Page 1

Page 2

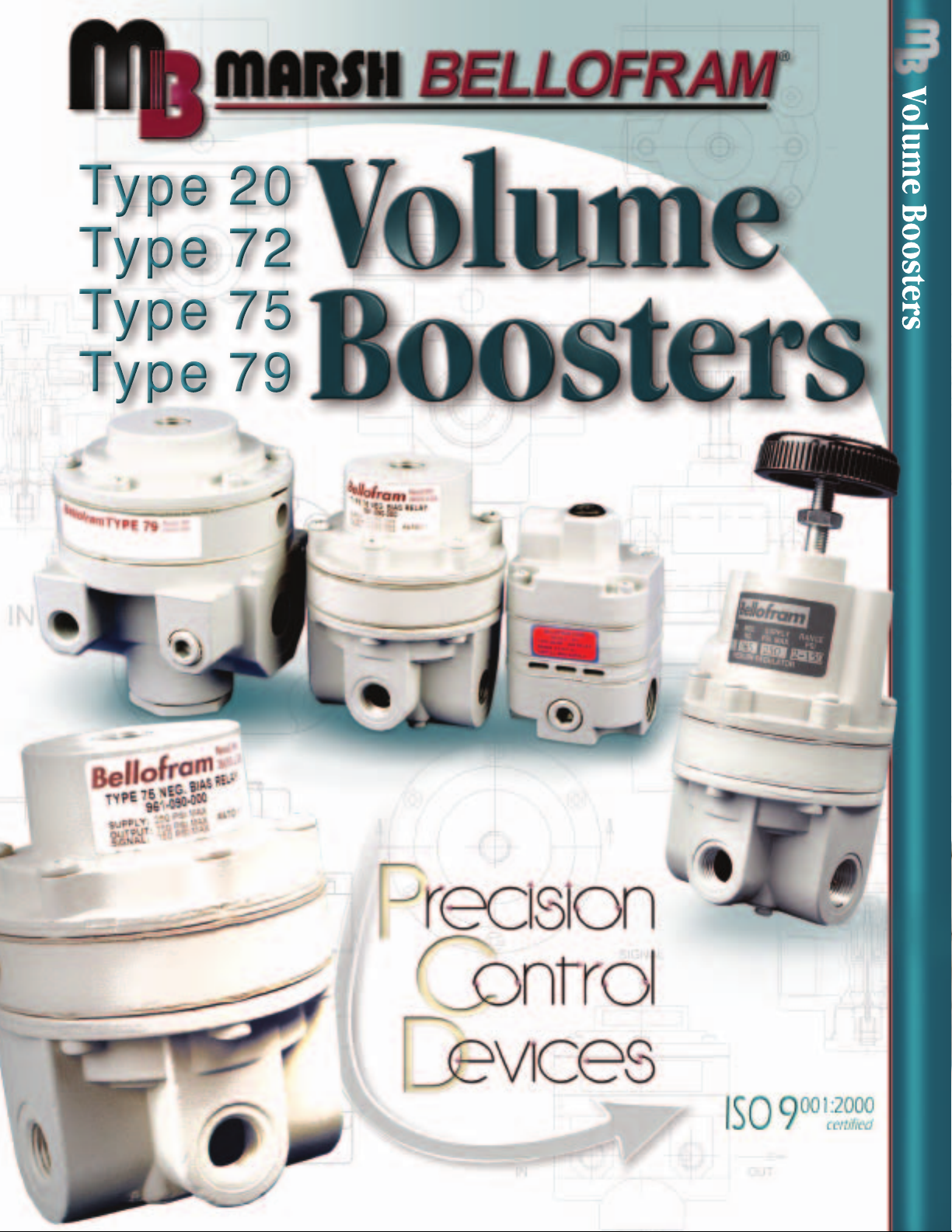

TYPE 20 PRECISION AIR RELAY

FEATURES

• Extreme accuracy

• Positive and negative

bias capability (±30 psig)

• Small size

• Rugged and stable

DESCRIPTION

The Type 20 Air Relay is a compact, two-stage, pilot operated 1:1 relay

with positive and negative bias adjustment capability. It accepts a signal

pressure and combined with the bias adjustment, maintains a resulting

output pressure with an accuracy and reliability unmatched by any other

pressure relay in its price range.

OUTPUT

MODELS

TYPE 20 - The basic relay is offered with a

choice of three port sizes.

TYPE 20HR & TYPE 20EXHR- High Relief

Relays - These relays provide extra fast

“blowdown” for very rapid release of output

pressure. The extra relief feature makes

this relay suitable for cylinder return stroke

actuation, air hoists, and similar applications requiring fast exhaust.

TYPE 20HF tions where the supply pressure is relatively low and a high flow rate is desired.

This relay is ideal for applica

PRESSURE

psig BAR

56 3.9

55 3.8

54 3.7

-

53 3.6

0.0

SCFM

LPM 0 60 115 170 225 280 340 400 450 510

FORWARD FLOW

Type 20, 20HR & 20EXHR

Flow Curve

@ 100 psig (6.9 BAR) Supply Pressure

10.0 12.0 14.0 16.0 18.0

2.0

4.0

6.0

8.0

APPLICATIONS

• Gate Actuators

•Air Hoists

Disc & Shoe Brakes

•

• Remote Positioning Devices

• Valve Rotors

• Control Valves

• Tensioning Systems

• Web Tracking Systems

Page 3

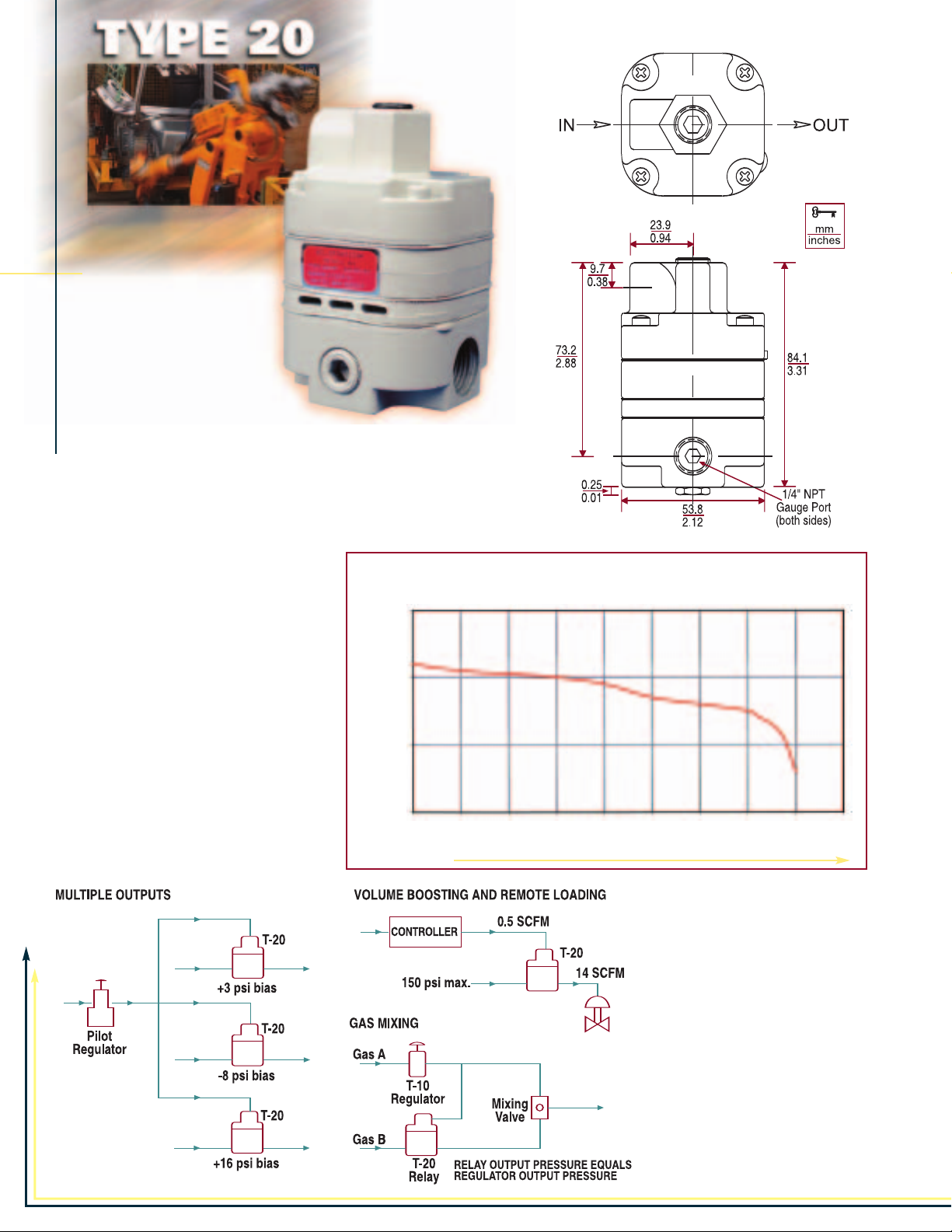

FEATURES

• Four adjustable positive bias ranges, from

0-10 psi (0-0.7 BAR) to 2-150 psi

(0.1-10.3 BAR)

• Flow capacity up to 50 SCFM

• Quick response to minute changes in

downstream pressure

• Dampening action of aspirator tube

maintains stable output pressure

• Output virtually unaffected by changes in

supply pressure

• Internal rolling diaphragm designed for millions of cycles

• Honking and buzzing eliminated by action of integral baffle and aspirator tube

• Can be disassembled and serviced without removing from line.

DESCRIPTION

The Type 72 Relay features an adjustable bias pressure which enables users to obtain an output pressure which is the sum of a controlled input signal pressure plus the bias. The relay offers

an exceptionally high flow capacity (up to 50 SCFM/1400 LPM) with minimal pressure droop.

Output pressure is accurately maintained under varying flow conditions by means of an

aspirator tube, which adjusts the air supply valve opening in proportion to flow velocity.

A balanced supply valve utilizing a rolling diaphragm makes the relay virtually immune to changes

in supply pressure. Simple design makes

maintenance easy, and the relay can be

serviced without removing it from the line.

The standard signal-to-output ratio is 1:1,

but 1:2, 1:4 and 1:6 ratios are available on

special request. The Type 72HR is available

for applications that require extra fast “blowdown” for rapid release of output pressure.

OUTPUT

PRESSURE

psig BAR

90.0 6.2

80.0 5.5

70.0 4.8

60.0 4.1

50.0 3.4

40.0 2.8

30.0 2.1

20.0 1.4

0.7

10.0

00

SCFM 0.0 10.0 20.0 30.0 40.0 50.0 60.0 70.0 80.0 90.0

LPM

FORWARD FLOW

300

0

Type 72 Flow Curves

@ 100 psig (6.9 BAR) Supply Pressure

575

850

1150 1400 1700 2000 2550 2550

TYPE 72 POSITIVE BIAS BOOSTER RELAY

APPLICATIONS

The Type 72 Relay is used when high

flow capacity is required in conjunction with a positive output pressure

bias. Typical applications include:

• Gas Flow Control

• Tensioning Control

• Clutch & Brake Controls

oosting

B

olume

V

•

• Dancer Roll Loading

Calendar

•

Cylinder Bucking Control

•

• Valve Motor Loading

www.marshbellofram.com

Roll Loading

800-727-5646

•

Page 4

TYPE 20 TYPE 20 HR TYPE 20 EXHR TYPE 20 HF

Maximum 150 psig (10.3 BAR) 150 psig (10.3 BAR) 150 psig (10.3 BAR) 50 psig (3.4 BAR)

Supply Pressure

Sensitivity

Supply Pressure 0.005 psig 0.005 psig 0.005 psig 0.005 psig

Sensitivity (0.35 mBAR) (0.35 mBAR) (0.35 mBAR) (0.35 mBAR)

Flow Capacity 14 SCFM (400 LPM) 14 SCFM (400 LPM) 14 SCFM (400 LPM) 40 SCFM (1130 LPM)

Exhaust Capacity 2 SCFM (55 LPM) @ 10 SCFM (285 LPM) @ 15 SCFM (425 LPM) @ 2 SCFM (55 LPM) @

VOLUME BOOSTERS

Temperature Limits -20 to 160

Air Consumption 8 SCFH (4 LPM) 8 SCFH (4 LPM) 8 SCFH (4 LPM) 8 SCFH (4 LPM)

Port Size

Output Pressure 2-120 psig 2-120 psig 2-120 psig 2-50 psig

Range (0.1 – 8.3 BAR) (0.1 – 8.3 BAR) (0.1 – 8.3 BAR) (0.1 – 3.5 BAR)

Maximum Signal 120 psig (8.3 BAR) 120 psig (8.3 BAR) 120 psig (8.3 BAR) 50 psig (3.5 BAR)

1

⁄8" H

O (3.2mm)

2

per 25 psig per 25 psig per 25 psig per 25 psig

(1.7 BAR) change

in supply pressure in supply pressure in supply pressure in supply pressure

@ 20 psig (1.4 BAR) @ 20 psig (1.4 BAR) @ 20 psig (1.4 BAR) @ 20 psig (1.4 BAR)

signal and100 psig signal and 100 psig signal and 100 psig signal and 50 psig

(6.9 BAR) supply (6.9 BAR) supply (6.9 BAR) supply (3.5 BAR) supply

5 psig (0.35 BAR) 5 psig (0.35 BAR) 5 psig (0.35 BAR) 5 psig (0.35 BAR)

above a 20 psig above a 20 psig above a 20 psig above a 20 psig

(1.4 BAR) setpoint (1.4 BAR) setpoint (1.4 BAR) setpoint (1.4 BAR) setpoint

ºF -20 to 160ºF -20 to 160ºF -20 to 160ºF

(-29 to 71ºC) (-29 to 71ºC) (-29 to 71ºC) (-29 to 71ºC)

1

⁄8", 1⁄4", 3⁄8"

NPT, BSPP, BSPT NPT, BSPP, BSPT NPT, BSPP, BSPT NPT, BSPP, BSPT

1

⁄8" H

O (3.2mm)

2

1

⁄8" H

O (3.2mm)

2

1

⁄8" H

O (3.2mm)

2

(1.7 BAR) change (1.7 BAR) change (1.7 BAR) change

1

⁄8", 1⁄4", 3⁄8"

1

⁄8", 1⁄4", 3⁄8"

3

⁄8"

Weight 1.4 lb. (0.6 kg.) 1.4 lb. (0.6 kg.) 1.4 lb. (0.6 kg.) 1.4 lb. (0.6 kg.)

Ratio of Accuracy <0.5% <0.5% <0.5% <0.5%

for a 12 psig span

Page 5

TYPE 72 TYPE 72HR TYPE 75 TYPE 75 HR TYPE 79

250 psig (17.2 BAR) 250 psig (17.2 BAR) 250 psig (17.2 BAR) 250 psig (17.2 BAR) 400 psig (27.6 BAR)

1

⁄4" H

O (6.4mm)

2

1

⁄4" H

O (6.4mm)

2

1

⁄4" H

O (6.4mm)

2

1

⁄4" H

O (6.4mm) 1" H2O (25mm)

2

< 0.6 psig < 0.6 psig < 0.6 psig < 0.6 psig <0.35 psig

(0.01 BAR) (0.01 BAR) (0.04 BAR) (0.04 BAR) (0.02 BAR)

per 50 psig per 50 psig per 50 psig per 50 psig per 100 psig

(1.4 BAR) change

(1.4 BAR) change (3.5 BAR) change (3.5 BAR) change (6.9 BAR) change

in supply pressure in supply pressure in supply pressure in supply pressure in supply pressure

40 SCFM (1150 LPM) 40 SCFM (1150 LPM) 40 SCFM (1150 LPM) 40 SCFM (1150 LPM) >125 SCFM (3500 LPM)

@ 20 psig (1.4 BAR) @ 20 psig (1.4 BAR) @ 20 psig (1.4 BAR) @ 20 psig (1.4 BAR) @ 20 psig (1.4 BAR)

signal and 100 psig signal and 100 psig signal and 100 psig signal and 100 psig signal and 100 psig

(6.9 BAR) supply (6.9 BAR) supply (6.9 BAR) supply (6.9 BAR) supply (6.9 BAR) supply

6 SCFM (170 LPM) @ 15 SCFM (425 LPM) @ 6 SCFM (170 LPM) @ 15 SCFM (425 LPM) @ 31 SCFM (875 LPM) @

10 psig (0.69 BAR) 10 psig (0.69 BAR) 10 psig (0.69 BAR) 10 psig (0.69 BAR) 5 psig (0.35 BAR)

above a 20 psig above a 20 psig above a 20 psig above a 20 psig above a 20 psig

(1.4 BAR) setpoint (1.4 BAR) setpoint (1.4 BAR) setpoint (1.4 BAR) setpoint (1.4 BAR) setpoint

-40 to 200

ºF -40 to 200ºF -40 to 200ºF -40 to 200ºF -40 to 200ºF

(-40 to 93ºC) (-40 to 93ºC) (-40 to 93ºC) (-40 to 93ºC) (-40 to 93ºC)

<12 SCFH (5.7 LPM) <12 SCFH (5.7 LPM) <12 SCFH (5.7 LPM) <12 SCFH (5.7 LPM) <12 SCFH (5.7 LPM)

1

⁄4", 3⁄8", 1⁄2"

1

⁄4", 3⁄8", 1⁄2"

1

⁄4", 3⁄8" 1⁄2"

1

⁄4", 3⁄8", 1⁄2"

3

⁄8", 1⁄2", 3⁄4", 1"

NPT, BSPP, BSPT NPT, BSPP, BSPT NPT, BSPP, BSPT NPT, BSPP, BSPT NPT, BSPP, BSPT

0-150 psig 0-150 psig 0-150 psig 0-150 psig 0-200 psig

(0–10.3 BAR) (0–10.3 BAR) (0–10.3 BAR) (0–10.3 BAR) (0-13.8 BAR)

150 psig (10.3 BAR) 150 psig (10.3 BAR) 150 psig (10.3 BAR) 150 psig (10.3 BAR) 200 psig (13.8 BAR)

for 1:1 ratio for 1:1 ratio

1.75 lb. (0.8 kg.) 1.75 lb. (0.8 kg.) 1.3 lb. (0.6 kg.) 1.3 lb. (0.6 kg.) 4.5 lb. (2.0 kg.)

< 2% < 2% < 2% (1:1) < 2% (1:1) <1.5%

COMPARISON & SPECIFICATION

: Our recommendations, if any

NOTICE

ANT

T

IMPOR

The greatest care is exercised in the selection of our raw materials and in our manufacturing, no guarantee

reliable.

or warranty, express or implied is made as to such use or effects incidental to such use, handling or possession or

the results to be obtained, whether in accordance with the directions or claimed so to be.

ly disclaims responsibility therefor

to use any product in conflict with existing laws and/or patents covering any material use.

. Furthermore, nothing contained herein shall be construed as a recommendation

, for the use of this product are based on tests believed to be

The manufacturer express

www.marshbellofram.com •800-727-5646

-

Page 6

Transducer

Signal

Input

Supply Pressure

0-100 psig

Supply Pressure

100 psig

Relay Output

Transducer Ouput (3-15 psig)

Signal

Pressure

T-75

1:4

with

negative

bias

0-44 psig

T-1000

I/P or E/P

Transducer

TYPE 75 RELAYS

FEATURES

• Balanced valve design

• High flow capacity

•

Field serviceable

• Multiple output ratios

• Negative biasing option

DESCRIPTION

The Type 75 relay uses signal pressure to accurately control output pressure over a wide range of flow

and supply pressure variation.

Under varying flow conditions

output pressure is maintained by

use of an aspirator tube, which

adjusts the air supply valve opening in accordance with the flow

velocity. A balanced supply valve,

utilizing a rolling diaphragm,

makes the relay virtually immune

to changes in supply pressure.

Maintenance is simple due to

the unit construction, and the

relay can be serviced without

removing it from the line.

Signal to output pressure ratios

of 1:1, 1:2, 1:4 and 1:6 are available. Maximum output is 150

psig (10.3 BAR).

OUTPUT

PRESSURE

BAR

psig

25.0 1.7

20.0 1.4

1.0

15.0

10.0 0.7

5.0

0

SCFM 0.0 10 20 30 40 50

LPM 0 300 575 850 1150 1400

W

FOR

0.4

0

ARD FLOW

Type 75 Flow Curve

@ 100 psig (6.9 BAR) Supply Pressure (1/4” NPT)

APPLICATIONS

• Volume Boosting

• Dancer Roll Loading

• Calendar Roll Loading

• Cylinder Bucking Control

• Clutch and Brake Controls

• Gas Flow Control

• Tensioning Control

• Valve Motor Loading

MODELS

TYPE 75 - The basic relay offers excellent precision along

with high forward flow rates.

TYPE 75 HIGH RELIEF RELAYS - These relays provide

extra fast “blowdown” for very rapid release of output pressure. The extra relief feature makes this relay suitable for

cylinder return stroke actuation, air hoists, and similar applications requiring fast exhaust.

TYPE 75 NEGATIVE BIAS - The Type 75 Relay is also

available with a 4 ± 1 psig (0.3 ± 0.07 BAR) negative bias

spring mounted internally. (See cross-sectional drawing on

previous page.) This bias spring automatically subtracts

4 ± 1 psig (0.3 ± 0.07 BAR) from any signal pressure introduced. The relay then multiplies the net signal pressure by

its ratio value to obtain final output pressure.

This option is particularly useful in obtaining zero pressure

from pneumatic devices such as I/P transducers that

normally cannot be adjusted this low, as well as

obtaining higher outputs from such devices.

ype 75 Relay with

ypical applications of the

T

fixed negative bias include the electronic

control of the applications listed for the

ype 75 Relay

standard

T

To calculate relay output:

Relay output = (signal pressure) - 4 psi bias x

(relay ratio factor) where the relay ratio factor is

defined as follows:

Relay Ratio Factor

1:1

1:2 2

1:4 4

1:6 6

T

.

1

Page 7

FEATURES

• Balanced pintle

•

High flow capacity (200 + SCFM)

• Field serviceable

• Large port sizes available

• High exhaust capacity

• 200 psig output

DESCRIPTION

The Type 79 1:1 Ratio High Flow Precision Air Relay brings additional precision and control to the Bellofram line of precision control products.

The Type 79 relay is designed for applications where a precise control of flow

is needed. This regulator offers low droop, high accuracy and fine adjustment

sensitivity. The use of a Bellofram rolling diaphragm provides greater sensitivity and improved accuracy. The balanced pintle minimizes output pressure

changes caused by fluctuations in supply pressure.

Careful design and quality materials throughout assure long, trouble-free

operation. The rugged die-cast zinc and aluminum housings are pressure

tested to assure safe operation. The Type 79 is designed to withstand

harsh and abusive environments. This is attributed to a chemical conversion coating of all cast

components, and a vinyl paint finish.

The Type 79 can achieve flow rates of well over

200 SCFM (5600 LPM). This relay can be pipe or

bracket mounted.

OUTPUT

PRESSURE

psig BAR

90.0 6.2

80.0 5.5

70.0 4.8

60.0 4.1

50.0 3.4

Type 79 Flow Curve

@ 100 psig (6.9 BAR) Supply Pressure

Contact Bellofram Applications Engineering

for information on the VALVE-CONTROL

VERSION

utilizes soft exhaust seats to minimize air

consumption, increased deadband to

ignore small valve oscillations, and an integral bypass valve that can be ‘tuned’ for

optimum valve response.

of the Type 79. The Type 79V

TYPE 79 HIGH FLOW PRECISION AIR RELAY

40.0 2.8

2.1

30.0

1.4

20.0

0.7

10.0

00

SCFM 0 50 100 150 200 250 300

LPM 0 1400 2800 4250 5650 7100 8500

FORWARD FLOW

––3/8" ––1/2" ––3/4" ––1"NPT

APPLICATIONS

Clutch & Brake Controls

•

• Cylinder Bucking Control

• Dancer (Calendar) Roll Loading

Gas Flow Control

•

Tension Control

•

• Valve Motor Loading

• Volume Boosting

www.marshbellofram.com •800-727-5646

Page 8

Port Size Range Range Part

Type (NPT) psig BAR Number

Type 20 1/8" 2-120 0.1-8.3 961-004-000

Precision Relay 1/4" 2-120 0.1-8.3 961-005-000

1:1 Ratio 3/8" 2-120 0.1-8.3 961-006-000

Type 20HR Precision Relay 1/8" 2-120 0.1-8.3 961-001-000

High Relief Capacity 1/4" 2-120 0.1-8.3 961-002-000

1:1 Ratio 3/8" 2-120 0.1-8.3 961-003-000

Type 20 HF Precision Relay 3/8" 2-50 0.1-3.5 961-071-000

High Flow Capacity 1:1 Ratio

ype 20 EXHR 1/8" 2-120 0.1-8.3 961-009-000

T

1:1 Ratio 1/4" 2-120 0.1-8.3 961-010-000

3/8" 2-120 0.1-8.3 961-011-000

Type 72 1/4" 0-10 0-0.7 961-052-000

Positive Bias Booster Relay 1/4" 0-30 0-2.1 961-053-000

1:1 Ratio 1/4" 1-60 0.07-4.1 961-054-000

1/4" 2-150 0.1-10.3 961-055-000

3/8" 0-10 0-0.7 961-062-000

ORDERING INFORMATION

Type 72 HR (High Relief) 1/4" 0-10 0-0.7 961-178-000

Positive Bias Booster Relay 1/4" 0-30 0-2.1 961-179-000

1:1 Ratio 1/4" 1-60 0.07-4.1 961-180-000

Type 75 Precision Relay

1:1 Ratio 1/4" 0-150 0-10.3 961-058-000

1:1 Ratio 3/8" 0-150 0-10.3 961-066-000

1:2 Ratio 1/4" 0-150 0-10.3 961-059-000

1:2 Ratio 3/8" 0-150 0-10.3 961-067-000

1:4 Ratio 1/4" 0-150 0-10.3 961-060-000

1:4 Ratio 3/8" 0-150 0-10.3 961-068-000

1:6 Ratio 1/4" 0-150 0-10.3 961-045-000

1:6 Ratio 3/8" 0-150 0-10.3 961-069-000

Type 75 Precision Relay - Fixed Negative Bias (4psi)

1:1 Ratio 1/4" 0-150 0-10.3 961-090-000

1:1 Ratio 3/8" 0-150 0-10.3 961-091-000

1:2 Ratio 1/4" 0-150 0-10.3 961-092-000

1:2 Ratio 3/8" 0-150 0-10.3 961-093-000

1:4 Ratio 1/4" 0-150 0-10.3 961-094-000

1:4 Ratio 3/8" 0-150 0-10.3 961-095-000

1:6 Ratio 1/4" 0-150 0-10.3 961-096-000

1:6 Ratio

ype 75HR Precision Relay

T

1:1 Ratio

1:1 Ratio 3/8" 0-150 0-10.3 961-145-000

1:1 Ratio 1/2" 0-150 0-10.3 961-146-000

1:2 Ratio

1:2 Ratio

1:2 Ratio 1/2" 0-150 0-10.3 961-149-000

Type 75HR Precision Relay - Fixed Negative Bias (4psi)

1:1 Ratio

1:1 Ratio

1:1 Ratio 1/2" 0-150 0-10.3 961-152-000

1:2 Ratio 1/4" 0-150 0-10.3 961-153-000

1:2 Ratio 3/8" 0-150 0-10.3 961-154-000

1:2 Ratio 1/2" 0-150 0-10.3 961-155-000

Type 79 3/8" 0-200 0-13.8 961-156-000

High Flow Capacity 1/2" 0-200 0-13.8 961-157-000

1:1 Ratio 3/4" 0-200 0-13.8 961-158-000

3/8" 0-30 0-2.1 961-063-000

3/8" 1-60 0.07-4.1 961-064-000

3/8" 2-150 0.1-10.3 961-065-000

1/4" 2-150 0.1-10.3 961-181-000

3/8" 0-10 0-0.7 961-182-000

3/8" 0-30 0-2.1 961-183-000

3/8" 1-60 0.07-4.1 961-184-000

3/8" 2-150 0.1-10.3 961-185-000

3/8"

1/4" 0-150 0-10.3 961-144-000

1/4"

3/8"

1/4"

3/8"

1" 0-200 0-13.8 961-159-000

0-150

0-150

0-150

0-150

0-150

0-10.3

0-10.3 961-147-000

0-10.3 961-148-000

0-10.3

0-10.3

961-097-000

961-150-000

961-151-000

For options and accessories, replace the last

three zeros in the relay part number with

three digits from the following tables:

Type 20

Option 8

8. Pressure Gauge 008

Type 72

Option 3 5 7 8 9

3. Kno b (standard)

Square Head 003 053 073 083

5. Epoxy Finish 005 075 085 095

7. Mounting Bracket 007 087 097

8. Pressure Gauge 008 098

9. Tamper Resistant Cover 009

Type 75

Option 5 7 8

5. Epoxy Finish 005 075 085

7. Mounting Bracket 007 087

8. Pressure Gauge 008

Type 79

Option 1 2 5 6 7

1. Low Bleed 001 051 061 071

2. Non-Relieving 002 052 062 072

5. Epoxy Finish 005 065 075

6. Tapped Vent 006 076

7. Tapped Supply Port 007

Pressure Gauge: Dual scale (English &

Metric) 2-inch (50.8 mm) gauges are available

Epoxy finish: Gray epoxy coating for greater

corrosion resistance.

Mounting Bracket: Zinc-plated steel bracket

for side mounting. (For T-79 order p/n 607-293-000)

Tamper Resistant Cover: A cover placed

over the adjusting screw to prevent ordinary

hand adjustments.

Low Bleed: Reduces steady-state air consumption by approximately 50%.

Non-Relieving: Used in applications where it

is desirable to relieve pressure downstream

of the relay

. Non-relieving relays should not be

used for low or no flow applications.

apped V

T

ent (Exhaust):

1/4" NPT

tapped port

to allow for installation of plumbing to capture

exhaust air.

Tapped Supply Gauge Port: 1/4" NPT

tapped port is offered as a pressure tap for

monitoring the inlet or upstream pressure

supplied to the regulator. (T-79 only)

BSPP

or BSPT

Threads can be ordered by adding ‘BSPP’

:

British Standard Pipe

or

‘BSPT’ to the end of the part number.

T0961 3m 4/04

L

info@marshbellofram.com

USA •

EUROPE

bellofram@aol.com

•

State Route 2, Box 305 9 Castle Park, Queens Drive

Newell, WV 26050 Nottingham NG2 1AH, UK

el +44 (0) 115 993 3300 • Fax +44 (0) 115 993 3301

(304) 387-1200 • F

AX (304) 387-4417

T

www.marshbellofram.com •800-727-5646

Loading...

Loading...