Page 1

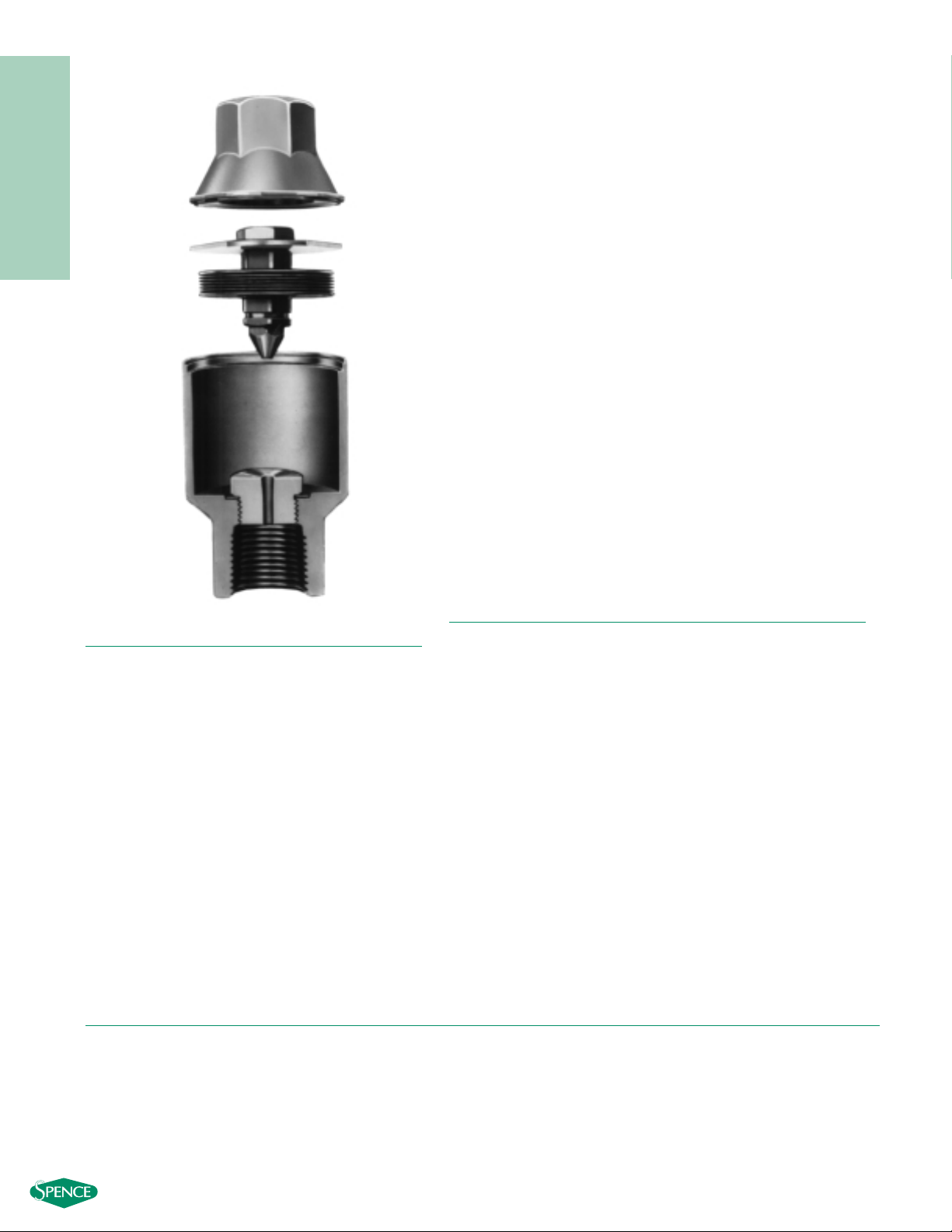

TAV THERMOSTATIC

AIR VENT

- 352 -

Thermal actuator is filled at it’s free length with a

liquid having a lower boiling point than water. As

assembled, valve is normally open. On startup, air

passes through vent.As air is eliminated, hot steam

reaches vent and the thermal actuator fill vaporizes

to a pressure higher than line pressure. This forces

valve into seat orifice to prevent any further flow. Should

more air collect, it takes heat from the actuator, lowering

internal pressure. Line pressure will then compress thermal

actuator to open valve and discharge air. Valve lift automatically adjusts to variations.

TAV SERIES

THERMOSTATIC AIR VENT

Pressures To 650 PSIG (44.8 barg)

Temperatures to 750°F (400°C)

Sealed Stainless Steel Body — Lightweight, compact and

corrosion resistant. No bolts or gaskets. Eliminates body

leaks.

Self Centering Valve — Leak tight shutoff. Improved

energy savings. Assembly of actuator and valve to

impingement plate allows valve to self-align with center of

valve seat orifice. Provides long lasting valve and seat.

Temperature Sensitive Actuators — One moving part.

Stainless Steel, fail open, welded actuator for maximum

corrosion, thermal and hydraulic shock resistance.

Thermal and Hydraulic Shock Resistant — Impingement

plate plus welded construction prevent damage to actuator.

Hardened Stainless Steel Valve and Seat — Long life.

Lapped as a matched set for steam tight seal.

Inexpensive — Low initial cost.

Maintenance Free — Sealed unit. Replacement traps cost

less than repair of more expensive in-line repairable vents.

Directional Discharge — Pipe thread erosion prevented

by directing discharge to center of pipe.

Guaranteed — Guaranteed for 3 years against defects in

materials or workmanship.

M

ODELS

●

TAV–High capacity w/welded SS actuator

APPLICA TIONS

●

Platen Presses

● Plating Tanks

● Sterilizers

● Tire Presses

● Cooking Equipment

● Laundry Equipment

● Other Process Equipment

Canadian Registration # OE0591.9C

O

PERATION

Page 2

Connections:

3/8" – 1" NPT or socketweld

Air vent shall be of balanced pressure design stainless steel welded

actuator capable of discharging air within 35°F of saturated

temperature. Thermostatic actuator shall employ a conical valve

lapped in matched sets with the seat ring assuring tight shut off. Vent

shall be stainless steel bodied suitable for pressures to 650 psig and

available in 3/8" through 1" NPT or socketweld.

MAXIMUM

OPERA TING CONDITIONS

PMO: Max. Operating Pressure 650 psig (44.8 barg)

TMO: Max. Operating Temperature 650°F (343°C)

PMA: Max. Allowable Pressure 650 psig (44.8 barg)

TMA: Max. Allowable Temperature 750°F (400°C)

MATERIALS OF

CONSTRUCTION

Body & Cover:………………ASTM A351 Grade CF3M (316L)

Actuator: ………………………………Welded Stainless Steel

Valve & Seat:……………………Hardened 416 Stainless Steel

TAV SERIES

THERMOSTATIC AIR VENT

SPECIFICATION

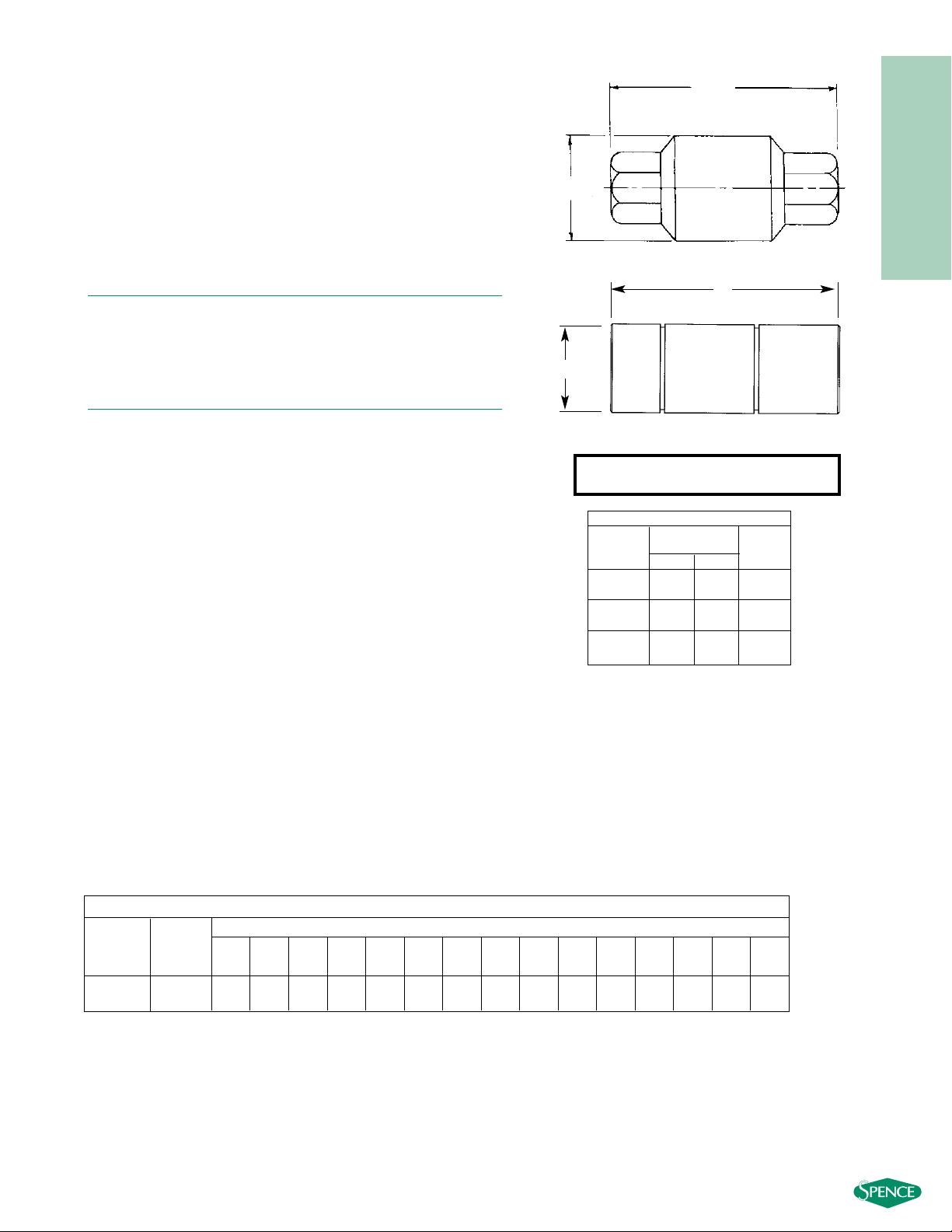

Dimensions

NPT or

inches

Weight

Socket (mm) Lbs.

weld A B (kg)

3

/8, 1/2"

33/4 13/4 1.1

(95) (44) (0.5)

3

/4"

315/16 13/4 1.2

(100) (44) (0.54)

1"

43/8 13/4 1.6

(111) (44) (0.73)

Air Capacity—SCFM for 14.7 PSIA @ 60°F (dm3/s)

Vent

Orifice Inlet Pressure (barg)

Inch 10 50 100 125 150 200 250 300 350 400 450 500 550 600 650

(mm) (0.7) (3.5) (6.9) (8.62) (10.3) (13.8) (17.2) (20.7) (24.1) (27.6) (31.0) (34.5) (37.9) (41.4) (44.8)

TAV 5/16 33 34 156 192 230 300 370 440 510 580 650 720 790 860 930

(8) (16) (20) (74) (91) (109) (142) (175) (208) (241) (274) (307) (340) (373) (406) (439)

B

A

B

A

3/8" - 3/4" BODY

1" BODY

- 353 -

TAV THERMOSTATIC

AIR VENT

Loading...

Loading...