Control Techniques SE11200037, SE11200025, SE2D200150, SE11200055, SE2D200110 User Manual

...Page 1

RGB ELEKTRONIKA AGACIAK CIACIEK

SPÓŁKA JAWNA

Jana Dlugosza 2-6 Street

51-162 Wrocław

Poland

biuro@rgbelektronika.pl

+48 71 325 15 05

www.rgbautomatyka.pl

www.rgbelektronika.pl

DATASHEET

www.rgbautomatyka.pl

www.rgbelektronika.pl

OTHER SYMBOLS:

SE23400150

CONTROL TECHNIQUES

Page 2

YOUR

PARTNER IN

MAINTENANCE

At our premises in Wrocław, we have a fully equipped servicing facility. Here we perform all the repair

works and test each later sold unit. Our trained employees, equipped with a wide variety of tools and

having several testing stands at their disposal, are a guarantee of the highest quality service.

OUR SERVICES

ENCODERS

SERVO

DRIVERS

LINEAR

ENCODERS

SERVO AMPLIFIERS

CNC

MACHINES

MOTORS

POWER

SUPPLIERS

OPERATOR

PANELS

CNC

CONTROLS

INDUSTRIAL

COMPUTERS

PLC

SYSTEMS

Repair this product with RGB ELEKTRONIKA

ORDER A DIAGNOSIS

∠

Buy this product at RGB AUTOMATYKA

BUY

∠

Page 3

www.controltechniques.com

EF

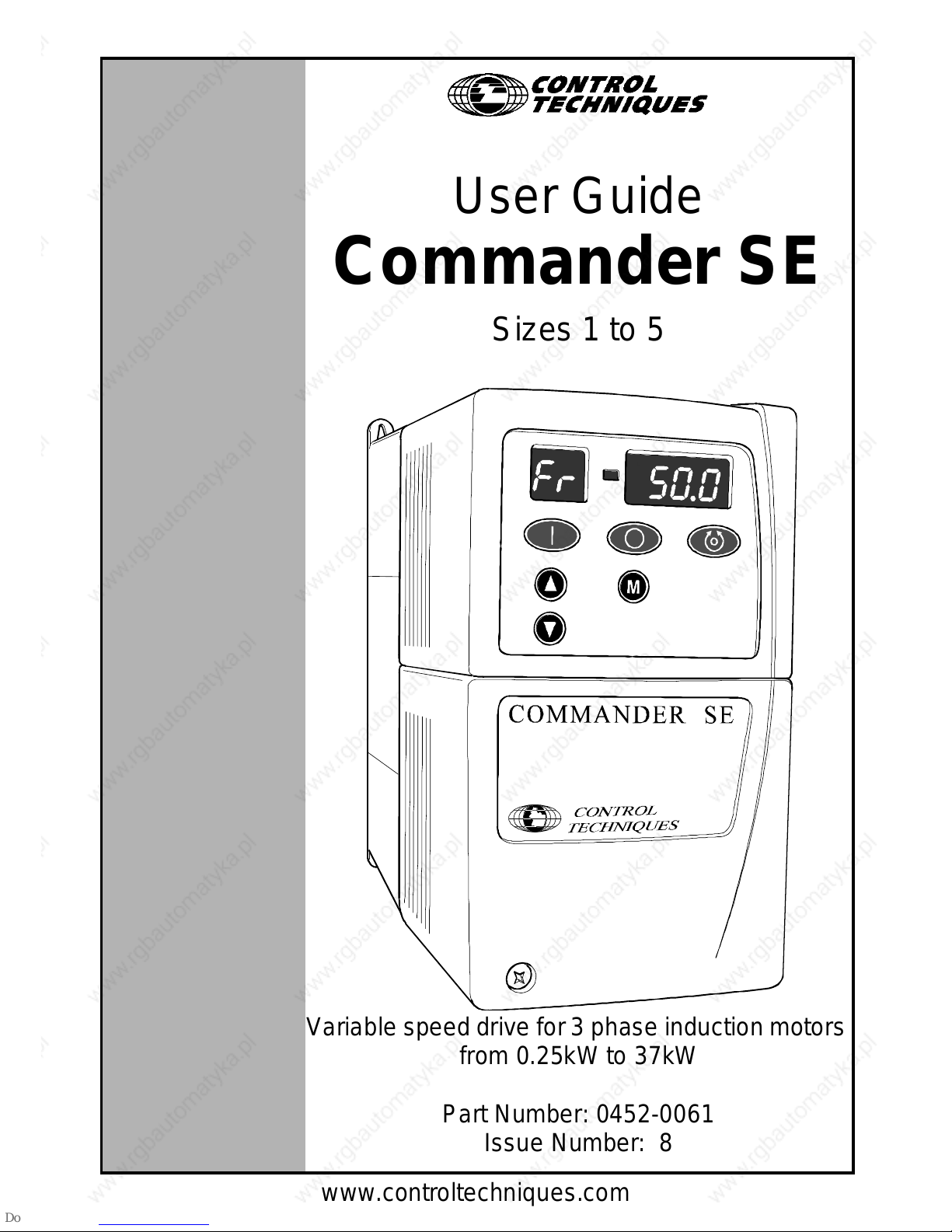

User Guide

Commander SE

Sizes 1 to 5

Variable speed drivefor 3 phase induction motors

from 0.25kW to 37kW

Part Number: 0452-0061

Issue Number: 8

Page 4

General Information

The manufacturer accepts no liability for anyconsequences resultingfrom inappro-

priate, negligent or incorrect installation or adjustment of the optional operating pa-

rameters ofthe equipment orfrom mismatching the variable speed drive (Drive) with

the motor.

The contentso f thisUser Guide are believed tobe correctat the time ofprinting. In

the interests of a commitment to a policy of continuous development and improve-

ment,themanufacturerreservestheright to changethespecificationof theproduct

or its performance, or the contents of the User Guide, withoutnotice.

All rights reserved. No parts of this User Guide may be reproduced or transmitted

in any form or by any means, electrical or mechanical including photocopying, re-

cording or by an information storage or retrievalsystem,without permissionin writ-

ing from the publisher.

Drive software version

Thisproductissuppliedwiththelatestversionofuser-interfaceandmachinecontrol

software. If this product is to be used in a new or existing system with other Com-

manderSE Drives,there may be some differences between their software and t he

software in this product. These differences may cause this product to function dif-

ferently. Thismay also applyto Drives returnedfroma Control TechniquesService

Centre.

If there is any doubt, contact a ControlTechniques Drive Centre.

Copyright © December 2001 Control Techniques Drives Limited

Issue Code: 8

Software: V02.00.00 onwards

Page 5

Commander SE User Guide

Issue Number 8

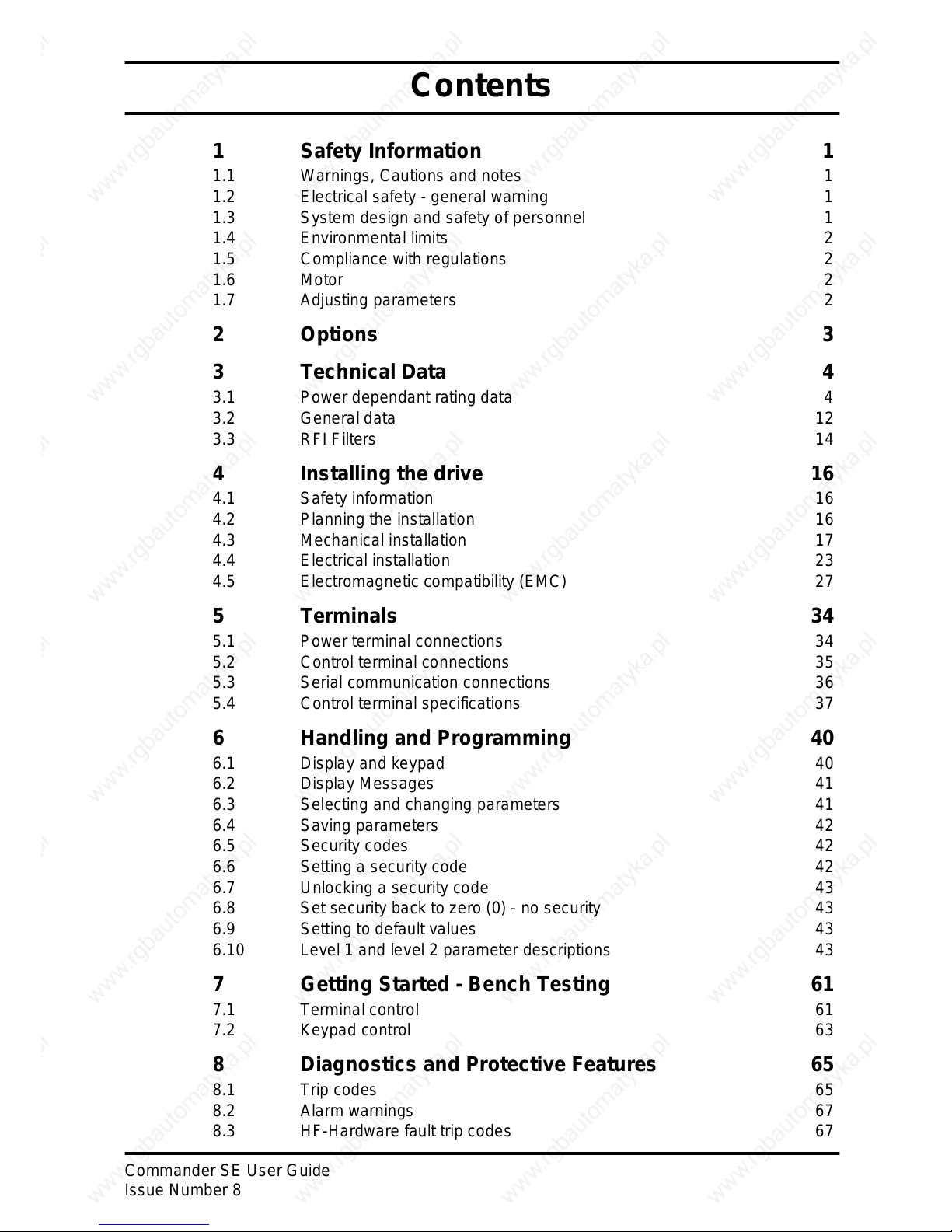

Contents

1 Safety Inform ation 1

1.1 Warnings, Cautions and notes 1

1.2 Electrical safety - general warning 1

1.3 System design and safety of personnel 1

1.4 Environmental limits 2

1.5 Compliance with regulations 2

1.6 Motor 2

1.7 Adjusting parameters 2

2Options 3

3 Technical Data 4

3.1 Power dependant ratingdata 4

3.2 Generaldata 12

3.3 RFI Filters 14

4 Installing the drive 16

4.1 Safety information 16

4.2 Planning the installation 16

4.3 Mechanical installation 17

4.4 Electrical installation 23

4.5 Electromagnetic compatibility (EMC) 27

5 Terminals 34

5.1 Power terminal connections 34

5.2 Control terminal connections 35

5.3 Serial communication connections 36

5.4 Control terminal specifications 37

6 Handling and Programming 40

6.1 Display and keypad 40

6.2 Display Messages 41

6.3 Selecting and changing parameters 41

6.4 Saving parameters 42

6.5 Security codes 42

6.6 Setting a security code 42

6.7 Unlocking a security code 43

6.8 Set security back to zero ( 0) - no security 43

6.9 Setting to default values 43

6.10 Level1 and level 2 parameter descriptions 43

7 Getting Started - Bench T esting 61

7.1 Terminal control 61

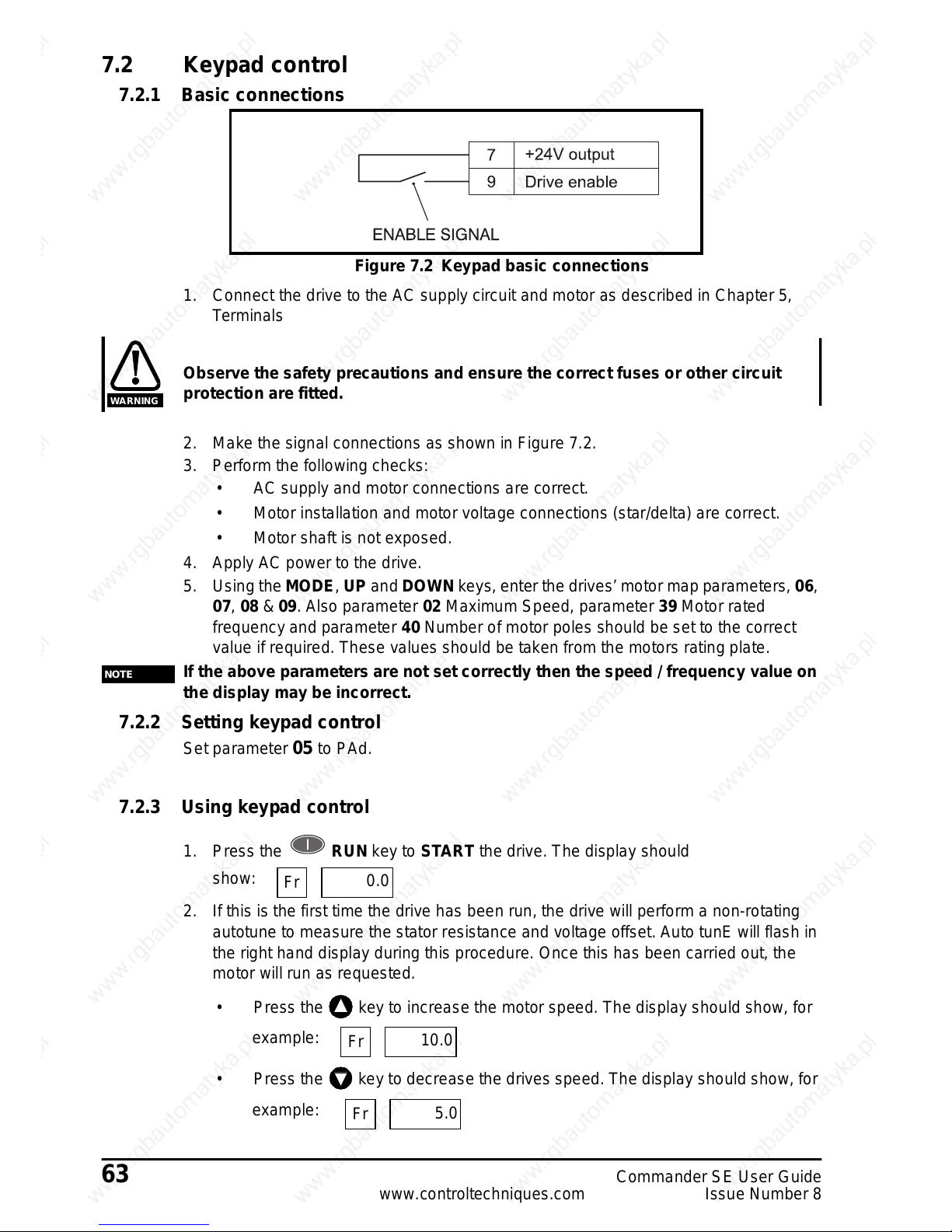

7.2 Keypad control 63

8 Diagnostics and Protective Features 65

8.1 Trip codes 65

8.2 Alarm warnings 67

8.3 HF-Hardware fault tripcodes 67

Page 6

Commander SE User Guide

Issue Number8

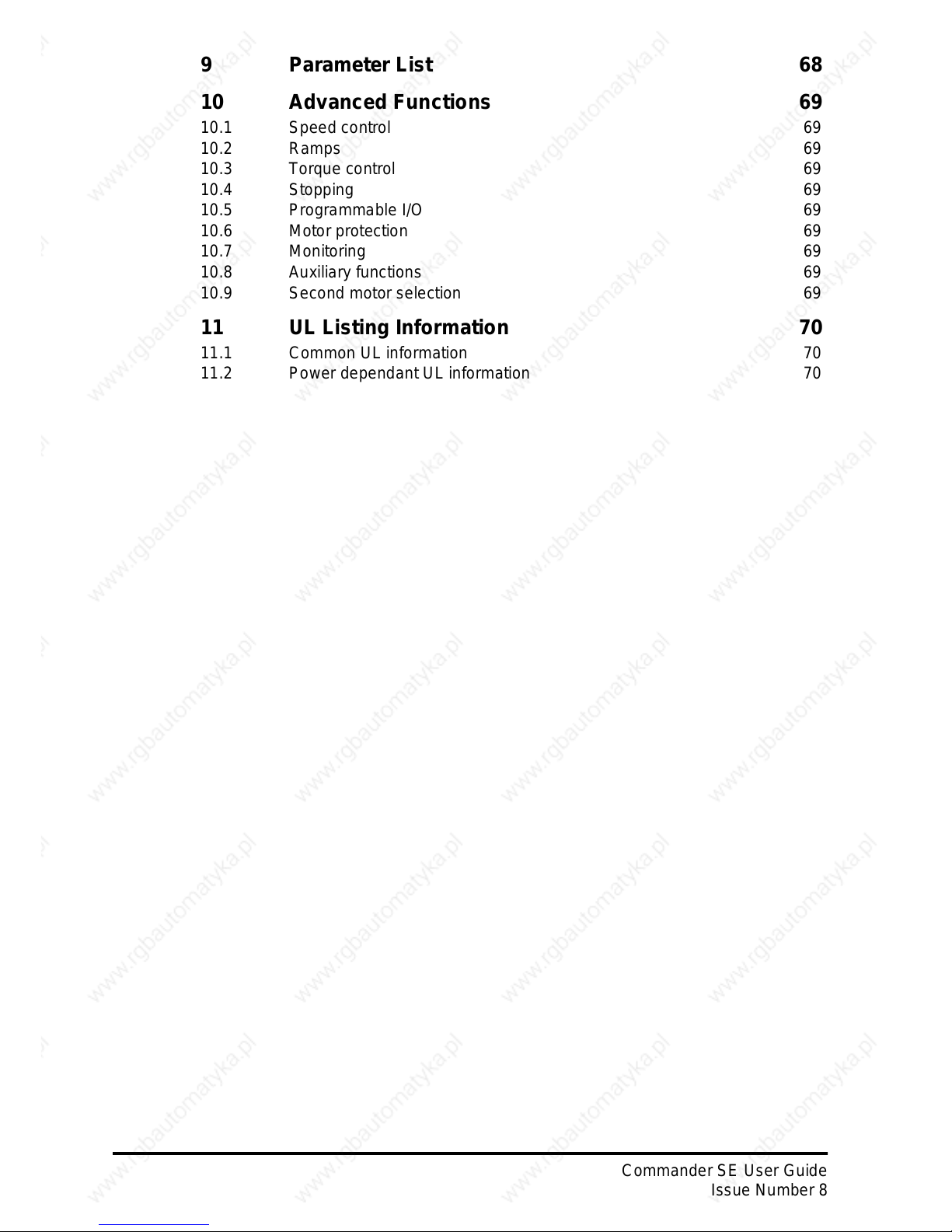

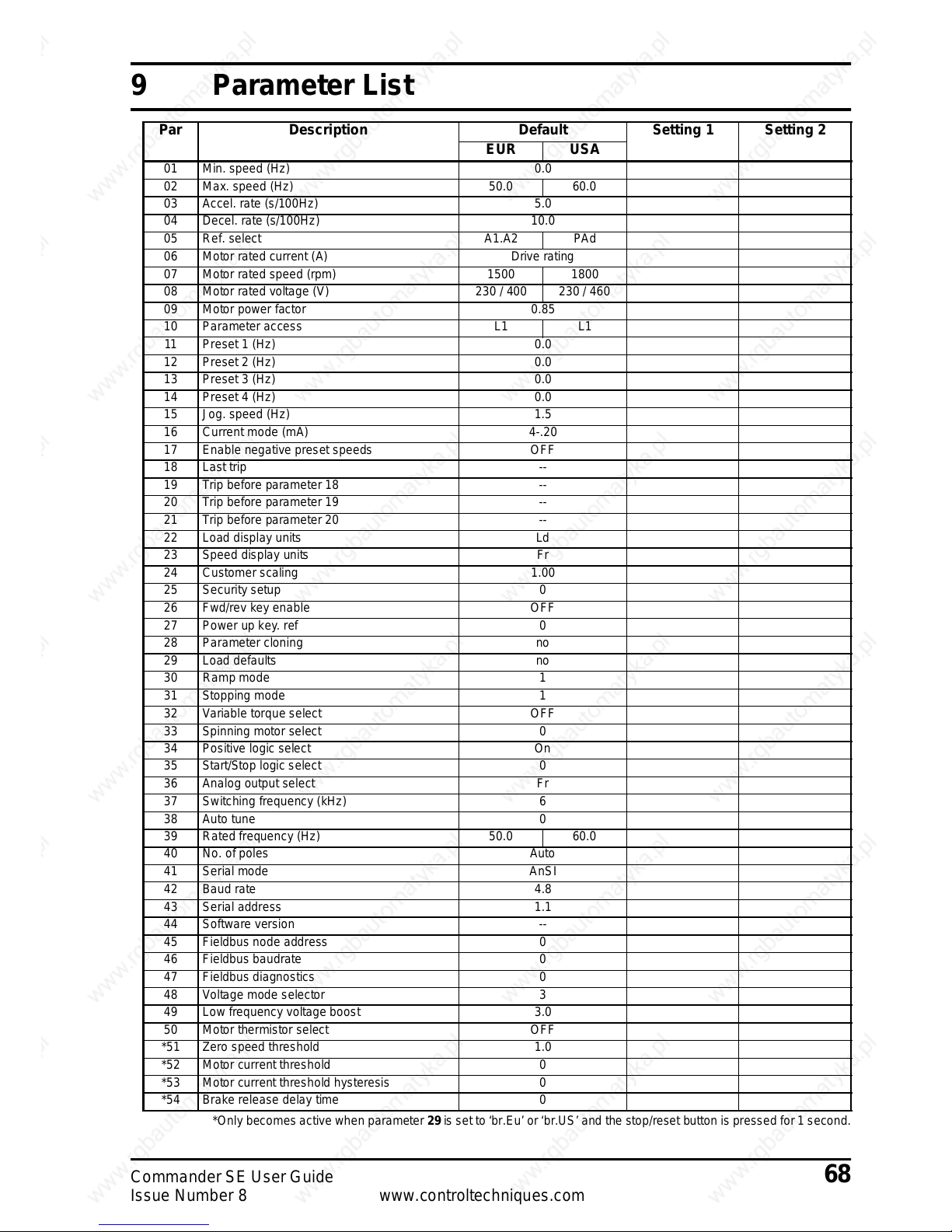

9 Parameter List 68

10 Advanced Functions 69

10.1 Speed control 69

10.2 Ramps 69

10.3 Torque control 69

10.4 Stopping 69

10.5 Programmable I/O 69

10.6 Motor protection 69

10.7 Monitoring 69

10.8 Auxiliary functions 69

10.9 Second motor selection 69

11 UL Listing Information 70

11.1 Common UL information 70

11.2 Power dependantUL information 70

Page 7

Commander SE User Guide

Issue Number 8

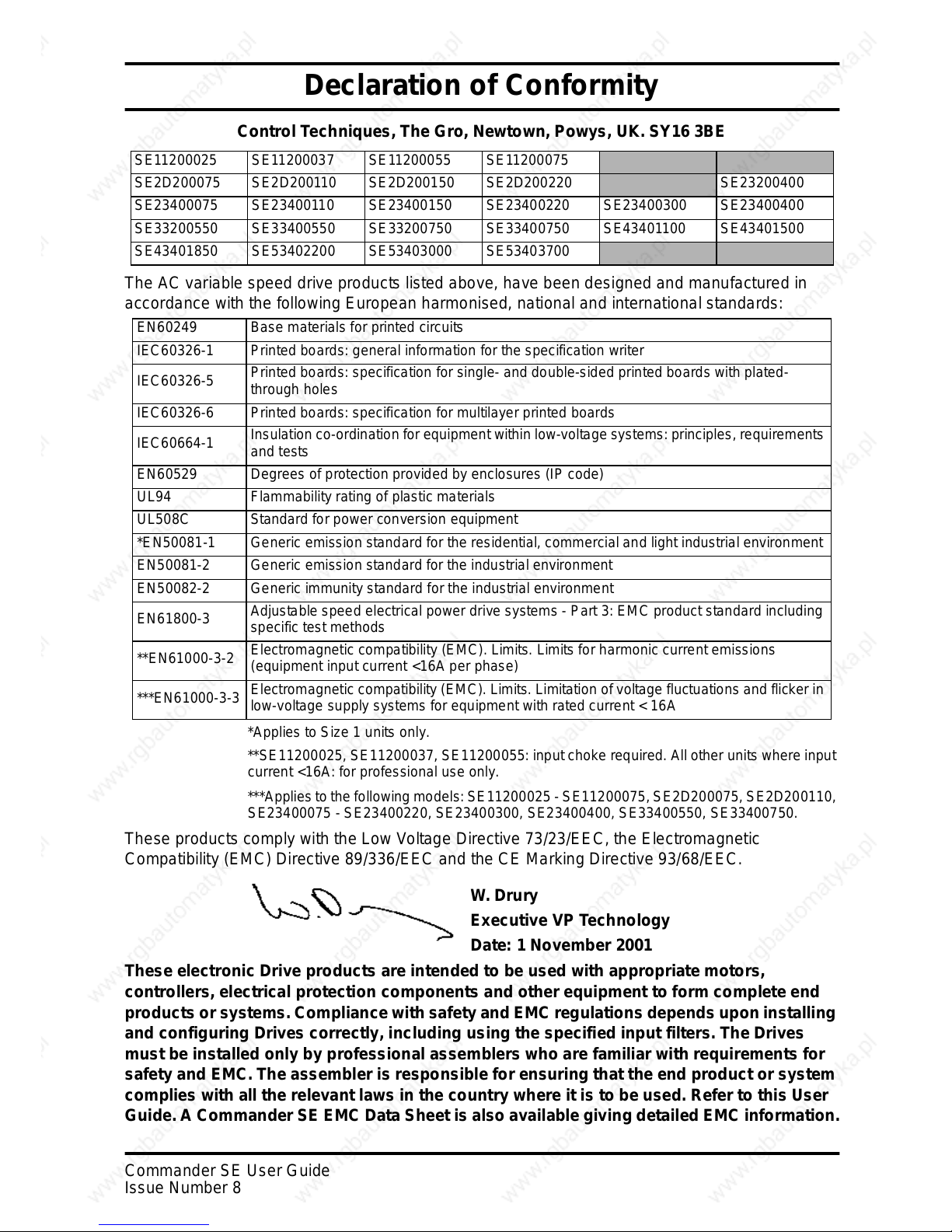

Declaration of Conformity

Control Techniques, The Gro, Newtown, Powys, UK. SY16 3BE

The AC variable speed drive products listed above, have been designed and manufactured in

accordance with the following European harmonised, national and international standards:

*Applies to Size 1 units only.

**SE11200025, SE11200037, SE11200055: input choke required. All other units where input

current <16A: for professional use only.

***Applies to the followingmodels:SE11200025 - SE11200075, SE2D200075, SE2D200110,

SE23400075 - SE23400220, SE23400300, SE23400400, SE33400550, SE33400750.

These productscomplywith the Low Voltage Directive 73/23/EEC,the Electromagnetic

Compatibility (EMC)Directive 89/336/EEC and the CE Marking D irective93/68/EEC.

These electronic Drive products are intended to be used with appropriate motors,

controllers, electrical protection components and other equipment to form complete end

products or systems. Compliance with safety and EMC regulations depends upon installing

and configuring Drives correctly, including using the specified input filters. The Drives

must be installed only by professional assemblers who are familiar with requirements for

safety and EMC. The assembler is responsible for ensuring that t he end product or system

complieswithalltherelevantlawsinthecountrywhereitistobeused.RefertothisUser

Guide.A Commander SE EMC Data Sheet is also available giving detailed EMC information.

SE11200025 SE11200037 SE11200055 SE11200075

SE2D200075 SE2D200110 SE2D200150 SE2D200220 SE23200400

SE23400075 SE23400110 SE23400150 SE23400220 SE23400300 SE23400400

SE33200550 SE33400550 SE33200750 SE33400750 SE43401100 SE43401500

SE43401850 SE53402200 SE53403000 SE53403700

EN60249 Base materials for printed circuits

IEC60326-1 Printed boards: general information for the specification writer

IEC60326-5

Printed boards: specification for single- and double-sided printed boards with plated-

through holes

IEC60326-6 Printed boards: specification for multilayer printed boards

IEC60664-1

Insulation co-ordination for equipment within low-voltage systems: principles, requirements

and tests

EN60529 Degrees of protection provided by enclosures (IP code)

UL94 Flammability rating of plastic materials

UL508C Standard for power conversion equipment

*EN50081-1 Generic emission standard for the residential, commercial and light industrial environment

EN50081-2 Generic emission standard for the industrial environment

EN50082-2 Generic immunity standard for the industrial environment

EN61800-3

Adjustable speed electrical power drive systems - Part 3: EMC product standard including

specific test methods

**EN61000-3-2

Electromagnetic compatibility (EMC). Limits. Limits for harmonic current emissions

(equipment input current <16A per phase)

***EN61000-3-3

Electromagnetic compatibility (EMC). Limits. Limitation of voltage fluctuations and flicker in

low-voltage supply systems for equipment with rated current < 16A

W. Drury

Executive VP Technology

Date: 1 November 2001

Page 8

1 Commander SE User Guide

www.controltechniques.com Issue Number 8

1 Safety Information

1.1 Warnings, Cautions and notes

A Warnin g contains information which is essential for avoiding a safety hazard.

A

Caution contains information which is necessary for avoiding a risk o f damage to

the product or other equipment.

A

Note contains information which helps to ensure correct operation of the product.

1.2 Electrical safety - general warning

The voltages used in the drive can cause severe electrical shock and/or burns, and

could be lethal. Extreme care is necessary at all times when working with or adjacent to

the drive.

Specificwarnings are givenat the relevant places in this User Guide.

1.3 System design and safety of personnel

The driveis intended as a component for professional incorporation into complete

equipment or a system. If installed incorrectly, the drivemay present a safety hazard.

The driveuses highvoltage and currents, carries a high level of storedelectrical energy,

and is used to control equipment whichcan cause injury.

Close attention is requiredto the electrical installation and the system design to avoid

hazards, either in normal operat ion or in the event of equipment malfunction. System

design, installation, commissioning and maintenance mustbe carried out by personnel

whohave the necessarytraining and experience. They must readthissafety information

and this User Guide carefully.

The STOP function of the drive does not remove dangerousvoltages fromthe outputof

the drive or from any external option unit.

Careful consideration must be given to the functions of the drive which might result in a

hazard, either through their intended functions or through incorrect operation due to a

fault.

In any application where a malfunction of the drive could lead to damage,loss or injury,

a risk analysis must be carried out,and where necessary, further measures takento

reduce the risk.

The STOP and START controls or electrical inputs of the drive must not be relied

upon to ensure safety of personnel. If a safety hazard could exist from

unexpected starting of the drive, an interlock that electrically isolates the drive

from the AC supply must be installed to prevent the motor being inadvertently

started.

To ensure mechanical safety, additional safetydevices such as electro-mechanical

interlocks and overspeed protection devices may be required. The drive must not be

used in a safety critical application without additional high integrity protectionagainst

hazards arising from a malfunction.

Under certainconditions, the drive can suddenly discontinue control of the motor. If t he

load on themotor could cause the motor speed to be increased (e.g. in hoists and

cranes), a separate method of braking and stopping must be used (e.g. a mechanical

brake).

WARNING

CAUTION

NOTE

Page 9

Commander SE User Guide 2

Issue Number 8 www.controltechniques.com

1.4 Environmental limits

Instructions in this User Guide regarding transport, storage, installation and use of the

drive must be complied with, including the specified environmental limits. Drives must

not be subjected to excessive physical force.

1.5 Compliance with regulations

The installer is responsible for complying with all relevant regulations, such as national

wiringregulations, accidentprevention regulations and electromagnetic compatibility

(EMC) regulations. Particular attention must be given to the cross-sectional areas of

conductors, the selection of fuses or otherprotection, and protective earth (ground)

connections.

This User Guide contains instruction for achieving compliance with specific EMC

standards.

Within the European Union, all machinery in which this product is used must comply

with the following directives:

• 97/37/EC: Safety of machinery.

• 89/336/EEC: Electromagnetic Compatibility.

1.6 Motor

Ensurethe motor is installed in accordance with the manufacturer’s recommendations.

Ensure the motor shaftis not exposed.

Standard squirrel cage induction motors are designed for single speed operation. If it is

intended t o use the capability of the driveto run a motor at speeds above its designed

maximum, it is strongly recommended that the manufacturer is consulted first.

Low speeds may cause the motor to overheat because the cooling fan becomes less

effective. The motor should be fitted with a protection thermistor. If necessary , an

electric forced vent fan should be used.

1.7 Adjusting parameters

Some parameters have a profound effect on the operation of the drive. They must not

be altered without careful consideration of the impact on the controlled system.

Measures must be taken to prevent unwanted changes due to error or tampering.

Page 10

3 Commander SE User Guide

www.controltechniques.com Issue Number 8

2Options

The following options are available for Commander SE;

• Quickey for rapid parametertransfer (SE55)

• Standard and low earth leakage footprint / side mounting RFI filters andlow cost

panel mounting RFI filters

• UniversalKeypad, IP65, hand held or door mounting plain t ext, LCD display

•SESoftWindows

™ based set-upsoftware for advanced programming

• +10V to -10V analog input card for bi-directional input reference (SE51)

• Cable screening bracket and screening clamps to provide a convenient way of

connecting supply, motor and control cable screens to ground (SE11, 12, 13, 14 &

15) (SE15 for Size 5 control cables only)

• EMC Data Sheets

• Through hole mounting plate drawings to allow heatsink to be put outside main

cubicle (Size 2 ~ 4 only)

• EIA232 to EIA485(2 wire) converterfor connecting betweenthe driveandPC when

using SE Soft (SE71 Communications lead)

• Fieldbus C ommunications:

Profibus DP (SE73)

Device Net (SE77)

CAN Open (SE77)

Interbus (SE74)

• Commander SE Advanced User Guide: (See Chapter 10 Advanced Functions on

page 69 for a list of advanced functions).

• AC input line r eactors

• Braking r esistors and mounting plate (Size 2 ~ 4 only)

For f urther details on the above options and availability, contact your local Control

Techniques Drive Centre or Distributor.

Page 11

Commander SE User Guide 4

Issue Number 8 www.controltechniques.com

3 Technical Data

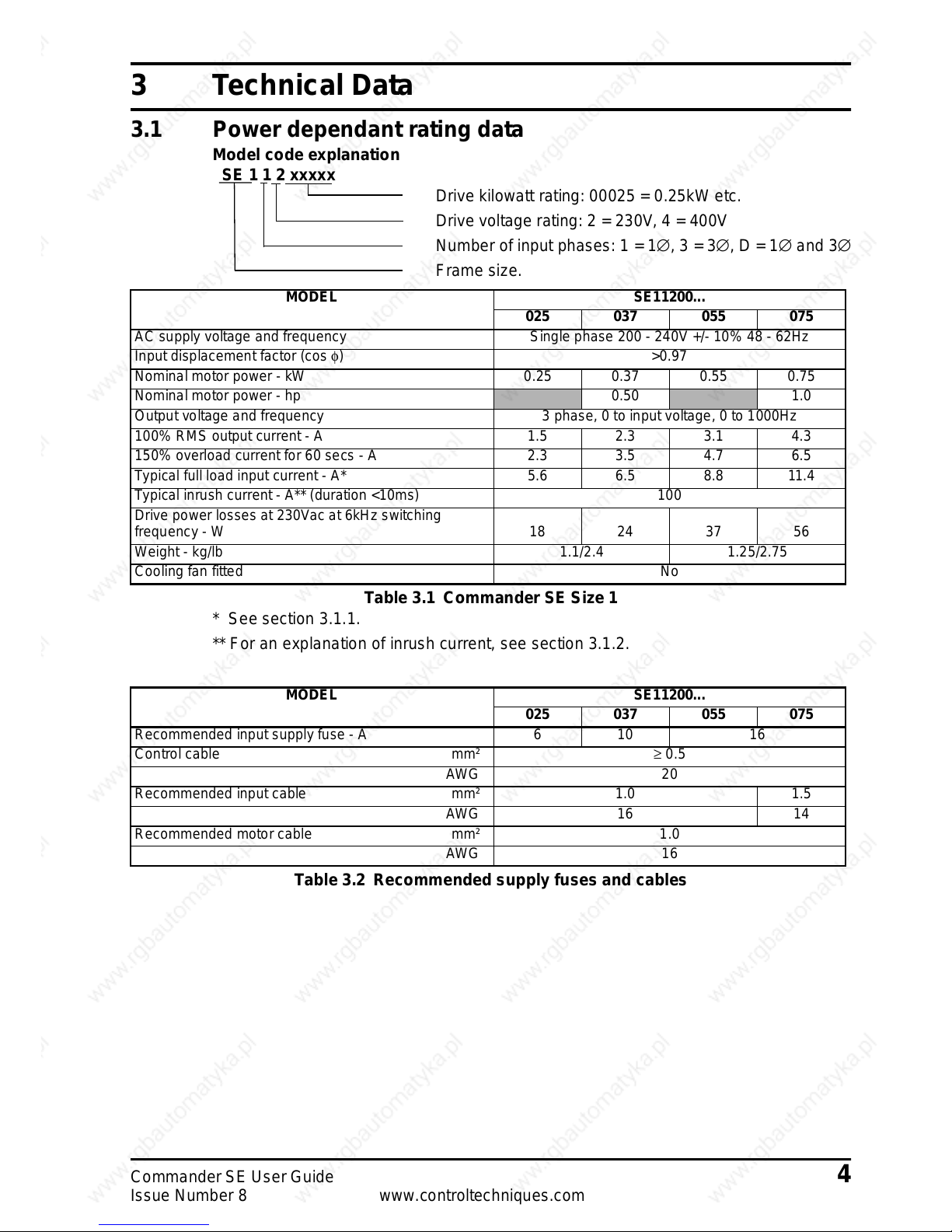

3.1 Power de pendant rating data

Model code explanation

SE 1 1 2 xxxxx

Drivekilowatt rating:00025 = 0.25kW etc.

Drive voltage rating: 2 = 230V, 4 = 400V

Number of input phases: 1 = 1∅,3=3∅,D=1∅ and 3∅

Frame size.

Table 3.1 Commander SE Size 1

* Seesection 3.1.1.

** For an explanation of inrush current, see section 3.1.2.

Table 3.2 Recommended supply fuses and cables

MODEL SE11200...

025 037 055 075

AC supply voltage and frequency Single phase 200 - 240V +/- 10% 48 - 62Hz

Input displacement factor (cos φ) >0.97

Nominal motor power - kW 0.25 0.37 0.55 0.75

Nominal motor power - hp

0.50 1.0

Output voltage and frequency 3 phase, 0 to input voltage, 0 to 1000Hz

100% RMS output current - A 1.5 2.3 3.1 4.3

150% overload current for 60 secs - A 2.3 3.5 4.7 6.5

Typical full load input current - A* 5.6 6.5 8.8 11.4

Typical inrush current - A** (duration <10ms) 100

Drive power losses at 230Vac at 6kHz switching

frequency - W 18 24 37 56

Weight - kg/lb 1.1/2.4 1.25/2.75

Cooling fan fitted No

MODEL SE11200...

025 037 055 075

Recommended input supply fuse - A 6 10 16

Control cable mm² ≥ 0.5

AWG 20

Recommended input cable mm² 1.0 1.5

AWG 16 14

Recommended motor cable mm² 1.0

AWG 16

Page 12

5 Commander SE User Guide

www.controltechniques.com Issue Number 8

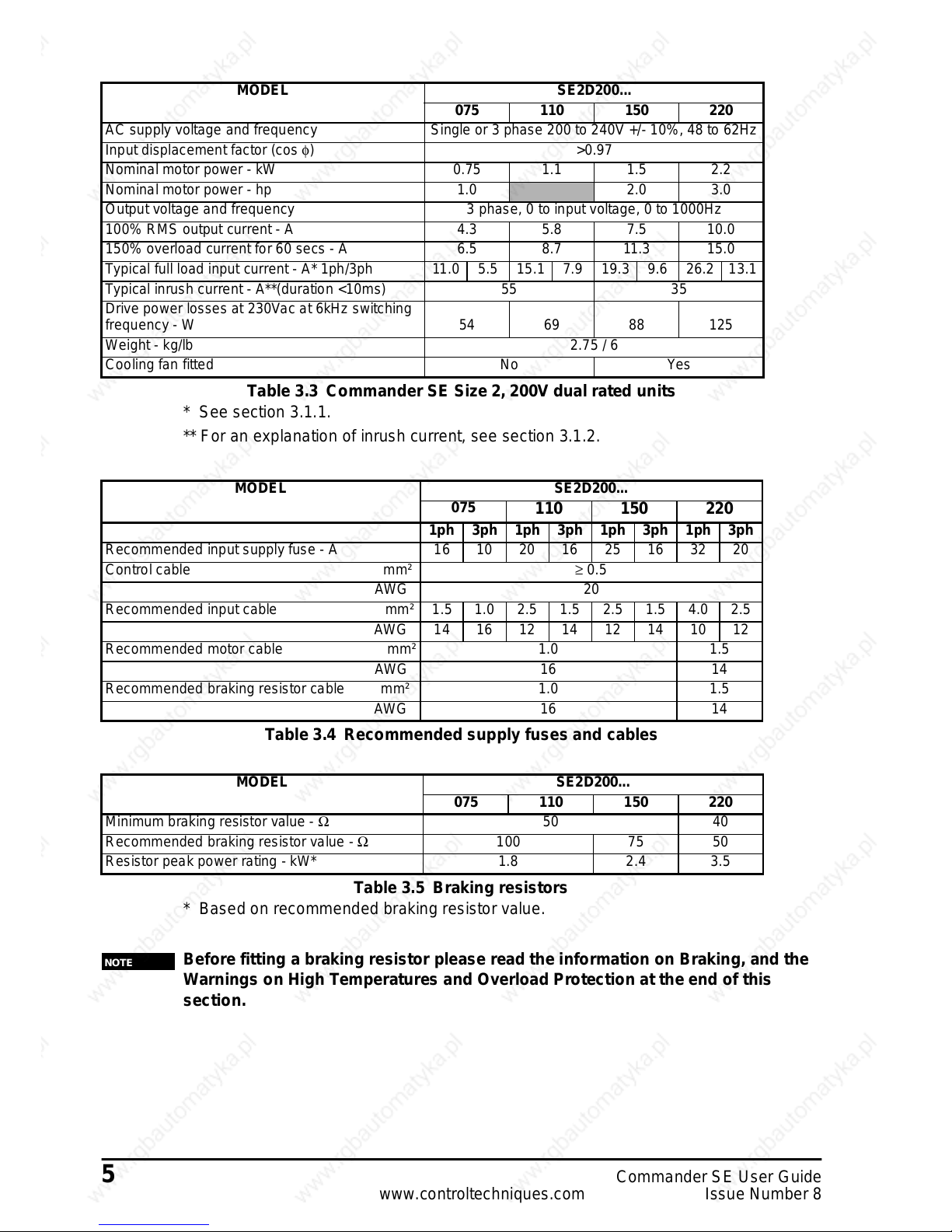

Table 3.3 Commander SE Size 2, 200V dual rated units

* See section 3.1.1.

** For an explanation of inrush current, see section 3.1.2.

Table 3.4 Recommended supply fuses and cables

Table 3.5 Braking resistors

* Based on recommended braking resistor value.

Before fitting a braking resistor please read the information on Braking, and the

Warnings on High Temperatures and Overload Protection at the end of this

section.

MODEL SE2D200...

075 110 150 220

AC supply voltage and frequency Single or 3 phase 200 to 240V +/- 10%, 48 to 62Hz

Input displacement factor (cos φ) >0.97

Nominal motor power - kW 0.75 1.1 1.5 2.2

Nominal motor power - hp 1.0

2.0 3.0

Output voltage and frequency 3 phase, 0 to input voltage, 0 to 1000Hz

100% RMS output current - A 4.3 5.8 7.5 10.0

150% overload current for 60 secs - A 6.5 8.7 11.3 15.0

Typical full load input current - A* 1ph/3ph 11.0 5.5 15.1 7.9 19.3 9.6 26.2 13.1

Typical inrush current - A**(duration <10ms) 55 35

Drive power losses at 230Vac at 6kHz switching

frequency - W 54 69 88 125

Weight - kg/lb 2.75 / 6

Cooling fan fitted No Yes

MODEL SE2D200...

075

110 150 220

1ph 3ph 1ph 3ph 1ph 3ph 1ph 3ph

Recommended input supply fuse - A 16 10 20 16 25 16 32 20

Control cable mm² ≥ 0.5

AWG 20

Recommended input cable mm² 1.5 1.0 2.5 1.5 2.5 1.5 4.0 2.5

AWG1416121412141012

Recommended motor cable mm² 1.0 1.5

AWG 16 14

Recommended braking resistor cable mm² 1.0 1.5

AWG 16 14

MODEL SE2D200...

075 110 150 220

Minimum braking resistor value - Ω 50 40

Recommended braking resistor value - Ω 100 75 50

Resistor peak power rating - kW* 1.8 2.4 3.5

NOTE

Page 13

Commander SE User Guide 6

Issue Number 8 www.controltechniques.com

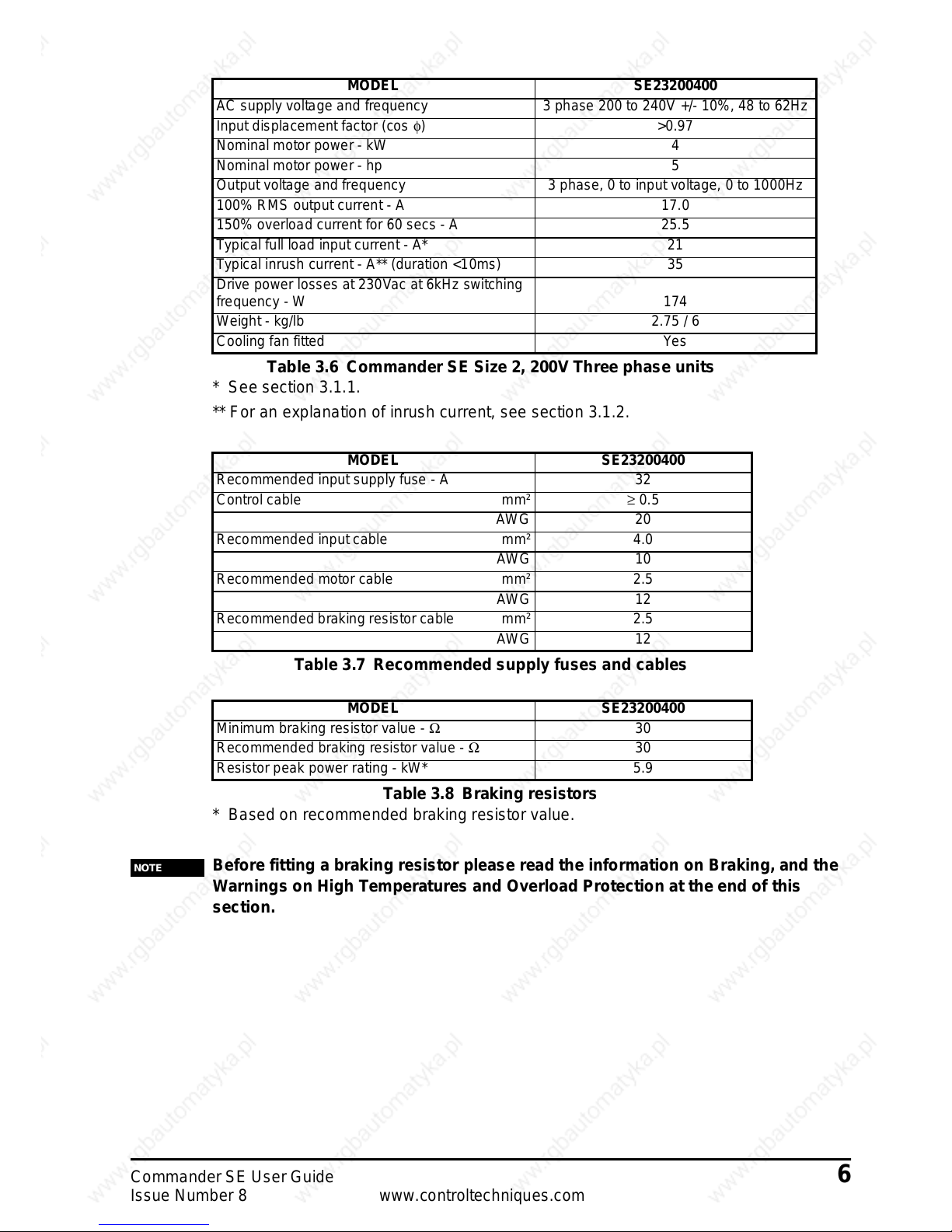

Table 3.6 Commander SE Size 2, 200VThree phase units

* Seesection 3.1.1.

** For an explanation of inrush current, see section 3.1.2.

Table 3.7 Recommended supply fuses and cables

Table 3.8 Braking resistors

* Based on recommended brakingresistor value.

Before fitting a braking resistor please read the information on Braking, and the

Warnings on High Temperatures and Overload Protection at the end of this

section.

MODEL SE23200400

AC supply voltage and frequency 3 phase 200 to 240V +/- 10%, 48 to 62Hz

Input displacement factor (cos φ) >0.97

Nominal motor power - kW 4

Nominal motor power - hp 5

Output voltage and frequency 3 phase, 0 to input voltage, 0 to 1000Hz

100% RMS output current - A 17.0

150% overload current for 60 secs - A 25.5

Typical full load input current - A* 21

Typical inrush current - A** (duration <10ms) 35

Drive power losses at 230Vac at 6kHz switching

frequency - W 174

Weight - kg/lb 2.75 / 6

Cooling fan fitted Yes

MODEL SE23200400

Recommended input supply fuse - A 32

Control cable mm² ≥ 0.5

AWG 20

Recommended input cable mm² 4.0

AWG 10

Recommended motor cable mm² 2.5

AWG 12

Recommended braking resistor cable mm² 2.5

AWG 12

MODEL SE23200400

Minimum braking resistor value - Ω 30

Recommended braking resistor value - Ω 30

Resistor peak power rating - kW* 5.9

NOTE

Page 14

7 Commander SE User Guide

www.controltechniques.com Issue Number 8

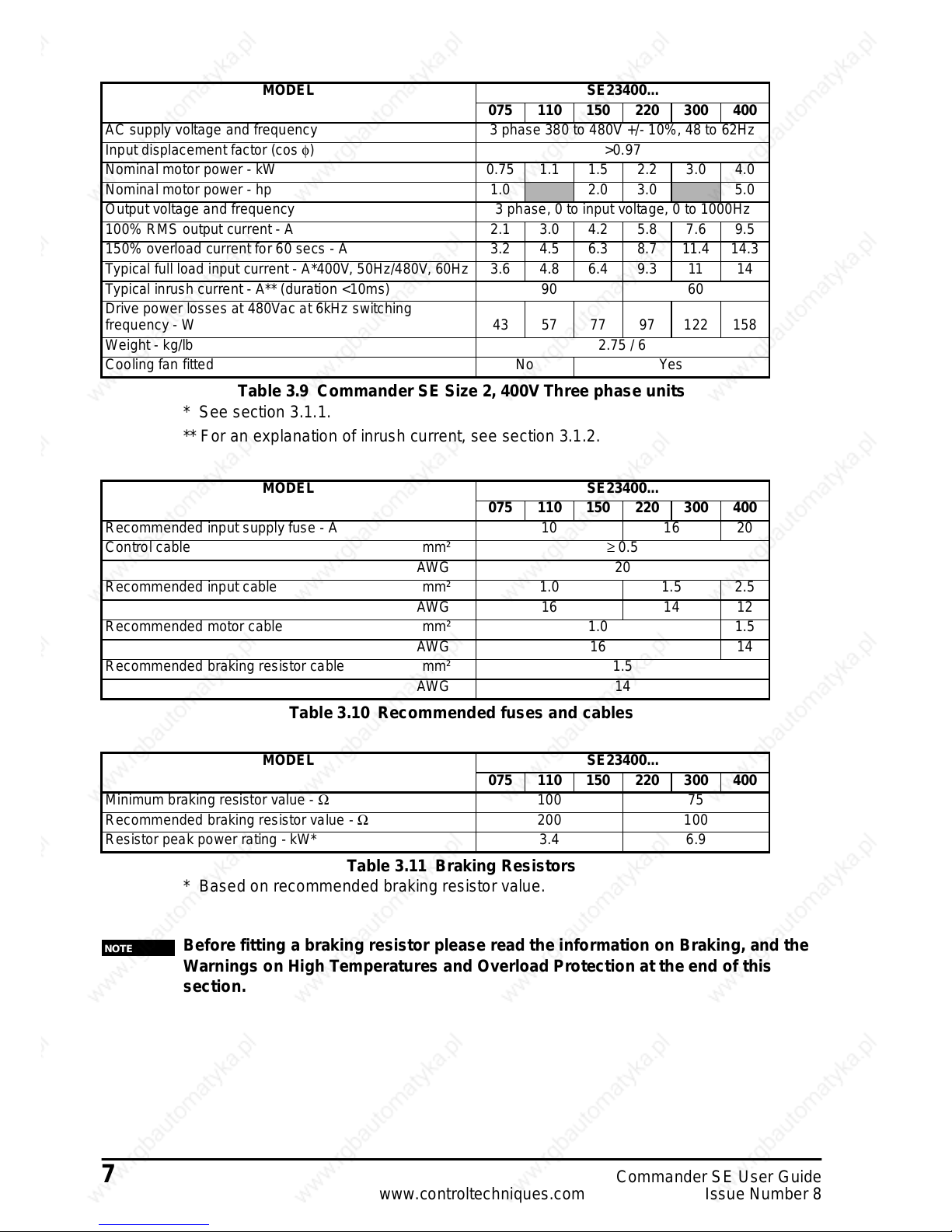

Table 3.9 Commander SE Size 2, 400V Three phase units

* See section 3.1.1.

** For an explanation of inrush current, see section 3.1.2.

Table 3.10 Recommended fuses and cables

Table 3.11 Braking Resistors

* Based on recommended braking resistor value.

Before fitting a braking resistor please read the information on Braking, and the

Warnings on High Temperatures and Overload Protection at the end of this

section.

MODEL SE23400...

075 110 150 220 300 400

AC supply voltage and frequency 3 phase 380 to 480V +/- 10%, 48 to 62Hz

Input displacement factor (cos φ) >0.97

Nominal motor power - kW 0.75 1.1 1.5 2.2 3.0 4.0

Nominal motor power - hp 1.0

2.0 3.0 5.0

Output voltage and frequency 3 phase, 0 to input voltage, 0 to 1000Hz

100% RMS output current - A 2.1 3.0 4.2 5.8 7.6 9.5

150% overload current for 60 secs - A 3.2 4.5 6.3 8.7 11.4 14.3

Typical full load input current - A*400V, 50Hz/480V, 60Hz 3.6 4.8 6.4 9.3 11 14

Typical inrush current - A** (duration <10ms) 90 60

Drive power losses at 480Vac at 6kHz switching

frequency - W 43 57 77 97 122 158

Weight - kg/lb 2.75 / 6

Cooling fan fitted No Yes

MODEL SE23400...

075 110 150 220 300 400

Recommended input supply fuse - A 10 16 20

Control cable mm² ≥ 0.5

AWG 20

Recommended input cable mm² 1.0 1.5 2.5

AWG 16 14 12

Recommended motor cable mm² 1.0 1.5

AWG 16 14

Recommended braking resistor cable mm² 1.5

AWG 14

MODEL SE23400...

075 110 150 220 300 400

Minimum braking resistor value - Ω 100 75

Recommended braking resistor value - Ω 200 100

Resistor peak power rating - kW* 3.4 6.9

NOTE

Page 15

Commander SE User Guide 8

Issue Number 8 www.controltechniques.com

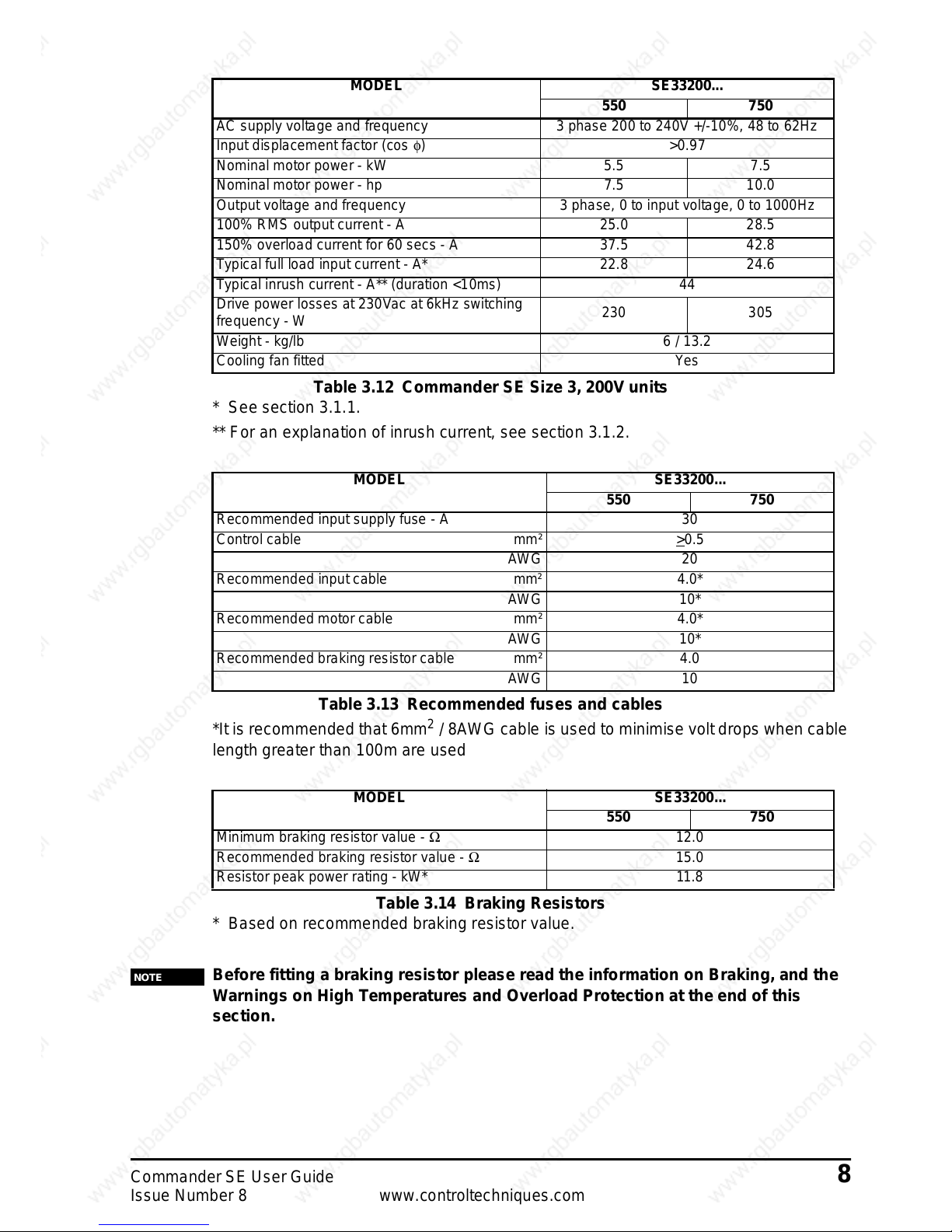

Table 3.12 Commander SE Size 3, 200V units

* Seesection 3.1.1.

** For an explanation of inrush current, see section 3.1.2.

Table3.13 Recommended fuses and cables

*It is recommended that6mm

2

/ 8AWG cable is used t o minimisevolt drops whencable

lengthgreaterthan 100m are used

Table 3.14 Braking Resistors

* Based on recommended brakingresistor value.

Before fitting a braking resistor please read the information on Braking, and the

Warnings on High Temperatures and Overload Protection at the end of this

section.

MODEL SE33200...

550 750

AC supply voltage and frequency 3 phase 200 to 240V +/-10%, 48 to 62Hz

Input displacement factor (cos φ)>0.97

Nominal motor power - kW 5.5 7.5

Nominal motor power - hp 7.5 10.0

Output voltage and frequency 3 phase, 0 to input voltage, 0 to 1000Hz

100% RMS output current - A 25.0 28.5

150% overload current for 60 secs - A 37.5 42.8

Typical full load input current - A* 22.8 24.6

Typical inrush current - A** (duration <10ms) 44

Drive power losses at 230Vac at 6kHz switching

frequency - W

230 305

Weight - kg/lb 6 / 13.2

Cooling fan fitted Yes

MODEL SE33200...

550 750

Recommended input supply fuse - A 30

Control cable mm² >

0.5

AWG 20

Recommended input cable mm² 4.0*

AWG 10*

Recommended motor cable mm² 4.0*

AWG 10*

Recommended braking resistor cable mm² 4.0

AWG 10

MODEL SE33200...

550 750

Minimum braking resistor value - Ω 12.0

Recommended braking resistor value - Ω 15.0

Resistor peak power rating - kW* 11.8

NOTE

Page 16

9 Commander SE User Guide

www.controltechniques.com Issue Number 8

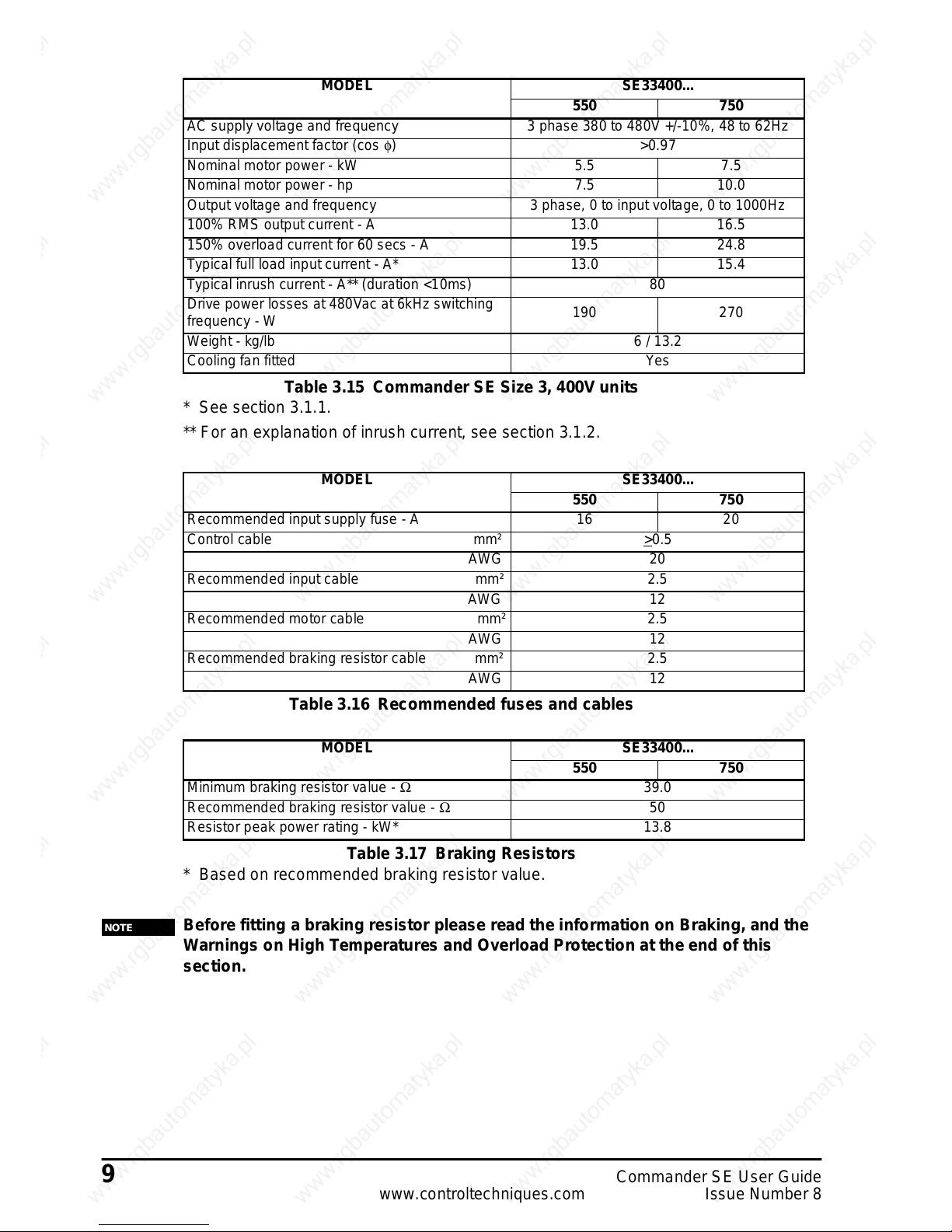

Table 3.15 Commander SE Size 3, 400V units

* See section 3.1.1.

** For an explanation of inrush current, see section 3.1.2.

Table 3.16 Recommended fuses and cables

Table 3.17 Braking Resistors

* Based on recommended braking resistor value.

Before fitting a braking resistor please read the information on Braking, and the

Warnings on High Temperatures and Overload Protection at the end of this

section.

MODEL SE33400...

550 750

AC supply voltage and frequency 3 phase 380 to 480V +/-10%, 48 to 62Hz

Input displacement factor (cos φ)>0.97

Nominal motor power - kW 5.5 7.5

Nominal motor power - hp 7.5 10.0

Output voltage and frequency 3 phase, 0 to input voltage, 0 to 1000Hz

100% RMS output current - A 13.0 16.5

150% overload current for 60 secs - A 19.5 24.8

Typical full load input current - A* 13.0 15.4

Typical inrush current - A** (duration <10ms) 80

Drive power losses at 480Vac at 6kHz switching

frequency - W

190 270

Weight - kg/lb 6 / 13.2

Cooling fan fitted Yes

MODEL SE33400...

550 750

Recommended input supply fuse - A 16 20

Control cable mm² >

0.5

AWG 20

Recommended input cable mm² 2.5

AWG 12

Recommended motor cable mm² 2.5

AWG 12

Recommended braking resistor cable mm² 2.5

AWG 12

MODEL SE33400...

550 750

Minimum braking resistor value - Ω 39.0

Recommended braking resistor value - Ω 50

Resistor peak power rating - kW* 13.8

NOTE

Page 17

CommanderSE User Guide 10

Issue Number 8 www.controltechniques.com

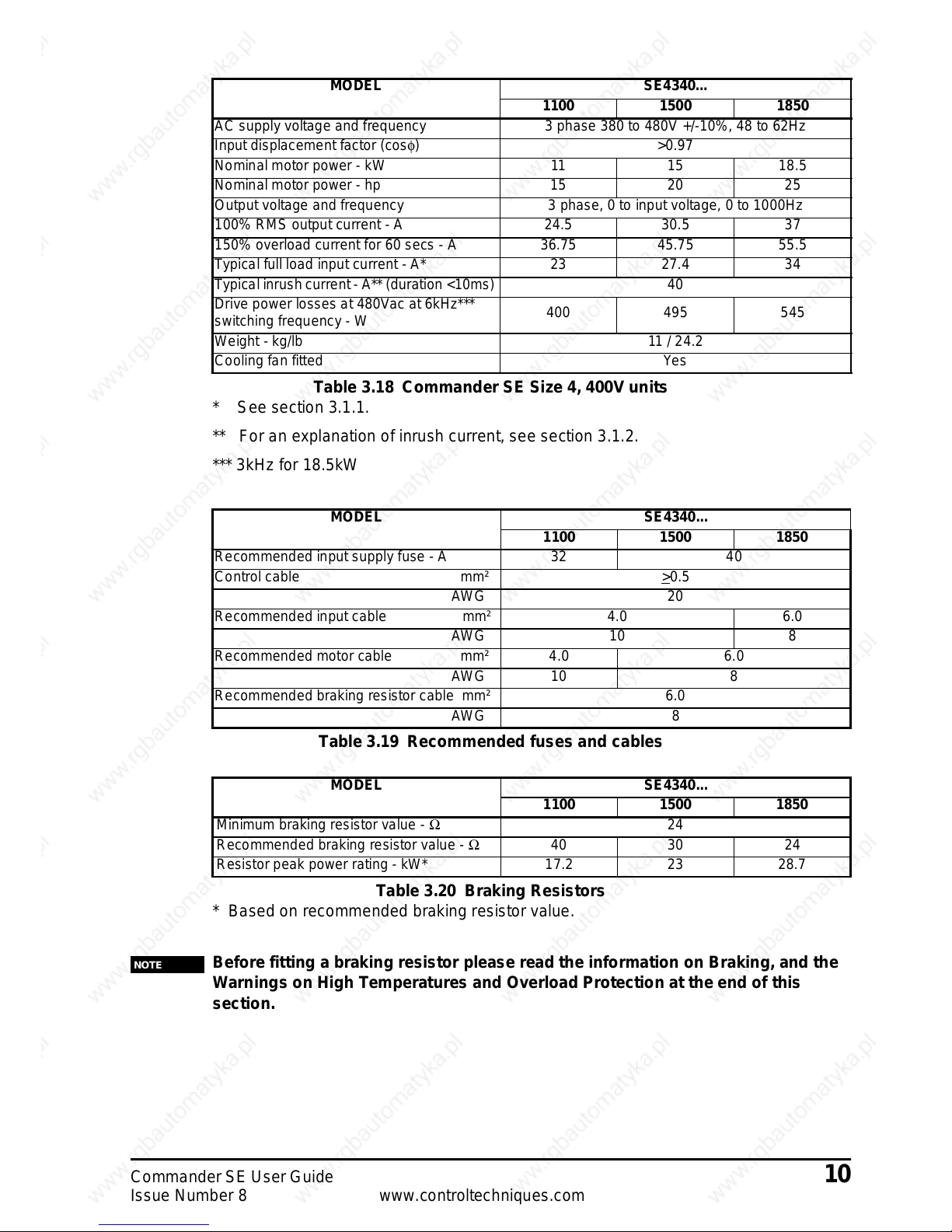

Table 3.18 Commander SE Size 4, 400V units

* See section 3.1.1.

** For an explanation of inrush current, see section 3.1.2.

*** 3kHz for 18.5kW

Table3.19 Recommended fuses and cables

Table 3.20 Braking Resistors

* Based on recommended brakingresistor value.

Before fitting a braking resistor please read the information on Braking, and the

Warnings on High Temperatures and Overload Protection at the end of this

section.

MODEL SE4340...

1100 1500 1850

AC supply voltage and frequency 3 phase 380 to 480V +/-10%, 48 to 62Hz

Input displacement factor (cosφ) >0.97

Nominal motor power - kW 11 15 18.5

Nominal motor power - hp 15 20 25

Output voltage and frequency 3 phase, 0 to input voltage, 0 to 1000Hz

100% RMS output current - A 24.5 30.5 37

150% overload current for 60 secs - A 36.75 45.75 55.5

Typical full load input current - A* 23 27.4 34

Typical inrushcurrent - A** (duration <10ms) 40

Drive power losses at 480Vac at 6kHz***

switching frequency - W

400 495 545

Weight - kg/lb 11/ 24.2

Cooling fan fitted Yes

MODEL SE4340...

1100 1500 1850

Recommended input supply fuse - A 32 40

Control cable mm² >

0.5

AWG 20

Recommended input cable mm² 4.0 6.0

AWG 10 8

Recommended motor cable mm² 4.0 6.0

AWG 10 8

Recommended braking resistor cable mm² 6.0

AWG 8

MODEL SE4340...

1100 1500 1850

Minimum braking resistor value - Ω 24

Recommended braking resistor value - Ω 40 30 24

Resistor peak power rating - kW* 17.2 23 28.7

NOTE

Page 18

11 Commander SE User Guide

www.controltechniques.com Issue Number 8

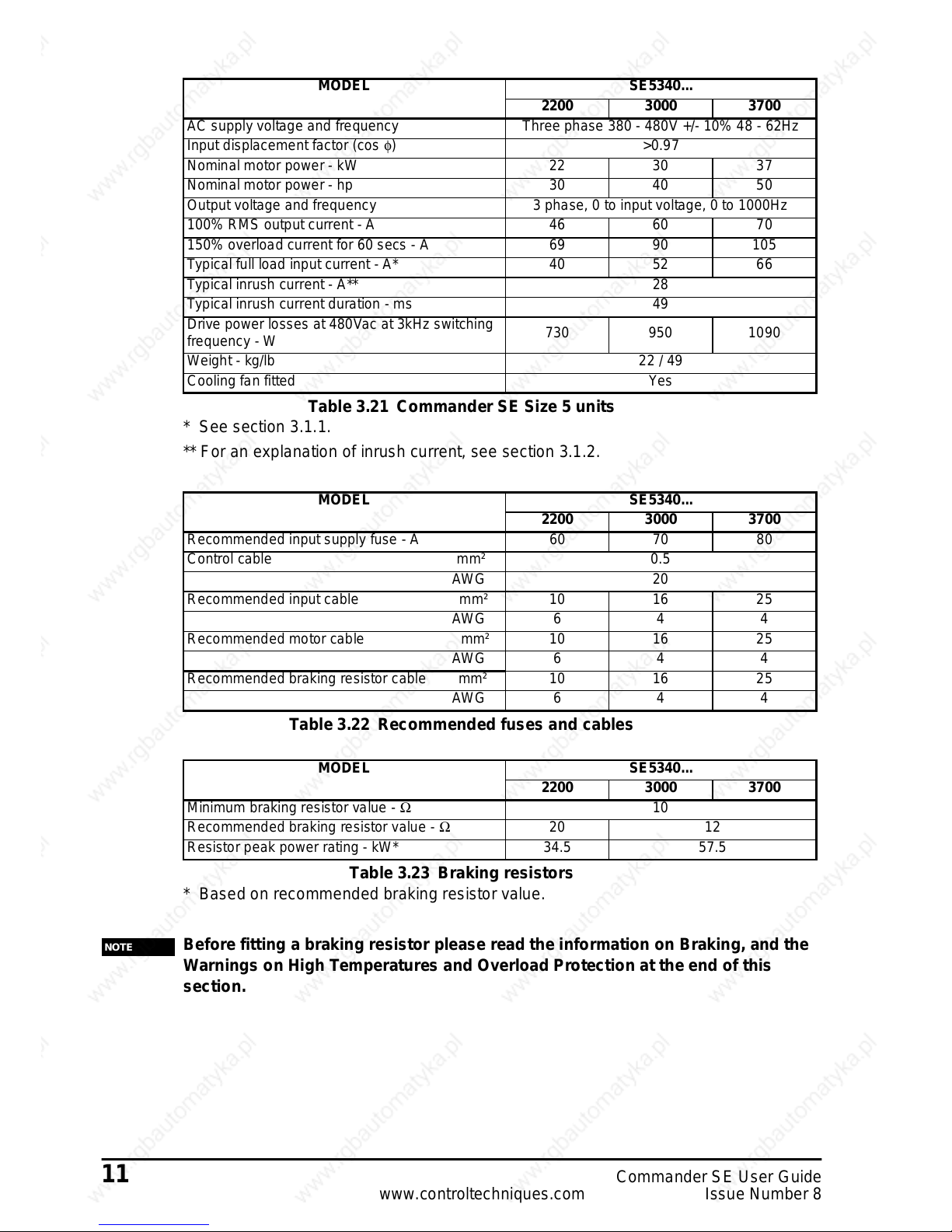

Table 3.21 Commander SE Size 5 units

* See section 3.1.1.

** For an explanation of inrush current, see section 3.1.2.

Table 3.22 Recommended fuses and cables

Table 3.23 Braking resistors

* Based on recommended braking resistor value.

Before fitting a braking resistor please read the information on Braking, and the

Warnings on High Temperatures and Overload Protection at the end of this

section.

MODEL SE5340...

2200 3000 3700

AC supply voltage and frequency Three phase 380 - 480V +/- 10% 48 - 62Hz

Input displacement factor (cos φ)>0.97

Nominal motor power - kW 22 30 37

Nominal motor power - hp 30 40 50

Output voltage and frequency 3 phase, 0 to input voltage, 0 to 1000Hz

100% RMS output current - A 46 60 70

150% overload current for 60 secs - A 69 90 105

Typical full load input current - A* 40 52 66

Typical inrush current - A** 28

Typical inrush current duration - ms 49

Drive power losses at 480Vac at 3kHz switching

frequency - W

730 950 1090

Weight- kg/lb 22/ 49

Cooling fan fitted Yes

MODEL SE5340...

2200 3000 3700

Recommended input supply fuse - A 60 70 80

Control cable mm² 0.5

AWG 20

Recommended input cable mm² 10 16 25

AWG 6 4 4

Recommended motor cable mm² 10 16 25

AWG 6 4 4

Recommended braking resistor cable mm² 10 16 25

AWG 6 4 4

MODEL SE5340...

2200 3000 3700

Minimum braking resistor value - Ω 10

Recommended braking resistor value - Ω 20 12

Resistor peak power rating - kW* 34.5 57.5

NOTE

Page 19

CommanderSE User Guide 12

Issue Number 8 www.controltechniques.com

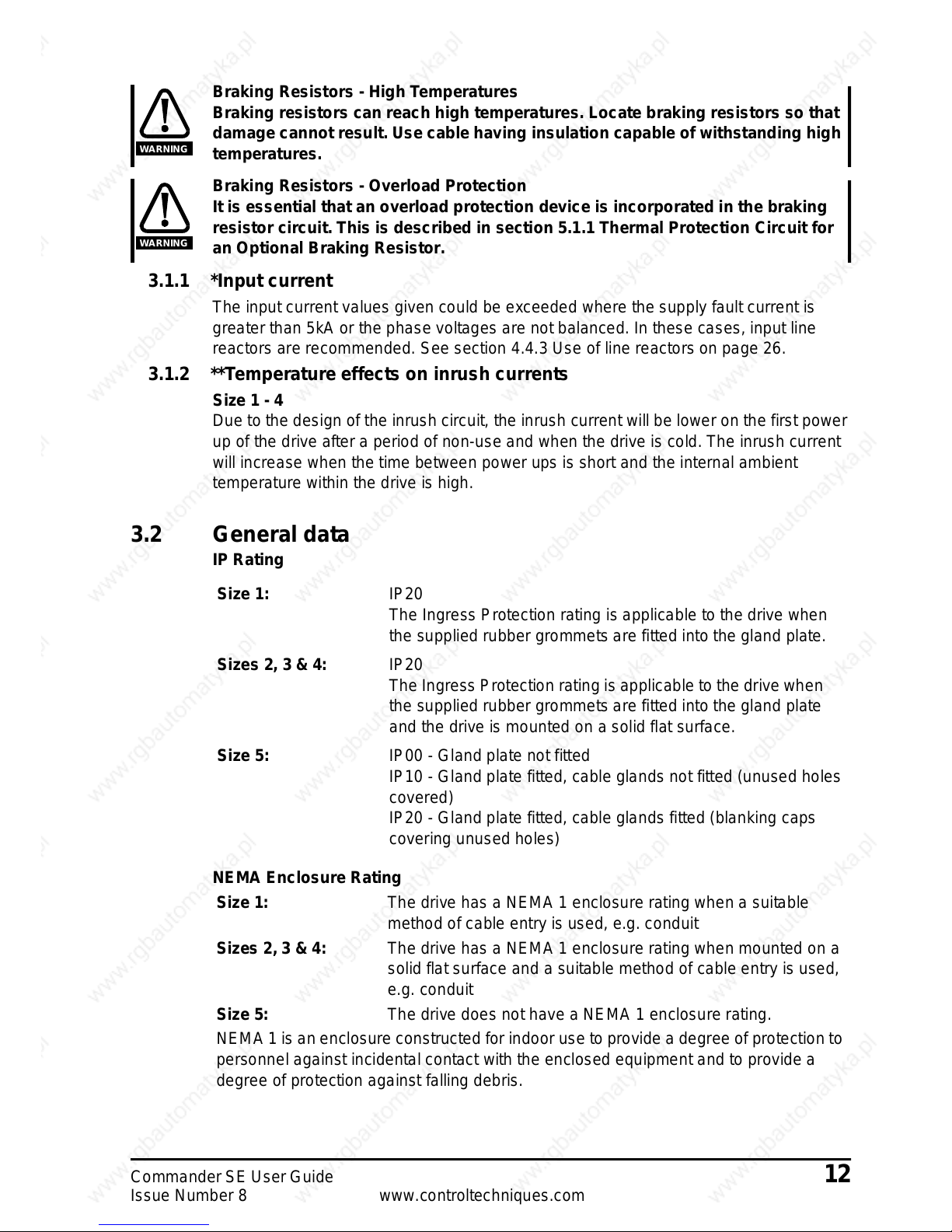

Braking R esist ors - High Temperatures

Braking resistors can reach high temperatures. Locate braking resistors so that

damage cannot result. Use cable having insulation capable of withstanding high

temperatures.

Braking R esist ors - Overload Protection

It is essential that an overload protection device is incorporated in the braking

resistor circuit. This is described in section 5.1.1 Thermal Protection Circuit for

an Optional Braking Resistor.

3.1.1 *Input current

The inputcurrentvalues given could be exceeded where the supply faultcurrent is

greater than 5kA or the phase voltages are not balanced. In thesecases, input line

reactors are recommended. See section 4.4.3 Useoflinereactorson page 26.

3.1.2 **Temperature effects on inrush currents

Size1-4

Due t o the design ofthe inrushcircuit, the inrush currentwill be lower on the firstpower

up of the drive after a period of non-use and when the drive is cold. The inrush current

will increase when the time between power ups is short and the internal ambient

temperature within the drive is high.

3.2 General data

IP Rating

NEMA Enclosure Rating

WARNING

WARNING

Size 1: IP20

The Ingress Protection rating is applicable to the drive when

the supplied rubber grommetsare fittedinto the gland plate.

Sizes 2, 3 & 4: IP20

The IngressProtectionratingis applicable to t he drivewhen

the supplied rubber grommetsare fittedinto the gland plate

and the drive is mounted on a solid flat surface.

Size 5: IP00 - Gland plate not fitted

IP10 - Glandplate fitted, cable glandsnot fitted (unused holes

covered)

IP20 - Glandplate fitted, cable glands fitted(blanking caps

covering unused holes)

Size 1: The drive has a NEMA 1 enclosure ratingwhen a suitable

methodof cable entry is used, e.g. conduit

Sizes 2, 3 & 4: ThedrivehasaNEMA1enclosureratingwhenmountedona

solid flat surface and a suitable method of cable entry is used,

e.g. conduit

Size 5: ThedrivedoesnothaveaNEMA1enclosurerating.

NEMA1isanenclosureconstructedforindoorusetoprovideadegreeofprotectionto

personnel against incidental contact with the enclosed equipment and to providea

degree of protection against falling debris.

Page 20

13 Commander SE User Guide

www.controltechniques.com Issue Number 8

If the drive is not mounted as indicated, hazardous live parts will be exposed and

the IP Rating or NEMA 1 enclosure rating of the drive will be invalid.

WARNING

Input phase

imbalance:

Phase imbalance not to exceed 2% negative phase sequence

Ambient

temperature:

-10°Cto+40°C(14°Fto104°F) at 6kHz switchingfrequency.

-10°Cto+50°C(14°Fto122°F) at 3kHz switchingfrequency

with derating on somemodels.

-10°Cto+40°C(14°Fto104°F) at 3kHz switching frequency for

SE4, 18.5kW and SE Size 5.

See CommanderSE AdvancedUser Guide for Derating

Curves.

Storage temperature: -40°Cto+60°C (-40°Fto140°F) for12 monthsmax

Altitude: Reduce the normal full-load current by 1% for every 100m

(325ft) above 1000m (3250ft) to a maximum of 4000m

(13000ft).

Humidity: Maximum relativehumidity 95% (non-condensing)

Materials: Flammability rating of main enclosure :UL94-5VA (Size 1 to 4)

Flammability rating of main enclosure:UL94-V0 (Size 5)

Grommets:UL94-V1

Vibration (random):

Vibration

(sinusoidal)

Unpackaged - tested to 0.01g²/Hz (equivalent to 1.2g rms) from

5 to 150Hz for 1 hour in each of 3 axes in accordance with

IEC68-2-34 and IEC68-2-36.

Unpackaged - tested from 2-9Hz, 3.5mm displacement; 9-

200Hz 10m/s

2

acceleration; 200-500Hz, 15m/s2acceleration.

Duration - 15 minutes in each of 3 axes. Sweep rate 1 octave/

minute.

Test in accordancewith IEC68-2-6.

Bump: Packaged - tested to 40g, 6ms, 100 times/direction for all 6

direct ions as in IEC68-2-29

Unpackaged - tested to 25g, 6ms, 100 times/direction for all 6

directions in accordance with IEC68-2-29

Frequency

accuracy:

0.01%

Resolution: 0.1Hz

Output frequency

range:

0to1000Hz

Starts per hour: By using the electronic control terminals: Unlimited

By switching of the supply: 20 starts per hour maximum (3

minute intervals between starts)

Power up delay: 1.5 seconds maximum (Allow at least 1 second for Sizes 1 to 4

and 1.5 seconds for Size 5 before monitoring the state of the

status relay contacts, communicating with the drive via serial

communications etc.)

Page 21

CommanderSE User Guide 14

Issue Number 8 www.controltechniques.com

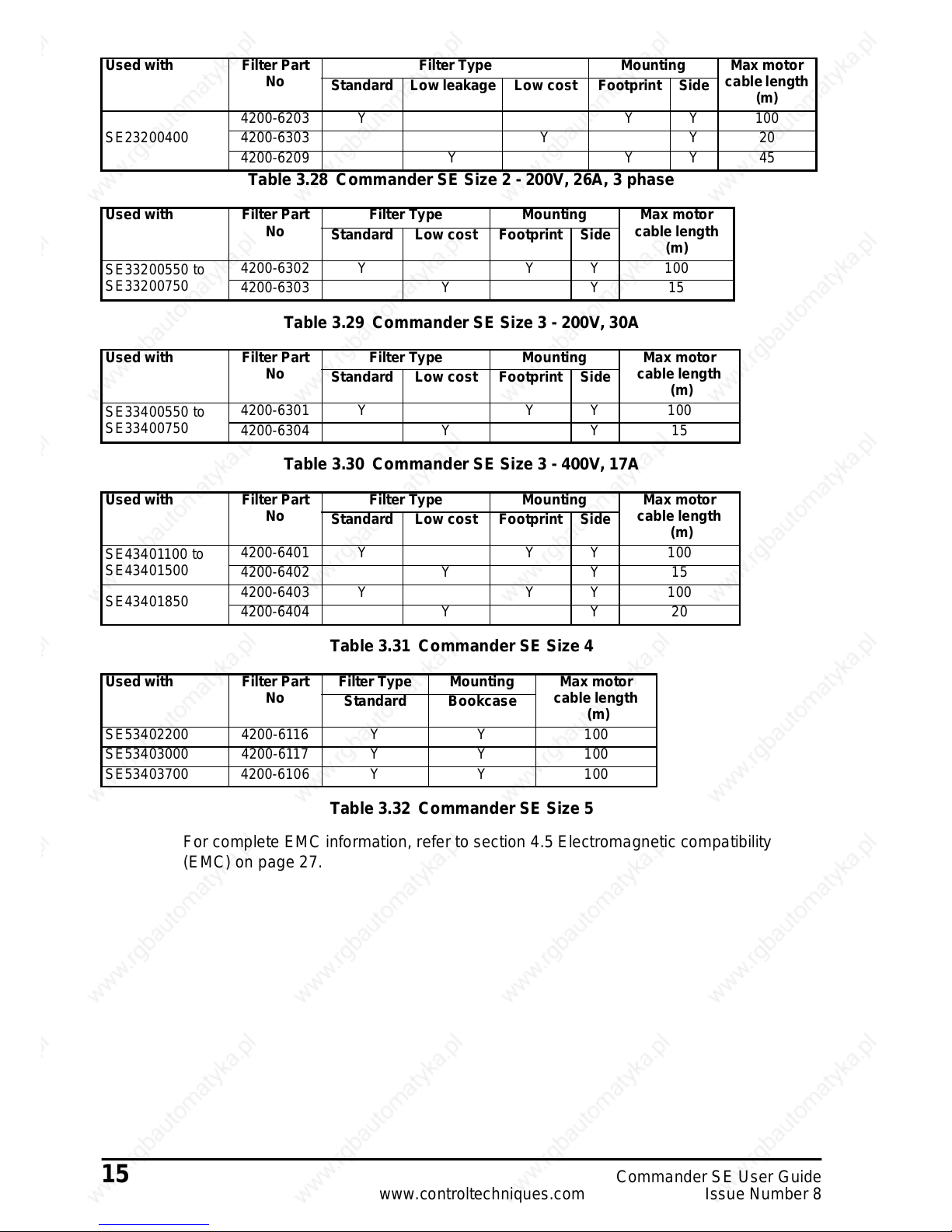

3.3 RFI Filters

RFI filters are available as optional extra parts where required.

Table 3.24 Commander SE Size 1

Table 3.25 Commander SE Size 2 - 200V, 26A, 1 phase

Table 3.26 Commander SE Size 2 - 200 / 400V, 16A, 3 phase

Table 3.27 Commander SE Size 2 - 200 / 400V, 16A, 3 phase

Serial

Communications:

2-wireEIA485 via RJ45 connector

ANSI and Modbus RTU protocols supported

Switching

Frequencies:

3, 6, and 12 kHz are available with Intelligent Thermal

Management software automatically changing the switching

frequenciesdepending on load conditions, heatsink

temperature and output frequency, to prevent heatsink

overtemperature trips.

EMC: EN50082-2 and EN61800-3for immunity

EN50081-1*, EN50081-2 and EN61800-3 first environment,

with optional RFI filter. See section 3.3 and section 4.5.

* Size 1 units only.

This is a product of the restricted distribution class

according to IEC61800-3.

In a domestic environment this product may c ause

radio interference in which case the user may be

required to take adequate measures.

WARNING

Used with Filter Part

No

Filter Type Mounting Max motor

cable length

(m)

Standard Low leakage Low cost Footprint Side

SE11200025 to

SE11200075

4200-6101 Y Y 20

4200-6102 Y Y Y 75

4200-6103 Y Y Y 15

Used with Filter Part

No

Filter Type Mounting Max motor

cable length

(m)

Standard Low leakage Low cost Footprint Side

SE2D200075 to

SE2D200220

4200-6201 Y Y Y 100

4200-6204 Y Y 50

4200-6205 Y Y Y 15

Used with Filter Part

No

Filter Type Mounting Max motor

cable length

(m)

Standard Low leakage Low cost Footprint Side

SE2D200075 to

SE2D200220

4200-6202 Y Y Y 100

4200-6304 Y Y 15

4200-6207 Y Y Y 45

Used with Filter Part

No

Filter Type Mounting Max motor

cable length

(m)

Standard Low leakage Low cost Footprint Side

SE23400075 to

SE23400400

4200-6202 Y Y Y 100

4200-6304 Y Y 15

4200-6207 Y Y Y 20

Page 22

15 Commander SE User Guide

www.controltechniques.com Issue Number 8

Table 3.28 Commander SE Size 2 - 200V, 26A, 3 phase

Table 3.29 Commander SE Size 3 - 200V, 30A

Table 3.30 Commander SE Size 3 - 400V, 17A

Table 3.31 Commander SE Size 4

Table 3.32 Commander SE Size 5

For complete EMC information, r efer to section 4.5 Electromagnetic compatibility

(EMC) on page 27.

Used with Filter Part

No

Filter Type Mounting Max motor

cable length

(m)

Standard Low leakage Low cost Footprint Side

SE23200400

4200-6203 Y Y Y 100

4200-6303 Y Y 20

4200-6209 Y Y Y 45

Used with Filter Part

No

Filter Type Mounting Max motor

cable length

(m)

Standard Low cost Footprint Side

SE33200550 to

SE33200750

4200-6302 Y Y Y 100

4200-6303 Y Y 15

Used with Filter Part

No

Filter Type Mounting Max motor

cable length

(m)

Standard Low cost Footprint Side

SE33400550 to

SE33400750

4200-6301 Y Y Y 100

4200-6304 Y Y 15

Used with Filter Part

No

Filter Type Mounting Max motor

cable length

(m)

Standard Low cost Footprint Side

SE43401100 to

SE43401500

4200-6401 Y Y Y 100

4200-6402 Y Y 15

SE43401850

4200-6403 Y Y Y 100

4200-6404 Y Y 20

Used with Filter PartNoFilter Type Mounting Max motor

cable length

(m)

Standard Bookcase

SE53402200 4200-6116 Y Y 100

SE53403000 4200-6117 Y Y 100

SE53403700 4200-6106 Y Y 100

Page 23

CommanderSE User Guide 16

Issue Number 8 www.controltechniques.com

4 Installing the drive

4.1 Safety information

Follow the instructions

The mechanical and electrical installation instructions must be adhered to. Any

questions or doubt should be referred to the supplier of the equipment. It is the

responsibility of the owner or user to ensure that the installation of the drive and

any external option unit, and the way in which they are operated and maintained,

comply with the requirements of the Health and Safety at Work Act in the United

Kingdom or applicable legislation and regulations and codes of practice in the

country in which the equipment is used.

Competence of the installer

The drive must be installed by professional assemblerswho are familiarwiththe

requirements for safety and EMC. The assembler is responsible for ensuring that

the end product or system complies with all the relevant laws in the country where

it is to be used.

4.2 Planning the installation

The following considerations must be made when planningthe installation:

Access

Access must be restricted to authorised personnel only. Safety regulations which apply

at the place of use must be complied with. If it is a requirement that authorised

personnel manually adjust drive settings while power is applied, t hen the drive itself

must meet the requirements of IP20. See section 3.2 General data on page 12 for

details.

Environmental protection

The drive must be protected from:

• moisture, including dripping water or spraying water and condensation. An anti-

condensation heatermay be required, whichmust be switchedoff whenthe driveis

running.

• contamination with electrically conductive material

• temperature beyond the specified operating and storage ranges

Cooling

The heat produced by the drive must be removedwithoutits specified operating

temperature being exceeded. Note that a sealed enclosure gives much reduced cooling

compared with a ventilated one, and may need to be larger and/or use internal air

circulating fans. For further information on enclosure design, please refer to the

Commander SE Advanced User Guide.

Electrical safety

The installation must be safe under normal and fault conditions. Electrical installation

instructions are given later in thischapter.

Fire protection

The drive enclosure is not classified as a fire enclosure. A separate fire enclosure must

be provided.

Electromagnetic compatibility

Variable speed drives are powerful electronic circuits which can cause electromagnetic

interference if not installed correctly with careful attention to the layout of the wiring.

Some simple routine precautions can prevent disturbance to typical industrial control

WARNING

WARNING

Page 24

17 Commander SE User Guide

www.controltechniques.com Issue Number 8

equipment.

If it is necessary to meet strictemission limits, or if it is knownthat electromagnetically

sensitive equipment is located nearby, then full precautions must be observed. These

willinclude the use of RFI filters at the drive i nputs, which must be locatedvery close to

the drives. Space must be made available for the filters and allowance made for

carefully segregated wiring. Both levels of precautions are given further on in this

chapter.

Hazardous areas

The drive must not be located in a classified hazardous areas unless it is installed in an

approved enclosure and the installation is certified.

4.3 Mechanical installation

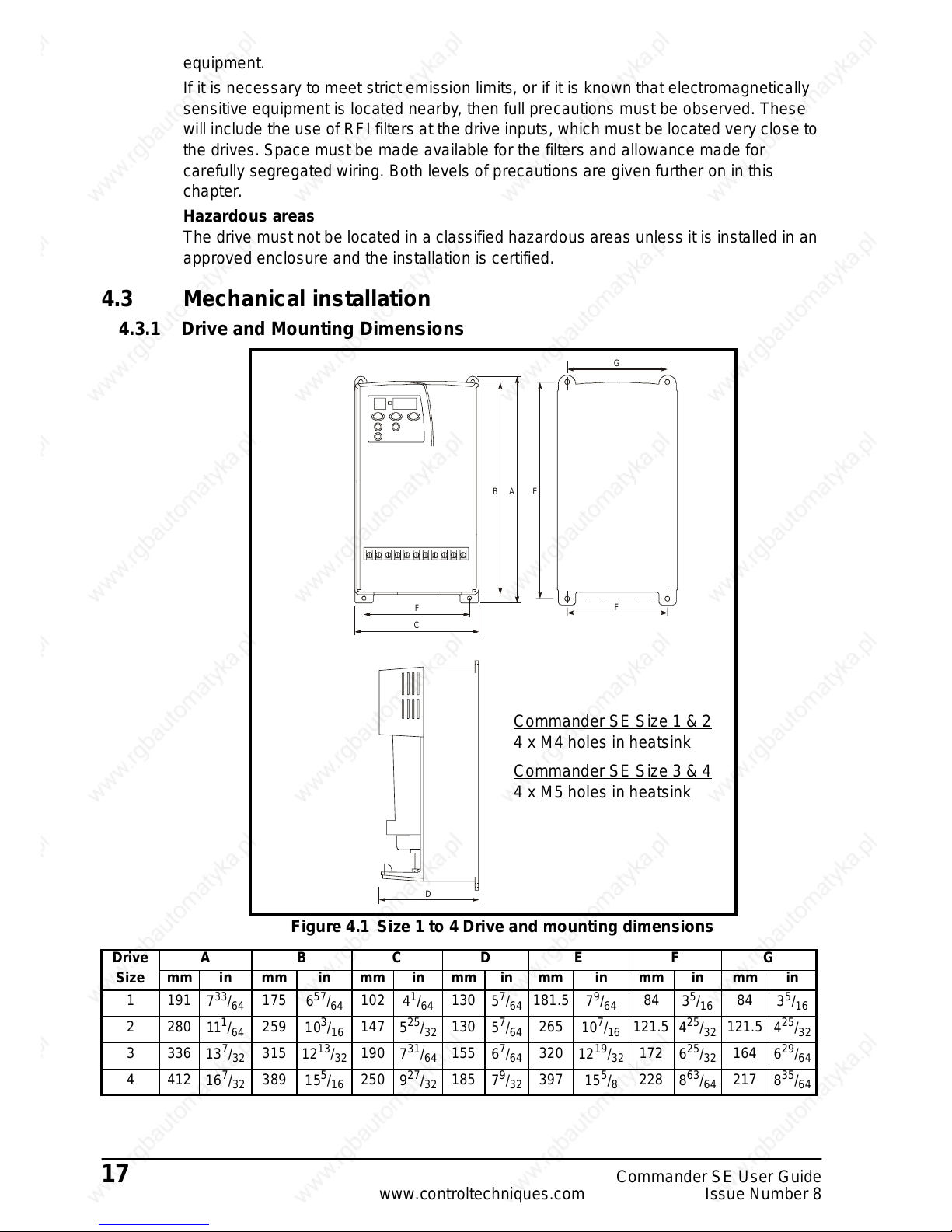

4.3.1 Drive and Mounting Dimensions

Figure 4.1 Size 1 to 4 Drive and mounting dimensions

C

D

F

B

EFA

G

Commander SE Size 1 & 2

4xM4holesinheatsink

Commander SE Size 3 & 4

4xM5holesinheatsink

Drive A B C D E F G

Size mm in mm in mm in mm in mm in mm in mm in

1 191

733/

64

175

6

57

/

64

102

4

1

/

64

130

5

7

/

64

181.5

7

9

/

64

84

3

5

/

16

84

3

5

/

16

2 280

11

1

/

64

259

10

3

/

16

147

5

25

/

32

130

5

7

/

64

265

10

7

/

16

121.5

4

25

/

32

121.5

4

25

/

32

3 336

13

7

/

32

315

12

13

/

32

190

7

31

/

64

155

6

7

/

64

320

12

19

/

32

172

6

25

/

32

164

6

29

/

64

4 412

16

7

/

32

389

15

5

/

16

250

9

27

/

32

185

7

9

/

32

397

15

5

/

8

228

8

63

/

64

217

8

35

/

64

Page 25

CommanderSE User Guide 18

Issue Number 8 www.controltechniques.com

Figure 4.2 Surface mounting Size 5 units

The drive should be mounted vertically. A mounting template is provided on the

drive packing cartonto aid installation.

When surface mounting a model size 5, allow a clearance of 150mm (6in) above

the drive; this is for dismounting. A minimum clearance of 100mm (4in) is

required for ventilation.

Figure 4.3 Through-panel mounting Size 5 units

Use M6 x 12mm max. (or equivalent) thread-forming screwsto screw into holes in the

heatsink, or tap the holes to a suitablethread size.

NOTE

Back-plate

13.189in 14.488in

1.772in

13.622in

6.890in

0.650in

0.650in

10.236in

7.382in

14.764in

375mm

187.5mm

335mm 368mm

260mm

16.5mm

16.5mm

346mm

175mm

45mm

NOTE

Back-plate

13.583in

0.650in

0.650in

11.299in

13.189in 14.331in

14.764in

10.236in

4.724in 5.512in

2.717in2.717in

5.177in 7.362in

14.094in

0.276in0.630

in

375mm

335mm 364mm

120mm

140mm

260mm

7mm 16mm

287mm

3

58mm

1

87mm

1

31.5mm

69mm 69mm

345mm

16.5mm

16.5mm

Page 26

19 Commander SE User Guide

www.controltechniques.com Issue Number 8

Table 4.1 Size 5 Mounting brackets

Figure4.4 Size5baffleplate

When a Commander SE size 5 is through-panel mounted a baffleplate is required to

ensurethe correct level of air flow is maintained through the heatsink. The fitting of a

baffle plate causes the heatsinkto act as a chimney; this enhancesthe air flow along

the heatsink fins to aid cooling (this naturallyoccurswhen the driveis surfacemounted).

You may make a baffle plate from any suitable conducting or non-conducting material.

Use M6 x 12mm max (or equivalent) thread-forming screws to screw into the holes in

the heatsink, or tap the holes to a suitable thread size.

Through-hole mounting

bracket

Surface mounting bracket

13.780in

3.583in 5.118in

0.276in

4.016in 7.697in

9.606in

=7mm

350mm

90mm

130mm

244mm

195.5mm102mm

Page 27

CommanderSE User Guide 20

Issue Number 8 www.controltechniques.com

4.3.2 CommanderSE standard and low earth leakage Footprint/Side mounting RF I

Filter:

Figure 4.5 RFI filter dimensions

* 60mm for Size 4, 18.5kW; 4200-6403

4.3.3 Commander SE Size 1 Low Cost RFI Filter mounting dimensions, 4200-6101.

Figure 4.6 Size 1 Low cost filter dimensions

D

F

C

ABE

Size1and2

Size3and4

8xM4holes

8xM5holes

for footprint mounting

Cable length

Earth stud: SE Size 1 - M4

SESize2~4-M5

Drive A B C D E F Cable Length

Size mm in mm in mm in mm in mm in mm in mm in

1242

9

17

/

32

195

7

43

/

64

100

3

15

/

16

40

1

37

/

64

225

8

7

/

8

80

3

5

/

32

190

7

31

/

64

2 330 13 281

11

1

/

16

148

5

13

/

16

45

1

49

/

64

313

12

21

/

64

122

4

51

/

64

250

9

27

/

32

3385

15

5

/

32

336

13

15

/

64

190

7

31

/

64

50

1

31

/

32

368

14

31

/

64

164

6

29

/

64

270

10

5

/

8

4467

18

25

/

64

414

16

19

/

64

246

9

11

/

16

55*

2

11

/

64

448

17

41

/

64

215

8

15

/

32

320

12

19

/

32

DC

AB

Cable length

230mm

∅

Z

M4

ABCDZ∅

mm in mm in mm in mm in mm in

113.5

4

15

/

32

103

4

1

/

16

58

2

9

/

32

45.5

1

51

/

64

4.4

3

/

16

Page 28

21 Commander SE User Guide

www.controltechniques.com Issue Number 8

4.3.4 Commander SE Size 2 and 3 Low cost single and three phase RFI Filter

mounting dimensions, 4200-6204 and 4200-6304.

Figure 4.7 RFI filter dimensions

4.3.5 Commander SE Size 2, 3 and 4 Low cost three phase R FI Filter mounting

dimensions, 4200-6303, 4200-6402 & 4200-6404.

Figure 4.8 RFI filter dimensions

Cable length

4200-6204 = 250mm

4200-6304 = 300mm

M5

∅

Z

ABCDEFG ∅ Z

mm in mm in mm in mm in mm in mm in mm in mm in

119

4

11

/

16

98.5

3

7

/

8

85.5

3

21

/

64

57.6

2

17

/

64

109

4

19

/

64

51 2 66

2

19

/

32

4.3x 7.5

3

/16x5/

16

A

B

C

D

E

F

G

H

Cable length

300mm

M5

Z

∅

ABCDEFG H∅ Z

mm in mm in mm in mm in mm in mm in mm in mm in mm in

4200-6303 133

515/

64

120

423/

32

118

441/

64

70

23/

4

80

35/

32

103

41/

16

90

335/

64

130.6

59/

64

6.5

1

/

4

4200-6402

4200-6404

143

55/

8

130

57/

64

128

51/

32

80

35/

32

80

35/

32

113

429/

34

100

315/

16

143

55/

8

6.5

1

/

4

Page 29

CommanderSE User Guide 22

Issue Number 8 www.controltechniques.com

4.3.6 SE53402200 bookcase mounted filter, 4200-6116

Figure 4.9 RFI filter dimensions

4.3.7 SE53403000 ~ SE53403700 bookcase mounted filter, 4200-6117, 4200-6106

Figure 4.10 RFI filter dimensions

C

F

A

B

D

E

G

A

B

C

D

E

F

G

4200-6117 = M6

4200-6106 = M8

ABCDEFG∅ Z

mm in mm in mm in mm in mm in mm in mm in mm in

4200-6116 337 13.27 259.5 10.22 90 3.54 100 3.94 275 10.83 50 1.97 290 11.42 7 0.28

4200-6117 377 14.84 300 11.81 150 5.9 103 4.05 315 12.4 105 4.13 330 12.99 7 0.28

4200-6106 380 14.96 294 11.57 150 5.9 107 4.21 310 12.2 105 4.13 325 12.79 7 0.28

Page 30

23 Commander SE User Guide

www.controltechniques.com Issue Number 8

4.3.8 Minimum Mounting Clearances

Figure 4.11 Minimum mounting clearances (applies to all drive sizes)

4.4 Electrical installation

Electric shock risk

Thevoltagespresentinthefollowinglocationscancausesevereelectricshock

and may be lethal:

• AC supply cables and connections

• Output cables and connections

• Many internal parts of the drive, and external option units

Isolation device

The AC supply must be disconnected from the drive using an approved isolation

device before any cover is removed from the drive or beforeany servicing work

is performed.

STOP function

The STOP function does not remove dangerous voltages from the drive or any

externaloption units.

Stored charge

The drive contains capacitors that remain charged t o a potentially lethal voltage

after the AC supply has been disconnected. If the drive has been energised, the

AC supply must be isolated at least ten minutes before work may continue.

Normally, the capacitors are discharged by an internal resistor. Under certain,

unusual fault conditions, it is possible that the capacitors may fail to discharge,

or be prevented from being discharged by a voltage applied to the output

terminals. If the drive has failed in a manner thatcauses the display to go blank

immediately, it is possible the capacitors will not be discharged. In this case,

consult Control Techniques or their authorised distributor.

1

8

1

8

100mm

(/in)

3

4

100mm

(/in)

3

4

10mm

(/in)

3

8

10mm

(/in)

3

8

20mm

(/in)

3

4

WARNING

WARNING

WARNING

WARNING

Page 31

CommanderSE User Guide 24

Issue Number 8 www.controltechniques.com

AC supply by plug and socket

Special attention must be given if the drive is installed in equipment which is

connected to the AC supply by a plug and socket. The AC supply terminals of the

drive a re connected to the internal capacitors through rectifier diodes which are

not intended to give safety isolation. If the plug terminals can be touched when

the plug is disconnected from the socket, a means of automatically isolating the

plug from the drive must be used (eg. a latching relay).

4.4.1 AC supply requirements

The following types of AC supply are suitable.

Single phase models:

• Single phase (i.e. between one phase and neutral of a star-connected three phase

supply)

• Between two phases of a three phase supply (any onephase can be grounded)

Three phase models:

• Three phase star or delta supply of the correct voltage (any one phase or neutral

can be grounded)

Dual rated 200V models:

• Any of the above

The input current differs for single phase and three phase supplies.

Supply voltageand currentinformation is given in Chapter 3 Technical Data.

4.4.2 Cables and fuses

Recommended cable sizes are given in Chapter 3 Technical Data. Theyare only a

guide. Refer to local wiring regulations for the correct size of cables. In some cases a

larger cable is required to avoid excessive voltage drop.

Use 105°C(221°F) (UL 60/75°C temp rise) pvc-insulated cable with copper conductors

having a suitable voltagerating,for the following power connections:

• AC supply to RFI filter (when used)

• AC supply (or RFI filter) to drive

•Drivetomotor

• Drive to braking resistor

Fuses

The AC supply to the drive must be fitted with suitable protection against

overload and short-circuits.The tables in Chapter 3 Technical Data show

recommended fuse ratings. Failure to observe this requirement will cause risk of

fire.

A fuse or other protection must be included in all live connections to the A C supply.

An MCB (miniaturecircuit breaker) or MCCB (moulded casecircuitbreaker) with type C

tripping characteristics and the same rating as the fuse(s), may be used in place of the

fuse(s), on condition that the fault current clearing capacity is sufficient for the

installation.

Fuse Types

Europe: Type gG fuses complying with EN60269parts 1 and 2.

USA: Bussman Limitron KTK series, class CC fast acting fuses.

Ground connections

The drive must be connected to the system groundof the AC supply. The ground wiring

must conform to local regulations and codes of practice.

WARNING

NOTE

WARNING

Page 32

25 Commander SE User Guide

www.controltechniques.com Issue Number 8

The ground loop impedance mustconform to the requirements of local safety

regulations. The ground connections must be inspectedand tested at appropriate

intervals.

Earth and ground leakage

Sizes 1 ~ 4

The drivehas a very small leakage current between the powerlines and ground, which

is of no consequence.

Size 5

Ground leakage currentis typically 9mA*. A fixed ground connection must be made

before the AC power is applied. In some applications,safety regulations require a

duplicate ground connection.

*9mA at 380V ac ~ 415V 50Hz AC supply. Measured by the method described in IEC950

Annex D.

The RFI filter has a higher leakage current, data is given in section 4.5.4, Tables

4.13 to 4.17. When the standard and low cost filters are used, a permanent fixed

ground connection must be provided which does not pass through a connector

or flexible power cord.

Motor cables

For routineEMC precautions

Use either of the following:

• Cables containing three power conductors plus a ground conductor

• Three separate power conductors plus a ground conductor

For full EMC precautions, where required (see section 4.5.2)

Use shielded (screened) or steel-wire armoured cable having three power conductors

plus a groundconductor.

If the cable between the drive and the motor is to be interrupted by a contactor or

circuit breaker, ensure that the drive is disabled before the contactor or circuit

breaker is opened or closed. Severe arcing may occur if this circuit is interrupted

with the motor running at high current and low speed.

Maximum motor cable lengths

The capacitiveloadingof the drive by the motorcablemeansthat the cablelengthlimits

shown in Table 4.2 must be observed. Failure to do so can result in spurious OI.AC

tripping of the drive. Iflongercable lengths are required,consultyour local DriveCentre

or Distributor.

The maximum cable lengths were measured using cable with capacitance of 412pF/m.

Table 4.2 Maximum motor cable lengths

* This cable length is f or 3kHz switching frequency.The cable length reduces in

proportionto the switching frequency; e.g. at 6kHz, it is reduced by a factorof 2 to 60m.

High Capacitance Cables

Most cables have an insulating jacket between the cores and the armour or shield;

these cables have a low capacitance and are recommended. Cables that do not have

WARNING

WARNING

WARNING

Drive Size Maximum motor cable length

Meters Feet

1 75 246

2 100 330

3 150 495

4 150 495

5 120* 394*

Page 33

CommanderSE User Guide 26

Issue Number 8 www.controltechniques.com

aninsulatingjackettend tohavehigh capacitance.

If a high capacitance cable is used, the maximum cable lengths in Table 4.2 should be

halved.

For further information please refer to the CommanderSE Advanced User Guide.

MultipleMotors

For advice on multiple motor applications where a number of small motors are

connected t o the output of one drive, please refer to the Commander SE Advanced

User Guide.

4.4.3 Use of line reactors

Linereactorscanbeusedtoreducesupplyharmonicsandalsoshouldbeusedifanyof

the following conditions apply:

• Supply capacity exceeds 200kVA

• Fault current exceeds 5kA

• Power-factor correction equipment is connected close to the drives

• Large DC drives having no or ineffective line reactors connected to the supply

• Direct on-line started motor(s) are connected to the supply and, when any of these

motors are started,a dip is produced in excess of 20% of the actual supply voltage

Duringanyof theaboveconditions, excessive peak current may flowin the inputbridge.

This may cause nuisancedrive tripping or, in extreme cases, failure of the input bridge.

A line reactorshould then be connected in each phaseof the supply to the input bridge.

Line reactor(s) add the required impedance to the AC supply in order to reduce current

transientstoa levelthatcan be tolerated bythe inputbridge. An impedance value of2%

is usually recommended.

Threeindividual reactors,or a single three-phase reactor should be used.Each network

of drivesmust have its own reactor(s).

RFI filters (for EMC purposes) do not give adequate protectionagainst these

conditions.

4.4.4 AC Line reactor values

Table 4.3 AC Line reactor values

CAUTION

Drives used with

Reactor

part number

Input

phases

Inductance Contin-

uousrms

current

Peak

current

Dimensions

(mm)

mH A A L D H

SE11200025, SE11200037 4402-0224

12.25

6.5 13 726590

SE11200055, SE11200075,

SE2D200075, SE2D200110

4402-0225

11.0

15.1 30.2 82 75 100

SE2D200150, SE2D200220 4402-0226

10.526.2 52.4 82 90 105

SE23400075, SE23400110,

SE23400150

4402-0227

32.0

7.9 15.8 150 90 150

SE2D200075, SE2D200110,

SE2D200150, SE23400220,

SE23400300, SE23400400,

SE33400550, SE33400750

4402-0228

31.0

15.4 47.4 150 90 150

SE23200400, SE2D200220,

SE33200550, SE33200750

4402-0229

30.4

24.6 49.2 150 90 150

SE43401100, SE43401500 4402-0232

30.627.4 54.8 180 100 190

*SE43401850, *SE53402200 4400-0240

30.4546 92 190 150 225

*SE53403000, *SE53403700 4400-0241

30.3

74 148 250 150 275

Page 34

27 Commander SE User Guide

www.controltechniques.com Issue Number 8

Commander SE sizes 3, 4 and 5 drives include DC chokes, AC reactors are only

required for harmonic reduction.

*These input reactors are not stocked by Control Techniques. Therefore they

should be ordered directly from the manufacturer, Skot Transformers, or sourced

locally.

sales@skot.co.uk

They can be order ed using the above part number s or S kot reference numbers:

4400-0240 = 35232

4400-0241 = 35233

Line reactors also improve the input current waveform and reduce the input current

harmonic levels. Further information is included in the EMC Data sheet which is

available from ControlTechniques’ Drive Centres or Distributors.

4.4.5 Input line r eactors for Harmonics standards EN61000-3-2 & IEC61000-3- 2

The following input line reactors allowthe Commander SE 0.25 - 0.55kW drives to

conform to harmonic standards EN61000-3-2 and IEC61000-3-2

EN61000-3-2 and IEC61000-3-2 applies to equipment with a supply voltage of 230Vac

and a line current up to 16A, single or three phase. Professional equipment with rated

input power exceeding 1kW has no limits - this applies to the 0.75kW drive.

Further information on EN61000-3-2 andIEC61000-3-2 is included on the EMC data

sheets available from your local ControlTechniques Drive Centre or distributor.

4.4.6 Voltage fluctuation (Flicker) standard EN61000-3-3 (IEC61000-3-3)

Those models which fall withinthe scope of EN61000-3-3, as stated in the Declaration

of Conformity, conform to the requirements for manual switching, i.e. the voltage dip

caused when a drive at room temperature is switched on is within the permitted limits.

The drivedoes not of itself cause periodic voltage fluctuation in normal operation. The

installer must ensure that the control of the drive is such that periodic fluctuations in

supplycurrentdo not infringe the flicker requirements where applicable. Note that large

periodic loadfluctuations in the frequencyrange of between 1Hz and 30Hz are

particularly inclined to cause irritating lighting flicker and are subject to stringent limits

under EN61000-3-3.

4.5 Electromagnetic compatibility (EMC)

This section gives installationguidelines for ensuring electromagnetic compatibility.

Further detailed information is provided in the EMC Data sheets which are available

from Control Techniques’ Drive Centres or distributors.

The drive meets the standards for electromagnetic immunity stated in section 3.2

without any special installation precautions. To prevent possible nuisance tripping, it is

recommended that all inductive circuits associated with the drive,for example relay

coils,electromagnetic brakes etc. shouldbe fitted with appropriat e suppression.

The following precautions should be taken t o prevent the drive from causing

interference with other electronic equipment.

For general use the guidelines in section 4.5.1 Routine EMC precautions should be

followed. Theseare sufficient to prevent inter ference to general purpose industrial and

similar equipment of good quality recent design.

NOTE

NOTE

Drive Reactor

part number

Power

de-rating

Input power Inductance Continuous

rms current

WmH

SE12200025 4400-0239 None 374 4.5 2.4

SE12200037 4400-0238 None 553 9.75 3.2

SE12200055 4400-0237 18% 715 16.25 4.5

Page 35

CommanderSE User Guide 28

Issue Number 8 www.controltechniques.com

Section 4.5.2 Full EMC precautions should be followed in the following cases:

• When compliance with strict emission standards such as EN50081-1 or EN50081-2

is required.

• Where sensitive radio receiving or similar equipment is in use nearby.

• Where sensitive electronic equipment with poor electromagnetic immunity is in use

nearby.

4.5.1 Routine EMC precautions

The routine precautions are based on the following principles:

1. The motor cablecarries a high level of electrical ‘noise’. It should be segregated

from all signal circuits, and should include a ground conductor linking the drive

grounddirectly to the motor frame.

2. The mainssupply wiring alsocarrieselectricalnoiseand shouldbe segregated from

signal circuits.

3. The drive also generates a noise field so sensitive circuits should not be passed

closetoit.

4. “Noise” current flows in power wiring and returns through the ground (earth). To

minimise noiseloop areas, groundwires should be run as close as possible t o their

associated power wires.

5. The drive groundtends to be ‘noisy’, so it is preferable for the control circuits to be

grounded only at thecontroller andnot at the drive.

4.5.2 Full EMC precautions

Figure 4.7 shows the requirements whichbe followed closely in order to meet EMC

emission standards.Furtherguidance and information on EMC standardsis givenin the

EMC Data sheets which are available from Control Techniques’ Drive Centres or

Distributors.

Figure 4.12 Full EMC precautions

The above guidelines are applicable to all drive sizes.

For further information on the cable screening bracketsand screening clampskit, refer

to the Commander SE Advanced User Guide and the EMC Datasheets which are

NOTE

Page 36

29 Commander SE User Guide

www.controltechniques.com Issue Number 8

available from ControlTechniques’ Drive Centres and Distributors.

4.5.3 Special requirements

Special considerations are required for the following requirements:

Meeting the residential emission standard, EN50081-1 (Size 1 only)

One of the footprint filters (part number 4200-6102 or 4200-6103) must be used.

Interruptions to the motor cable

The motor cable shouldideallybe a singlerun of shieldedcablehaving no interruptions.

In some situationsit may be necessaryto interruptthecable,forexampleto connectthe

motor cable to a terminal block within the drive enclosure, or to fit an isolator switch to

allowsafe working on the motor. In these cases both motor cable shield connections

must be clamped directly to the back-plate or other flatmetallic structure, as illustrated

in figures 4.13 and 4.14. Keep the length of unscreened power conductors to a

minimum, keep them as close as possible to the metal plate, and ensure that all

sensitive equipment and circuits are at least 0.3m (12in) away from them.

Terminal block within enclosure

Refer to Figure 4.13.

Figure 4.13 Connecting the motor cable to a terminal block in the enclosure.

Using a motor isolator switch

Refer to Figure 4.14.

Figure 4.14 Connecting the motor cable to an isolating switch.

4.5.4 RFI filter recommendations and data.

Use one RFI filter for each drive. Filters of appropriate current rating may be shared

between drives, but small deviations from the stated standards may then occur.

The filter performancedepends upon the motor cablelength and switching frequency.

The filter performancefor the maximummotorcable length for residentialand industrial

standards is shown in Table 4.4 to Table 4.13.For furtherdetails on filter performance

with shorter cable lengths, see the EMC Datasheets which are available from Control

Techniques’ Drive Centres or Distributors.

From the Drive

To the motor

Back-plate

Enclosure

Isolator

Couplingbar

From the

Drive

To the

motor

(If required)

Page 37

CommanderSE User Guide 30

Issue Number 8 www.controltechniques.com

High ground leakage current

Most RFI filters have ground leakage current exceeding 3.5mA. All equipment

using these filters must be provided with a permanent fixed ground connection.

Speciallow-leakage filters are providedfor applications where a permanent ground

connection is not practical.

Commander SE Size 1

Table 4.4 Commander SE Size 1

Commander SE Size 2

Table 4.5 Drive Range: SE2D200075 to SE2D200220, single phase

Table 4.6 Drive Range: SE2D200075 to SE2D200220, three phase

Table 4.7 Drive Range: SE23400075 to SE23400400, three phase

WARNING

Motor cable

length

m

Filter and Switching Frequency

Standard

(4200-6102)

Low Cost

(4200-6101)

Low Leakage

(4200-6103)

3kHz 6kHz 12kHz 3kHz 6kHz 12kHz 3kHz 6kHz 12kHz

5 RRRRR I R I #

15 R R I R R I I # #

20 R R I R R I

50 R I I

75 I # #

Motor cable

length

m

Filter and Switching Frequency

Standard

(4200-6201)

Low Cost

(4200-6204)

Low Leakage

(4200-6205)

3kHz 6kHz 12kHz 3kHz 6kHz 12kHz 3kHz 6kHz 12kHz

15 RRRIIIII#

50 R R I

I##

80 R R I

100 I I I

Motor cable

length

m

Filter and Switching Frequency

Standard

(4200-6202)

Low Cost

(4200-6304)

Low Leakage

(4200-6207)

3kHz 6kHz 12kHz 3kHz 6kHz 12kHz 3kHz 6kHz 12kHz

15 RRR

I##II#

45 RRR

I##

100 R R I

Motor cable

length

m

Filter and Switching Frequency

Standard

(4200-6202)

Low Cost

(4200-6304)

Low Leakage

(4200-6207)

3kHz 6kHz 12kHz 3kHz 6kHz 12kHz 3kHz 6kHz 12kHz

15 R R I

I##I##

20 R R I

I##

50 R I I

100 I # #

Page 38

31 Commander SE User Guide

www.controltechniques.com Issue Number 8

Table4.8 Drive Range: SE23200400,three phase

Commander SE Size 3

Table 4.9 Drive Range: SE33200550 to SE33200750

Table 4.10 Drive Range: SE33400550 to SE33400750

Commander SE Size 4, 11-15kW

Table 4.11 Drive Range: SE43401100 to SE43401850

Commander SE Size 4, 18.5kW

Table 4.12 Drive Range: SE43401850

Motor cable

length

m

Filter and Switching Frequency

Standard

(4200-6203)

Low Cost

(4200-6303)

Low Leakage

(4200-6209)

3kHz 6kHz 12kHz 3kHz 6kHz 12kHz 3kHz 6kHz 12kHz

20 R R I

IIII##

45 I I I I##

100 I # #

Motor cable

length

m

Filter and Switching Frequency

Standard

(4200-6302)

Low Cost

(4200-6303)

3kHz 6kHz 12kHz 3kHz 6kHz 12kHz

15 R I I

II#

20 R I I

100 I # #

Motor cable

length

m

Filter and Switching Frequency

Standard

(4200-6301)

Low Cost

(4200-6304)

3kHz 6kHz 12kHz 3kHz 6kHz 12kHz

15 R R I

III

30 R I I

100 I # #

Motor cable

length

m

Filter and Switching Frequency

Standard

(4200-6401)

Low Cost

(4200-6402)

3kHz 6kHz 12kHz 3kHz 6kHz 12kHz

15 R I I I##

20 R I I

100 I # #

Motor cable

length

m

Filter and Switching Frequency

Standard

(4200-6403)

Low Cost

(4200-6404)

3kHz 6kHz 12kHz 3kHz 6kHz 12kHz

20 R R R

I##

70 I I I

100 I I #

Page 39

CommanderSE User Guide 32

Issue Number 8 www.controltechniques.com

Commander SE Size 5

Table 4.13 Drive range SE53402200 ~ SE53403700

* Filter used on drive range SE53402200

** Filter used on SE53403000

*** Filter used on SE53403700

Key:

R EN50081-1 Conducted emission requirements of the generic emission standard for

the residential, commercial and light industrial environment.

I EN50081-2 Conducted emission requirements of the generic emission standard for

the industrialenvironment.

# Special techniques required e.g. outputfilters. Contact your Local Control

Techniques Drive Centre.

Further data for the filters is given in the following tables:

Table 4.14 Commander SE Size 1

Table 4.15 Commander SE Size 2

Table 4.16 Commander SE Size 3

*AlsousedonSize2units.

Motor cable

length

m

Filter and Switching Frequency

4200-6116* 4200-6117** 4200-6106***

3kHz 6kHz 12kHz 3kHz 6kHz 12kHz 3kHz 6kHz 12kHz

10

RRIRR I RR I

50

I##I##I##

100

I##I##I##

Part Number

Maximum

Power

Losses

W

IP Rating Weight

kg

Operational

Leakage

Current

mA

Worst Case

Leakage

Current

mA

Terminal

Torques

Nm / lb ft

4200-6101 6 21 0.49 4.0 8.0 0.8 / 0.6

4200-6102 6 20 0.60 40.7 77.5 0.8 / 0.6

4200-6103 6 21 0.60 2.9 5.7 0.8 / 0.6

Part Number

Maximum

Power

Losses

W

IP Rating Weight

kg

Operational

Leakage

Current

mA

Worst Case

Leakage

Current

mA

Terminal

Torques

Nm / lb ft

4200-6201 10.1 20 1.2 89 128 0.8 / 0.6

4200-6202 10.1 20 1.1 45.7 184.2 0.8 / 0.6

4200-6203 15.4 20 1.3 26.4 106.3 0.8 / 0.6

4200-6204 6 20 0.7 29.5 58.9 0.8 / 0.6

4200-6205 10.1 20 1.2 2.8 5.7 0.8 / 0.6

4200-6207 10.1 20 1.1 3 18.3 0.8 / 0.6

4200-6209 15.4 20 1.3 2.6 15.5 0.8 / 0.6

Part Number

Maximum

Power

Losses

W

IP Rating Weight

kg

Operational

Leakage

Current

mA

Worst Case

Leakage

Current

mA

Terminal

Torques

Nm / lb ft

4200-6301 12.4 20 1.6 45.7 184.2 0.8 / 0.6

4200-6302 19.5 20 1.7 26.4 106.3 0.8 / 0.6

4200-6303

*

10.8 20 0.8 14.1 68 0.8 / 0.6

4200-6304

*

6.1 20 0.6 33 148 0.8 / 0.6

Page 40

33 Commander SE User Guide

www.controltechniques.com Issue Number 8

Table 4.17 Commander SE Size 4

Table 4.18 Commander SE Size 5

Discharge resistors

1.5MΩ in a starconnection between phases with star point connect ed by a 680kΩ

resistor to ground.

This may cause an earth leakage indication in monitored ungrounded power

systems such as IT systems.

Fortables4.13to4.17,pleasebeawareofthefollowing:

Weight is unpacked weight.

Worst case leakage current:

Single phase filters - when the neutral is disconnected.

Three phase filters - when an input phase is disconnected.

The data is given for an input voltage of 230V, 50Hz.

Part Number

Maximum

Power

Losses

W

IP Rating Weight

kg

Operational

Leakage

Current

mA

Worst Case

Leakage

Current

mA

Terminal

Torques

Nm / lb ft

4200-6401 26.1 20 3.1 29.4 280 2.2 / 1.6

4200-6402 11.7 20 1.1 14.1 68 2.2 / 1.6

4200-6403 30 20 3.1 38 220 2.2 / 1.6

4200-6404 16 20 1.2 24.5 132 2.2 / 1.6

Part Number

Maximum

Power

Losses

W

IP Rating Weight

kg / lb

Operational

Leakage

Current

mA

WorstCase

Leakage

Current

mA

Terminal

Torques

Nm / lb ft

Ground

connection

torque

Nm / lb ft

4200-6116 12.8 20 3.8 / 9 31 143 4.5 / 3.3 2.2 / 1.6

4200-6117 14.3 20 3.8 / 9 29 126 4.5 / 3.3 4.0 / 2.9

4200-6106 25.5 20 7.8 / 17 48.5 209 8.0 / 5.9 9.0 / 6.6

NOTE

NOTE

Page 41

CommanderSE User Guide 34

Issue Number 8 www.controltechniques.com

5 Terminals

5.1 Power t erminal connections

Figure 5.1 Commander SE Size 1 power terminal connections

Figure 5.2 Commander SE Size 2 to 4 power terminal connections

Whena CommanderSE Size 2 200Vunit is used onsinglephase, use terminalsL1

and L2.

L1 L2/N PE U V W

Optional

RFI filter

Optional

line reactor

Mains

Supply

Fuses

L1 L2/N

Supply

Ground

Motor

Motor

Ground

Circuit breaker

/Isolator

*

*SeeFuses on page24

L1 L2

L2

L1

+

-

L3 PEDBR U V W

Optional RFI

filter

Optional

linereactor

Fuses

L3

Supply

Ground

Mains

Supply

Motor

Motor

Ground

Start/

Reset

Stop

Optional

Thermal

protection

device

Braking

Resistor

NOTE

Drive Size Maximum Power Terminal Screw Torque

1&2 1Nm(9lbin)

3 & 4 2Nm (18lb in)

5 15Nm (11lb ft)

Page 42

35 Commander SE User Guide

www.controltechniques.com Issue Number 8

Figure 5.3 Commander SE Size 5 power terminal connections

5.1.1 Thermal protection for an optional braking resistor

Figure 5.2 shows a typical circuit arrangement for braking resistor protection.