Page 1

"Y" (WYE) STRAINER

®

TITAN

f

CAST BRONZE

TITAN FLOW CONTROL, INC.

THREADED AND SOLDER ENDS

MODELS: YS 55-BZ

YS 56-BZ

(T h R E A d E d E N d S - B R o N Z E )

(S o L d E R E N d S - B R o N Z E )

SIZE RANGE : 1/4" ~ 3"

f

ANSI CLASS 125

YS5556-0311

3" YS 56-BZ

2½" YS 55-BZ

FEATURES

F

s

L A R g E S T R A i n i n g c A p A c i T Y

w I T h I T S L A R G E B o d y A N d S I Z A B L E S T R A I N I N G E L E M E N T , T h E y S 55 A N d y S 56

P R o v I d E E x C E L L E N T o P E N A R E A R A T I o S T h A T A R E T y P I C A L L y T w o - A N d - A -h A L f

T I M E S L A R G E R T h A N T h E C o R R E S P o N d I N G P I P E L I N E , M I N I M I Z I N G P R E S S U R E d R o P

A C R o S S T h E v A L v E .

s

p R E c i S i O n m A c H i n E D S E A T S

P R EC I S Io N M A C h I N E d S C R E E N S E A T S IN B o T h T h E B o d y A N d C A P h E L P T o

E N S U R E A C C U R A T E P o SIT I oNI N G o f T h E S C R E E N d U R I N G R E A S S E M B L y A f T E R

C L E A N I N G . A L S o , T h E M A C h I N E d B o d y S E A T S E N A B L E f I N E R f I L T R A T I o N B y

P R E v E N T I N G d E B R I S B y P A S S .

s

S E L f - c L E A n i n g c A p A B i L i T Y

w I T h A T A P P E d N P T B L o w -o f f C o N N E C T I o N , T h I S U N I T C A N B E f I T T E d w I T h A

B L o w -d o w N v A L v E w h I C h fA CI L I TATES C L E A N I N G o f T h E S T R A I N I N G E L E M E N T .

P L E A S E C o N T A C T f A C T o R y f o R M o R E I N f o R M A T I o N .

s

T H R E A D E D c A p

T I T A N ' S y S 55 A N d y S 56 h A v E S T R A I G h T T h R E A d S T o P E R M I T E A S y C A P R E M o v A L

f o R C L E A N I N G A N d P R o P E R A L I G N M E N T w h E N R E A S S E M B L I N G S T R A I N E R .

g E n E R A L A p p L i c A T i O n : y -S T R A I N E R S A R E I N S TA L L E d I N A P I P I N G S y S TE M T o R E M o v E U N w A N T E d d E B R I S f R o M T h E

P I P E L I N E , P R o T E C T I N G E x P E N S I v E E q U I P M E N T d o w N S T R E A M S U C h A S P U M P S , M E T E R S , S P R A y N o Z Z L E S , C o M P R E S S o R S , A N d

T U R B I N E S . T h E y C A N B E P L A C E d I N A h o R I Z o N T A L o R v E R T I C A L P I P E L I N E A S L o N G A S T h E S C R E E N IS I N A d o w N w A R d

P o S I T I o N . S T R A I N I N G I S A C C o M P L I S h E d v I A A N I N T E R N A L P E R f o R A T E d o R M E S h L I N E d S T R A I N I N G E L E M E N T , T h E S I Z E o f

w h I C h S h o U L d B E d E T E R M I N E d B A S E d o N T h E S I Z E o f T h E S M A L L E S T P A R T I C L E T o B E R E M o v E d .

TECHNICAL

T

PRESSURE/ TEMPERATURE RATING

BZ - C84400 - ASTM B584 - CLASS 125

YS 55-BZ (THREADED)

(Non-shock): 200 PSI @ 150 °F

WOG

Saturated Steam: 125 PSI @ 353°F

Maximum Liquid: 125 PSI @ 400 °F

PRESSURE/ TEMPERATURE RATING

BZ - C84400 - ASTM B584 - CLASS 125

YS 56-BZ (SOLDER)

WOG (Non-shock): 200 PSI @ 100 °F

Saturated Steam: Not Applicable

Maximum Liquid: 125 PSI @ 400 °F

1. The above listed temperatures are theoretical and may vary

during actual operating conditions.

2. The internal working pressure rating for a solder joint strainer

is dependent, not only on the strainer, but also on the

composition of the solder used for the joint. The working

pressure ratings shown for model YS 56-BZ (Solder) are

representative of using an alloy Sb5 95-5 tin-antimony solder.

For other solder joints, please consult factory.

(1)

(1)

(2)

A

S E Rv ic in g: T h E S T R A I N I N G E L E M E N T N E E d S R E G U L A R C L E A N I N G T o P R E v E N T d E B R I S B U I L d U P . IT I S N o T A d v I S A B L E T o

A L L o w T h E d I f f E R E N T I A L P R E S S U R E T o I N C R E A S E B y 20 P S I . A L T h o U G h C L E A N I N G N o R M A L L y R E q U I R E S T h E R E M o v A L o f T h E

S T R A I N I N G E L E M E N T , I N S T A L L I N G A N d U S I N G A T I T A N B L o w - o f f d R A I N v A L v E C A N I N C R E A S E T h E T I M E B E T w E E N C L E A N I N G S .

Th e ab ov e d at a rep res ents c om mo n m arket a nd se rv ic e a pp li cat ions . No r epr esen ta ti on or gua ra nte e, ex pre ss ed or imp li ed , i s g iven d ue t o th e num ero us

APPLICATIONS

variations of concentrations, temperatures and flow conditions that may occur during actual ser vice.

TITAN FLOW CONTROL, INC.

YOUR PIPELINE TO THE FUTURE!

s

Tel: 910-735-0000

290 Corporate Drive

Fax: 910-738-3848

s

s

titan@titanfci.com

PO Box 7408

s

s

Lumberton, NC 28358

www.titanfci.com

Page 2

YS5556-0311

®

TITAN

1

2

4

3

5

0

50

100

150

200

250

-20 100 200 300 400

Pressure (PSI)

Temperature (°F)

SOURCE: ASME/ANSI B16.15

Bronze (C84400) - ASTM B584

ANSI 125

Threaded Ends - YS 55

A

B

C

D

TITAN FLOW CONTROL, Inc.

290 Corporate Drive E-mail: titan@titanfci.com

Lumberton, NC 28358 Web: www.titanfci.com

Tel: 910.735.0000 Fax: 910.738.3848

"Y" (WYE) STRAINER

YS 55-BZ - (Threaded)

YS 56-BZ - (Solder)

Threaded or Solder Ends • ANSI Class 125 • Bronze

ANSI Class

125

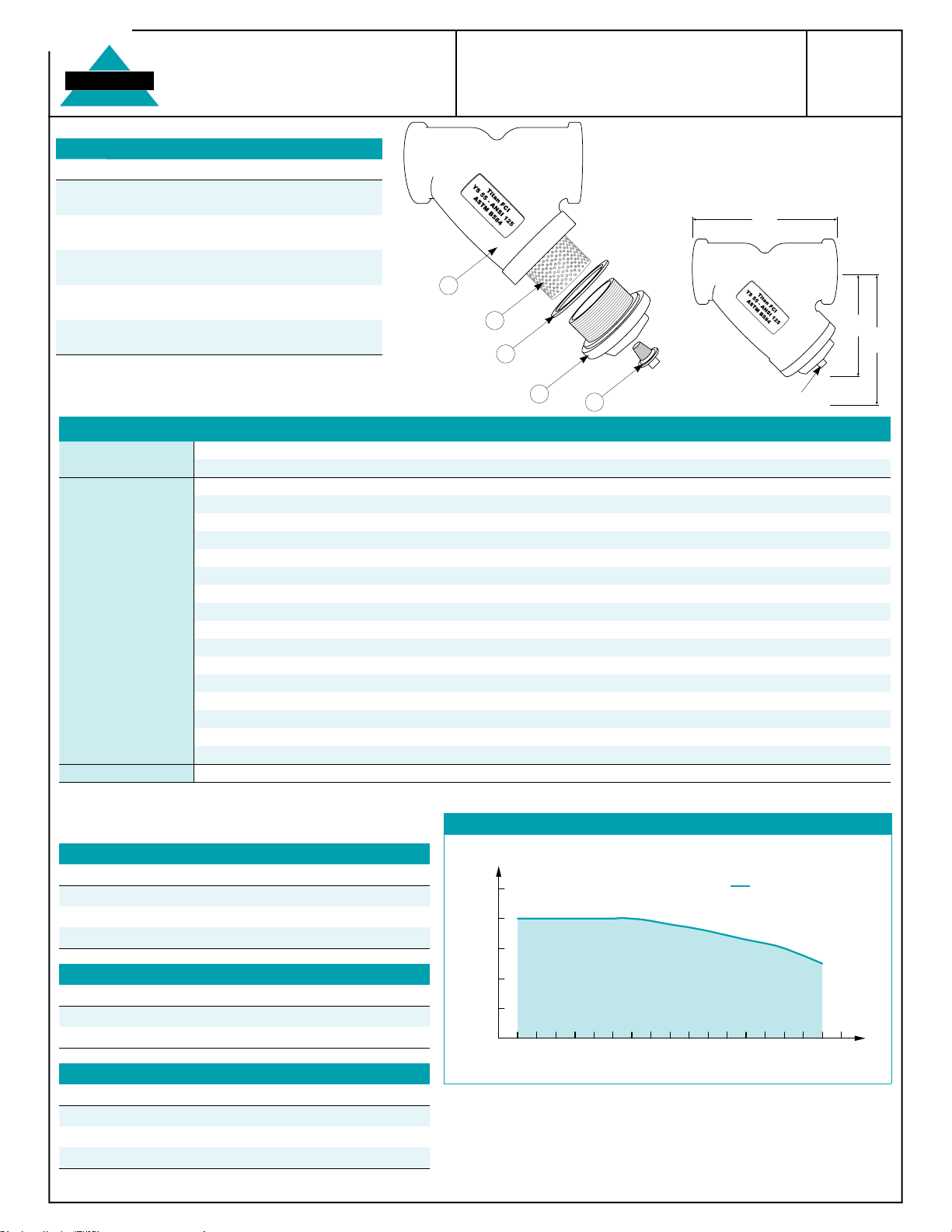

BILL OF MATERIALS

(1)

No. PART YS 55/56 - BZ

1 Body

2 Cap

3 Straining Element

4 Gasket

(2)

(2)

5 NPT Plug (Blow-off)

1. Bill of Materials represents standard materials. Equivalent or better

materials may be substituted at the manufacturer's discretion.

2. Denotes recommended spare parts.

Bronze (C84400)

ASTM B584

Bronze (C84400)

ASTM B584

Stainless Steel

Teon

Bronze (C84400)

ASTM B584

DIMENSIONS AND PERFORMANCE DATA

SIZE

A DIMENSION

FACE TO FACE (YS 55)

A DIMENSION

FACE TO FACE (YS 56)

B DIMENSION

CENTER LINE TO BOTTOM (YS 55)

B DIMENSION

CENTER LINE TO BOTTOM (YS 56)

C DIMENSION

SCREEN REMOVAL

D NPT Plug

BLOW-OFF

ASSEMBLED WEIGHT

YS 55- THREADED (APPROXIMATE)

ASSEMBLED WEIGHT

YS 56 - SOLDER (APPROXIMATE)

(2)

(2)

FlowCoefcient

1. Dimensions and weights are for reference only. When required, request

certieddrawings.

2. Face to face values have a tolerance of ±0.06 in (±2.0 mm).

in 1/4 3/8 1/2 3/4 1

mm 8 10 15 20 25 32 40 50 65 80

in 2.50 2.50 2.563 3.063 3.25 4.438 4.875 5.25 6.875 7.875

mm 64 64 65 78 83 113 124 133 175 200

in 2.0 3.0 3.125 4.125 4.938 5.688 6.688 8.281 9.75 11.375

mm 51 76 79 105 125 144 170 210 248 289

in 1.75 1.938 2.031 2.375 2.438 3.563 3.75 4.75 5.625 6.75

mm 44 49 52 60 62 90 95 121 143 171

in 1.563 1.75 1.938 2.281 2.797 3.188 3.813 4.75 6.125 7.5

mm 40 44 49 58 71 81 97 121 156 191

in 3.0 3.75 4.0 4.25 4.75 6.0 7.0 8.0 9.0 10.0

mm 76 95 102 108 121 152 178 203 229 254

in 1/8 1/8 1/4 3/8 1/2 1/2 3/4 1 1 1/4 1 1/2

mm 6 6 8 10 15 15 20 25 32 40

lb < 0.5 < 0.5 0.5 1.0 1.5 3.0 4.0 5.5 9.0 15.5

kg < 0.2 < 0.2 0.2 0.5 0.7 1.4 1.8 2.5 4.1 7.0

lb < 0.5 < 0.5 0.5 1.0 1.5 2.0 3.5 5.5 9.5 15.5

kg < 0.2 < 0.2 0.2 0.5 0.7 0.9 1.6 2.5 4.3 7.0

C

v

0.7 2 8 15 22 38 42 70 110 160

1.5" YS 55-BZ

Threaded Ends

Illustrations are representative of YS 55-BZ (Threaded-end

connections) only. Materials, as listed to the left, and Dimensions

and Performance Data, as listed below, include both the YS 55BZ and the YS 56-BZ (Solder-end connections). Please ask for

certied drawings when required.

(1)

1

1

/4 1 1/2

2

PRESSURE - TEMPERATURE RATINGS

1

2

/2

(1)

3

pRESSURE - TEmpERATURE RATing

B283-80 YS 55-BZ (Threaded) YS 56-BZ (Solder)

(1)

WOG (Non-shock): 200 PSI @ 150 °F 200 PSI @ 100 °F

Saturated Steam

Max Liquid

: 125 PSI @ 353°F N/A

: 125 PSI @ 400 °F 125 PSI @ 400 °F

STAnDARD ScREEn SELEcTiOnS

Size Liquid Open Area Steam Open Area

1/4" ~ 2" 20 mesh 51.8% 30 mesh 44.8%

2 1/2" ~ 3" 1/16 (.0625) 41% 3/64 (.045) 36%

REFERENCED STANDARDS & CODES

CODE DESCRIPTION

ASME/ANSI B16.15 Cast Bronze Threaded Fittings

ASME/ANSI B16.18 Cast Copper Alloy Solder Joint Pressure Fittings

ASME/ANSI B16.50 Copper Alloy Braze-Joint Pressure Fittings

Titan FCI makes every effort to ensure the information presented on our literature accurately reects exact product specications. However, as product changes occur, there may be short-term differences between actual product

specications and the information contained within our literature. Titan FCI reserves the right to make design and specication changes to improve our products without prior notication. When required, request certied drawings.

1. The pressure-temperature ratings given are ONLY for the YS 55-BZ (Threaded) per ASME B16.15.

The internal working pressure rating for a solder joint strainer is dependent, not only on the

strainer, but also on the composition of the solder used for the joint. The working pressure

ratings shown for model YS 56-BZ (Solder) are representative of using an alloy Sb5 95-5

tin-antimony solder. For other solder joints, please consult factory.

Loading...

Loading...