Control Techniques NT Motor 230 V Catalog Supplement

NT

Motor

230

V

Compact NEMA

AC

Servo

The

NT

motor

motor designed

motor uses powerful magnets and

segmented core

These

motors are

terminations for

and

Epsilon

Key Features

• Torque range: 7.5

•

Very

English

•

Available

•

Motors

is

a compact, high performance brush

to

maximize torque and minimize

to

available

Control

EP

servo

low inertia for high acceleration and cycle rates

(NEMA

23

with or without holding brakes

or

maximize

Metric

is

stator

Flange

manufactured with a

efficiency.

with direct motor-to-drive connector

Techniques' brand

drives

- cable lengths

to

56

lb-in

or

34) or Metric

(0.85

Un

up

to

6.3

(IEC-

72-1) flanges

id

rive

to 20 ft are

Nm)

less

size.

M,

AC

The

Digitax

available.

• Direct connect available - no additional cables required!

Flying-lead

•

improved ingress protection;

without

IP65

•

cabling option

MS

connectors

conformance

(IP67S

(ex:

NTE-320-LONS-0005)

flying

leads are available with or

and

IP68S

optional)

with

• Standard 2048 encoder

all

• Installed shaft seal are standard with

• Optional white epoxy food-grade

motors

finish

Servo

NT

ST

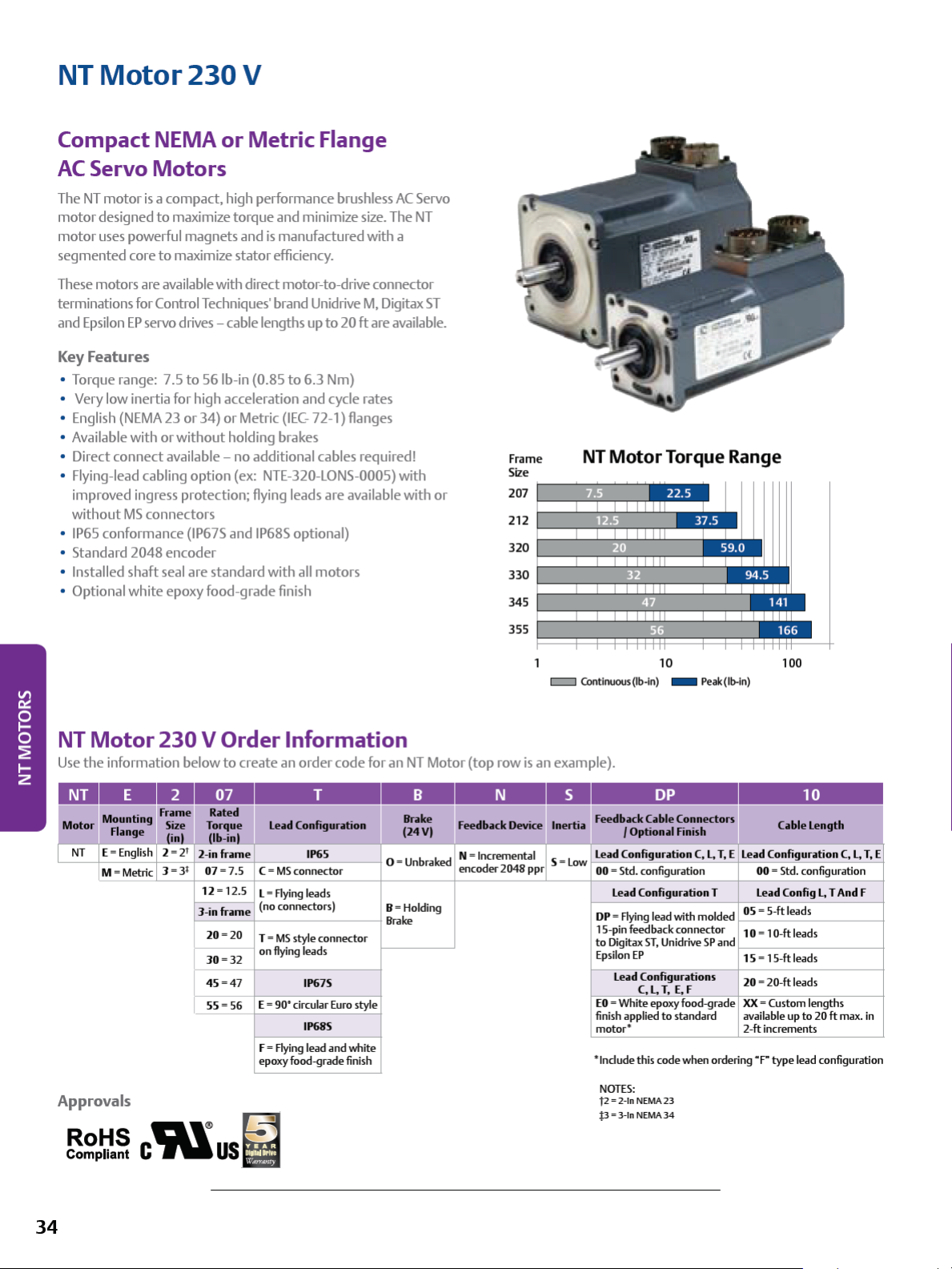

Frame

Size

207

212

320

330

345

;---

-'--::;;

l---~~

I---~~~

I---~~~~

NT

.:::l;.-

Motor

~~

.:;=;

c...,....,~~-

.;:,:;:

:,....,..~

:;:;..~-~~~

Torque Range

-~~

NT

Motor

Use

the information below

NT

Approvals

230

V Order Information

to

create an order code for an

Le,id

Configuriltion

2-in frame

12 = 12.5

J-in frame

20=20

30=

32

45=4

7

55=

56

+---------1

L =

(no connectors)

T =

on

E = 90' circular

f =

epoxy food-grade

IP65

MS

connector

Aying

leads

MS

style connector

flying

leads

IP6

IP68S

Aying

lead and white

7S

Euro

0

B=

Brake

style

finish

355 t===i==i::::::i:::::i::

c::::::::J

NT

Motor (top row

= Unbraked N = Incremental S =

encoder 2048 ppr

Holding

is

an example).

m~

=:::i::::=i=:::i::::i:

10 1

Contlnuous(lb-ln) - Peak(lb-ln)

Low

Lead Configuration C,

00

= Std. configuration 00 = Std. configuration 07 =7.5 C =

Lead Configuration T Lead Config

DP=

Aying

lead with molded OS = S-ft leads

15-pin feedback connector 1

to

Digitax ST,

Epsilon

EP

Lead

Configurations

C,

EO

finish

motor•

'lndu

NOTES:

f2 = 2-

p =

L,

= White epoxy food-grade

applied

de this code when ordering •p-type lead configuration

ln

NEMA

3-

ln

NEMA

Unidrive

T,

E, f

to

standard

23

34

L,

SP

T, E

Le,id

o = 10-ft leads

and

>----------<

1 S = 15-ft leads

20 = 20-ft leads

XX=

available up to

2-ft increments

~m~

00

Co1ble

Length

Configuration

Custom lengths

__j_

L.

20

C,

L, T, E

T And f

ft

max.

in

~~~

c'i\lus~

34

NT

Motor

Motor

Frame Size (in)

Voltage

Mo

Continuous Stall Torque (lb-in)

Continuous Stall Torque (Nm)

Cogging (lb-in) (typ.)

Cogging (Nm) (typ.)

.

-

-

NOTES:

•

.6.t=

212

'F

subject to.,.,_

• Stall torque, rated torque and power relate

operation above

• Maximum

(100 '

10%

intermittent

2-inch Frame Ratings and Dimensions

(Vrms)

del

Peak Torque (lb-in)

Peak

Torque (Nm)

Inertia (lb-in-sec')

Inertia (kgm') 0.0000106 0.0000185

Motor Weight (lbs)

Motor Weight (kg)

Kt

(lb-in/Al=

Kt(Nm

Ke

(V/k

rpm)=

Rated Torque (lb-in)

Rated Torque (Nm)

Stall Current

Rated Power

R (ph-ph) (Ohms)

L (ph-ph) (mH)

CJ

winding 104 ' F (40

tolerance

10

kHz drive switching frequency

winding

0.000094 0.000164

/AI

= 0.58 0.57

(A)

(kW)

'CJ

temperature

NT-207

7.5 12.5

0.85

22.5

2.54

0.094

0.011

3.0

1.36

5.12

35

7.50 12.50

0.85

1.7

0.432 0.740

11.1 4.56

39.1 18.9

maximum ambien

to

NT-212

1.4

37.5

4.24

0.12

0.014

4.0

1.81

5.08

34.7

1.4

2.7

maximum continuous

is

284

'F (140

t;

'CJ

all

data

I,

H

ue1so.stJ

,k45.21)

J_

__

l_

-

----

1---------

-

---

ENCOOER

MATIIG

CONN:

CONN:

BRAKE

MATIIG

~

-

------

,,

A

PT02Eo16-23P

PT(MjE-16-23S

CONN:

PT02E..g.JP

CONN:

MOTOR

MATING

(<ONSand<BNS)

PT(MjEo&-JS

CONN:

CONN:

1-•-

i

[

(-CSNS)

PT02Eo1&-8P

PTO&E-16-8S

>-K

I

- J

I

(<ONSand<BNS)

Motor

Dimensions

Unbraked length-CONS/EONS•

Braked Length -

Un

braked length-CBNS/EBNS •

length -TBNS/LBNS/FBNS

Braked

Bolt Circle Diameter

Connector Height -

Height-

Connector

Keyway

are

repres

NOTE:

• Not

Connector

Connector Height -

all

variations

English Flange

NTE-207 NTE-212

llllmlllllmllllllmllllllffl!D

5.55 141.0 6.55 166.4

TONS/LONS/FONS

Flange Square

Flange Thickness C 0.29 7.5 0.29 7.5

Pilot Diameter

Pilot Thickness

Bolt Hole Diameter

CONS

TONS/LONS

Height-

CBNS

TBNS/LBNS

Shaft Length

Shaft Diameter

length

(mini K 0.70 17.8 0.70 17.8

Keyway

Depth l 0.08 2.0 0.08 2.0

Keyway Width

ented

above; see

4.39 111.5 5.39 136.9

A

6.94 176.4 7.94 201.8

6.28 159.4 7.94 201.8

B 2.27 57.7 2.27 57.7

D 1.50 38.1 1.50 38.1

E 0.10 2.5 0.10 2.5

F 0.21 5.2 0.21 5.2

c;

2.63 66.7 2.63 66.7

1.92 48.9 1.92 48.9

1.78 45.2 1.78 45.2

H

1.98 50.4 1.98 50.4

1.78 45.2 1.78 45.2

I 1.21

0.37 9.5 0.37 9.5

I

M 0.13

our

website for complete mechanical dimension drawings

30.7

Shaft

3.2

Key

Dimen

1.21

sio

0.13

ns

30.7

3.2

I

Metric Flange

~

(in) (mm ) (in) (mm )

5.55 141.0 6.55 166.4

4.39 111.5 5.39 136.9

6.94 176.4 7.94 201.8

6.28 159.4 7.28 184.8

2.57 65.2 2.57 65.2

0.29 7.5 0.29 7.5

2.36 60.0 2.36 60.0

0.10 2.5 0.10 2.5

0.23

2.95 75.0 2.95 75.0

1.92

1.78

1.98

1.78 45.2 1.78 45.2

0.93 23.5 0.93 23.5

0.43 11.0 0.43 11.0

0.51 13.0 0.51 13.0

0.08 2.1 0.08 2.1

0.16

5.8

48.9

45.2

50.4

Shaft Key Dimensions

4.0

0.23

1.92

1.78

1.98

0.16

I

5.8

48.9

45.2

50.4

4.0

35

Loading...

Loading...