Page 1

Mentor II

A

P

P

R

O

V

A

L

I

S

O

9

0

0

2

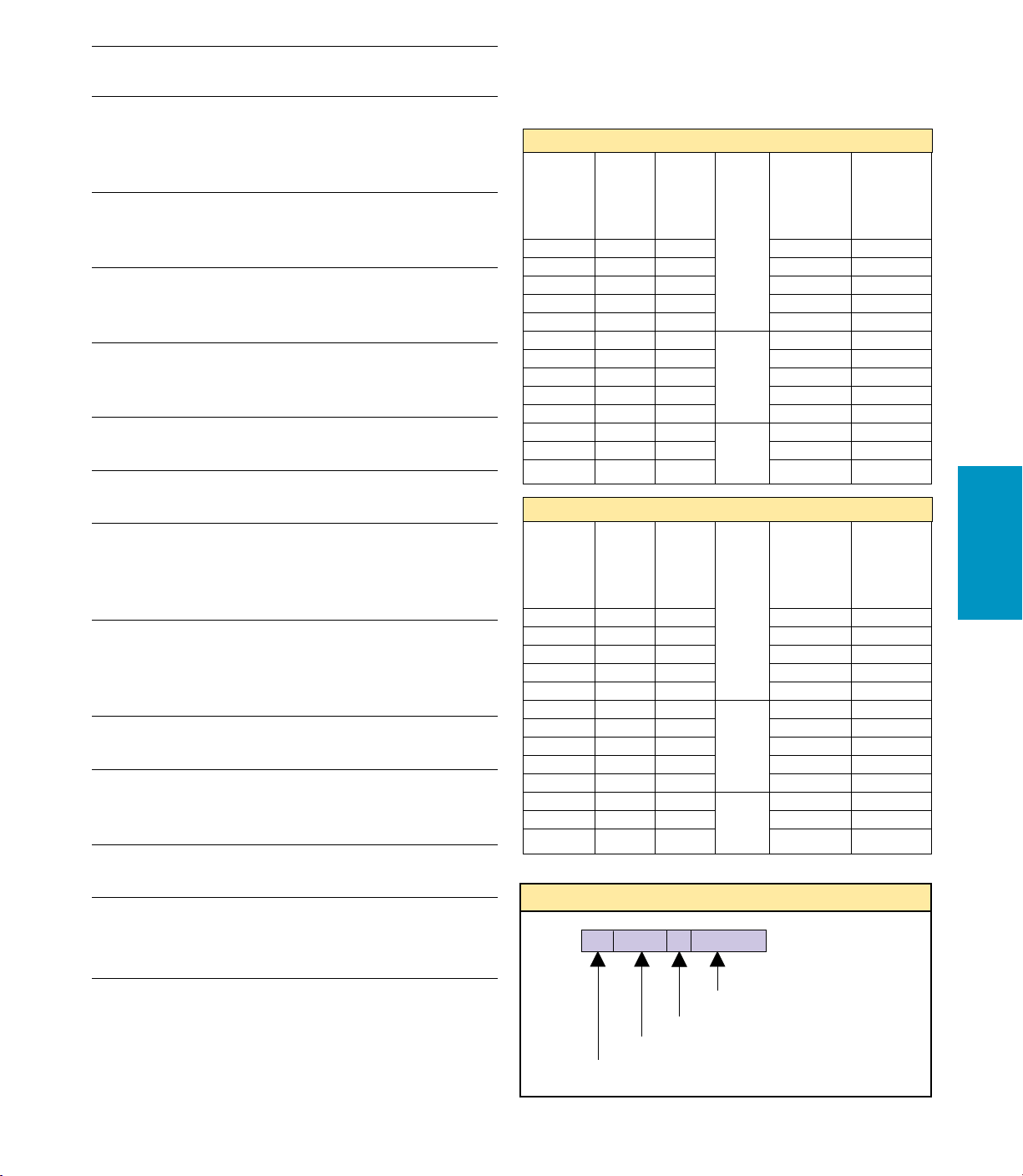

Digital Drive

▲

▲

▲

▲

R

E

S

E

T

D

r

i

v

e

R

e

a

d

y

A

l

a

r

m

Z

e

r

o

s

p

e

e

d

R

u

n

f

o

r

w

a

r

d

R

u

n

r

e

v

e

r

s

e

B

r

i

d

g

e

1

B

r

i

d

g

e

2

A

t

s

p

e

e

d

C

u

r

r

e

n

t

l

i

m

i

t

P

ARAMETER D

ATA

P

ARAMETER INDEX

M

O

D

E

0.0

0.2

0.4

0.6

0.8

1.0

Mentor II

The Intelligent DC Drive

DC drives are widely used in applications that

require regeneration, precise speed control, dynamic

performance, and constant torque over wide speed

ranges. The Mentor II delivers the universal DC drive

solution.

Simple stand-alone applications are easily configured

to control motor speed, voltage or current using

standard internal settings. Set-up is convenient using

the drive keypad, or MentorSoft, a Windows™-based

drive configuration tool. The Mentor II has extensive

diagnostic and communication abilities that enhance

system reliability. The drive’s standard yet powerful

microprocessor is a versatile system component that

can eliminate the need for a PLC with integral functions

such as thresholds, timers and logic gates that perform

basic control.

The simple addition of the MD29, a 32-bit application

coprocessor card, provides high performance drive

systems with local intelligence for true distributed

control. The MD29 enables users to incorporate custom

or proprietary process control application programs to

their drive. The Mentor II also provides a wide range of

communication protocol options.

—Extrusion

—Intelligent

306

Mentor II systems have proven to be extremely reliable

and are ideally suited to web handling, winders, slitters,

extruders, wire drawing, converting lines, and plastics

production. The Mentor II’s integrated design and highly

programmable features make it an ideal choice for

OEMs and System Integrators, as well as replacement or

retrofit drives for End Users.

Note: UL only available through 400 hp @ 460V and 200 hp @ 230V

• Microprocessor Based Digital DC Drive

• 5 to 1000 hp, 3 phase, 208 to 660 VAC input

• Regenerative and non-regenerative models

• RS485 serial communications

• Extensive fieldbus communication

capabilities

• Plug-in 32-bit application coprocessor

card (MD29)

• MentorSoft Windows-based

drive configuration tool

• Complete Motor Solutions

Page 2

FEATURE/PERFORMANCE ADVANTAGE

Accepts wide range of supply voltage (208 to 660 VAC)

Can be applied to worldwide voltages

Non-regen and regen models share the same footprint up

to M825

Allows for common mechanical design and

mounting

MentorSoft Windows-based drive configuration tool

Provides easy programming and diagnostics

of the drive

32-bit application coprocessor card (MD29)

Enables customized applications for distributed

control system architectures

Profibus-DP, Modbus Plus, Modbus RTU, Interbus-S,

DeviceNet, and CTNet plug-in communication cards

Communicates on user’s preferred network

Built-in RS485 serial communications

Allows for easy programming and control of drive

Extensive and configurable analog and digital I/O

Customizes drive to specific applications

Programmable boolean logic (AND, NAND, OR, NOR)

gates with delay outputs

Assists with general system interface logic needs,

expanding application possibilities

Programmable threshold comparators

Expands application possibilities by providing a pair

of independent numerical comparators with

adjustable hysteresis

Accepts DC tachometer and encoder feedback

Enables precise speed control

Built-in digital lock function for frequency following

Allows accurate master/follower applications

Includes reference encoder connector

Extensive diagnostics and fault indicators

Special Field supply option

Three Phase Input Field Output

(208-230 VAC) (240 VDC)

RATINGS: MENTOR II

THREE PHASE INPUT DC Arm Output Field Output

3 to 500 hp (208-230 VAC) (240 VDC) (150 VDC)

5 to 1000 hp (380-460 VAC) (500 VDC) (300 VDC)

Special Order (525 / 660 VAC), Models M350(R)–M1850(R) only)

208 / 240 VAC

Motor HP

3 - 7 25 20 M25-14M M25R-14M

7.5 - 10 45 38 M45-14M M45R-14M

15 75 55 M75-14M M75R-14M

20 - 35 105 89 M105-14M

30 155 125 M155-14M

40 - 50 210 172 M210-14M

75 350 255 M350-14M

100 420 338 M420-14M

125 550 428 M550-14M

150 700 508 M700-14M

200 825 675 M825-14M

250 900 820 M900-14M

300 - 350 1200 1150 M1200-14M

400 - 500 1850 1620 M1850-14M

380 / 480 VAC

Motor HP

5 - 10 25 20 M25-14M M25R-14M

15 - 20 45 38 M45-14M M45R-14M

25 - 30 75 55 M75-14M M75R-14M

40 - 50 105 89 M105-14M M105R-14M

60 - 75 155 125 M155-14M M155R-14M

100 210 172 M210-14M M210R-14M

150 350 255 M350-14M M350R-14M

200 420 338 M420-14M M420R-14M

250 550 428 M550-14M M550R-14M

300 700 508 M700-14M M700R-14M

400 825 675 M825-14M M825R-14M

500 900 820 M900-14M M900R-14M

600 - 700 1200 1150 M1200-14M

800 - 1000 1850 1620 M1850-14M

For field control, add external field regulator P/N 9500-9035.

Order String

Output

Current

(@40°C)

Output

Current

(@40°C)

M xxx R –14M

(A)

(A)

Output

Current

(A)

(@55°C)

Output

Current

(A)

(@55°C)

Output

Current

Current

Regulated

Voltage

20A Fixed

Voltage

Output

Current

Current

Regulated

Voltage

20A Fixed

Voltage

Field

8A

10A

Fixed

Field

8A

10A

Fixed

Non-Regen

Order

Code

Non-Regen

Order

Code

Regen

Order

Code

M105R-14M

M155R-14M

M210R-14M

M350R-14M

M420R-14M

M550R-14M

M700R-14M

M825R-14M

M900R-14M

M1200R-14M

M1850R-14M

Regen

Order

Code

M1200R-14M

M1850R-14M

Mentor II

Factory Assigned

Regen (omit for Non-regen)

Output Armature Current

Mentor II Product Family

307

Page 3

SPECIFICATIONS: MENTOR II

▲

▲

▲

▲

R

ES

ET

D

rive

R

eady

A

la

rm

Zero speed

R

un forw

ar

d

R

un reverse

B

ridge

1

B

ridge

2

A

t speed

C

urrent limit

P

A

R

A

M

E

T

E

R

D

A

T

A

P

A

R

A

M

E

T

E

R

I

N

D

E

X

MO

DE

▲

▲

▲

▲

RE

SET

Drive Ready

A

larm

Zero speed

Run forw

ar

d

Ru

n reverse

Bridge

1

Bridge

2

At speed

C

urrent lim

it

P

A

R

A

M

E

T

E

R

D

A

T

A

P

A

R

A

M

E

T

E

R

I

N

D

E

X

M

O

DE

Environment

Ambient Operating 0 to 40°C (32 to 104°F)

Temperature Derate current 1.5% per °C to 55°C (32 to131°F)

Cooling Method Convection and forced convection, model

dependent

Humidity 95% non-condensing at 40°C (104°F)

Storage Temperature -40 to 55°C (-40 to 131°F)

Altitude

Derate 1% per 100 m (328

(3,280 ft) and 4000 m (13,120 ft).

Enclosure Chassis (IP00)

AC Supply Requirements

Voltage 208 to 480 VAC -5%, +10%

525/575/660 VAC ±10%

(Optional M350 and above)

Phase 3Ø

Frequency 45 to 62 Hz

Efficiency 98%

Standard Field Size 1 – 0.9 X input VAC (Regulated),

Output Voltage Size 2-3 – .67 X input VAC (Non-Regulated)

Non-Standard Field – Consult Factory

Armature Output Non-Regen – 1.15 X input VAC,

Voltage Regen – 1.05 X input VAC

Control

Feedback Methods Armature Voltage (resolution .83 volts)

DC Tachometer (resolution 0.1%)

Encoder (resolution .01%)

Field Control Current regulated 8 Amps max

(M210/M210R and smaller)

Voltage regulated .675 or .9 X Line-to-line

voltage (M350/M350R and larger)

Analog Input Resolution 12-bit (Qty 1), 10-bit (Qty 4)

Serial Communications 4-wire RS422 or RS485, optically-isolated

Protocol is ANSI x 3.28-2.5-A4

Baud rate is 4800 or 9600

Protection

AC Line 180 VAC

Undervoltage Trip

MOV Voltage Input transient suppression

Transient Protection

Instantaneous 300% armature current

Overcurrent Trip

Armature Open Circuit Armature circuit is open

Drive Overload Trip Inverse time, 150% for 30 seconds

Phase Loss Trip Loss of input phase

Overtemperature Trip Heatsink exceeds 100°C (212°F)

Motor Thermal Trip Motor over-temp switch or Thermistor

Feedback Loss Loss of motor feedback

Feedback Reversal Tachometer or Encoder wired backwards

Field Loss No field current

Field On Field current during auto-tune

Field Overcurrent Field current greater than field demand

Current Loop Loss Loss of 4-20 mA reference

External Power Supply Short circuit on +24 VDC user power supply

Power Supply Internal power supply out of tolerance

0 to 4000 m (13,120 ft).

ft) between 1000 m

Protection continued

Serial Communications Mode 3 serial comms data loss

Loss

Processor 1 Main control processor fault

Watchdog Trip

Processor 2 Second control processor fault (MD29)

Watchdog Trip

Hardware Fault Hardware malfunction on control board

Memory Fault Stored parameter checksum fault

External Trip User interlock fault (programmed)

Software Fault (A29) MD29 software fault

Approvals & Listings

UL, cUL File #E58592 Vol. 5C Section 1

(M25 to M825 and M25R to M825R)

CE Designed for marking

DIMENSIONS

Size Order Code Size* (in)

H x W x D

M25-14M thru M75-14M 15 x 10 x 6 22

M25R-14M thru M75R-14M 15 x 10 x 6 24

1

M105-14M thru M210-14M 15 x 10 x 8 31

M105R-14M thru M210R-14M 15 x 10 x 8 33

M350-14M thru M420-14M 16 x 18 x 11 48

M350R-14M thru M420R-14M 16 x 18 x 11 51

2

M550-14M thru M825-14M 17 x 18 x 11 59

M550R-14M thru M825R-14M 17 x 18 x 11 66

M900-14M thru M1850-14M 41 x 18 x 20 154

3

M900R-14M thru M1850R-14M 61 x 18 x 20 264

* Approximate, not to be used for construction purposes.

Approx.

Weight (lbs.)

Mentor II

309

Loading...

Loading...