fitted code

ô

0 ~ 100

16.01 indicates the type of small option module that is fitted in the D rive,

as follows:

0 No small option module

1 UD50 Additional I/O

2 UD51 Second encoder interface

3 UD53 Resolver interface

4UD52

SIN-COS encoder interface

16.02SIN-COS encoder RPM

ô

±30 000

16.02 indicates the speed of rotation of the encoder. This depends on the

correct value having been entered in 16.12 SIN-COS encoder – No. of lines per

revolution.

16.03SIN-COS encoder – revolution count

ô

0 ~ 32767

When a multiple-turns encoder and an appropriate value has been entered in

16.13 SIN-COS encoder – No. of revolutions, 16.03 indicates the absolute

position. In other cases, 16.03 indic ates relative position.

When the Drive is powered-up and the serial communications link is used,

the value of 16.03 is set at the value stored in the encoder. The value

increases to a maximum value determ ined by the setting of param eter

16.13 S

IN-COS encoder – No. of revolutions. On the following revolution, the

value of 16.03 returns to zero ready to count up again.

ð

ð

ð

RO Uni P

RPM RO Bi P

Revolutions RO Uni P

16.04 indicates the absolute position of the moto r shaft. This position

information is derived by the UD52 counting the changes in sign of the

encoder outputs, some of the interpolated information and the initial

position information.

See 16.05 S

UD52 User Guide

Issue code: 52nu3

16.04SIN-COS encoder – incremental position (coarse)

ô

0 ~ 16383

IN-COS encoder – incremental position (fine).

ð

rev/16384 RO Uni P

19

Page 24

16.05SIN-COS encoder – incremental position (fine)

ô

0 ~ 255

ð

rev/4194304 RO Uni P

16.04 and 16.05 indicate the position of the motor shaft to a resolu tion

given by:

256 1604 1605

××++[.][.]

((

))

4194304

revolution

When the number of encoder lines is less than 2048 (see 16.12), 16.05

indicates the following increments:

No. of lines 16.05 increment Available resolution

256 8 524288

512 4 1048576

1024 2 2097152

2048 1 4194304

4098 1 4194304

The least significant digit is not available

16.06 Simulated-encoder output select

ô

0 ~ 1

The simulated encoder outputs appear on the following terminals:

ð

0 RW Bit

20

Terminal Name

50 A (F)

51 A\ (F\)

53 B (D)

54 B\ (D\)

Set 16.06 to select the source of the simu lated encoder ou tputs as follows:

16.06 Source

0SIN-COS encoder

1Encoder 1

The simulated encoder outputs are derived only from the counted sign

reversals of the source encoder and do not include interpolation. No zeropulse information is produced.

UD52 User Guide

Issue code: 52nu3

Page 25

16.07Simulated-encoder output scaling

ô

0 ~ 15

ð

02

n

RWUni

Enter the required value in 16.07 for scaling the simulated-encoder output.

The scaling factor is as follows:

1

1607[.]

2

16.08 Simulated encoder– F/D output enable

ô

0 ~ 1

ð

0 RW Bit

Use 16.08 to select the output mode of term inals 50, 51, 53, 54, as follows:

16.08 Output mode

0 A/B quadrature signals

1 Frequency and direction signals

16.09SIN-COS encoder– phase offset

ô

0 ~ 6143

16.09 indicates the value of phase offset. See Phase offset in Chapter 5

Setting up the UD52 for ways in which the value is entered.

The value is saved at power-down and is changed only when one of the

procedures in Phase offset is performed.

When the operating mode of the Drive is changed, 16.09 i s reset to zero.

Restoring default values does not affect the value of 16.09.

ð

1/6143 rev. RWUni S P

Set 16.10 at 1 to initiate the encoder phasing test (on com pletion, 16.10

automatically returns to 0). See Phase offset in Chapter 5 Setting up the

UD52.

UD52 User Guide

Issue code: 52nu3

16.10SIN-COS encoder phasing test

ô

0 ~ 1

ð

0 RW Bit

21

Page 26

16.11 SIN-COS encoder update disable

ô

0 ~ 1

ð

0 RW Bit

When 16.11 is set at 0 (default), and the SIN-COS encoder shaft position is

being read from parameters 16.03, 16.04 and 16.05 by a large option

module (eg. UD70) or via serial communications, the values of these

parameters are free to change during the read process. This can result in

large position-errors being read.

To ensure that the position information from all three parameters is

consistent when reading the values, set 16.11 at 1 to hold the three

parameters at the last complete set of values. When the read proc ess is

completed, return 16.11 at 0 to allow the parameter values to contin ue to

be updated.

16.12SIN-COS encoder – No. of lines per revolution

ô

256 ~ 4096

ð

512 lines RWUni

Enter the number of lines per revolution of the SIN-COS encoder being used.

The value can only be a power of 2.

16.13 SIN-COS encoder – No. of revolutions

ô

0 ~ 15

Enter the required value to give the number of revolutio ns that parameter

16.03 SIN-COS encoder – revolution count is to count to before being reset.

The entered value must be the required power of 2, as follows:

ð

0 RWUni

22

16.13 16.03 counts up

to...

008255

119511

2 3 10 1023

37112047

415124095

531138191

6631416383

71271532767

16.13 16.03 counts up

to...

For use with a single-turn encoder, set 16.13 at 0.

UD52 User Guide

Issue code: 52nu3

Page 27

Caution

16.14SIN-COS as reference encoder

ô

0 ~ 1

ð

0 RW Bit

To use the SIN-COS encoder for speed and position reference, set 16.14 at 1.

See Alternative configurations in Appendix B Advanced functions.

16.15SIN-COS encoder– voltage select

ô

0 ~ 1

A 5V encoder can be damaged if it is supplied with 8V

ð

0 RW Bit

Use 16.15 to select the encoder

DC supply voltage from terminal 45,

as follows:

16.15 Voltage

0 +5.15V

1+8.0V

16.16 SIN-COS encoder– serial comms. disable

ô

0 ~ 1

ð

0 RW Bit

When the initial-position information is not required (or not available) from

the encoder, set 16.16 at 1 to disable the serial communications link. (See

Serial communications in Chapter 5 Setting Up)

16.17 SIN-COS encoder– interpolation disable

ô

0 ~ 1

Set 16.17 at 1 when the position information is to consist only of the basic

line count (without interpolation being obtained from the intermediate

values of the sine wave outputs of the encoder).

ð

0 RW Bit

UD52 User Guide

Issue code: 52nu3

23

Page 28

24

UD52 User Guide

Issue code: 52nu3

Page 29

A Specifications

A.1 Inputs and outputs

Inputs SININ, SINREF, COSIN, COSREF (terminals 40, 41, 42, 43)

Type Differential voltage

Signal level 1.1V peak-to-peak

Maximum input frequency 105kHz (not all SIN-COS encoders are designed to operate at this

maximum frequency)

Absolute maximum DC voltage

that can be applied

Input resistance 1kΩ ±5% (to 0V)

Encoder DC supply (VENC) (terminal 45)

Nominal voltage +5.15V or +8V

Tolerance ±3%

Maximum output current 300mA

Protection Protected against short-circuit and overload

Serial communications (terminals 46, 47)

±4V

Transceiver mode EIA485 2-wire master-slave

Bias resistors 1KΩ (If the inputs are not connected, the bias resistors will ensure

logic 1 is detected)

Termination resistor 120Ω ±5% (internal, no series capacitor)

Mode of operation Differential

Maximum permissible number of drivers on the serial link 32

Maximum cable length 1200m (4000 ft)

Maximum data rate (20kbps) 10Mbaud

Maximum-common mode voltage –7V ~ +12V

Driver output signal ±1.5V

Driver load 60Ω

Receiver input resistance >12kΩ

Receiver sensitivity ±300mV

within the common-mode

voltage range

UD52 User Guide

Issue code: 52nu3

A-1

Page 30

Freeze inputs (terminals 48, 49)

EIA485 differential (see terminals 46, 47)

Simulated-encoder outputs (terminals 50, 51, 53, 54)

Output type EIA 485

Maximum output frequency Quadrature: 205kHz

Frequency and direction: 410kHz

Output voltage Conforms to EIA 485

Absolute maximum voltage that can be applied to

each terminal

Protection Current limit with thermal protection

Output state Typical output voltage

relative to 0V

5mA load 25mA load

Low 1.0V 1.5V

High 4.5V 4V

–10V ~ +15V

0V common (terminals 44, 52, 55)

Absolute maximum current that can be applied

through each terminal

A-2

200mA

UD52 User Guide

Issue code: 52nu3

Page 31

B Advanced Functions

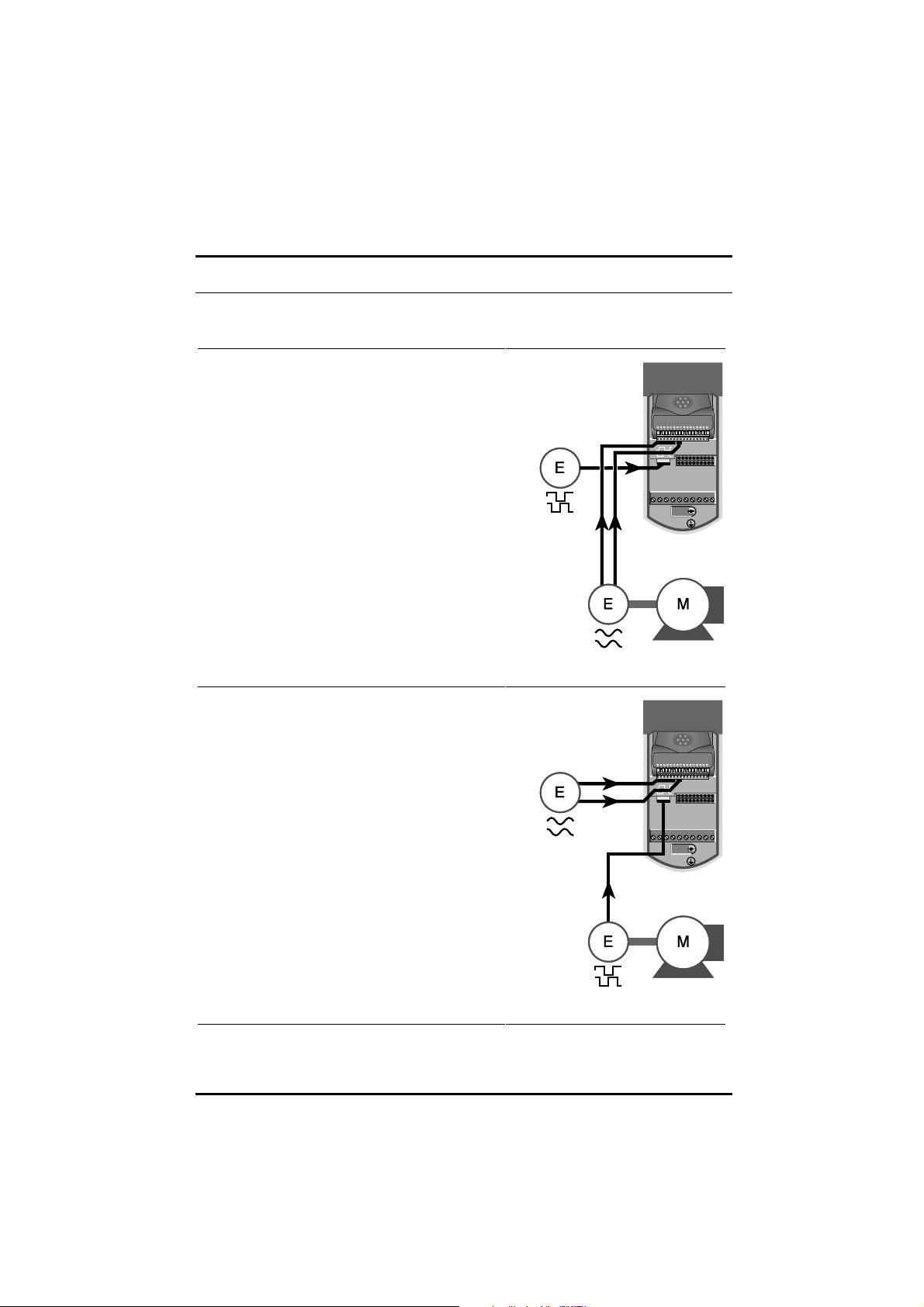

B.1 Alternative configurations

Reference: Quadrature encoder connected to the 15-way

D-type in the Drive

Main feedback: S

Refer to Menus 3, 13, 16

Reference: SIN-COS encoder connected to the UD52

Main feedback: Quadrature encoder connected to the

15-way D-type in the Drive

Refer to Menus 3, 13, 16

IN-COS encoder connected to the UD52

Reference

encoder

SIN

COS

Main feedback

SIN-COS

encoder

Reference

SIN-COS

encoder

SCDATA

SIN

COS

UD52 User Guide

Issue code: 52nu3

SCDATA

Main feedback

encoder

B-1

Page 32

B.2 Aligning the encoder mechanically

(Closed-loop Servo mode)

Note

Use this procedure only when the procedure described in

Phase offset in Chapter 5 Setting Up the UD52 cannot be

performed.

When the SIN-COS encoder is used as the feedback, use the following

procedure to precisely align the encoder with the mo tor (for zero

phase-offset). Precise alignment can be achieved only when the encoder is

connected to the Drive.

The Drive detects the exact points of polarity reversal of the (sine wave)

outputs. It would not be possible to identify these accurately on an

oscilloscope as in the case of standard encoders.

During this procedure, the motor shaft will be rotated

suddenly to a new position. Before starting, make sure it

will be safe for the motor shaft to be rotated.

Warning

1 Disconnect the motor from the Drive.

2 Ensure the shaft is unloaded and free to rotate.

3 Apply a direct current of 50% of the motor rated current through the

motor windings, as shown in Figure B–1.

Figure B–1 Connecting a motor to a DC source for mechanically aligning the

encoder shaft

The motor shaft will rotate to one of several positions depen ding on the

number of pole-pairs. For example, the shaft of a 6-pole motor will stop at

one of three places.

IN-COS encoder –

UD52 User Guide

Issue code: 52nu3

B-2

The encoder position is indicated by parameter 16.04 S

incremental position (coarse). The value will be given by:

n

Nopolepairs[. ]

××16384

Page 33

If the encoder is correctly aligned, the value of n will always be an integer

(varying from 0 to [number of pole pairs – 1). For a 6-pole motor, this value

would be 0, 1 or 2 depending on the shaft position. The value of 16.04 will

then be one of the following:

0

5461

10923

If the encoder is not aligned with the motor windings, 16.04 w ill indicate

other values (n will not be an integer). To align the encoder, continue to

pass direct current through the motor windings and rotate the encoder

relative to the motor until parameter 16.04 indicates one of the correct

values.

When the

configurations), ensure the value of parameter 16.09 SIN-COS encoder –

phase offset is zero.

0

16384××

[[]]

3

1

16384××

[[]]

3

2

16384××

[[]]

3

SIN-COS encoder is used for feedback (Stand-alone and Slave

UD52 User Guide

Issue code: 52nu3

B-3

Page 34

B-4

UD52 User Guide

Issue code: 52nu3

Page 35

C Diagnostics

C.1 Trip codes

The following trip codes are associated with the UD52:

Drive

display

SEP 9

Encoder DC supply short-circuit (terminals 44 and 45).

ENC.PH7 17

The SIN and COS connections from the encoder are incorrectly made or the phase

sequence of the motor connections is reversed.

SEP EC 35

Failure of the serial communications link to the encoder. Absolute position

information will then not be obtained. After rectifying the fault, remove then reconnect the

The trip could be due to any of the following:

Incorrect serial comms. connections (terminals 46 and 47)

Encoder

Encoder

Encoder

SEP EF 36

Fault in the SIN-COS encoder.

SEP.diS 180

The type of small option module that the Drive has been programmed to operate

with has been removed or is not fitted correctly.

Perform either of the following:

Ensure the appropriate type of small option module is correctly fitted

To operate the Drive in the present configuration, set parameter 00 at 1000 and

press the STOP/RESET key.

No. Conditions

AC supply to the Drive in order to obtain absolute position information.

DC supply not connected (terminals 44 and 45)

DC supply voltage incorrect (parameter 16.15)

DC supply failed

UD52 User Guide

Issue code: 52nu3

C-1

Page 36

C-2

UD52 User Guide

Issue code: 52nu3

Loading...

Loading...