Page 1

EF

www.controltechniques.com

User Guide

SM-Universal

Encoder Plus

Solutions module for

Unidrive SP

Part Number: 0471-0005-06

Issue Number: 6

Version: 04.xx.xx

Page 2

General Information

The manufacturer accepts no liability for any consequences resulting from

inappropriate, negligent or incorrect installation or adjustment of the optional

operating parameters of the equipment or from mismatching the variable speed

drive with the motor.

The contents of this guide are believed to be correct at the time of printing. In the

interests of a commitment to a policy of continuous development and improvement,

the manufacturer reserves the right to change the specification of the product or its

performance, or the contents of this guide, without notice.

All rights reserved. No parts of this guide may be reproduced or transmitted in any

form or by any means, electrical or mechanical including photocopying, recording or

by an information storage or retrieval system, without permission in writing from the

publisher.

Drive software version

The SM-Universal Encoder Plus can only be used with drive software version

00.11.00 onwards.

Some features of the SM-Universal Encoder Plus may not be available if the drive

software is not the latest version (01.07.00)

Option module software version

The issue 4 SM-Universal Encoder Plus option module must only be programmed

with software versions 04.xx.xx.

Failure to comply with this will result in module failure.

Copyright © May 2005 Control Techniques Drives Ltd

Issue Code: 6

Page 3

Contents

1 How to use this guide ................................................... 5

1.1 Intended personnel .................................................................................5

1.2 Information .............................................................................................. 5

2 Safety Information ......................................................... 6

2.1 Warnings, Cautions and Notes ...............................................................6

2.2 Electrical safety - general warning ..........................................................6

2.3 System design and safety of personnel ..................................................6

2.4 Environmental limits ................................................................................7

2.5 Compliance with regulations ...................................................................7

2.6 Motor ....................................................................................................... 7

2.7 Adjusting parameters ..............................................................................7

3 Introduction .................................................................... 8

3.1 Features .................................................................................................. 8

3.2 Solutions Module identification ................................................................8

3.3 Set-up parameters ..................................................................................9

3.4 Compatible with encoder types ...............................................................9

4 Encoder feedback selection ....................................... 18

4.1 Encoder selection ..................................................................................18

4.2 Considerations ...................................................................................... 20

4.3 Drive resolution / Feedback accuracy ...................................................22

5 Installing the SM-Universal Encoder Plus ................. 24

5.1 Solutions Module slots ..........................................................................24

5.2 Installation ............................................................................................. 24

5.3 Terminal descriptions ............................................................................26

5.4 Power supply .........................................................................................28

5.5 Encoder shield connections ..................................................................28

5.6 Grounding hardware .............................................................................29

6 Getting Started ............................................................. 37

6.1 Installation ............................................................................................. 37

6.2 Termination resistors .............................................................................44

6.3 Simulated encoder outputs ...................................................................45

6.4 Marker inputs ........................................................................................51

6.5 Marker outputs ......................................................................................51

6.6 Freeze inputs ........................................................................................52

6.7 Thermistor input ....................................................................................55

7 Encoder feedback positional information ................. 56

7.1 Encoder feedback positional information ..............................................56

8 Advanced Operation ................................................... 58

8.1 Serial communications ..........................................................................58

8.2 Electronic nameplate transfers ..............................................................66

SM-Universal Encoder Plus User Guide 3

Issue Number: 6 www.controltechniques.com

Page 4

9 Parameters ................................................................... 70

9.1 Introduction ............................................................................................70

9.2 Single line descriptions ..........................................................................71

9.3 Parameter descriptions ..........................................................................76

10 Diagnostics .................................................................. 98

10.1 Display ...................................................................................................98

10.2 Displaying the trip history ......................................................................99

10.3 Fault finding .........................................................................................103

11 Terminal Data .............................................................104

11.1 Encoder inputs SK2 .......................................................... ...................104

11.2 Simulated encoder outputs SK2 ..........................................................105

11.3 Drive encoder power supply ................................................................106

11.4 Encoder inputs PL1 .............................................................................107

11.5 Encoder outputs PL1 ...........................................................................107

4 SM-Universal Encoder Plus User Guide

www.controltechniques.com Issue Number: 6

Page 5

1 How to use this guide

1.1 Intended personnel

This guide is intended for personnel who have the necessary training and experience in

system design, installation, commissioning and maintenance.

1.2 Information

This guide contains information covering the identification of the Solutions Module,

terminal layout for installation, fitting of the Solutions Module to the drive, parameter

details and diagnosis information. Additional to the aforementioned are the

specifications of the Solutions Module.

SM-Universal Encoder Plus User Guide 5

Issue Number: 6 www.controltechniques.com

Page 6

2 Safety Information

2.1 Warnings, Cautions and Notes

A Warning contains information, which is essential for avoiding a safety hazard.

WARNING

A Caution contains information, which is necessary for avoiding a risk of damage to the

CAUTION

product or other equipment.

NOTE

A Note contains information, which helps to ensure correct operation of the product.

2.2 Electrical safety - general warning

The voltages used in the drive can cause severe electrical shock and/or burns, and

could be lethal. Extreme care is necessary at all times when working with or adjacent to

the drive.

Specific warnings are given at the relevant places in this User Guide.

2.3 System design and safety of personnel

The drive is intended as a component for professional incorporation into complete

equipment or a system. If installed incorrectly, the drive may present a safety hazard.

The drive uses high voltages and currents, carries a high level of stored electrical

energy, and is used to control equipment which can cause injury.

Close attention is required to the electrical installation and the system design to avoid

hazards either in normal operation or in the event of equipment malfunction. System

design, installation, commissioning and maintenance must be carried out by personnel

who have the necessary training and experience. They must read this safety information

and this User Guide carefully.

The STOP and SECURE DISABLE functions of the drive do not isolate dangerous

voltages from the output of the drive or from any external option unit. The supply must

be disconnected by an approved electrical isolation device before gaining access to the

electrical connections.

With the sole exception of the SECURE DISABLE function, none of the drive

functions must be used to ensure safety of personnel, i.e. they must not be used

for safety-related functions.

Careful consideration must be given to the functions of the drive which might result in a

hazard, either through their intended behaviour or through incorrect operation due to a

fault. In any application where a malfunction of the drive or its control system could lead

to or allow damage, loss or injury, a risk analysis must be carried out, and where

necessary, further measures taken to reduce the risk - for example, an over-speed

protection device in case of failure of the speed control, or a fail-safe mechanical brake

in case of loss of motor braking.

6 SM-Universal Encoder Plus User Guide

www.controltechniques.com Issue Number: 6

Page 7

The SECURE DISABLE function has been approved

EN954-1 category 3 for the prevention of unexpected starting of the drive. It may be

used in a safety-related application. The system designer is responsible for

ensuring that the complete system is safe and designed correctly acc ording to

the relevant safety standards.

1

Independent approval by BIA has been given for sizes 1 to 5.

2.4 Environmental limits

Instructions in the Unidrive SP User Guide regarding transport, storage, installation and

use of the drive must be complied with, including the specified environmental limits.

Drives must not be subjected to excessive physical force.

2.5 Compliance with regulations

The installer is responsible for complying with all relevant regulations, such as national

wiring regulations, accident prevention regulations and electromagnetic compatibility

(EMC) regulations. Particular attention must be given to the cross-sectional areas of

conductors, the selection of fuses or other protection, and protective earth (ground)

connections.

The Unidrive SP User Guide contains instruction for achieving compliance with specific

EMC standards.

Within the European Union, all machinery in which this product is used must comply

with the following directives:

98/37/EC: Safety of machinery.

89/336/EEC: Electromagnetic Compatibility.

2.6 Motor

Ensure the motor is installed in accordance with the manufacturer’s recommendations.

Ensure the motor shaft is not exposed.

Standard squirrel cage induction motors are designed for single speed operation. If it is

intended to use the capability of the drive to run a motor at speeds above its designed

maximum, it is strongly recommended that the manufacturer is consulted first.

Low speeds may cause the motor to overheat because the cooling fan becomes less

effective. The motor should be fitted with a protection thermistor. If necessary, an

electric forced vent fan should be used.

The values of the motor parameters set in the drive affect the protection of the motor.

The default values in the drive should not be relied upon.

It is essential that the correct value is entered in parameter 0.46 (Pr 5.09) motor rated

current. This affects the thermal protection of the motor.

1

as meeting the requirements of

2.7 Adjusting parameters

Some parameters have a profound effect on the operation of the drive. They must not

be altered without careful consideration of the impact on the controlled system.

Measures must be taken to prevent unwanted changes due to error or tampering.

SM-Universal Encoder Plus User Guide 7

Issue Number: 6 www.controltechniques.com

Page 8

3Introduction

3.1 Features

The SM-Universal Encoder Plus allows for various types of feedback device to be

connected to the Unidrive SP, and to be configured for either reference or main

feedback. The SM-Universal Encoder Plus also has a simulated encoder output which

can be programmed to operate in either Ab, Fd or SSI mode (software simulation). Or

alternatively use a hardware simulated encoder output from either the modules encoder

input or the drives main encoder input. No scaling is possible with the hardware

simulated encoder outputs.

A total of three Solutions Modules can be fitted to the drive at any one time, with these

being used for position and speed feedback. See Figure 5-1 Location of slots 1, 2 and 3

on the Unidrive SP on page 24

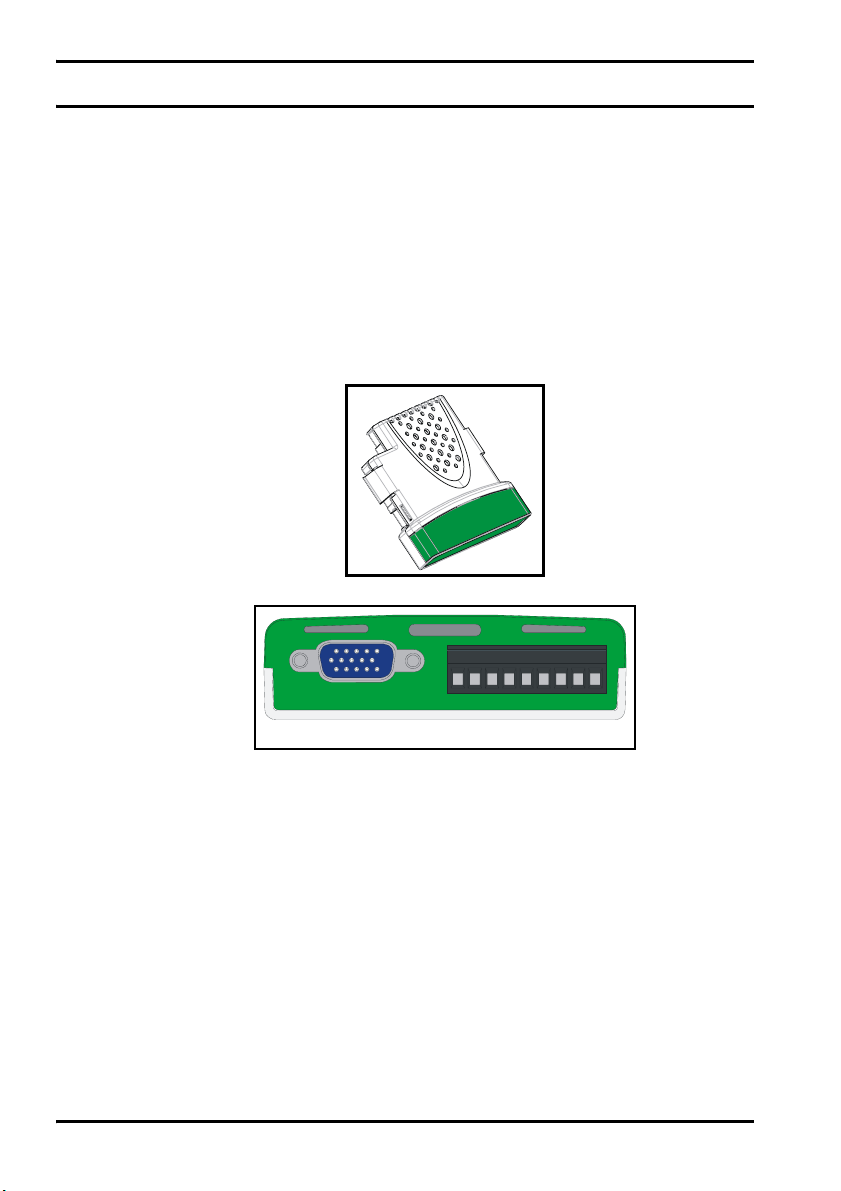

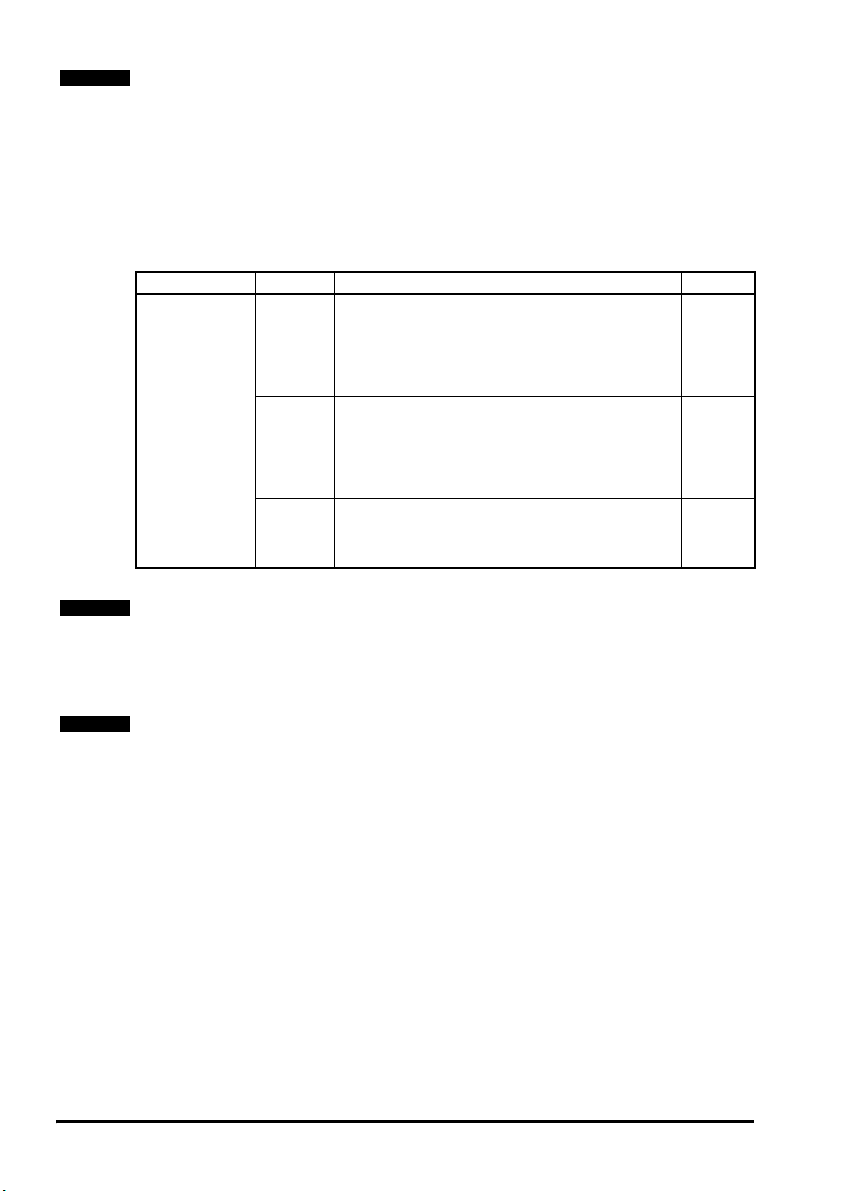

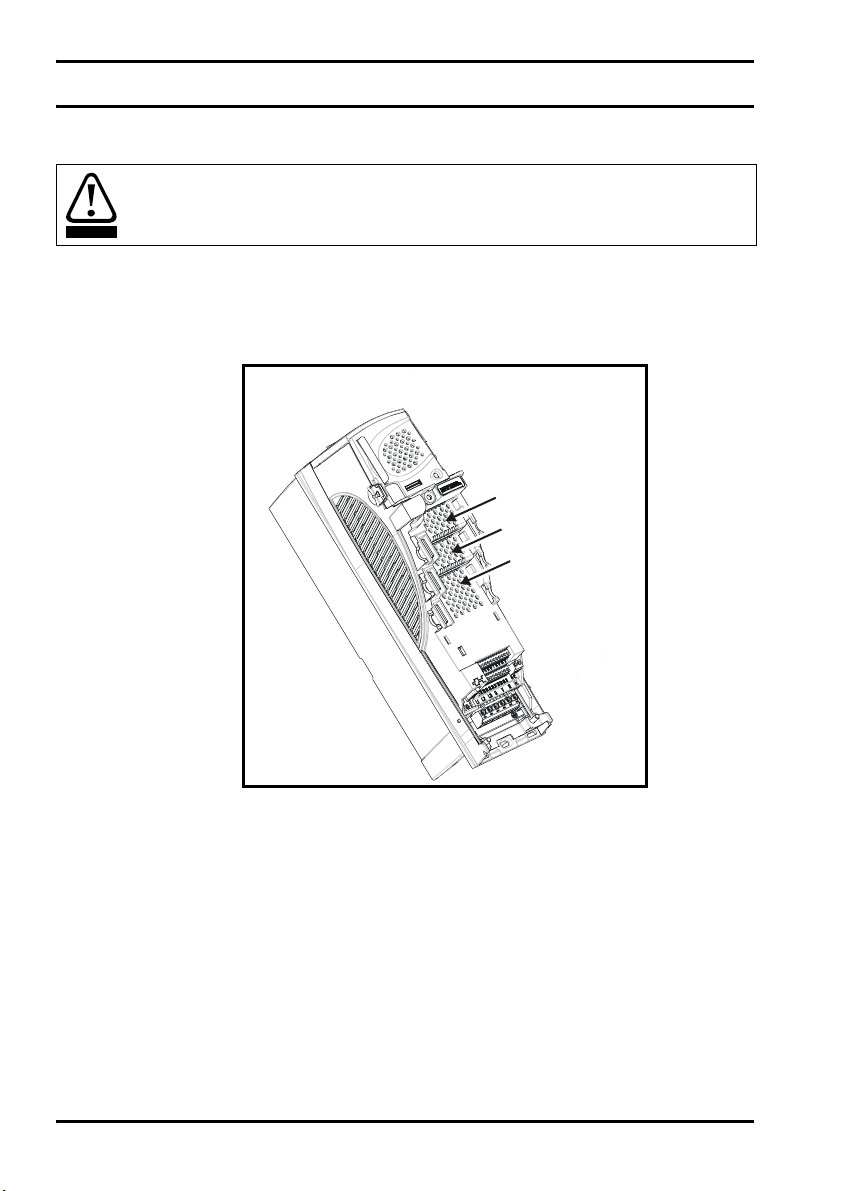

Figure 3-1 SM-Universal Encoder Plus

Figure 3-2 SM-Universal Encoder Plus connectors

234567189

SK2

PL1

3.2 Solutions Module identification

The SM-Universal Encoder Plus can be identified by:

1. The label located on the underside of the Solutions Module.

2. The colour coding across the front of the Solutions Module. All Unidrive SP

Solutions Modules are colour coded, with the SM-Universal Encoder Plus being

light green.

3. The packaging label which identifies the module as either an issue 3 or issue 4

module e.g (firmware V04.xx.xx being an issue 4 module).

4. Pr x.02 e.g (04.xx) being an issue 4 module (Pr x.02 where x refers to either menu

15, 16 or 17 as detailed in section 4.1).

8 SM-Universal Encoder Plus User Guide

www.controltechniques.com Issue Number: 6

Page 9

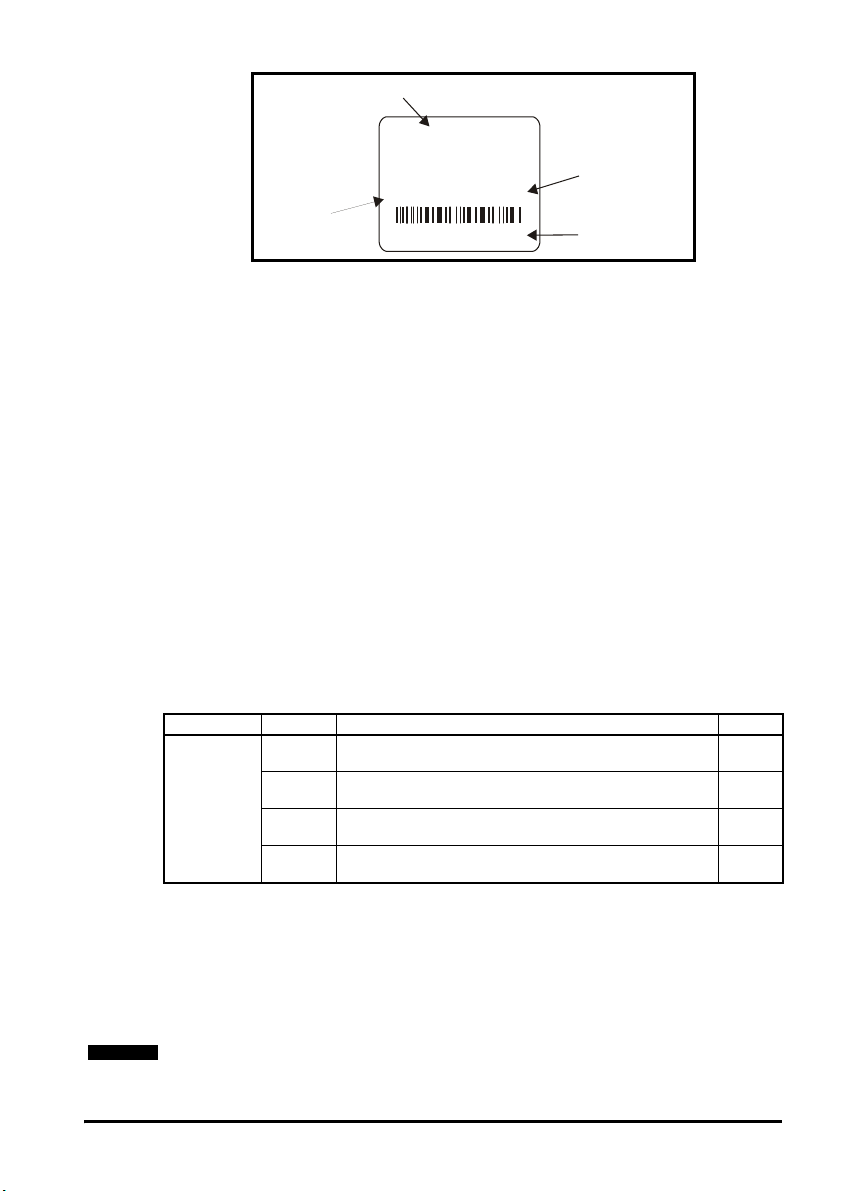

Figure 3-3 SM-Universal Encoder Plus label

e

Solutions Module

name

SM-Universal

Encoder Plus

Firmware

04.xx.xx

Firmware

Ser No : 3000005001

3.2.1 Date code format

The date code is split into two sections: a letter followed by a number.

The letter indicates the year, and the number indicates the week number (within the

year) in which the Solutions Module was built.

The letters go in alphabetical order, starting with A in 1990 (B in 1991, C in 1992 etc.).

Example:

A date code of L35 would correspond to week 35 of year 2002.

3.3 Set-up parameters

All parameters associated to the SM-Universal Encoder Plus can be found in either

menu 15, 16, or 17. Each of menus 15, 16, and 17 refer to one of the available slots into

which the SM-Universal Encoder Plus can be fitted. See Figure 5-1 on page 24.

3.4 Compatible with encoder types

The SM-Universal Encoder Plus will allow for the following encoders to be used with

Unidrive SP:

3.4.1 Incremental encoders Ab, Fd, Fr and SC

These types of encoders give incremental position and can only be used for control in

Closed Loop Vector mode, or alternatively could be used for operation in servo mode. If

used in servo mode a phasing test is required at every power-up.

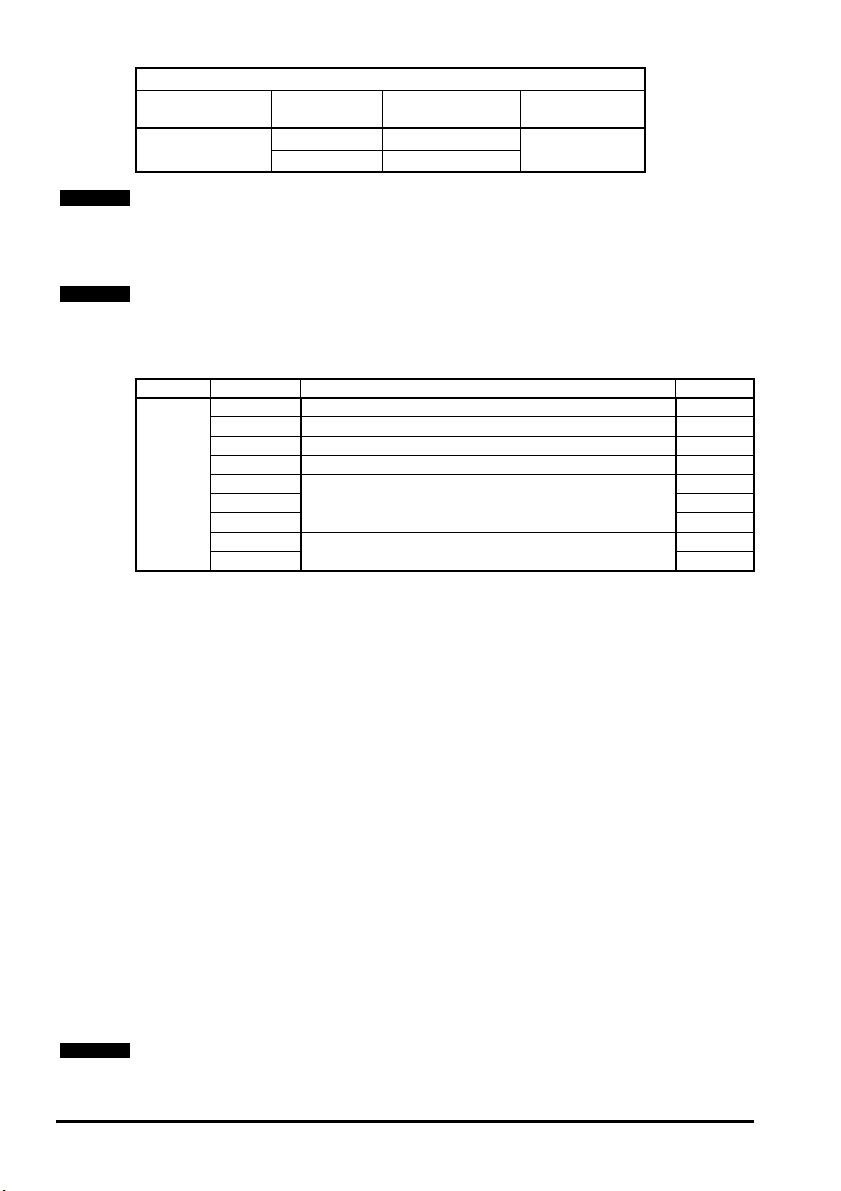

Type Encoder Description Pr x.15

Quadrature incremental encoder.

Ab

With or without marker pulse.

Incremental encoder with frequency and direction outputs.

Fd

Incremental

With or without marker pulse.

Incremental encoder with forward and reverse outputs.

Fr

With or without marker pulse.

SinCos encoder with no serial communications

SC

No optional marker pulse.

StdJ41

Customer

and date cod

Serial number

0

1

2

6

Quadrature detection logic determines rotation from the phase relationship of the two

channels.

These encoders are available with a marker pulse, which identifies each individual

rotation of the disc, and is also used to reset the drive position parameter. The

incremental encoder can be used when operating in Closed Loop Vector mode, with the

optional marker pulse not being required for correct operation.

NOTE

With this type of feedback the Unidrive SP must carry out a phasing test to find the phase

offset angle on power up for operation in servo mode.

SM-Universal Encoder Plus User Guide 9

Issue Number: 6 www.controltechniques.com

Page 10

NOTE

NOTE

SC

In this case the incremental positional information and rotation is determined from the

phase relationship of the analogue sine/cosine feedback signals. The incremental

SinCos encoder can be used when operating in the Closed Loop Vector mode.

Refer to for section 3.4.6 Comms only, (absolute encoders) SSI and EndAt on page 15

for further information on the SinCos encoder feedback signals.

Limitations

Type Encoder Max Input Frequency Max no. of Lines (LPR)

Ab

Incremental

Fd 600kHz*

Fr

SC

115kHz* (full resolution)

250kHz (reduced resolution)

50,000

* Max input frequency = LPR x max rpm / 60

The maximum speed in rpm which an encoder connected to the SM-Encoder Plus can

reach can be calculated from:

Max rpm = (60 x Max input frequency) / Encoder LPR

e.g. For a 4096 line encoder the maximum rpm would be:

(60 x 600 x 10

3

) / 4096 = 8789rpm

NOTE

The absolute maximum input frequency for any SC, SinCos encoder used with the SMUniversal Encoder Plus is 250 kHz.

NOTE

With this type of feedback the Unidrive SP must carry out a phasing test to find the phase

offset angle on power up for operation in servo mode.

3.4.2 SinCos encoder feedback signals

For the SinCos encoder to be compatible with the SM-Universal Encoder Plus, the

output signals from the encoder must be a 1V peak to peak differential voltage (across

sinref to sin and cosref to cos).

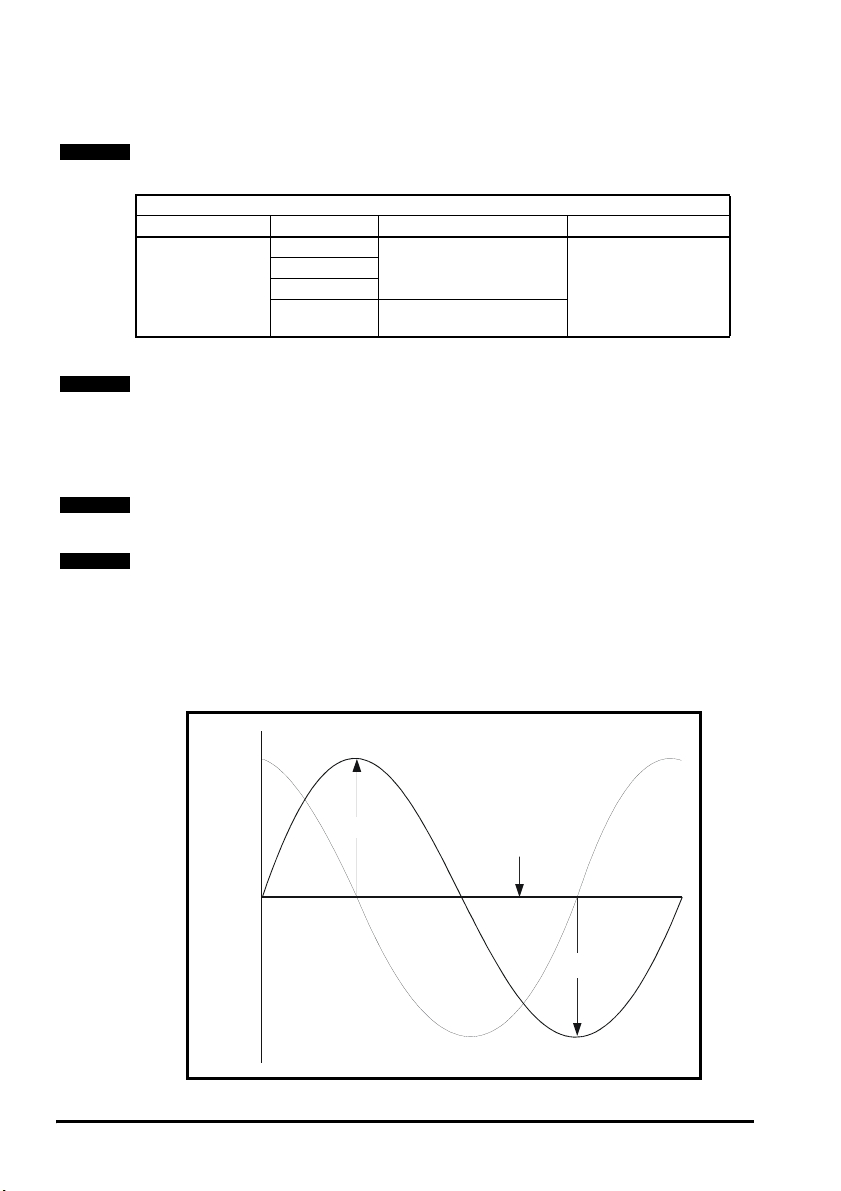

Figure 3-4 Stegmann SinCos encoder feedback signals

0.5 Vdc

2.5Vdc

SIN

COS

REFSIN,

REFCOS

.

0.5 Vdc

10 SM-Universal Encoder Plus User Guide

www.controltechniques.com Issue Number: 6

Page 11

Stegmann

s

Stegmann encoders typically have a 2.5Vdc offset. The sinref and cosref are a flat DC

level at 2.5Vdc and the cos and sin signals have a 1V peak to peak waveform biased at

2.5Vdc.

The result is a 1V peak to peak differential voltage as show in Figure 3-4.

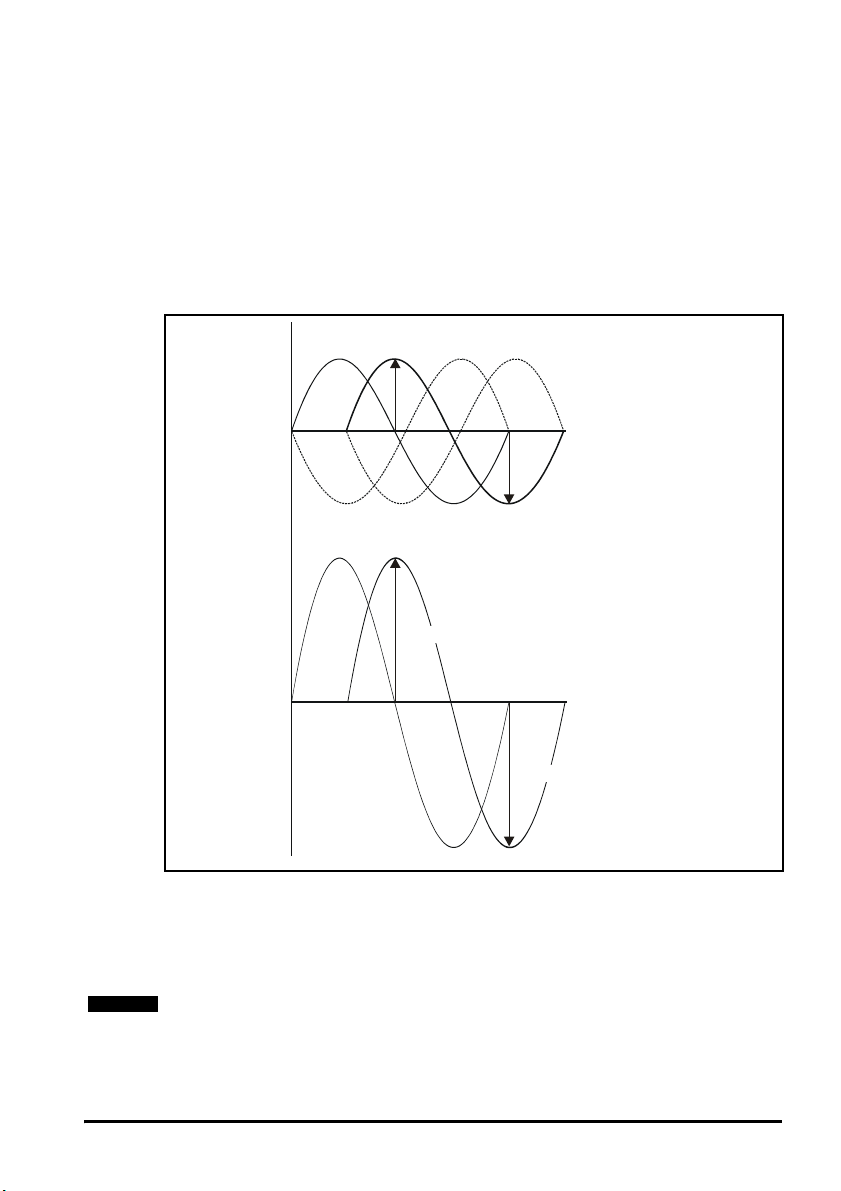

Heidenhain

The Heidenhain Sin and Cos signals with respect to zero volts are offset at 2.5Vdc as

shown in Figure 3-5.

The feedback signals which are seen by the SM-Universal Encoder Plus are the

differential signals Sin - Sin\ and Cos - Cos\ as in Figure 3-5, these being 90° phase

shifted and at 1Vdc peak to peak.

Figure 3-5 Heidenhain SinCos encoder feedback signals

0.25Vdc

NOTE

2.5Vdc

COS

SIN

SIN, COS signals

with respect to 0V

(offset at 2.5Vdc)

COS ref SIN ref

0.25Vdc

0.5Vdc

Differential signal

received by

SM-Universal

Encoder Plus

0Vdc

SIN

COS

0.5Vdc

Encoders are available which have a 1V peak to peak voltage on sinref, sin, cos and

cosref. This results in a 2V peak to peak voltage seen at the Solutions Module terminals.

The drive will still function with this type of encoder, however reduced performance in

the form of speed and torque ripple at four times the line rate will result.

(line rate = no. of lines per revolution x revolutions per second.)

It is recommended that encoders of this type are not used with Unidrive SP, and that the

encoder feedback signals should meet the above parameters (1V peak to peak).

SM-Universal Encoder Plus User Guide 11

Issue Number: 6 www.controltechniques.com

Page 12

3.4.3 SinCos Signal Values

When operating with a SinCos encoder, which has no comms or commutation signal

inputs (Pr x.15 = 6), the internal differential SinCos signal values are written to both

Pr x.42 (Sin) and Pr x.43 (Cos) as an unsigned numbers.

For further details refer to both Pr x.42 and Pr x.43

3.4.4 Incremental plus commutation, (absolute encoders) Ab.SErvo, Fd.SErvo, Fr.SErvo and SC.SErvo.

Type Encoder Description Pr x.15

Quadrature incremental encoder with commutation

outputs.

With or without marker pulse.

Incremental encoder with frequency, direction and

commutation outputs.

With or without marker pulse.

Incremental encoder with forward, reverse and

commutation outputs

With or without marker pulse.

Absolute SinCos encoder plus commutation signals

without marker pulse.

3

4

5

12

NOTE

Ab.SErvo

Incremental

plus

commutation

(absolute

encoders)

Fd.SErvo

Fr.SErvo

SC.SErvo

The incremental encoder with commutation works in the same way as the incremental

encoder except that multiple channels are used to give a discrete code for every

position increment.

When operating the drive in closed loop servo absolute position of the machine shaft is

required as soon as the drive is enabled. Because the marker signal is not effective until

the shaft passes a particular position, this cannot be used to determine the absolute

position. Therefore an encoder with additional commutation is required.

The U, V and W commutation signals should have a period that is one electrical

revolution as shown in Figure 3-6.

Therefore with a 6 pole machine the U, V and W commutation signals will repeat three

times per mechanical revolution, or with an 8 pole machine four times per mechanical

revolution etc.

The U, V and W commutation signals are used when the drive is enabled to locate the

position of the machine shaft within 60° electrical so that the current vector can be

applied within 30° electrical either side of the correct position for maximum torque

production. At certain positions of the shaft, the torque capability of the drive during this

period is reduced to 0.866 of the nominal level during initialisation.

Once the shaft has moved through a maximum of 60° electrical, one of the U, V or W

signals will change state. The location of the waveform edge is used to locate the

machine position exactly. This information is then stored by the option module and used

until power-down to place the current vector in the correct position for maximum torque.

To ensure that this process is carried out correctly the control algorithm waits for two

changes of the state of the U,V and W waveforms, at this point there will be no

additional torque ripple and maximum torque is available for all shaft positions.

Using this type of encoder does not result in any jump in position when the drive is first

enabled after power-up, but only the small reduction in specification described above for

the first 60 to 120° electrical of movement.

12 SM-Universal Encoder Plus User Guide

www.controltechniques.com Issue Number: 6

Page 13

NOTE

In Ab.SErvo, Fd.SErvo or Fr.SErvo mode only, the value in Pr x. 42 provides information

on the commutation signal inputs (UVW). Pr x.42 permits the user to determine the

current segment and status of the commutation signal inputs.

For further details refer to Pr x.42

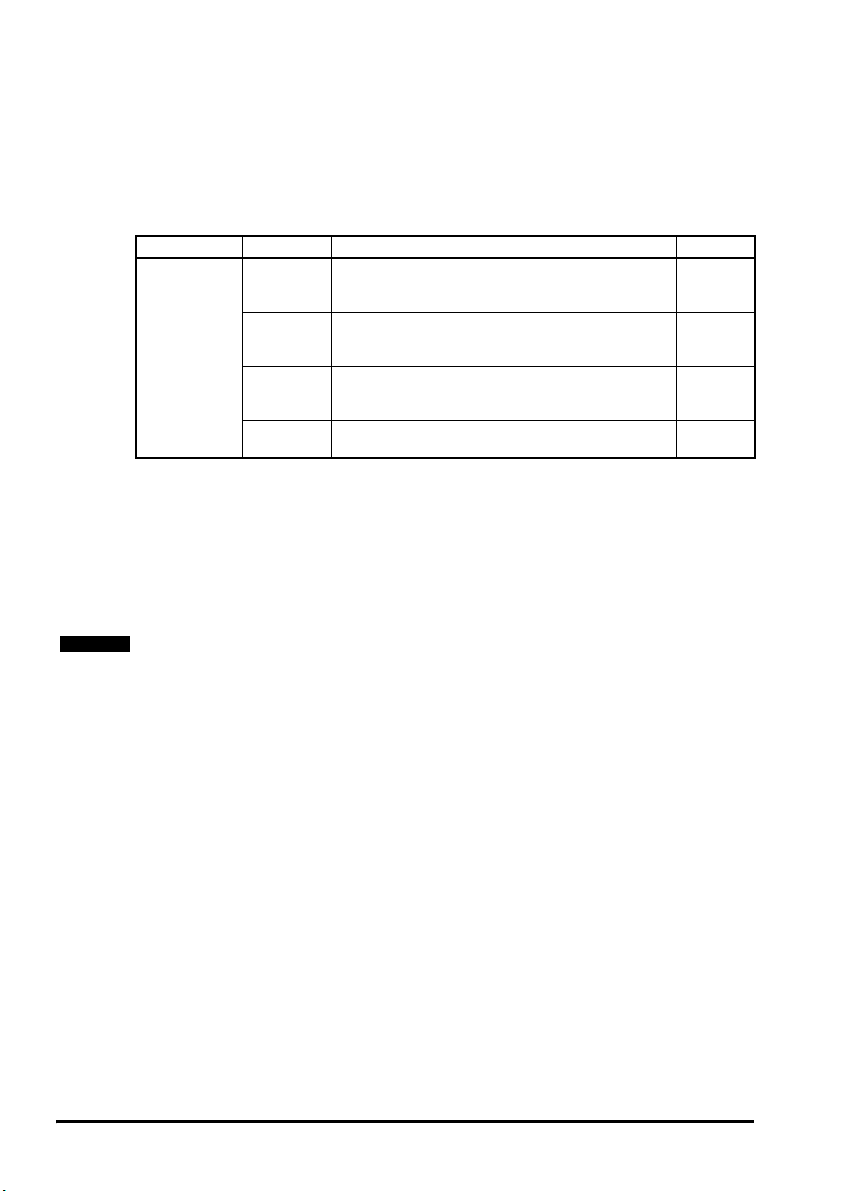

Figure 3-6 Example of encoder feedback signals

360 electrical degrees (encoder)

°

A

Incremental

/A

signals

B

/B

90 separation of A and B

°

Z

min

max

Marker

signals

/Z

Index

alignment

reference

U

Commutation

signals

V

W

1

/

3

1

/

2

2

/

3

1

Mechanical revolution

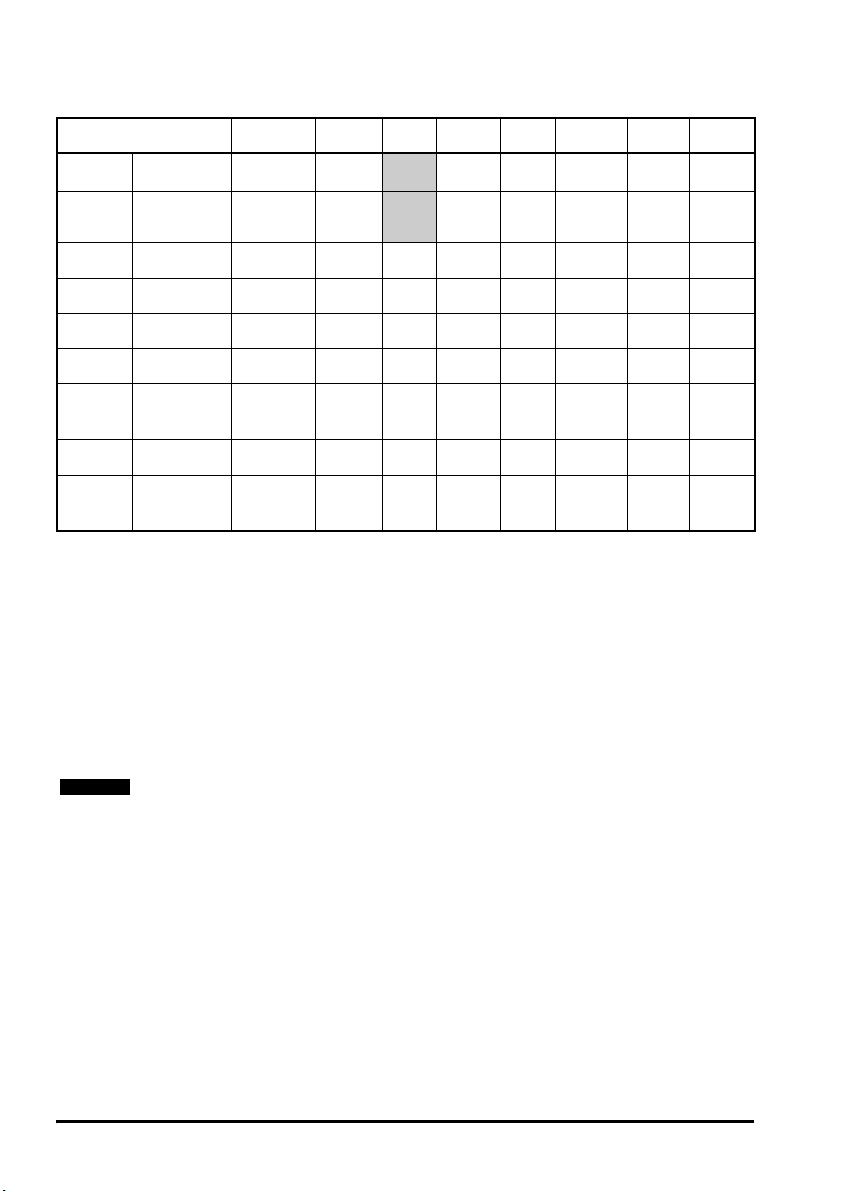

Limitations

Type Encoder Max Input Frequency Max no. of

Ab.SErvo

Incremental

plus

commutation

Fd.SErvo

Fr.SErvo

SC.SErvo

250kHz (reduced resolution)

600kHz*

115kHz* (full resolution)

Lines (LPR)

50,000

* Max input frequency = LPR x max rpm / 60

SM-Universal Encoder Plus User Guide 13

Issue Number: 6 www.controltechniques.com

Page 14

NOTE

The maximum speed in rpm which an encoder connected to the SM-Universal Encoder

Plus can reach can be calculated from:

Max rpm = (60 x Max input frequency) / Encoder LPR

e.g. For a 4096 line encoder the maximum rpm would be:

(60 x 600 x 10

3

) / 4096 = 8789rpm

3.4.5 Incremental plus comms (absolute encoders) SC.HiPEr, SC.EndAt and SC.SSI

Type Encoder Description Pr x.15

Absolute SinCos encoder using Stegmann RS485

comms protocol (HiperFace).

The option module checks the position from the sine

and cosine waveforms against the internal encoder

position using serial communications.

If an error occurs the drive trips.

Absolute SinCos encoder using EndAt comms

protocol

The option module checks the position from the sine

and cosine waveforms against the internal encoder

position using serial communications.

If an error occurs the drive trips.

Absolute SinCos encoder using SSI comms protocol

The option module checks the position from the sine

and cosine waveforms against the internal encoder

position using serial communications.

Incremental

plus

comms

(absolute

encoders)

SC.HiPEr

SC.EndAt

SC.SSI

7

9

11

NOTE

It should be noted that the SC.HiPEr, SC.EndAt and SC.SSI encoders must be initialised

before their position data can be used. The encoder is automatically initialised at powerup, after all trips are reset, or when the initialisation parameter (Pr 3.47) is set to 1. If the

encoder is not initialised or the initialisation is invalid, the Solutions Module initiates a trip

7, and the drive will trip on SLX.Er.

NOTE

A flux alignment test is required during set up to determine the phase offset angle for

operation in servo mode.

The SC.HiPEr and SC.EndAt encoders can be considered as a mixture of an

incremental encoder (analogue SinCos feedback signals) and an absolute encoder

(serial link used for absolute position). The only difference between the encoders being

the serial link protocol.

The RS 485 serial link allows the drive at power up to interrogate the SinCos encoder in

comms channel order to determine the initial absolute position of the encoder shaft.

When the interrogation is complete and the initial absolute position is known the position

is incremented from the absolute value using the analogue sine/cosine interface.

The comms channels can then be used for either error checking, Pr x.17 or data

transfer, Pr x.42 to Pr x.43. The incremental SinCos encoder can be used when

operating in either Closed Loop Vector or Closed Loop Servo modes.

14 SM-Universal Encoder Plus User Guide

www.controltechniques.com Issue Number: 6

Page 15

Limitations

Type Encoder Max Input Frequency * Max no. of

Incremental plus

commutation

SC.HiPEr

SC.EndAt

SC.SSI

115khz (full resolution)

250kHz (reduced resolution)

* Max input frequency = LPR x max rpm / 60

Lines (LPR)

50,000 9600k

Max Baud

Rate (bits/s)

2M

NOTE

The maximum speed in rpm which an encoder connected to the SM-Encoder Plus can

reach can be calculated from:

Max rpm = (60 x Max input frequency) / Encoder LPR

e.g. For a 4096 line encoder the maximum rpm would be:

3

) / 4096 = 8789rpm

NOTE

(60 x 600 x 10

The absolute maximum input frequency for any SC, SinCos encoder used with the SMUniversal Encoder Plus is 250 kHz.

3.4.6 Comms only, (absolute encoders) SSI and EndAt

Type Encoder Description Pr x.15

Absolute EndAt only encoder

Additional communications with the encoder is not

possible.

Absolute SSI only encoder.

SSI

Additional communications with the encoder is not

possible.

NOTE

Comms

EndAt

(absolute)

It should be noted that EndAt and SSI encoders must be initialised before their position

data can be used. The encoder is automatically initialised at power-up, after trips 1 - 8

are reset, or when the initialisation parameter (Pr 3.47) is set to 1. If the encoder is not

initialised or the initialisation is invalid the Solutions Module initiates a trip 7, and the drive

will trip on SLX.Err.

SSI, EndAt

Encoders with either an EndAt (transfer standard from Heidenhain) or SSI

(Synchronous Serial) interface can transmit data synchronised with a CLOCK signal

provided from the drive. This makes it possible to transmit position values quickly and

reliably with only four signal lines.

The main difference between the SSI and the EndAt being that the standard SSI

encoder is Uni-directional whereas the EndAt is Bi-directional. The data transfer for both

the SSI and the EndAt takes the form of EIA Standard RS 485.

The SSI (Synchronous Serial interface) and EndAt (Encoder Data) encoders have a

serial link between the encoder and drive which passes all positional information.

The encoder operates in the following manner:

1. A clock signal at a user defined frequency is sent out to the encoder.

2. Once a downward latching signal is detected by the encoder.

3. Followed by the data request.

4. The encoder then returns data to the drive at the clock frequency.

8

10

SM-Universal Encoder Plus User Guide 15

Issue Number: 6 www.controltechniques.com

Page 16

Limitations

Type Encoder Max Baud

Comms Only

EndAt 2Mbits/sec

SSI 2Mbits/sec

Rate (bits/sec)

Max Speed

rpm

40,000rpm

NOTE

The SSI input at default is configured to operate in Gray code through Pr x.18, this can

be configured to operate in binary format by setting Pr x.18 = 1. The simulated SSI

encoder output will operate with both binary format and Gray code, the mode being

configured through Pr x.28.

NOTE

A flux alignment test is required during set up to determine the phase offset angle for

operation in servo mode.

3.4.7 Linear Encoders

Type Encoder Description Pr x.15

Ab.SErvo Digital hall effect + Linear quadrature incremental encoder 3

SC.SErvo Digital hall effect + Linear SinCos incremental encoder 12

SC.HiPEr

SC.EndAt 9

SC.SSI 11

EndAt

NOTE

Linear

encoder

Linear Quadrature / SinCos Encoder

These types of encoder are purely incremental and have no information for

commutation. With this type of feedback the Unidrive SP must carry out a phasing test

to find the phase offset angle on every power up for operation in servo mode.

Digital Hall Effect + Linear Quadrature / SinCos Incremental encoder

These types of encoder have digital hall effect signals U, V, W plus complements that

supply the necessary signals for deriving the position at power-up. The quadrature

signals, incremental or SinCos are used for speed feedback. A flux alignment test is

required during set-up to determine the phase offset angle for operation in servo mode.

Linear Absolute SinCos encoder

These types of encoder derive the absolute position at power-up via the comms

protocol, Hiperface, EndAt or SSI with the incremental signals, SinCos, being used for

incremental position and speed feedback.

A flux alignment test is required during set-up to determine the phase offset angle for

operation in servo mode.

Linear Absolute encoder

These types of feedback are comms only encoders, which derive the position at powerup via either the EndAt or SSI comms protocols. The position feedback is also passed

via comms during operation. The comms only encoders operate with the drive being the

master and passing the required clock signal. A flux alignment test is required during

set-up to determine the phase offset angle for operation in servo mode.

Refer to section 3.4.2 SinCos encoder feedback signals on page 10 for further

information on the SinCos encoder feedback signals.

Ab Linear quadrature encoder 0

SC Linear SinCos encoder 6

Linear absolute SinCos encoder

Linear absolute encoder

SSI 10

7

8

16 SM-Universal Encoder Plus User Guide

www.controltechniques.com Issue Number: 6

Page 17

NOTE

Type Encoder Max input frequency Max no. of

Ab

Ab.SErvo

SC

Linear

encoder

SC.SErvo

SC.HiPEr 9600k

SC.EndAt

SC.SSI

EndAt

250kHz (reduced resolution)

SSI

Limitations

600kHz

115kHz (full resolution)

lines

50,000

Max baud

rate

2Mbits/sec

In some applications using Closed Loop Vector control, the maximum speed of the

system is above the speed at which the encoder feedback frequency is too high to be

used by the drive. For these types of applications Pr 3.24 Closed Loop Vector Mode

should be set to 2 (Closed Loop Vector Mode with no maximum speed limit) for low

speed operation and 3 (Closed Loop Vector Mode without position feedback and with

no maximum speed limit) for high-speed operation. It should be noted that the drive no

longer checks that the maximum encoder frequency cannot be exceeded, and so the

user must ensure that Pr 3.24 is set to 3 before the encoder frequency limit is reached.

SM-Universal Encoder Plus User Guide 17

Issue Number: 6 www.controltechniques.com

Page 18

4 Encoder feedback selection

4.1 Encoder selection

The SM-Universal Encoder Plus option module supports a total of 12 encoder types.

These range from Quadrature relative encoders to Quadrature plus Commutation,

SinCos plus Comms and Comms only absolute encoders.

When selecting an encoder there are essentially two groups these being absolute and

relative. Absolute encoders providing the absolute position at power-up to the drive and

only requiring a phasing test during the initial set-up when used for closed loop servo

operation. Relative encoders requiring a phasing test at every power up when used for

closed loop servo operation.

Either absolute or relative encoders can be used for closed loop vector operation.

4.1.1 Absolute encoders

The absolute encoders which are compatible with Unidrive SP are as follows:

• Ab.SErvo, Fd.SErvo, Fr.SErvo, SC.SErvo

• SC.HiPEr, SC.EndAt, SC.SSI

• EndAt, SSI

4.1.2 Non absolute encoders

At power up the encoder counters will start to increment from the incremental position

as the encoder rotates, the position is reset to zero on detection of the first marker.

Compatible relative encoders being:

• Ab, Fd, Fr

•SC

4.1.3 Standard feedback

Basic encoder (Ab, Fd, Fr)

• 6 wire (+ 2 for marker if required)

• Up to 50,000ppr

• Ab - quadrature signals (best noise immunity)

• Fd - frequency and direction

• Fr - forward and reverse

• Marker input (only connect if needed, low noise immunity)

• Freeze based directly on the encoder counter

• Termination control

• Wirebreak detection

NOTE

A quadrature encoder will provide sufficient performance for most applications once tuned.

Servo encoders (Ab.SErvo, Fd.SErvo, Fr.SErvo, SC.SErvo)

• 12 wire (+ 2 for marker if required not SC.SErvo)

• Commutation signals used for motor control until two valid changes

• Ab, Fd, Fr and SC signals used for motor control after initial movement, and

continuously for speed feedback.

• PPR non power of 2 from S/W version 1.06.01

• Marker input (not SC.SErvo)

• Freeze based directly on the encoder counter

• Termination control (not for commutation signals)

• Wirebreak detection

• Phase error detection based on commutation signals

18 SM-Universal Encoder Plus User Guide

www.controltechniques.com Issue Number: 6

Page 19

Non-absolute SINCOS encoder (SC)

•6 wire

• Nominally the feedback resolution is sine waves per revolution plus 9 additional bits

of interpolation information

• High resolution speed feedback, generally for induction motors but also servo

motors with use of minimal movement phasing test

• No marker input

• Freeze is based on the time of the freeze event and interpolation between samples

• Wirebreak detection

• Initialisation required to align the analogue signals with the encoder counter

4.1.4 High resolution feedback

Stegmann Hiperface SINCOS encoders (SC.HiPEr)

•8 wire

• 8 - 12V supply

• Absolute position determined via asynchronous comms

• Nominally the feedback resolution is sine waves per revolution plus 9 additional bits

of interpolation information

• No marker input

• Freeze is based on the time of the freeze event and interpolation between samples

• Wirebreak detection

• Auto-configuration is possible

• Encoder phase error detection using comms

• Comms includes message XOR checksum

• Initialisation required to obtain the absolute position via comms and to align the

analogue signals with the encoder counter

NOTE

An SC.HiPEr encoder will provide high performance and is recommended for precision

applications.

Heidenhain EndAt SINCOS encoders (SC.EndAt)

• 10 wire

• 5V supply

• Absolute position determined via synchronous comms

• Nominally the feedback resolution is sine waves per revolution plus 9 additional bits

of interpolation information

• No marker input

• Freeze is based on the time of the freeze event and interpolation between samples

• Wirebreak detection

• Encoder phase error detection using comms

• Comms includes CRC check

• Auto-configuration is possible

• Initialisation required to obtain the absolute position via comms and to align the

analogue signals with the encoder counter

• Compatible with EndAt 2.1

NOTE

An SC.EndAt encoder will provide high performance and is recommended for precision

applications.

SM-Universal Encoder Plus User Guide 19

Issue Number: 6 www.controltechniques.com

Page 20

NOTE

SSI SINCOS encoders (SC.SSI)

• 10 wire

• Absolute position determined via synchronous comms

• Nominally the feedback resolution is sine waves per revolution plus 9 additional bits

of interpolation information

• No marker input

• Freeze is based on the time of the freeze event and interpolation between samples

• Wirebreak detection

• Auto-configuration is not possible

• Encoder phase error detection using comms

• The comms protocol does not include any error checking

• Initialisation required to take the absolute position via comms and to align the

analogue signals with the encoder counter

• Gray code or binary format encoders

• Power supply fail bit monitoring

SSI only encoder (SSI)

•8 wire

• Position obtained via synchronous comms

• Not auto configurable, no error checking, too slow for use as motor feedback

• Feedback resolution defined by comms resolution

• No marker input

• Freeze is based on the time of the freeze event and interpolation between samples

• Wirebreak detection by comms error

• Gray code or binary format encoders

• Power supply fail bit monitoring

SSI only encoders are not recommended for use as motor feedback, but can be used

for either positioning or reference.

EndAt only encoders (EndAt)

•8 wire

• 5V supply

• Position obtained via synchronous comms

• Feedback resolution defined by comms resolution

• No marker input

• Freeze is based on the time of the freeze event and interpolation between samples

• Wirebreak detection by comms error

• Comms includes CRC check

• Auto-configuration is possible

• Compatible with EndAt 2.1 (present version)

• Will allow access to interpolated position, but not extended functions with EndAt 2.2

NOTE

An EndAt encoder will provide high performance and is recommended for precision

applications.

4.2 Considerations

When selecting an encoder there are a number of considerations, as follows, with these

being application, drive operation, and encoder specification dependant.

4.2.1 Application dependant

1. Operating mode

2. Is the application a positioning application where high resolution is required

20 SM-Universal Encoder Plus User Guide

www.controltechniques.com Issue Number: 6

Page 21

3. Is absolute position required at every power up, for example for operation in servo

mode where a phasing test is not possible at every power-up

4. What resolution is required (e.g. AB 1024 encoder = 10bit resolution, SC.HiPEr

1024 = 19 bit resolution)

5. What environment is the encoder to be installed in

6. What cable lengths are to be used (encoders with comms do have restricted cable

lengths due to comms baud rate)

7. Encoder supply voltage should be selected dependant upon the cable lengths due

to voltage drop

8. Are motor objects to be saved to the encoder

4.2.2 Drive operation dependant

1. When operating in closed loop servo mode the drive requires the absolute position

at power-up, be this from an absolute encoder or through a phasing test at every

power-up

2. When operating in closed loop vector either an absolute or non-absolute encoder

can be used

3. Encoder power supply and loading when operating with long cable lengths

4.2.3 Encoder specification dependant

1. Encoder voltage levels, are these compatible with the drive

2. Incremental encoder signals are these compatible (SC, Ab, Fr, Fd)

3. Incremental signals do not exceed maximum input frequency for option module

4. Comms encoder protocol is compatible (HiPEr, EndAt, SSI)

5. Comms encoder baud rate is compatible with drive

6. Application cable lengths do not exceed incremental signals cable length

7. Application cable lengths do not exceed the recommended cable length for comms

operation, this being baud rate specific.

8. Encoder loading does not exceed encoder power supply from module (external

power supply should be used if this is the case).

SM-Universal Encoder Plus User Guide 21

Issue Number: 6 www.controltechniques.com

Page 22

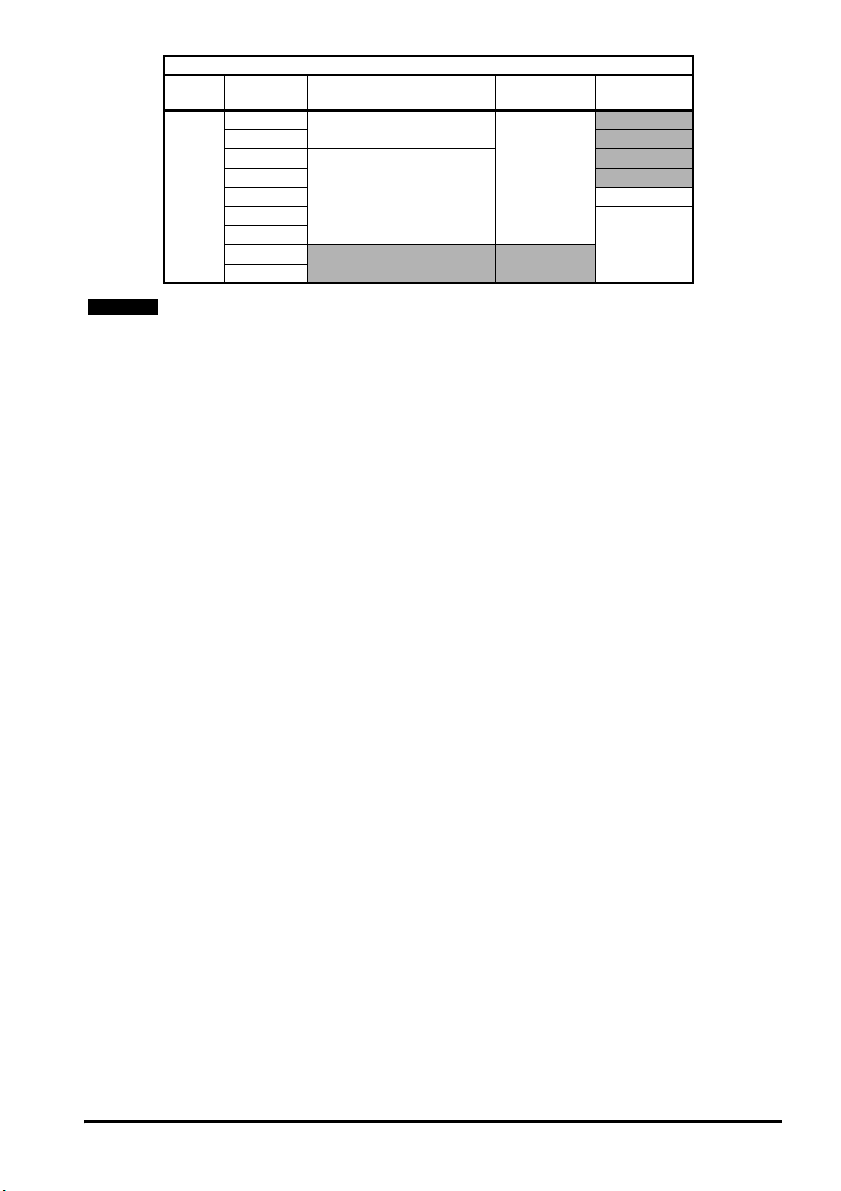

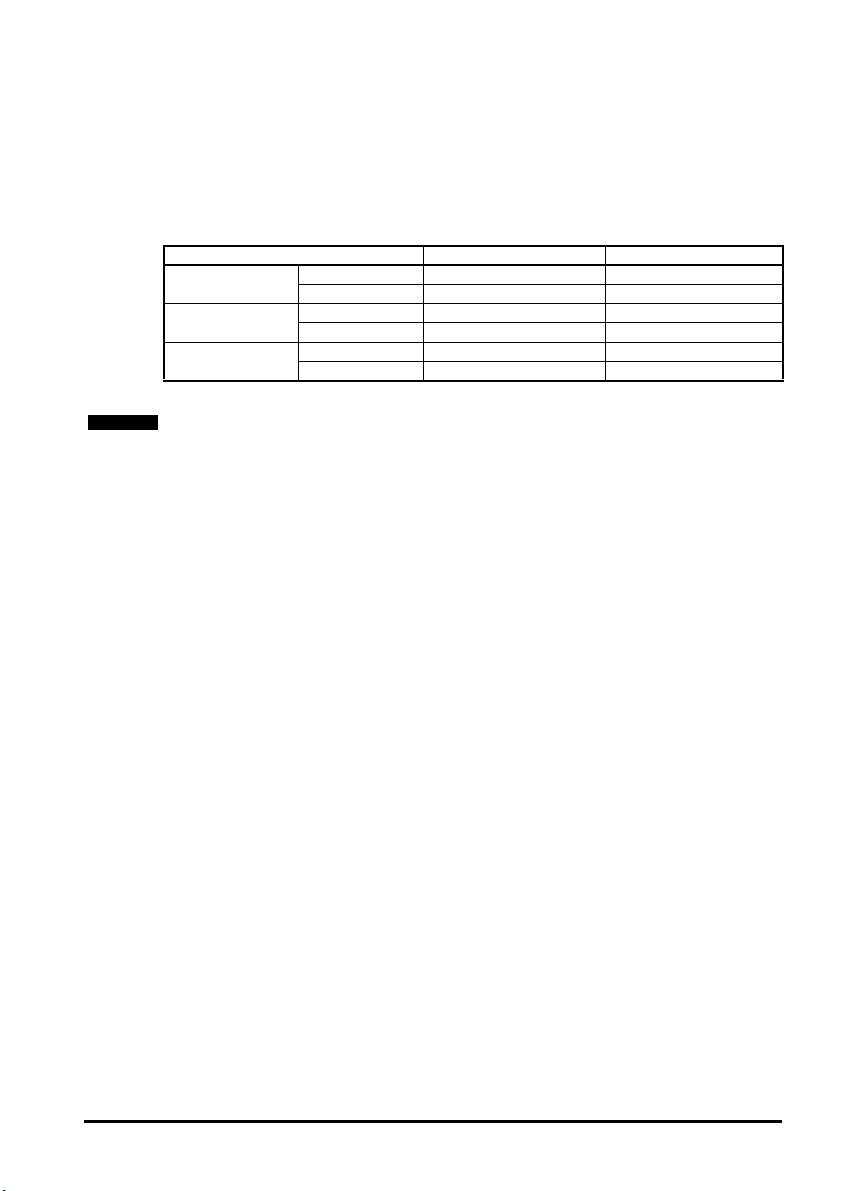

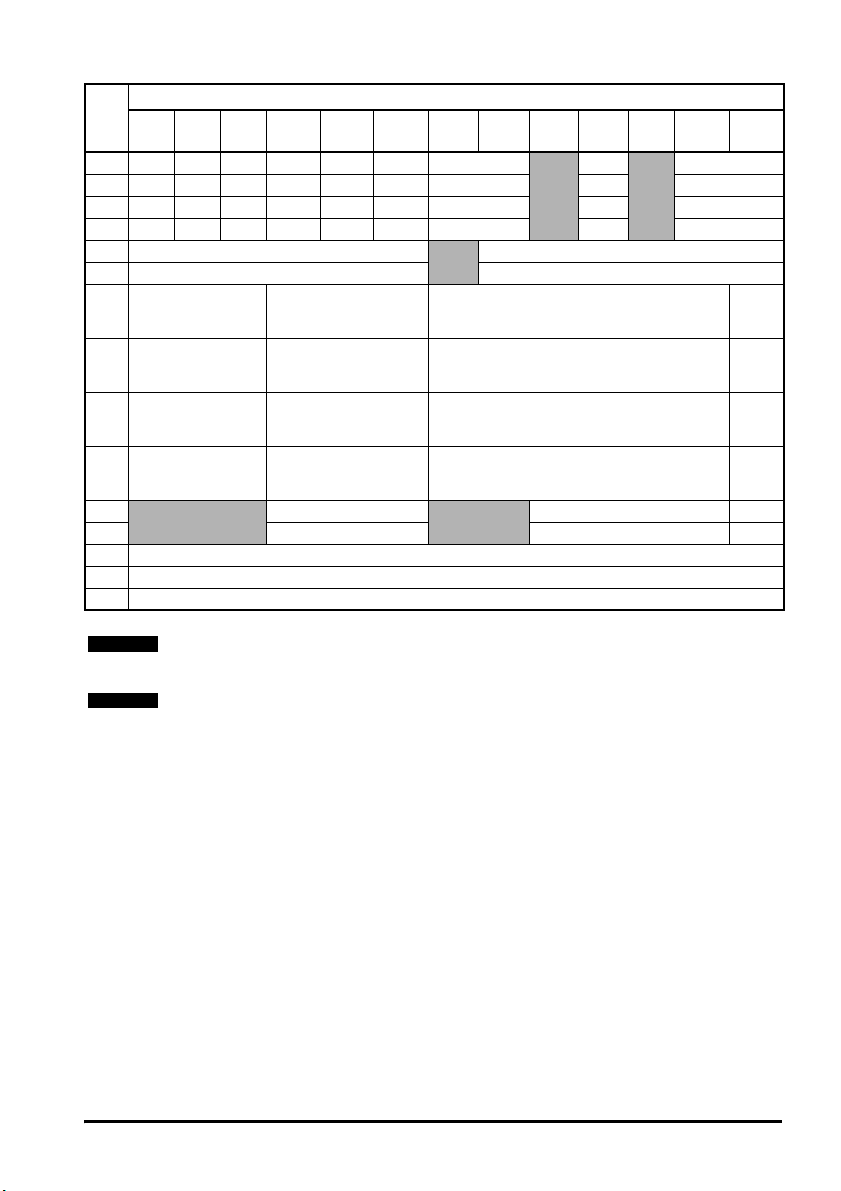

4.2.4 Encoder data

The following table compares compatible encoders for Unidrive SP

Type

AB, Fd, Fr

AB.SErvo

Fd.SErvo

Fr.SErvo

SinCos Incremental

SC.SErvo

SC.HiPEr

SC.EndAt

SC.SSI

EndAt Comms 15 Full

Incremental +

Marker

Incremental +

Commutation +

Marker

Incremental +

Commutation

Incremental +

Comms

Incremental +

Comms

Incremental +

Comms

SSI Comms 15 Full

Positional

Resolution

15bit None

15bit Cntrl.only

15bit + 9bit =

24bit

15 bits Full

15bit + 9bit =

24bit

15bit + 9bit =

24bit

15bit + 9bit =

24bit

Absolute

Mode

None

Full

Full

Full

Turns Cost Wires

Lowest 6 Fast

Low 12/14 Fast

Single

Medium 6 Fast

or Multi

Single

Medium 12 Fast

or Multi

Single

or Multi

Single

or Multi

Single

or Multi

Single

or Multi

Single

or Multi

High 8 Fast

High 10 Fast

High 10 Fast

High 6 Fast

Medium 6 Slow

4.3 Drive resolution / Feedback accuracy

The following values calculated are not a direct representation of performance at the

motor shaft, with the motors inductance and load inertia smoothing out the shaft value to

a much lower level. The value calculated is the instantaneous change in the internal

speed feedback value seen by the drive between sample periods, and when the

number of counts per revolution changes by 1 count.

This change is due to at any given speed it is unlikely that the number of counts per

sample period will always be a whole number i.e. 1 in 10 sample periods may have an

extra pulse to ensure the average speed is as demanded.

4.3.1 Available resolution

NOTE

The following Quadrature and SinCos type incremental encoders are available with

various lines per revolution with the Unidrive SP being compatible with encoders

ranging from 1 PPR (4 CPR) to 50,000 PPR (200,000CPR).

The comms only encoders which include both EndAt and SSI are also available with

various comms resolutions with Unidrive SP being compatible up to 32bits.

Ab Quadrature Incremental Encoder

• A 4096 LPR encoder has 4096 pulses per channel, and 16,384 edges. Available

resolution = 16,384 counts / turn.

SC Incremental Encoder

• An SCS50 SinCos encoder has 1024 sine waves per revolution with the drive

interpolating each sine wave to 9bits worth of resolution giving a total resolution of 2

x 1024 x 512 = 1,048,576 counts per revolution

Update

rate

IP

Rating

50

64

50

64

40 7 – 12

40 7 – 12

40 7 – 12

67 5

64

656610 – 32

67 5

64

656610 – 32

Supply

voltage

5 – 30

5 – 30

22 SM-Universal Encoder Plus User Guide

www.controltechniques.com Issue Number: 6

Page 23

EndAt Comms Only Encoder

• An EndAt comms only encoder has 13 bits giving a total resolution of = 8192 counts

per revolution

Comparing a 4096 PPR incremental encoder to a SCS50 SinCos encoder the SCS50

SinCos encoder will have a factor of 128 less ripple than the 4096 PPR encoder.

Therefore the encoder selected can influence the digital torque ripple significantly and

should be considered on high resolution / accuracy applications. The following table

shows both the digital torque ripple and available resolution for various encoder types.

NOTE

Feedback Device Digital Torque Ripple Available Resolution

Quadrature

Incremental

Comms

SinCos

Incremental

The above figures are independent of the operating speed. If the figures are

1024 59rpm 4096

4096 14rpm 16384

EndAt 29.43rpm 13bit

EndAt 1.83rpm 17bit

512 0.23rpm 2048 * 512

1024 0.11rpm 4096 * 512

recalculated for a 750 rpm then the number of counts is halved but the speed change

for 1 count is the same.

4.3.2 Internal digital torque ripple calculation

Following is an example of the internal digital torque ripple calculation

AB Quadrature Encoder

1024 line encoder running at 1500rpm and Unidrive SP speed loop sample time =

250us

• 1500rpm / 60s = 25 rev / s

• 25 rev / s x 1024ppr = 25600 pulses / s

• 25600 pulses / s x 4edges = 102400 edges / s

• 102400 edges / s x 250 x 10 -6 = 25.6 edges per sample period

Therefore due to the digitisation of the encoder feedback the average number of edges

seen will be 25.6, but this must be due to the relevant number of 25 and 26 edges over

an infinite length of time. As such:

25 edges / 250 x 10 -6 = 100,000 edges / sec.

100,000 / 4 = 25,000 edges

25,000 / 1024 = 24.4 rev / s

24.4 x 60 = 1464.8 rpm

26 edges / 250 x 10 -6 = 104,000 edges/ sec.

104,000 / 4 = 26,000 edges

26,000 / 1024 = 25.4 rev / s

25.4 x 60 = 1523.4 rpm

1523 - 1464 = 59rpm

The difference of 1 pulse gives an instantaneous speed change of 59 rpm.

SM-Universal Encoder Plus User Guide 23

Issue Number: 6 www.controltechniques.com

Page 24

5 Installing the SM-Universal Encoder Plus

e

5.1 Solutions Module slots

Before installing the SM-Universal Encoder Plus, refer to Chapter 2 Safety

WARNING

Information on page 6.

There are three slots available, which the Solutions Module can be plugged into as

shown in Figure 5-1. The Solutions Module can be plugged into either one of these, but

it is recommended that slot 3 be used for the first Solutions Module then slot 2 and slot

1. This ensures maximum mechanical support for the Solutions Module once fitted.

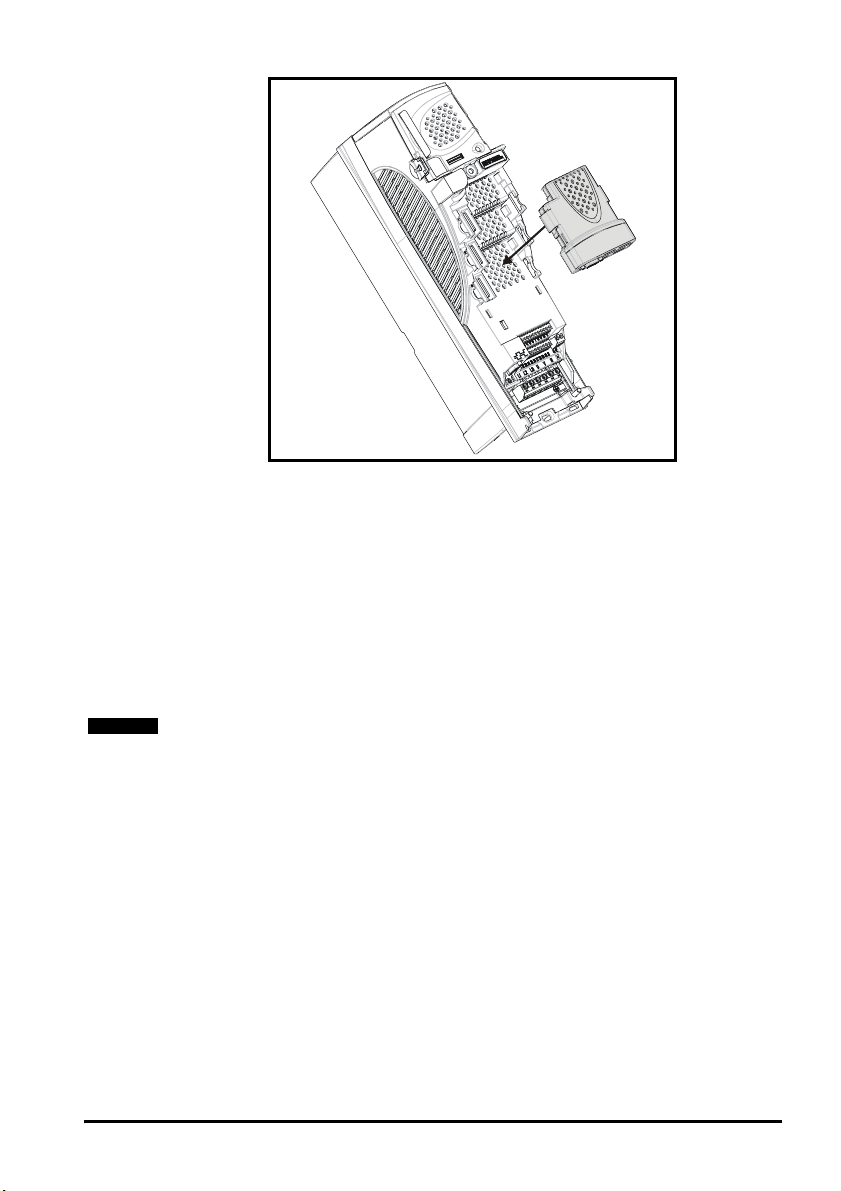

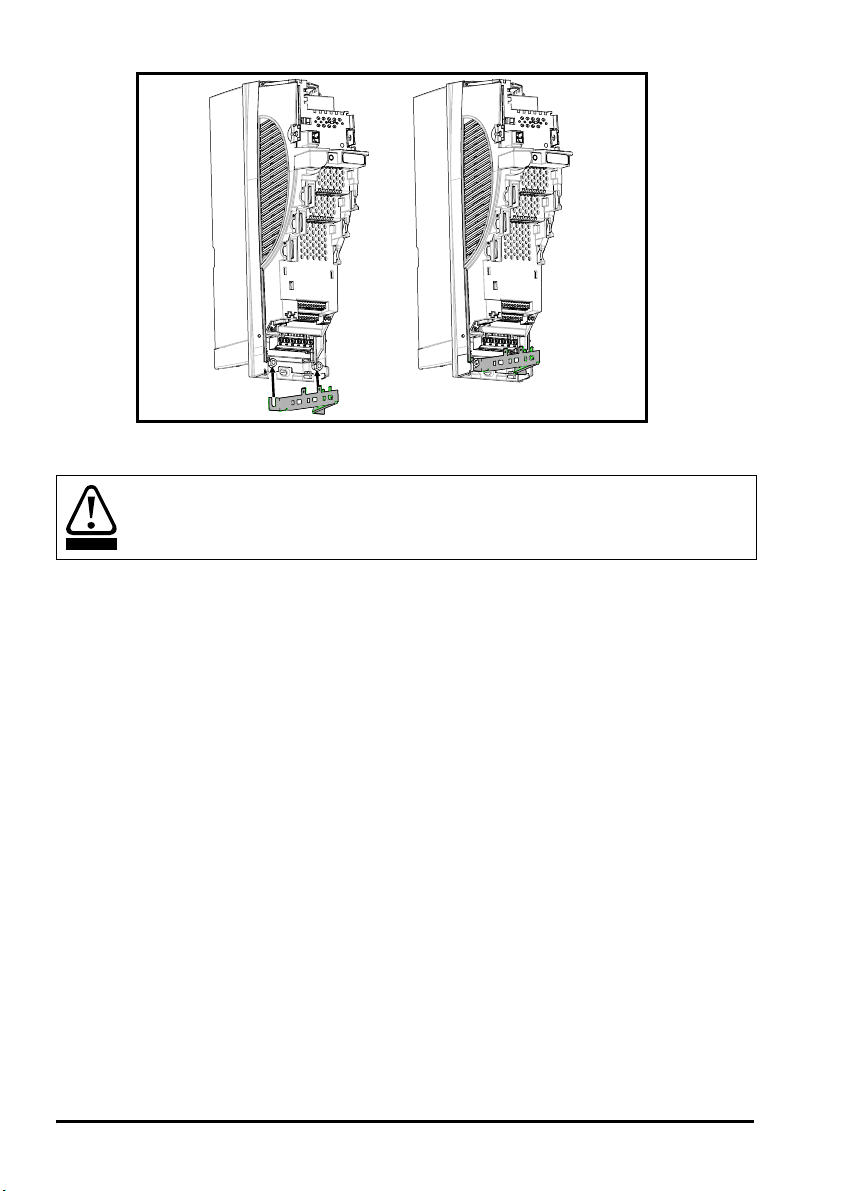

Figure 5-1 Location of slots 1, 2 and 3 on the Unidrive SP

Solutions Module

slot 1 (Menu 15)

Solutions Module

slot 2 (Menu 16)

Solutions Modul

slot 3 (Menu 17)

5.2 Installation

1. Before installing the SM-Universal Encoder Plus in the Unidrive SP, ensure the AC

supply has been disconnected from the drive for at least 10 minutes.

2. Ensure that both the +24V, and +48V backup power supplies are disconnected from

the drive for at least 10 minutes.

3. Check that the exterior of the SM-Universal Encoder Plus is not damaged, and that

the multi-way connector is free from dirt and debris.

4. Do not install a damaged or dirty SM-Universal Encoder Plus in the drive.

5. Remove the termin al cover from the drive. (For removal / re-fitting instructions, see

Unidrive SP Solutions Module Installation Sheet provided with the Solutions

Module.)

6. Position the drive connector of the SM-Universal Encoder Plus over the connector

of the appropriate slot in the drive and push downwards until it locks into place.

24 SM-Universal Encoder Plus User Guide

www.controltechniques.com Issue Number: 6

Page 25

NOTE

Figure 5-2 Fitting the SM-Universal Encoder Plus

7. Re-fit the terminal cover to the drive. (For removal / re-fitting instructions, see

Unidrive SP Solutions Module Installation Sheet provided with the Solutions

Module.)

8. Connect the AC supply to the drive.

9. Set Pr 0.49 to L2 to unlock read only security.

10. Check that Menu 15 (slot 1), 16 (slot 2), or 17 (slot 3) parameters are now available.

11. Check that Pr 15.01, Pr 16.01 or Pr 17.01 show the correct code for the SM-

Universal Encoder Plus (code = 102).

12. If the checks in steps 10 and 11 fail, either the SM-Universal Encoder Plus is not

fully inserted, or the Solutions Module is fault.

13. If a trip code is now present refer to Chapter 10 Diagnostics on page 98.

Check the SM-Universal Encoder Plus is the correct issue and has the correct software.

• Issue 3 - V.03.xx.xx

• Issue 4 - V.04.xx.xx

Encoder connections

In order to ensure correct operation there are a number of checks which should be

carried out:

• Ensure the encoder is securely mounted to the motor as spurious operation can

result due to the encoder slipping whilst the motor is rotating.

• Ensure encoder connections to both the encoder and the Solutions Module

terminals are secured, intermittent connections can result in spurious operation or

the Solutions Module not detecting the feedback signals.

• Ensure screen and grounding recommendations as specified in Chapter

5.5 Encoder shield connections on page 28, Encoder, Shield connections of this

User guide are followed to prevent noise being induced on the encoder feedback

signals. Noise induced on encoder feedback cables cannot only result in spurious

operation but in extreme cases can result in encoder failure and/or damage to the

Solutions Modules encoder input.

SM-Universal Encoder Plus User Guide 25

Issue Number: 6 www.controltechniques.com

Page 26

• Encoder feedback and communications data is transmitted from an encoder as low

S

voltage analogue or digital signals. Ensure that electrical noise from the drive or

motor does not adversely affect the encoder feedback. Also refer to drive and motor

instructions given in Chapter 4 Electrical Installation in the Unidrive SP User Guide,

and that the encoder feedback wiring and shielding recommendations are followed

in section 5.5 Encoder shield connections on page 28.

5.3 Terminal descriptions

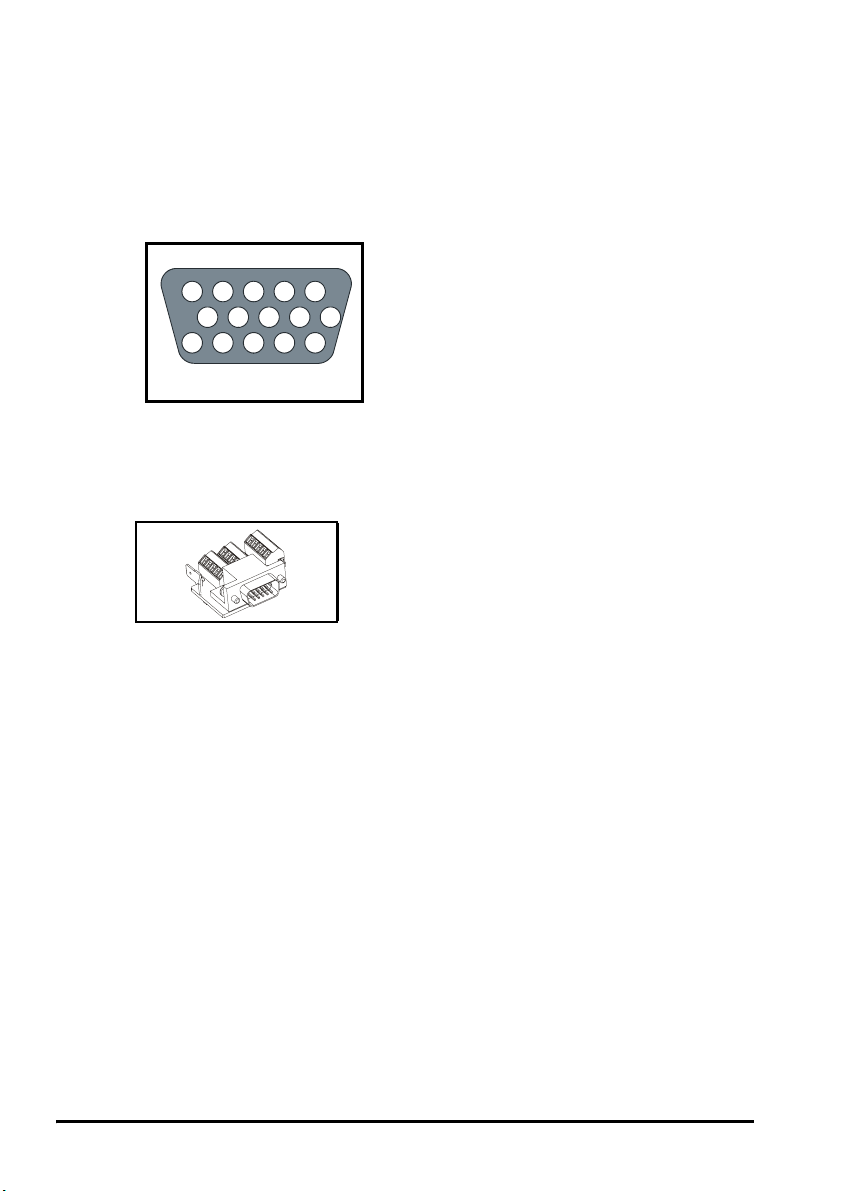

Figure 5-3 Connector SK2 terminal descriptions

K2

12345

678910

1112131415

15 way female D-type

The standard connector SK2 provided on the SM-Universal Encoder Plus is a 15 way DType requiring a similar 15 way D-Type for connection of an encoder. A standard 15 way

D-Type has solder connections, the following UT01 allows direct connection to the 15

way D-Type on the Solutions Module providing screw terminals for encoder connection.

Figure 5-4 15-way D-type converter

Each terminal is appropriately labelled on the printed circuit board.

26 SM-Universal Encoder Plus User Guide

www.controltechniques.com Issue Number: 6

Page 27

Figure 5-5 Connector SK2 terminal descriptions

Encoder

Term

Ab Fd Fr

1AFF A F F Cos

2 A\ F\ F\ A\ F\ F\ Cosref Cosref Cosref

3BDR B D R Sin Sin Sin

4 B\ D\ R\ B\ D\ R\ Sinref Sinref Sinref

5Z

6 Z\ Encoder input - Data\ (input/output)

Simulated encoder

7

8

9

10

11 W Encoder input - Clock (output) W

12 W\ Encoder input - Clock\ (output) W\

13 +V

14 0V common

15 th

Aout, Fout,

Data SSI (output)

Simulated encoder

Aout\, Fout\,

Data\ SSI (output)

Simulated encoder

Bout, Dout,

Clock\ SSI (input)

Simulated encoder

Bout\, Dout\,

Clock SSI (input)

Ab.

SErvo

Fd.

SErvo

U

U\

V

V\

Fr.

SErvo

SC.

SC

HiPEr

Encoder input - Data (input/output)

Simulated encoder

Aout, Fout, Data SSI (output)

Simulated encoder

Aout\, Fout\, Data\ SSI (output)

Simulated encoder

Bout, Dout, Clock\ SSI (input)

Simulated encoder

Bout\, Dout\, Clock SSI (input)

SC.

EndAt

EndAt

Cos Cos

SSI

SC.

SSI

SC.

SErvo

U

U\

V

V\

NOTE

The simulated encoder outputs present on terminals 7, 8,9,10 (A.A\, B.B\, F.F\, D.D\) can

be through either software simulation or hardware, this being determined by Pr x.28

NOTE

No simulated encoder output is available when operating with either of the following

encoders configured at the modules input, Ab.SErvo, Fd.SErvo, Fr.SErvo, SC.SErvo due

to the commutation signals using the same inputs/outputs as used by the simulated

encoder output.

SM-Universal Encoder Plus User Guide 27

Issue Number: 6 www.controltechniques.com

Page 28

Figure 5-6 Connector PL1

Table 5.1 Connector PL1 terminal descriptions

Terminal

1

2 0V common

3

4 A\ F\ Data\

5BDClock\ (input)

6B\D\Clock (input)

7 0V common

8Freeze

9 Freeze\ Z\

Freeze

RS485

input

5.4 Power supply

The total user load of the drive and Solutions Modules if exceeded will result in a 24V

internal power supply overload, trip ‘PS.24V’.

The user load comprises of:

• the drive’s digital outputs plus the SM-I/O Plus digital outputs

or

• the drive’s main encoder supply plus the SM-Universal Encoder Plus encoder

supply

Example

If exceeding the user load:

• the drive’s main encoder supply, SM-Universal Encoder Plus encoder supply,

drive’s digital output and SM-I/O Plus digital outputs

an external 24V >50W power supply will be required. The external 24V supply should

be connected to the drives control terminals 1 and 2.

NOTE

If the encoder will exceed the SM-Universal Encoder Plus and encoder supply (5V, 8V

>300mA, 15V >200mA), the encoder must be supplied externally without a power

supply connection to the module. Ensure the 0V connection is common between both

the SM-Universal Encoder Plus and the encoder.

PL1

123456789

Freeze inputs / Encoder outputs

Freeze

+24V input

Freeze

Ab output Fd output SSI output

AFData

Marker

output

Z

NOTE

There should be no parallel connection of the external 24V supply and the encoder

supply from the drive.

5.5 Encoder shield connections

Shielding considerations are important for PWM drive installations due to the high

voltages and currents present in the output circuit with a very wide frequency spectrum,

typically from 0 to 20 MHz. Encoder inputs are liable to be disturbed if careful attention

is not given to managing the cable shields.

28 SM-Universal Encoder Plus User Guide

www.controltechniques.com Issue Number: 6

Page 29

5.6 Grounding hardware

The Unidrive SP is supplied with a grounding clamp and a grounding bracket to facilitate

EMC compliance. They provide a convenient method for direct grounding of cable

shields without the use of "pig-tails". Cable shields can be bared and clamped to the

grounding bracket using metal clips or clamps

shield must in all cases be continued through the clamp to the intended terminal on the

drive, in accordance with the connection details for the specific signal.

A suitable clamp is the Phoenix DIN rail mounted SK14 cable clamp (for cables with a

maximum outer diameter of 14mm).

See Figure 5-2 and Figure 5-3 for details on fitting the grounding clamp.

See Figure 5-4 for details on fitting the grounding bracket.

Figure 5-2 Fitting of grounding clamp (size 1 and 2)

1

(not supplied) or cable ties. Note that the

Figure 5-3 Fitting of grounding clamp (size 3)

SM-Universal Encoder Plus User Guide 29

Issue Number: 6 www.controltechniques.com

Page 30

WARNING

Figure 5-4 Fitting of grounding bracket (sizes 1 to 6)

Loosen the ground connection nuts and slide the grounding bracket in the direction

shown. Once in place, re-tighten the ground connection nuts.

On Unidrive SP size 1 and 2, the grounding bracket is secured using the power ground

terminal of the drive. Ensure that the supply ground connection is secure after fitting /

removing the grounding bracket. Failure to do so will result in the drive not being

grounded.

A faston tab is located on the grounding bracket for the purpose of connecting the drive

0V to ground should the user require to do so.

When a Unidrive SP size 4 or 5 is through-panel mounted, the grounding link bracket

must be folded upwards. A screw can be used to secure the bracket or it can be located

under the mounting bracket to ensure that a ground connection is made. This is

required to provide a grounding point for the grounding bracket as shown in Figure 5-4.

30 SM-Universal Encoder Plus User Guide

www.controltechniques.com Issue Number: 6

Page 31

Figure 5-5 Grounding link bracket in its surface mount position (as supplied

bracke

with drive)

Grounding

link bracket

Figure 5-6 Grounding link bracket folded up into its through- panel mount position

Grounding

link bracket

Mounting

t

SM-Universal Encoder Plus User Guide 31

Issue Number: 6 www.controltechniques.com

Page 32

If the control wiring is to leave the enclosure, it must be shielded and the shield(s)

clamped to the drive using the grounding bracket as shown in Figure 5-7. Remove the

outer insulating cover of the cable to ensure the shield(s) make contact with the bracket,

but keep the shield(s) intact until as close as possible to the terminals

Alternatively, wiring may be passed through a ferrite ring, part no. 3225-1004.

Figure 5-7 Grounding of signal cable shields using the grounding bracket

Encoder mounting methods

There are three methods for mounting an encoder onto a motor:

1. Galvanic isolation between encoder and motor

2. Galvanic isolation between encoder circuit and encoder body

3. No Isolation

32 SM-Universal Encoder Plus User Guide

www.controltechniques.com Issue Number: 6

Page 33

5.6.1 Encoder with galvanic isolation from motor

When galvanically isolated the encoder device is mounted to the motor with isolation

fitted between the motor housing / shaft and encoder as shown in Figure 5-7.

Figure 5-7 Galvanic Isolation from Motor

Isolation

between motor shaft

and encoder

Motor

Housing

Motor

Shaft

+5V

+5V

+5V

0V

A

A

0V

B

B

0V

Z

Z

Encoder

Circuit

Encoder

Connection

Encoder

Body

Isolation

between motor housing

and encoder housing

Encoder

Housing

An example of this is the Unimotor where isolation from the motor is achieved by

inserting a plastic mounting plate between the motor housing and encoder housing and

a plastic insert fitted in the motor shaft for encoder mounting to the motor shaft. With this

preferred method of mounting noise current is prevented from passing from the motor

housing into the encoder housing, and hence into the encoder cable. The ground

connection of the cable shield is optional, this may be required to comply with safety

measures or to reduce radiated radio frequency emissions from either the drive or

encoder.

5.6.2 Encoder circuit with galvanic isolation from encoder body

In this case the encoder device is mounted directly on the motor housing with contact

being made between the motor housing/shaft and encoder. With this mounting method

the encoder internal circuits are exposed to electrical noise from the motor housing

through the stray capacitance, and they must be designed to withstand this situation.

However this arrangement still prevents large noise currents from flowing from the

motor body into the encoder cable. The ground connection of the cable shield is

optional, this may be required to comply with safety measures or to reduce radiated

radio frequency emissions from either the drive or encoder.

SM-Universal Encoder Plus User Guide 33

Issue Number: 6 www.controltechniques.com

Page 34

Figure 5-8 Encoder Galvanically Isolated from Encoder Body

5.6.3 No isolation

As shown in Figure 5-9 the encoder 0V connection may be permanently connected to

the housing. This has the advantage that the encoder body can form a shield for its

internal circuits. However it permits noise current from the motor body to flow into the

encoder cable shield. A good quality shielded cable correctly terminated protects the

data against this noise current, but much more care is needed in ensuring correct cable

management than for the isolated cases.

Motor

Housing

Motor

Shaft

No Isolation

between motor housing

and encoder housing

No Isolation

between motor shaft

and encoder

0V

A

A

+5V

0V

B

B

+5V

0V

Z

Z

+5V

Galvanic

Isolation

Figure 5-9 No Isolation

No Isolation

between motor shaft

and encoder

Encoder

Encoder

Housing

Circuit

Encoder

Circuit

Stray

Capacitance

Encoder

Connection

Encoder

Body

Stray

Motor

Housing

Motor

Shaft

No Isolation

between motor housing

and encoder housing

0V

+5V

0V

+5V

0V

+5V

Encoder

Housing

A

A

B

B

Z

Z

Encoder

Body

Capacitance

Encoder

Connection

Optional

0V

connection

to encoder

housing

34 SM-Universal Encoder Plus User Guide

www.controltechniques.com Issue Number: 6

Page 35

5.6.4 Cable requirements

p

All mounting methods:

• Shield connection at drive terminal to 0V

• Shield connection at encoder to 0V

• It is recommended that the shielded cable should be run in a continuous length to

the terminal, to avoid the injection of noise at intermediate pigtails and to maximise

the shielding benefit.

• The shield connections ("pigtails") to the drive and encoder should be kept as short

as possible

Mounting with no isolation:

• Shield connected to ground at both ends. The connection must be made by direct

fixing of the cable to the grounded metal parts, i.e. to the encoder body and the

drive grounding bracket, as illustrated in Figure 5-7 on page 33. "Pigtails" must be

avoided. The outer sheath of the cable should be stripped back enough to allow for

the ground clamp to be fitted. The shield connection should not be broken. The

ground clamps should be located as close as possible to the drive and encoder.

• It is essential that the shielded cable should be run in a continuous length to the

terminal, to avoid the injection of noise at intermediate "pigtails" and to maximise the

shielding benefit.

In this case under no circumstances must the cable shield connection be omitted at

either end of the cable in this case, since the noise voltage may well be sufficient to

CAUTION

WARNING

destroy the line driver and receiver chips in the encoder and the drive.

Cable shield ground connection

For all mounting methods, grounding of the feedback cable shield has added benefits. It

can protect the drive and encoder from induced fast electrical transients, and prevent

radiated radio-frequency emission. However it is essential that it be carried out in the

correct manner as explained above and shown in Figure 5-11 on page 36.

Connecting the cable shield to ground at both ends carries the risk that an electrical fault

might cause excessive power current to flow in the cable shield and overheat the cable.

There must be an adequately rated safety ground connection between the motor/

encoder and the drive.

Recommended cable

The recommended cable for feedback signals is a twisted pair, shielded with an overall

shield as shown in Figure 5-10

Figure 5-10 Feedback Cable, Twisted Pair

Cable overall shield

Twisted

pair

cable

Twisted

air shield

Cable

Using this type of cable also allows for the connection of the outer shield to ground and

the inner shields to 0V alone at both drive and encoder end, when required.

SM-Universal Encoder Plus User Guide 35

Issue Number: 6 www.controltechniques.com

Page 36

NOTE

Twi

on shield

Ensure that feedback cables are kept as far away as possible from power cables and

avoid parallel routing.

Figure 5-11 Feedback cable connections

sted

pair

shield

Shield

connection

to 0V

Shield

connection

to 0V

Twisted

pair

shield

Cable

Connection

at drive

Cable

shield

Ground clamp

Cable

shield

Connection

at motor

36 SM-Universal Encoder Plus User Guide

www.controltechniques.com Issue Number: 6

Page 37

6 Getting Started

6.1 Installation

The control circuits are isolated from the power circuits in the drive by basic insulation

only, as specified in IEC60664-1. The installer must ensure that the external control

WARNING

circuits are insulated from human contact by at least one layer of insulation rated for use

at the AC supply voltage.

If the control circuits are to be connected to other circuits classified as Safety Extra Low

Voltage (SELV) (e.g. to a personal computer) an additional isolating barrier must be

included in order to maintain the SELV classification.

Encoder connections

In order to ensure correct operation there are a number of checks which should be

carried out:

• Ensure the encoder is securely mounted to the motor as spurious operation can

result due to the encoder slipping whilst the motor is rotating.

• Ensure encoder connections to both the encoder and the Solutions Module

terminals are secured, intermittent connections can result in spurious operation or

the Solutions Module not detecting the feedback signals.

• Ensure screen and grounding recommendations as specified in Chapter

5.5 Encoder shield connections on page 28, Encoder, Shield connections of this

User guide are followed to prevent noise being induced on the encoder feedback

signals. Noise induced on encoder feedback cables cannot only result in spurious

operation but in extreme cases can result in encoder failure and/or damage to the

Solutions Modules encoder input.

Encoder feedback and communications data is transmitted from an encoder as low

voltage analogue or digital signals. Ensure that electrical noise from the drive or motor

does not adversely affect the encoder feedback. Also refer to drive and motor

instructions given in Chapter 4 Electrical Installation in the Unidrive SP User Guide, and

that the encoder feedback wiring and shielding recommendations are followed in

section 5.5 Encoder shield connections on page 28.

Encoder initialisation

Encoder initialisation will occur as follows: at drive power-up, when requested by the user

via Pr

3.47

or when trips in this module (which are option module specific) are reset.

Initialisation causes an encoder with comms to be re-initialised and auto-configuration to

be performed if selected. After initialisation Ab.SErvo, Fd.SErvo, Fr.SErvo and SC.SErvo

encoders will use the UVW commutations signals to give position feedback for the first

120

°

(electrical) of rotation when the motor is restarted.

A delay is provided during initialisation for some encoders to allow the encoder to be

ready to provide position information after it has powered up. The delay is provided

during initialisation because this occurs during drive power-up and after encoder power

supply trips are reset. The delays are as follows:

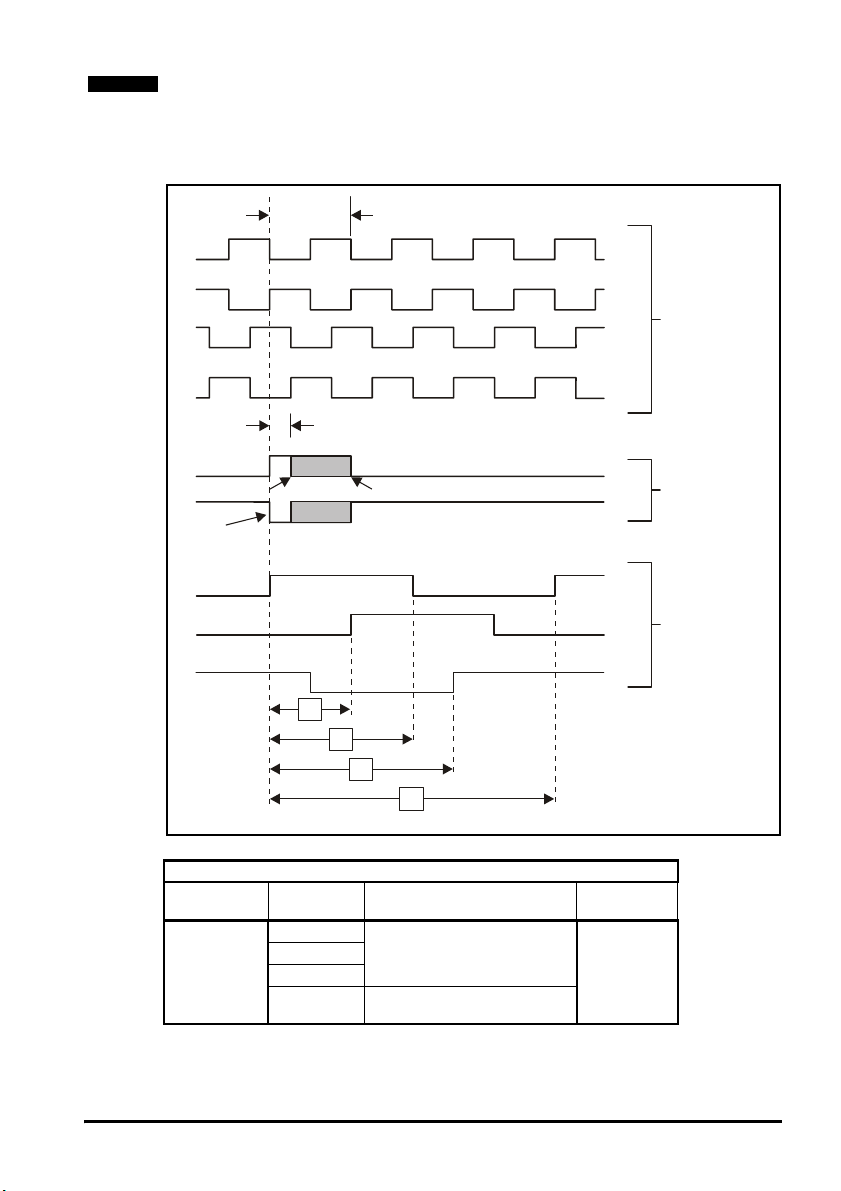

Encoder type Initialisation delay

Ab, Fd, Fr, Ab.SErvo, Fd.SErvo, Fr.SErvo, SC.SErvo 250ms

SC.HiPEr 150ms, then encoder reset, then 400ms

SC.EndAt, EndAt 1.25s

All other types 1.45s

SM-Universal Encoder Plus User Guide 37

Issue Number: 6 www.controltechniques.com

Page 38

NOTE

Encoder initialisation will only occur when trips 1 through to 74 in Pr x.50, Solutions

Module error status are reset.

Pr x.18 Auto-configuration enable\SSI binary format select

When a SC.HiPEr or SC.EndAt encoder is being used, the Solutions Module will interroga te the encoder on

power-up. If Pr x.18 is set and the encoder type is recognised based on the information provided by the

encoder, the Solutions Modul e will set the encoder turns Pr x.09, the equivalent lines per revolution Pr x.10 and

the encoder comms resolution Pr x.11 for the encoder. If the encoder is recognised these parameters will all

become read only. If the encoder is not recognised, the Solutions Module will initiate a 7 trip to prompt the user

to enter the information. The Solutions Module should be able to auto-configure with any EndAt encoder where

the number of turns and lines per revolution are a power of 2, and the following Hiperface encoders: SCS 60/70,

SCM 60/70, SRS 50/60, SRM 50/60, SHS 170, LINCODER, SCS-KIT 101, SKS36, SKM36, SEK52, SEK53.

NOTE

NOTE

When operating with an SSI encoder, Pr x.18 is used to set-up the data format: 0 = Gray

code and 1 = binary format.

When using only the simulated encoder outputs from the SM-Universal Encoder Plus,

the error detection Pr x.17 should be disabled to avoid Enc2 trips.

38 SM-Universal Encoder Plus User Guide

www.controltechniques.com Issue Number: 6

Page 39

6.1.1 Incremental encoders

The following parameter set-up should be followed when configuring an Incremental

Encoder.

Incremental Encoders, Ab, Fd, Fr, SC

Before powerup

Power-up drive

Slot

identification

Select

Solutions

Module

Set-up

encoder power

supply

Set-up

encoder type

Set-up

encoder lines

per revolution

Set-up

encoder turns

Error detection

Initialisation

Ensure:

• Feedback device is connected

• Drive secure disable is not given (terminal 31)

Ensure:

• Drive displays “inh”

• If the drive trips refer to Chapter 10 Diagnostics on page 98

Identify:

• Identify slot and associated menu, 15, 16, or 17

Enter:

• Speed feedback selector Pr 3.26

1: Slot 1, 2: Slot 2, 3: Slot 3

Enter:

• Encoder power supply Pr x.13

0: 5v, 1: 8v, 2:15v

Enter:

• Encoder Type Pr x.15

0 (Ab), 1 (Fd), 2 (Fr), 6(SC)

• Equivalent lines per revolution Pr x.10

Set according to encoder, see belo w for restrictions

• Line per revo l u ti o n divider Pr x.46

The equivalent lines per revolution Pr x.10 is divided by the value in Pr x.46. This can be used

when an encoder is used where the number of lines or sine waves per pole is not an integer e.g.

128.123 lines per rev = 128.123 in Pr x.10 and 1000 in Pr x.46 giving 128123/1000 = 128.123.

Encoder Pr x.10 Equivalent lines per revolution

Ab Number of lines per revolution

Fd, Fr Number of lines per revolution / 2

SC Number of sine waves per revolution

• Encoder turns Pr x.09

Defines the maximum number of the revolution counter (when operating with an incremental

encoder) before it rolls over at zero e.g. if Pr x.09 = 5, then Pr x.04 counts up to 31 before rolling

over at zero.

Ensure:

• The required error detection is set-up in Pr x.17

Ensure:

• Position feedback is initialised Pr x.45

• A re-initialise can be carried out enabling Pr 3.47

NOTE

When operating in servo mode with either of the above Incremental encoders a flux

alignment test (Pr 5.12) is required at every power up in order to determine the phase

offset angle. The miminal movement flux alignment test can be set-up through Pr 5.14

to carry out the required test automatically at every power up.

SM-Universal Encoder Plus User Guide 39

Issue Number: 6 www.controltechniques.com

Page 40

6.1.2 Incremental plus commutation, absolute encoders

The following parameter set-up should be followed when operating with an incremental

plus commutation absolute encoder.

Incremental plus commutation, absolute encoders, Ab.SErvo, Fd.SErvo, Fr.SErvo, SC.SErvo

Before powerup

Power-up drive

Slot

identification

Select Solutions

Module

Set-up encoder

power supply

Set-up encoder

type

Set-up encoder

lines per

revolution

Set-up encoder

turns

Error detection

Initialisation

NOTE

Ensure:

• Feedback device is connected

• Drive secure disable is not given (terminal 31)

Ensure: